front SUZUKI GRAND VITARA 1999 2.G Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1999, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1999 2.GPages: 656, PDF Size: 14.31 MB

Page 569 of 656

10-2 RESTRAINT SYSTEM

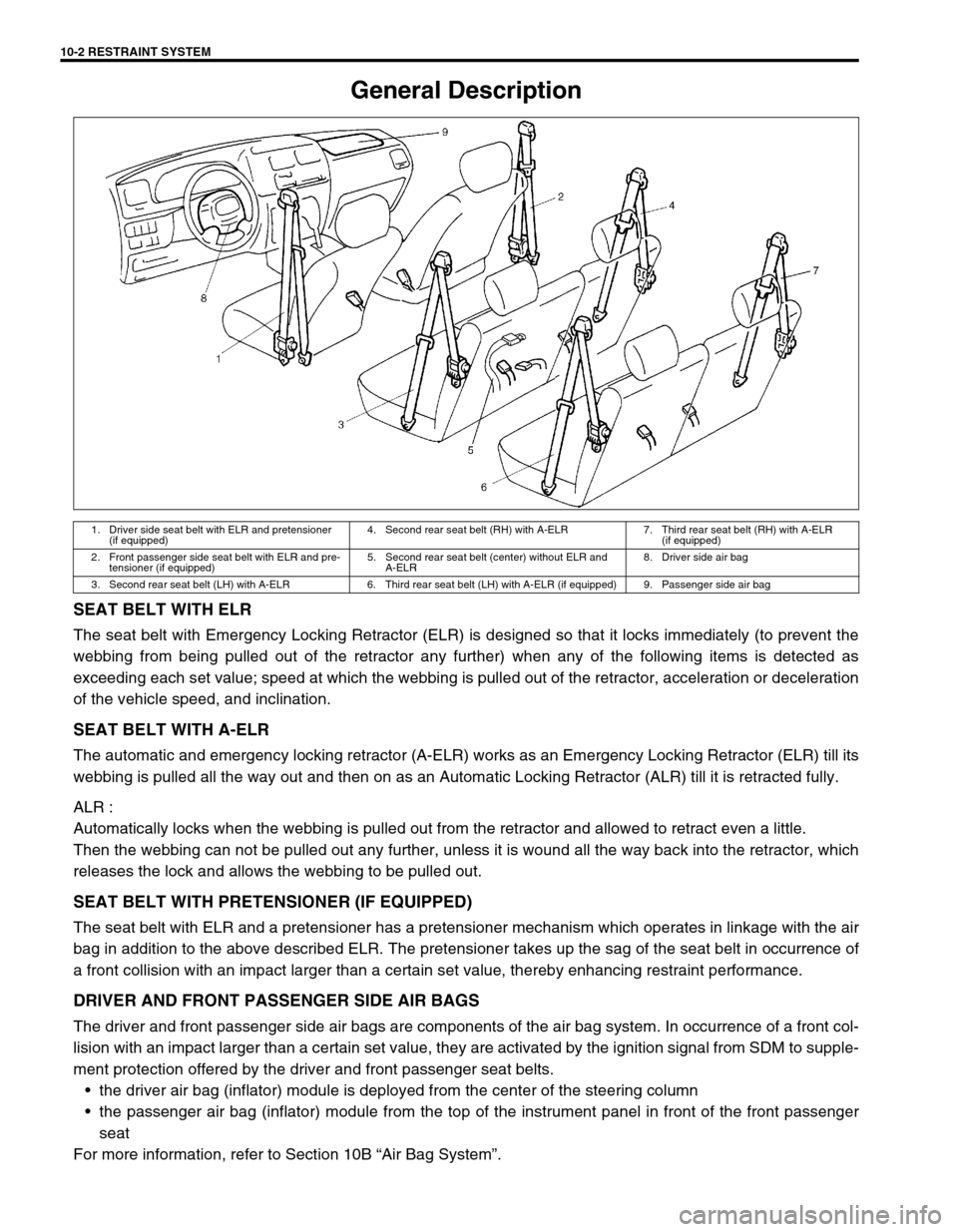

General Description

SEAT BELT WITH ELR

The seat belt with Emergency Locking Retractor (ELR) is designed so that it locks immediately (to prevent the

webbing from being pulled out of the retractor any further) when any of the following items is detected as

exceeding each set value; speed at which the webbing is pulled out of the retractor, acceleration or deceleration

of the vehicle speed, and inclination.

SEAT BELT WITH A-ELR

The automatic and emergency locking retractor (A-ELR) works as an Emergency Locking Retractor (ELR) till its

webbing is pulled all the way out and then on as an Automatic Locking Retractor (ALR) till it is retracted fully.

ALR :

Automatically locks when the webbing is pulled out from the retractor and allowed to retract even a little.

Then the webbing can not be pulled out any further, unless it is wound all the way back into the retractor, which

releases the lock and allows the webbing to be pulled out.

SEAT BELT WITH PRETENSIONER (IF EQUIPPED)

The seat belt with ELR and a pretensioner has a pretensioner mechanism which operates in linkage with the air

bag in addition to the above described ELR. The pretensioner takes up the sag of the seat belt in occurrence of

a front collision with an impact larger than a certain set value, thereby enhancing restraint performance.

DRIVER AND FRONT PASSENGER SIDE AIR BAGS

The driver and front passenger side air bags are components of the air bag system. In occurrence of a front col-

lision with an impact larger than a certain set value, they are activated by the ignition signal from SDM to supple-

ment protection offered by the driver and front passenger seat belts.

•the driver air bag (inflator) module is deployed from the center of the steering column

•the passenger air bag (inflator) module from the top of the instrument panel in front of the front passenger

seat

For more information, refer to Section 10B “Air Bag System”.

