SUZUKI GRAND VITARA 1987 Service Repair Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 231 of 962

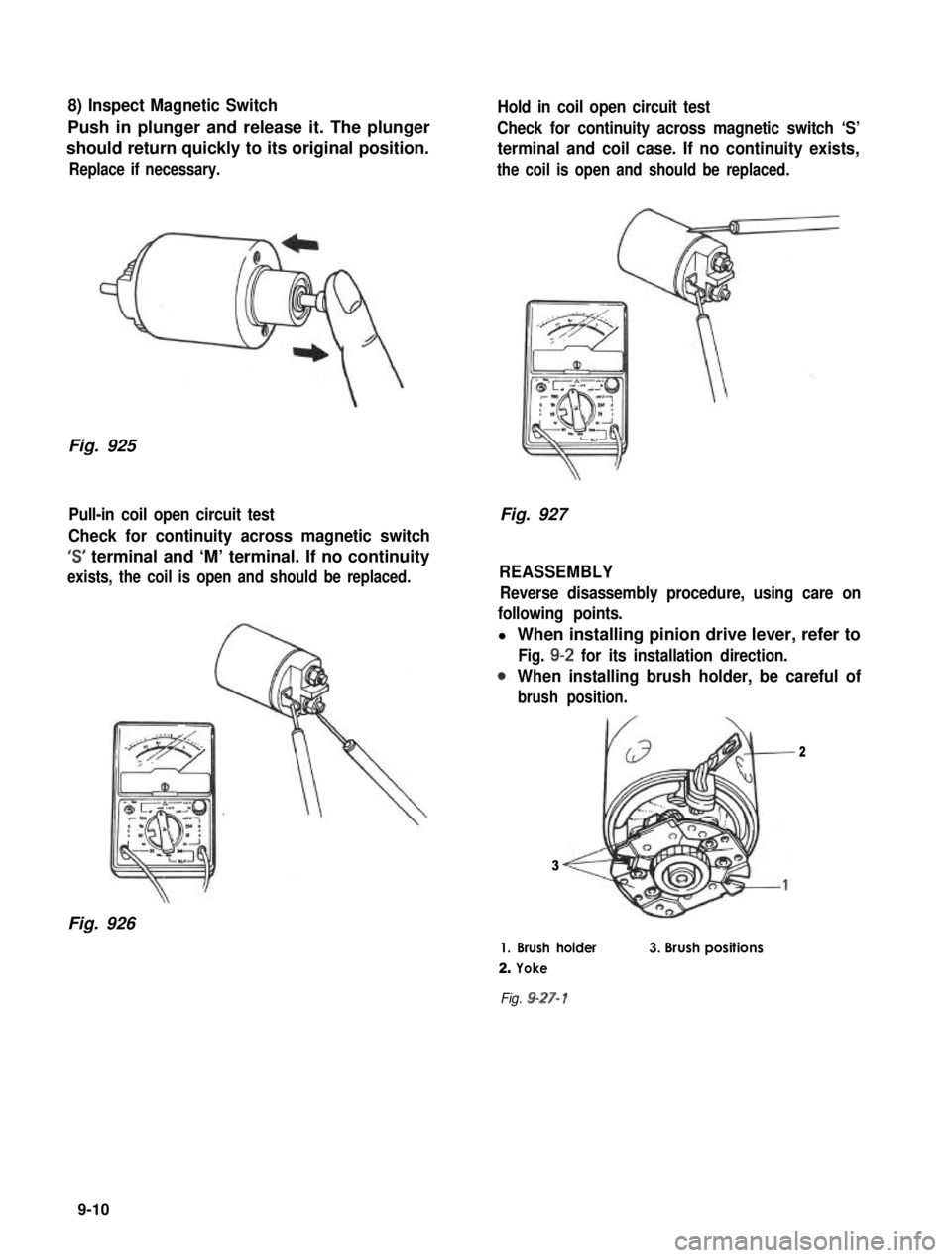

8) Inspect Magnetic SwitchHold in coil open circuit test

Push in plunger and release it. The plungerCheck for continuity across magnetic switch ‘S’

should return quickly to its original position.terminal and coil case. If no continuity exists,

Replace if necessary.the coil is open and should be replaced.

Fig. 925

Pull-in coil open circuit test

Check for continuity across magnetic switch

‘s’ terminal and ‘M’ terminal. If no continuity

exists, the coil is open and should be replaced.

Fig. 926

Fig. 927

REASSEMBLY

Reverse disassembly procedure, using care on

following points.

l When installing pinion drive lever, refer to

Fig. g-2 for its installation direction.

0. When installing brush holder, be careful of

brush position.

