SUZUKI GRAND VITARA 1999 2.G Owners Manual

GRAND VITARA 1999 2.G

SUZUKI

SUZUKI

https://www.carmanualsonline.info/img/20/7583/w960_7583-0.png

SUZUKI GRAND VITARA 1999 2.G Owners Manual

Trending: section 6E2, warning, alternator belt, crankshaft Sensor wiring v6, fuse 29, seat memory, power steering

Page 91 of 656

3E-2 REAR SUSPENSION

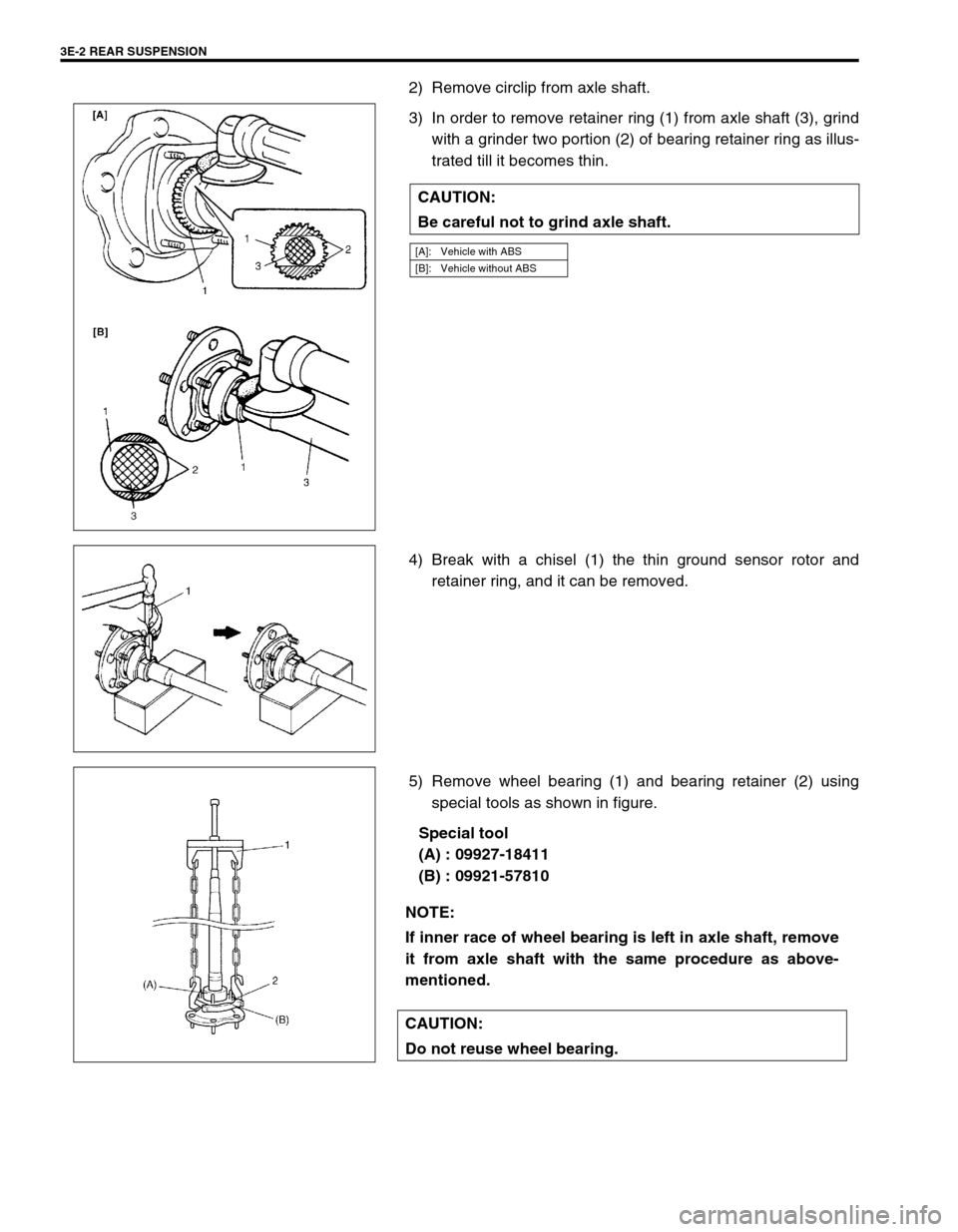

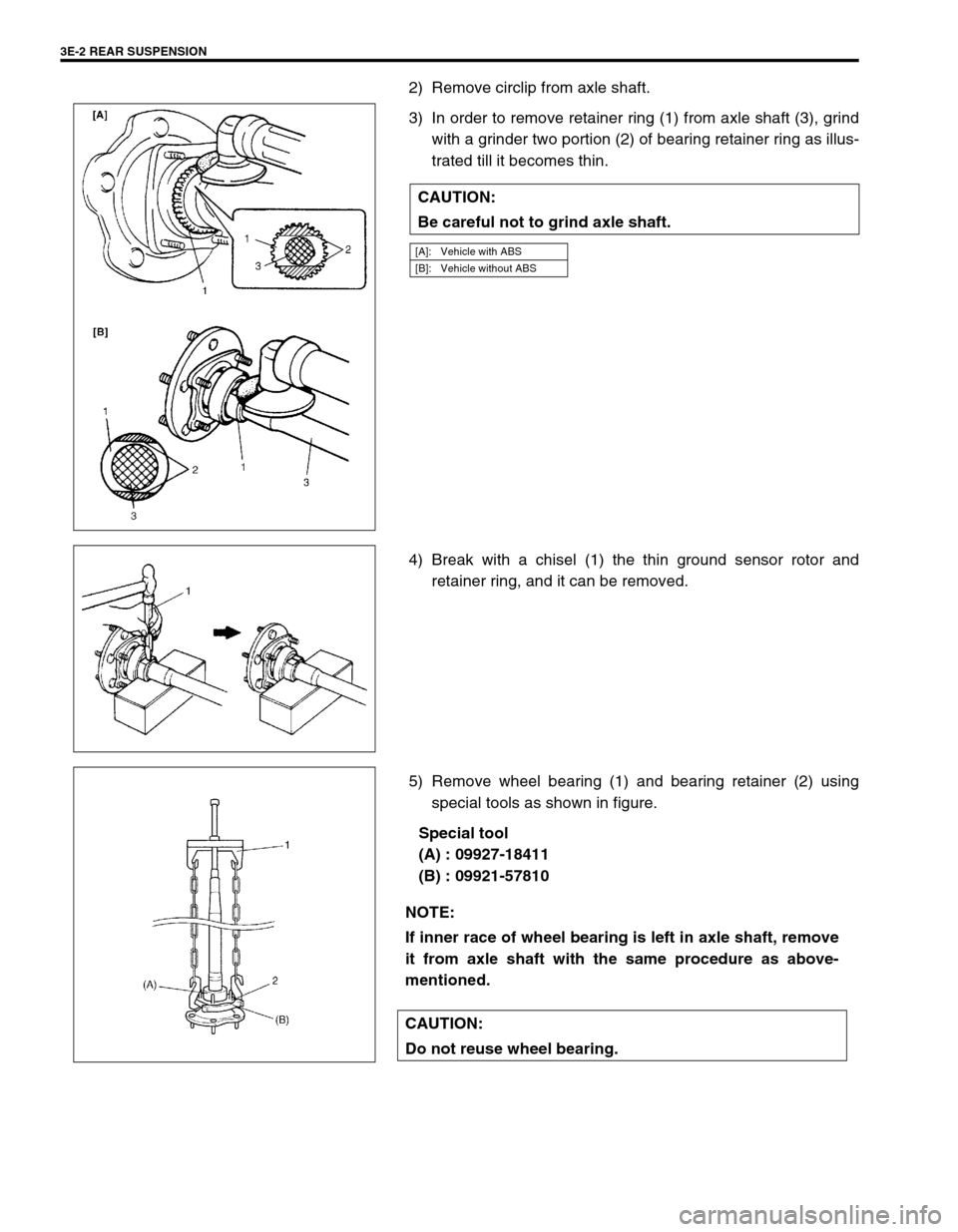

2) Remove circlip from axle shaft.