1. Driver side seat belt with ELR and pretensioner

(if equipped) 4. Second rear seat belt (RH) with A-ELR 7. Third rear seat belt (RH) with A-ELR

(if equipped)

2. Front passenger side seat belt with ELR and pre-

tensioner (if equipped) 5. Second rear seat belt (center) without ELR and

A-ELR8. Driver side air bag

3. Second rear seat belt (LH) with A-ELR 6. Third rear seat belt (LH) with A-ELR (if equipped) 9. Passenger side air bag

Page 570 of 656

SEAT BELT 10A-1

10A

SECTION 10A

SEAT BELT

CONTENTS

On-Vehicle Service....................................... 10A-2

Service Precautions ................................... 10A-2

Service and diagnosis ............................ 10A-2

Disabling air bag system ........................ 10A-2

Enabling air bag system ......................... 10A-2

Handling and storage ............................. 10A-2Disposal ................................................. 10A-2

Front Seat Belt ........................................... 10A-3

Second Rear Seat Belt .............................. 10A-6

Third Rear Seat Belt (If Equipped) ............. 10A-7

Tightening Torque Specification ................ 10A-8

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

CAUTION:

When fasteners are removed, always reinstall them at the same location from which they were

removed. If a fastener needs to be replaced, use the correct part number fastener for that application.

If the correct part number fastener is not available, a fastener of equal size and strength (or stronger)

may be used. Fasteners that are not reused, and those requiring thread-locking compound, will be

called out. The correct torque value must be used when installing fasteners that require it. If the above

procedures are not followed, parts or system damage could result.

Page 572 of 656

SEAT BELT 10A-3

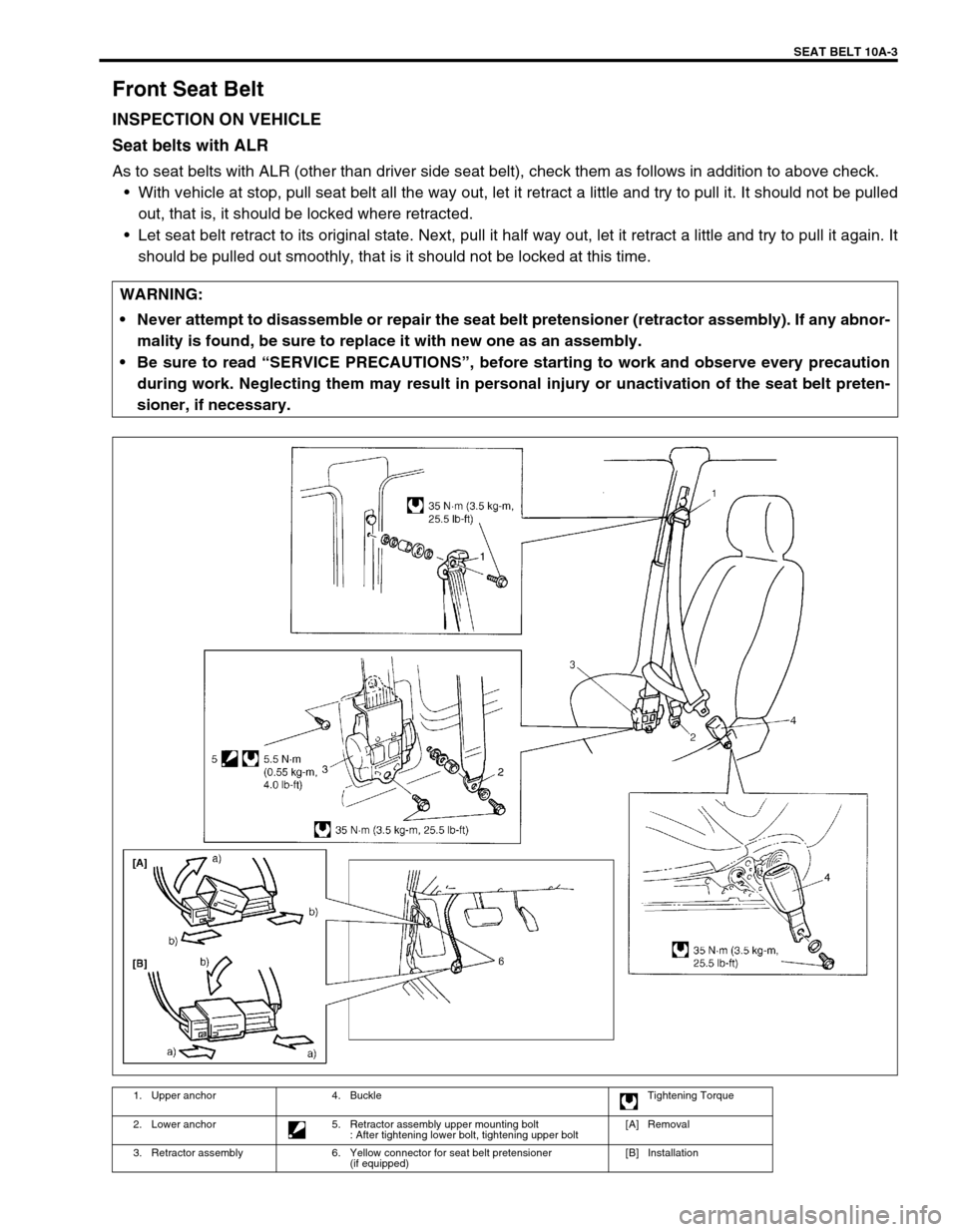

Front Seat Belt

INSPECTION ON VEHICLE

Seat belts with ALR

As to seat belts with ALR (other than driver side seat belt), check them as follows in addition to above check.

•With vehicle at stop, pull seat belt all the way out, let it retract a little and try to pull it. It should not be pulled

out, that is, it should be locked where retracted.

