SUZUKI GRAND VITARA 1987 Service Repair Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 251 of 962

Release Bearing

Replace release bearing if it sticks, rattles or

makes abnormal noise when spun anaturned by

hand.

Fig. 11-10

Input Shaft Bearing

Replace input shaft bearing if it sticks, rattles or

makes abnormal noise when spun and turned by

hand.

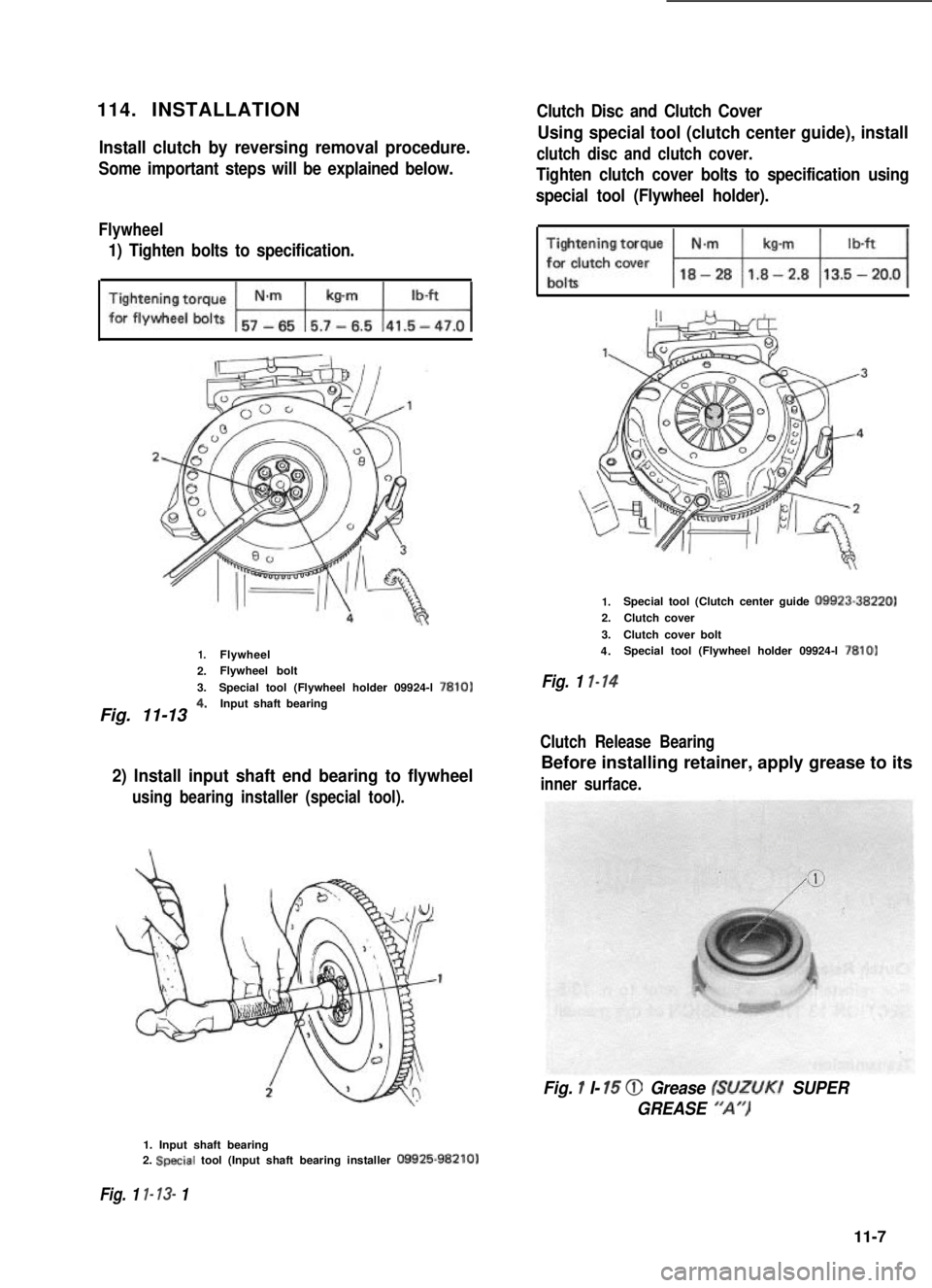

Flywheel

Check surface contacting clutch disc for any

wear or damage.

Fig. 11-12

Fig. 1 I- 11

11-6

Page 252 of 962

114. INSTALLATION

Install clutch by reversing removal procedure.

Some important steps will be explained below.

Flywheel

1) Tighten bolts to specification.

1.Flywheel

2.Flywheel bolt

3.Special tool (Flywheel holder 09924-l 7810)

Fig. 11-13 4*Input shaft bearing

2) Install input shaft end bearing to flywheel

using bearing installer (special tool).

1. Input shaft bearing2. Special tool (Input shaft bearing installer 09925-98210)

Fig. 1 l- 13- 1

Clutch Disc and Clutch Cover

Using special tool (clutch center guide), install

clutch disc and clutch cover.

Tighten clutch cover bolts to specification using

special tool (Flywheel holder).

1.2.

3.

4.

Fig. 1 l-14

Special tool (Clutch center guide 09923-38220)

Clutch cover

Clutch cover boltSpecial tool (Flywheel holder 09924-l 7810)

Clutch Release Bearing

Before installing retainer, apply grease to its

inner surface.

Fig. 1 I- 15 @ Grease (SUZUKI SUPER

GREASE “A’,)

11-7

Page 253 of 962

Clutch Release Shaft Fork

Apply grease to end of fork.

