timing belt SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 21 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual 1-2. ENGINE AND EMISSION CONTROL

1. WATER PUMP BELT INSPECTION

AND REPLACEMENT

[INSPECTION]

1) Disconnect negative battery lead at battery.

2) Inspect belt for cracks, cuts, deformation,

wear and clea SUZUKI GRAND VITARA 1987 Service Repair Manual 1-2. ENGINE AND EMISSION CONTROL

1. WATER PUMP BELT INSPECTION

AND REPLACEMENT

[INSPECTION]

1) Disconnect negative battery lead at battery.

2) Inspect belt for cracks, cuts, deformation,

wear and clea](/img/20/57437/w960_57437-20.png)

1-2. ENGINE AND EMISSION CONTROL

1. WATER PUMP BELT INSPECTION

AND REPLACEMENT

[INSPECTION]

1) Disconnect negative battery lead at battery.

2) Inspect belt for cracks, cuts, deformation,

wear and cleanliness. If any defect, replace.

Check belt for tension. The belt is in’ proper

tension if it deflects 6 to 9 mm (0.24 - 0.35

in.) under thumb pressure (about 10 kg or

22 lb.)..

Belt tension6 - 9 mm (0.24 - 0.35 in.)

specificationas deflection

pulley

3) If the belt is too tight or too loose, adjust it

to specification by adjusting alternator

position.

4) Tighten alternator adjusting bolt and pivot

bolts.

5) Connect negative battery lead to battery.

[REPLACEMENT]

1) Disconnect negative battery lead at battery.

2) Loosen alternator adjusting bolt and pivot

bolts.

3) Replace water pump belt.

4) Adjust belt tension to specification and

tighten alternator adjusting bolt and pivot

bolts.

5) Connect negative battery lead to battery.

2. CAMSHAFT TIMING BELT INSPECTION

1) Disconnect negative battery lead at battery.

2) Loosen fan drive belt, and remove 4 bolts

securing radiator shroud panel and 4 nuts

securing engine cooling fan & clutch. Then

remove radiator shroud and cooling fan &

clutch at the same time.

3) Remove water pump belt and pump pulley.

4) Remove crankshaft pulley by removing 4

pulley bolts. The crankshaft timing belt

pulley bolt at the center need not be loosen-

ed.2 1

‘31. Key

2. Crankshaft pulley

3. Pulley bolt

1-5

Page 22 of 962

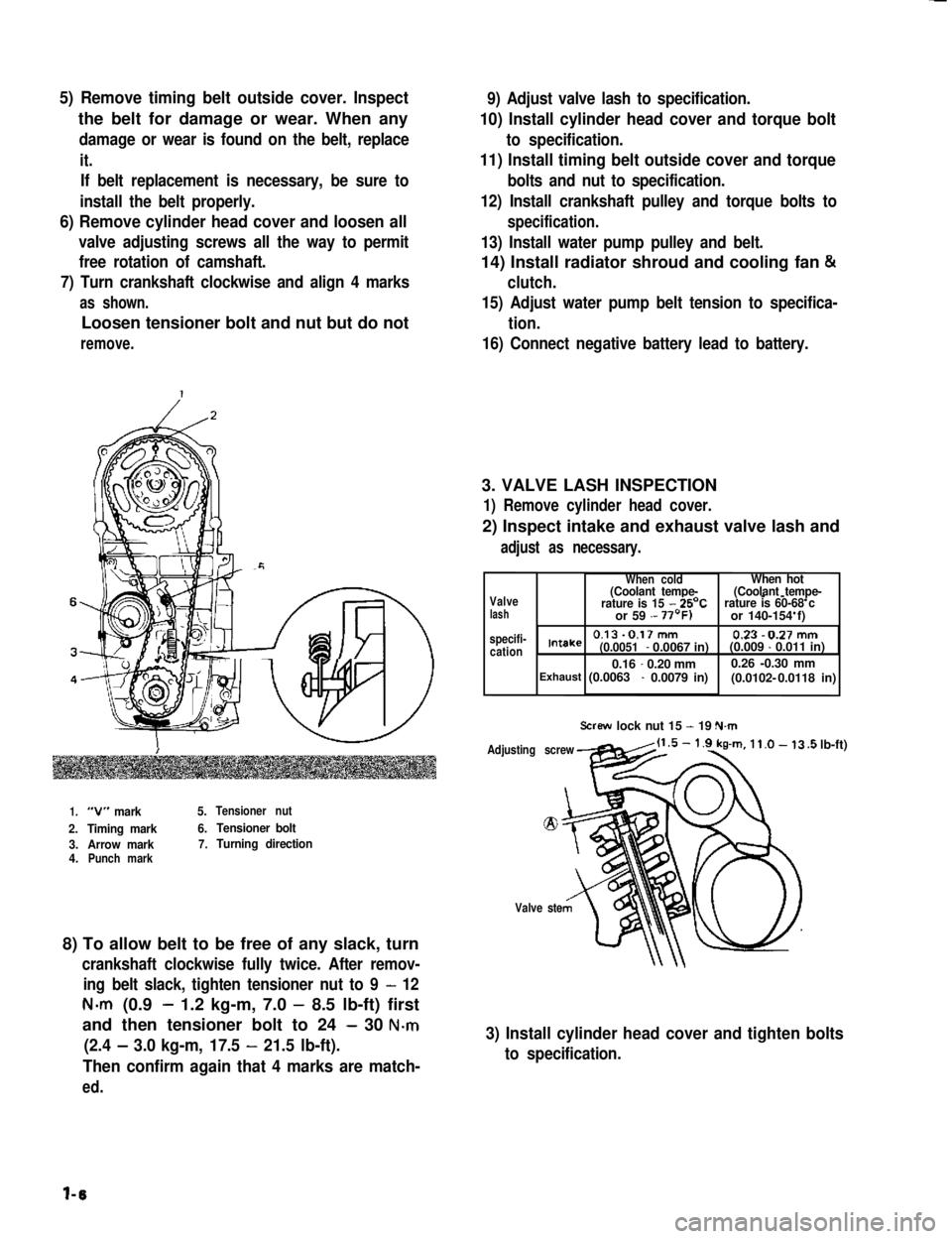

5) Remove timing belt outside cover. Inspect

the belt for damage or wear. When any

damage or wear is found on the belt, replace

it.

If belt replacement is necessary, be sure to

install the belt properly.