2

3

1. Brush holder

2. Yoke

3. Brush positions

Fig. 9-27- 1

9-10

Page 232 of 962

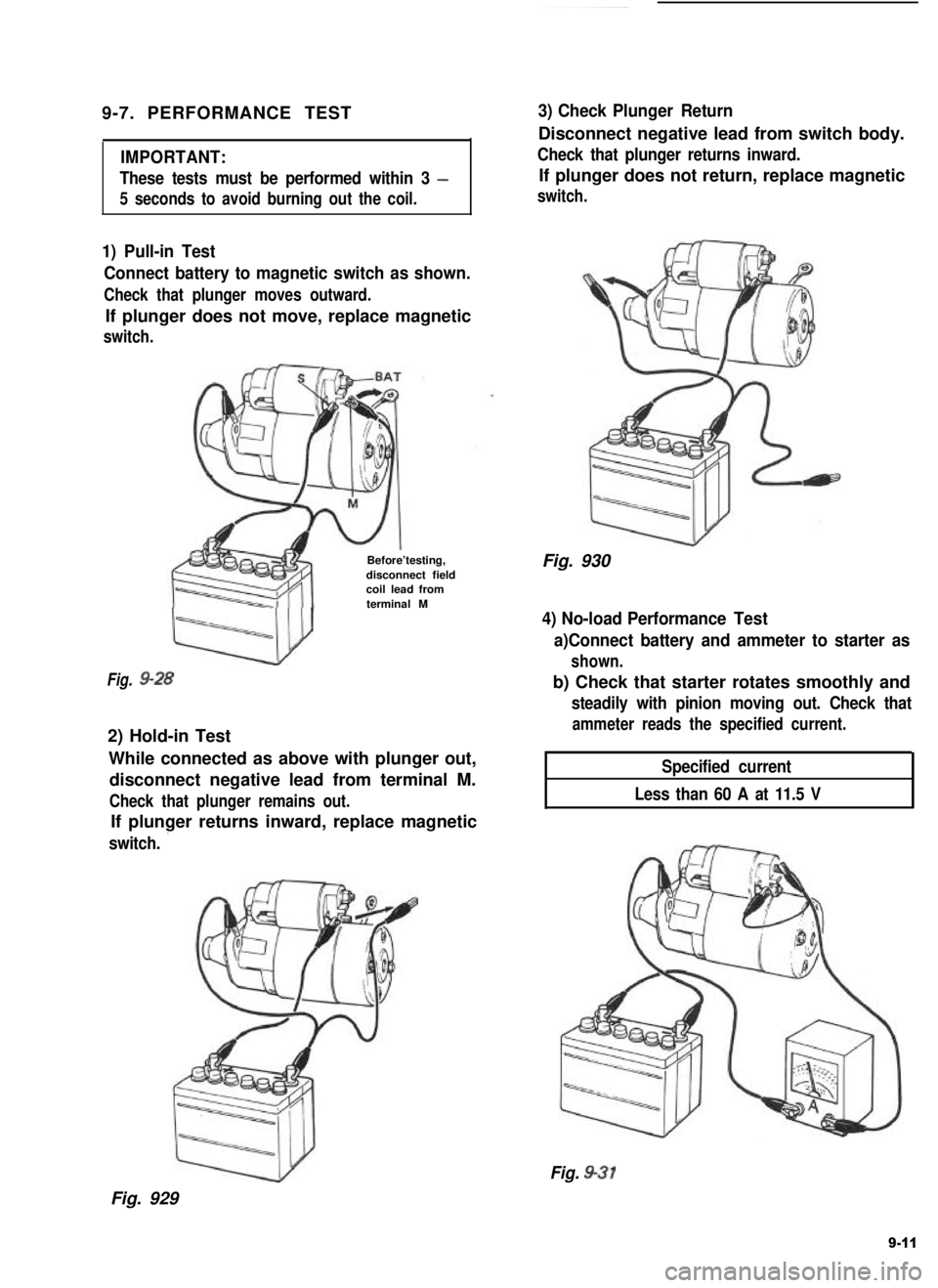

9-7. PERFORMANCE TEST

IMPORTANT:

These tests must be performed within 3 -

5 seconds to avoid burning out the coil.

3) Check Plunger Return

Disconnect negative lead from switch body.

Check that plunger returns inward.

If plunger does not return, replace magnetic

switch.

1) Pull-in Test

Connect battery to magnetic switch as shown.

Check that plunger moves outward.

If plunger does not move, replace magnetic

switch.

Fig.

Before’testing,disconnect fieldcoil lead fromterminal M

w

9-28

2) Hold-in Test

While connected as above with plunger out,

disconnect negative lead from terminal M.

Check that plunger remains out.

If plunger returns inward, replace magnetic

switch. ’

Fig. 930

4) No-load Performance Test

a)Connect battery and ammeter to starter as

shown.

b) Check that starter rotates smoothly and

steadily with pinion moving out. Check that

ammeter reads the specified current.