Fig. I l- 16 @ Grease (SUZUKI SUPER

GREASE “‘A “)

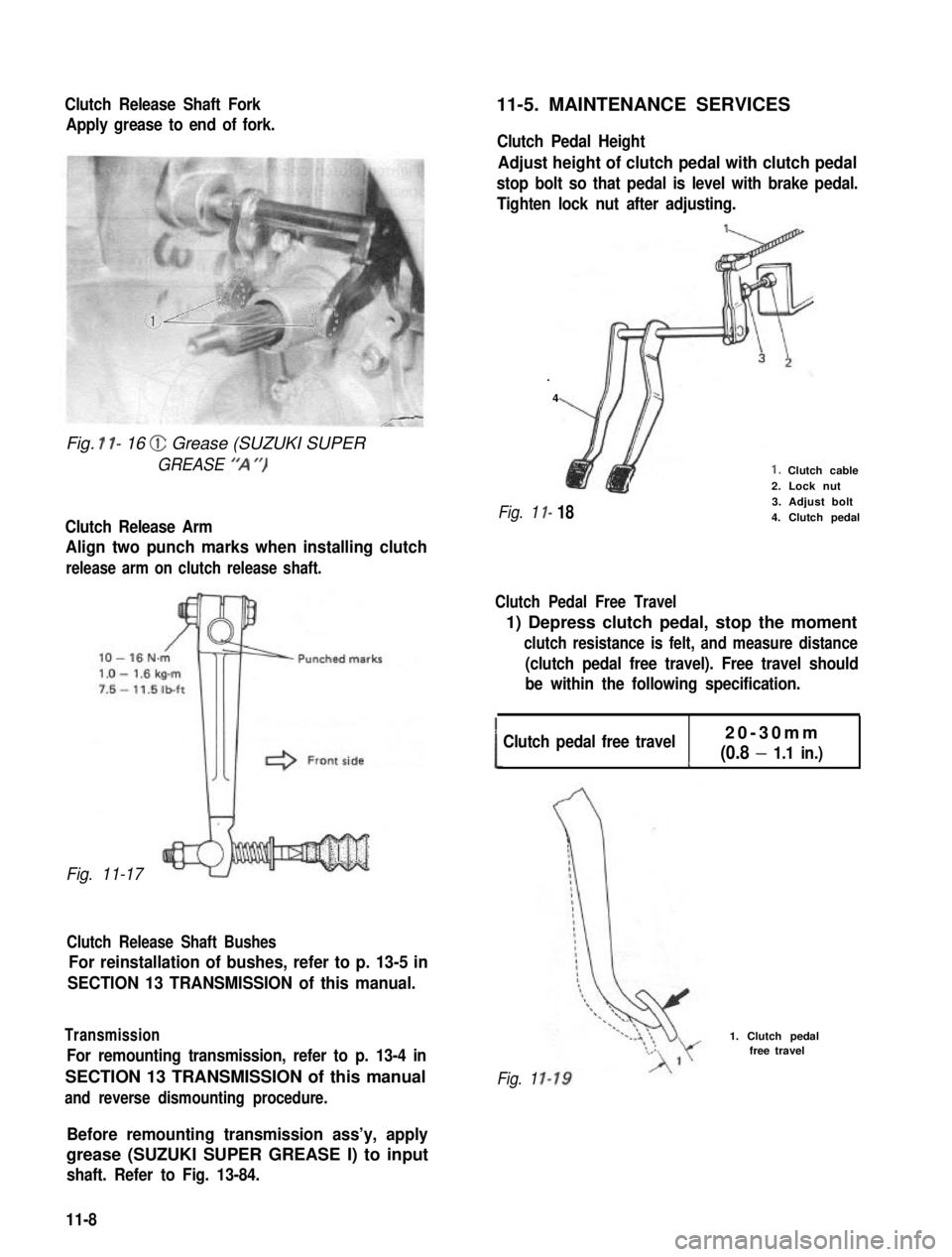

Clutch Release Arm

Align two punch marks when installing clutch

release arm on clutch release shaft.

Fig. 11-17

Clutch Release Shaft Bushes

For reinstallation of bushes, refer to p. 13-5 in

SECTION 13 TRANSMISSION of this manual.

Transmission

For remounting transmission, refer to p. 13-4 in

SECTION 13 TRANSMISSION of this manual

and reverse dismounting procedure.

11-5. MAINTENANCE SERVICES

Clutch Pedal Height

Adjust height of clutch pedal with clutch pedal

stop bolt so that pedal is level with brake pedal.

Tighten lock nut after adjusting.

.

4

I-

I- 18

1. Clutch cable2. Lock nut3. Adjust bolt4. Clutch pedalFig. 1

Clutch Pedal Free Travel

1) Depress clutch pedal, stop the moment

clutch resistance is felt, and measure distance

(clutch pedal free travel). Free travel should

be within the following specification.

!Clutch pedal free travel20-30mm

(0.8 - 1.1 in.)c

Fig. 1

1. Clutch pedalfree travel

Before remounting transmission ass’y, apply

grease (SUZUKI SUPER GREASE I) to input

shaft. Refer to Fig. 13-84.

11-8

Page 254 of 962

2) If free travel is out of specification, adjust it

with clutch cable outer nuts.

NOTE:

After adjusting free travel, make sure that the

clutch cable end protrudes at least 5 mm from

joint nut

1.Clutch cable joint nutAt least 5 mm (0.196 in.)