3) In order to remove retainer ring (1) from axle shaft (3), grind

with a grinder two portion (2) of bearing retainer ring as illus-

trated till it becomes thin.

4) Break with a chisel (1) the thin ground sensor rotor and

retainer ring, and it can be removed.

5) Remove wheel bearing (1) and bearing retainer (2) using

special tools as shown in figure.

Special tool

(A) : 09927-18411

(B) : 09921-57810 CAUTION:

Be careful not to grind axle shaft.

[A]: Vehicle with ABS

[B]: Vehicle without ABS

NOTE:

If inner race of wheel bearing is left in axle shaft, remove

it from axle shaft with the same procedure as above-

mentioned.

CAUTION:

Do not reuse wheel bearing.

Page 92 of 656

REAR SUSPENSION 3E-3

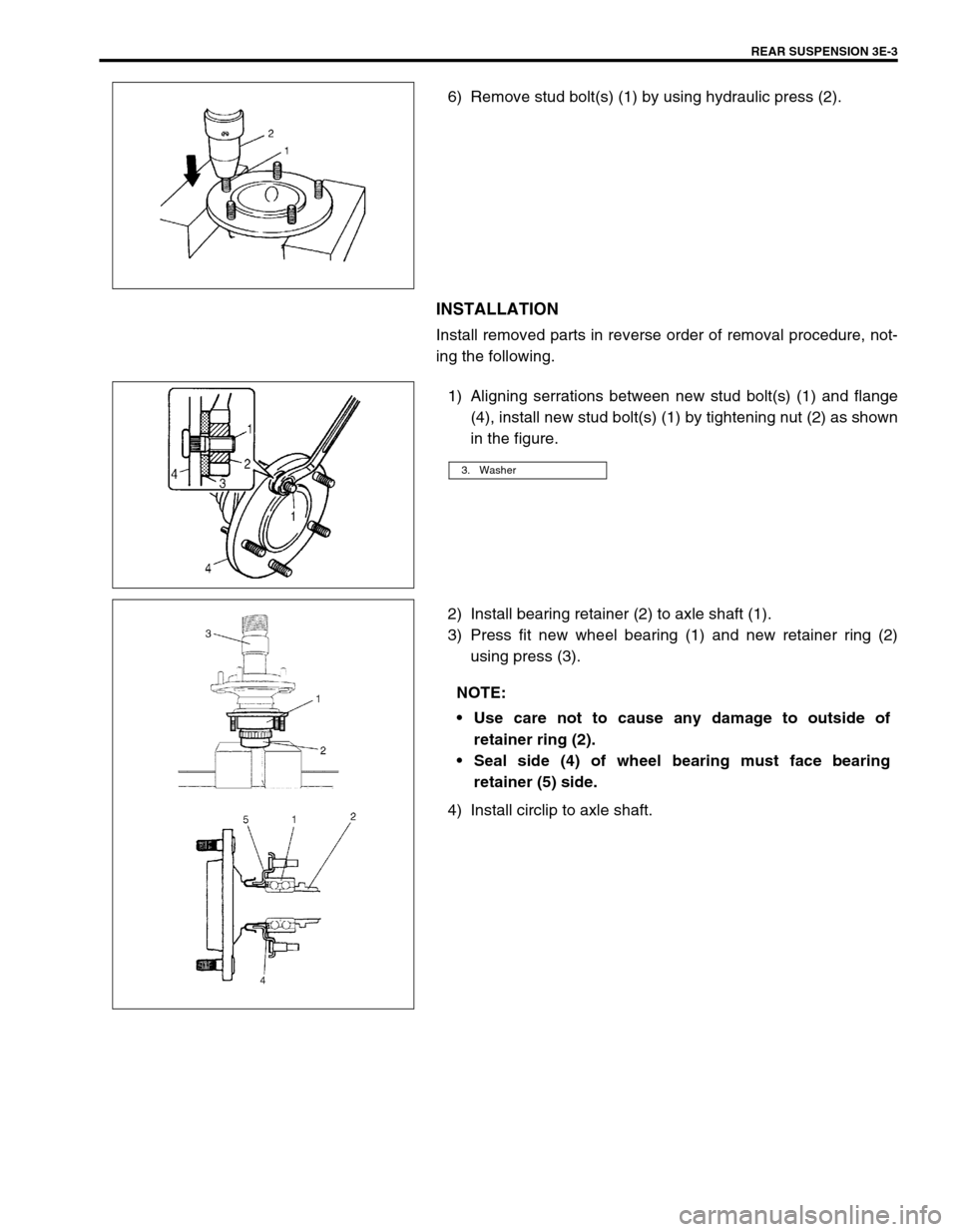

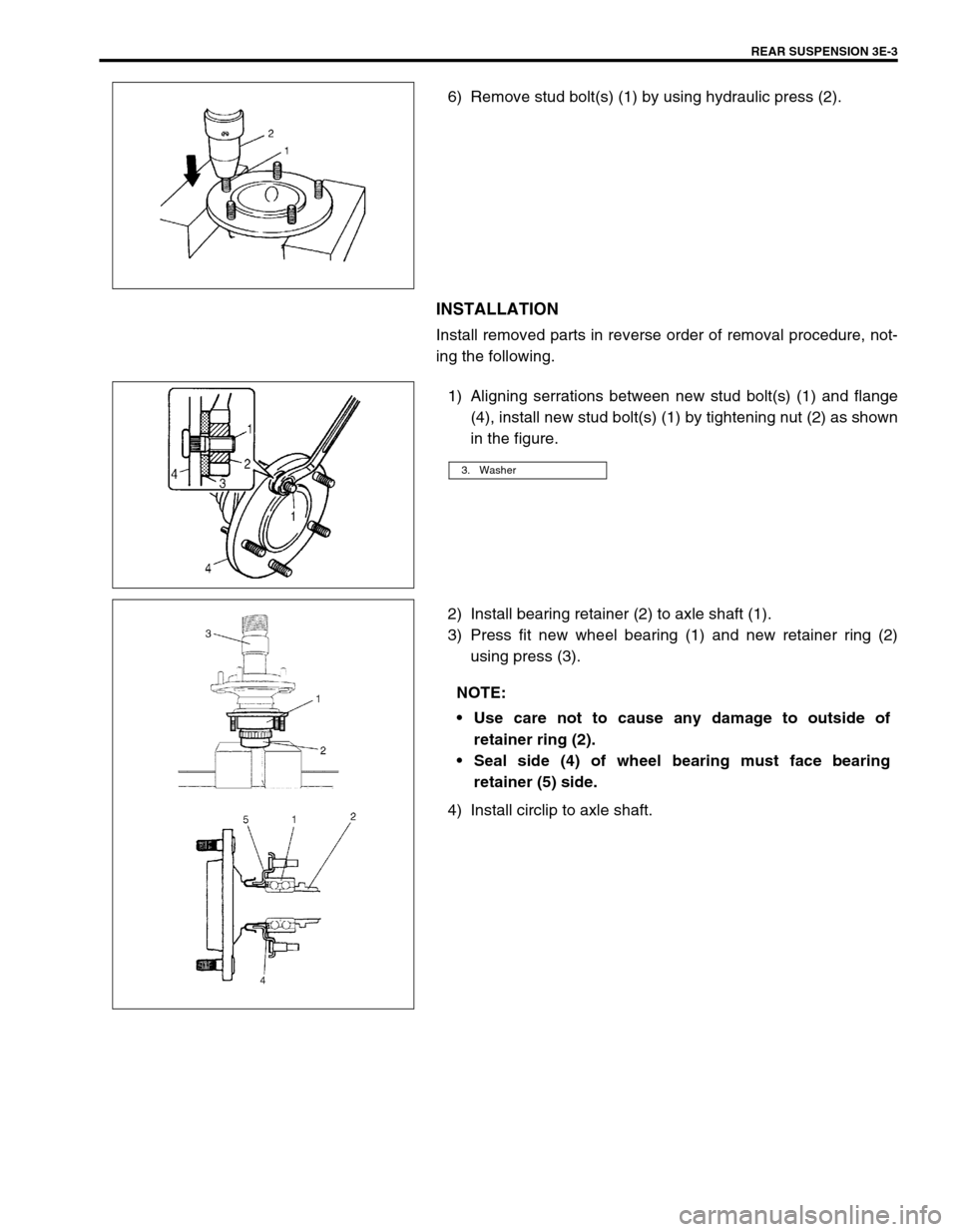

6) Remove stud bolt(s) (1) by using hydraulic press (2).

INSTALLATION

Install removed parts in reverse order of removal procedure, not-

ing the following.

1) Aligning serrations between new stud bolt(s) (1) and flange

(4), install new stud bolt(s) (1) by tightening nut (2) as shown

in the figure.

2) Install bearing retainer (2) to axle shaft (1).

3) Press fit new wheel bearing (1) and new retainer ring (2)

using press (3).

4) Install circlip to axle shaft.

3. Washer

NOTE:

Use care not to cause any damage to outside of

retainer ring (2).

Seal side (4) of wheel bearing must face bearing

retainer (5) side.

