SUZUKI GRAND VITARA 1987 Service Repair Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 331 of 962

16-5. REASSEMBLY

Reverse disassembly procedure for reassembly,

noting the following.

NOTE:

Bevel pinion and bevel gear are supplied as a

set. Even when only bevel pinion or bevel gear

replacement is necessary, be sure to replace

both as a set.

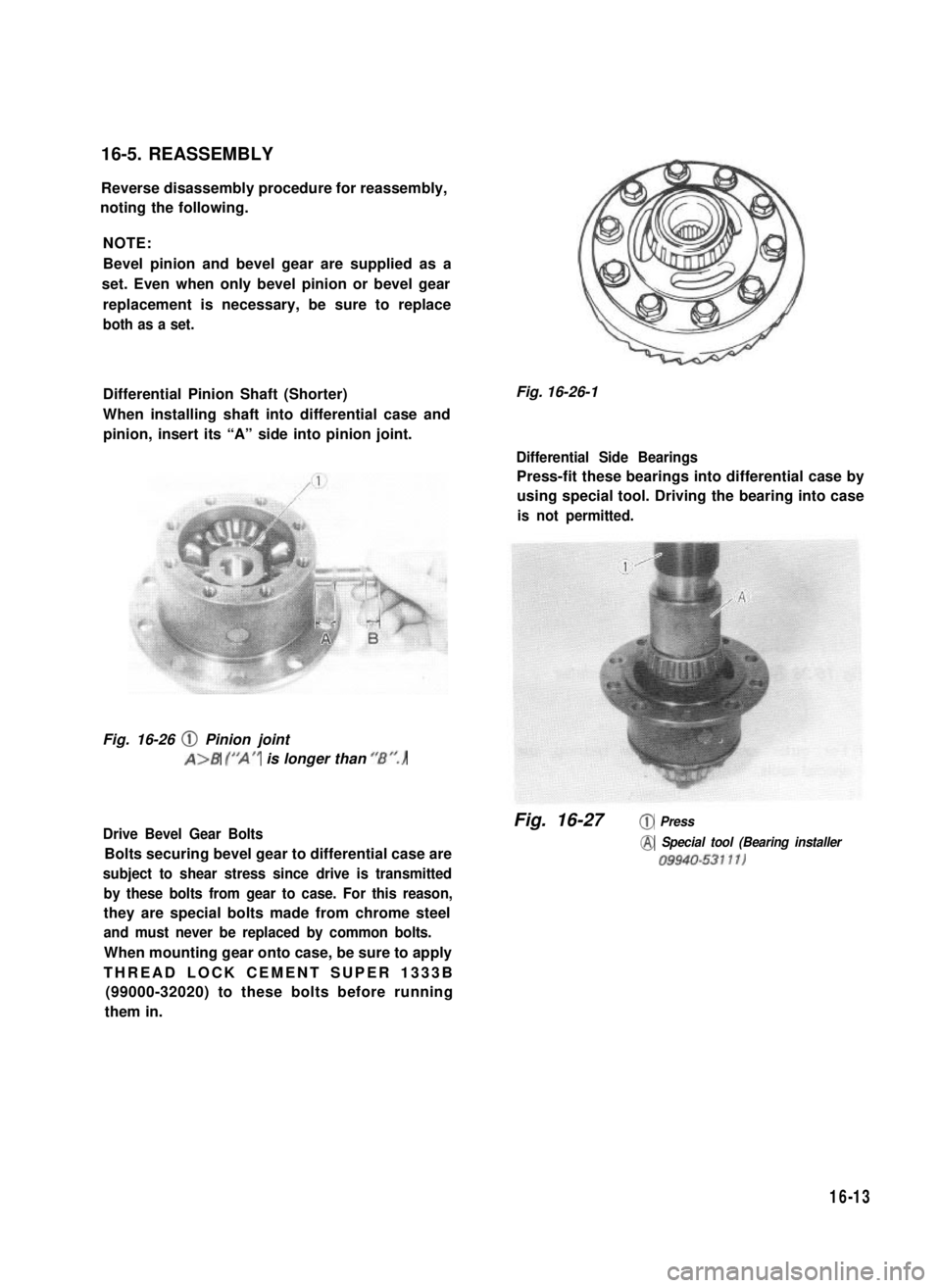

Differential Pinion Shaft (Shorter)

When installing shaft into differential case and

pinion, insert its “A” side into pinion joint.

Fig. 16-26 @ Pinion joint

A>B (“A” is longer than ‘/Br’.)

Drive Bevel Gear Bolts

Bolts securing bevel gear to differential case are

subject to shear stress since drive is transmitted

by these bolts from gear to case. For this reason,

they are special bolts made from chrome steel

and must never be replaced by common bolts.