Fig. 1 l-20

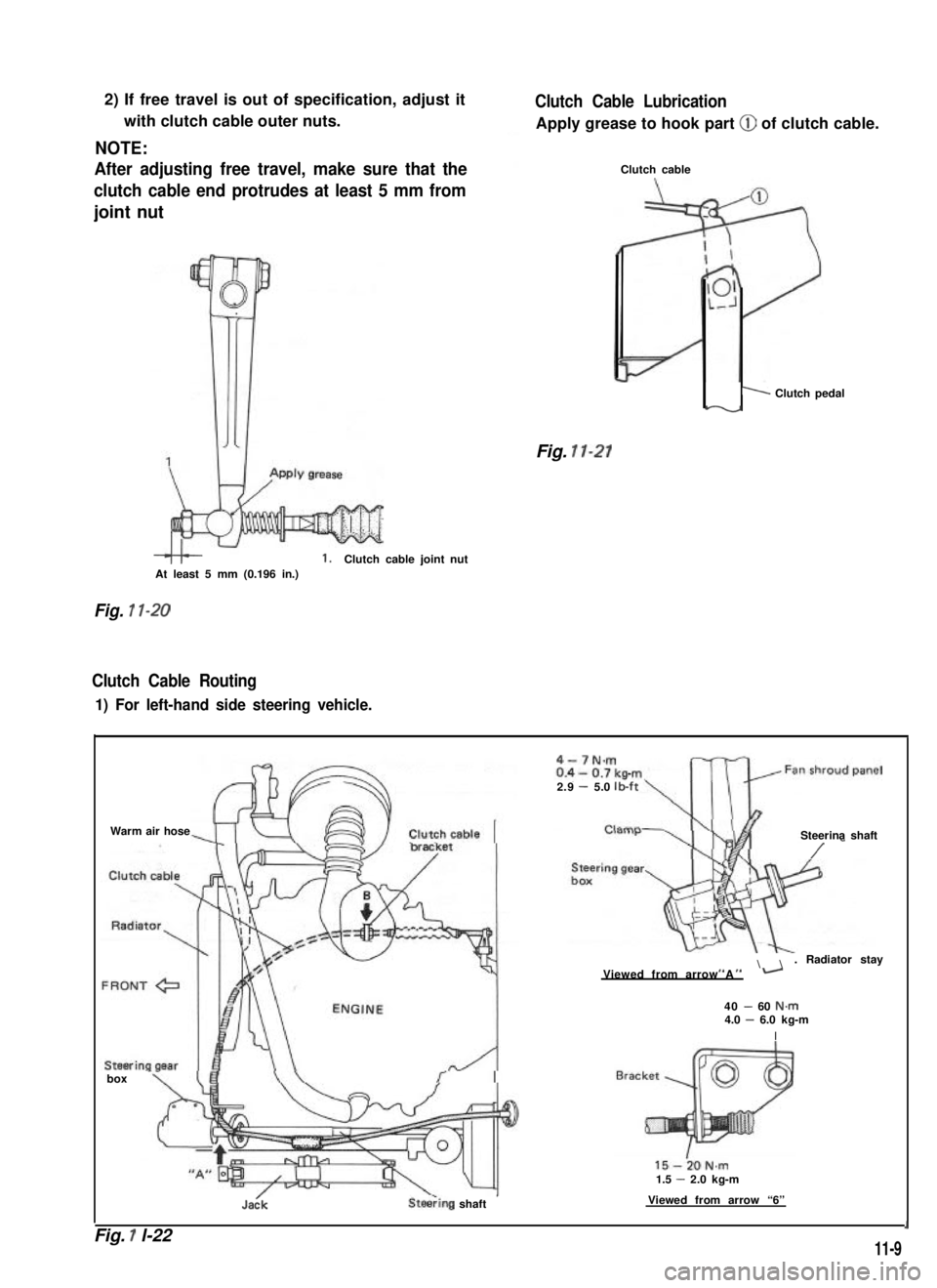

Clutch Cable Routing

1) For left-hand side steering vehicle.

Clutch Cable Lubrication

Apply grease to hook part @ of clutch cable.

Clutch cable

1 Clutch pedaly-v

Fig. 11-21

Warm air hose

box -

Jadk

15-i0N.m1.5 - 2.0 kg-m

SteeTing shaft’Viewed from arrow “6”