Page 93 of 656

3E-4 REAR SUSPENSION

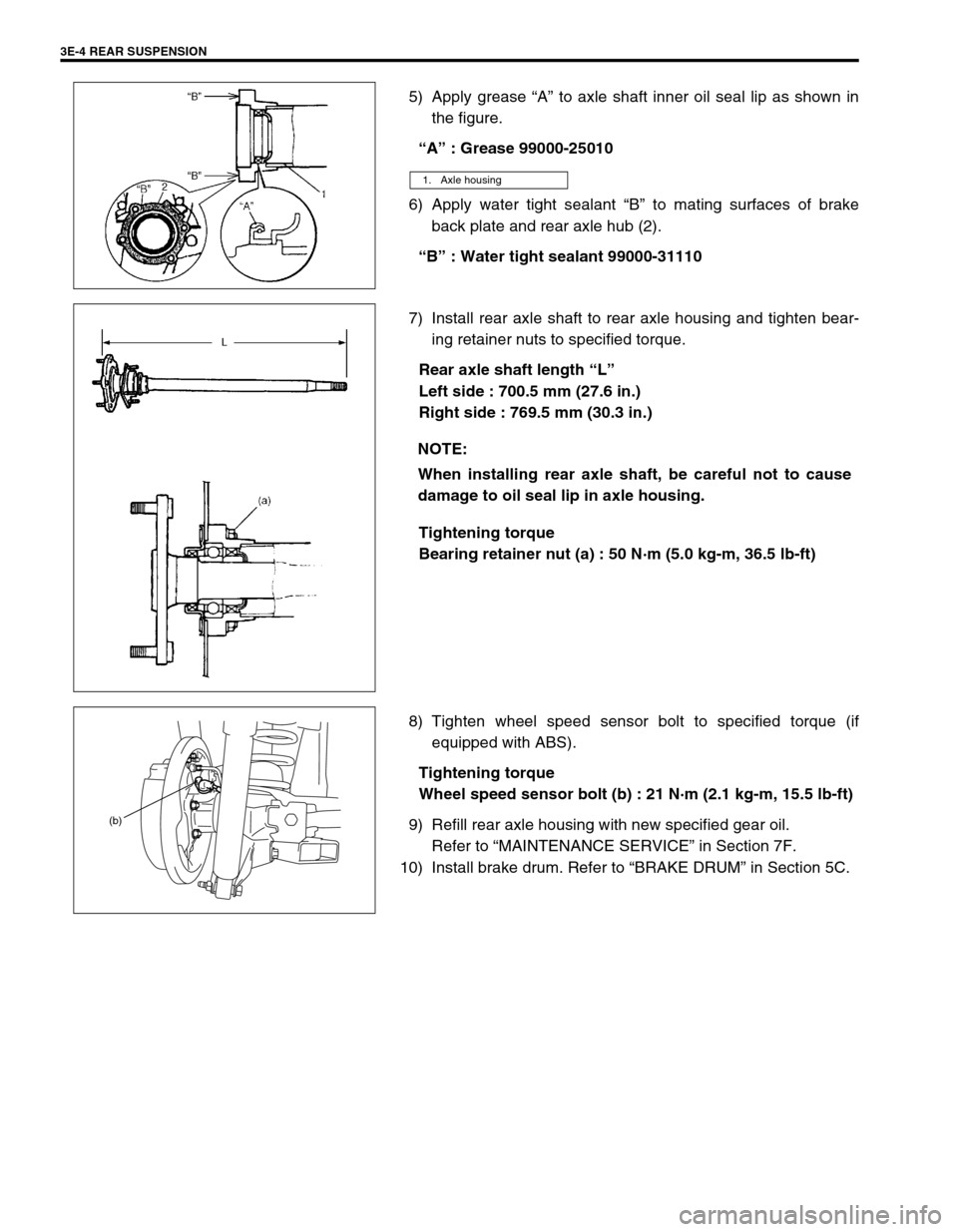

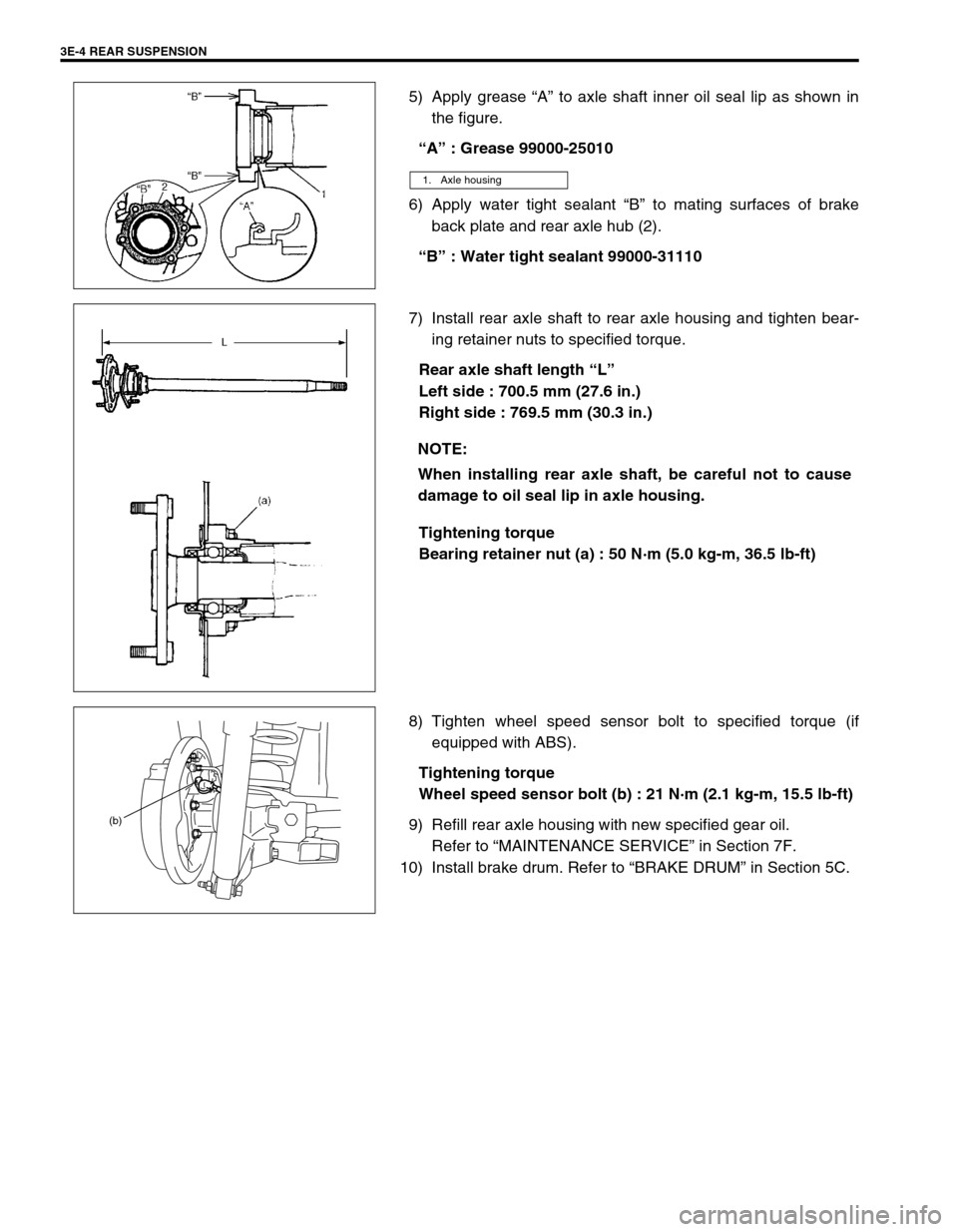

5) Apply grease “A” to axle shaft inner oil seal lip as shown in

the figure.

“A” : Grease 99000-25010

6) Apply water tight sealant “B” to mating surfaces of brake

back plate and rear axle hub (2).

“B” : Water tight sealant 99000-31110

7) Install rear axle shaft to rear axle housing and tighten bear-

ing retainer nuts to specified torque.

Rear axle shaft length “L”

Left side : 700.5 mm (27.6 in.)

Right side : 769.5 mm (30.3 in.)

Tightening torque

Bearing retainer nut (a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

8) Tighten wheel speed sensor bolt to specified torque (if

equipped with ABS).

Tightening torque

Wheel speed sensor bolt (b) : 21 N·m (2.1 kg-m, 15.5 lb-ft)

9) Refill rear axle housing with new specified gear oil.

Refer to “MAINTENANCE SERVICE” in Section 7F.

10) Install brake drum. Refer to “BRAKE DRUM” in Section 5C.

1. Axle housing

NOTE:

When installing rear axle shaft, be careful not to cause

damage to oil seal lip in axle housing.

(b)