•Let seat belt retract to its original state. Next, pull it half way out, let it retract a little and try to pull it again. It

should be pulled out smoothly, that is it should not be locked at this time.

WARNING:

Never attempt to disassemble or repair the seat belt pretensioner (retractor assembly). If any abnor-

mality is found, be sure to replace it with new one as an assembly.

Be sure to read “SERVICE PRECAUTIONS”, before starting to work and observe every precaution

during work. Neglecting them may result in personal injury or unactivation of the seat belt preten-

sioner, if necessary.

1. Upper anchor 4. Buckle Tightening Torque

2. Lower anchor 5. Retractor assembly upper mounting bolt

: After tightening lower bolt, tightening upper bolt[A] Removal

3. Retractor assembly 6. Yellow connector for seat belt pretensioner

(if equipped)[B] Installation

Page 573 of 656

10A-4 SEAT BELT

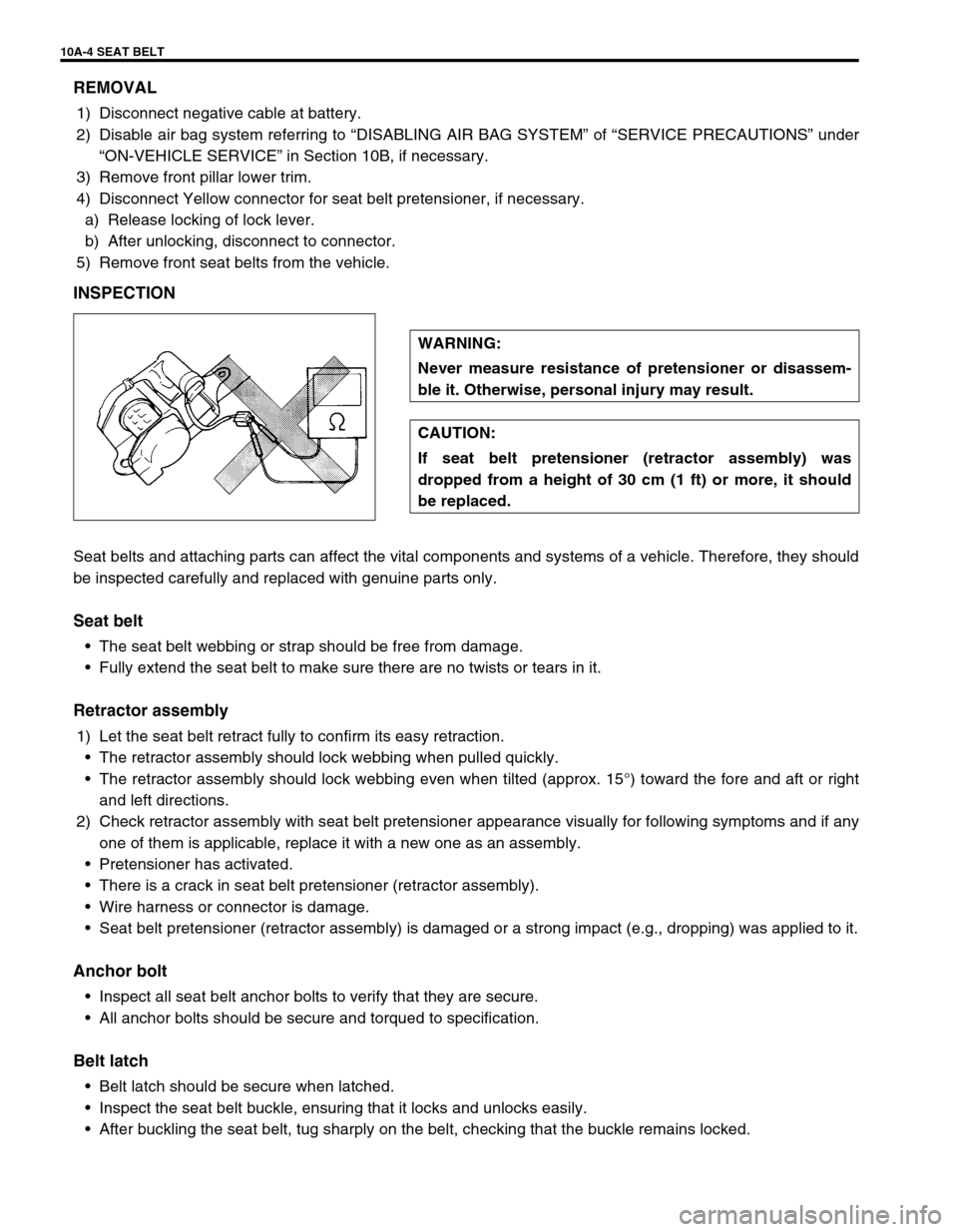

REMOVAL

1) Disconnect negative cable at battery.

2) Disable air bag system referring to “DISABLING AIR BAG SYSTEM” of “SERVICE PRECAUTIONS” under

“ON-VEHICLE SERVICE” in Section 10B, if necessary.

3) Remove front pillar lower trim.

4) Disconnect Yellow connector for seat belt pretensioner, if necessary.

a) Release locking of lock lever.

b) After unlocking, disconnect to connector.

5) Remove front seat belts from the vehicle.

INSPECTION

Seat belts and attaching parts can affect the vital components and systems of a vehicle. Therefore, they should

be inspected carefully and replaced with genuine parts only.

Seat belt

•The seat belt webbing or strap should be free from damage.

•Fully extend the seat belt to make sure there are no twists or tears in it.

Retractor assembly

1) Let the seat belt retract fully to confirm its easy retraction.

•The retractor assembly should lock webbing when pulled quickly.