4-7N.m

2.9- 5.0lb-ft

Steerina shaft

/ -

\. Radiator stayI, ,IViewed from arrow A-

40 - 60 N.m4.0 - 6.0 kg-m

I

Fig. 1 l-221

11-9

Page 255 of 962

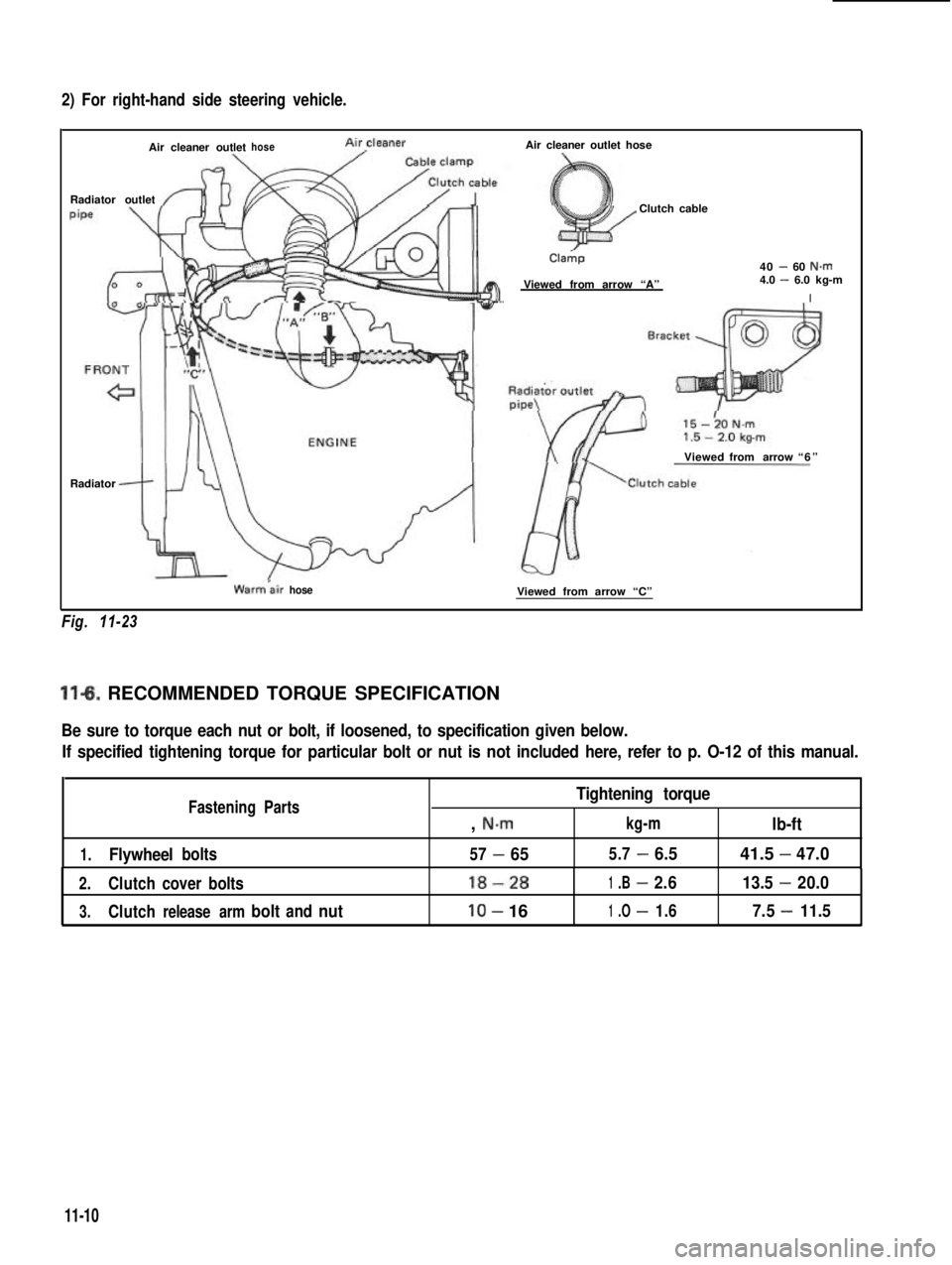

2) For right-hand side steering vehicle.

Air cleaner outlethoseAircleaner

Radiator outlet

Air cleaner outlet hose

Clutch cable

Cla&p

Viewed from arrow “A”

40 - 60 N.m4.0 - 6.0 kg-m

I

Viewedfrom arrow“6”

Radiator

Fig. 11-23

Warmair hoseViewed from arrow “C”

