manual transmission SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 65 of 962

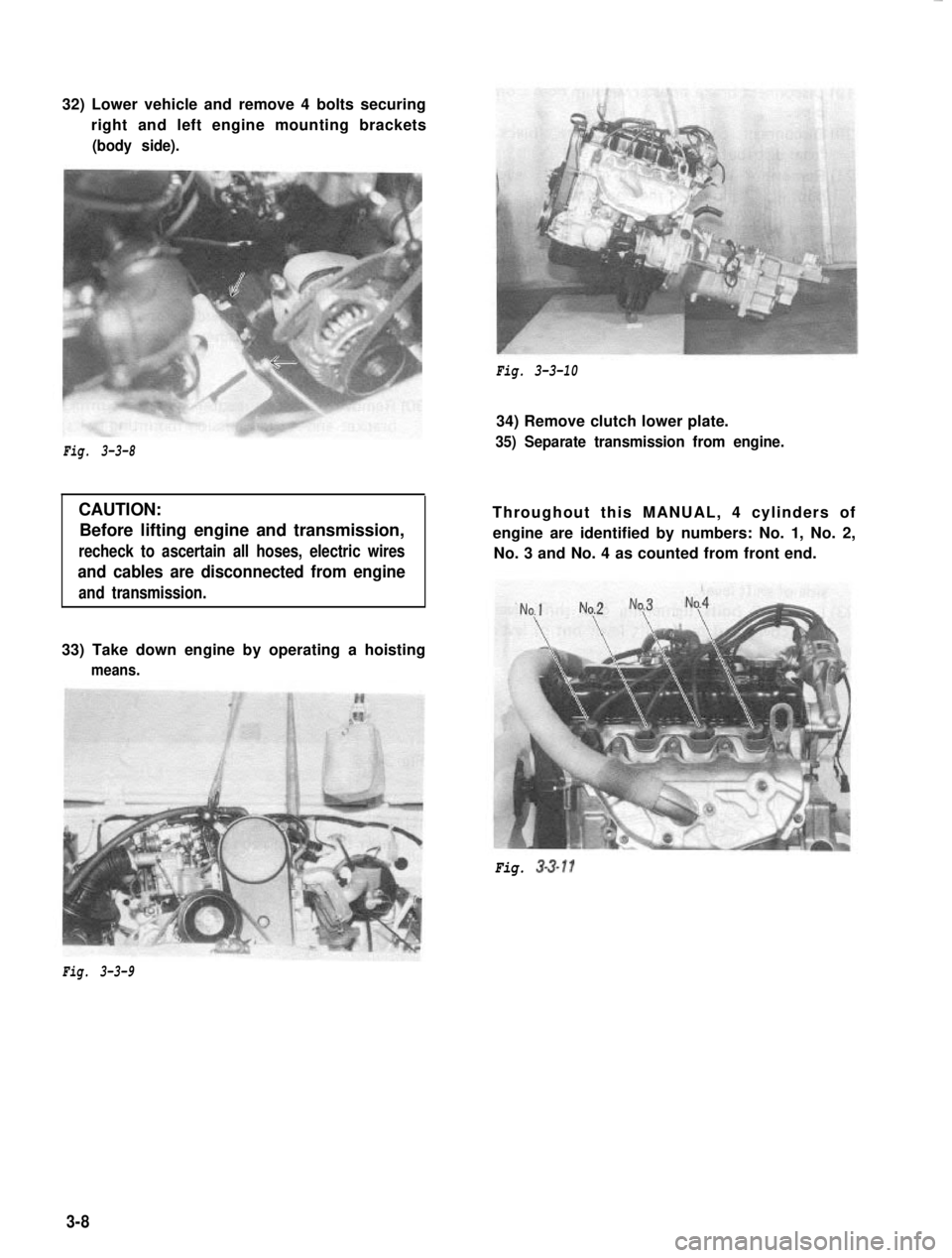

32) Lower vehicle and remove 4 bolts securing

right and left engine mounting brackets(body side).

Fig. 3-3-10

Fig. 3-3-8

CAUTION:Before lifting engine and transmission,

recheck to ascertain all hoses, electric wires

and cables are disconnected from engine

and transmission.

34) Remove clutch lower plate.

35) Separate transmission from engine.

Throughout this MANUAL, 4 cylinders ofengine are identified by numbers: No. 1, No. 2, No. 3 and No. 4 as counted from front end.