•The retractor assembly should lock webbing even when tilted (approx. 15°) toward the fore and aft or right

and left directions.

2) Check retractor assembly with seat belt pretensioner appearance visually for following symptoms and if any

one of them is applicable, replace it with a new one as an assembly.

•Pretensioner has activated.

•There is a crack in seat belt pretensioner (retractor assembly).

•Wire harness or connector is damage.

•Seat belt pretensioner (retractor assembly) is damaged or a strong impact (e.g., dropping) was applied to it.

Anchor bolt

•Inspect all seat belt anchor bolts to verify that they are secure.

•All anchor bolts should be secure and torqued to specification.

Belt latch

•Belt latch should be secure when latched.

•Inspect the seat belt buckle, ensuring that it locks and unlocks easily.

•After buckling the seat belt, tug sharply on the belt, checking that the buckle remains locked.WARNING:

Never measure resistance of pretensioner or disassem-

ble it. Otherwise, personal injury may result.

CAUTION:

If seat belt pretensioner (retractor assembly) was

dropped from a height of 30 cm (1 ft) or more, it should

be replaced.

Page 574 of 656

SEAT BELT 10A-5

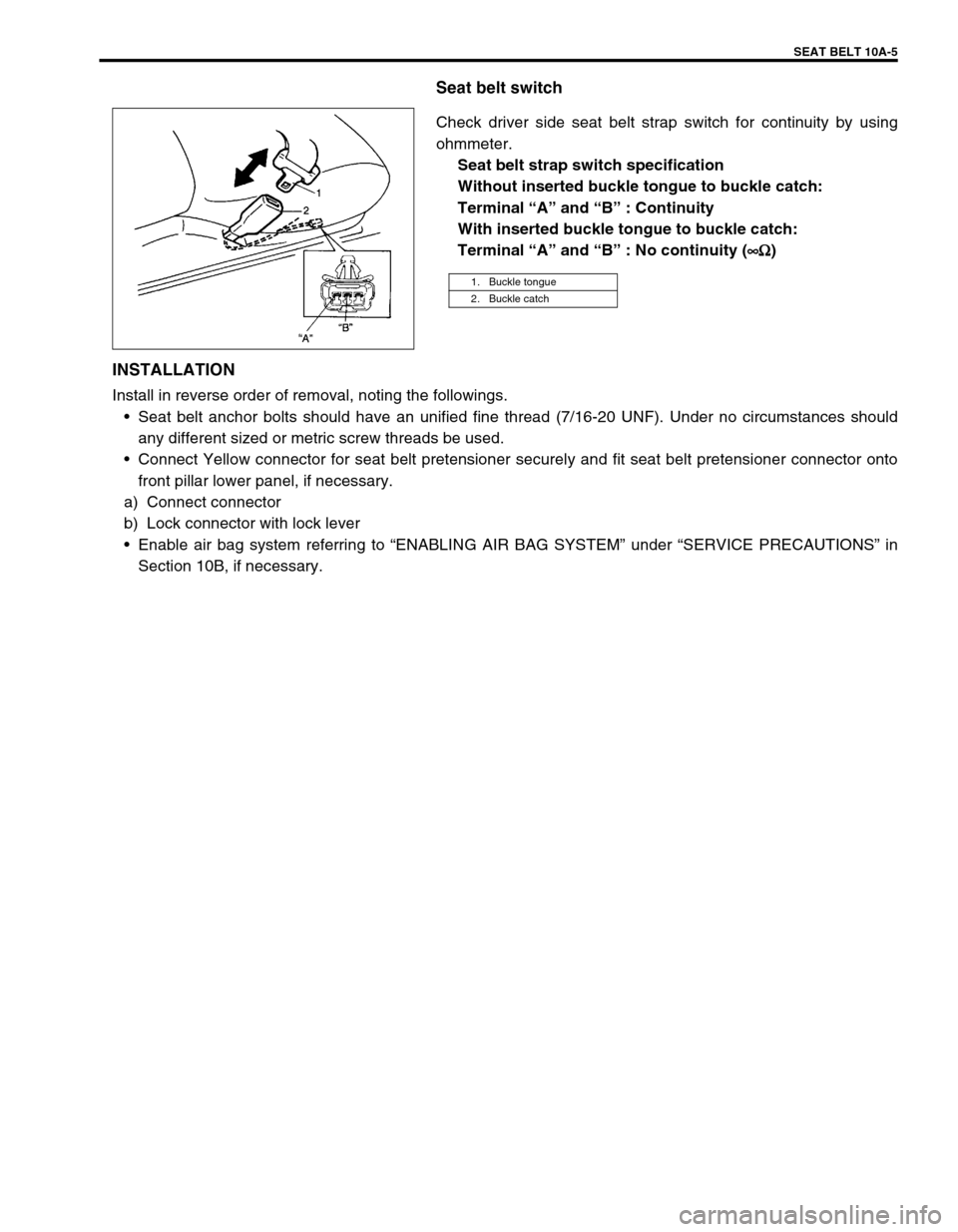

Seat belt switch

Check driver side seat belt strap switch for continuity by using

ohmmeter.

Seat belt strap switch specification

Without inserted buckle tongue to buckle catch:

Terminal “A” and “B” : Continuity

With inserted buckle tongue to buckle catch:

Terminal “A” and “B” : No continuity (∞Ω

∞Ω∞Ω ∞Ω)

INSTALLATION

Install in reverse order of removal, noting the followings.

•Seat belt anchor bolts should have an unified fine thread (7/16-20 UNF). Under no circumstances should

any different sized or metric screw threads be used.

•Connect Yellow connector for seat belt pretensioner securely and fit seat belt pretensioner connector onto

front pillar lower panel, if necessary.

a) Connect connector

b) Lock connector with lock lever

•Enable air bag system referring to “ENABLING AIR BAG SYSTEM” under “SERVICE PRECAUTIONS” in

Section 10B, if necessary.

