SUZUKI GRAND VITARA 1987 Service Repair Manual

GRAND VITARA 1987

SUZUKI

SUZUKI

https://www.carmanualsonline.info/img/20/57437/w960_57437-0.png

SUZUKI GRAND VITARA 1987 Service Repair Manual

Trending: coolant reservoir, tire pressure, drain bolt, technical specifications, height adjustment, fuel cap release, air suspension

Page 341 of 962

[For car not equipped with free wheeling hub]

5. Remove the front axle shaft cap.

6. Remove the circlip retaining the front axle

shaft drive flange on front drive shaft, using

the circlip remover @.

Fig. 17-1-12-3 @ Circlip Remover

7. Loosen securing bolts of front axle shaft

drive flange and take off drive flange.

Fig. 17-1-13

8. Straighten bent part of lock washer and

remove wheel bearing lock nut with special

tool @I.

Fig. 17-1-15 Special tool @

(Front Wheel Bearing Nut Socket

Wrench 09941-58010)

9. After loosening front wheel bearing nut

with the same special tool @I as mentioned

in the foregoing step 8, take nut and washer

off the front wheel spindle.

\

Fig. 17-1-16

10. Pull front wheel hub off the front wheel

spindle.

Fig. 17-1-17

17-7Fig. 17-1-14

Page 342 of 962

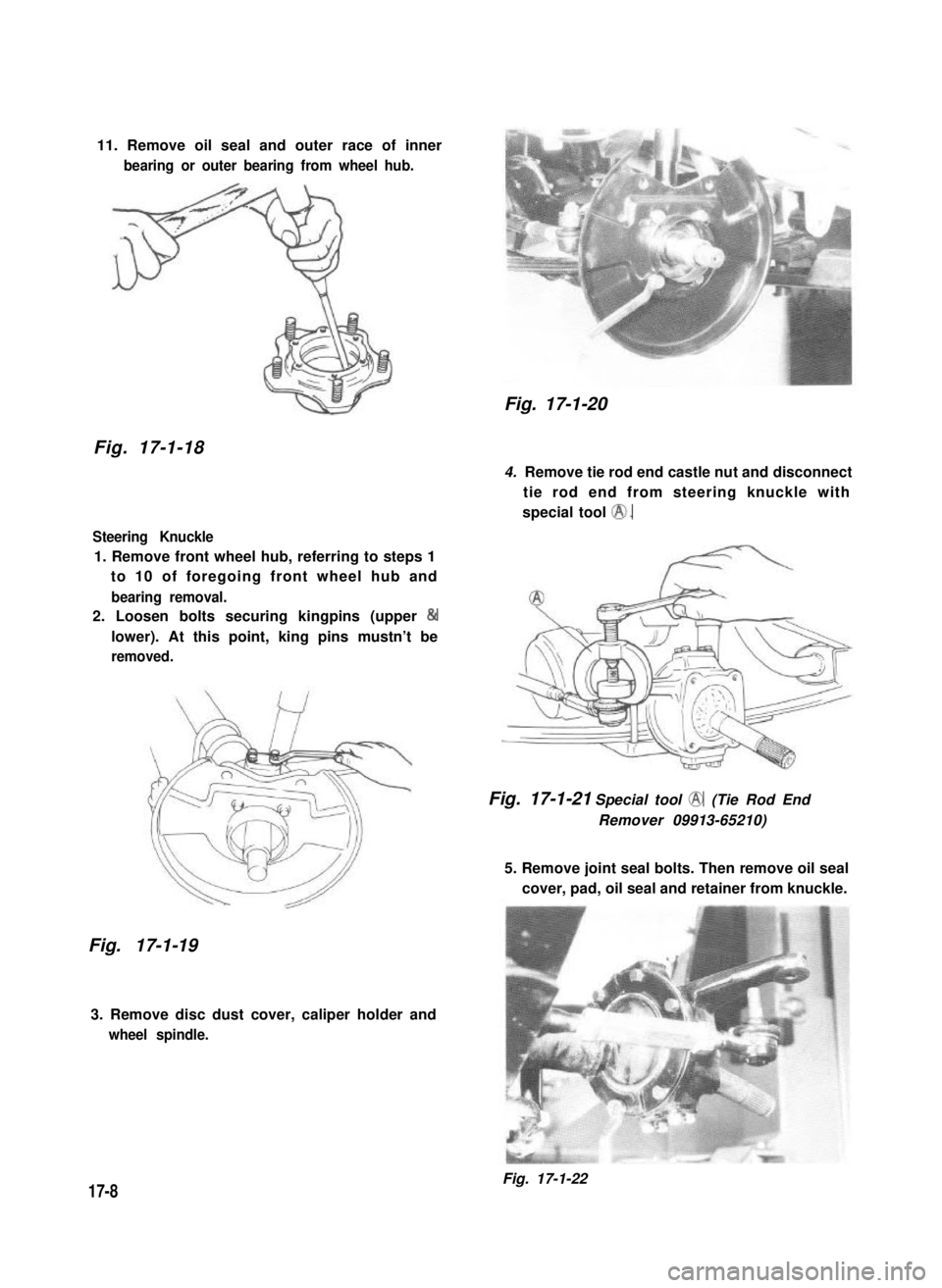

11. Remove oil seal and outer race of inner

bearing or outer bearing from wheel hub.

Fig. 17-1-18

Steering Knuckle

1. Remove front wheel hub, referring to steps 1

to 10 of foregoing front wheel hub and

bearing removal.

2. Loosen bolts securing kingpins (upper &

lower). At this point, king pins mustn’t be

removed.

Fig. 17-1-19

3. Remove disc dust cover, caliper holder and

wheel spindle.

Fig. 17-1-20

4.Remove tie rod end castle nut and disconnect

tie rod end from steering knuckle with

special tool @.

Fig. 17-1-21 Special tool @ (Tie Rod End

Remover 09913-65210)

5. Remove joint seal bolts. Then remove oil seal

cover, pad, oil seal and retainer from knuckle.

Fig. 17-1-22 17-8

Page 343 of 962

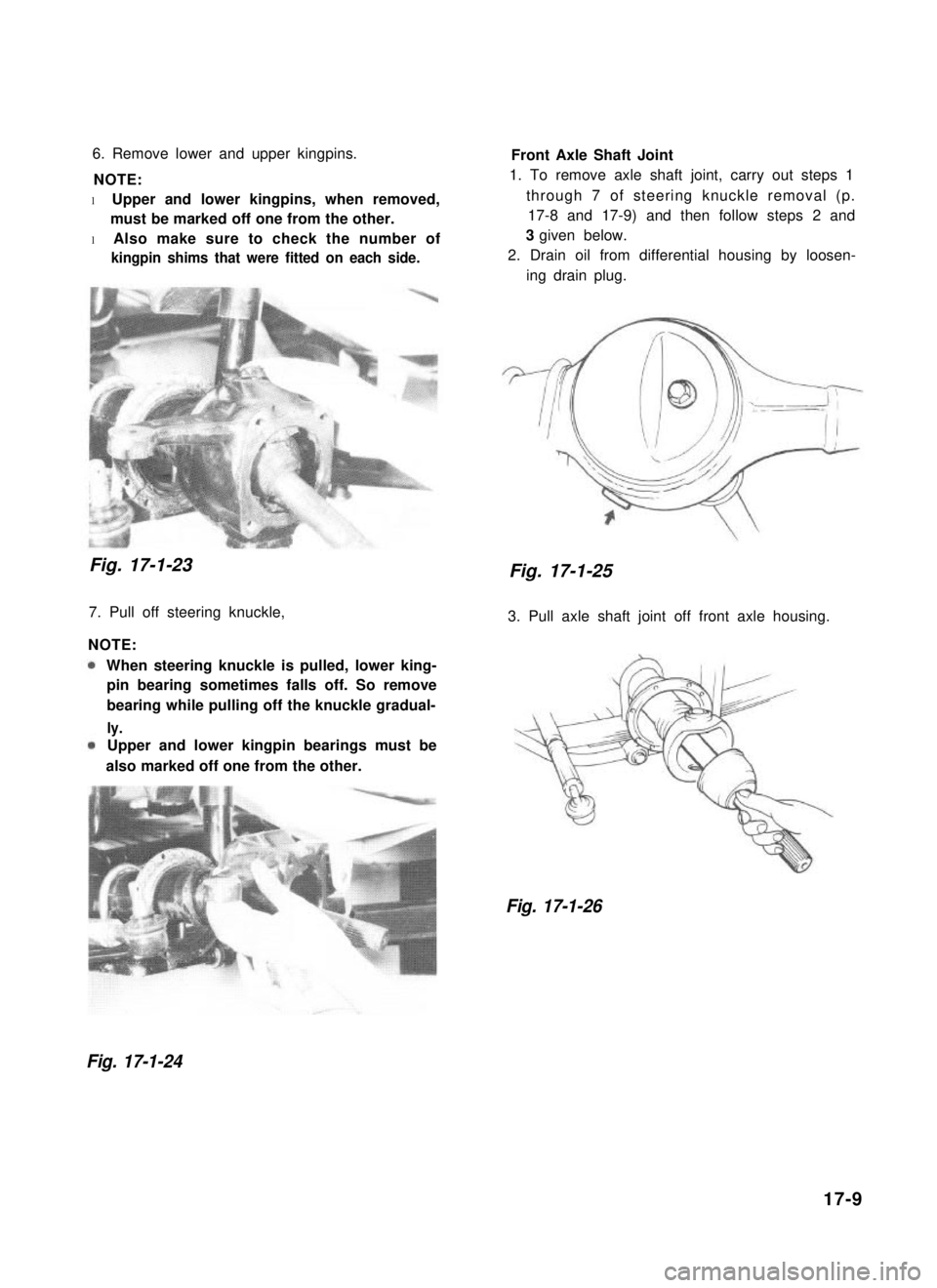

6. Remove lower and upper kingpins.

NOTE:

l Upper and lower kingpins, when removed,

must be marked off one from the other.

l Also make sure to check the number of

kingpin shims that were fitted on each side.

Front Axle Shaft Joint

1. To remove axle shaft joint, carry out steps 1

through 7 of steering knuckle removal (p.

17-8 and 17-9) and then follow steps 2 and

3 given below.

2. Drain oil from differential housing by loosen-

ing drain plug.

Fig. 17-1-23

7. Pull off steering knuckle,

NOTE:

When steering knuckle is pulled, lower king-

pin bearing sometimes falls off. So remove

bearing while pulling off the knuckle gradual-

ly.

Upper and lower kingpin bearings must be

also marked off one from the other.

Fig. 17-1-25

3. Pull axle shaft joint off front axle housing.

Fig. 17-1-26

Fig. 17-1-24

17-9

Page 344 of 962

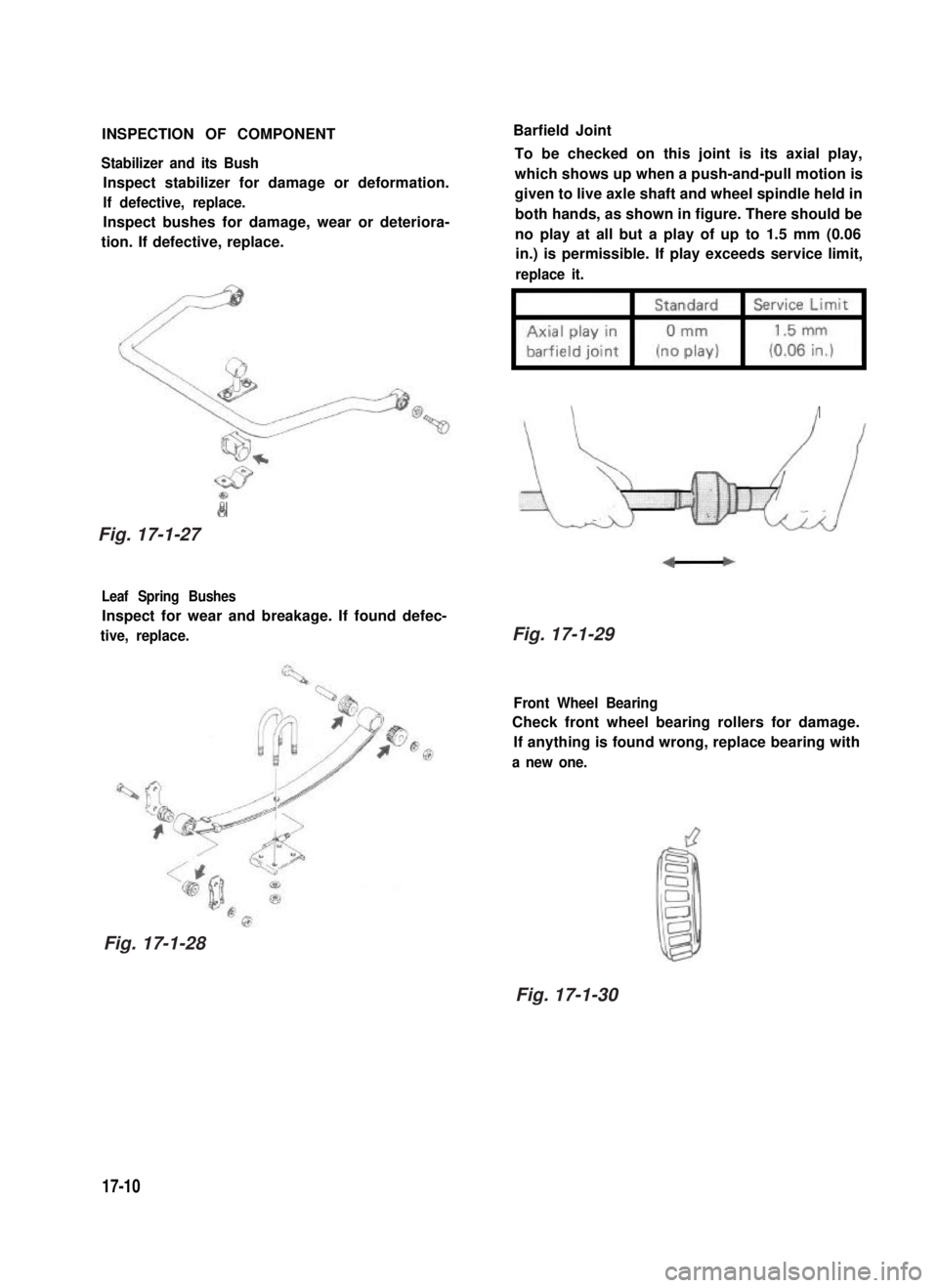

INSPECTION OF COMPONENT

Stabilizer and its Bush

Inspect stabilizer for damage or deformation.

If defective, replace.

Inspect bushes for damage, wear or deteriora-

tion. If defective, replace.

8

Barfield Joint

To be checked on this joint is its axial play,

which shows up when a push-and-pull motion is

given to live axle shaft and wheel spindle held in

both hands, as shown in figure. There should be

no play at all but a play of up to 1.5 mm (0.06

in.) is permissible. If play exceeds service limit,

replace it.

\/

Leaf Spring Bushes

Inspect for wear and breakage. If found defec-

tive, replace.

Front Wheel Bearing

Check front wheel bearing rollers for damage.

If anything is found wrong, replace bearing with

a new one.

17-10

Fig. 17-1-27

Fig. 17-1-28

Fig. 17-1-30

Fig. 17-1-29

Page 345 of 962

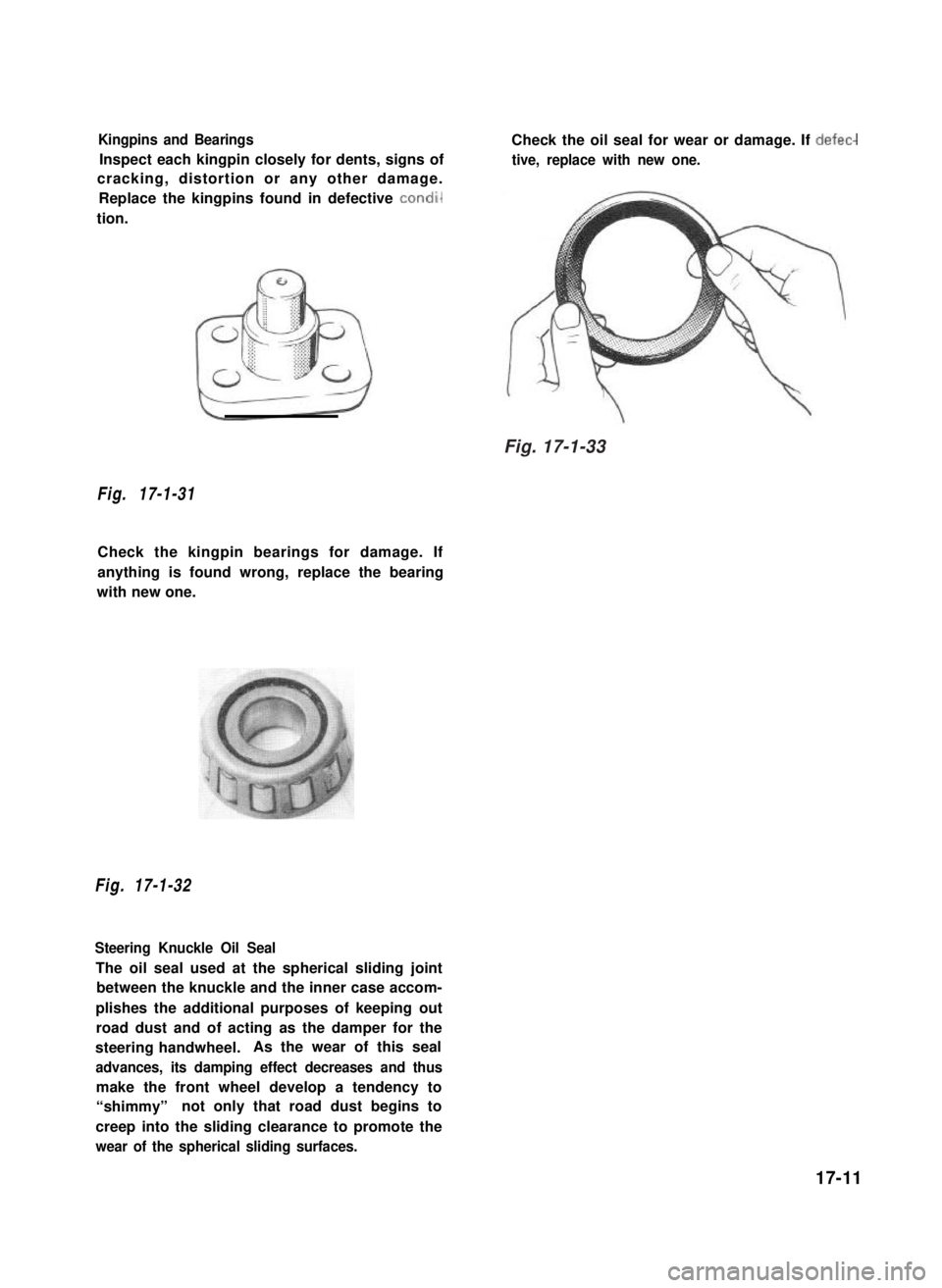

Kingpins and Bearings

Inspect each kingpin closely for dents, signs of

cracking, distortion or any other damage.

Replace the kingpins found in defective condi.

tion.

Check the oil seal for wear or damage. If defec-

tive, replace with new one.

Fig. 17-1-31

Check the kingpin bearings for damage. If

anything is found wrong, replace the bearing

with new one.

Fig. 17-1-32

Steering Knuckle Oil Seal

The oil seal used at the spherical sliding joint

between the knuckle and the inner case accom-

plishes the additional purposes of keeping out

road dust and of acting as the damper for the

steering handwheel.As the wear of this seal

advances, its damping effect decreases and thus

make the front wheel develop a tendency to

“shimmy”not only that road dust begins to

creep into the sliding clearance to promote the

wear of the spherical sliding surfaces.