33) Take down engine by operating a hoisting

means.

Fig. 3-3-11

Fig. 3-3-9

3-8

Page 109 of 962

Clutch Disc and Cover?

Install clutch disc and cover.

For installation, refer to p. 11-7 of SECTION 11

CLUTCH in this manual and torque each bolt to

specification.

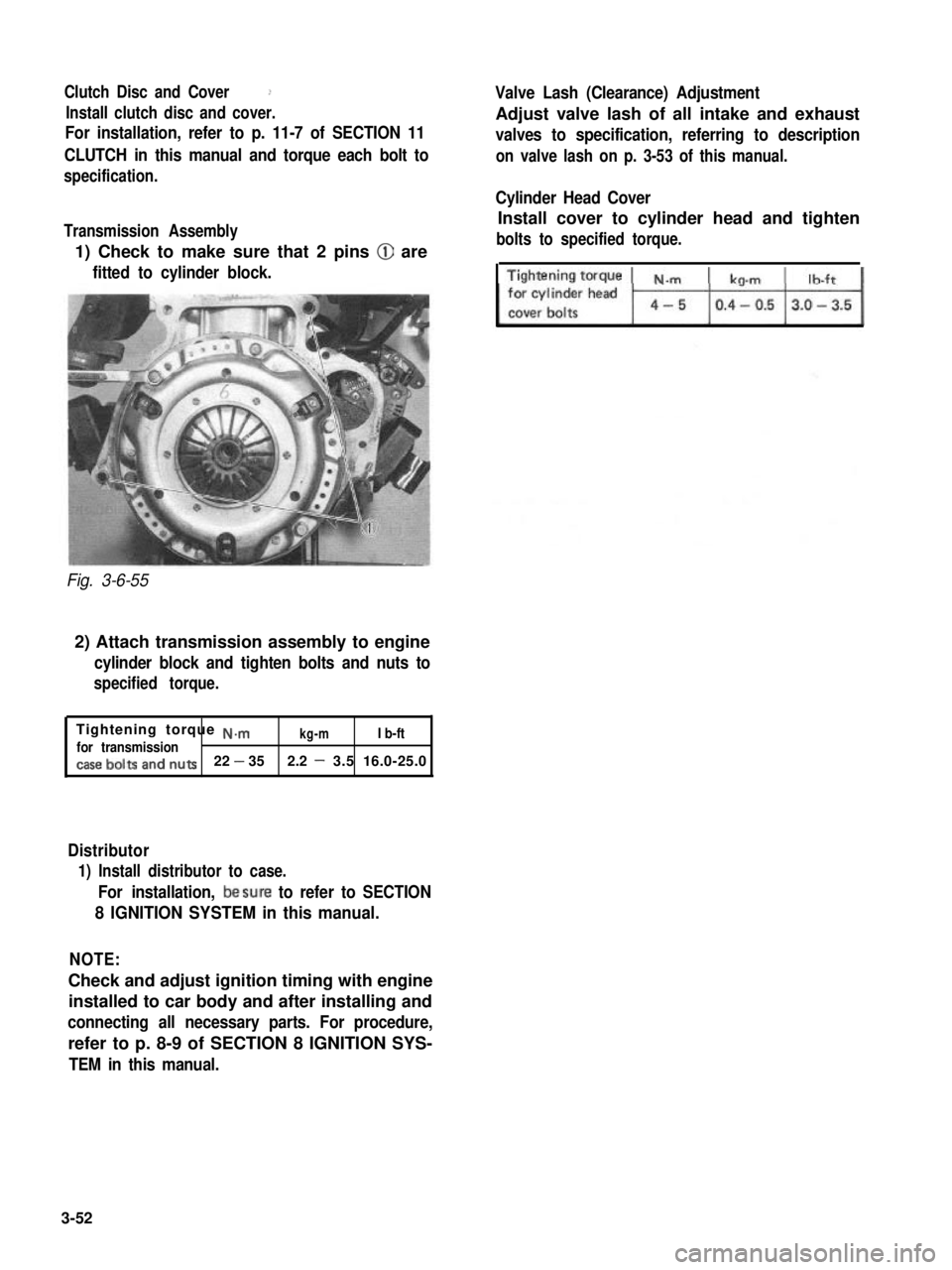

Transmission Assembly

1) Check to make sure that 2 pins @ are

fitted to cylinder block.