Page 94 of 656

REAR SUSPENSION 3E-5

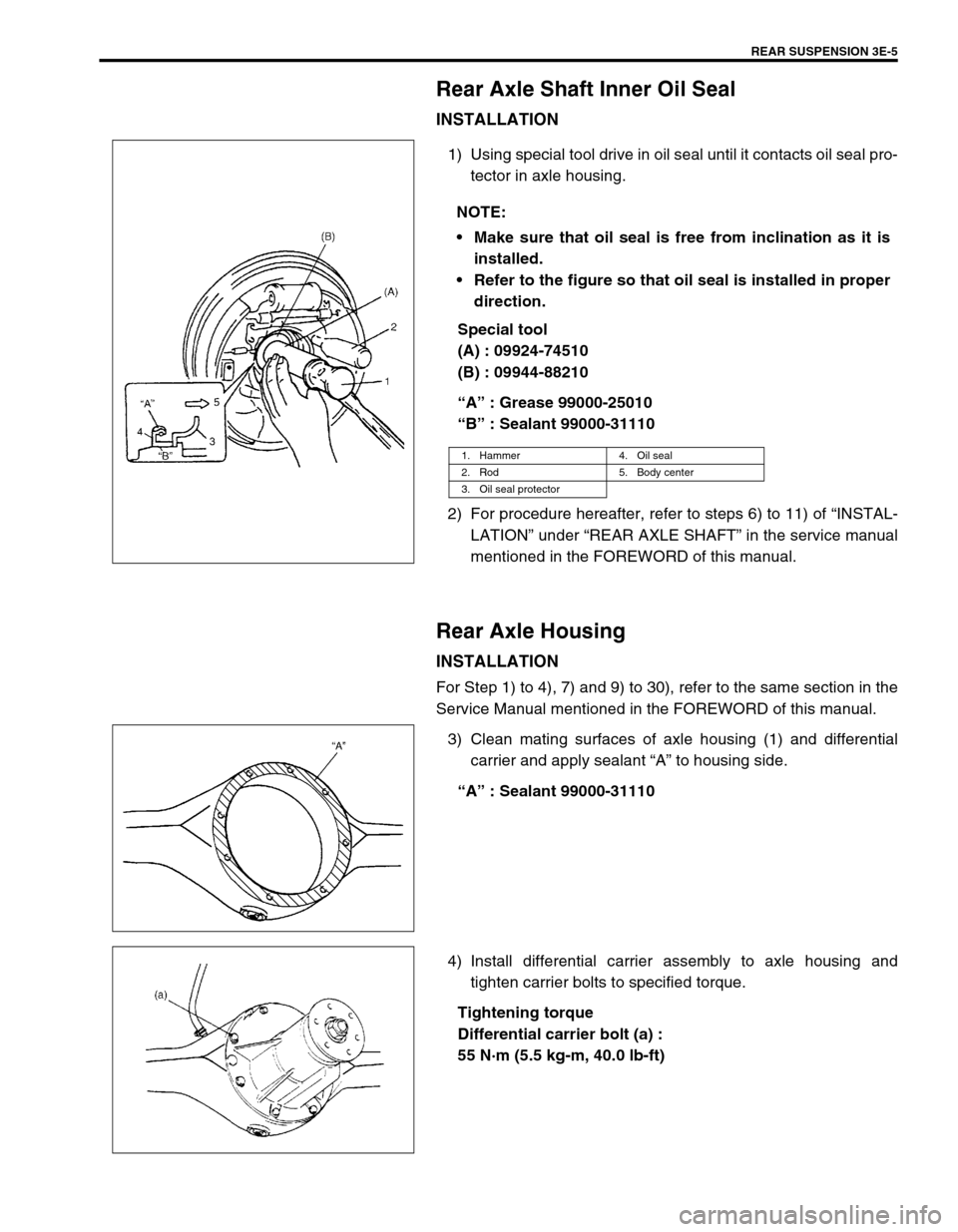

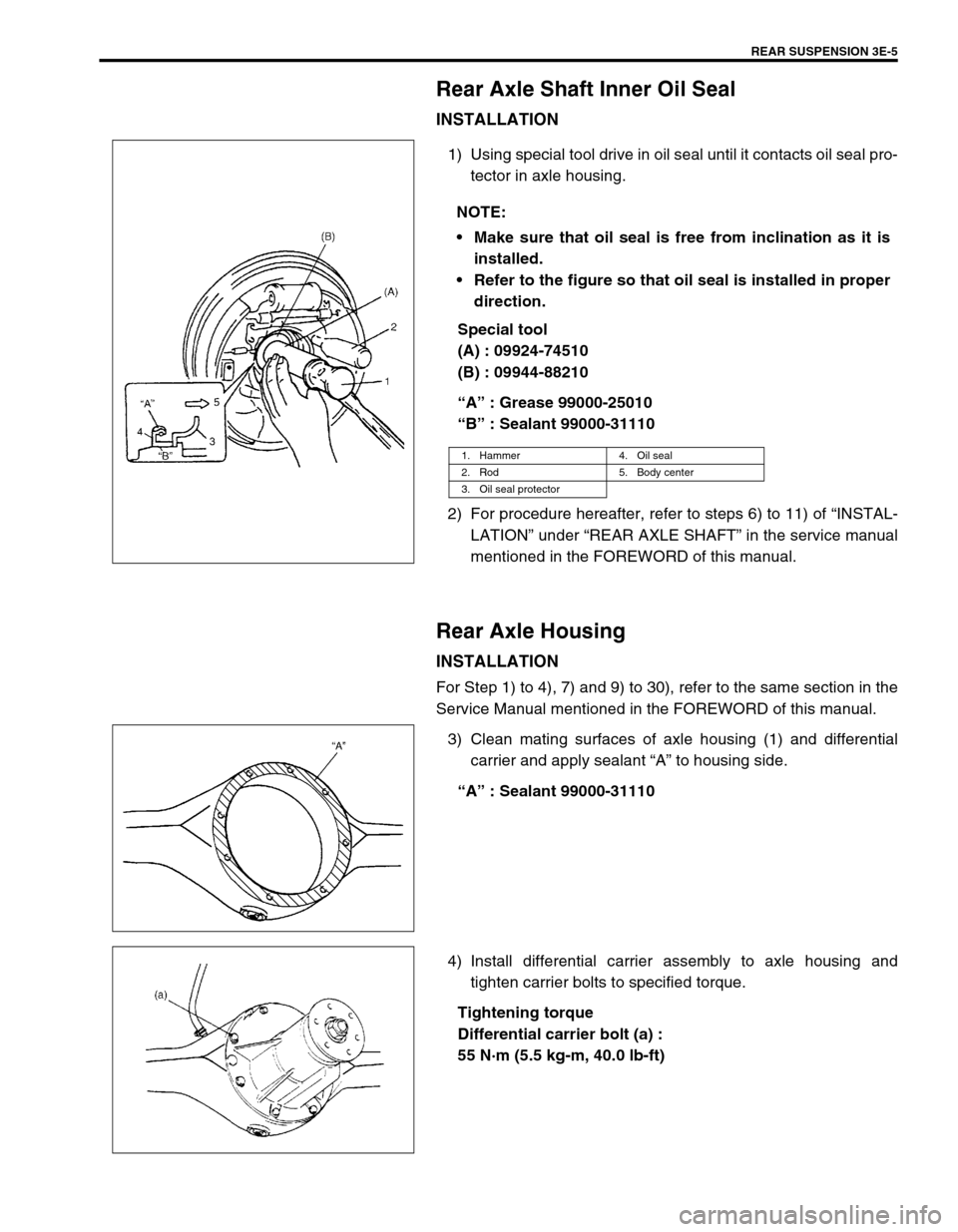

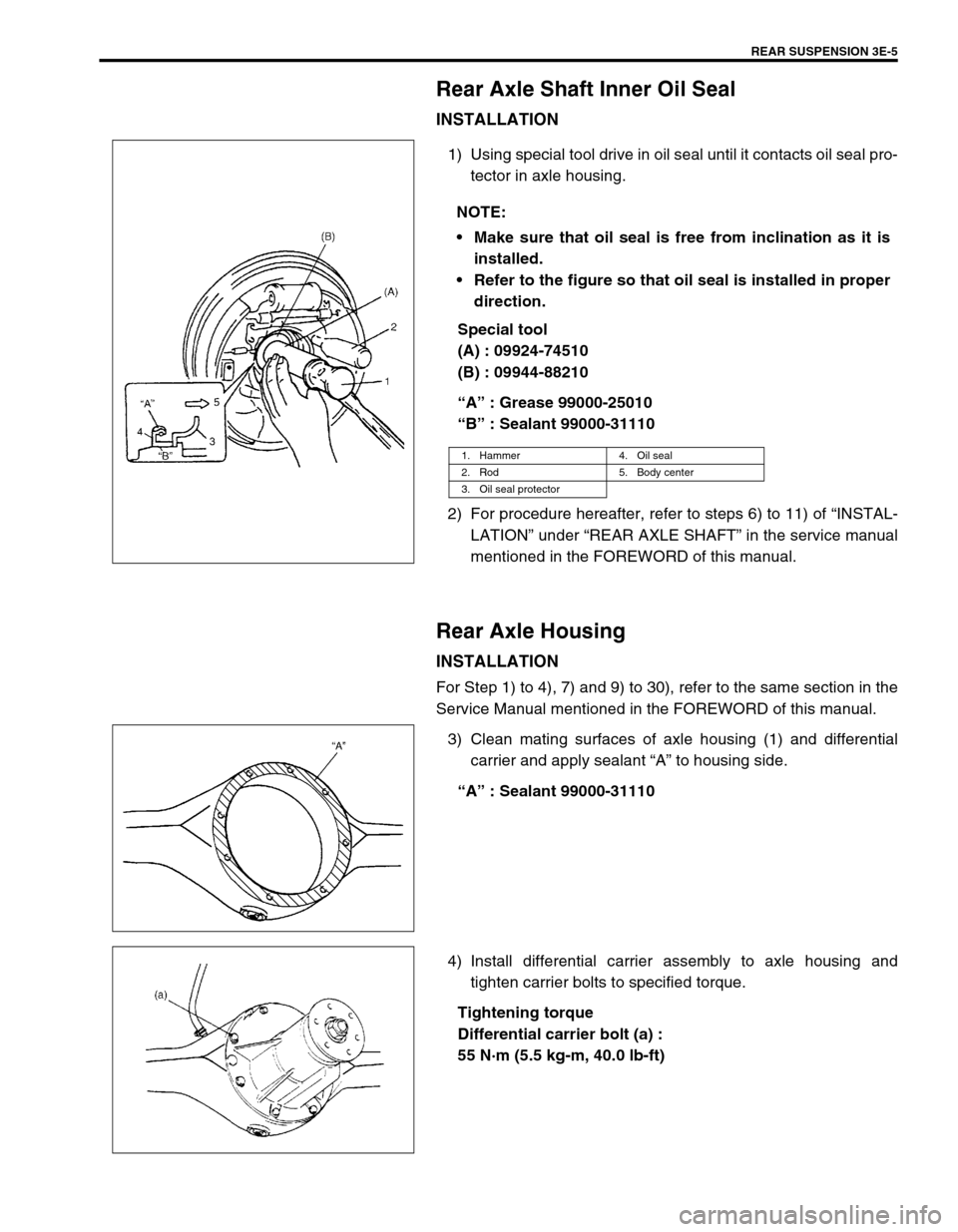

Rear Axle Shaft Inner Oil Seal

INSTALLATION

1) Using special tool drive in oil seal until it contacts oil seal pro-

tector in axle housing.

Special tool

(A) : 09924-74510

(B) : 09944-88210

“A” : Grease 99000-25010

“B” : Sealant 99000-31110

2) For procedure hereafter, refer to steps 6) to 11) of “INSTAL-

LATION” under “REAR AXLE SHAFT” in the service manual

mentioned in the FOREWORD of this manual.