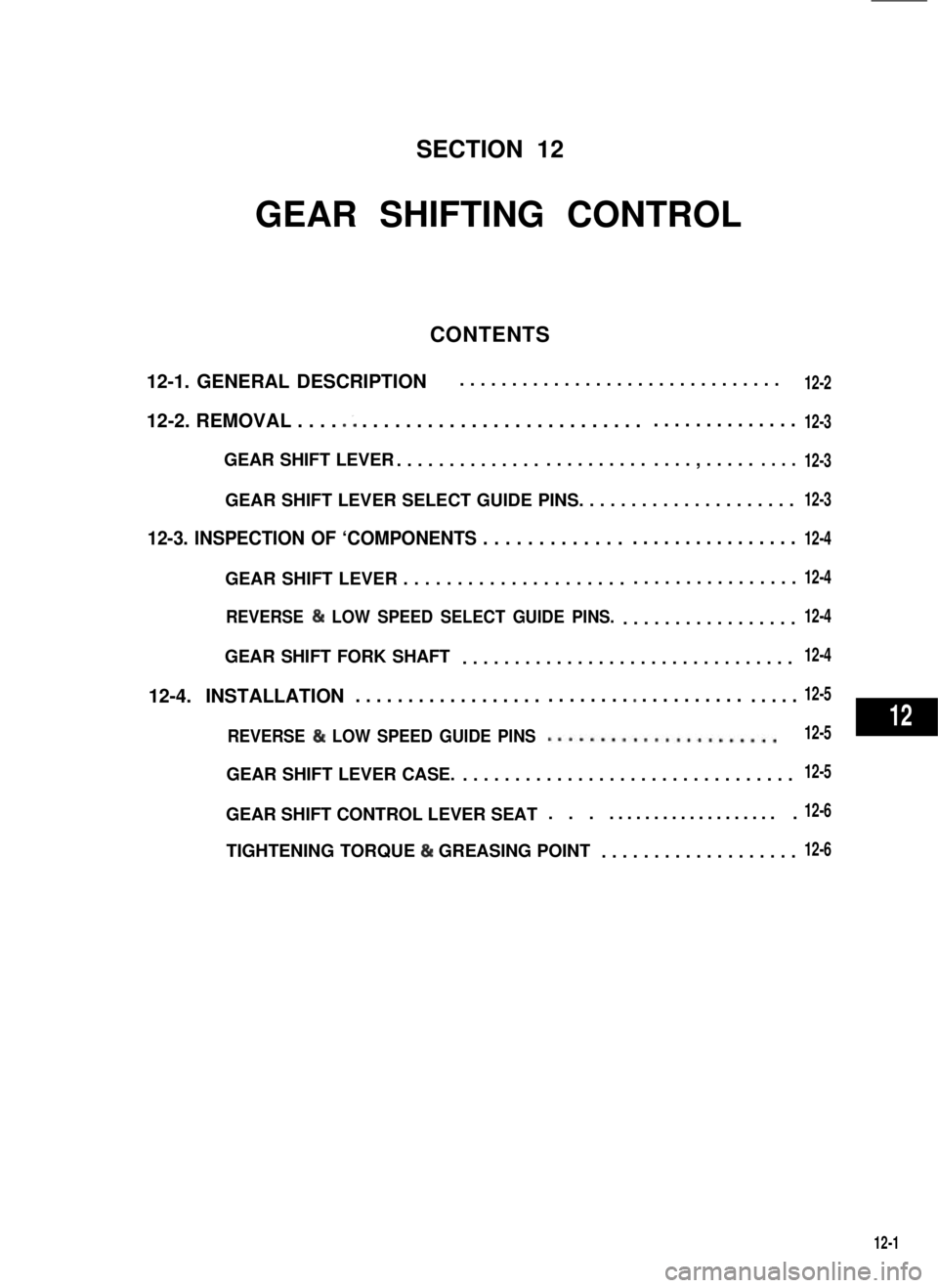

11-6. RECOMMENDED TORQUE SPECIFICATION

Be sure to torque each nut or bolt, if loosened, to specification given below.

If specified tightening torque for particular bolt or nut is not included here, refer to p. O-12 of this manual.

Fastening PartsTightening torque

, N.mkg-mlb-ft

1.Flywheelbolts57-655.7-6.541.5-47.0

2.Clutchcover bolts18-281.B-2.613.5-20.0

3.Clutchrelease armboltandnutlo- 161.O-1.67.5-11.5.

11-10

Page 256 of 962

SECTION 12

GEAR SHIFTING CONTROL

CONTENTS

12-1. GENERAL DESCRIPTION

12-2. REMOVAL . . . . .; . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . .

GEAR SHIFT LEVER. . . . . . . . . . . . . .. . . . . . . . . .. . . . , . . . . .. . . .

GEAR SHIFT LEVER SELECT GUIDE PINS. . . . . . . . . . . . . . . . . . . . .

12-3. INSPECTION OF ‘COMPONENTS . . . . . . . . . . . . .. . . . . . . . . . . . . . . .

GEAR SHIFT LEVER . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .

REVERSE & LOW SPEED SELECT GUIDE PINS..................

GEAR SHIFT FORK SHAFT................................

12-4. INSTALLATION. . . . . . . . . . . . . . . . . .. . . . . . . . * . . . . . . . . . .. . . . .

REVERSE & LOW SPEED GUIDE PINS......................

GEAR SHIFT LEVER CASE.................................

GEAR SHIFT CONTROL LEVER SEAT. . . ....................

TIGHTENING TORQUE & GREASING POINT. . . . . . . . . . . . . . . . . . .