Fig. 3-6-55

2) Attach transmission assembly to engine

cylinder block and tighten bolts and nuts to

specified torque.

Tightening torque ~.mkg-mI b-ftfor transmission,.aSe bolts an,-j nutS22 - 352.2 - 3.5 16.0-25.0

Distributor

1) Install distributor to case.

For installation, besure to refer to SECTION

8 IGNITION SYSTEM in this manual.

Valve Lash (Clearance) Adjustment

Adjust valve lash of all intake and exhaust

valves to specification, referring to description

on valve lash on p. 3-53 of this manual.

Cylinder Head Cover

Install cover to cylinder head and tighten

bolts to specified torque.

NOTE:

Check and adjust ignition timing with engine

installed to car body and after installing and

connecting all necessary parts. For procedure,

refer to p. 8-9 of SECTION 8 IGNITION SYS-

TEM in this manual.

3-52

Page 110 of 962

3-7. ENGINE INSTALLATION

1) Lower engine with transmission into vehicle,

but do not remove lifting device.

2) Tighten engine mounting bracket bolts

(right and left) and transmission mounting

bolts to specification. Refer to p. 3-58.

3) Remove lifting device.

4) Reverse removal procedures for installation

of remainder.

5) Adjust accelerator cable play and clutch

cable play.

6) Connect vacuum hoses securely. Refer to

section 5 “EMISSION CONTROL SYSTEM”

for correct connection.

7) Connect wire harnesses and couplers secure-

IY.

8) Tighten bolts and nuts to specified torque.

For individual specification, refer to each

section.

9) Fill specified amount of specified trans-

mission oil and engine oil. For the detail,

refer to SECTION 1 PERIODIC MAINTE-

NANCE SERVICE of this manual.

10) After adjusting water pump belt tension to

specification, fill specified amount of engine

cooling water.

11) Before starting engine, check again to ensure

that all parts once disassembled or discon-

nected are back in place securely.

12)Start engine and check ignition timing. If

it is not to specified timing, adjust it, referr-

ing to SECTION 8 of this manual.

13) After engine is started, check for oil leak,

abnormal noise and other malcondition.

Also, check each part for operation.

3-8. ENGINE MAINTENANCE SERVICE

Fan Belt

Adjust belt tension as outlined in SECTION 6

ENGINE COOLING SYSTEM (p. 6-10).

Ignition Timing

Refer to IGNITION TIMING, Page 8-9.

Carburetor

fidjustments to be made are detailed in SEC-

TION 4 (p. 4-19).

Valve Lash (Clearance)

Valve lash specifications:

Valve lash refers to gap between rocker arm

adjusting screw and valve stem. Use a thickness

gauge to measure this gap @.

When coldWhen hot(Coolant tempe-(Coolant tempa-

Valve lashrature is 15 - 25%rature is 60 - 66’C

(gap A)or 69 - 77’F)or 140 - 154’F)

specif i-0.13 - 0.17 mm0.23 - 0.27 mmcationIntake(0.0051 - 0.0067 in) (0.009 - 0.011 in)

Exhaust0.16 -0.20 mm0.26 - 0.30 mm(0.0063 - 0.0079 in) (0.0102 - 0.0116 in)

Screw lock nut 15 - 19 N.m(1.5 - 1.9 kg-m, 11 .O - 13.5 lb-ft)

Adjusting screw

8

Valve stem

Fig. 3-8-l

Checking and adjusting procedures:

NOTE:

l Refer to Fig. 3-3-11 of SECTION 3 for

cylinder numbers (No. 1, No. 2, No. 3 and

No. 4) mentioned in this section.

l When adjustment becomes necessary in step

4), loosen adjusting screw lock nut and then

make adjustment by turning adjusting screw.

After adjustment, tighten lock nut to specifi-

ed torque while holding adjusting screw

stationary with straight headed screwdriver,

and then make sure again that gap @ is

within specification.

