front SUZUKI GRAND VITARA 1999 2.G Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1999, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1999 2.GPages: 656, PDF Size: 14.31 MB

Page 488 of 656

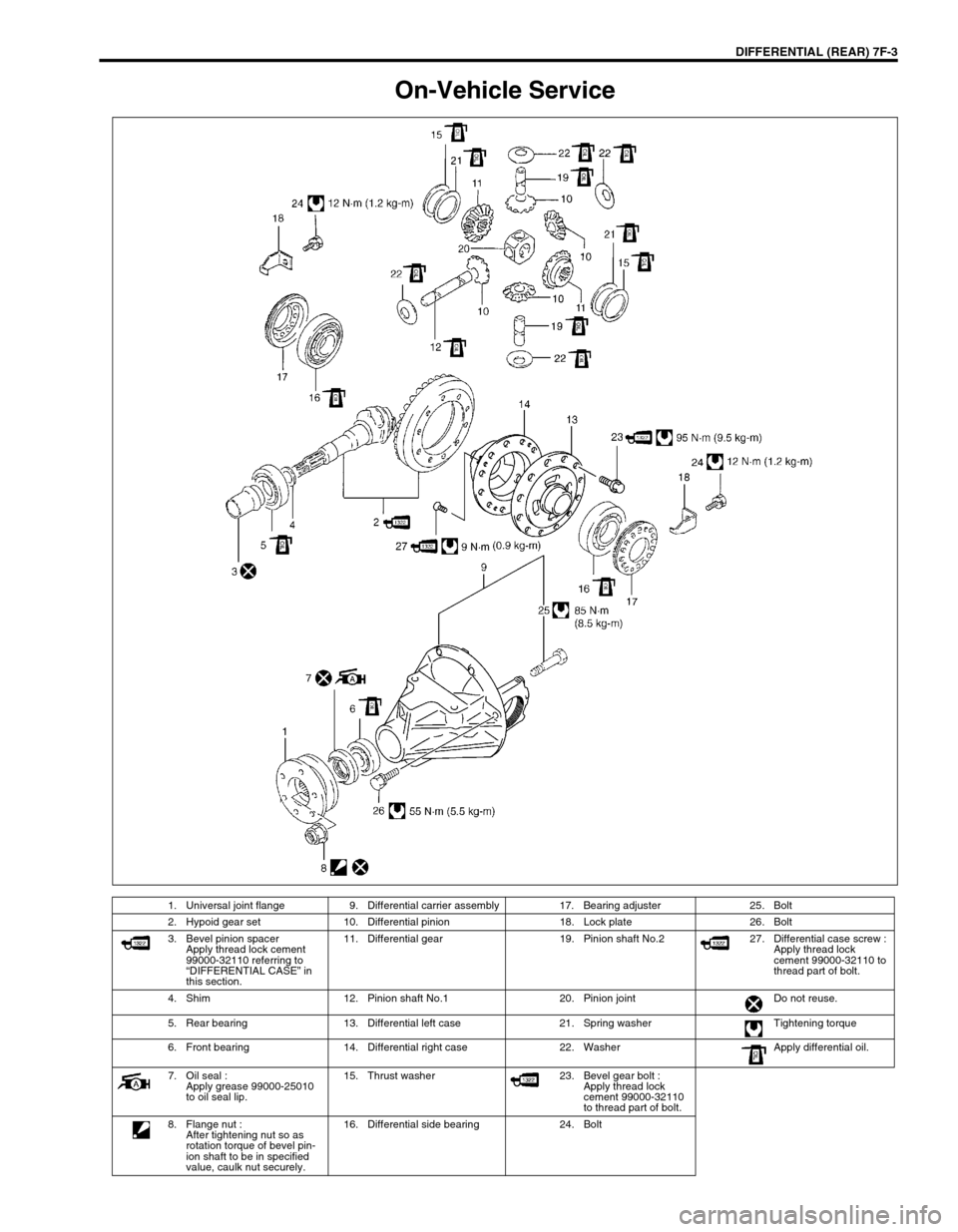

DIFFERENTIAL (REAR) 7F-3

On-Vehicle Service

1. Universal joint flange 9. Differential carrier assembly 17. Bearing adjuster 25. Bolt

2. Hypoid gear set 10. Differential pinion 18. Lock plate 26. Bolt

3. Bevel pinion spacer

Apply thread lock cement

99000-32110 referring to

“DIFFERENTIAL CASE” in

this section.11. Differential gear 19. Pinion shaft No.2 27. Differential case screw :

Apply thread lock

cement 99000-32110 to

thread part of bolt.