1. Buckle tongue

2. Buckle catch

Page 575 of 656

10A-6 SEAT BELT

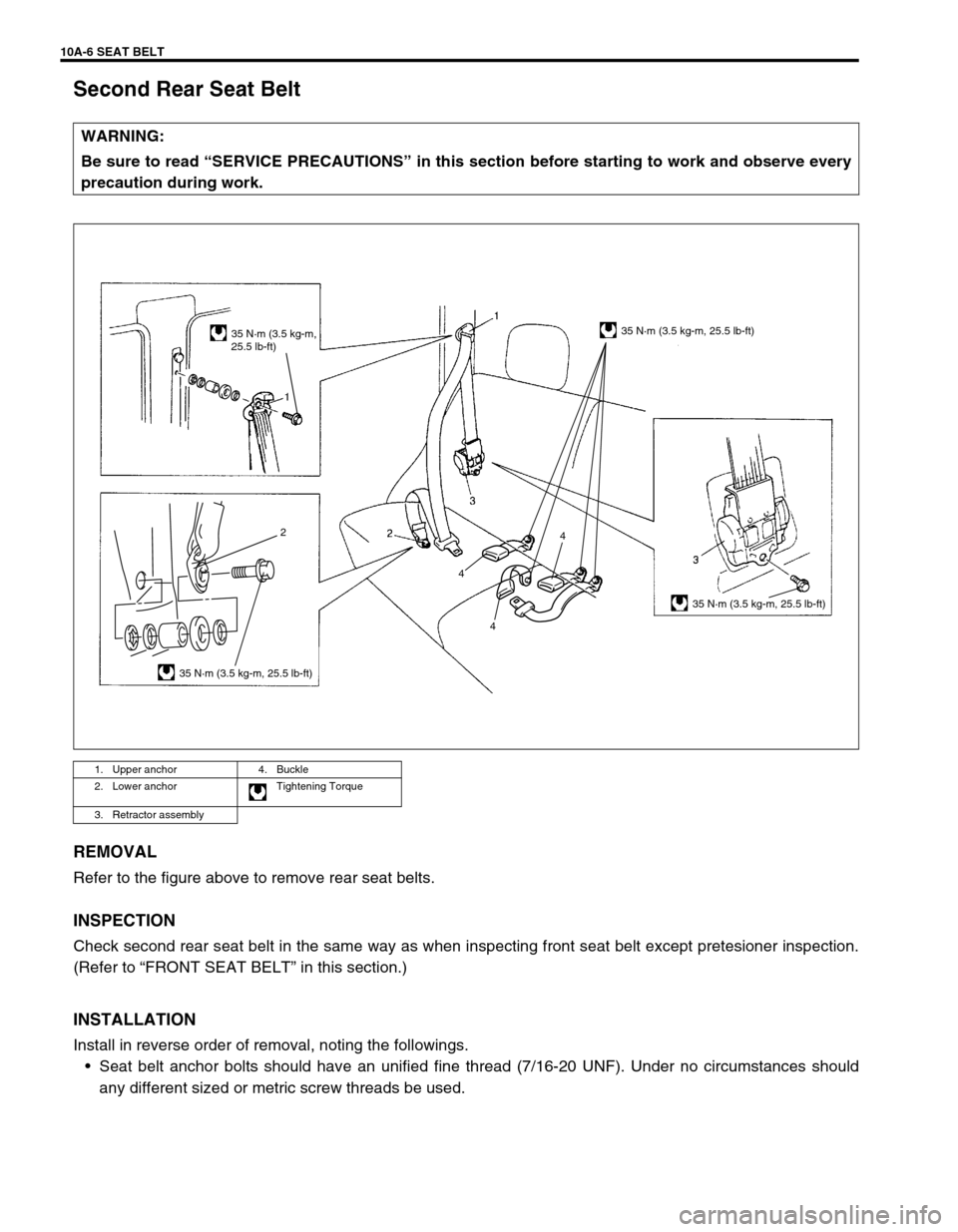

Second Rear Seat Belt

REMOVAL

Refer to the figure above to remove rear seat belts.

INSPECTION

Check second rear seat belt in the same way as when inspecting front seat belt except pretesioner inspection.

(Refer to “FRONT SEAT BELT” in this section.)

INSTALLATION

Install in reverse order of removal, noting the followings.

•Seat belt anchor bolts should have an unified fine thread (7/16-20 UNF). Under no circumstances should

any different sized or metric screw threads be used. WARNING:

Be sure to read “SERVICE PRECAUTIONS” in this section before starting to work and observe every

precaution during work.

1. Upper anchor 4. Buckle

2. Lower anchor Tightening Torque

3. Retractor assembly

2

35 N·m (3.5 kg-m, 25.5 lb-ft)

35 N·m (3.5 kg-m, 25.5 lb-ft)

35 N·m (3.5 kg-m, 25.5 lb-ft)

35 N·m (3.5 kg-m,

25.5 lb-ft)