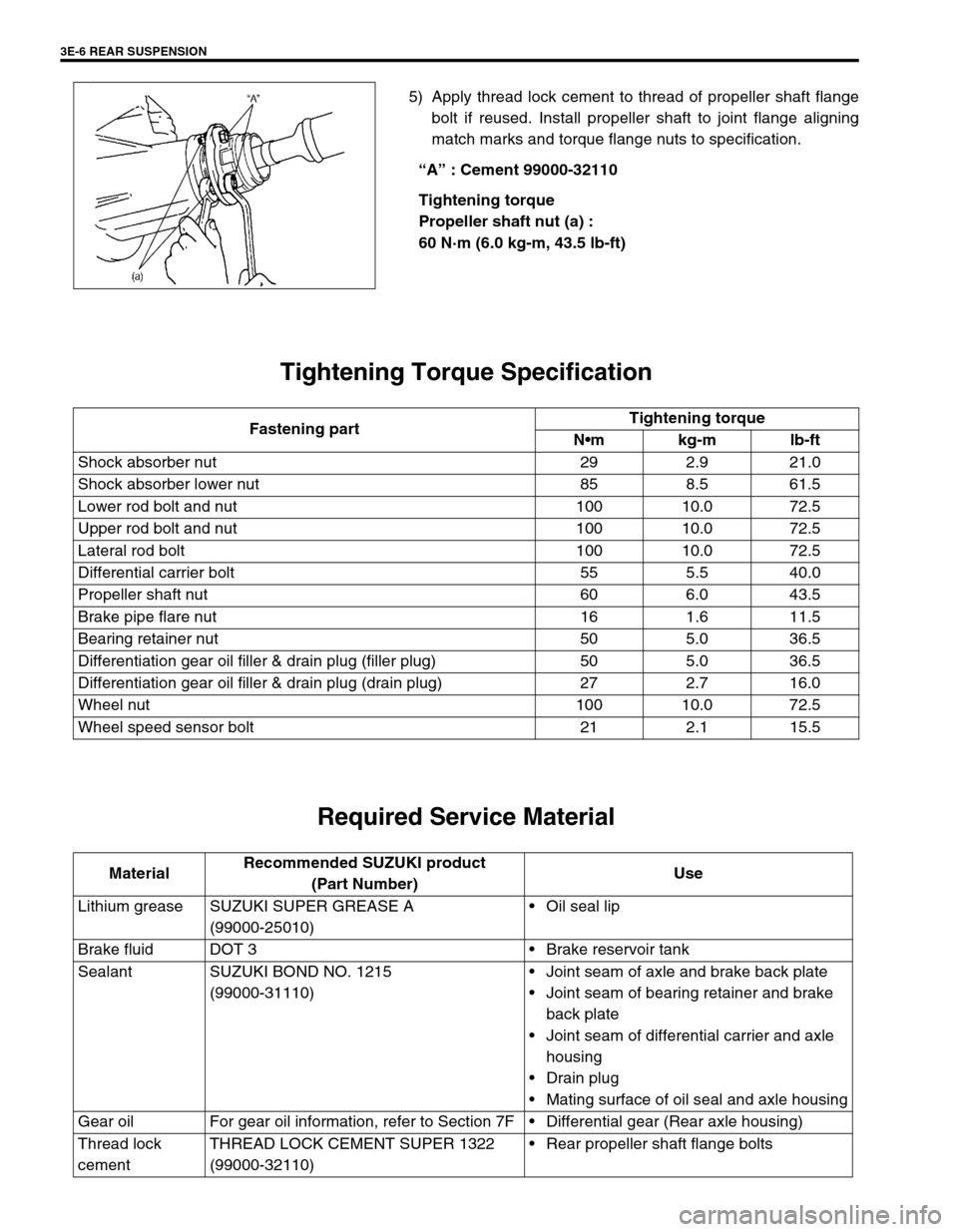

Rear Axle Housing

INSTALLATION

For Step 1) to 4), 7) and 9) to 30), refer to the same section in the

Service Manual mentioned in the FOREWORD of this manual.

3) Clean mating surfaces of axle housing (1) and differential

carrier and apply sealant “A” to housing side.

“A” : Sealant 99000-31110

4) Install differential carrier assembly to axle housing and

tighten carrier bolts to specified torque.

Tightening torque

Differential carrier bolt (a) :

55 N·m (5.5 kg-m, 40.0 lb-ft) NOTE:

Make sure that oil seal is free from inclination as it is

installed.

Refer to the figure so that oil seal is installed in proper

direction.