6) Remove cylinder head cover and loosen all

valve adjusting screws all the way to permit

free rotation of camshaft.

7) Turn crankshaft clockwise and align 4 marks

as shown.

Loosen tensioner bolt and nut but do not

remove.

9) Adjust valve lash to specification.

10) Install cylinder head cover and torque bolt

to specification.

11) Install timing belt outside cover and torque

bolts and nut to specification.

12) Install crankshaft pulley and torque bolts to

specification.

13) Install water pump pulley and belt.

14) Install radiator shroud and cooling fan &

clutch.

15) Adjust water pump belt tension to specifica-

tion.

16) Connect negative battery lead to battery.

3. VALVE LASH INSPECTION

1) Remove cylinder head cover.

2) Inspect intake and exhaust valve lash and

adjust as necessary.

1.“V” mark5.Tensioner nut

2.Timing mark6.Tensioner bolt

3.Arrow mark7.Turning direction4.Punch mark

8) To allow belt to be free of any slack, turn

crankshaft clockwise fully twice. After remov-

ing belt slack, tighten tensioner nut to 9 - 12

N-m (0.9- 1.2 kg-m, 7.0 - 8.5 lb-ft) first

and then tensioner bolt to 24 - 30 N-m

(2.4 - 3.0 kg-m, 17.5 - 21.5 lb-ft).

Then confirm again that 4 marks are match-

ed.

Valvelash specifi-cation

When coldWhen hot(Coolant tempe-(Coolant tempe---rature is 15 - 25’Crature is 60-68 c or 59 - or 140-154 f)

0.13-0.17mm 0.23-0.27mmIntake(0.0051- 0.0067 in)(0.009 - 0.011 in)

0.16-0.20 mm0.26 -0.30 mm(0.0102- Exhaust (0.0063 - 0.0079 in) 0.0118 in)

Screw lock nut 15 - 19 N.m

Adjusting screw

Valve ste

.5 lb-ft)

3) Install cylinder head cover and tighten bolts

to specification.

l-6

Page 41 of 962

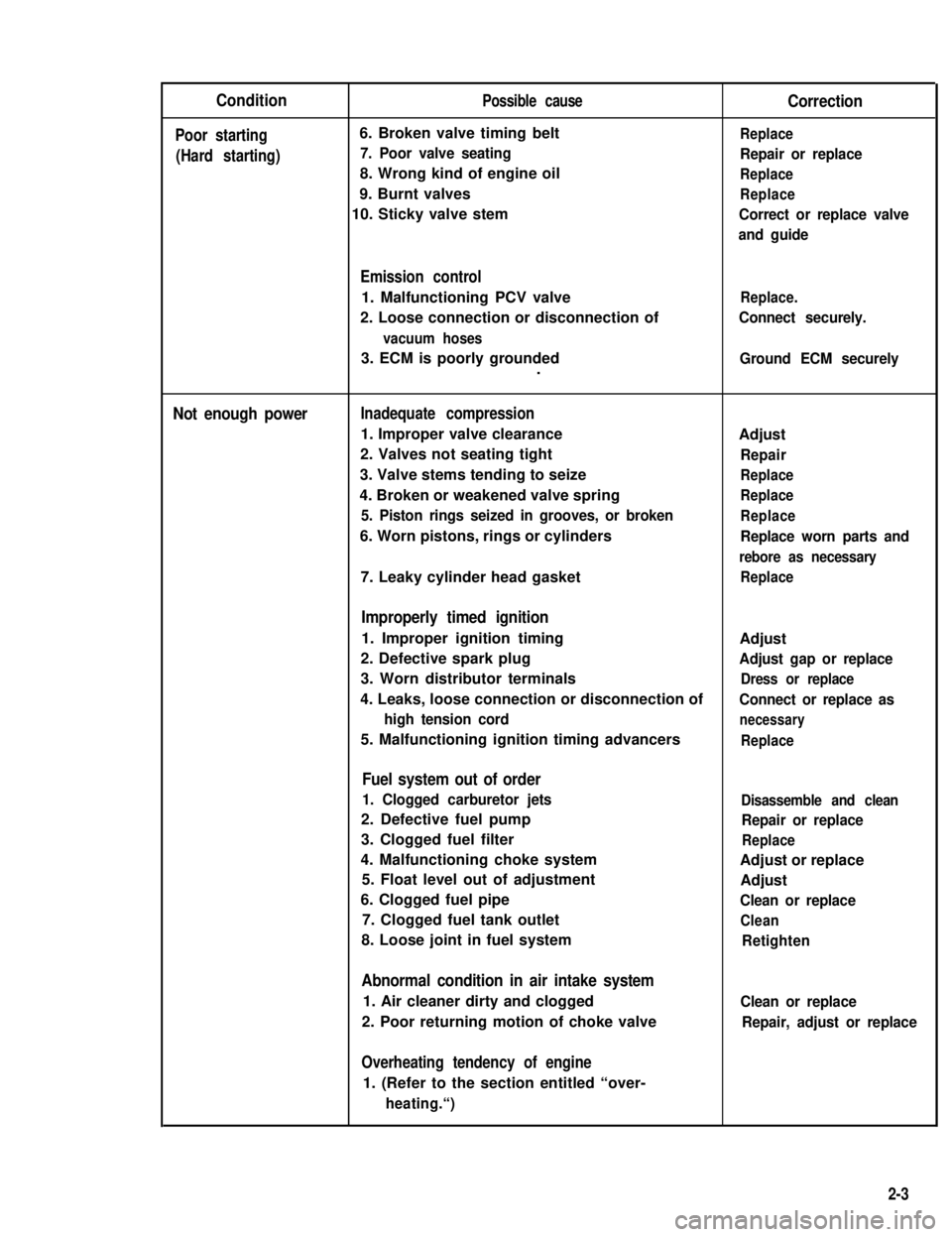

Condition

Poor starting

(Hard starting)

Possible cause

6. Broken valve timing belt

7. Poor valve seating

8. Wrong kind of engine oil

9. Burnt valves

10. Sticky valve stem

Correction

Replace

Repair or replace

Replace

Replace

Correct or replace valve

and guide

Emission control

1. Malfunctioning PCV valve

2. Loose connection or disconnection of

vacuum hoses

Replace.

Connect securely.