When mounting gear onto case, be sure to apply

THREAD LOCK CEMENT SUPER 1333B

(99000-32020) to these bolts before running

them in.

Fig. 16-26-1

Differential Side Bearings

Press-fit these bearings into differential case by

using special tool. Driving the bearing into case

is not permitted.

Fig. 16-27@ Press

@ Special tool (Bearing installer

09940-53111)

16-13

Page 332 of 962

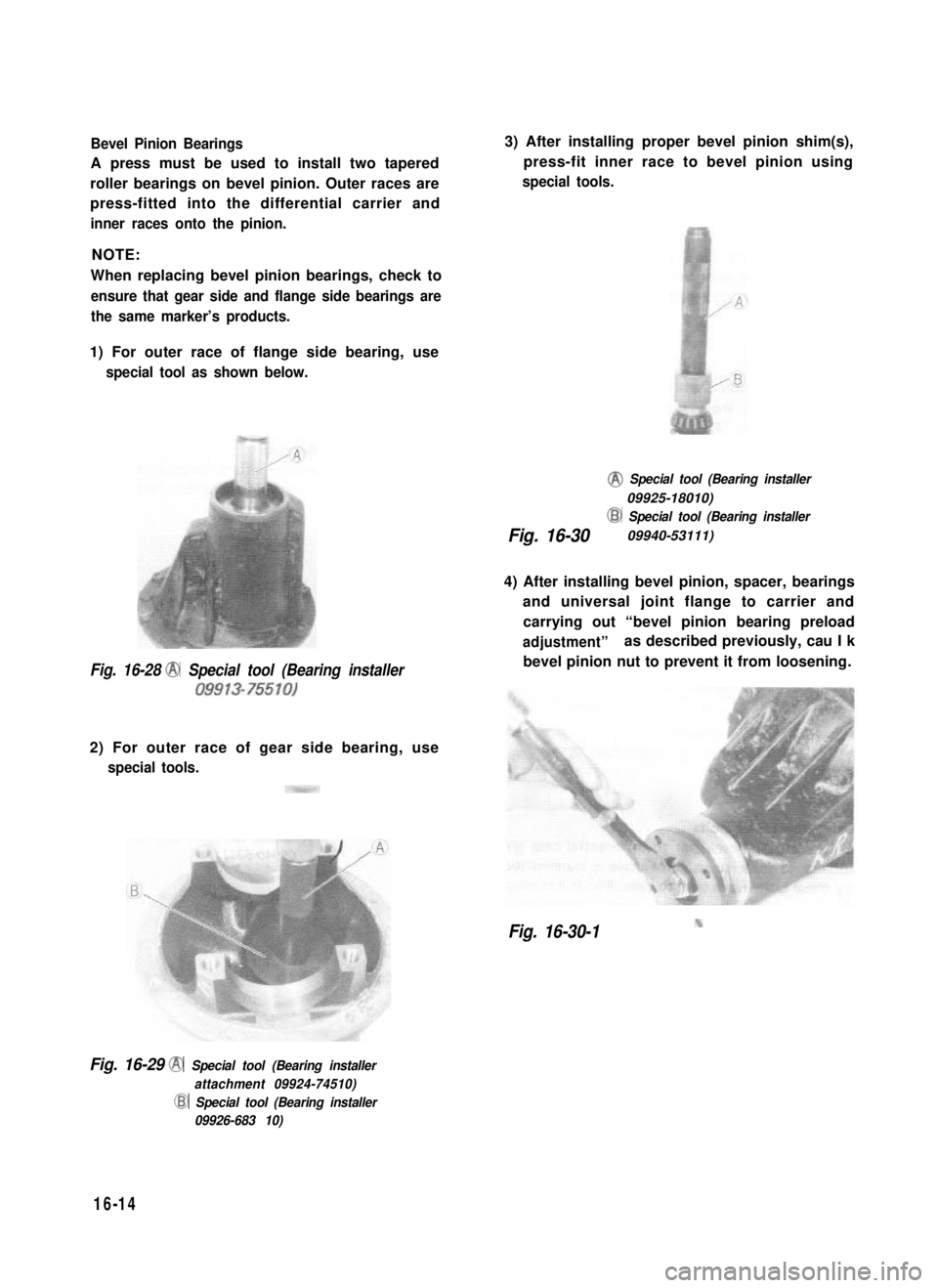

Bevel Pinion Bearings

A press must be used to install two tapered

roller bearings on bevel pinion. Outer races are

press-fitted into the differential carrier and

inner races onto the pinion.

