SUZUKI GRAND VITARA 1987 Service Repair Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 371 of 962

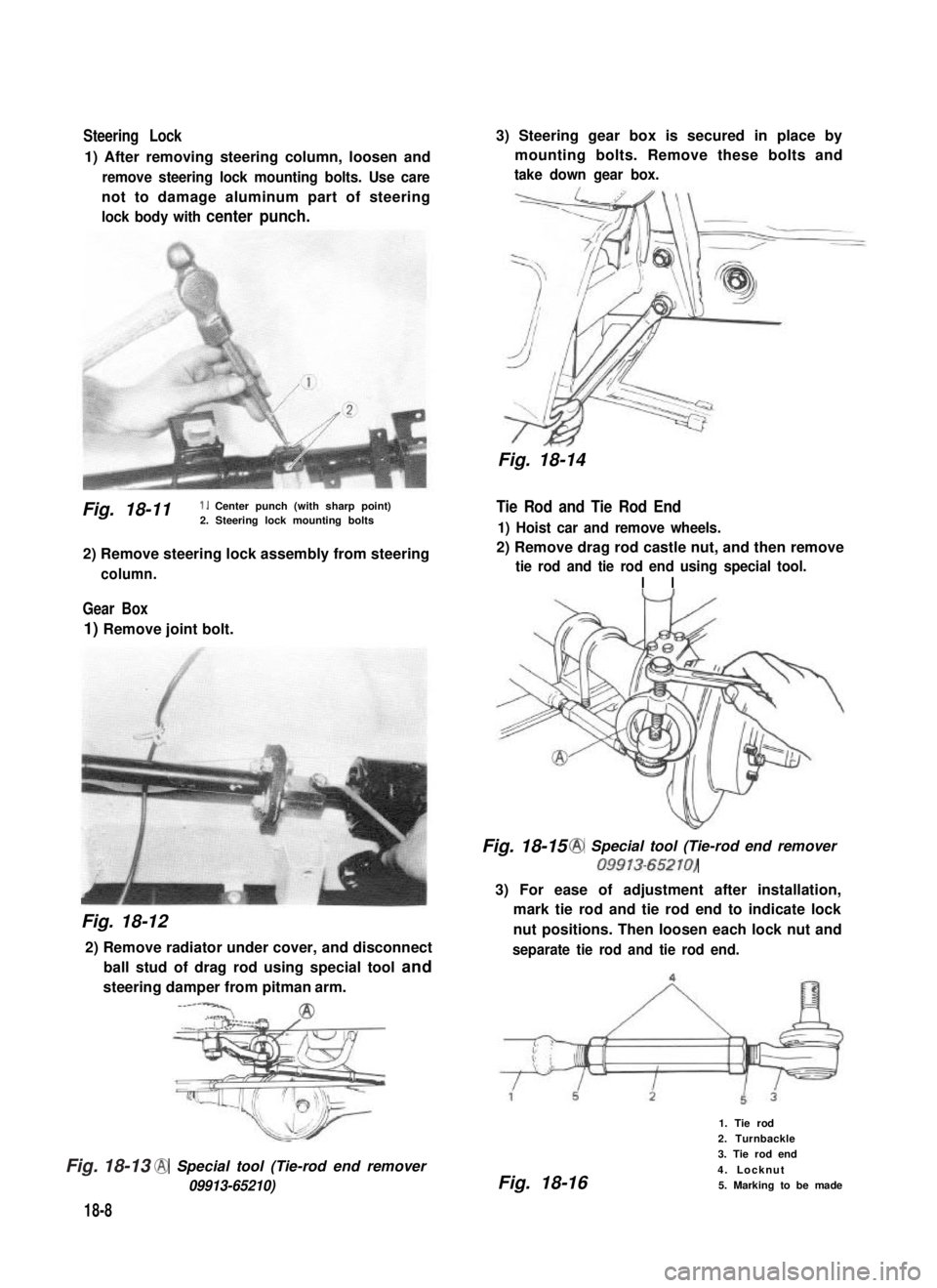

Steering Lock

1) After removing steering column, loosen and

remove steering lock mounting bolts. Use care

not to damage aluminum part of steering

lock body with center punch.

Fig. 18-11 1. Center punch (with sharp point)2. Steering lock mounting bolts

2) Remove steering lock assembly from steering

column.

Gear Box

1) Remove joint bolt.

Fig. 18-12

2) Remove radiator under cover, and disconnect

ball stud of drag rod using special tool and

steering damper from pitman arm.

-----‘CA2

@ Special tool (Tie-rod end remover

09913-65210)

18-8

3) Steering gear box is secured in place by

mounting bolts. Remove these bolts and

take down gear box.

Fig. 18-14

Tie Rod and Tie Rod End

1) Hoist car and remove wheels.

2) Remove drag rod castle nut, and then remove

tie rod and tie rod end using special tool.

I I

Fig. 18-15 @ Special tool (Tie-rod end remover

09913-65210)

3) For ease of adjustment after installation,

mark tie rod and tie rod end to indicate lock

nut positions. Then loosen each lock nut and

separate tie rod and tie rod end.

Fig. 18-16

1. Tie rod

2. Turnbackle

3. Tie rod end

4. Locknut

5. Marking to be made

Fig. 18-13

Page 372 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual 18-5. INSPECTION OF COMPONENTS

Steering Gear Box

[Oil level]

Oil surface should be up to the level as shown

in below figures. If not, add prescribed gear oil,

SAE 90.

Right hand steering vehicle

Fig. SUZUKI GRAND VITARA 1987 Service Repair Manual 18-5. INSPECTION OF COMPONENTS

Steering Gear Box

[Oil level]

Oil surface should be up to the level as shown

in below figures. If not, add prescribed gear oil,

SAE 90.

Right hand steering vehicle

Fig.](/img/20/57437/w960_57437-371.png)

18-5. INSPECTION OF COMPONENTS

Steering Gear Box

[Oil level]

Oil surface should be up to the level as shown

in below figures. If not, add prescribed gear oil,

SAE 90.