3. ECM is poorly grounded.Ground ECM securely

Not enough powerInadequate compression

1. Improper valve clearance

2. Valves not seating tight

3. Valve stems tending to seize

4. Broken or weakened valve spring

5. Piston rings seized in grooves, or broken

6. Worn pistons, rings or cylinders

Adjust

Repair

Replace

Replace

Replace

Replace worn parts and

rebore as necessary

7. Leaky cylinder head gasketReplace

Improperly timed ignition

1. Improper ignition timing

2. Defective spark plug

3. Worn distributor terminals

4. Leaks, loose connection or disconnection of

high tension cord

5. Malfunctioning ignition timing advancers

Adjust

Adjust gap or replace

Dress or replace

Connect or replace as

necessary

Replace

Fuel system out of order

1. Clogged carburetor jets

2. Defective fuel pump

3. Clogged fuel filter

4. Malfunctioning choke system

5. Float level out of adjustment

6. Clogged fuel pipe

7. Clogged fuel tank outlet

8. Loose joint in fuel system

Disassemble and clean

Repair or replace

Replace

Adjust or replace

Adjust

Clean or replace

Clean

Retighten

Abnormal condition in air intake system

1. Air cleaner dirty and clogged

2. Poor returning motion of choke valve

Clean or replace

Repair, adjust or replace

Overheating tendency of engine

1. (Refer to the section entitled “over-

heating.“)