Specified current

Less than 60 A at 11.5 V

Fig. 931

Fig. 929

9-11

Page 233 of 962

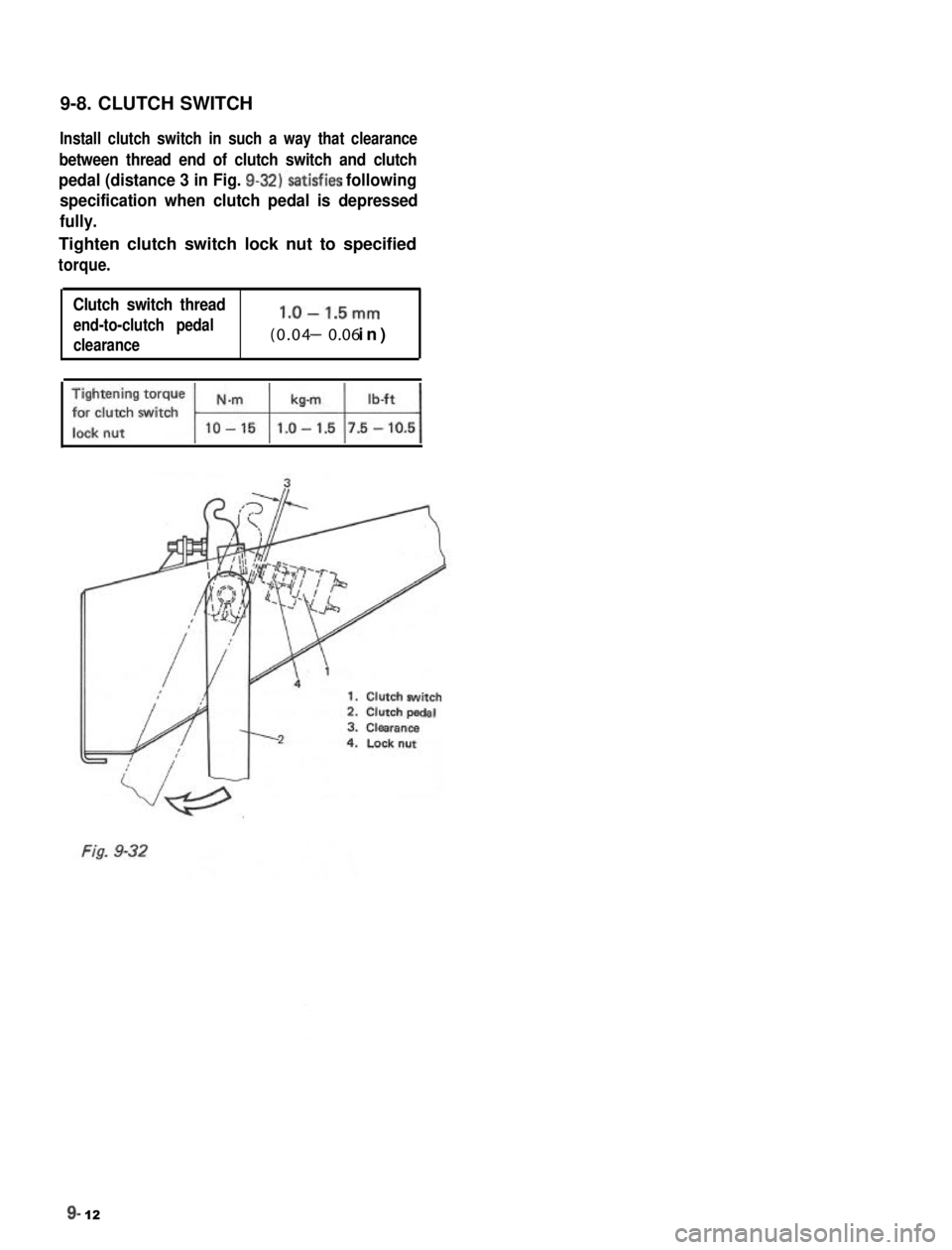

9-8. CLUTCH SWITCH

Install clutch switch in such a way that clearance

between thread end of clutch switch and clutch

pedal (distance 3 in Fig. 9-32)‘satisfies following

specification when clutch pedal is depressed

fully.

Tighten clutch switch lock nut to specified

torque.

Clutch switch thread

end-to-clutch pedall.O-1.5mm

clearance(0.04 - 0.06 in)

9- 12

Page 234 of 962

SECTION 10

CHARGING SYSTEM

CONTENTS

10-l. ALTERNATOR. . . . . . . . . . ..L.............. . . . . . . . . . . .:. . .

GENERAL DESCRIPTION10-2

DATA AND SPECIFICATION...............................10-3

DIAGNOSIS............................................10-3

REMOVAL............................................ 10-6

DISASSEMBLY.........................................10-6

INSPECTION...........................................10-8

ASSEMBLY............................................ 10-9

10-2. BATTERY.............................................10-10

GENERAL DESCRIPTION................................ 10-10

CARE OF THE BATTERY................................10-10

REMOVE AND REPLACE................................ 10-12

BATTERY CABLE...................................... 10-12

..............................