Right hand steering vehicle

Fig. 18-17

Left hand steering vehicle

I

35mm(1.4 in.)

Fig. 18-18

[Adjustment of worm shaft starting torque]

The steering gear box is provided with adjust-

ing bolt @ which gives preload to sector shaft.

Fig. 18-19 (1)Adjusting bolt

Make an adjustment according to the following

procedure.

1) Check worm shaft to ensure that it is free

from thrust play.

2) Position pitman arm in parallel with worm

shaft as shown below.

(With pitman arm in this position, front

wheel is in straightforward state.)

Worm shaft

Fig. 18-20

Pitman arm

18-9

Page 373 of 962

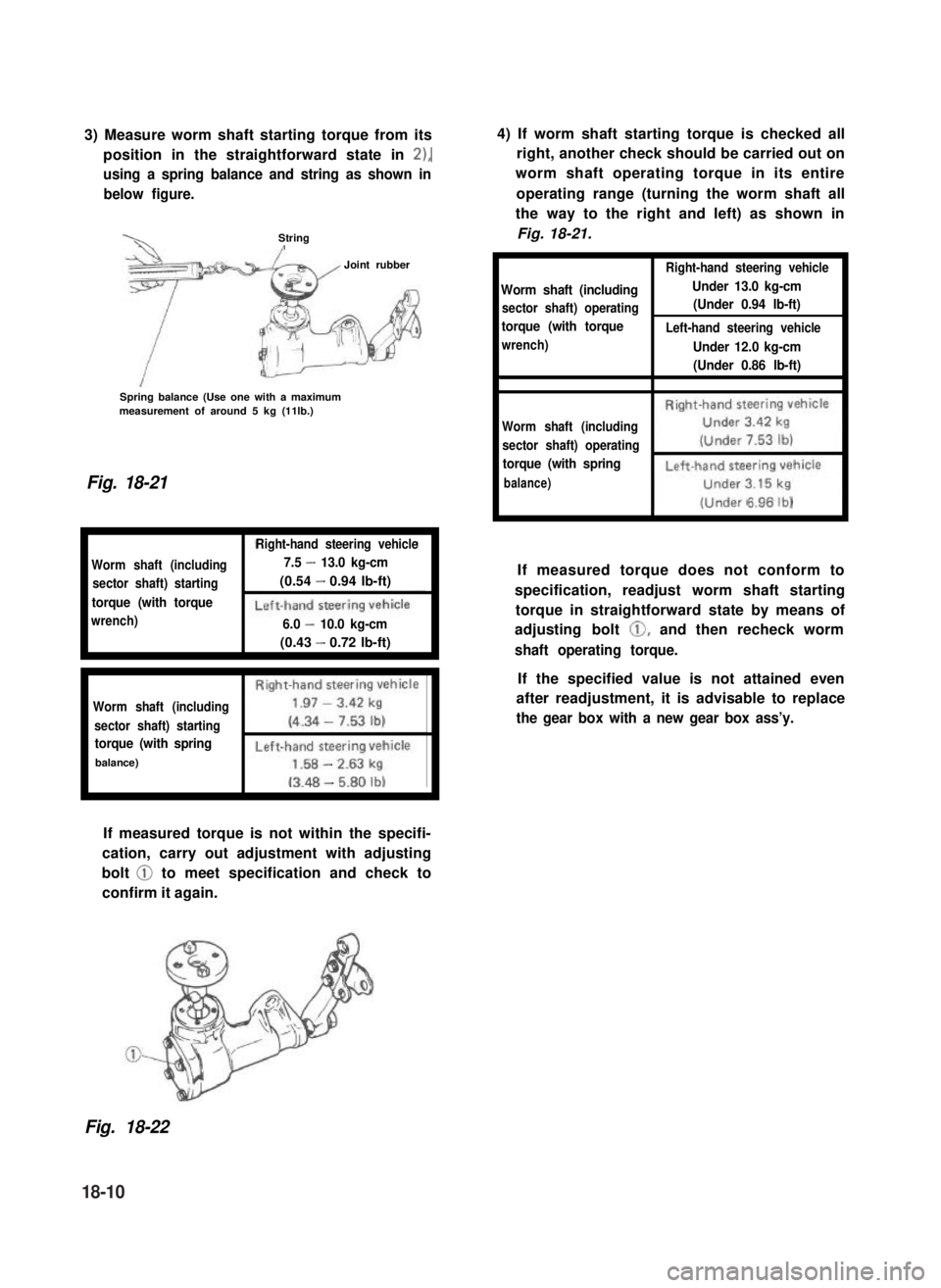

3) Measure worm shaft starting torque from its

position in the straightforward state in 2),

using a spring balance and string as shown in

below figure.

StringI

Joint rubber

Spring balance (Use one with a maximummeasurement of around 5 kg (11lb.)

Fig. 18-21

Worm shaft (including

sector shaft) starting

torque (with torque

wrench)

Right-hand steering vehicle

7.5 - 13.0 kg-cm

(0.54 - 0.94 lb-ft)

6.0 - 10.0 kg-cm

(0.43 - 0.72 lb-ft)

Right-hand steering vehicle

Worm shaft (including1.97 - 3.42 kg

sector shaft) starting(4.34 - 7.53 lb)

torque (with spring

I----

balance)-

-

If measured torque is not within the specifi-

cation, carry out adjustment with adjusting

bolt @ to meet specification and check to

confirm it again.

4) If worm shaft starting torque is checked all

right, another check should be carried out on

worm shaft operating torque in its entire

operating range (turning the worm shaft all

the way to the right and left) as shown in

Fig. 18-21.