2-3

Page 45 of 962

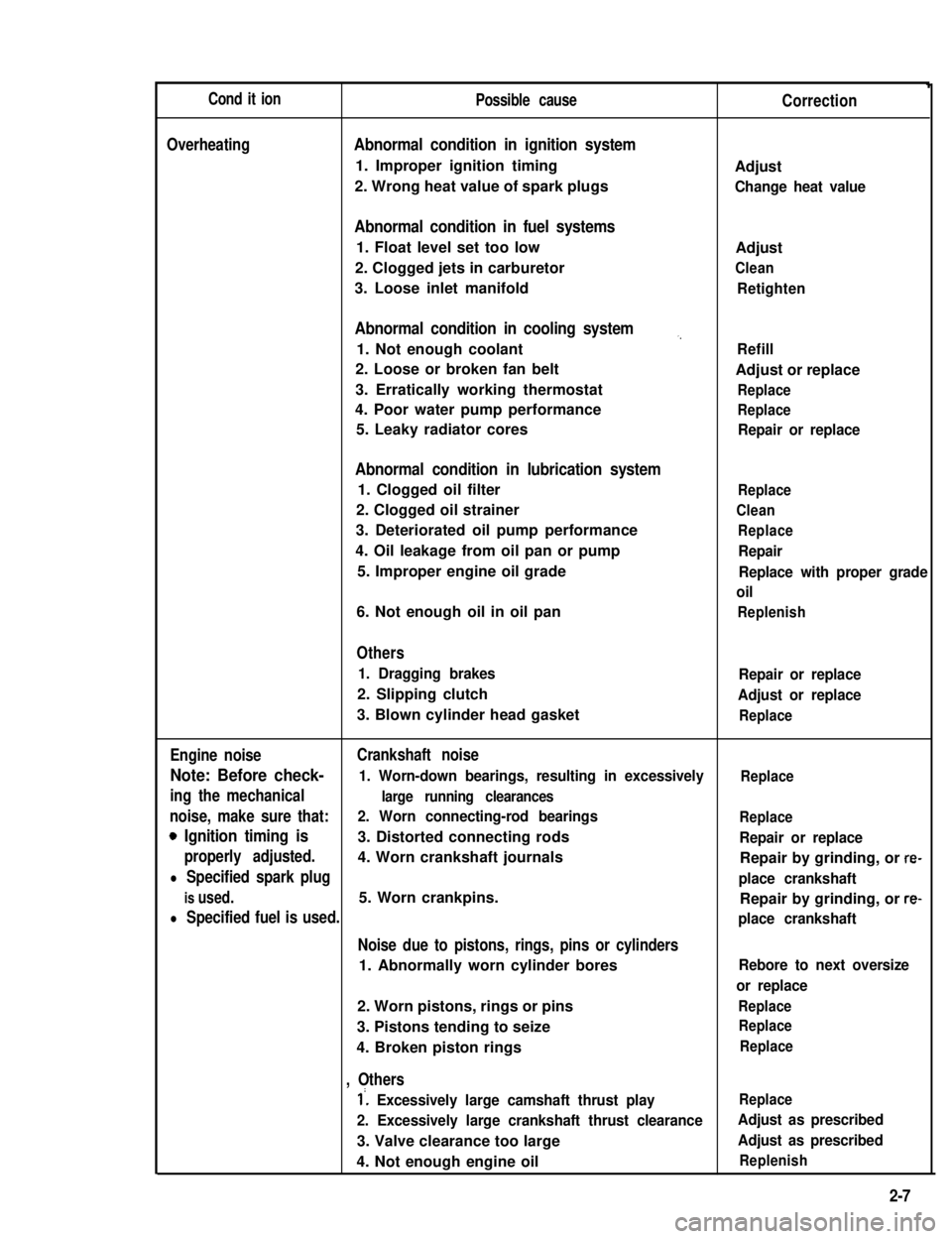

9

Cond it ionPossible causeCorrection

OverheatingAbnormal condition in ignition system

1. Improper ignition timingAdjust

2. Wrong heat value of spark plugsChange heat value

Abnormal condition in fuel systems

1. Float level set too lowAdjust

2. Clogged jets in carburetorClean

3. Loose inlet manifoldRetighten

Abnormal condition in cooling system,,

1. Not enough coolantRefill

2. Loose or broken fan beltAdjust or replace

3. Erratically working thermostatReplace

4. Poor water pump performanceReplace

5. Leaky radiator coresRepair or replace

Abnormal condition in lubrication system

1. Clogged oil filterReplace

2. Clogged oil strainerClean

3. Deteriorated oil pump performanceReplace

4. Oil leakage from oil pan or pumpRepair

5. Improper engine oil gradeReplace with proper grade

oil

6. Not enough oil in oil panReplenish

Others

1. Dragging brakesRepair or replace

2. Slipping clutchAdjust or replace

3. Blown cylinder head gasketReplace

Engine noiseCrankshaft noise

Note: Before check- 1. Worn-down bearings, resulting in excessivelyReplace

ing the mechanicallarge running clearances

noise, make sure that:2. Worn connecting-rod bearingsReplace

0 Ignition timing is3. Distorted connecting rodsRepair or replace

properly adjusted.4. Worn crankshaft journalsRepair by grinding, or re-

l Specified spark plugplace crankshaft

is used.5. Worn crankpins.Repair by grinding, or re-

l Specified fuel is used.place crankshaft

Noise due to pistons, rings, pins or cylinders

1. Abnormally worn cylinder boresRebore to next oversize

or replace

2. Worn pistons, rings or pinsReplace

3. Pistons tending to seizeReplace

4. Broken piston ringsReplace

, Others

1’. Excessively large camshaft thrust playReplace

2. Excessively large crankshaft thrust clearanceAdjust as prescribed

3. Valve clearance too largeAdjust as prescribed

4. Not enough engine oilReplenish

2-7

Page 59 of 962

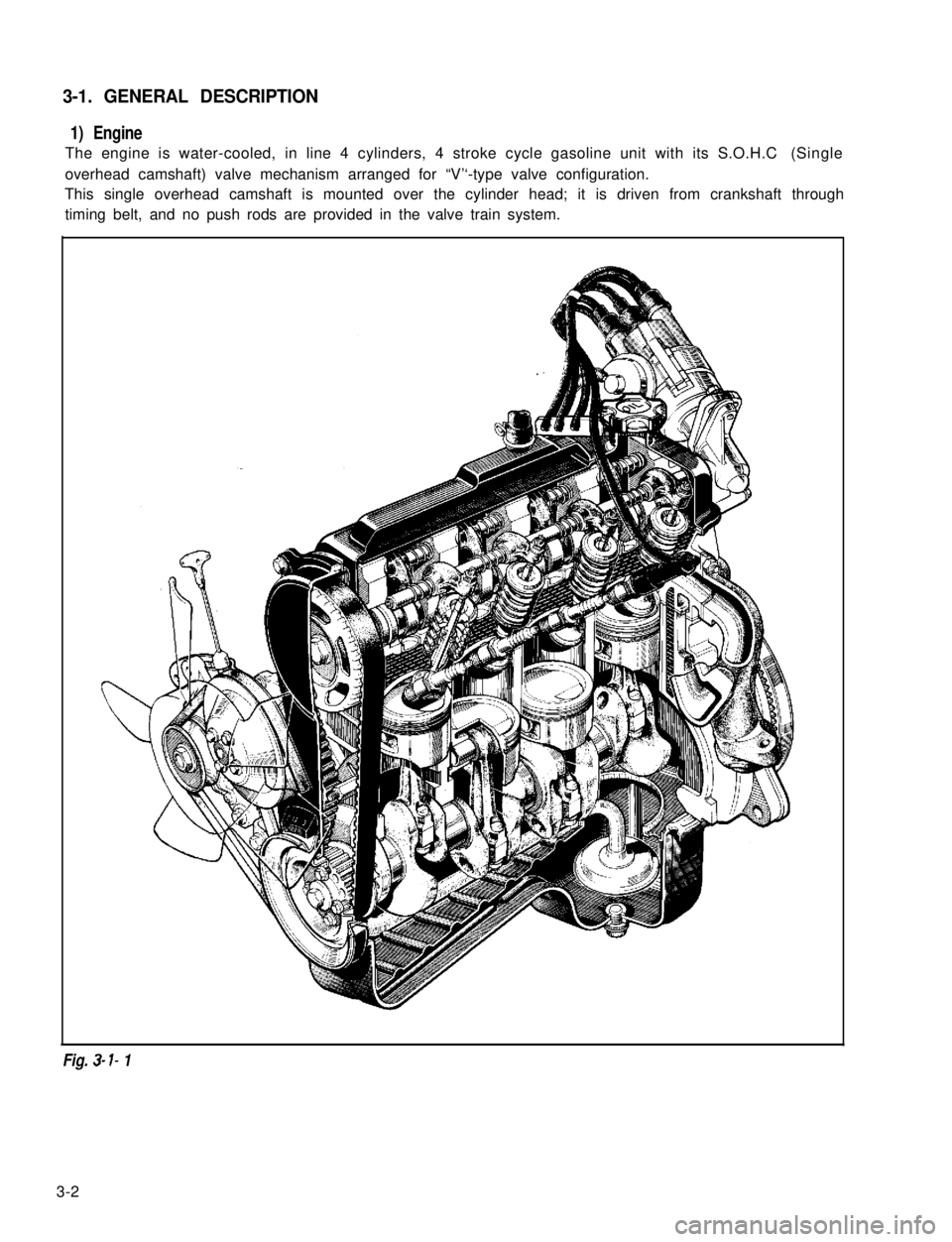

3-1. GENERAL DESCRIPTION

1) Engine

The engine is water-cooled, in line 4 cylinders, 4 stroke cycle gasoline unit with its S.O.H.C (Single

overhead camshaft) valve mechanism arranged for “V’‘-type valve configuration.

This single overhead camshaft is mounted over the cylinder head; it is driven from crankshaft through

timing belt, and no push rods are provided in the valve train system.