10-2

10

10-1

Page 235 of 962

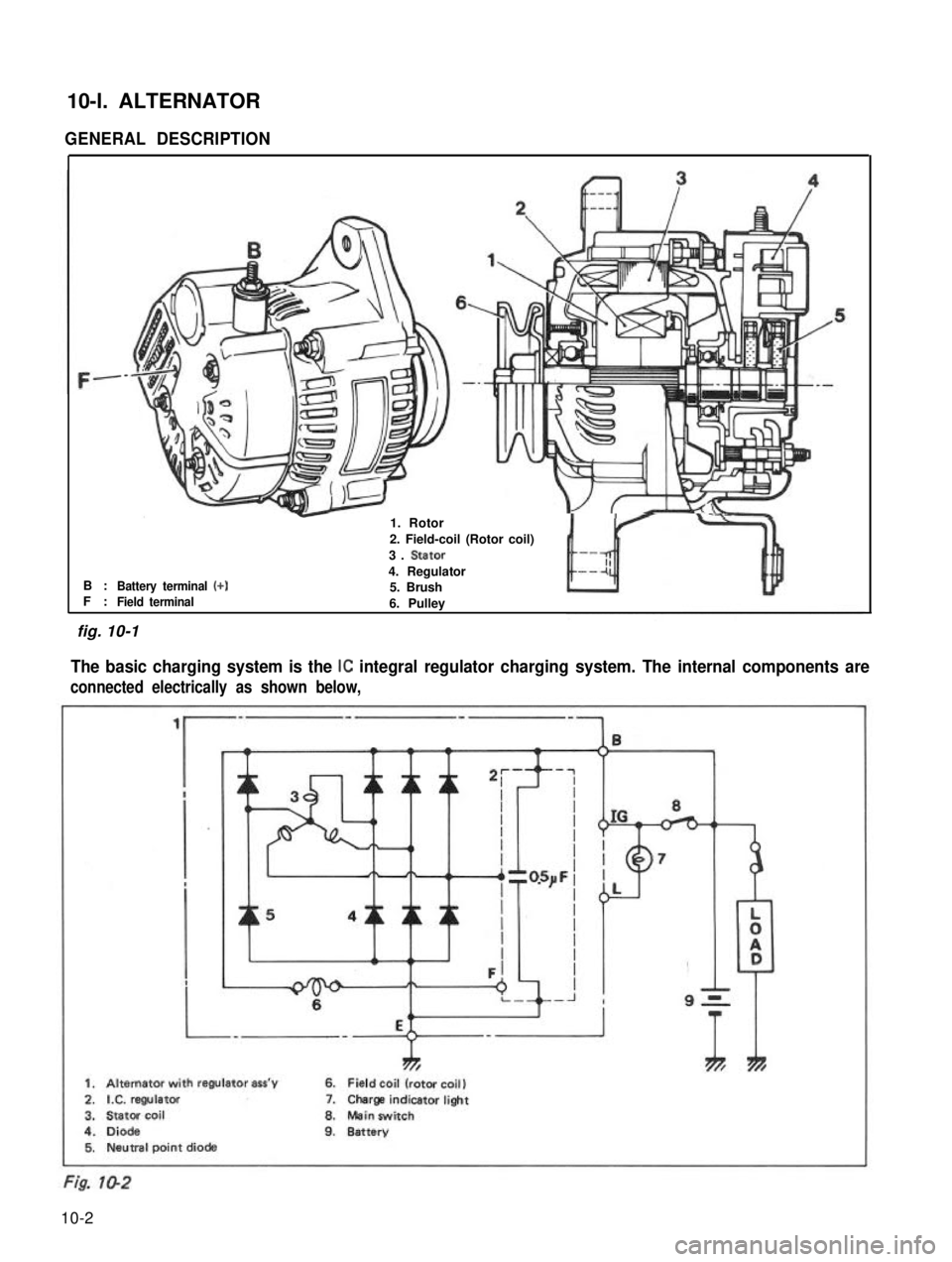

10-l. ALTERNATOR

GENERAL DESCRIPTION

B :F :Battery terminal (+)

-1. Rotor

2. Field-coil (Rotor coil)

3. Stator

4. Regulator5. BrushField terminal6. Pulley

The basic charging system is the IC integral regulator charging system. The internal components are

connected electrically as shown below,

ThTh*

1. Alternator with regulator ass’y6. Field coil (rotor coil)

2.IX. regulator7.Charge indicatorlight

3.Stator coil8.Mein switch

4.Diode9.Battery5. Neutral point diode

fig. 10-1

10-2

Page 236 of 962

The alternator features a solid state regulator

that is mounted inside the alternator. All regula-

tor components are enclosed into a solid mold,

and this unit along with the brush holder assemb-

ly is attached to the slip ring end frame. The

regulator voltage setting cannot be adjusted.

The alternator rotor bearings contain enough

grease to eliminate the need for periodic lubri-

cation. Two brushes carry current through the

two slip rings to the field coil mounted on the

rotor, and under normal conditions will provide

long period of attention-free service.

The stator windings are assembled on the inside

of a laminated core that forms part of the

alternator frame. A rectifier bridge connected

to the stator windings contains six diodes,

and electrically changes the stator A.C. voltages

to a D.C. voltage which appears at the generator

output terminal.

The neutral diodes serve to convert the voltage

fluctuation at the neutral point to direct current

for increasing the alternator output.

A condenser mounted in the end frame protects

the diodes from high voltages and suppresses

radio noise.

DATA AND SPECIFICATION

Nominal operating

voltaga

Max. alternator output

12 volts

45A

No-load alternator speed

IDirection of rotationClockwise as view-

ed from oullev side

Maximum permissible

alternator speed

Working temperature

range

Rectification

15,000 rpm (r/min)

-3o- 90°C

(-22 - 194” F)

Full wave

rectification

Noisy Alternator

Noise from the alternator may be caused by a

loose drive pulley, loose mounting bolts, worn

or dirty bearings, defective diode, or defective

stator.

DIAGNOSIS

A charging circuit wiring diagram for alternator

connection is shown above. To avoid damage,

always follow these precautions:

1) Do not mistake the polarities of IG terminal

and L terminal.

2) Do not create short circuit between IG and

L terminals. Always connect these terminals

through a lamp.

3) Do not connect any load between L and E.

Trouble in the charging system will show up

as one or more of the following conditions:

a.Faulty indicator lamp operation.

b. An undercharged battery as evidenced by

slow cranking or indicator clear with red

dot.

c. An overcharged battery as evidenced by

excessive spewing of electrolyte from the

vents.