NOTE:

When replacing bevel pinion bearings, check to

ensure that gear side and flange side bearings are

the same marker’s products.

1) For outer race of flange side bearing, use

special tool as shown below.

Fig. 16-28 @ Special tool (Bearing installer

09913-75510)

2) For outer race of gear side bearing, use

special tools.

3) After installing proper bevel pinion shim(s),

press-fit inner race to bevel pinion using

special tools.

@ Special tool (Bearing installer

09925-18010)

Fig. 16-30

@ Special tool (Bearing installer

09940-53111)

4) After installing bevel pinion, spacer, bearings

and universal joint flange to carrier and

carrying out “bevel pinion bearing preload

adjustment”as described previously, cau I k

bevel pinion nut to prevent it from loosening.

Fig. 16-30-1

Fig. 16-29 @ Special tool (Bearing installer

attachment 09924-74510)

@ Special tool (Bearing installer

09926-683 10)

16-14

Page 333 of 962

Side Bearings Caps

When putting on side bearing caps, be sure to

discriminate the right-hand cap from the left-

hand one by referring to match marks scribed

at the time of disassembly.

Then, after carrying out “Bevel gear backlash

adjustment” as described on p. 16-10 torque cap

bolts to specification.

16-6. INSTALLATION

Reverse removal procedure for installation,

noting the following.

Differential

Before installing differential ass’y to axle hous-

ing, clean mating surfaces of differential carrier

and housing and apply sealant to them.

Fig. 16-31 0 Scribed match marks

Fig. 16-32 @ Sealant (SUZUKI BOND NO.

1215 99000-31110)

Front Axle Shaft and Steering Knuckle

For installation them, refer to “Front Suspen-

sion Installation” in SECTION 17 of this manual.

Rear Brake Drum

For installation of rear brake drum, refer to

“Rear Brake Installation” in SECTION 19 of

this manual.

Differential Gear Oil

Refill differential housing with new specified

oil. Refer to “MAINTENANCE SERVICE” in

this section for refill.

Brake Circuit Air Purging

If brake pipe (right & left) was disconnected

from wheel cylinder as in Fig. 16-9-2, make sure

to purge air out of brake circuit. Refer to

section 19. BRAKES for “air purging" operation.

Then check to ensure that joint seam of pipe is

free from oil leak.

16-15

Page 334 of 962

16-7. MAINTENANCE SERVICES

Inspection

Inspect differential and differential housing for

evidence of oil leakage.

Oil level ‘is checked by means of its oil level

plug. Refer to p 1-20 for level inspection,

Fig. 16-33 @ Drain plug

CD Oil level & filler plug

Oil Change

1 ) Remove oil drain plug and drain oil.

2) Reinstall drain plug and tighten it to specified

tightening torque.

3) Remove oil level & filler plug and fill diffe-

rential housing with new specified oil.

Differential oilHypoid gear oil

specificationSAE 8OW-90,75W-80 or 75W-90

OilFront2.0 litres (4.2/3.5 US/Imp pt.)

capacityRear1.5 litres (3.2/2.6 US/Imp pt.)

It is highly recommended to use SAE 75W-90

gear oil.

For viscosity chart, refer to P. 1-20.

16-8. RECOMMENDED TORQUE

SPECIFICATIONS

ITightening torqueI

IFastening partsN.m1 kg-m 11

Side bearing capbolt70- 1007.0-10.051 .O-72.0

Drive bevel gearbolt80- 908.0-9.058.0-66.0

Differential casebolt37-453.7-4.527.0-32.5I

4) Reinstall oil level & filler plug and tighten it

to specified tightening torque.

16-16

Side bearing adjusterlock bolt

Differential carrier bolt

Oil level & filler plug

Oil drain plug

Page 335 of 962

SECTION 17

SUSPENSION

CONTENTS

17-1. FRONT SUSPENSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-2

17-2. REAR SUSPENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-15

17-3. MAINTENANCE SERVICES.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-20

17-4. RECOMMENDED TORQUE SPECIFICATIONS.. . . . . . . . . . . . . . . . 17-26

17-5. FRONT FREE WHEELING HUB (OPTIONAL) . . . . . . . . . . . . . . . . . 17-27

NOTE:

l All suspension fasteners are an important attaching part in that it could affect the

performance of vital parts and systems, and/or could result in major repair expense.

They must be replaced with one of the same part number or with an equivalent part if

replacement becomes necessary. Do not use a replacement part of lesser quality or

substitute design. Torque values must be used as specified during reassembly to assure

proper retention of this part.

l Never attempt to heat, quench or straighten any suspension part. Replace it with a new

part, or damage to the part may result.

l The leaf spring number or shape shown in this manual may differ from the car being

actually serviced, depending on specification.