Fig. 3- I- 1

3-2

Page 61 of 962

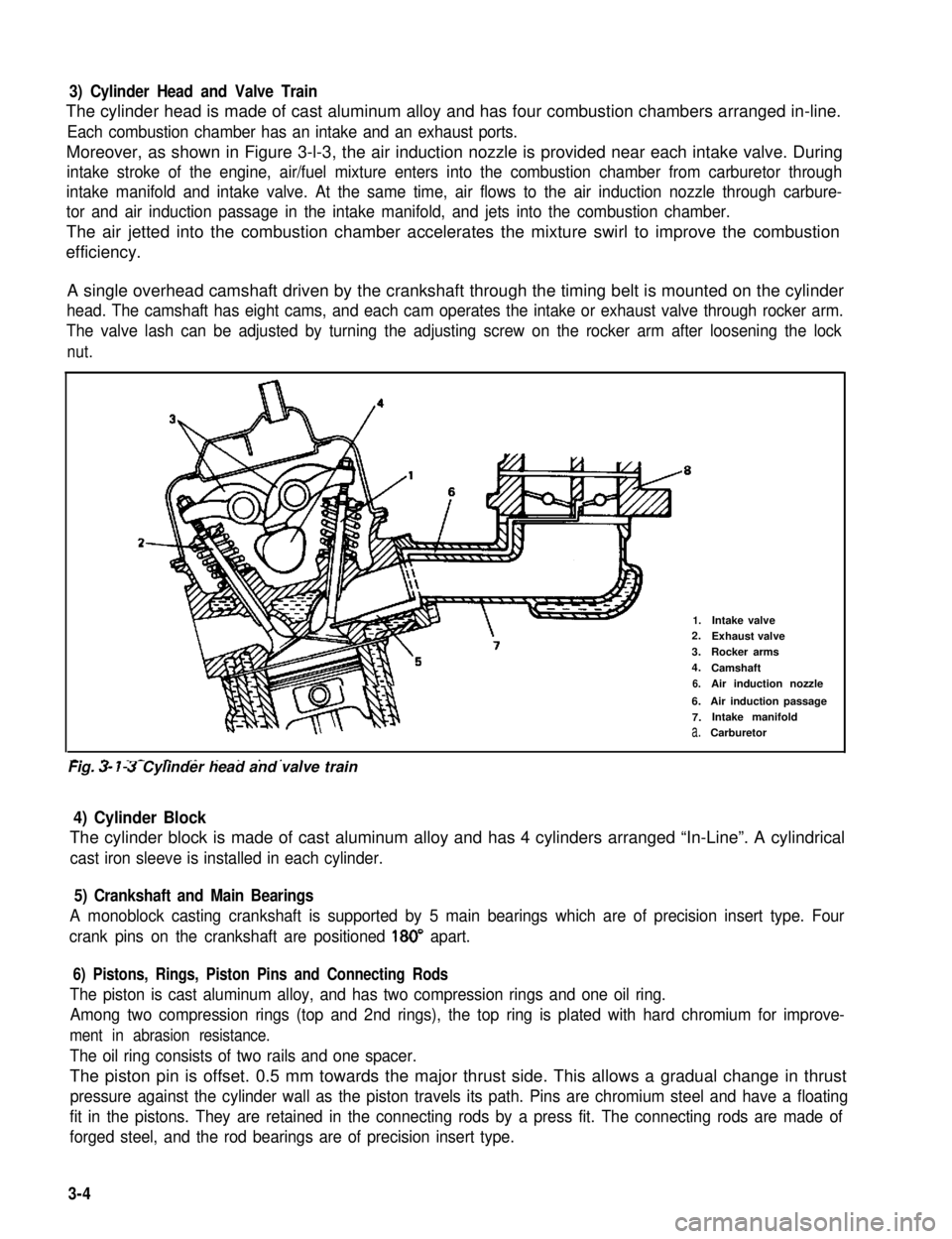

3) Cylinder Head and Valve Train

The cylinder head is made of cast aluminum alloy and has four combustion chambers arranged in-line.

Each combustion chamber has an intake and an exhaust ports.

Moreover, as shown in Figure 3-l-3, the air induction nozzle is provided near each intake valve. During

intake stroke of the engine, air/fuel mixture enters into the combustion chamber from carburetor through

intake manifold and intake valve. At the same time, air flows to the air induction nozzle through carbure-

tor and air induction passage in the intake manifold, and jets into the combustion chamber.

The air jetted into the combustion chamber accelerates the mixture swirl to improve the combustion

efficiency.

A single overhead camshaft driven by the crankshaft through the timing belt is mounted on the cylinder

head. The camshaft has eight cams, and each cam operates the intake or exhaust valve through rocker arm.

The valve lash can be adjusted by turning the adjusting screw on the rocker arm after loosening the lock

nut.

2-

1.Intake valve2.Exhaust valve

3.Rocker arms

4.Camshaft

6.Air induction nozzle

6.Air induction passage

7.Intake manifold

a.Carburetor

-. - _- - ._ . . . . .Fig. 3- 7-3 Cylinder head and valve train

4) Cylinder Block

The cylinder block is made of cast aluminum alloy and has 4 cylinders arranged “In-Line”. A cylindrical

cast iron sleeve is installed in each cylinder.

5) Crankshaft and Main Bearings

A monoblock casting crankshaft is supported by 5 main bearings which are of precision insert type. Four

crank pins on the crankshaft are positioned 180” apart.

6) Pistons, Rings, Piston Pins and Connecting Rods

The piston is cast aluminum alloy, and has two compression rings and one oil ring.

Among two compression rings (top and 2nd rings), the top ring is plated with hard chromium for improve-

ment in abrasion resistance.

The oil ring consists of two rails and one spacer.

The piston pin is offset. 0.5 mm towards the major thrust side. This allows a gradual change in thrust

pressure against the cylinder wall as the piston travels its path. Pins are chromium steel and have a floating

fit in the pistons. They are retained in the connecting rods by a press fit. The connecting rods are made of

forged steel, and the rod bearings are of precision insert type.