3-53

Page 111 of 962

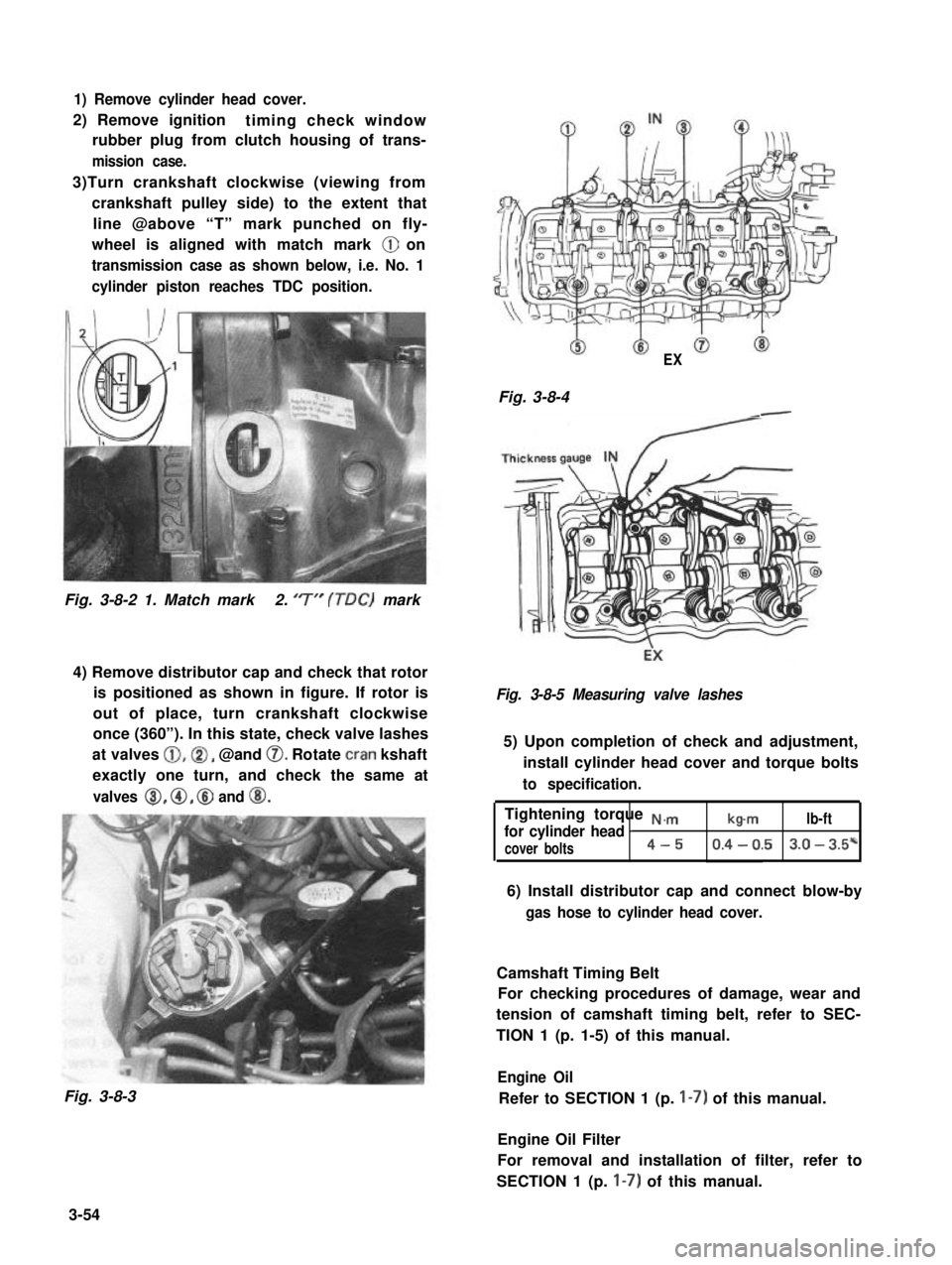

1) Remove cylinder head cover.

2) Remove ignitiontiming check window

rubber plug from clutch housing of trans-

mission case.

3)Turn crankshaft clockwise (viewing from

crankshaft pulley side) to the extent that

line @above “T” mark punched on fly-

wheel is aligned with match mark @ on

transmission case as shown below, i.e. No. 1

cylinder piston reaches TDC position.

Fig. 3-8-2 1. Match mark2. ‘7” (TDC) mark

4) Remove distributor cap and check that rotor

is positioned as shown in figure. If rotor is

out of place, turn crankshaft clockwise

once (360”). In this state, check valve lashes

at valves @,@I, @and 0. Rotate cran kshaft

exactly one turn, and check the same at

valves 8, @, @ and @I.

Fig. 3-8-3

EX

Fig. 3-8-4-

Fig. 3-8-5 Measuring valve lashes

5) Upon completion of check and adjustment,

install cylinder head cover and torque bolts

to specification.