10-3

Page 237 of 962

A. Faulty Indicator Lamp Operation

Problem

Charge light does not light

with ignition ON and engine

off

Charge light does not go out

with engine running

(battery requires frequent

re-

charging) Possible cause

Correcti on

Fuse blown

Check fuse

Light burned outReplace light

Wiring connection loose Tighten loose connections

IC regulator faultyReplace IC regulator

Drive belt loose or worn Adjust or replace drive belt

Battery cables loose, corroded or worn Repair or replace cables

IC regulator or alternator faultyCheck charging system

Wiring faulty.Repair wiring

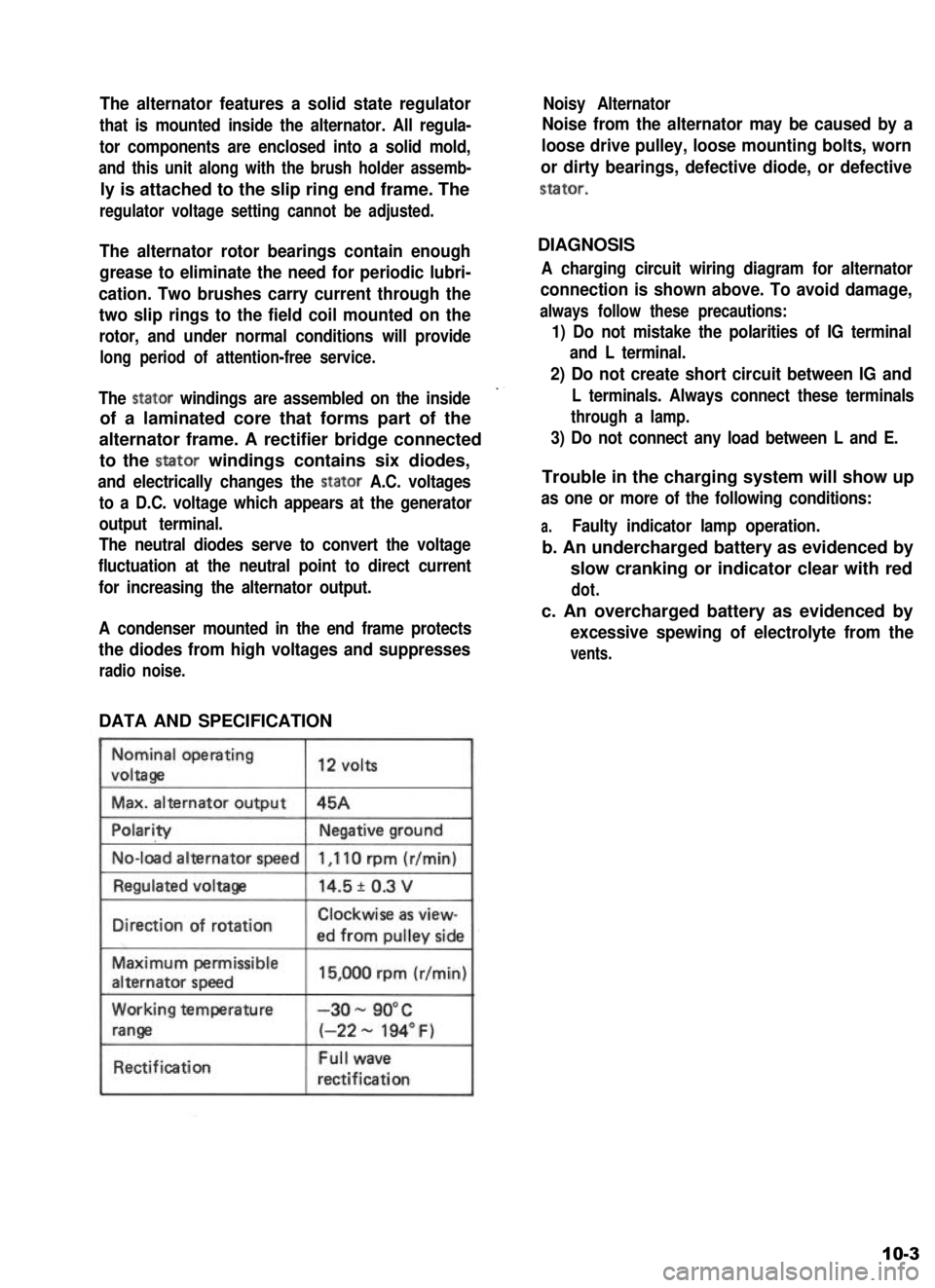

B. Undercharged Battery a. Voltmeter

This condition, as shown by slow cranking or indicator clear with red dot, can be caused by

one or more of the following conditions even

though the indicator lamp may be operating

normally. The following procedures also apply

to cars with a voltmeter.

1) Insure that the undercharged condition has

not been caused by accessories left on for

extended period.

2) Check drive belt for proper tension.

3) If a battery defect is suspected, refer to

latter part of this section, p. 10-l 0 - p, 1 O-

11.

4) Inspect wiring for defects. Check all connec- tions for tightness and cleanliness, including

slip connectors at alternator and bulkhead,

and battery cable connections at battery,

starter and ignition ground cable.

5) Connect voltmeter and ammeter as shown inthe diagram below.

Set between alternator (B) terminal and

ground.

b. Ammeter

Set between alternator (B) terminal and

battery (+) terminal.

6) Current and voltage measurements

a. No-load check

Run engine from idling up to 2,000 r/min

(rpm) and read meters.

NOTE:

Consideration should be taken that the voltage

will vary somewhat with regulator case tempe-

rature.