3-4

Page 62 of 962

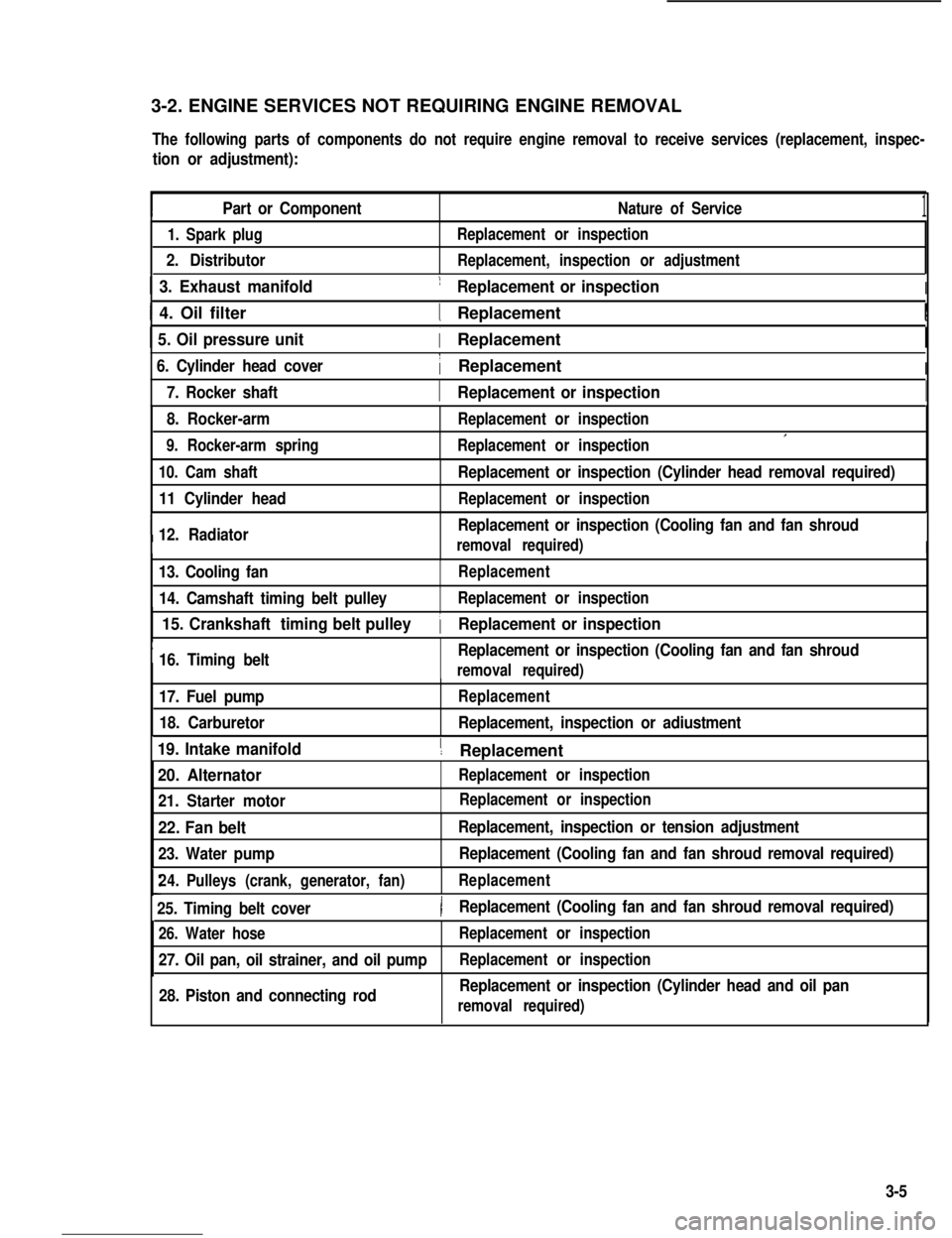

3-2. ENGINE SERVICES NOT REQUIRING ENGINE REMOVAL

The following parts of components do not require engine removal to receive services (replacement, inspec-

tion or adjustment):

Part or ComponentNature of Service1

1. Spark plug

2. Distributor

Replacement or inspection

Replacement, inspection or adjustment

1 3. Exhaust manifold1 Replacement or inspectionI

I 4. Oil filter1 ReplacementI

1 5. Oil pressure unit( Replacement

6. Cylinder head cover1 ReplacementI

I7. Rocker shaft1 Replacement or inspectionI

8. Rocker-arm

9. Rocker-arm spring

Replacement or inspection

Replacement or inspectionI

10. Cam shaft

11 Cylinder head

I12. Radiator

Replacement or inspection (Cylinder head removal required)

Replacement or inspection

Replacement or inspection (Cooling fan and fan shroud

removal required)I

13. Cooling fan

14. Camshaft timing belt pulley

Replacement

Replacement or inspection

I

15. Crankshaft timing belt pulley

16. Timing beltReplacement or inspection (Cooling fan and fan shroud

1 Replacement or inspection

removal required)

17. Fuel pump

18. Carburetor

Replacement

Replacement, inspection or adiustment

19. Intake manifold1 ReplacementI

20. Alternator

21. Starter motor

Replacement or inspection

22. Fan belt

23. Water pump

Replacement, inspection or tension adjustment

Replacement (Cooling fan and fan shroud removal required)

24.Pulleys (crank, generator, fan)Replacement

25. Timing belt cover)Replacement (Cooling fan and fan shroud removal required)

26. Water hose

27. Oil pan, oil strainer, and oil pump

Replacement or inspection

Replacement or inspection

28. Piston and connecting rodReplacement or inspection (Cylinder head and oil pan

removal required)