4. Shim 12. Pinion shaft No.1 20. Pinion joint Do not reuse.

5. Rear bearing 13. Differential left case 21. Spring washer Tightening torque

6. Front bearing 14. Differential right case 22. Washer Apply differential oil.

7. Oil seal :

Apply grease 99000-25010

to oil seal lip.15. Thrust washer 23. Bevel gear bolt :

Apply thread lock

cement 99000-32110

to thread part of bolt.

8. Flange nut :

After tightening nut so as

rotation torque of bevel pin-

ion shaft to be in specified

value, caulk nut securely.16. Differential side bearing 24. Bolt

Page 494 of 656

DIFFERENTIAL (REAR) 7F-9

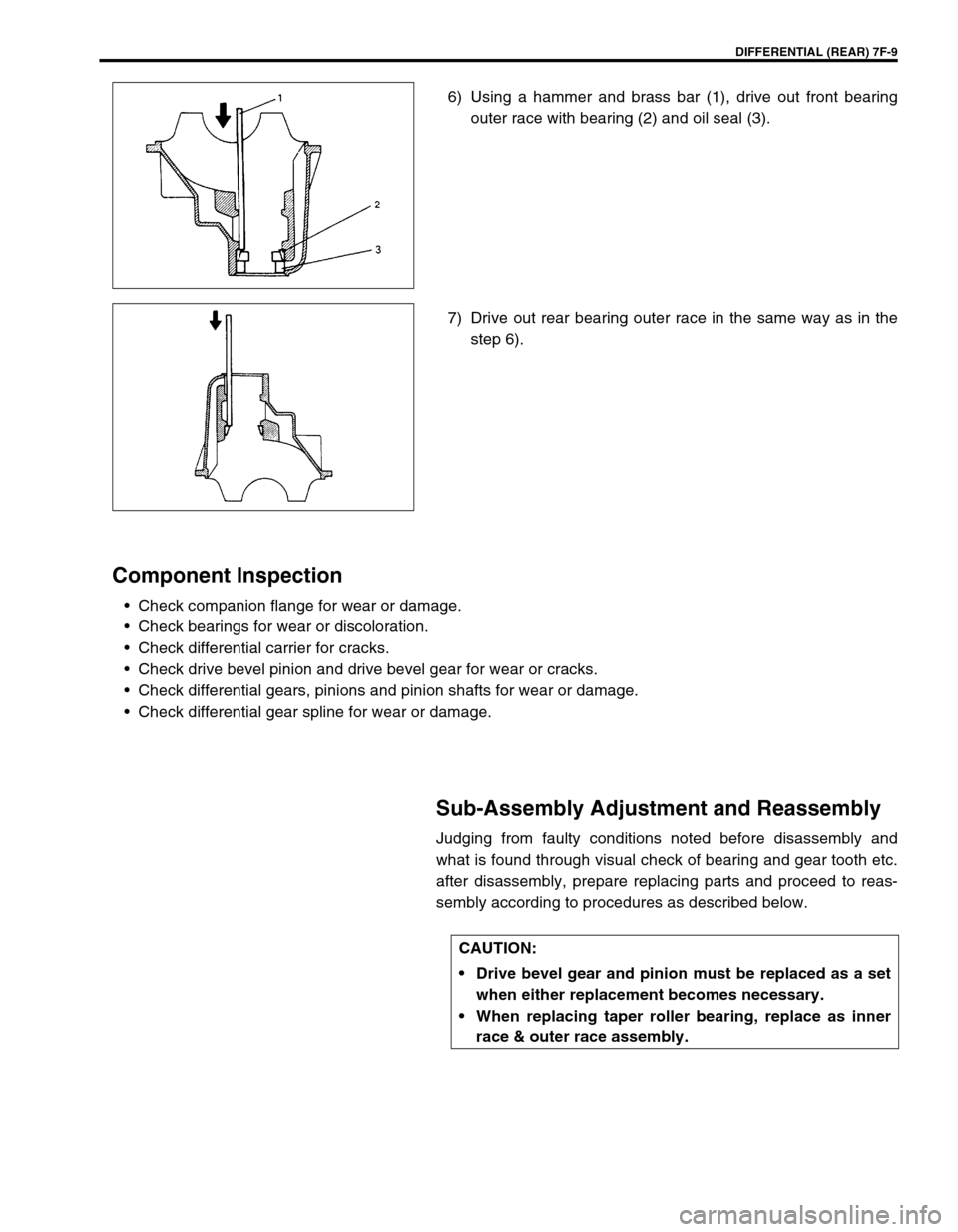

6) Using a hammer and brass bar (1), drive out front bearing

outer race with bearing (2) and oil seal (3).

7) Drive out rear bearing outer race in the same way as in the

step 6).

Component Inspection

•Check companion flange for wear or damage.

•Check bearings for wear or discoloration.

•Check differential carrier for cracks.

•Check drive bevel pinion and drive bevel gear for wear or cracks.

•Check differential gears, pinions and pinion shafts for wear or damage.

•Check differential gear spline for wear or damage.

Sub-Assembly Adjustment and Reassembly

Judging from faulty conditions noted before disassembly and

what is found through visual check of bearing and gear tooth etc.

after disassembly, prepare replacing parts and proceed to reas-

sembly according to procedures as described below.

CAUTION:

Drive bevel gear and pinion must be replaced as a set

when either replacement becomes necessary.

When replacing taper roller bearing, replace as inner

race & outer race assembly.