Tightening torque N.,.,.,

for cylinder head Ib-mlb-ft

cover bolts4-50.4 - 0.53.0 - 3.5*

6) Install distributor cap and connect blow-by

gas hose to cylinder head cover.

Camshaft Timing Belt

For checking procedures of damage, wear and

tension of camshaft timing belt, refer to SEC-

TION 1 (p. 1-5) of this manual.

Engine Oil

Refer to SECTION 1 (p. I-7) of this manual.

Engine Oil Filter

For removal and installation of filter, refer to

SECTION 1 (p. I-7) of this manual.

3-54

Page 115 of 962

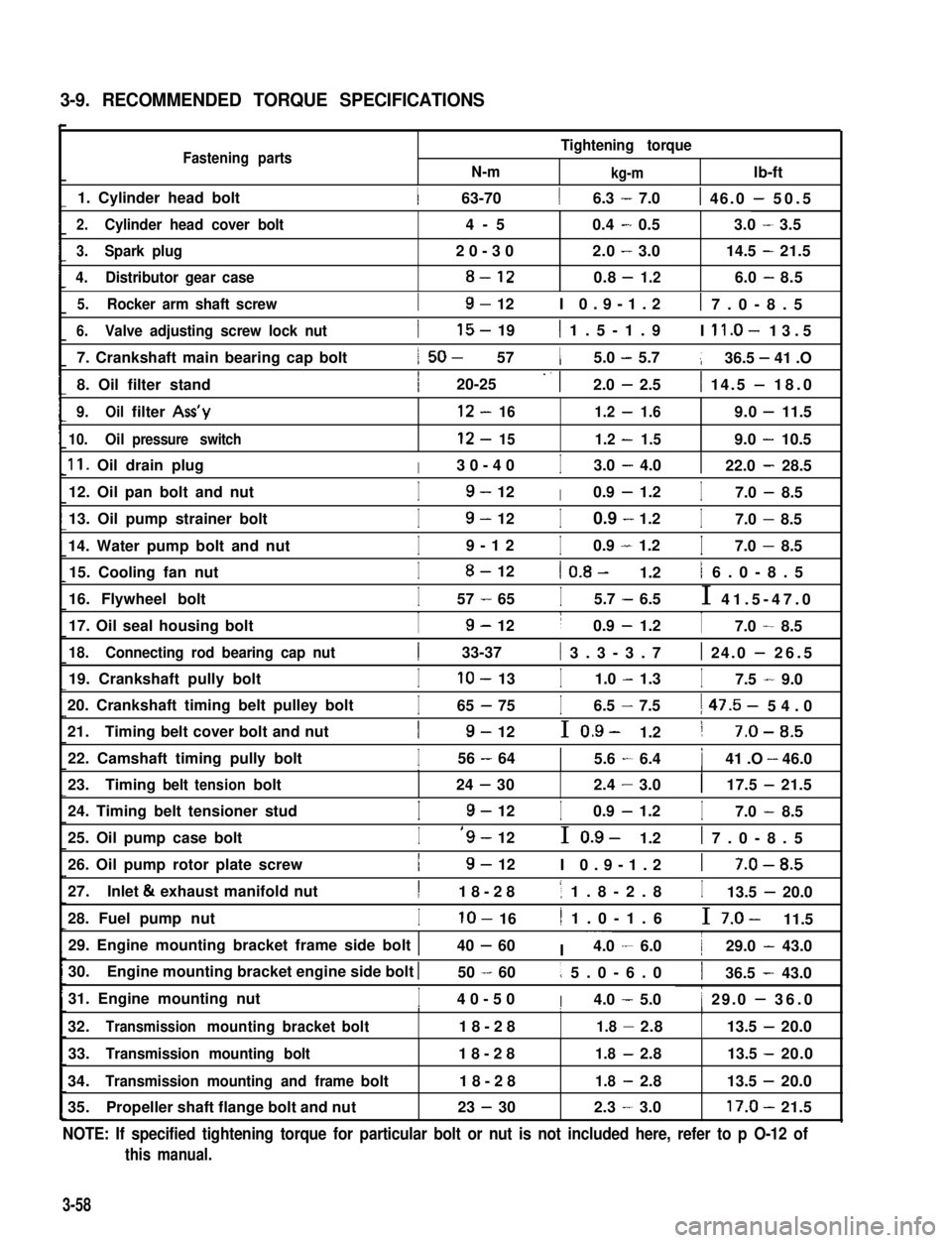

3-9. RECOMMENDED TORQUE SPECIFICATIONS

Fastening partsN-m

Tightening torque

kg-mlb-ft

1. Cylinder head bolt1 63-7016.3 - 7.01 46.0 - 50.5

2.Cylinder head cover bolt4-50.4-0.53.0-3.5

3.Spark plug20-302.0-3.014.5-21.5

4.Distributor gear case8-120.8-1.26.0-8.5

5.Rocker arm shaft screwI9- 12I 0.9-1.21 7.0-8.5

6.Valve adjusting screw lock nut

7. Crankshaft main bearing cap bolt

8. Oil filter stand

I15- 191 1.5-1.9I ll.O- 13.5

1 50- 5715.0 - 5.7136.5 - 41 .O

I20-25 -. 12.0 - 2.51 14.5 - 18.0

9.Oilfilter Ass’y12-161.2-1.69.0-11.5

10.Oilpressure switch12-151.2-1.59.0-10.5

11. Oil drain plugI30-40I3.0 - 4.0122.0 - 28.5

12. Oil pan bolt and nutI9- 12I0.9 - 1.2I7.0 - 8.5

13. Oil pump strainer bolt

14. Water pump bolt and nut

I9- 12I0.9 - 1.2I7.0 - 8.5

I9-12I0.9 - 1.2I7.0 - 8.5