Replacement or inspection

3-5

Page 67 of 962

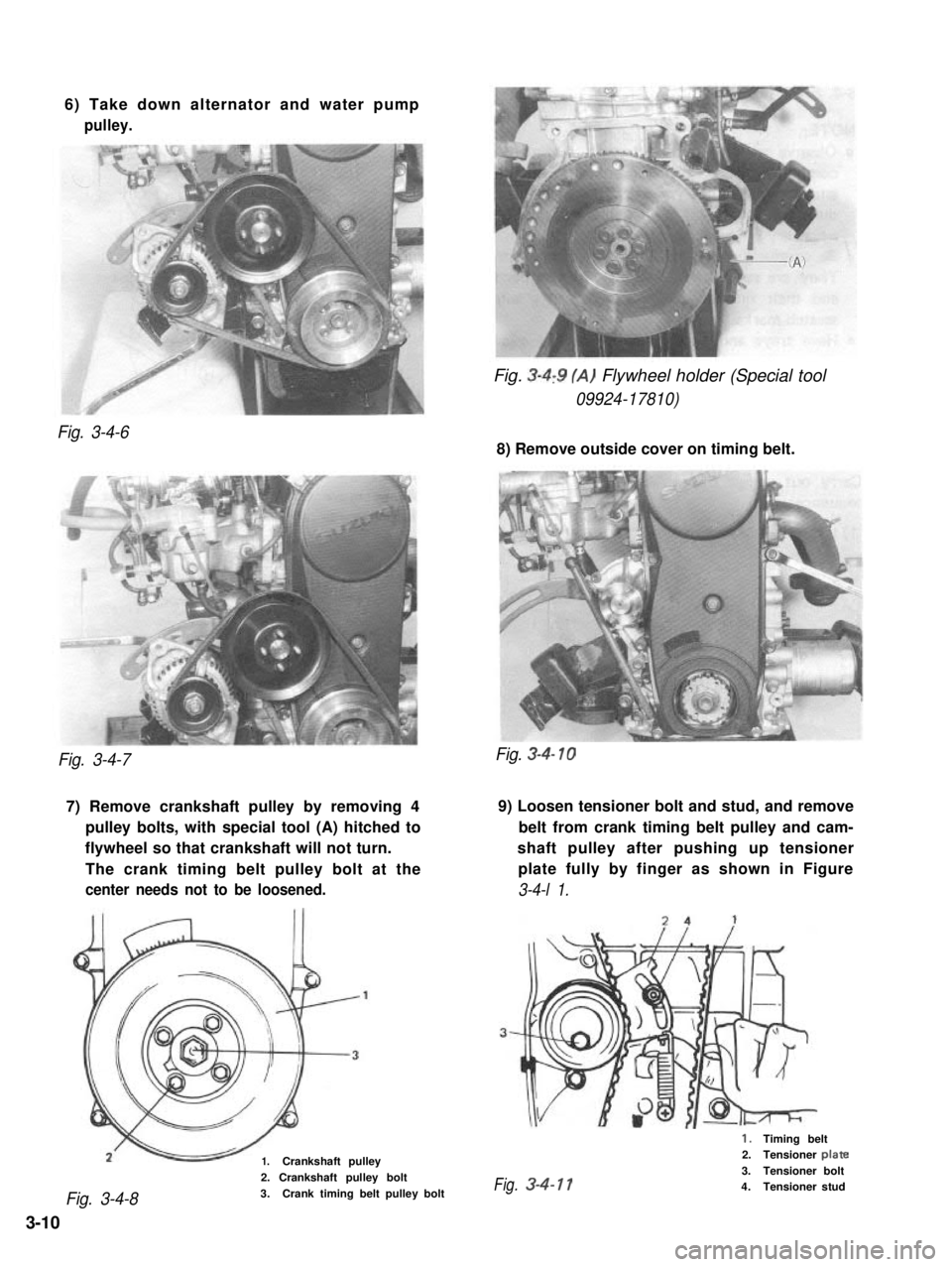

6) Take down alternator and water pump

pulley.

Fig. 3-4,9 (A) Flywheel holder (Special tool

09924-17810)

Fig. 3-4-6

8) Remove outside cover on timing belt.

Fig. 3-4-7

7) Remove crankshaft pulley by removing 49) Loosen tensioner bolt and stud, and remove

pulley bolts, with special tool (A) hitched tobelt from crank timing belt pulley and cam-

flywheel so that crankshaft will not turn.shaft pulley after pushing up tensioner

The crank timing belt pulley bolt at theplate fully by finger as shown in Figure

center needs not to be loosened.3-4-l 1.

1.Crankshaft pulley

Fig. 3-4-8

2. Crankshaft pulley bolt

3.Crank timing belt pulley bolt

Fig. 3-4- 10

1.Timing belt2.Tensioner plate

3.Tensioner boltFig.3-4-114.Tensioner stud

3-10

Page 68 of 962

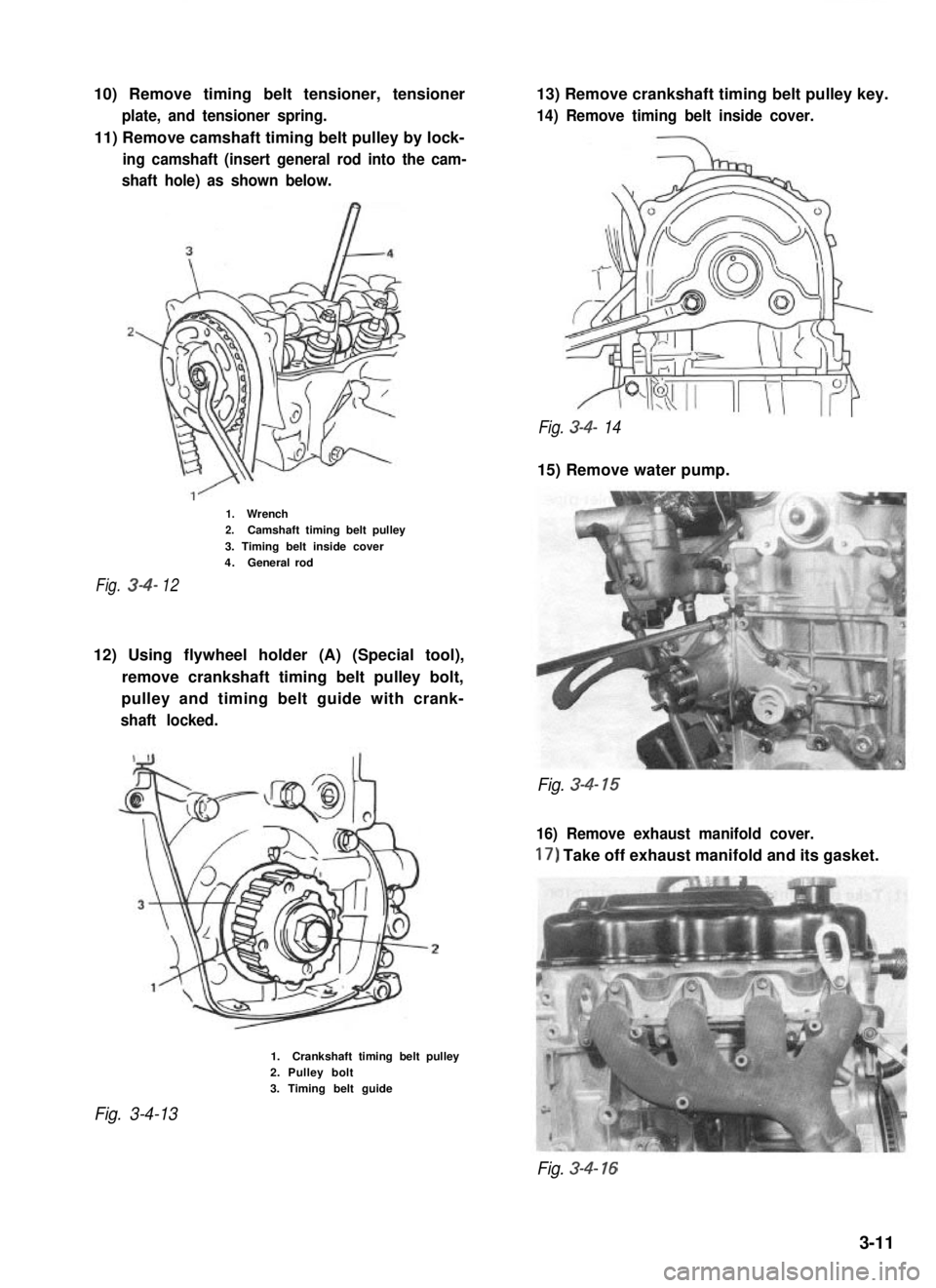

10) Remove timing belt tensioner, tensioner

plate, and tensioner spring.

11) Remove camshaft timing belt pulley by lock-

ing camshaft (insert general rod into the cam-

shaft hole) as shown below.