Page 498 of 656

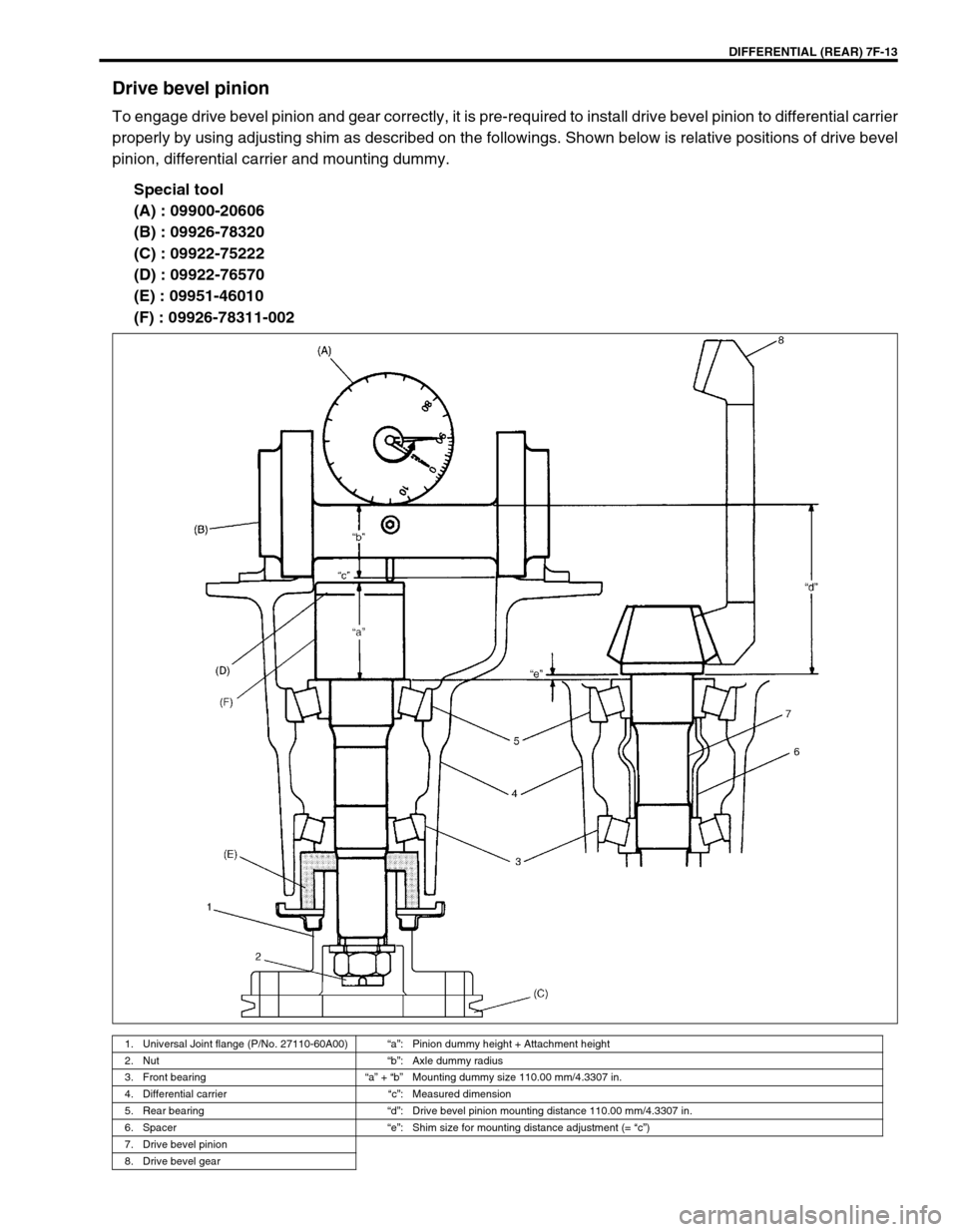

DIFFERENTIAL (REAR) 7F-13

Drive bevel pinion

To engage drive bevel pinion and gear correctly, it is pre-required to install drive bevel pinion to differential carrier

properly by using adjusting shim as described on the followings. Shown below is relative positions of drive bevel

pinion, differential carrier and mounting dummy.

Special tool

(A) : 09900-20606

(B) : 09926-78320

(C) : 09922-75222

(D) : 09922-76570

(E) : 09951-46010

(F) : 09926-78311-002

1. Universal Joint flange (P/No. 27110-60A00)“a”: Pinion dummy height + Attachment height

2. Nut“b”: Axle dummy radius

3. Front bearing“a” + “b”Mounting dummy size 110.00 mm/4.3307 in.

4. Differential carrier“c”: Measured dimension

5. Rear bearing“d”: Drive bevel pinion mounting distance 110.00 mm/4.3307 in.

6. Spacer“e”: Shim size for mounting distance adjustment (= “c”)

7. Drive bevel pinion

8. Drive bevel gear

Page 501 of 656

7F-16 DIFFERENTIAL (REAR)