4

4

4

Page 579 of 656

10B-2 AIR BAG SYSTEM

DTC B1031 – Power Source Voltage

High........................................................... 10B-33

DTC B1032 – Power Source Voltage

Low ........................................................... 10B-33

DTC B1035 – RH Forward Sensor Circuit

Open or Short to Ground .......................... 10B-36

DTC B1036 – RH Forward Sensor Circuit

Short Between Two Wires or Short to

Power Circuit............................................. 10B-36

DTC B1037 – LH Forward Sensor Circuit

Open or Short to Ground .......................... 10B-36

DTC B1038 – LH Forward Sensor Circuit

Short Between Two Wires or Short to

Power Circuit............................................. 10B-36

DTC B1041 – Driver Pretensioner Initiator

Circuit Resistance High............................. 10B-40

DTC B1042 – Driver Pretensioner Initiator

Circuit Resistance Low ............................. 10B-40

DTC B1043 – Driver Pretensioner Initiator

Circuit Short to Ground ............................. 10B-40

DTC B1044 – Driver Pretensioner Initiator

Circuit Short to Power Circuit .................... 10B-40

DTC B1045 – Passenger Pretensioner

Initiator Circuit Resistance High ................ 10B-40

DTC B1046 – Passenger Pretensioner

Initiator Circuit Resistance Low................. 10B-40

DTC B1047 – Passenger Pretensioner

Initiator Circuit Short to Ground ................ 10B-40

DTC B1048 – Passenger Pretensioner

Initiator Circuit Short to Power Circuit ....... 10B-40

DTC B1051 – Frontal Crash Detected

(System Activation Command Outputted). 10B-46DTC B1061 – “AIR BAG” Warning Lamp

Circuit Failure............................................ 10B-47

DTC B1071 – Internal SDM Fault ............. 10B-48

DTC B1013 – System Specifications

Different from SDM Specifications ............ 10B-48

On-Vehicle Service ..................................... 10B-49

Service Precautions .................................. 10B-49

Service and diagnosis ........................... 10B-49

Disabling air bag system ....................... 10B-50

Enabling air bag system........................ 10B-50

Handling and storage ............................ 10B-51

Repairs and Inspections Required after

an Accident ............................................... 10B-56

Accident with deployment/activation -

component replacement ....................... 10B-56

Accident with or without deployment/

activation - component inspections....... 10B-57

SDM .......................................................... 10B-60

Forward Sensor ........................................ 10B-62

Seat Belt Pretensioner .............................. 10B-64

Air Bag (Inflator) Module and Seat Belt

Pretensioner Disposal................................ 10B-65

Deployment/Activation Outside Vehicle .... 10B-66

Deployment/Activation Inside Vehicle....... 10B-72

Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner

Disposal .................................................... 10B-76

Tightening Torque Specification............... 10B-77

Special Tool ................................................ 10B-77

Page 580 of 656

AIR BAG SYSTEM 10B-3

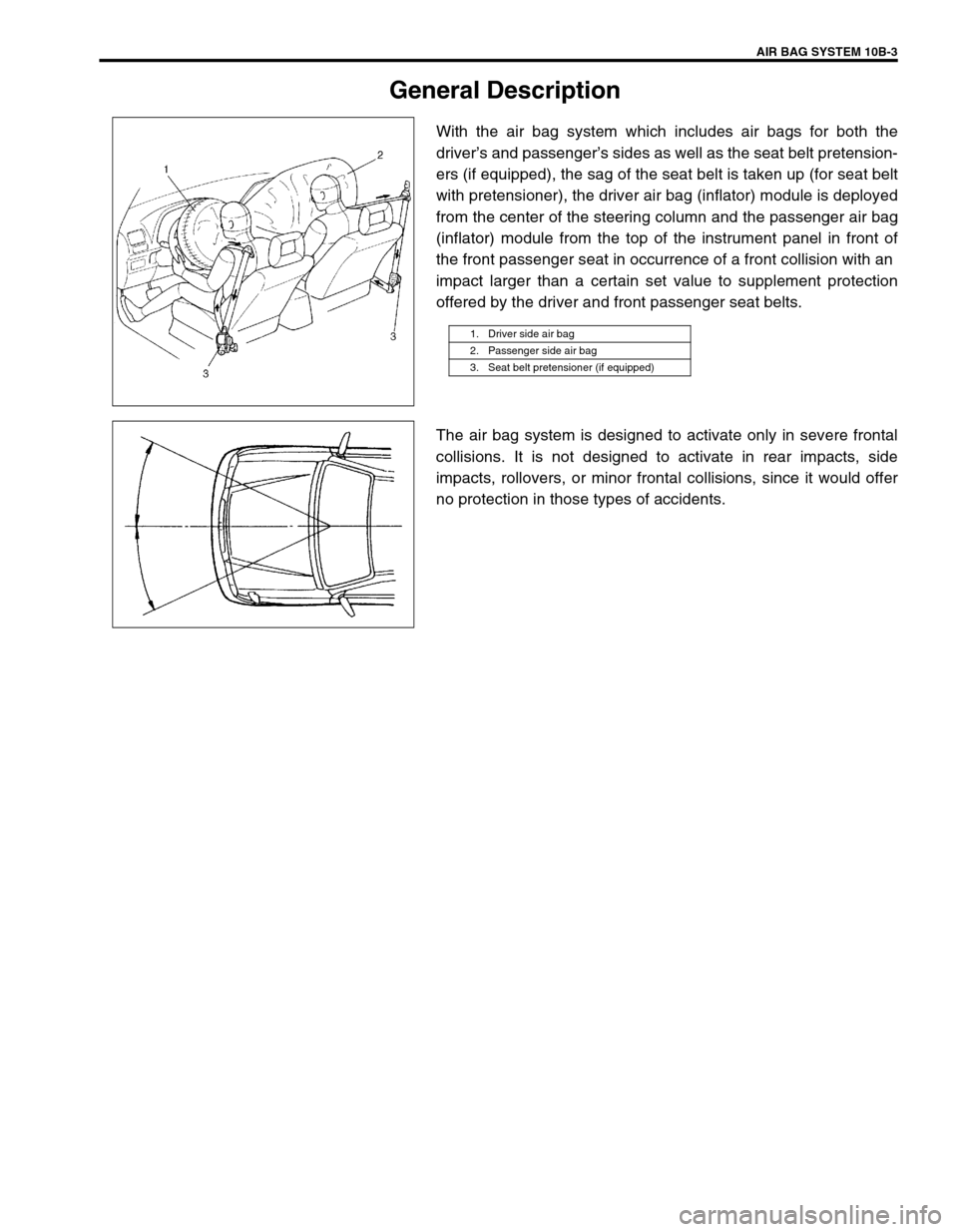

General Description

With the air bag system which includes air bags for both the

driver’s and passenger’s sides as well as the seat belt pretension-

ers (if equipped), the sag of the seat belt is taken up (for seat belt

with pretensioner), the driver air bag (inflator) module is deployed

from the center of the steering column and the passenger air bag

(inflator) module from the top of the instrument panel in front of

the front passenger seat in occurrence of a front collision with an

impact larger than a certain set value to supplement protection

offered by the driver and front passenger seat belts.

The air bag system is designed to activate only in severe frontal

collisions. It is not designed to activate in rear impacts, side

impacts, rollovers, or minor frontal collisions, since it would offer

no protection in those types of accidents.

1. Driver side air bag

2. Passenger side air bag

3. Seat belt pretensioner (if equipped)

Page 592 of 656

AIR BAG SYSTEM 10B-15

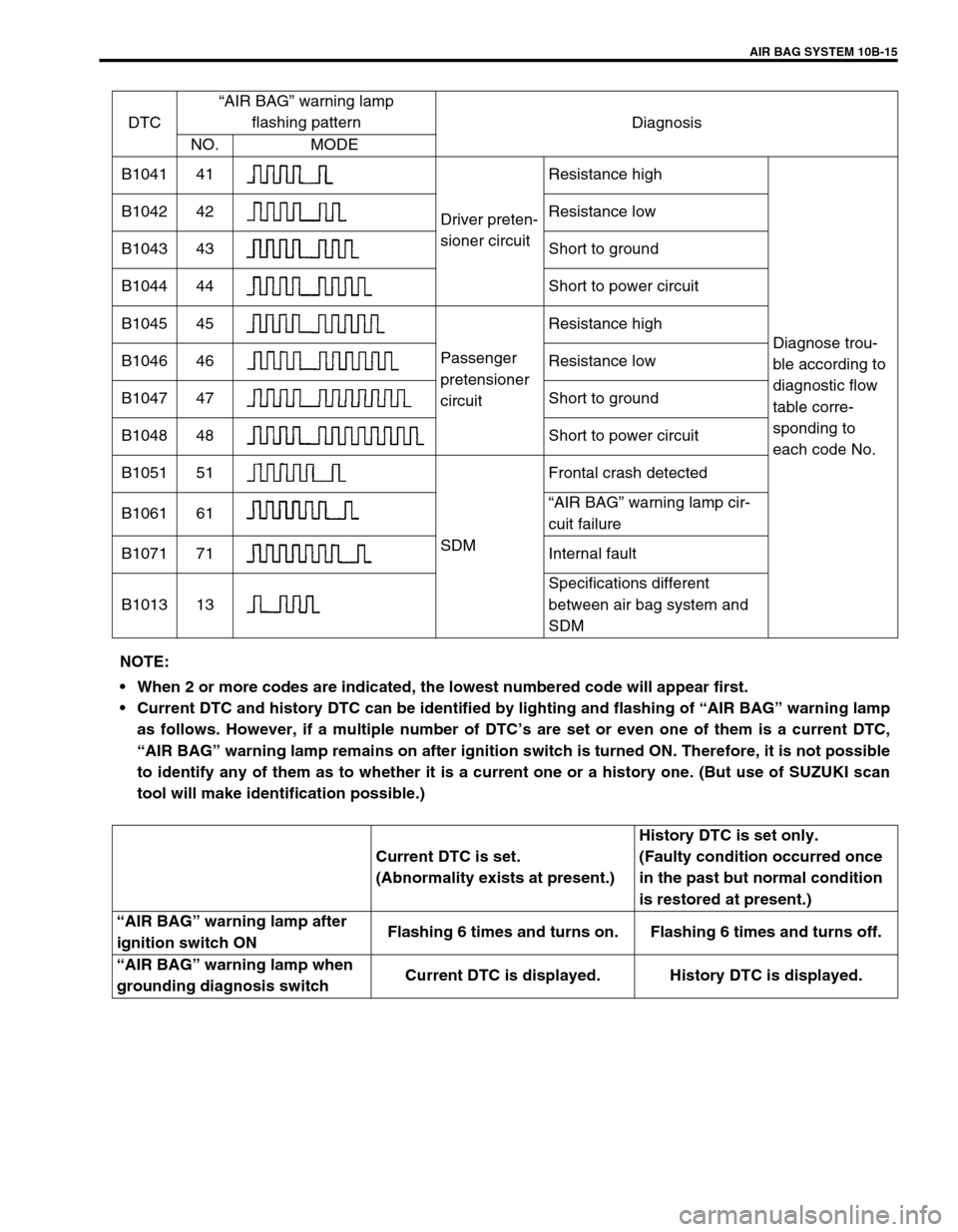

DTC“AIR BAG” warning lamp

flashing pattern

Diagnosis

NO. MODE

B1041 41

Driver preten-

sioner circuitResistance high

Diagnose trou-

ble according to

diagnostic flow

table corre-

sponding to

each code No. B1042 42 Resistance low

B1043 43 Short to ground

B1044 44 Short to power circuit

B1045 45

Passenger

pretensioner

circuitResistance high

B1046 46 Resistance low

B1047 47 Short to ground

B1048 48 Short to power circuit

B1051 51

SDMFrontal crash detected

B1061 61“AIR BAG” warning lamp cir-

cuit failure

B1071 71 Internal fault

B1013 13Specifications different

between air bag system and

SDM

NOTE:

When 2 or more codes are indicated, the lowest numbered code will appear first.