15. Cooling fan nutI8- 121 0.8- 1.21 6.0-8.5

16. Flywheel boltI57 - 65I5.7 - 6.5I 41.5-47.0

17. Oil seal housing boltI9- 12I0.9 - 1.2I7.0 - 8.5

18.Connecting rod bearing cap nut1 33-37( 3.3-3.71 24.0 - 26.5

19. Crankshaft pully boltIlo- 13I1.0 - 1.3I7.5 - 9.0

20. Crankshaft timing belt pulley bolt

21.Timing belt cover bolt and nut

I65 - 75I6.5 - 7.51 47.5- 54.0

I9- 12I 0.9- 1.21 7-O-8.5

22. Camshaft timing pully boltI56 - 6415.6 - 6.4141 .O - 46.0III

23.Timingbelttensionbolt24-302.4-3.0117.5-21.5

24. Timing belt tensioner studI9- 12I0.9 - 1.2I7.0 - 8.5

25. Oil pump case boltI‘9- 12I 0.9- 1.21 7.0-8.5

26. Oil pump rotor plate screwI9- 12I 0.9-1.21 7-O-8.5

27.Inlet & exhaust manifold nutI18-281 1.8-2.8I13.5 - 20.0

28. Fuel pump nutIlo- 161 1.0-1.6I 7.0- 11.5

29. Engine mounting bracket frame side bolt 140 - 60I ~~~4.0 - 6.0129.0 - 43.0

30.Engine mounting bracket engine side bolt I50 - 601 5.0-6.0136.5 - 43.0

31. Engine mounting nutI40-50I4.0 - 5.01 29.0 - 36.0I1I

32.Transmissionmountingbracketbolt18-281.8-2.8113.5-20.0

33.Transmission mounting bolt18-281.8-2.813.5 -20.0

34.Transmission mounting and framebolt18-281.8-2.813.5 -20.0

35.Propeller shaft flange bolt and nut23 - 302.3-3.017.0-21.5

NOTE: If specified tightening torque for particular bolt or nut is not included here, refer to p O-12 of

this manual.