17-11

Fig. 17-1-33

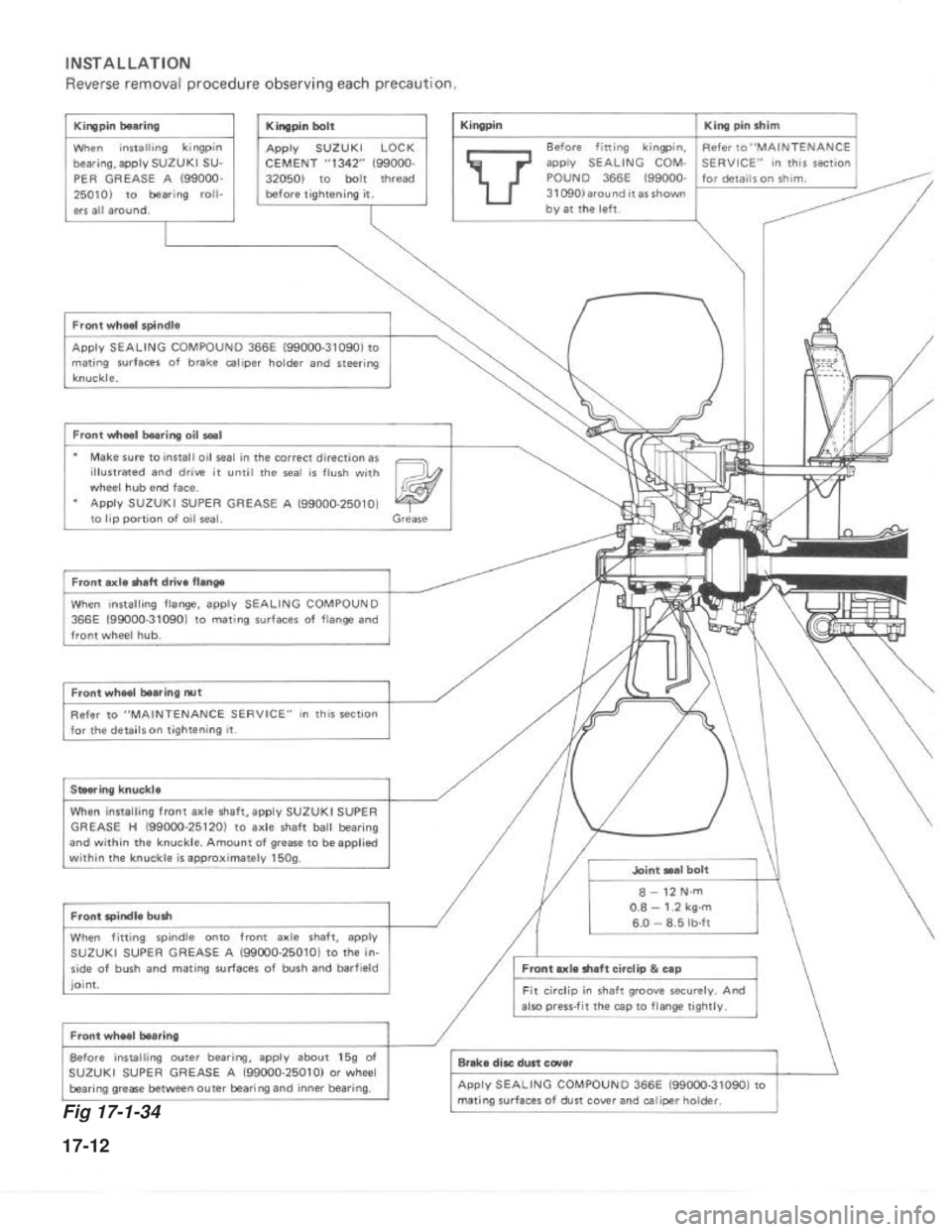

Page 346 of 962

Page 347 of 962

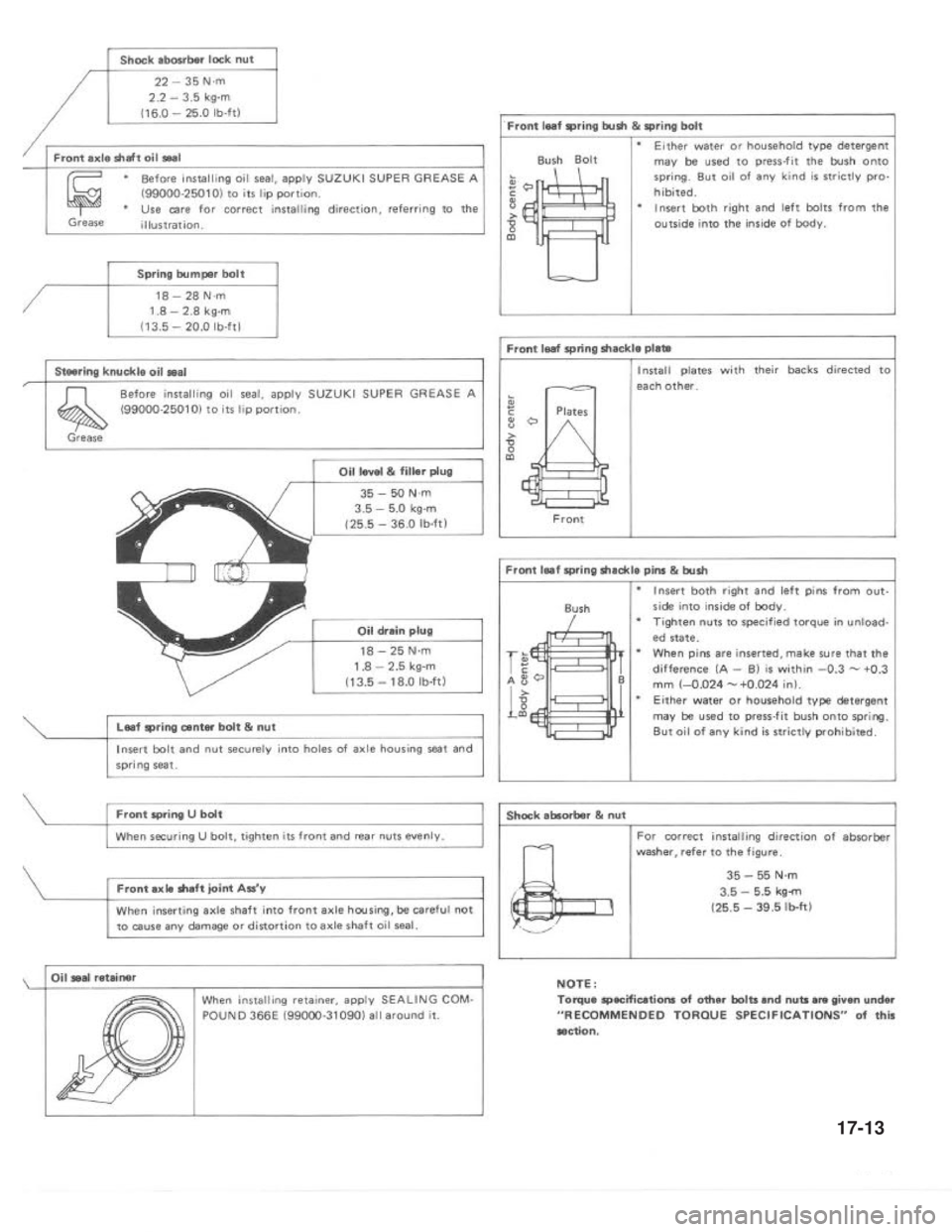

Page 348 of 962

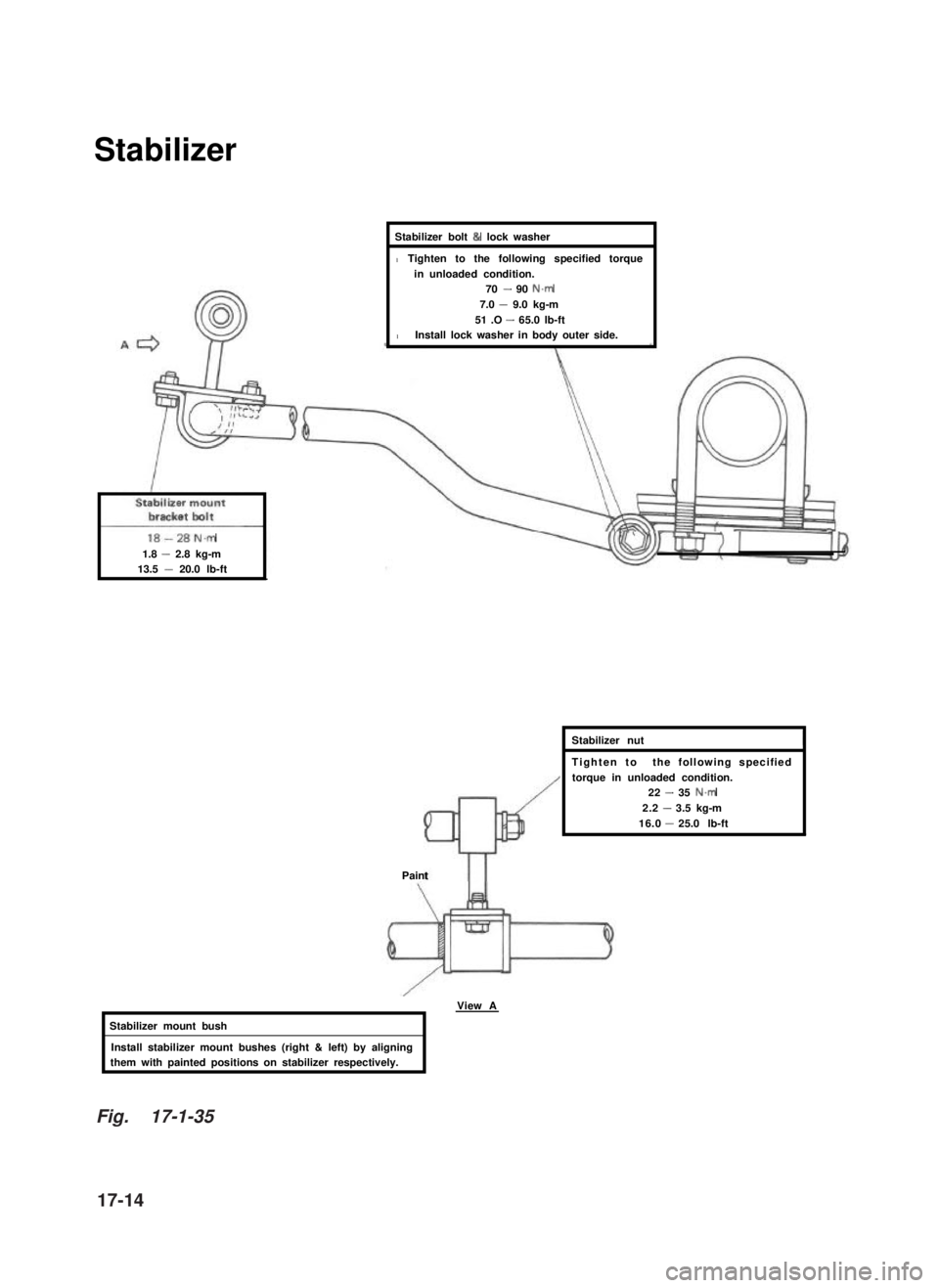

Stabilizer

Stabilizer bolt & lock washerI

18-28N.m

1.8 - 2.8 kg-m13.5 - 20.0 lb-ft

l Tighten to the following specified torque

in unloaded condition.70 - 90 N.m

l

7.0 - 9.0 kg-m

51 .O - 65.0 lb-ftInstall lock washer in body outer side.

1 Stabilizer nut

qPaint

Tighten tothe following specified

torque in unloaded condition.22-35 N.m

2.2-3.5 kg-m

16.0-25.0 lb-ft

Stabilizer mount bush

View A

Install stabilizer mount bushes (right & left) by aligningthem with painted positions on stabilizer respectively.