17-1

Page 336 of 962

17-1. FRONT SUSPENSION

GENERAL DESCRIPTION

The front suspension consists of the double-acting shock absorbers, stabilizer bar, semi-elliptical leaf

springs, axle housing, etc. as shown below.

The Barfield universal joints are used in the front axle to enable the axle shafts to drive the front wheels

while allowing the wheels to be steered. This type of joint provides for a larger steering angle range and,

what is more important, constant-velocity drive to the wheel.

If a single two-yoke (or Hooke’s) universal joint is used to connect the axle shaft to the wheel on each

side of the front end, the wheels will run with the same speed, but not with the same constant velocity, as

that of the axle shafts when the wheels are turned around their kingpins for steering action. The Barfield

joint transmits drive without varying the angular velocity of drive.

The Barfield joint is enclosed by the knuckle, which is shaped integral with the knuckle arm, and has a

two-piece kingpin, namely, upper and lower kingpins.

The end of the dead axle sleeve is in the shape of dish. This dish is rotatably fitted into the knuckle

structure to form a flexible connection, the sliding clearance between the two being sealed with a felt

packing (against road dust and mud) and also with an oil seal (against the oil inside). The upper and lower

kingpins, bolted to the knuckle extend into the knuckle and, inside, are held by the dish-like inner case

through tapered roller bearings.