3-58

Page 253 of 962

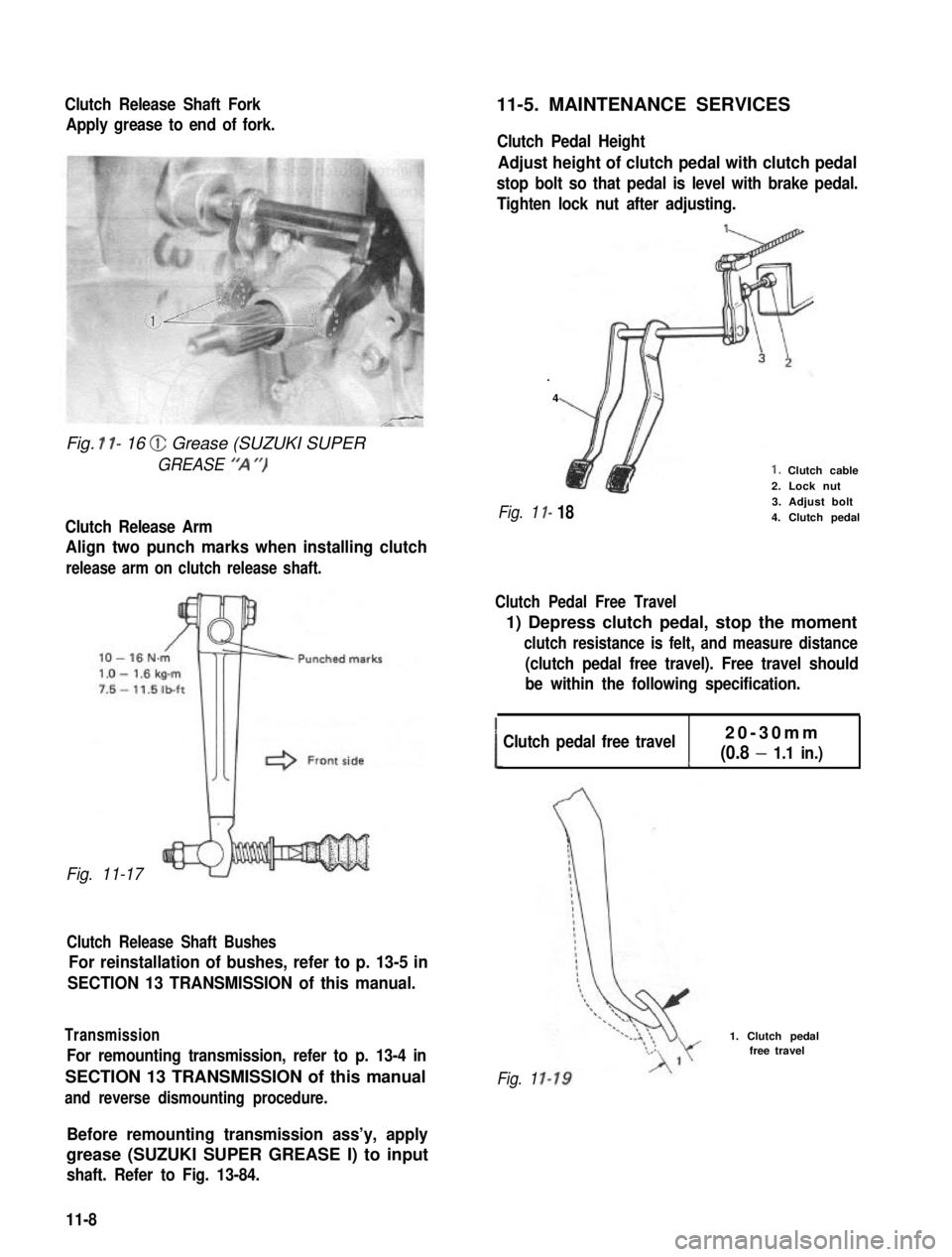

Clutch Release Shaft Fork

Apply grease to end of fork.

Fig. I l- 16 @ Grease (SUZUKI SUPER

GREASE “‘A “)

Clutch Release Arm

Align two punch marks when installing clutch

release arm on clutch release shaft.

Fig. 11-17

Clutch Release Shaft Bushes

For reinstallation of bushes, refer to p. 13-5 in

SECTION 13 TRANSMISSION of this manual.

Transmission

For remounting transmission, refer to p. 13-4 in

SECTION 13 TRANSMISSION of this manual

and reverse dismounting procedure.

11-5. MAINTENANCE SERVICES

Clutch Pedal Height

Adjust height of clutch pedal with clutch pedal

stop bolt so that pedal is level with brake pedal.

Tighten lock nut after adjusting.

.

4

I-

I- 18

1. Clutch cable2. Lock nut3. Adjust bolt4. Clutch pedalFig. 1

Clutch Pedal Free Travel

1) Depress clutch pedal, stop the moment

clutch resistance is felt, and measure distance

(clutch pedal free travel). Free travel should

be within the following specification.

!Clutch pedal free travel20-30mm

(0.8 - 1.1 in.)c

Fig. 1

1. Clutch pedalfree travel

Before remounting transmission ass’y, apply

grease (SUZUKI SUPER GREASE I) to input

shaft. Refer to Fig. 13-84.