Fig. 10-3

10-4

1.Generator

2.Ammeter

3. Volt meter

4. Battery

6. Load

6. Switch

Page 238 of 962

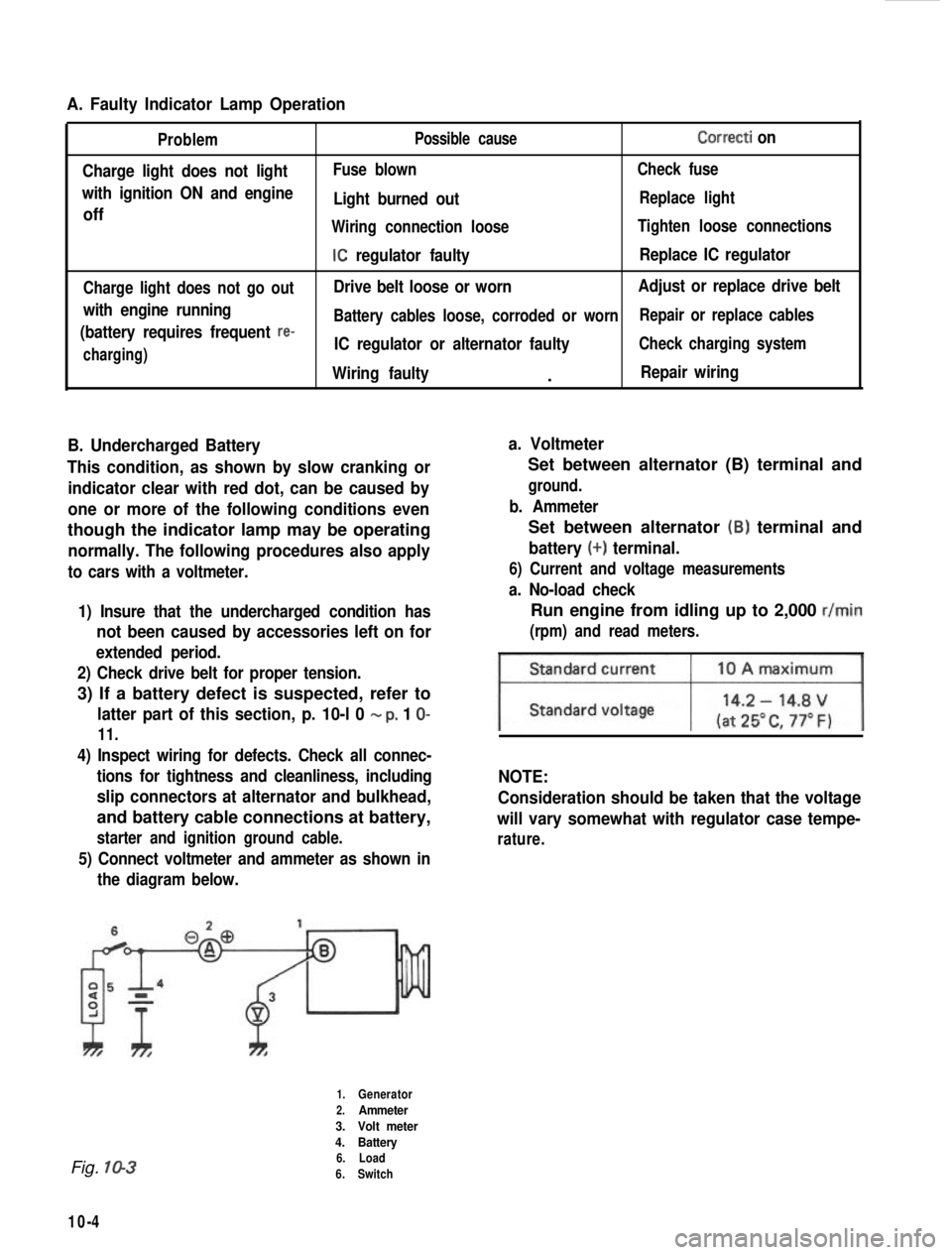

Volt

15.5 . .

14.5 _,

13.5 .,

15.32

15.02

Run engine at 2,000 r/min (rpm) and turn

on headlamps and heater motor.

Measure current and if less than 20A, repair

alternator.

C. Overcharged Battery

1) If an obvious overcharge condition exists

as evidenced by excessive spewing of elec-

trolyte, proceed to DISASSEMBLY underIIIIALTERNATOR SERVICE on p. 10-6 and

-40°C 025Oc135Occheck field windings for grounds and shorts.!-4O“FI(77’F)(275*F)If defective, replace rotor.