Right-hand steering vehicle

Worm shaft (includingUnder 13.0 kg-cm

sector shaft) operating(Under 0.94 lb-ft)

torque (with torqueLeft-hand steering vehicle

wrench)Under 12.0 kg-cm

(Under 0.86 lb-ft),

Right-hand steering vehicle

Worm shaft (includingUnder 3.42 kg

sector shaft) operating(Under 7.53 lb)

torque (with spring

l-----i

balance)

6.96lb)

If measured torque does not conform to

specification, readjust worm shaft starting

torque in straightforward state by means of

adjusting bolt 0, and then recheck worm

shaft operating torque.

If the specified value is not attained even

after readjustment, it is advisable to replace

the gear box with a new gear box ass’y.

Fig. 18-22

18-10

Page 374 of 962

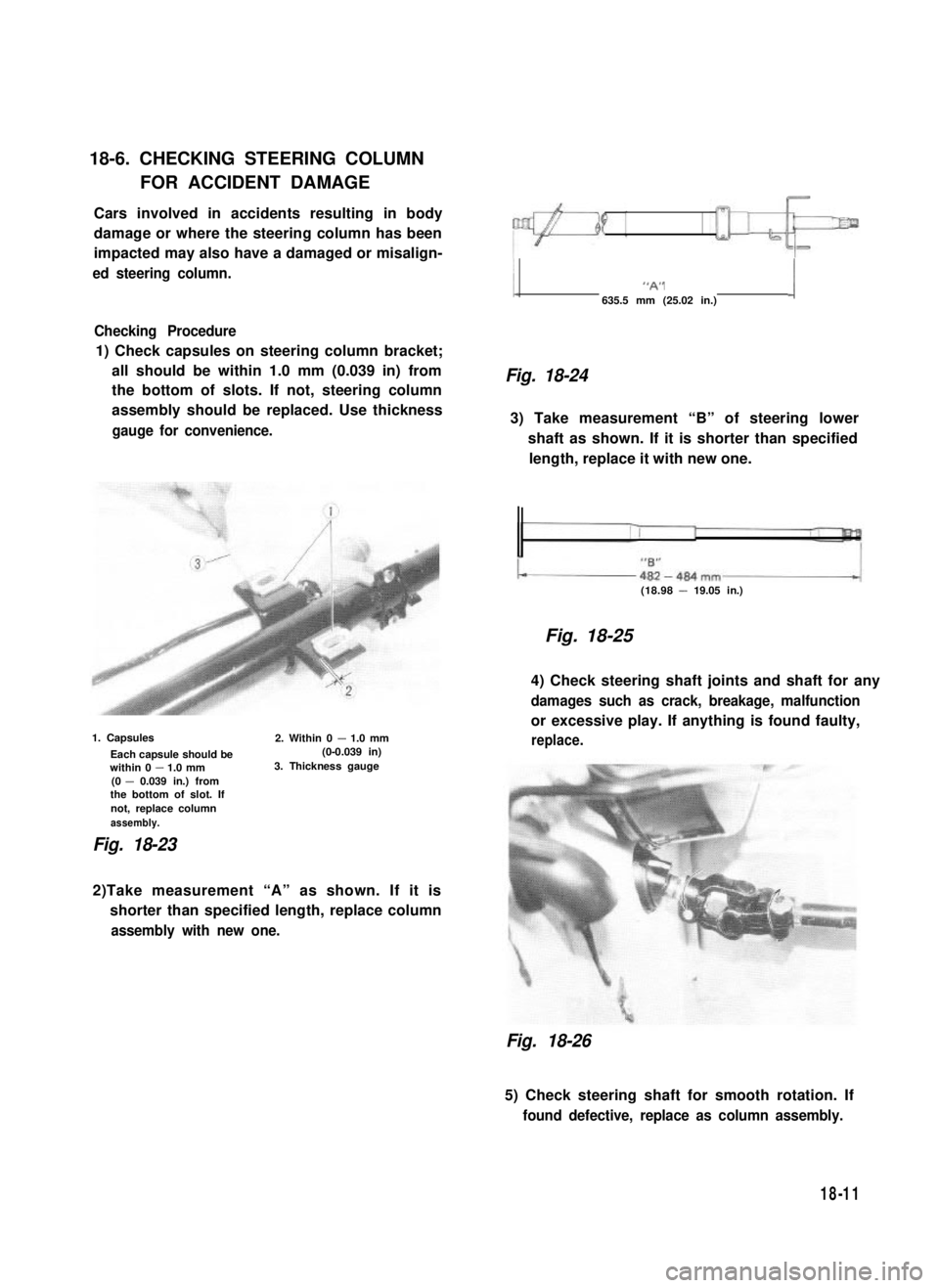

18-6. CHECKING STEERING COLUMN

FOR ACCIDENT DAMAGE

Cars involved in accidents resulting in body

damage or where the steering column has been

impacted may also have a damaged or misalign-

ed steering column.

Checking Procedure

1) Check capsules on steering column bracket;

all should be within 1.0 mm (0.039 in) from

the bottom of slots. If not, steering column

assembly should be replaced. Use thickness

gauge for convenience.

1. Capsules

Each capsule should bewithin 0 - 1.0 mm(0 - 0.039 in.) fromthe bottom of slot. Ifnot, replace columnassembly.

2. Within 0 - 1.0 mm (0-0.039 in)3. Thickness gauge

Fig. 18-23

1 “A” j

635.5 mm (25.02 in.)

Fig. 18-24

3) Take measurement “B” of steering lower

shaft as shown. If it is shorter than specified

length, replace it with new one.

(18.98 - 19.05 in.)

Fig. 18-25

4) Check steering shaft joints and shaft for any

damages such as crack, breakage, malfunction

or excessive play. If anything is found faulty,

replace.

2)Take measurement “A” as shown. If it is

shorter than specified length, replace column

assembly with new one.

Fig. 18-26

5) Check steering shaft for smooth rotation. If

found defective, replace as column assembly.