1. Hammer 4. Oil seal

2. Rod 5. Body center

3. Oil seal protector

Page 95 of 656

3E-6 REAR SUSPENSION

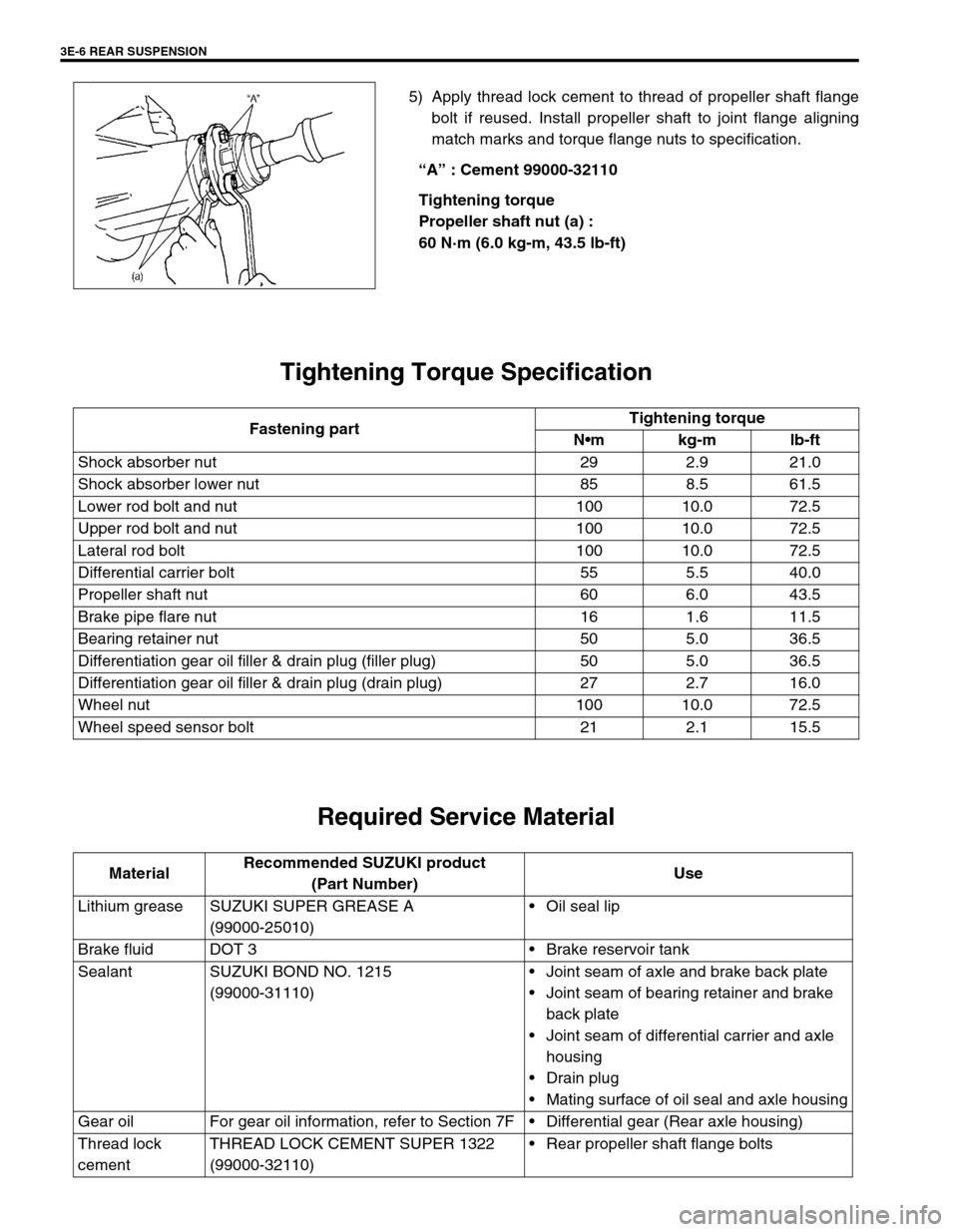

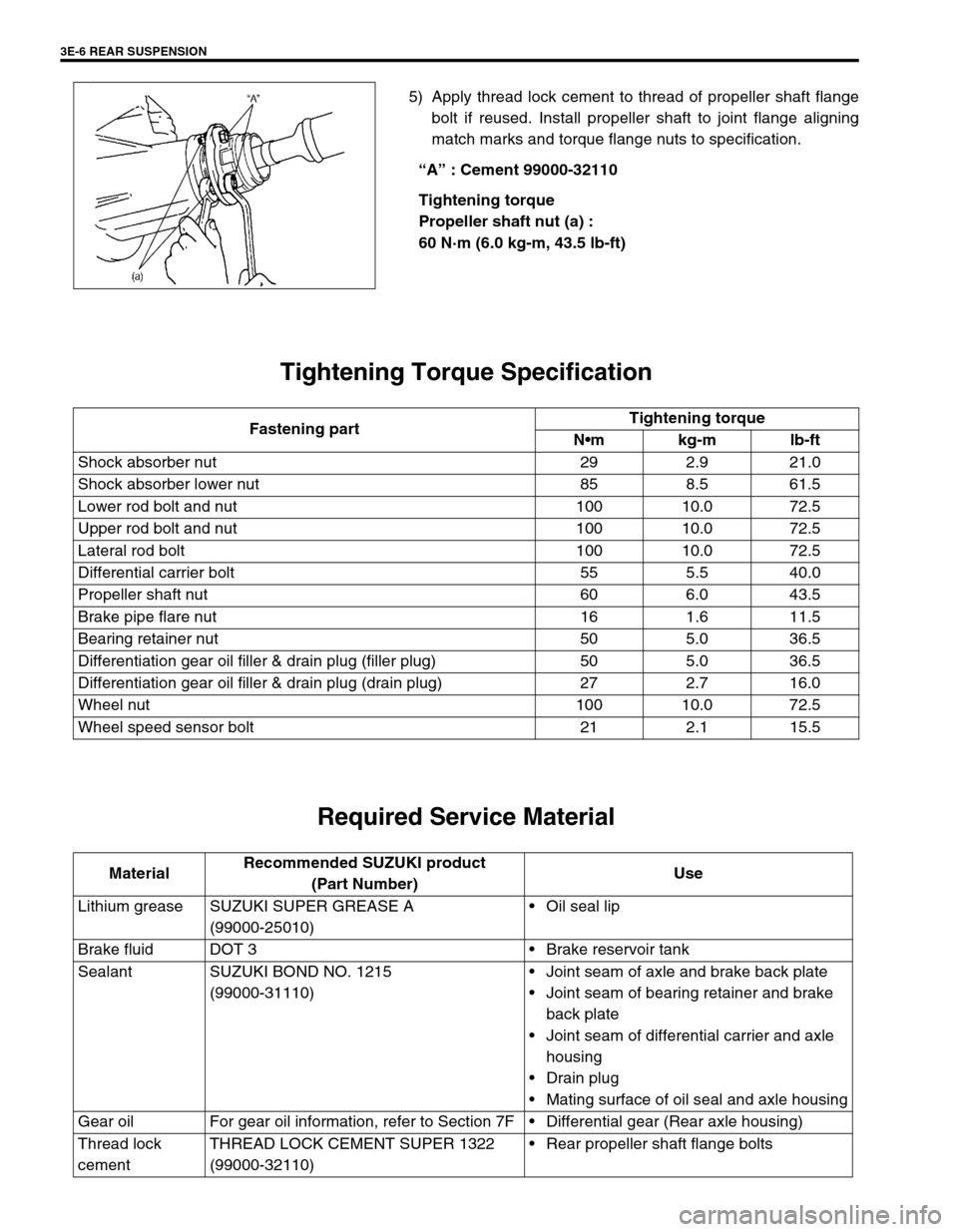

5) Apply thread lock cement to thread of propeller shaft flange

bolt if reused. Install propeller shaft to joint flange aligning

match marks and torque flange nuts to specification.

“A” : Cement 99000-32110

Tightening torque

Propeller shaft nut (a) :

60 N·m (6.0 kg-m, 43.5 lb-ft)

Tightening Torque Specification

Required Service Material

Fastening partTightening torque

Nm kg-m lb-ft

Shock absorber nut 29 2.9 21.0

Shock absorber lower nut 85 8.5 61.5

Lower rod bolt and nut 100 10.0 72.5

Upper rod bolt and nut 100 10.0 72.5

Lateral rod bolt 100 10.0 72.5

Differential carrier bolt 55 5.5 40.0

Propeller shaft nut 60 6.0 43.5

Brake pipe flare nut 16 1.6 11.5

Bearing retainer nut 50 5.0 36.5

Differentiation gear oil filler & drain plug (filler plug) 50 5.0 36.5

Differentiation gear oil filler & drain plug (drain plug) 27 2.7 16.0

Wheel nut 100 10.0 72.5

Wheel speed sensor bolt 21 2.1 15.5

MaterialRecommended SUZUKI product

(Part Number)Use

Lithium grease SUZUKI SUPER GREASE A

(99000-25010)Oil seal lip

Brake fluid DOT 3Brake reservoir tank

Sealant SUZUKI BOND NO. 1215

(99000-31110)Joint seam of axle and brake back plate

Joint seam of bearing retainer and brake

back plate

Joint seam of differential carrier and axle

housing

Drain plug

Mating surface of oil seal and axle housing

Gear oil For gear oil information, refer to Section 7FDifferential gear (Rear axle housing)