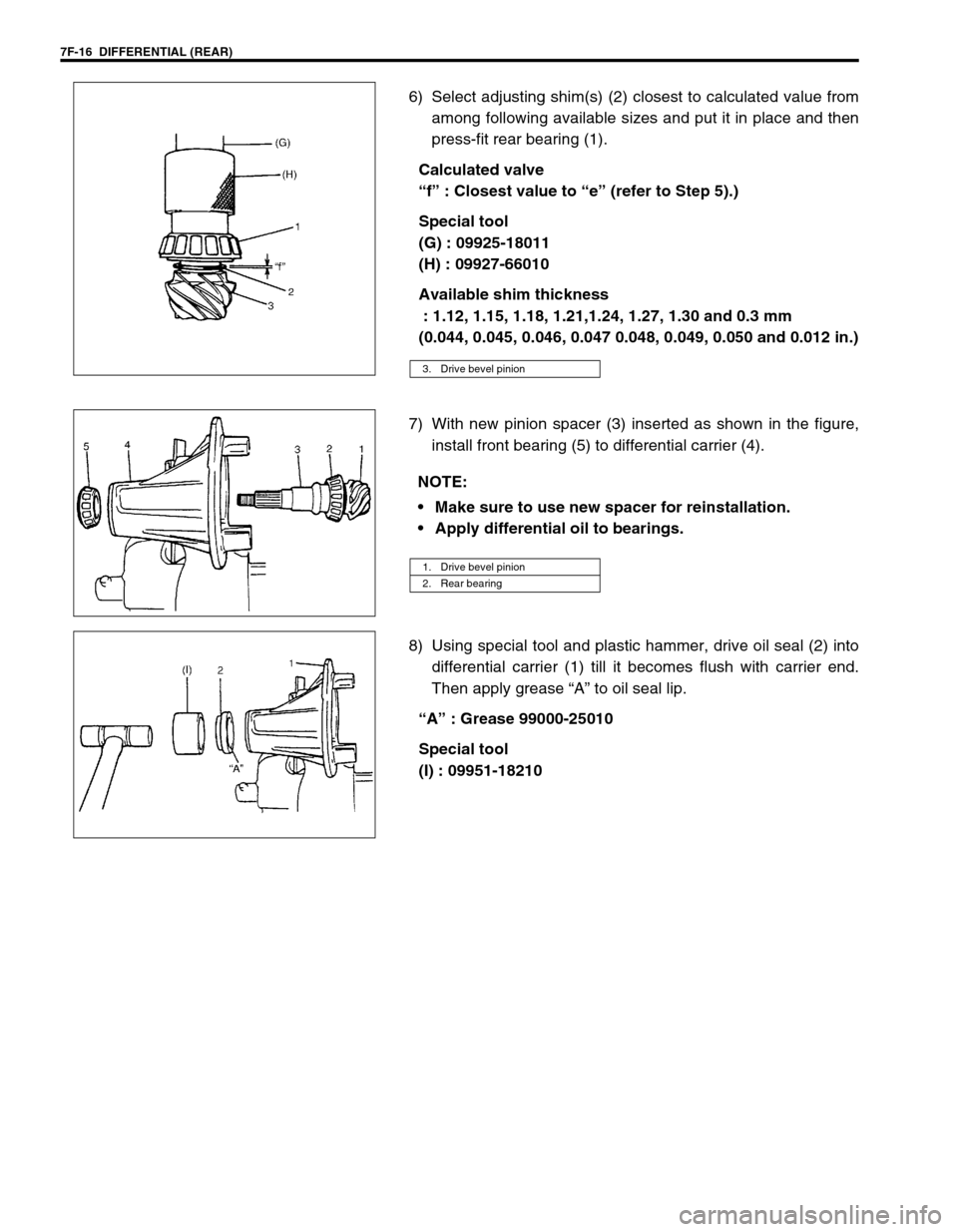

6) Select adjusting shim(s) (2) closest to calculated value from

among following available sizes and put it in place and then

press-fit rear bearing (1).

Calculated valve

“f” : Closest value to “e” (refer to Step 5).)

Special tool

(G) : 09925-18011

(H) : 09927-66010

Available shim thickness

: 1.12, 1.15, 1.18, 1.21,1.24, 1.27, 1.30 and 0.3 mm

(0.044, 0.045, 0.046, 0.047 0.048, 0.049, 0.050 and 0.012 in.)

7) With new pinion spacer (3) inserted as shown in the figure,

install front bearing (5) to differential carrier (4).

8) Using special tool and plastic hammer, drive oil seal (2) into

differential carrier (1) till it becomes flush with carrier end.

Then apply grease “A” to oil seal lip.

“A” : Grease 99000-25010

Special tool

(I) : 09951-18210

3. Drive bevel pinion

NOTE:

Make sure to use new spacer for reinstallation.

Apply differential oil to bearings.