12-1

...............................12-2

12-3

12-3

12-3

12-4

12-4

12-4

12-4

12-5

12-5

12-5

12-6

12-6

12

Page 257 of 962

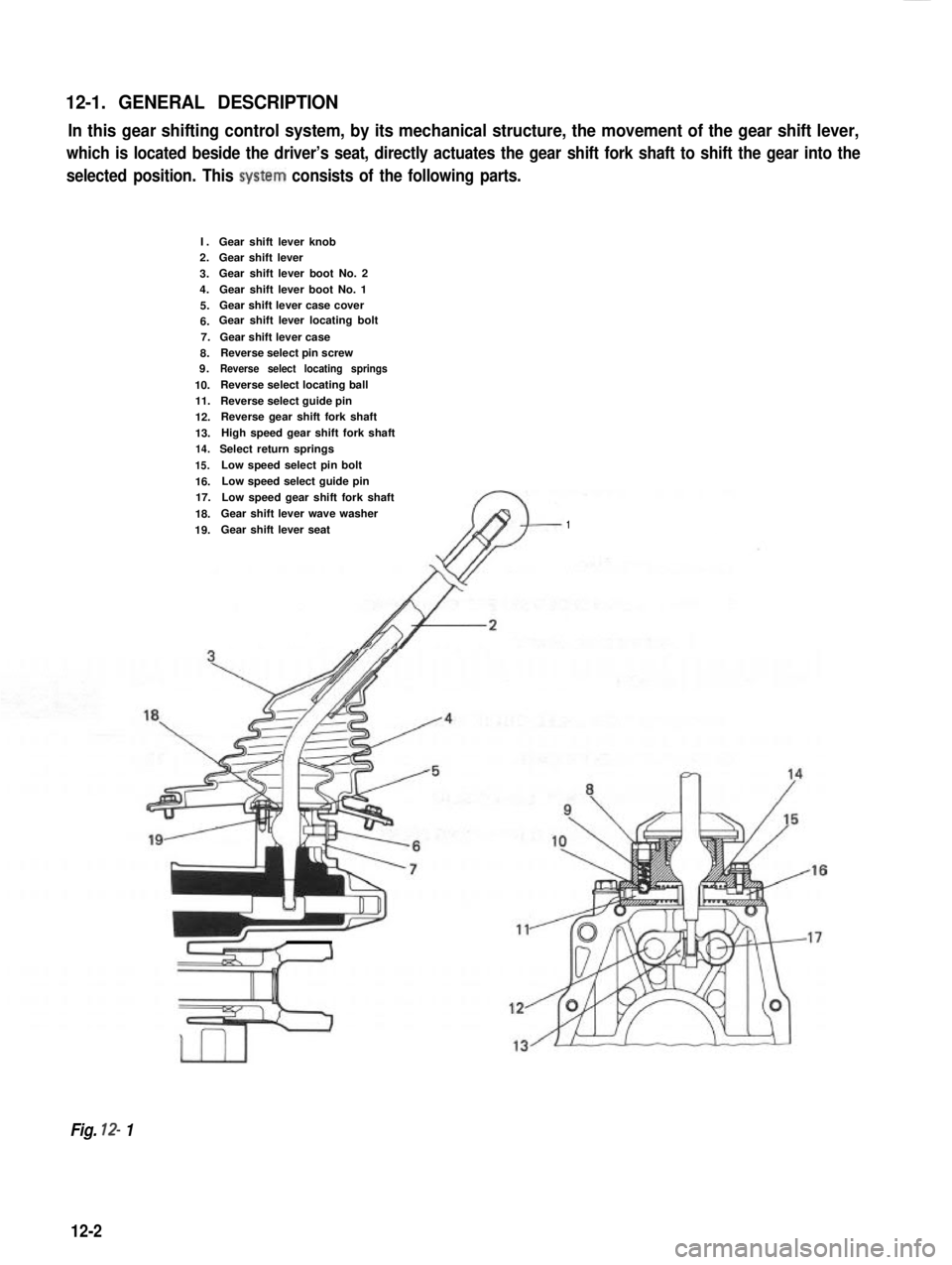

12-1. GENERAL DESCRIPTION

In this gear shifting control system, by its mechanical structure, the movement of the gear shift lever,

which is located beside the driver’s seat, directly actuates the gear shift fork shaft to shift the gear into the

selected position. This system consists of the following parts.

I.2.

3.4.

5.6.7.

8.9.

10.11.

12.

13.14.

15.

16.17.

18.

19.

Gear shift lever knobGear shift leverGear shift lever boot No. 2

Gear shift lever boot No. 1Gear shift lever case coverGear shift lever locating bolt