18-11

Page 375 of 962

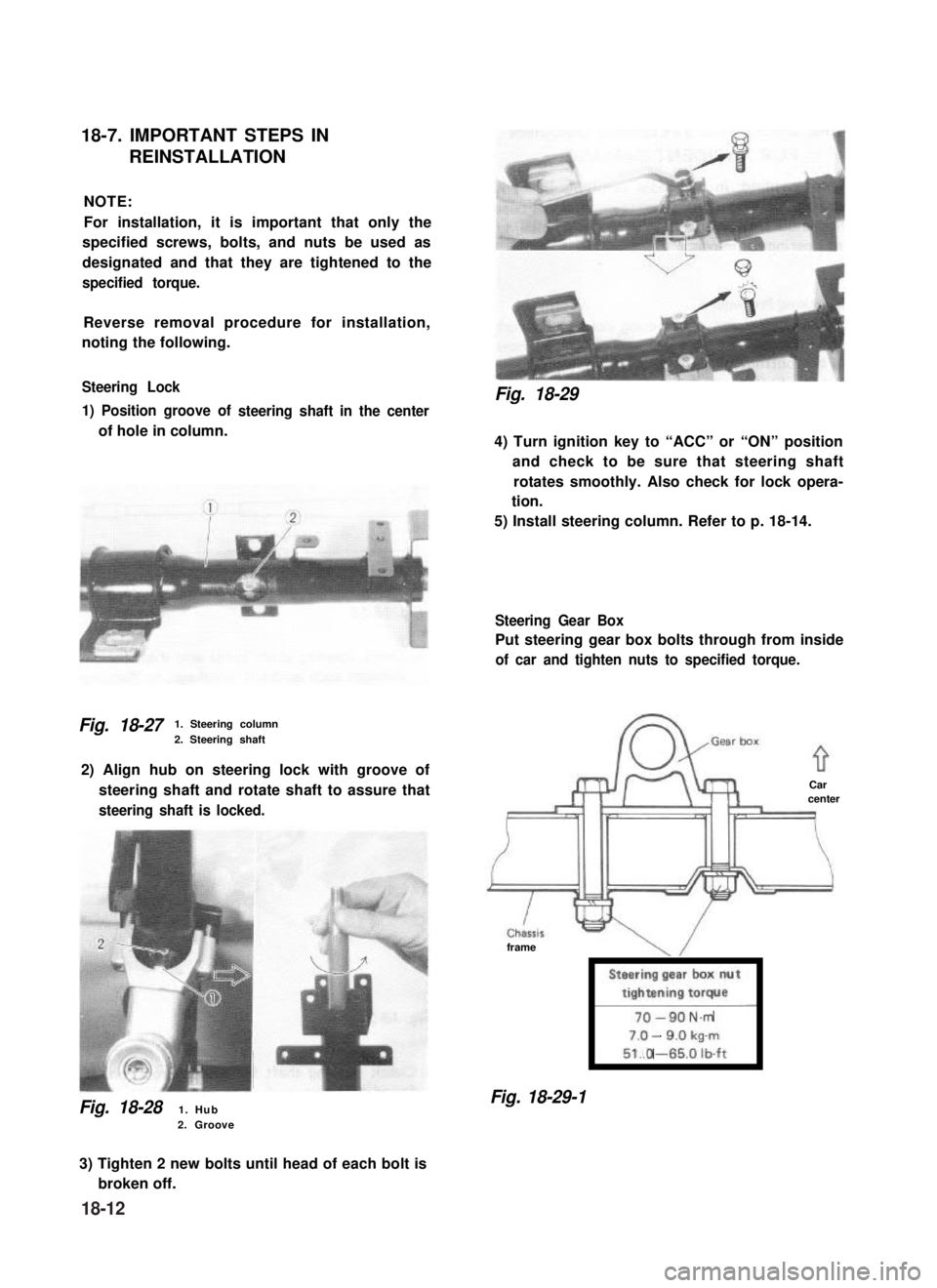

18-7. IMPORTANT STEPS IN

REINSTALLATION

NOTE:

For installation, it is important that only the

specified screws, bolts, and nuts be used as

designated and that they are tightened to the

specified torque.

Reverse removal procedure for installation,

noting the following.

Steering Lock

1) Position groove of

of hole in column.

steering shaft in the center

Fig. 18-271. Steering column

2. Steering shaft

2) Align hub on steering lock with groove of

steering shaft and rotate shaft to assure that

steering shaft is locked.

Fig. 18-281. Hub2. Groove

Fig. 18-29

4) Turn ignition key to “ACC” or “ON” position

and check to be sure that steering shaft

rotates smoothly. Also check for lock opera-

tion.

5) Install steering column. Refer to p. 18-14.

Steering Gear Box

Put steering gear box bolts through from inside

of car and tighten nuts to specified torque.

Carcenter

frame

Steering gear box nut

tightening torque

l-----i

-N.m

-

.O -

Fig. 18-29-1

3) Tighten 2 new bolts until head of each bolt is

broken off.