1. Drive bevel pinion

2. Rear bearing

Page 518 of 656

WINDOWS, MIRRORS, SECURITY AND LOCKS 8D-1

8D

SECTION 8D

WINDOWS, MIRRORS, SECURITY AND LOCKS

CONTENTS

General Description ....................................... 8D-2

Rear Wiper and Washer (If Equipped) ......... 8D-2

On-Vehicle Service......................................... 8D-3

Windshield Wipers ....................................... 8D-3

Front wiper and washer ............................ 8D-3Rear Window Wiper and Washer

(For Vehicle with Cruise Control System) .... 8D-4

Rear Wiper and Washer Switch ............... 8D-4

Rear Window Wiper and Washer

(For Vehicle without Cruise Control

System) ........................................................ 8D-4

Rear Wiper Intermittent Relay...................... 8D-4

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

For the descriptions (items) not found in this section, refer to the same section of the Service Manual

mentioned in FOREWORD of this manual.

Page 520 of 656

WINDOWS, MIRRORS, SECURITY AND LOCKS 8D-3

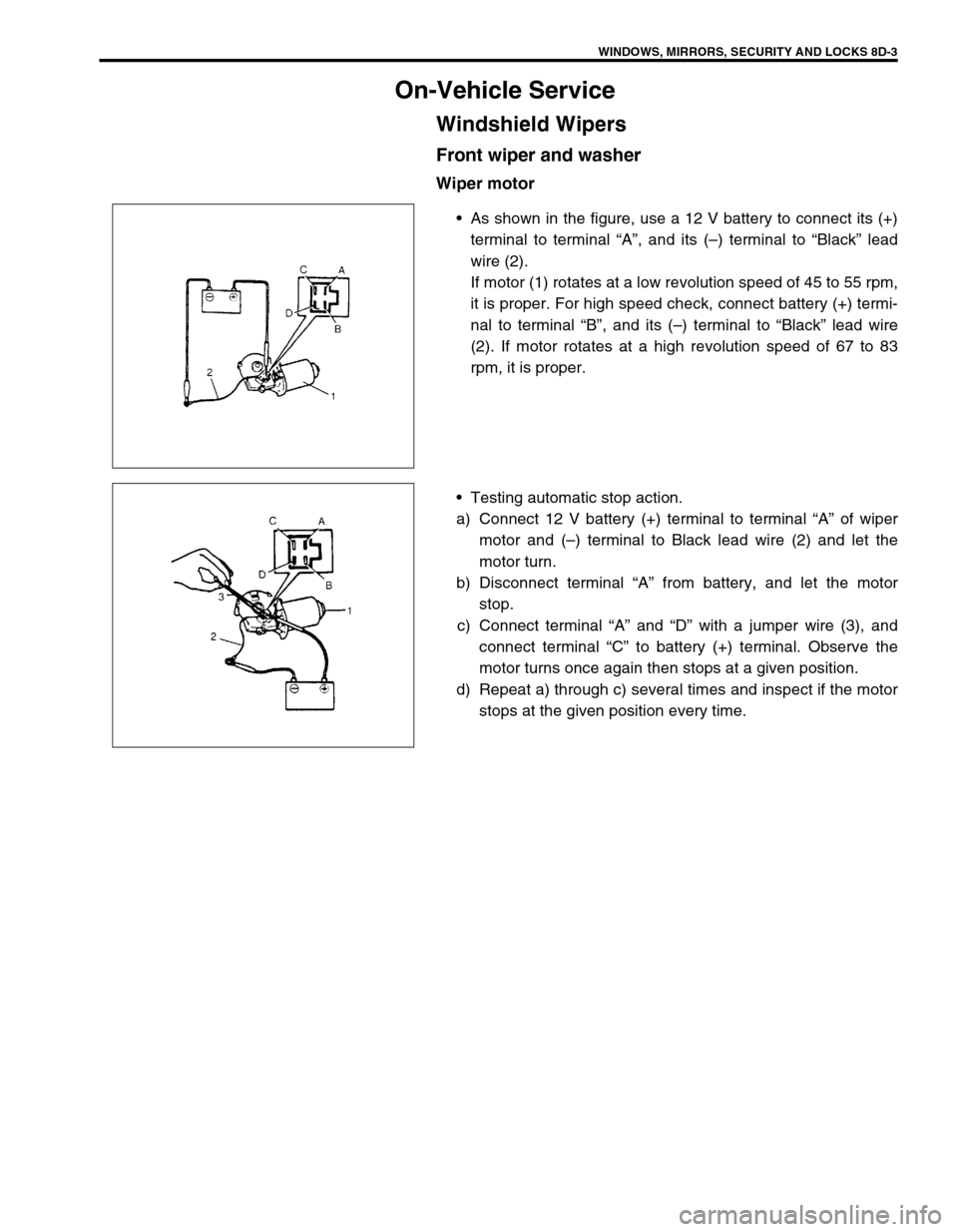

On-Vehicle Service

Windshield Wipers

Front wiper and washer

Wiper motor

•As shown in the figure, use a 12 V battery to connect its (+)

terminal to terminal “A”, and its (–) terminal to “Black” lead

wire (2).

If motor (1) rotates at a low revolution speed of 45 to 55 rpm,

it is proper. For high speed check, connect battery (+) termi-

nal to terminal “B”, and its (–) terminal to “Black” lead wire

(2). If motor rotates at a high revolution speed of 67 to 83

rpm, it is proper.

•Testing automatic stop action.

a) Connect 12 V battery (+) terminal to terminal “A” of wiper

motor and (–) terminal to Black lead wire (2) and let the

motor turn.

b) Disconnect terminal “A” from battery, and let the motor

stop.

c) Connect terminal “A” and “D” with a jumper wire (3), and

connect terminal “C” to battery (+) terminal. Observe the

motor turns once again then stops at a given position.

d) Repeat a) through c) several times and inspect if the motor