Gear shift lever caseReverse select pin screwReverse select locating springs

Reverse select locating ball

Reverse select guide pinReverse gear shift fork shaft

High speed gear shift fork shaft

Select return springs

Low speed select pin bolt

Low speed select guide pin

Low speed gear shift fork shaft

Gear shift lever wave washer

Gear shift lever seat1

Fig. 12- 1

12-2

Page 258 of 962

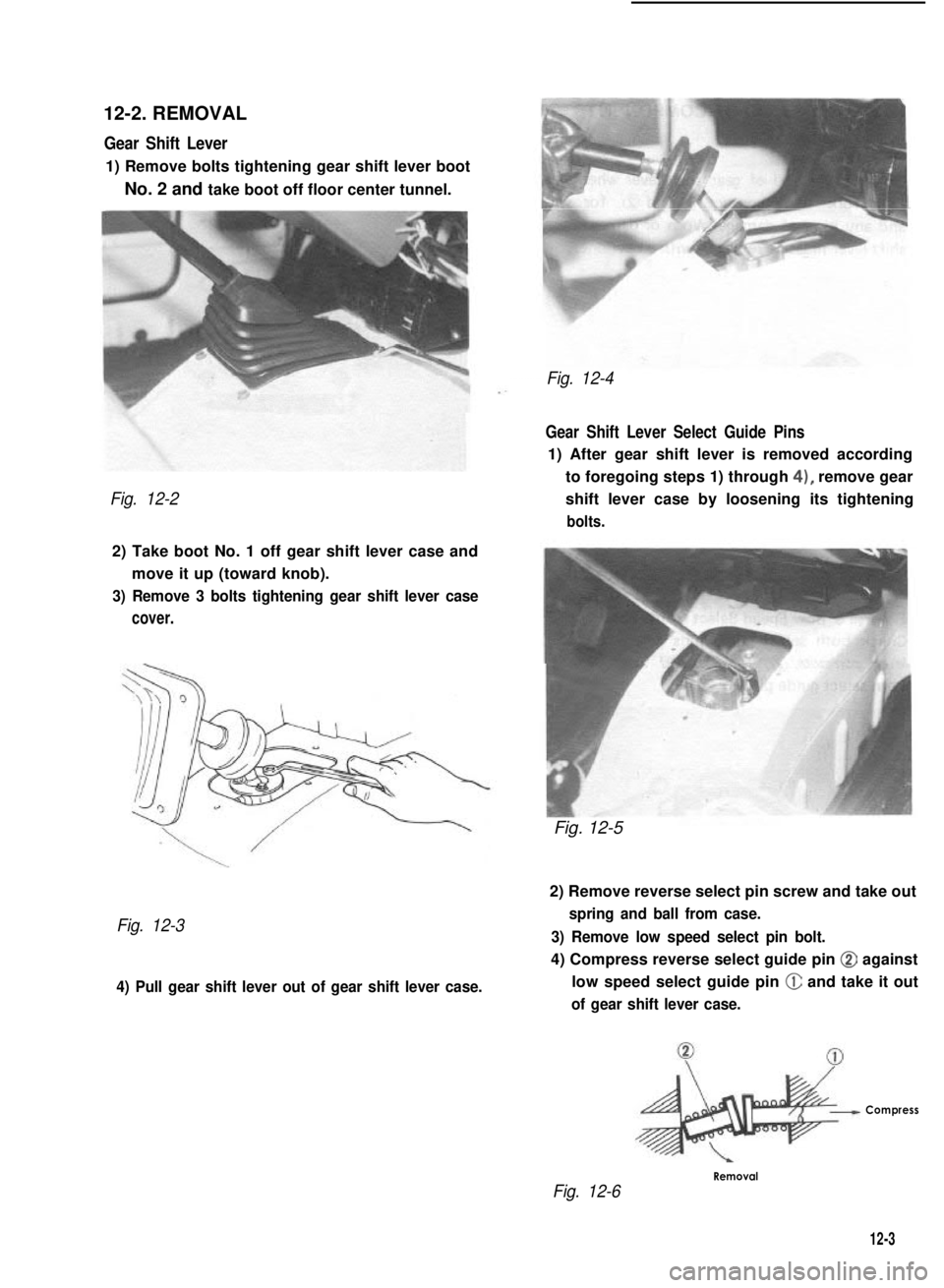

12-2. REMOVAL

Gear Shift Lever

1) Remove bolts tightening gear shift lever boot

No. 2 and take boot off floor center tunnel.

Fig. 12-2

2) Take boot No. 1 off gear shift lever case and

move it up (toward knob).

3) Remove 3 bolts tightening gear shift lever case

cover.

Fig. 12-3

4) Pull gear shift lever out of gear shift lever case.

Fig. 12-4

Gear Shift Lever Select Guide Pins

1) After gear shift lever is removed according

to foregoing steps 1) through 4), remove gear

shift lever case by loosening its tightening

bolts.

Fig. 12-5

2) Remove reverse select pin screw and take out

spring and ball from case.

3) Remove low speed select pin bolt.

4) Compress reverse select guide pin @ against

low speed select guide pin @ and take it out

of gear shift lever case.

Compress

Fig. 12-6

Removal

12-3

Page 259 of 962

12-3. INSPECTION OF COMPONENTS

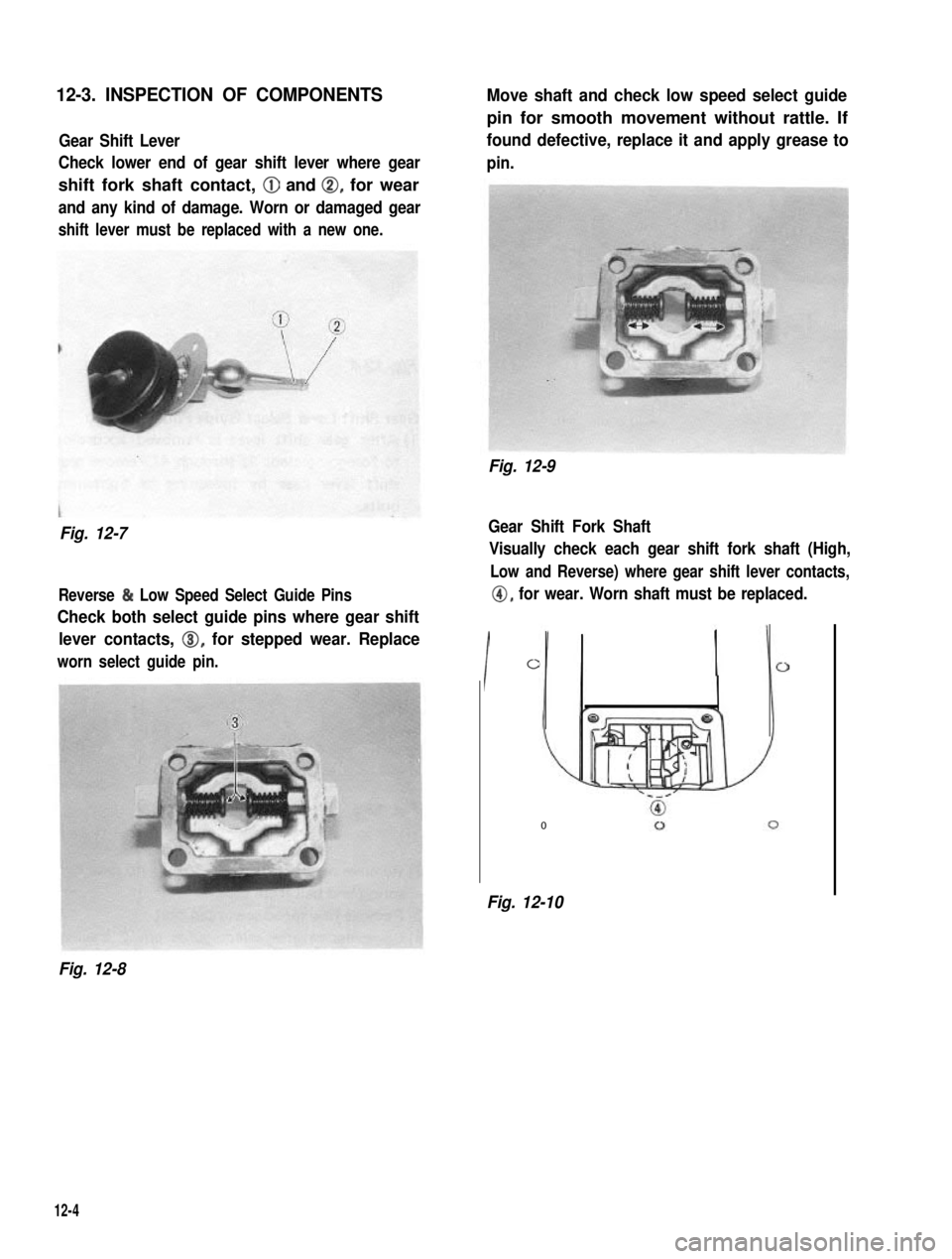

Gear Shift Lever

Check lower end of gear shift lever where gear

shift fork shaft contact, @ and 0, for wear

and any kind of damage. Worn or damaged gear

shift lever must be replaced with a new one.