BushWasher

Front axle housing

Oil seal cover

retainer ISteeringLn,,rlrlo

Front wheel hub

Front wheel bearing

1\;lEkl bearing nutFront wheelbearina

Shacklebush

outerplateASta ilizer\drive flange

nut

Fig. 17-1-1

17-2

Page 337 of 962

1. Front brake disc

2.Wheel bearing

3. Axle shaft drive flange4.Wheel hub

5.Dust cover6.Oil seal7.King pin8. King pin bearing

9.Oil seal

10.Steering knuckle

11. Disc brake holder12. Disc brake caliper

13.Shock absorber

14.Spring bumper

15. Axle shaft joint16.Leaf spring

17-3

Fig. 17-1-2

Page 338 of 962

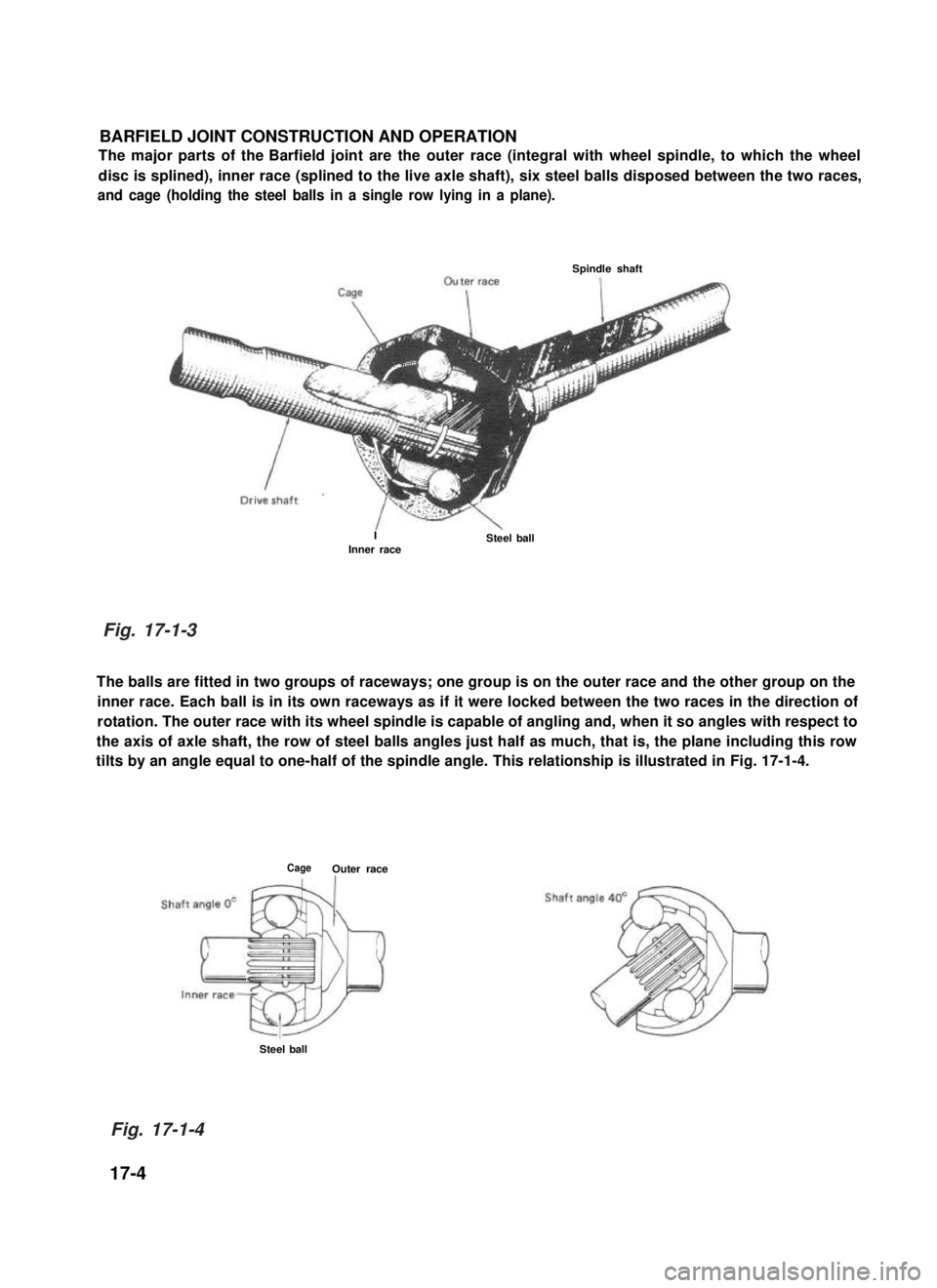

BARFIELD JOINT CONSTRUCTION AND OPERATION

The major parts of the Barfield joint are the outer race (integral with wheel spindle, to which the wheel

disc is splined), inner race (splined to the live axle shaft), six steel balls disposed between the two races,

and cage (holding the steel balls in a single row lying in a plane).

Spindle shaft

IInner raceSteel ball

The balls are fitted in two groups of raceways; one group is on the outer race and the other group on the

inner race. Each ball is in its own raceways as if it were locked between the two races in the direction of

rotation. The outer race with its wheel spindle is capable of angling and, when it so angles with respect to

the axis of axle shaft, the row of steel balls angles just half as much, that is, the plane including this row

tilts by an angle equal to one-half of the spindle angle. This relationship is illustrated in Fig. 17-1-4.

CageOuter race

Steel ball

17-4

Fig. 17-1-3

Fig. 17-1-4

Page 339 of 962

REMOVAL

Shock Absorber

The shock absorber is non-adjustable, non-

refillable, and cannot be disassembled.

The only service the shock absorber requires is

replacement when it has lost its resistance, is

damaged, or leaking fluid.

1. Hoist car.

2. Loosen lower and upper mounting nuts and

remove shock absorber.

7Shacklepin

Washer

Fig. 17-1-6

Washer

Washer

by

D

Nut

Stabilizer

1. Hoist car.

2. Remove stabilizer bolts.

3. After removing stabilizer mount bush

bracket bolts, remove stabilizer.

Fig. 17-1-5

Leaf Spring

1. Raise car. In this operation, garage jack or

hoist must not be positioned against front

suspension related parts. When garage jack

is used, place safety stands under chassis to

support raised body.

2. Remove front wheel.

3. Remove stabilizer bolt.

4. Remove U-bolt nuts.

5. Remove shackle nuts and leaf spring nut.

NOTE:

Removal of leaf spring causes axle housing to

hang. Support it with safety stand to prevent it

from damaging universal joint of propeller shaft

and others.

Stabilizer

F

fBracket boltFig. 17-1-7

6. Pull out leaf spring bolt and remove leaf

spring from shackle pin.

17-5

Page 340 of 962

Front Wheel Hub 81 Bearing

1. Loosen the five nuts securing the wheel.

Raise the front end by jacking.

Rest the machine steady on safety stands.

2. Remove the five nuts and take off the wheel.

Fig. 17-1-8

3. Remove the caliper with carrier by loosen-

ing carrier bolts.

NOTE:

Hang removed caliper with a wire hook or the

like so as to prevent brake hose from bending

and twisting excessively or being pulled.

Don’t operate brake pedal with caliper removed.

Fig. 17-1-9

4. Remove brake disc.

NOTE:

If brake disc can not be removed by hand, use

8 mm bolts as shown below.

f

@

[For car equipped with free wheeling hub]

5. Remove free wheeling hub cover and circlip.

Fig. 17-1-12-1 @ Circlip remover (09900-06107)

6. Remove free wheeling hub body.

Fig. 17-1-10

17-6Fig. 17-1-12-2

8mm BoltFig. 17-1-11