stops at the given position every time.

Page 546 of 656

BODY SERVICE 9-1

9

SECTION 9

BODY SERVICE

CONTENTS

Glass, Windows and Mirror .............................. 9-2

Quarter Window .............................................. 9-2

Body Structure .................................................. 9-3

Under Body Dimensions ................................. 9-3

Body Dimensions ............................................ 9-4

Seat..................................................................... 9-8

Second Seat .................................................... 9-8

Third Seat (If Equipped) .................................. 9-9

Paint and Coatings.......................................... 9-10Sealant Application Area............................... 9-10

Undercoating/Anti-corrosion Compound

Application Area ............................................ 9-17

Exterior and Interior Trim ............................... 9-19

Floor Carpet .................................................. 9-19

Front floor carpet ....................................... 9-19

Rear floor carpet (without third seat

vehicle) ...................................................... 9-20

Head Lining ................................................... 9-20

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

When body servicing, if shock may be applied to air bag system component parts, remove those

parts beforehand. (Refer to Section 10B.)

NOTE:

For the descriptions (items) not found in this section, refer to the same section of the Service Man-

ual mentioned in the FOREWORD of this manual.

Fasteners are important attaching parts in that they could affect the performance of vital compo-

nents and systems, and/or could result in major repair expense. They must be replaced with one of

the same part number of with an equivalent part if replacement becomes necessary.

Do not use a replacement part of lesser quality or substitute a design. Torque values must be used

as specified during reassembly to assure proper retention of these parts.