11-8

Page 312 of 962

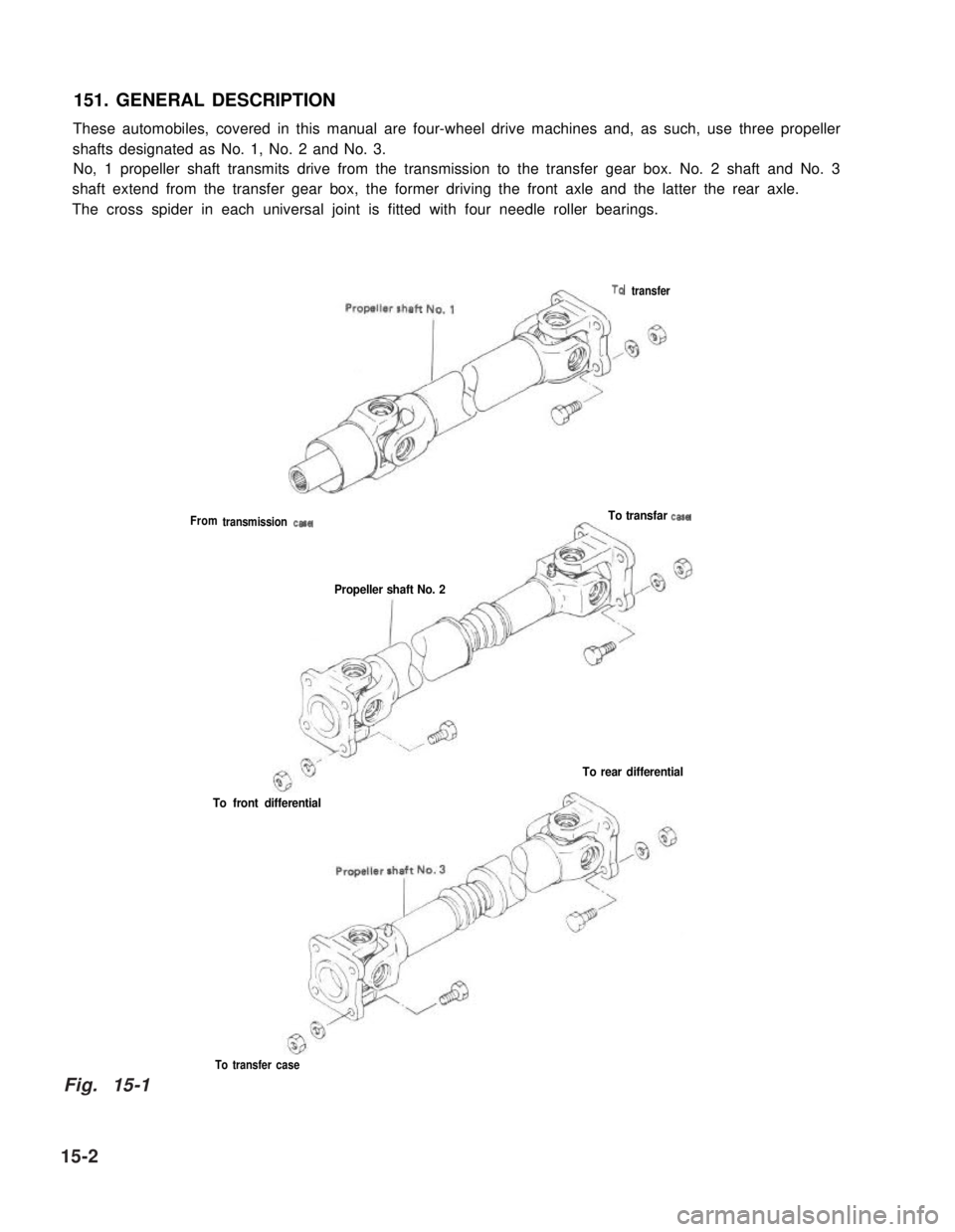

151. GENERAL DESCRIPTION

These automobiles, covered in this manual are four-wheel drive machines and, as such, use three propeller

shafts designated as No. 1, No. 2 and No. 3.

No, 1 propeller shaft transmits drive from the transmission to the transfer gear box. No. 2 shaft and No. 3

shaft extend from the transfer gear box, the former driving the front axle and the latter the rear axle.

The cross spider in each universal joint is fitted with four needle roller bearings.

From

TQ transfer

transmission casaTo transfar casa

Propeller shaft No. 2

To rear differential

To front differential

To transfer case

15-2

Fig. 15-1