18-12

Page 376 of 962

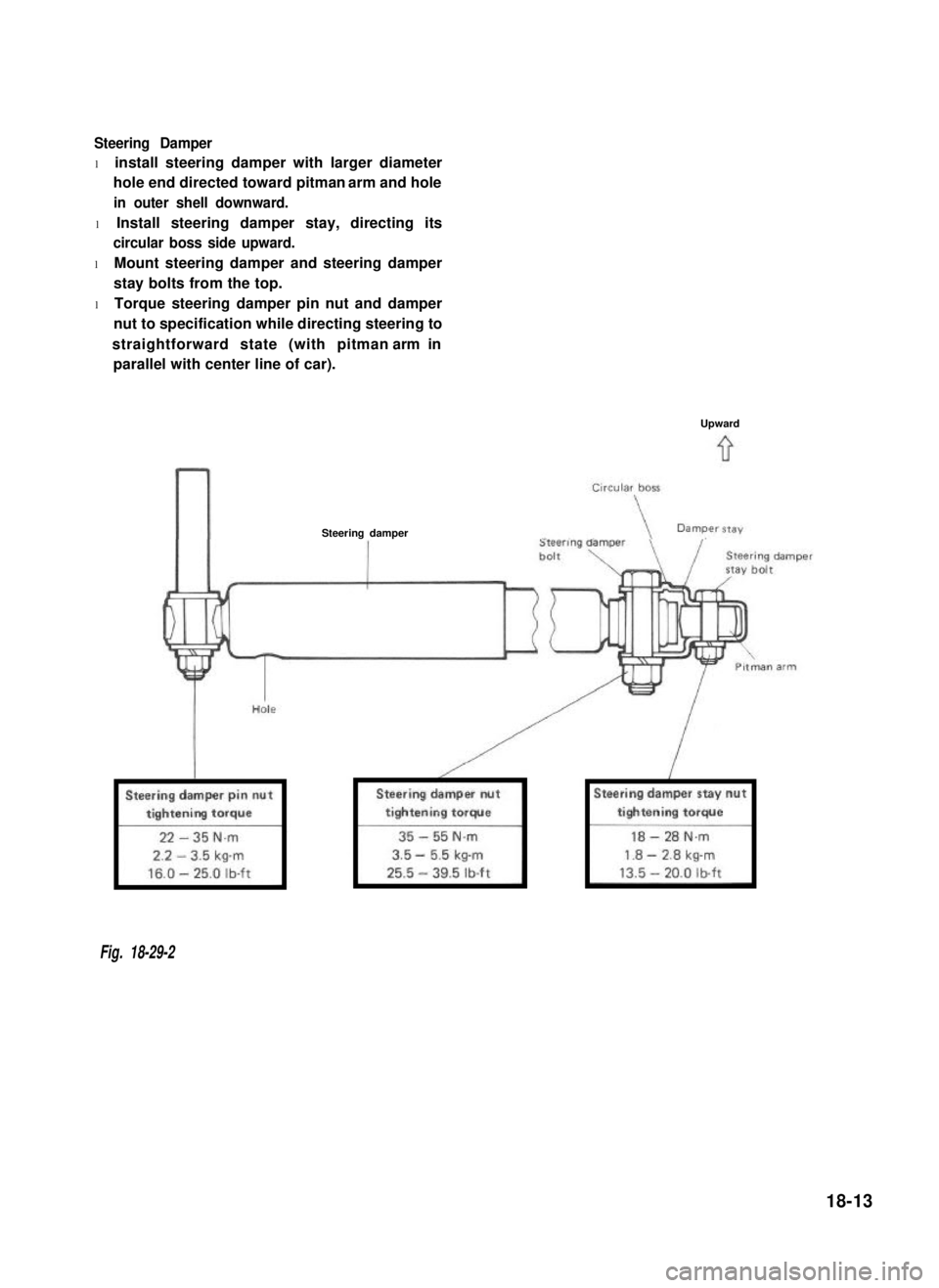

Steering Damper

l install steering damper with larger diameter

hole end directed toward pitman arm and hole

in outer shell downward.

l Install steering damper stay, directing its

circular boss side upward.

l Mount steering damper and steering damper

stay bolts from the top.

l Torque steering damper pin nut and damper

nut to specification while directing steering to

straightforward state (with pitman arm in

parallel with center line of car).