Page 547 of 656

9-2 BODY SERVICE

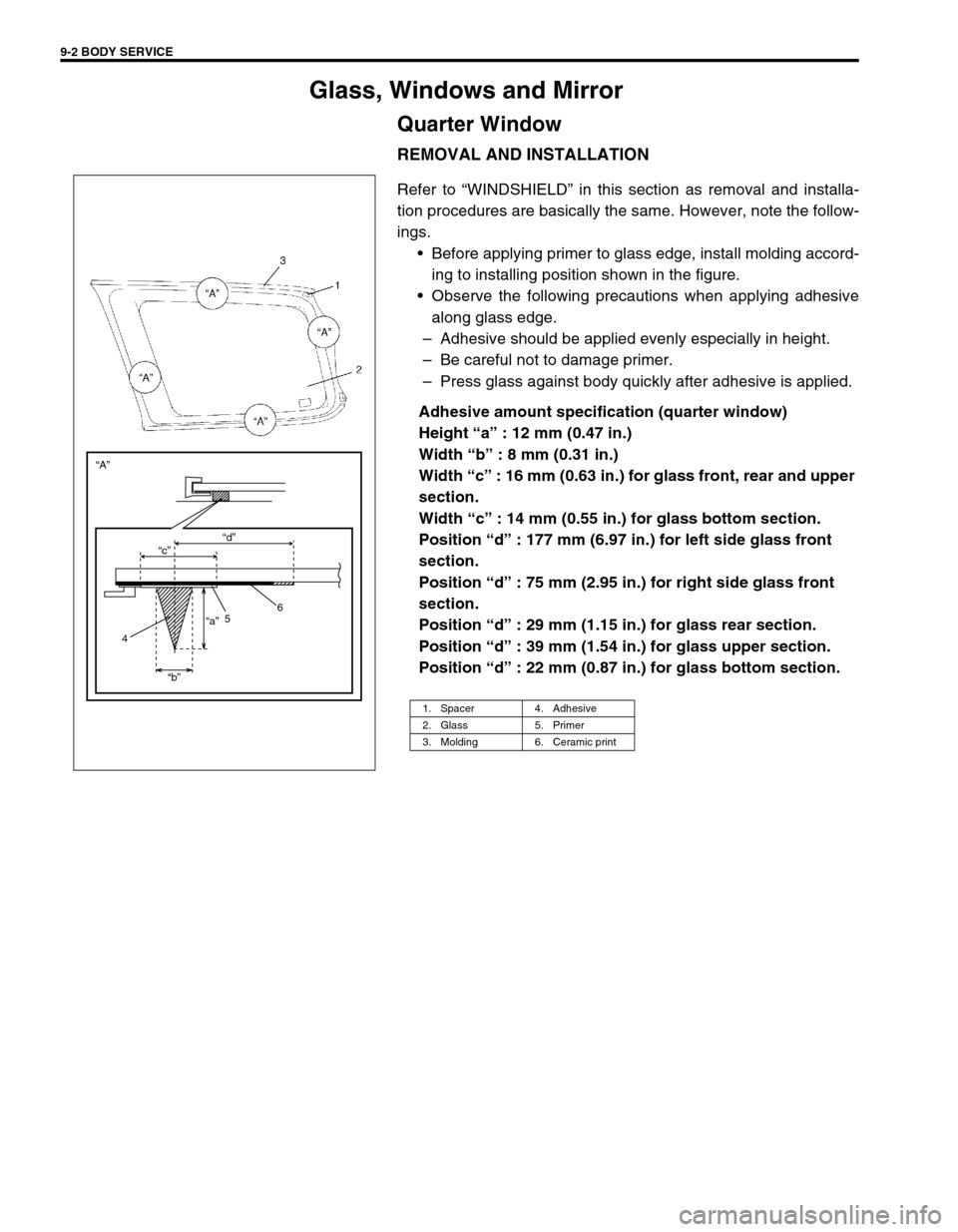

Glass, Windows and Mirror

Quarter Window

REMOVAL AND INSTALLATION

Refer to “WINDSHIELD” in this section as removal and installa-

tion procedures are basically the same. However, note the follow-

ings.

•Before applying primer to glass edge, install molding accord-

ing to installing position shown in the figure.

•Observe the following precautions when applying adhesive

along glass edge.

–Adhesive should be applied evenly especially in height.

–Be careful not to damage primer.

–Press glass against body quickly after adhesive is applied.

Adhesive amount specification (quarter window)

Height “a” : 12 mm (0.47 in.)

Width “b” : 8 mm (0.31 in.)

Width “c” : 16 mm (0.63 in.) for glass front, rear and upper

section.

Width “c” : 14 mm (0.55 in.) for glass bottom section.

Position “d” : 177 mm (6.97 in.) for left side glass front

section.

Position “d” : 75 mm (2.95 in.) for right side glass front

section.

Position “d” : 29 mm (1.15 in.) for glass rear section.

Position “d” : 39 mm (1.54 in.) for glass upper section.

Position “d” : 22 mm (0.87 in.) for glass bottom section.

1. Spacer 4. