SUZUKI GRAND VITARA 1987 Service Repair Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 261 of 962

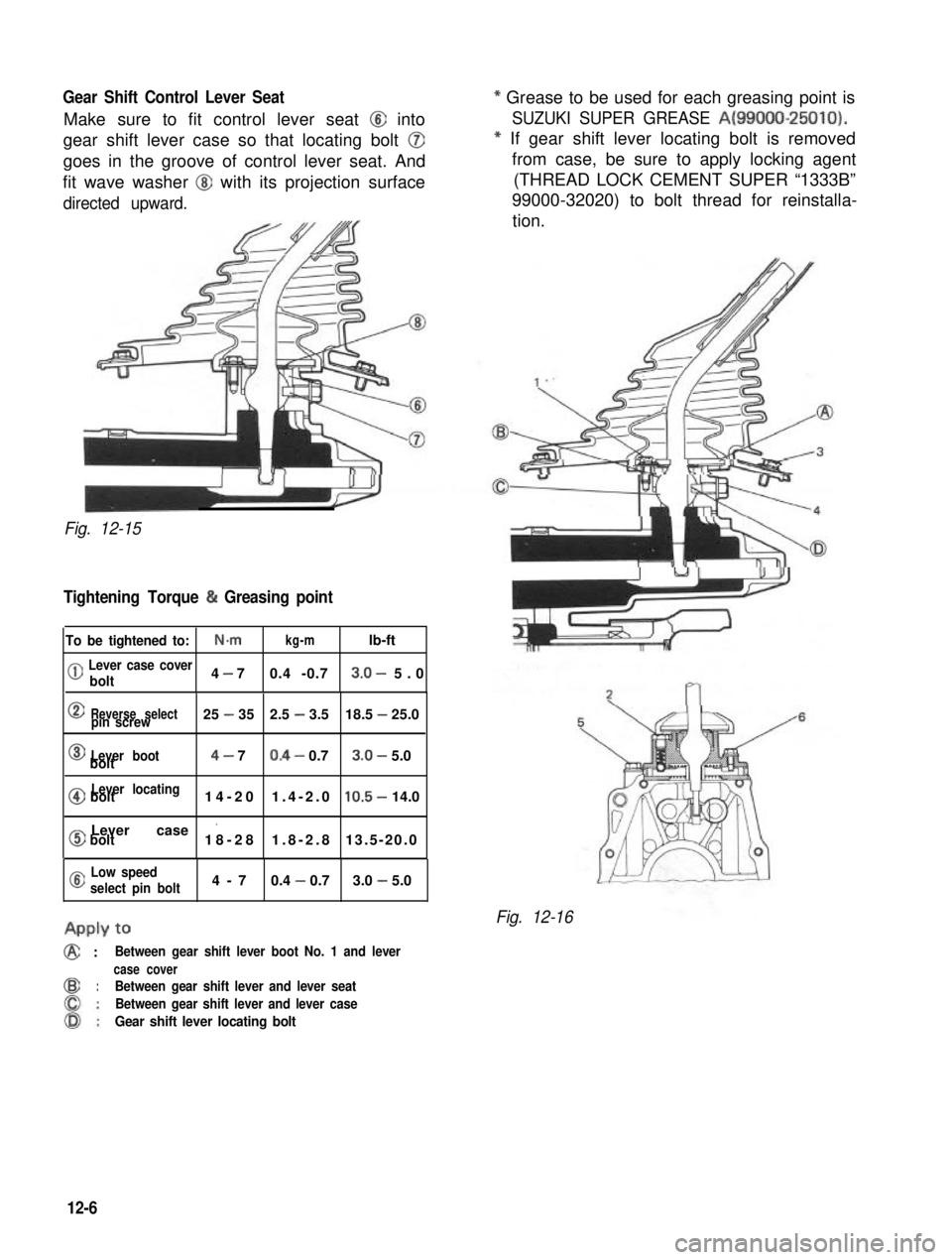

Gear Shift Control Lever Seat

Make sure to fit control lever seat @I into

gear shift lever case so that locating bolt @

goes in the groove of control lever seat. And

fit wave washer @J with its projection surface

directed upward.

--

Fig. 12-15

Tightening Torque (h Greasing point

To be tightened to:N-mkg-mlb-ft

(jj Lever case cover

bolt4 - 70.4 -0.73.0- 5.0

0Reverse selectpin screw25 - 352.5 - 3.518.5 - 25.0

0Lever bootbolt4- 70.4- 0.73.0- 5.0

@Lever locatingbolt14-201.4-2.010.5- 14.0

0Lever case ’bolt18-281.8-2.813.5-20.0

a Low speed

select pin bolt4-70.4 - 0.73.0 - 5.0

APPLY to

@ :Between gear shift lever boot No. 1 and lever

case cover

@:Between gear shift lever and lever seat

Between gear shift lever and lever case

Gear shift lever locating bolt

* Grease to be used for each greasing point is

SUZUKI SUPER GREASE A(99000-25010).

* If gear shift lever locating bolt is removed

from case, be sure to apply locking agent

(THREAD LOCK CEMENT SUPER “1333B”

99000-32020) to bolt thread for reinstalla-

tion.