Thread lock

cementTHREAD LOCK CEMENT SUPER 1322

(99000-32110)Rear propeller shaft flange bolts

Page 96 of 656

REAR SUSPENSION 3E-7

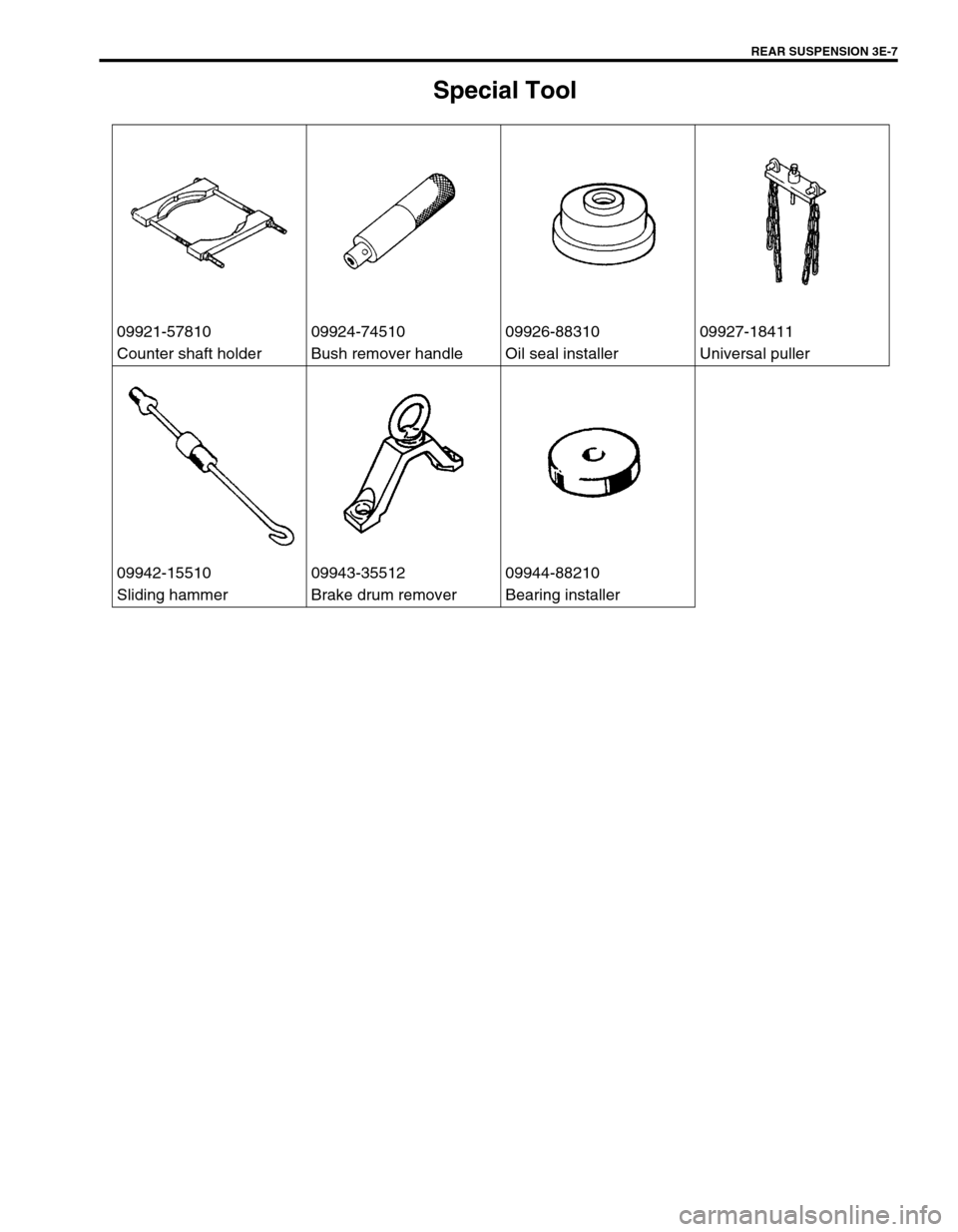

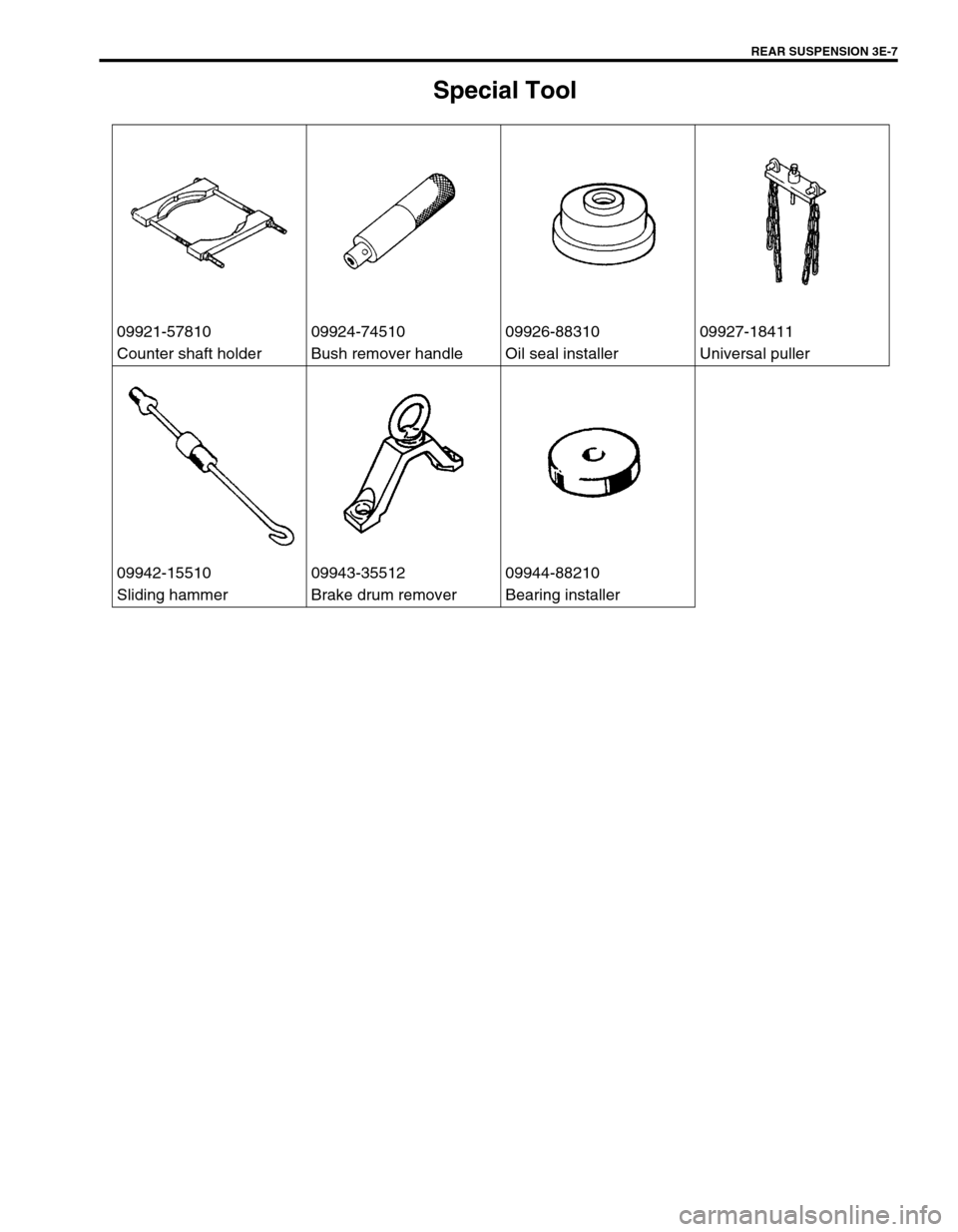

Special Tool

09921-57810 09924-74510 09926-88310 09927-18411

Counter shaft holder Bush remover handle Oil seal installer Universal puller

09942-15510 09943-35512 09944-88210

Sliding hammer Brake drum remover Bearing installer

Page 97 of 656

Page 98 of 656

WHEELS AND TIRES 3F-1

3F

SECTION 3F

WHEELS AND TIRES

CONTENTS

General Description ....................................... 3F-1

Tires ............................................................. 3F-1

Wheels ......................................................... 3F-1

General Description

Tires

This vehicle is equipped with following tire.

Tire specification :

P235/60 R16 or 235/60 R16

The tires are of tubeless type. The tires are designed to operate satisfactorily with loads up to the full rated load

capacity when inflated to the recommended inflation pressure.

Correct tire pressures and driving habits have an important influence on tire life. Heavy cornering, excessively

rapid acceleration, and unnecessary sharp braking increase tire wear.

Wheels

Standard equipment wheels are following steel wheels.

Wheel specification :

16 x 7 JJ NOTE:

For the descriptions (items) not found in this section, refer to the same section of the Service Man-

ual mentioned in the FOREWORD of this manual.

All wheel fasteners are important attaching parts in that they could affect the performance of vital

parts and systems, and/or could result in major repair expense. They must be replaced with one of

the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified

during reassembly to assure proper retention of all parts.

There is to be no welding as it may result in extensive damage and weakening of the metal.

Page 99 of 656

Page 100 of 656

FRONT DRIVE SHAFT/SHAFT BEARING, OIL SEAL 4A2-1

4A2

SECTION 4A2

FRONT DRIVE SHAFT/SHAFT BEARING,

OIL SEAL

CONTENTS

On-Vehicle Service....................................... 4A2-2

Drive Shaft ................................................. 4A2-2Required Service Material ........................... 4A2-4

NOTE:

For the descriptions (items) not found in this section, refer to the same section of the Service Manual

mentioned in the FOREWORD of this manual.

Trending: diagram, coolant, starter motor, Trans, brake sensor, lubrication, wheel alignment