Fig. 17-1-35

17-14

Page 349 of 962

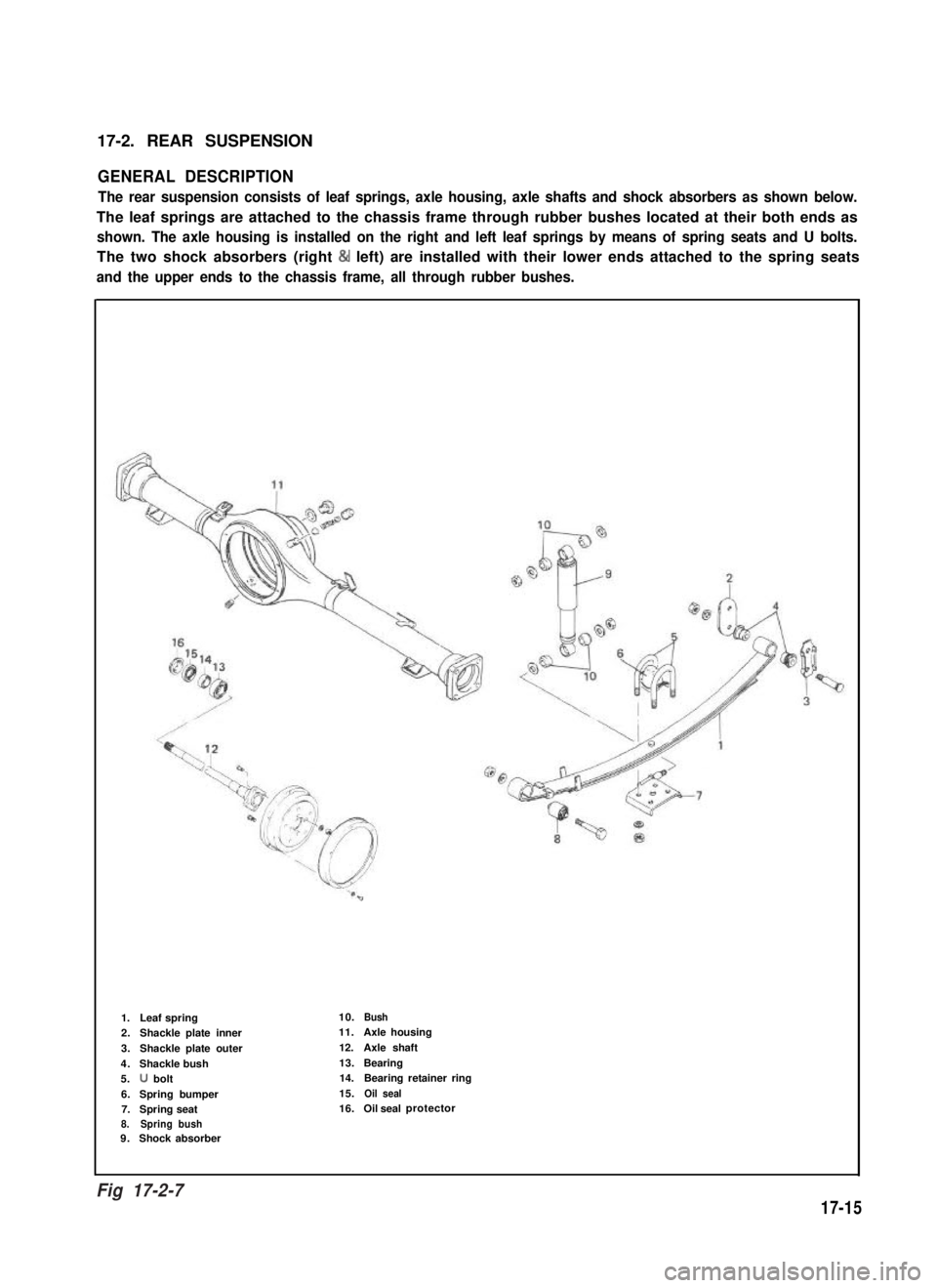

17-2. REAR SUSPENSION

GENERAL DESCRIPTION

The rear suspension consists of leaf springs, axle housing, axle shafts and shock absorbers as shown below.

The leaf springs are attached to the chassis frame through rubber bushes located at their both ends as

shown. The axle housing is installed on the right and left leaf springs by means of spring seats and U bolts.

The two shock absorbers (right & left) are installed with their lower ends attached to the spring seats

and the upper ends to the chassis frame, all through rubber bushes.

1. Leaf spring10.Bush

2.Shackle plate inner11.Axle housing

3.Shackle plate outer12.Axle shaft

4.Shackle bush13.Bearing

5.U bolt14.Bearing retainer ring

6.Spring bumper15.Oil seal

7.Spring seat16.Oil sealprotector

8. Spring bush9.Shock absorber

t-lg.

17-15

Fig 17-2-7

Page 350 of 962

REMOVALRear Axle Shaft

Shock Absorber

The shock absorber is non-adjustable, non-

refillable, and cannot be disassembled. The only

service the shock absorber requires is replace-

ment when it has lost its resistance, is damaged,

or leaking oil or gas.

1) Remove rear brake drum. Refer to item 19-3

“REAR DRUM BRAKE”.I /

1) Hoist car.

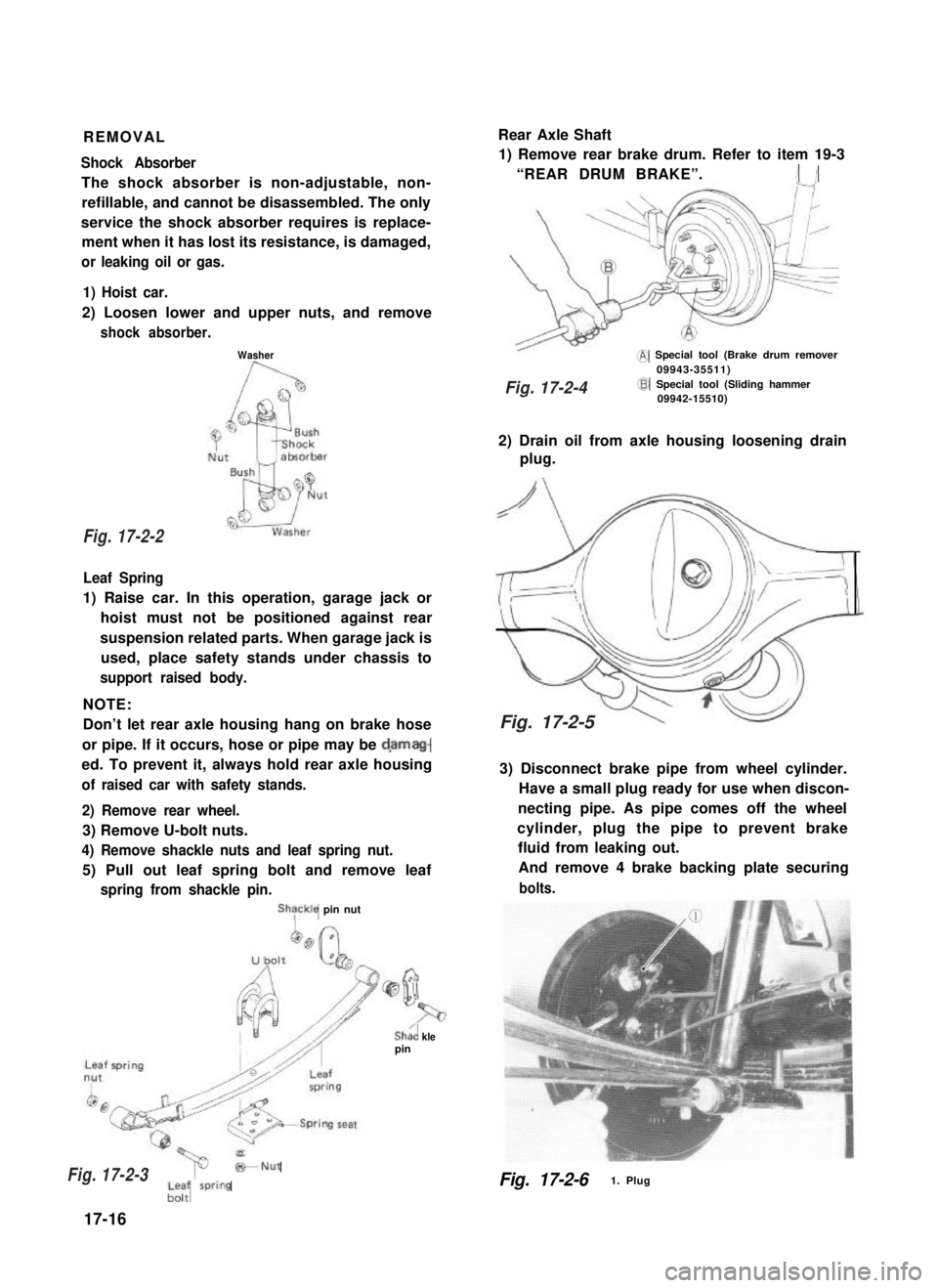

2) Loosen lower and upper nuts, and remove

shock absorber.