Fig. 12-7

Reverse & Low Speed Select Guide Pins

Check both select guide pins where gear shift

lever contacts, 0, for stepped wear. Replace

worn select guide pin.

Move shaft and check low speed select guide

pin for smooth movement without rattle. If

found defective, replace it and apply grease to

pin.

Fig. 12-9

Gear Shift Fork Shaft

Visually check each gear shift fork shaft (High,

Low and Reverse) where gear shift lever contacts,

@, for wear. Worn shaft must be replaced.

I

0

0

Fig. 12-10

Fig. 12-8

12-4

Page 260 of 962

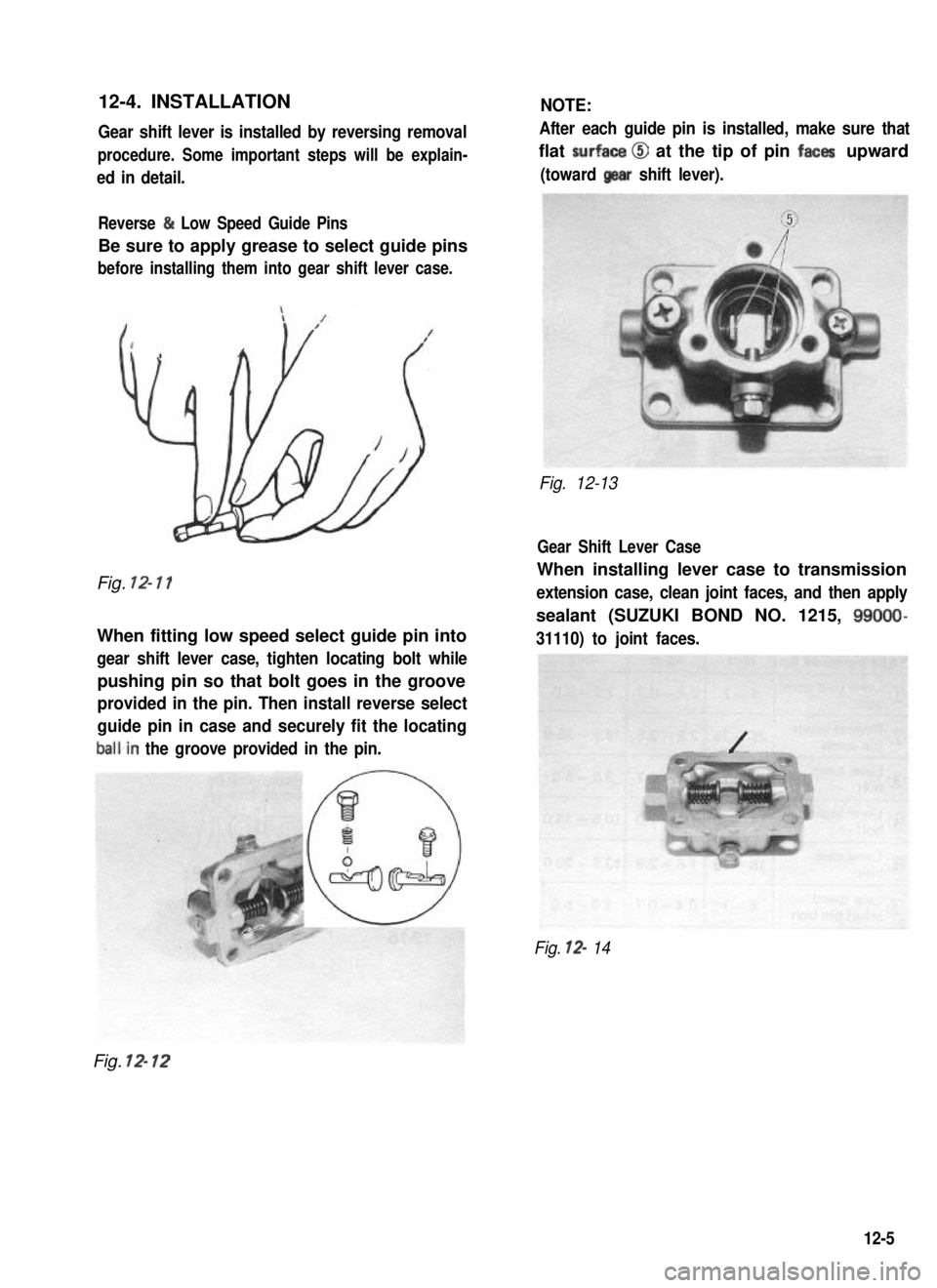

12-4. INSTALLATION

Gear shift lever is installed by reversing removal

procedure. Some important steps will be explain-

ed in detail.

NOTE:

After each guide pin is installed, make sure that

flat surfaca @I at the tip of pin faces upward

(toward gear shift lever).

Reverse & Low Speed Guide Pins

Be sure to apply grease to select guide pins

before installing them into gear shift lever case.

Fig. 12- 11

When fitting low speed select guide pin into

gear shift lever case, tighten locating bolt while

pushing pin so that bolt goes in the groove

provided in the pin. Then install reverse select

guide pin in case and securely fit the locating

balkin the groove provided in the pin.

Fig. 12-13

Gear Shift Lever Case

When installing lever case to transmission

extension case, clean joint faces, and then apply

sealant (SUZUKI BOND NO. 1215, 99009

31110) to joint faces.

Fig. 12- 14

Fig. 12- 12

12-5