13) Remove crankshaft timing belt pulley key.

14) Remove timing belt inside cover.

Fig. 3-4- 14

15) Remove water pump.

1.Wrench2.Camshaft timing belt pulley

3. Timing belt inside cover4.Generalrod

Fig.3412

12) Using flywheel holder (A) (Special tool),

remove crankshaft timing belt pulley bolt,

pulley and timing belt guide with crank-

shaft locked.

Fig. 3-4- 15

16) Remove exhaust manifold cover.

17) Take off exhaust manifold and its gasket.

Fig. 3-4-13

1.Crankshaft timing belt pulley2. Pulley bolt3. Timing belt guide

Fig. 3-4- 16

3-11

Page 92 of 962

3-6. ENGINE REASSEMBLY

NOTE:

l All parts to be used in reassembly must be

perfectly clean.

l Oil sliding and rubbing surfaces of engine

parts just before using them in reassembly.

Use engine oil (Refer to page l-8).

l Have liquid packing ready for use. SUZUKI

BOND NO. 1215 is specified for it. Use it

wherever its use is specified in order to

ensure leak-free (oil and water) workmanship

of reassembly.

l There are many running clearances. During

the course of engine reassembly, be sure to

check these clearances, one after another,

as they form.

l Gaskets, “0” rings and similar sealing mem-

bers must be in perfect condition. For these

members, use replacement parts in stock.

l Tightening torque is specified for impor-

tant fasteners - mainly bolts and nuts -of

the engine and other components. Use torque

wrenches and constantly refer to the specified

values given on p. 3-58.

l Do not disregard match marks provided on

parts. Some of them are those given at the

time of disassembly.

l There are many sets of parts. Crankshaft

bearings, connecting rods, pistons, etc., are

in combination sets. Do not disturb such

combinations and make sure that each part

goes back to where it came from.

Engine reassembly is the reverse of engine disas-

sembly as far as sequence is concerned, but

there are many reassembling steps that involve

measures necessary for restoring engine as close

to factory-assembled condition as possible. Only

those steps will be dealt with here.

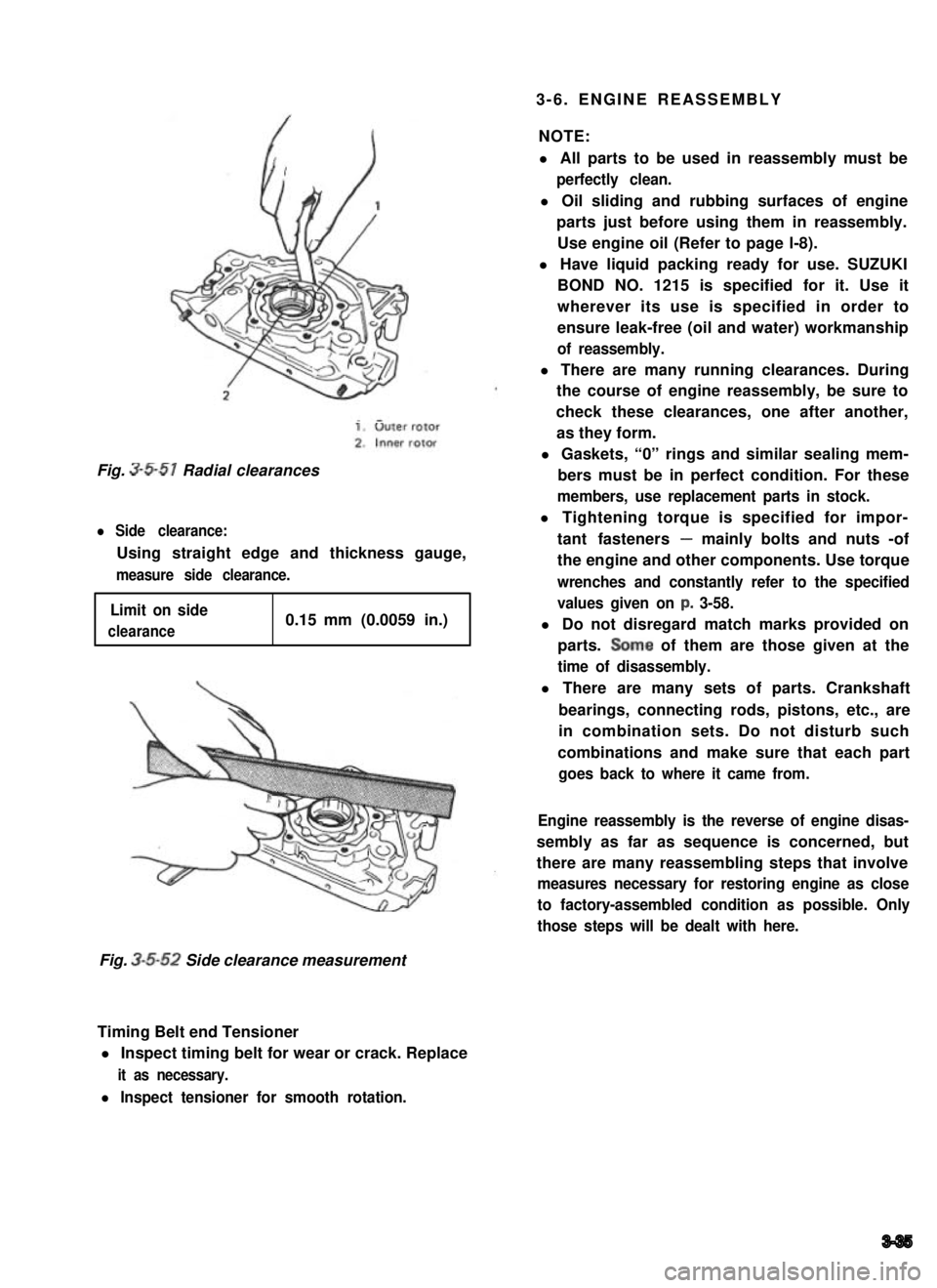

Fig. 3-5-51 Radial clearances

l Side clearance:

Using straight edge and thickness gauge,

measure side clearance.

Limit on side

clearance0.15 mm (0.0059 in.)

Fig. 3-5-52 Side clearance measurement

Timing Belt end Tensioner

l Inspect timing belt for wear or crack. Replace

it as necessary.

l Inspect tensioner for smooth rotation.

3-35