Current DTC and history DTC can be identified by lighting and flashing of “AIR BAG” warning lamp

as follows. However, if a multiple number of DTC’s are set or even one of them is a current DTC,

“AIR BAG” warning lamp remains on after ignition switch is turned ON. Therefore, it is not possible

to identify any of them as to whether it is a current one or a history one. (But use of SUZUKI scan

tool will make identification possible.)

Current DTC is set.

(Abnormality exists at present.)History DTC is set only.

(Faulty condition occurred once

in the past but normal condition

is restored at present.)

“AIR BAG” warning lamp after

ignition switch ONFlashing 6 times and turns on. Flashing 6 times and turns off.

“AIR BAG” warning lamp when

grounding diagnosis switchCurrent DTC is displayed. History DTC is displayed.

Page 623 of 656

10B-46 AIR BAG SYSTEM

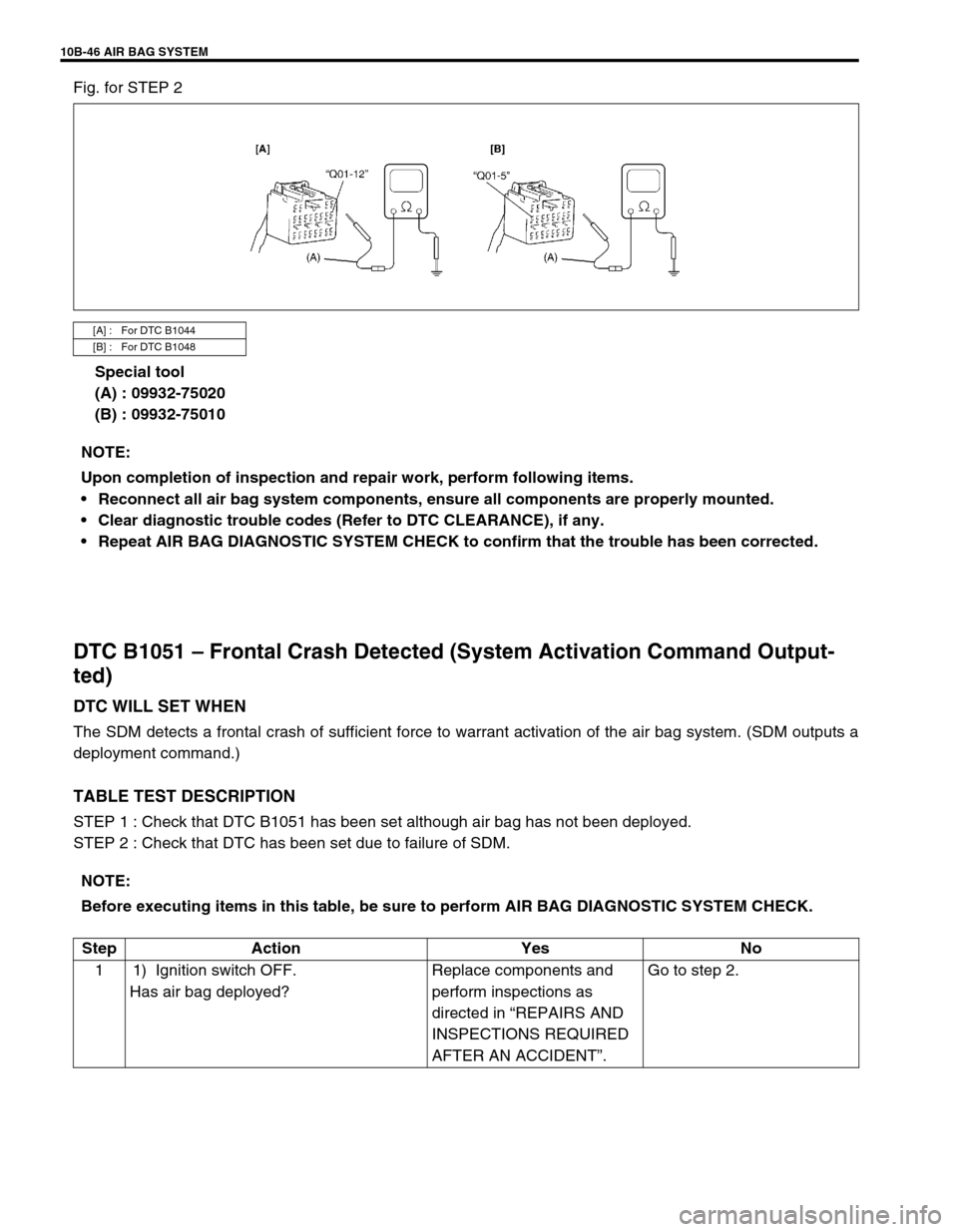

Fig. for STEP 2

Special tool

(A) : 09932-75020

(B) : 09932-75010

DTC B1051 – Frontal Crash Detected (System Activation Command Output-

ted)

DTC WILL SET WHEN

The SDM detects a frontal crash of sufficient force to warrant activation of the air bag system. (SDM outputs a

deployment command.)

TABLE TEST DESCRIPTION

STEP 1 : Check that DTC B1051 has been set although air bag has not been deployed.

STEP 2 : Check that DTC has been set due to failure of SDM.

[A] : For DTC B1044

[B] : For DTC B1048

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Clear diagnostic trouble codes (Refer to DTC CLEARANCE), if any.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

NOTE:

Before executing items in this table, be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK.

Step Action Yes No

1 1) Ignition switch OFF.

Has air bag deployed?Replace components and

perform inspections as

directed in “REPAIRS AND

INSPECTIONS REQUIRED

AFTER AN ACCIDENT”.Go to step 2.