Upward

Steering damper

Fig. 18-29-2

18-13

Page 377 of 962

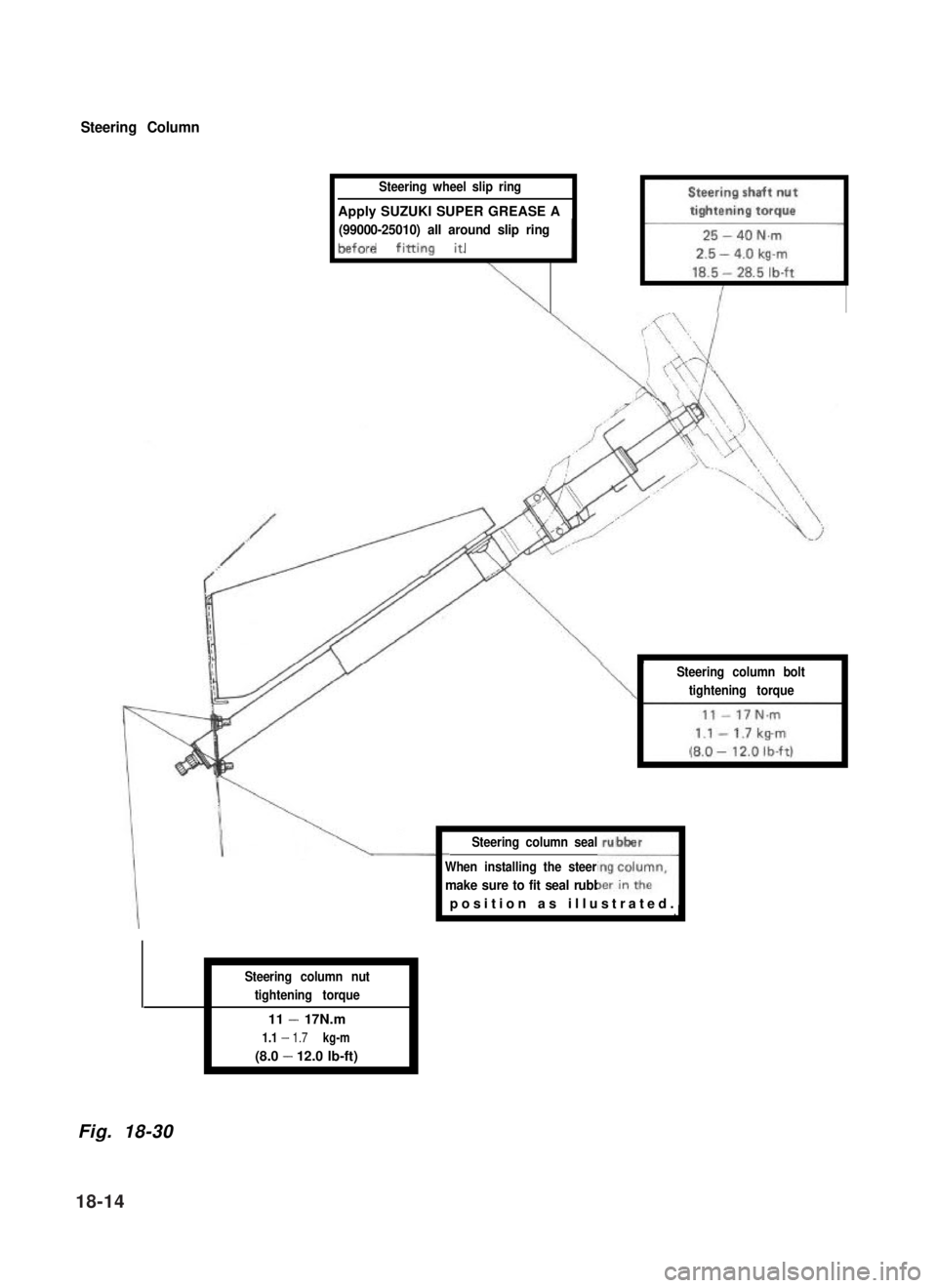

Steering Column

Steering wheel slip ring

Apply SUZUKI SUPER GREASE A

(99000-25010) all around slip ring

IIbefore fining it. , 1

Steering column seal

\I

Steering column bolt

tightening torqueI

When installing the steering column,

1.

make sure to fit seal rubber in the

rubber

1J

Steering column nut

tightening torque

11 - 17N.m

1.1 - 1.7 kg-m

(8.0 - 12.0 lb-ft)