b. Load check

Fig. 10-4

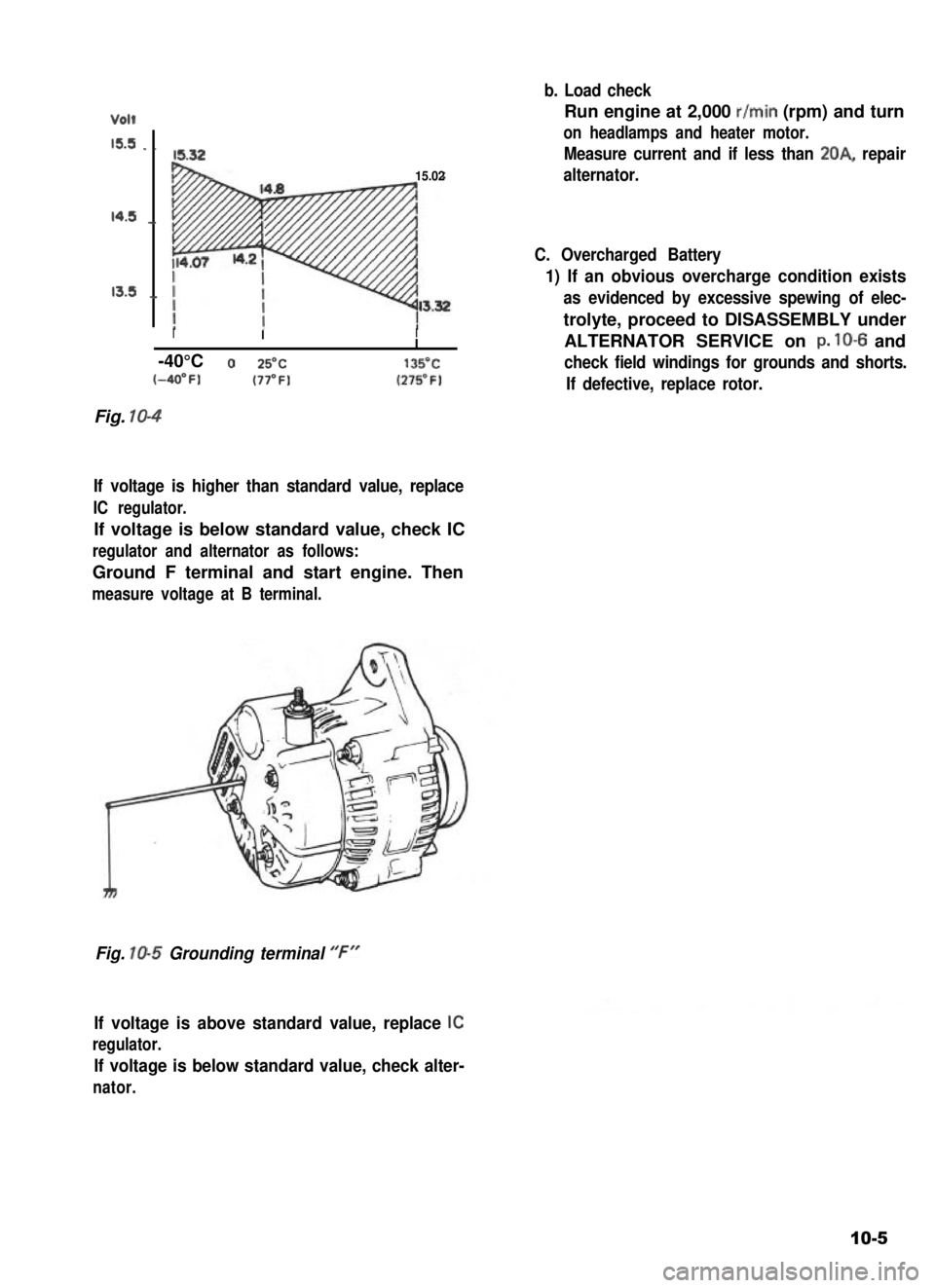

If voltage is higher than standard value, replace

IC regulator.

If voltage is below standard value, check IC

regulator and alternator as follows:

Ground F terminal and start engine. Then

measure voltage at B terminal.

Fig. 105 Grounding terminal ‘F”

If voltage is above standard value, replace IC

regulator.

If voltage is below standard value, check alter-

nator.

10-5

Page 239 of 962

ALTERNATOR SERVICE

REMOVAL

1) Remove battery (-) terminal.

2) Disconnect alternator lead wires (coupler & white lead wire).

3) Unclamp brake pipe from pipe clamp on radiator under cover and remove radiator under cover.

4) Remove alternator mounting bolts and alternator drive belt adjusting bolt.

5) Take down alternator.

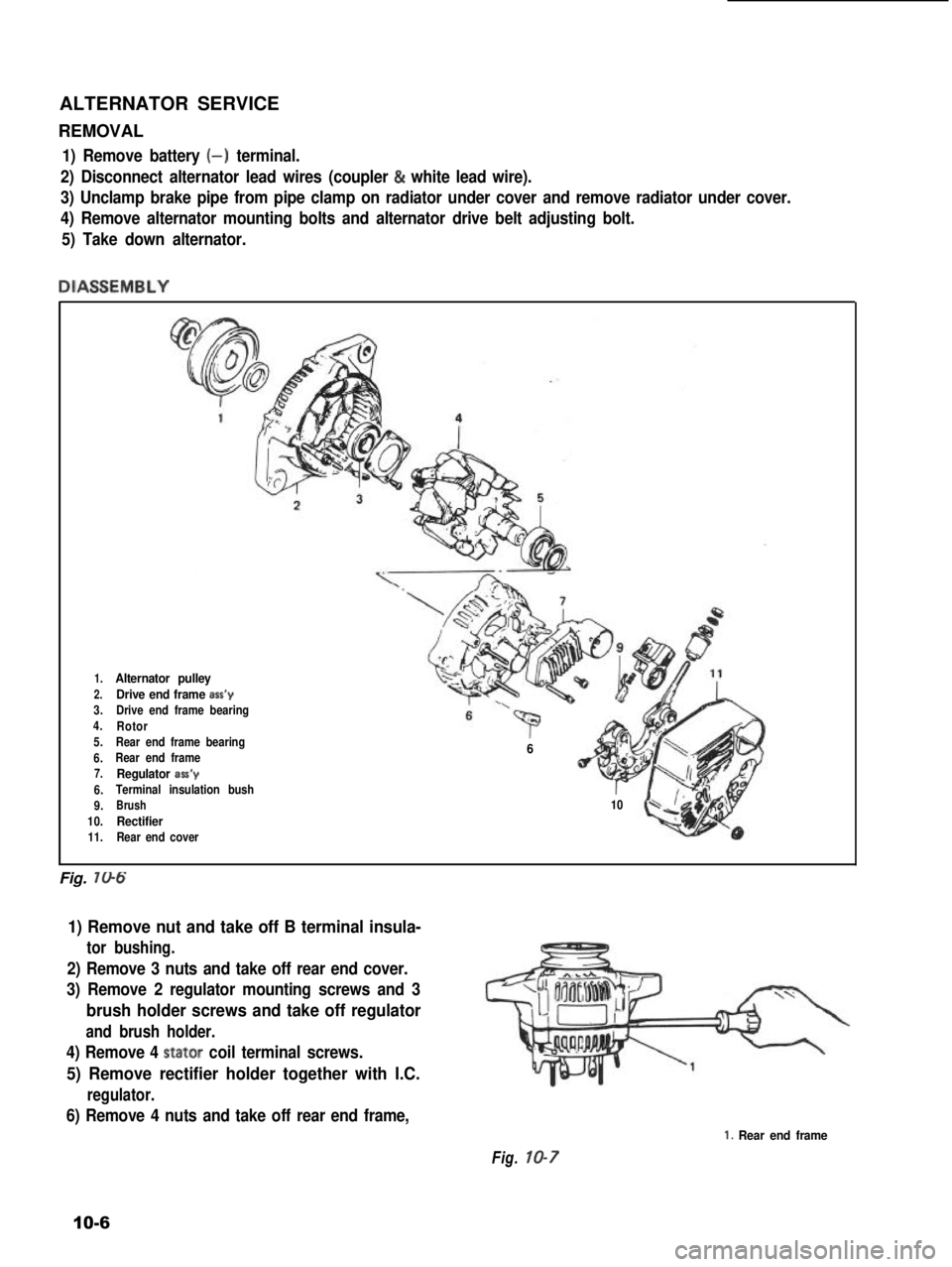

DIASSEMBLY

1.Alternator pulley

2.Drive end frame ass’y3.Drive end frame bearing4.Rotor5.Rear end frame bearing

6.Rear end frame7.Regulator aa’y

6.Terminal insulation bush

9.Brush

10.Rectifier11.Rear end cover

‘p” “i6

r10

Fig. 706

1) Remove nut and take off B terminal insula-

tor bushing.

2) Remove 3 nuts and take off rear end cover.

3) Remove 2 regulator mounting screws and 3

brush holder screws and take off regulator

and brush holder.

4) Remove 4 stator coil terminal screws.

5) Remove rectifier holder together with I.C.

regulator.

6) Remove 4 nuts and take off rear end frame,

Fig. 10-7

1. Rear end frame

10-6

Page 240 of 962

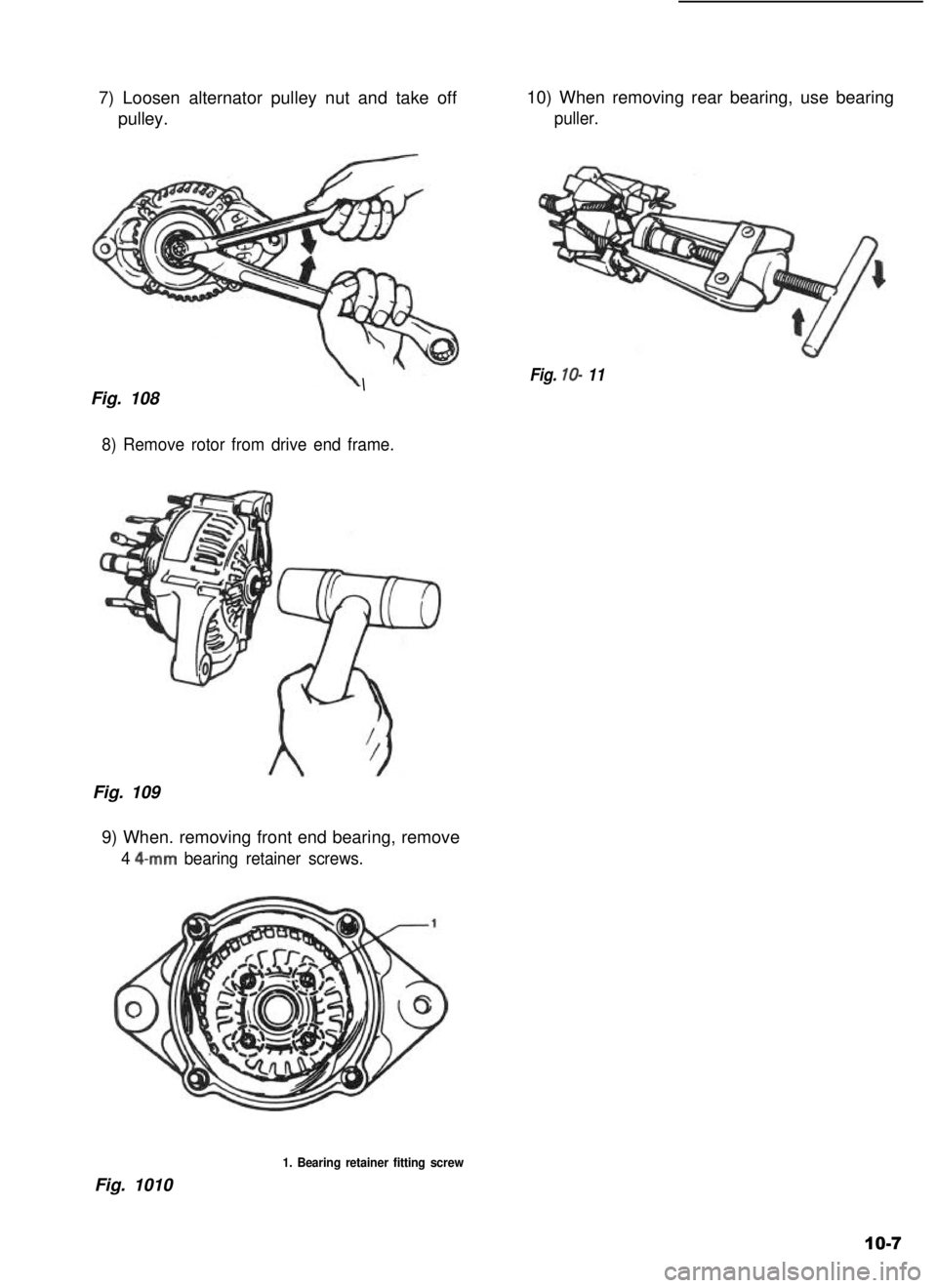

7) Loosen alternator pulley nut and take off

pulley.

10) When removing rear bearing, use bearing

puller.

Fig. 108\Fig. lo- 11

8) Remove rotor from drive end frame.

Fig. 109

9) When. removing front end bearing, remove

4 4-mm bearing retainer screws.

Fig. 1010

1. Bearing retainer fitting screw

10-7