Washer@ Special tool (Brake drum remover09943-35511)

Leaf Spring

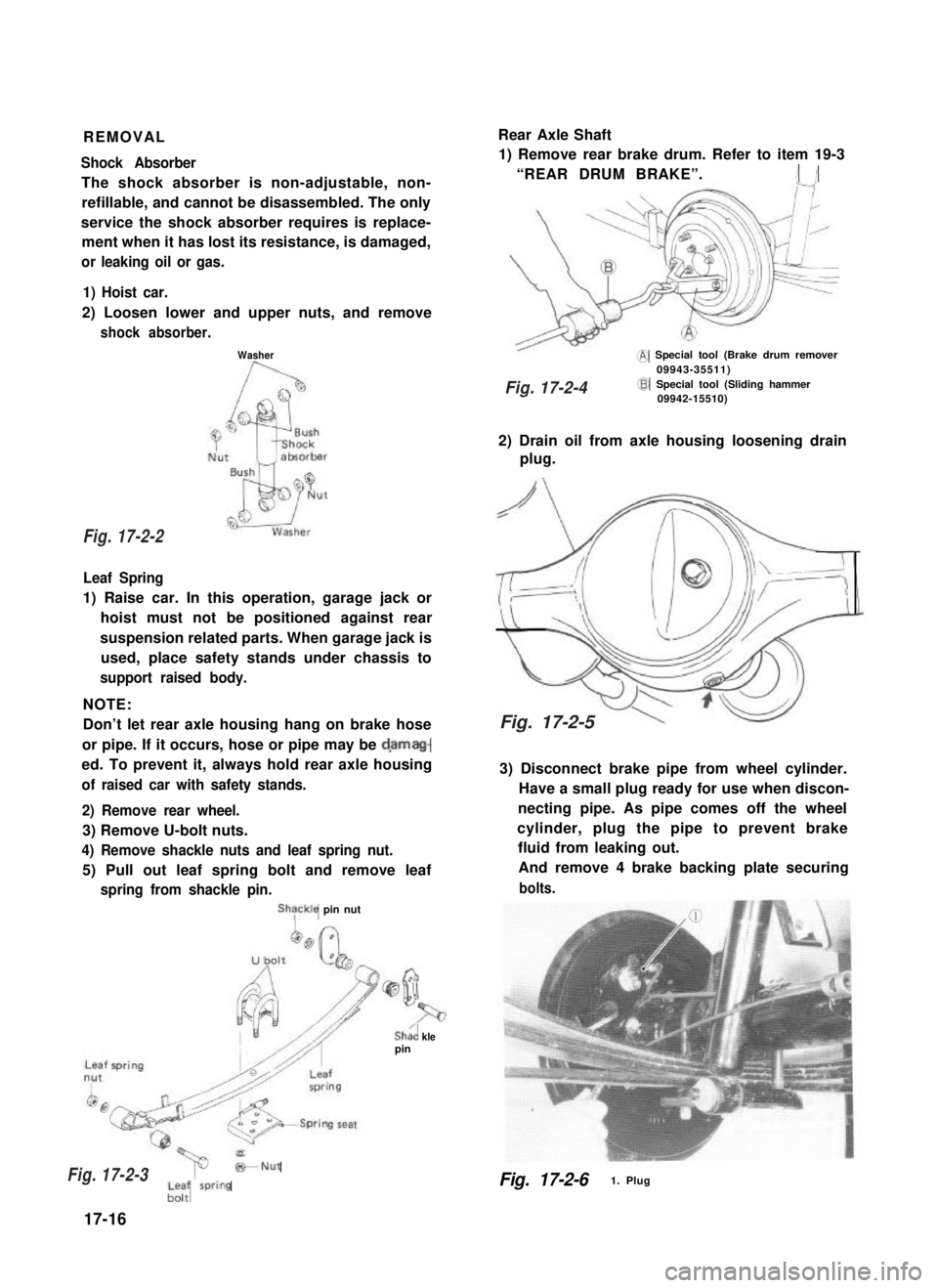

1) Raise car. In this operation, garage jack or

hoist must not be positioned against rear

suspension related parts. When garage jack is

used, place safety stands under chassis to

support raised body.

NOTE:

Don’t let rear axle housing hang on brake hose

or pipe. If it occurs, hose or pipe may be d,amag-

ed. To prevent it, always hold rear axle housing

of raised car with safety stands.

2) Remove rear wheel.

3) Remove U-bolt nuts.

4) Remove shackle nuts and leaf spring nut.

5) Pull out leaf spring bolt and remove leaf

spring from shackle pin.

ShTckle pin nut

Sha’, klepin

@Special tool (Sliding hammer09942-15510)

2) Drain oil from axle housing loosening drain

plug.

3) Disconnect brake pipe from wheel cylinder.

Have a small plug ready for use when discon-

necting pipe. As pipe comes off the wheel

cylinder, plug the pipe to prevent brake

fluid from leaking out.

And remove 4 brake backing plate securing

bolts.

*Nut

;-; wring

17-16

Fig. 17-2-61. Plug

Fig. 17-2-2

Fig. 17-2-3

Fig. 17-2-4

Fig. 17-2-5

Trending: jump cable, torque, coolant reservoir, coolant temperature, cooling, transmission fluid, maintenance

![SUZUKI GRAND VITARA 1987 Service Repair Manual [For car not equipped with free wheeling hub]

5. Remove the front axle shaft cap.

6. Remove the circlip retaining the front axle

shaft drive flange on front drive shaft, using

the circlip remover @.

F SUZUKI GRAND VITARA 1987 Service Repair Manual [For car not equipped with free wheeling hub]

5. Remove the front axle shaft cap.

6. Remove the circlip retaining the front axle

shaft drive flange on front drive shaft, using

the circlip remover @.

F](/img/20/57437/w960_57437-340.png)