Fig. 18-30

position as illustrated

18-14

Page 378 of 962

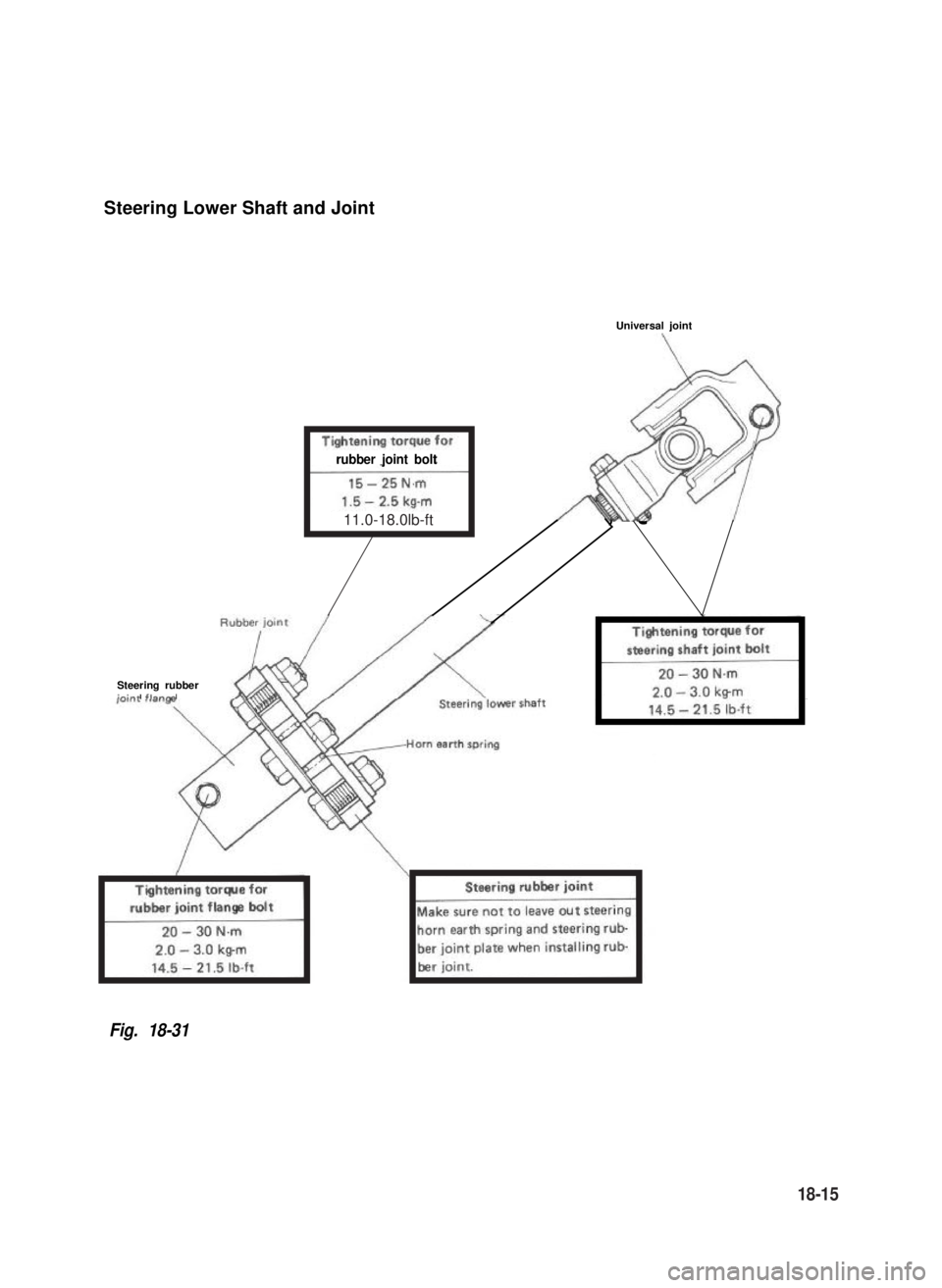

Steering Lower Shaft and Joint

Universal joint

rubber joint bolt

Steering rubberir:..,

Fig. 18-31

11.0-18.0lb-ft

18-15

Page 379 of 962

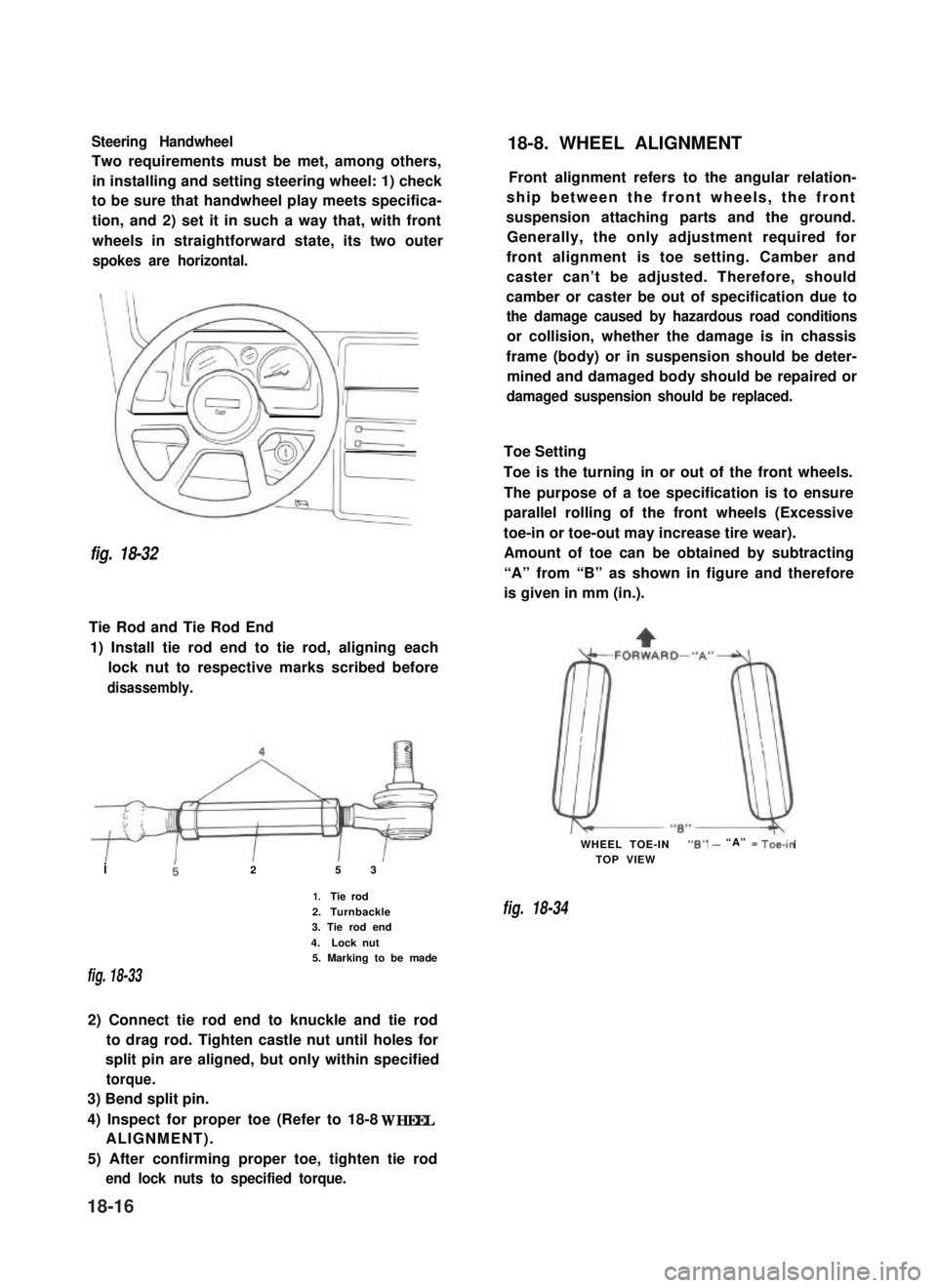

Steering Handwheel

Two requirements must be met, among others,

in installing and setting steering wheel: 1) check

to be sure that handwheel play meets specifica-

tion, and 2) set it in such a way that, with front

wheels in straightforward state, its two outer

spokes are horizontal.

fig. 18-32

Tie Rod and Tie Rod End

1) Install tie rod end to tie rod, aligning each

lock nut to respective marks scribed before

disassembly.

i25 3

1.Tie rod

2.Turnbackle3. Tie rod end

4.Lock nut5. Marking to be made

fig. 18-33

2) Connect tie rod end to knuckle and tie rod

to drag rod. Tighten castle nut until holes for

split pin are aligned, but only within specified

torque.

3) Bend split pin.

4) Inspect for proper toe (Refer to 18-8 WHEEL

ALIGNMENT).

5) After confirming proper toe, tighten tie rod

end lock nuts to specified torque.

18-8. WHEEL ALIGNMENT

Front alignment refers to the angular relation-

ship between the front wheels, the front

suspension attaching parts and the ground.

Generally, the only adjustment required for

front alignment is toe setting. Camber and

caster can’t be adjusted. Therefore, should

camber or caster be out of specification due to

the damage caused by hazardous road conditions

or collision, whether the damage is in chassis

frame (body) or in suspension should be deter-

mined and damaged body should be repaired or

damaged suspension should be replaced.

Toe Setting

Toe is the turning in or out of the front wheels.

The purpose of a toe specification is to ensure

parallel rolling of the front wheels (Excessive

toe-in or toe-out may increase tire wear).

Amount of toe can be obtained by subtracting

“A” from “B” as shown in figure and therefore

is given in mm (in.).