Fig. 12-16

12-6

Page 262 of 962

SECTION 13

TRANSMISSION

CONTENTS

13-l. GENERAL DESCRIPTION..................................13-1

TRANSMISSION GEAR RATIO..............................13-3

13-3. DISMOUNTING...........................................13-4

DISASSEMBLY............................................13-5

13-5. INSPECTION OF COMPONENTS............................13-12

13-6. IMPORTANT STEPS IN INSTALLATION.....................13-15

13-7. MAINTENANCE SERVICES................................13-25

13-8. RECOMMENDED TORQUE SPECIFICATION.................. 13-26

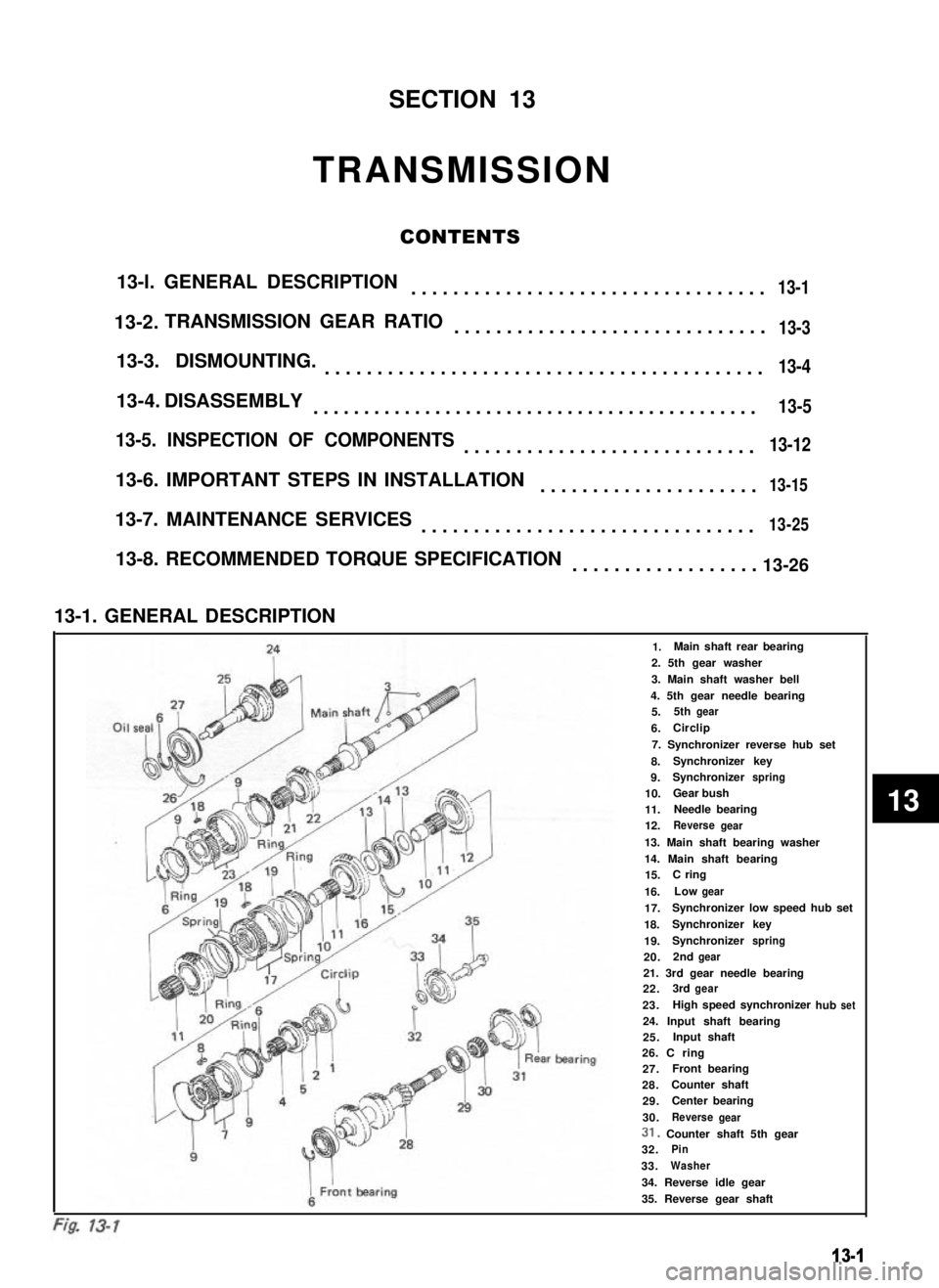

13-1. GENERAL DESCRIPTION

241.Main shaft rear bearing

2. 5th gear washer

3. Main shaft washer bell

4. 5th gear needle bearing

Oil sealfiMain shi5.5thgear

6.ICirclip

7. Synchronizer reverse hub set

8.Synchronizer key

9.Synchronizerspring

10.Gear bush

11.Needle bearing

12.Reversegear

13. Main shaft bearing washer

14. Main shaft bearing15.C ring

16.Lowgear

17.Synchronizer low speed hub set

18.Synchronizerkey

19.Synchronizerspring

20.2ndgear

F21. 3rd gear needle bearing22.3rdgear

23.hub

I

1High speed synchronizerset

I

24. Input shaft bearing25.Input shaft

i ’

IL’

ear bearing26. C ring27.AFront bearing

28.Counter shaft

429.Center bearing

930.ReversegearI i31. Counter shaft 5th gear

932.Pin

33.Washer

34. Reverse idle gear

35. Reverse gear shaft

13-1

13-2.

13-4.

13

Page 263 of 962

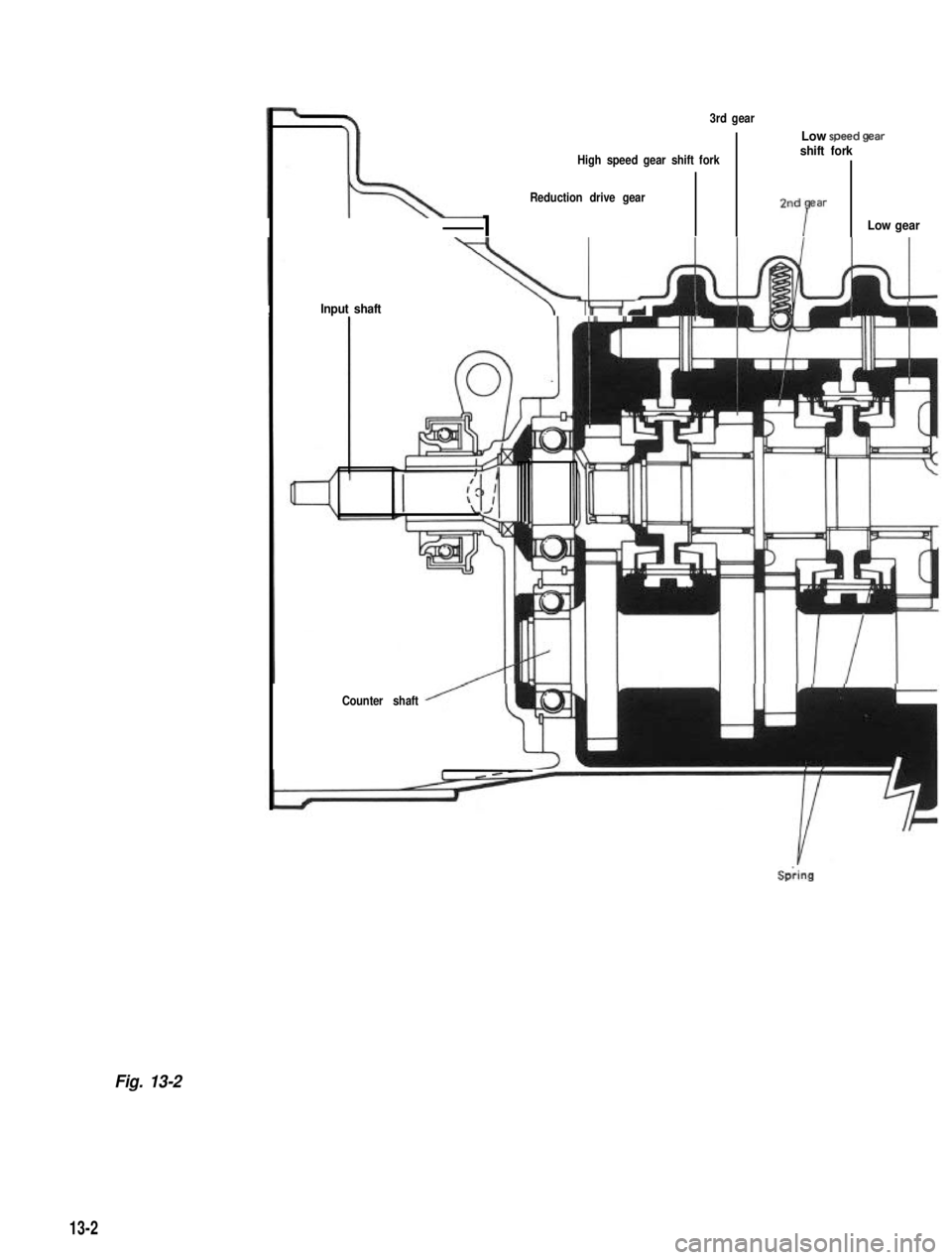

3rd gear

Low soeed qear. -shift forkHigh speed gear shift fork

Reduction drive gear

2ndqsarLow gear Tar

Input shaft\ -ha-A

Counter shaft

Spking

Fig. 13-2

13-2

Page 264 of 962

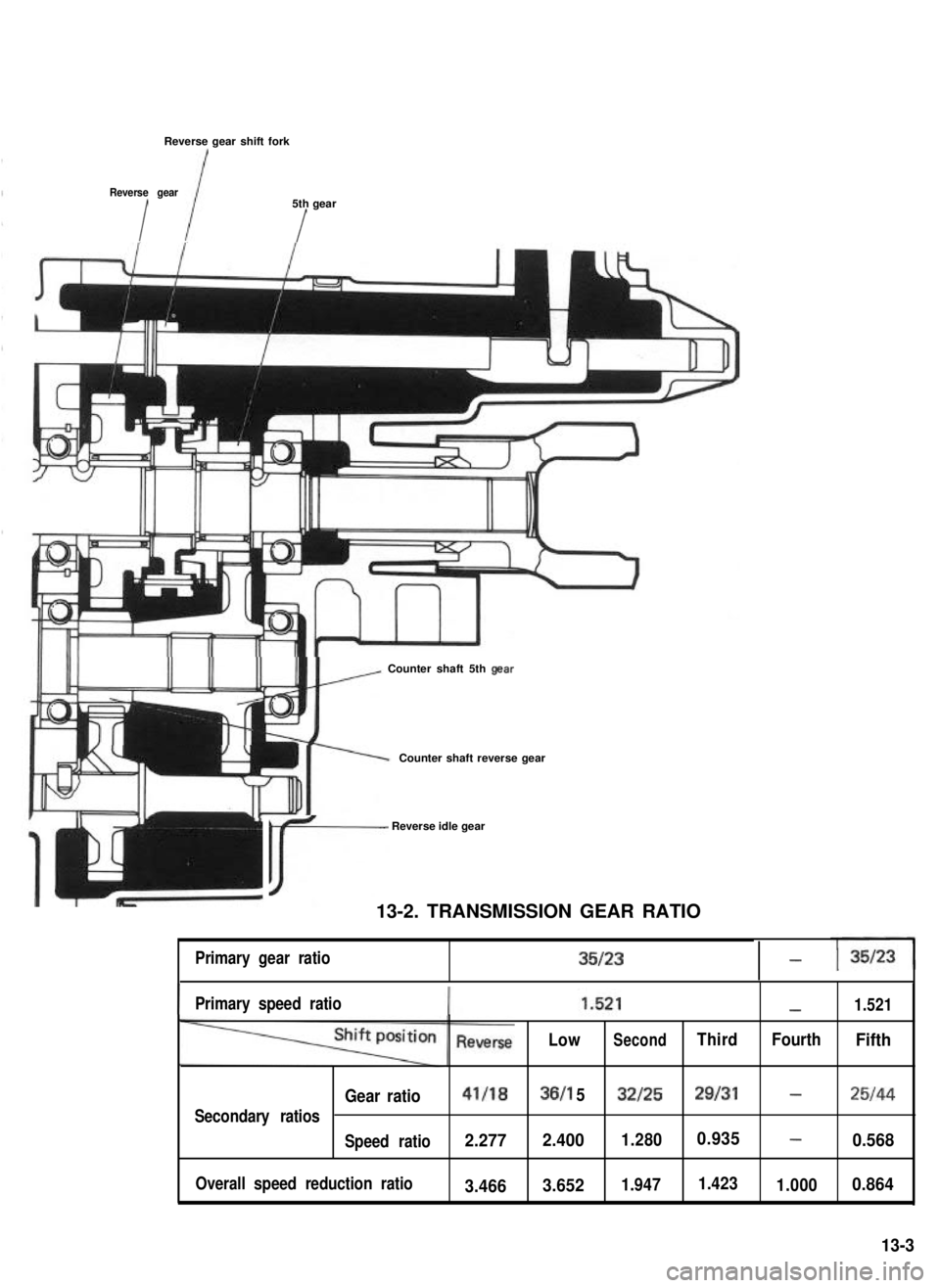

Reverse gear shift fork

Reverse gear

Ii

5th gear

I

Counter shaft 5th gaar

Counter shaft reverse gear

r

Reverse idle gear

13-2. TRANSMISSION GEAR RATIO

Primary gear ratio35123-

IPrimary speed ratio

Gear ratio

Secondary ratios

Speed ratio

Overall speed reduction ratio

41/18

2.277

3.466

-1.521

LowSecondThirdFourthFifth

36/l53212529131-25144

2.4001.2800.935-0.568

3.6521.9471.4231.0000.864

13-3

Page 265 of 962

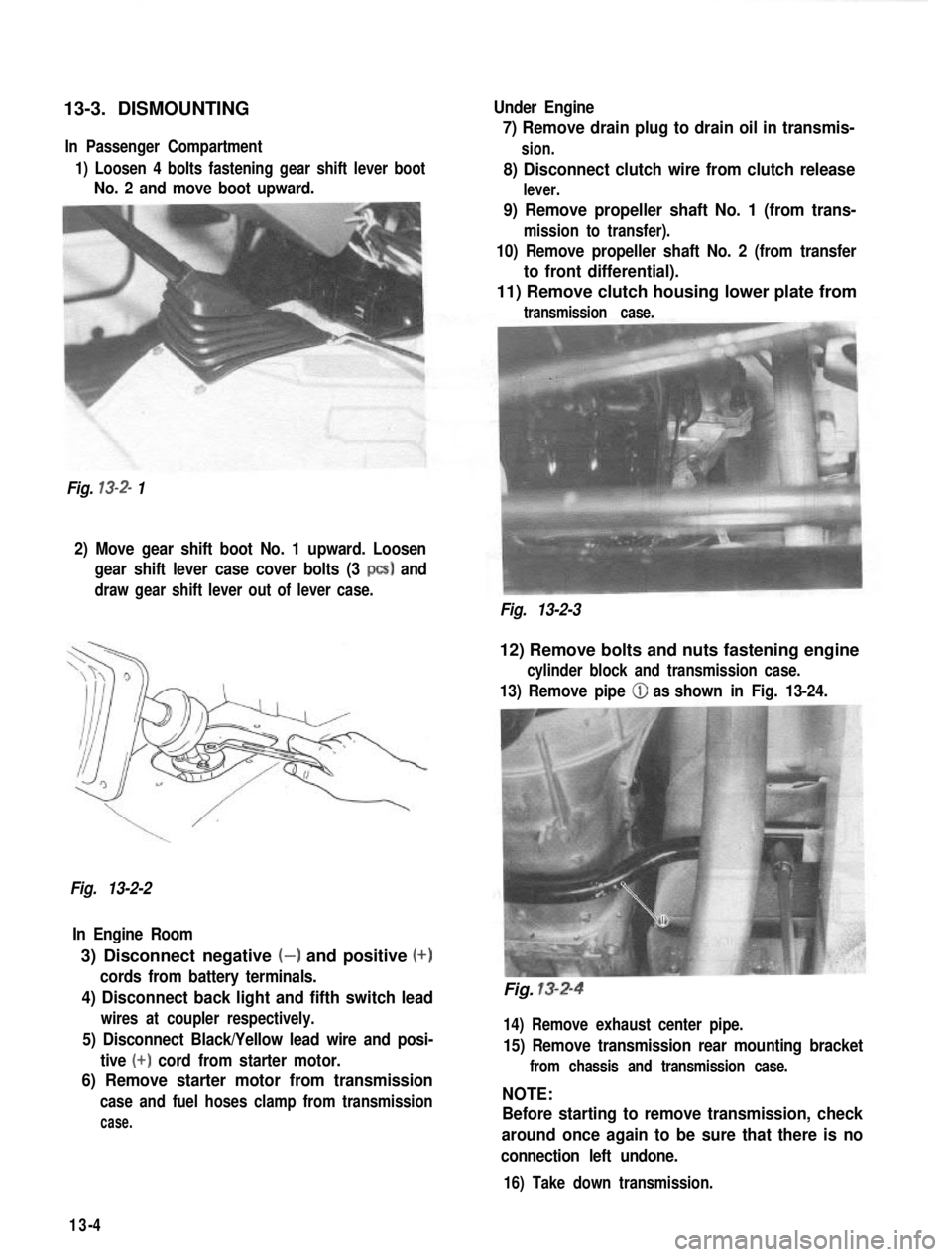

13-3. DISMOUNTINGIn Passenger Compartment

1) Loosen 4 bolts fastening gear shift lever boot

No. 2 and move boot upward.

Fig.

13-2- 1 Under Engine

7) Remove drain plug to drain oil in transmis-

sion.

8) Disconnect clutch wire from clutch release

lever.

9) Remove propeller shaft No. 1 (from trans-

mission to transfer).

10) Remove propeller shaft No. 2 (from transfer

to front differential).

11) Remove clutch housing lower plate from

transmission case.

2) Move gear shift boot No. 1 upward. Loosen

gear shift lever case cover bolts (3

PCS) and

draw gear shift lever out of lever case.

Fig. 13-2-3

Fig. 13-2-2 In Engine Room

3) Disconnect negative (-) and positive (+)

cords from battery terminals.

4) Disconnect back light and fifth switch lead

wires at coupler respectively.

5) Disconnect Black/Yellow lead wire and posi- tive

(+) cord from starter motor.

6) Remove starter motor from transmission

case and fuel hoses clamp from transmission

case.

12) Remove bolts and nuts fastening engine

cylinder block and transmission case.

13) Remove pipe (iJ as shown in Fig. 13-24.

Fig. 13-2-4

14) Remove exhaust center pipe.

15) Remove transmission rear mounting bracket

from chassis and transmission case.

NOTE:

Before starting to remove transmission, check

around once again to be sure that there is no

connection left undone.

16) Take down transmission.

13-4

Page 266 of 962

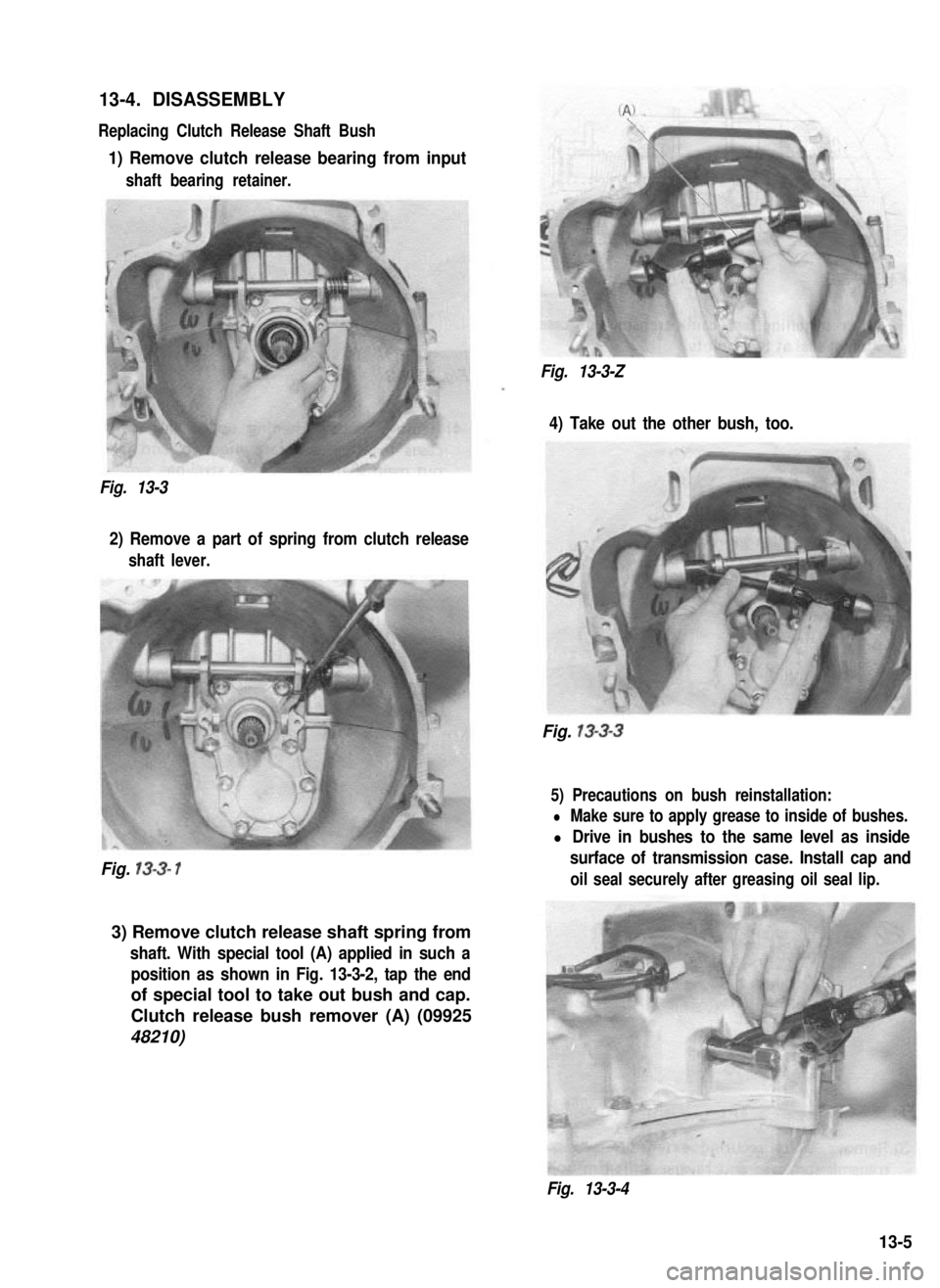

13-4. DISASSEMBLY

Replacing Clutch Release Shaft Bush

1) Remove clutch release bearing from input

shaft bearing retainer.

Fig. 13-3-Z

4) Take out the other bush, too.

Fig. 13-3

2) Remove a part of spring from clutch release

shaft lever.

Fig. 13-3-3

Fig. 13-3- 1

3) Remove clutch release shaft spring from

shaft. With special tool (A) applied in such a

position as shown in Fig. 13-3-2, tap the end

of special tool to take out bush and cap.

Clutch release bush remover (A) (09925

48210)

5) Precautions on bush reinstallation:

l Make sure to apply grease to inside of bushes.

l Drive in bushes to the same level as inside

surface of transmission case. Install cap and

oil seal securely after greasing oil seal lip.

Fig. 13-3-4

13-5

Page 267 of 962

Fig. 13-3-5

l After installing seal, caulk transmission case

against seal at two points.

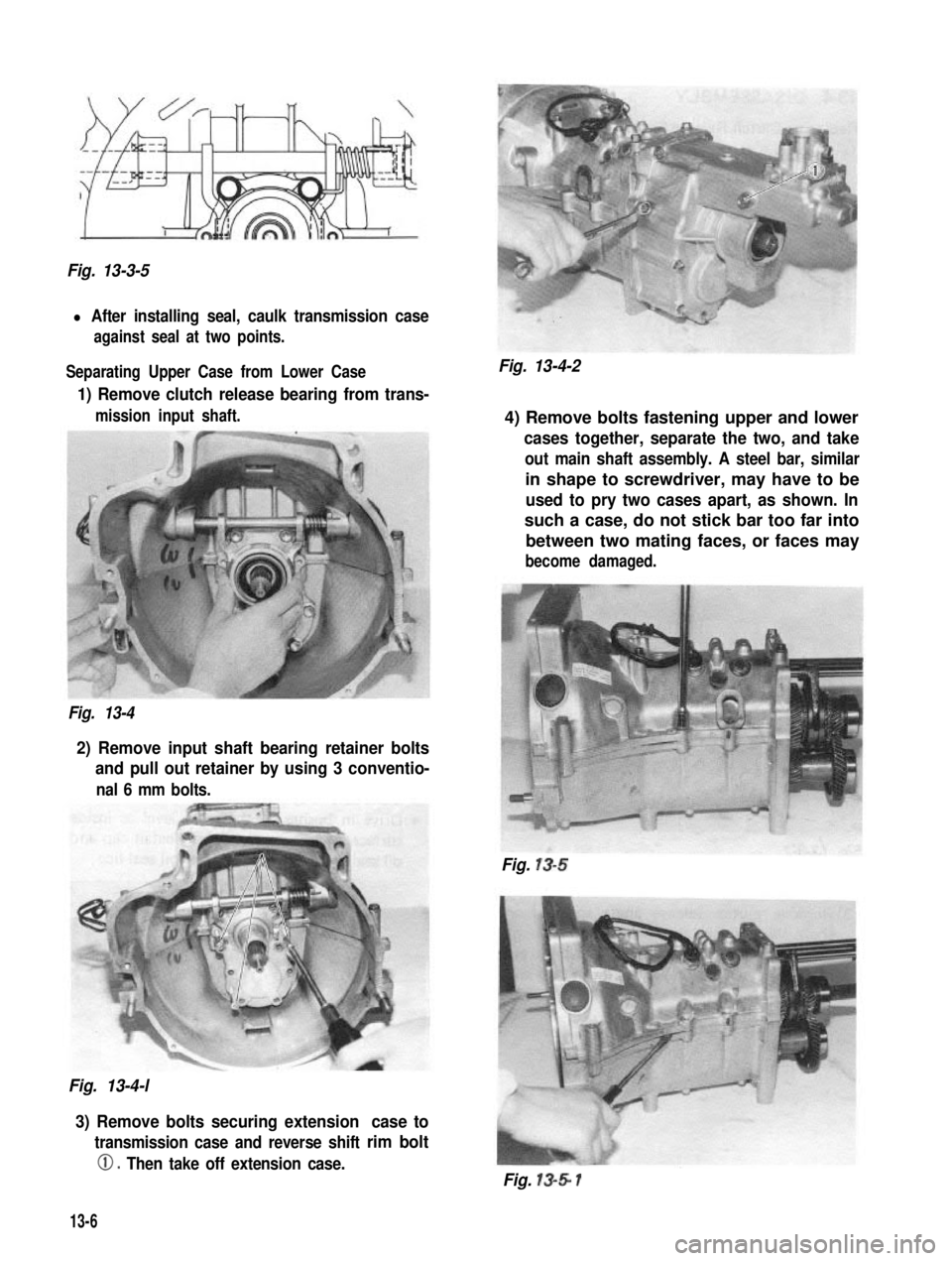

Separating Upper Case from Lower Case

1) Remove clutch release bearing from trans-

mission input shaft.

Fig. 13-4-2

4) Remove bolts fastening upper and lower

cases together, separate the two, and take

out main shaft assembly. A steel bar, similar

in shape to screwdriver, may have to be

used to pry two cases apart, as shown. In

such a case, do not stick bar too far into

between two mating faces, or faces may

become damaged.

Fig. 13-4

2) Remove input shaft bearing retainer bolts

and pull out retainer by using 3 conventio-

nal 6 mm bolts.

Fig. 13-5

Fig. 13-4-l

3) Remove bolts securing extension

transmission case and reverse shift

0. Then take off extension case.

13-6

case to

rim bolt

Fig. 13-5 1

Page 268 of 962

3) Remove counter-shaft 5th gear and counter-

shaft reverse gear.

Fig. 13-5-2

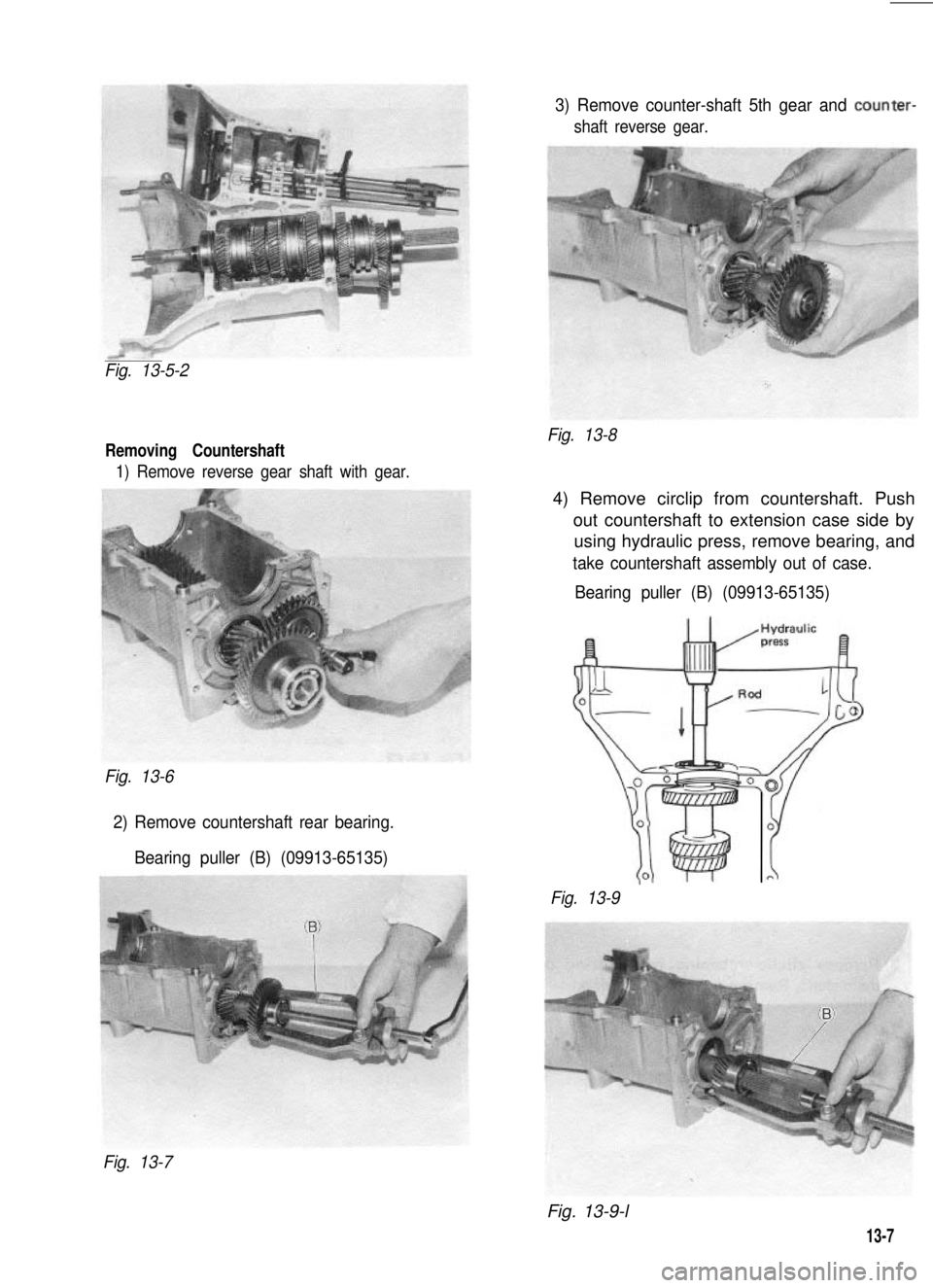

Removing Countershaft

1) Remove reverse gear shaft with gear.

Fig. 13-8

Fig. 13-6

2) Remove countershaft rear bearing.

Bearing puller (B) (09913-65135)

Fig. 13-7

4) Remove circlip from countershaft. Push

out countershaft to extension case side by

using hydraulic press, remove bearing, and

take countershaft assembly out of case.

Bearing puller (B) (09913-65135)

Fig. 13-9

Fig. 13-9-l

13-7

Page 269 of 962

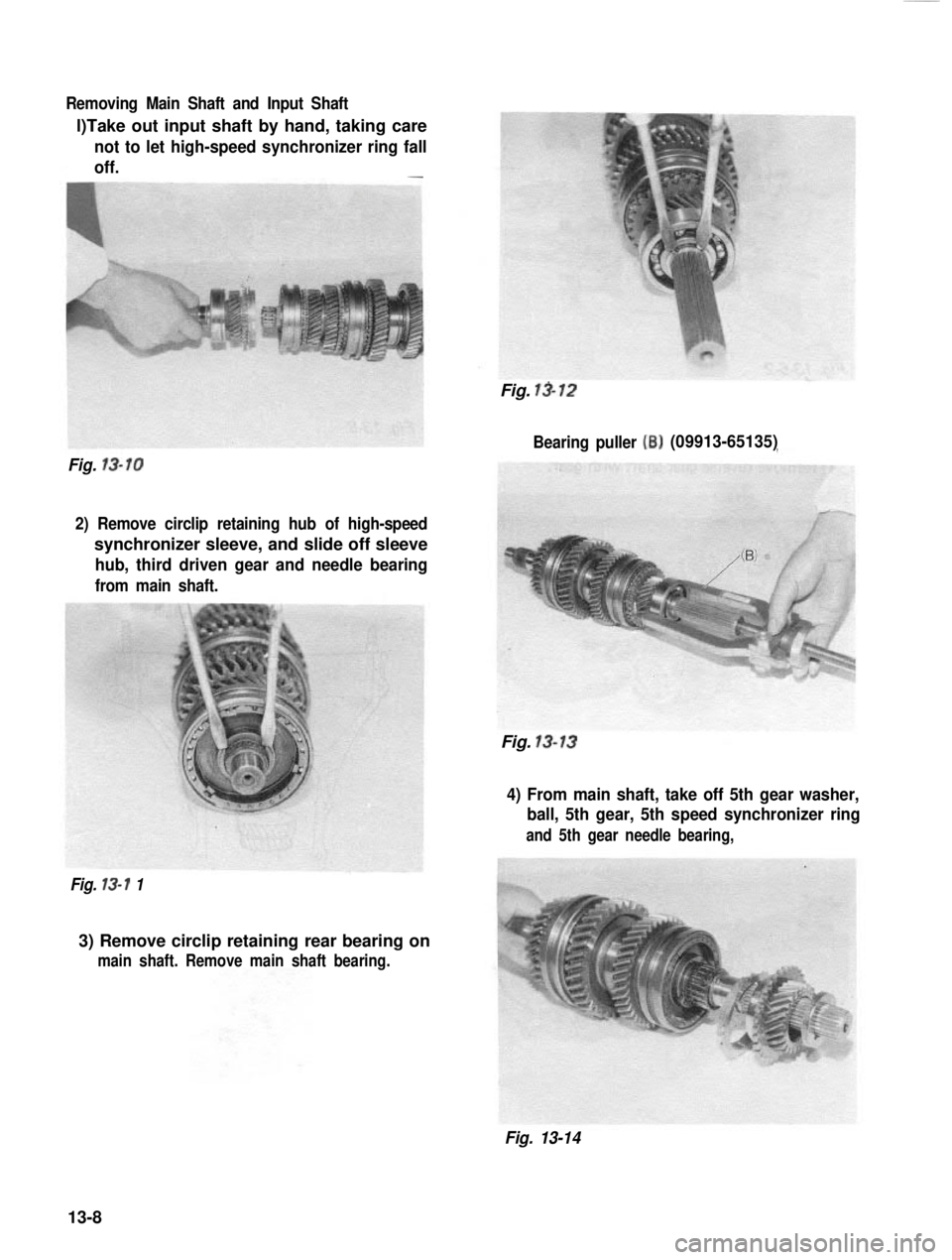

Removing Main Shaft and Input Shaft

l)Take out input shaft by hand, taking care

not to let high-speed synchronizer ring fall

off.

-

Fig. 13-12

Bearing puller

(B)(09913-65135)

Fig.

13-10

2) Remove circlip retaining hub of high-speed

synchronizer sleeve, and slide off sleeve

hub, third driven gear and needle bearing

from main shaft.

Fig. 13-13

Fig.

13-l 1

3) Remove circlip retaining rear bearing on

main shaft. Remove main shaft bearing.

4) From main shaft, take off 5th gear washer,

ball, 5th gear, 5th speed synchronizer ring

and 5th gear needle bearing,

Fig. 13-14

13-8

Page 270 of 962

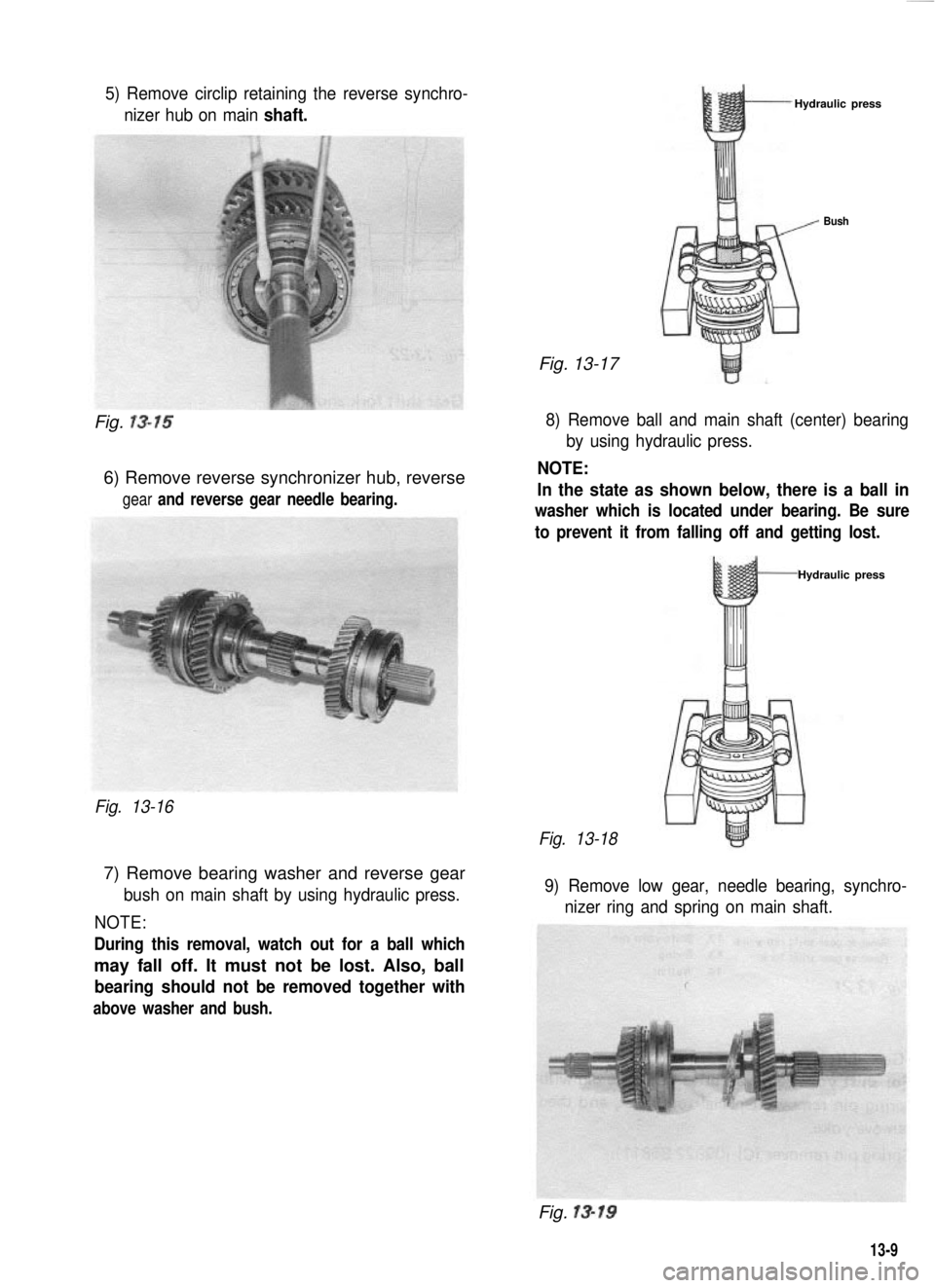

5) Remove circlip retaining the reverse synchro-

nizer hub on main shaft.

Fig. 13-15

6) Remove reverse synchronizer hub, reverse

gear and reverse gear needle bearing.

Hydraulic press

Bush

Fig. 13-17

8) Remove ball and main shaft (center) bearing

by using hydraulic press.

NOTE:

In the state as shown below, there is a ball in

washer which is located under bearing. Be sure

to prevent it from falling off and getting lost.

Hydraulic press

Fig. 13-16

Fig. 13-18

7) Remove bearing washer and reverse gear

bush on main shaft by using hydraulic press.

NOTE:

During this removal, watch out for a ball which

may fall off. It must not be lost. Also, ball

bearing should not be removed together with

above washer and bush.

9) Remove low gear, needle bearing, synchro-

nizer ring and spring on main shaft.

Fig. 13-19

13-9