WHEEL TOE-IN“6” - “A” = Toe-in

TOP VIEW

fig. 18-34

18-16

Page 380 of 962

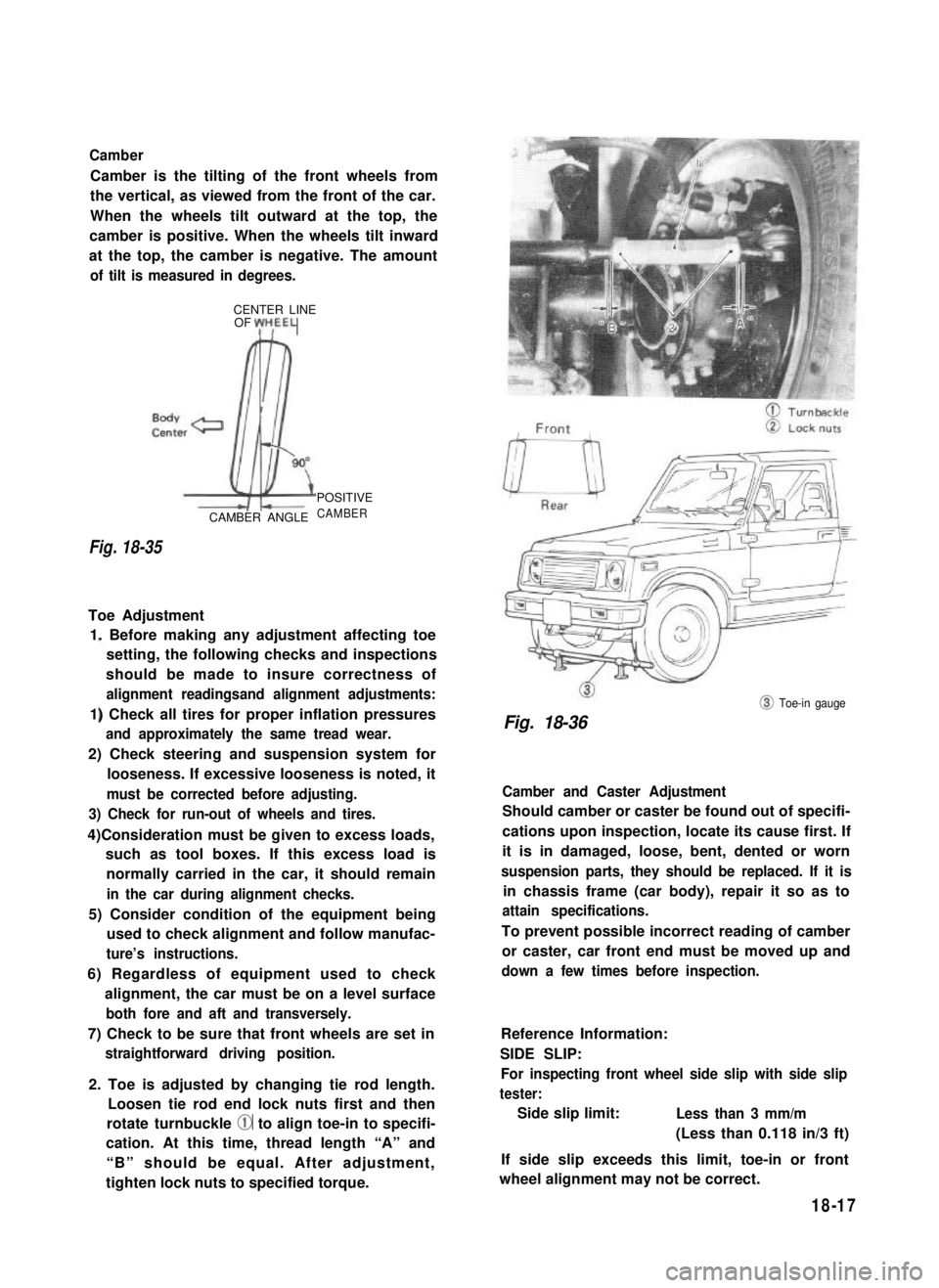

Camber

Camber is the tilting of the front wheels from

the vertical, as viewed from the front of the car.

When the wheels tilt outward at the top, the

camber is positive. When the wheels tilt inward

at the top, the camber is negative. The amount

of tilt is measured in degrees.

CENTER LINEOF yH,EEL

Fig. 18-35

CAMBER ANGLE

‘POSITIVE

CAMBER

Toe Adjustment

1. Before making any adjustment affecting toe

setting, the following checks and inspections

should be made to insure correctness of

alignment readingsand alignment adjustments:

1) Check all tires for proper inflation pressures

and approximately the same tread wear.

2) Check steering and suspension system for

looseness. If excessive looseness is noted, it

must be corrected before adjusting.

3) Check for run-out of wheels and tires.

4)Consideration must be given to excess loads,

such as tool boxes. If this excess load is

normally carried in the car, it should remain

in the car during alignment checks.

5) Consider condition of the equipment being

used to check alignment and follow manufac-

ture’s instructions.

6) Regardless of equipment used to check

alignment, the car must be on a level surface

both fore and aft and transversely.

7) Check to be sure that front wheels are set in

straightforward driving position.

2. Toe is adjusted by changing tie rod length.

Loosen tie rod end lock nuts first and then

rotate turnbuckle @ to align toe-in to specifi-

cation. At this time, thread length “A” and

“B” should be equal. After adjustment,

tighten lock nuts to specified torque.

@ Toe-in gauge

Fig. 18-36

Camber and Caster Adjustment

Should camber or caster be found out of specifi-

cations upon inspection, locate its cause first. If

it is in damaged, loose, bent, dented or worn

suspension parts, they should be replaced. If it is

in chassis frame (car body), repair it so as to

attain specifications.

To prevent possible incorrect reading of camber

or caster, car front end must be moved up and

down a few times before inspection.

Reference Information:

SIDE SLIP:

For inspecting front wheel side slip with side slip

tester:

Side slip limit:Less than 3 mm/m

(Less than 0.118 in/3 ft)

If side slip exceeds this limit, toe-in or front

wheel alignment may not be correct.

18-17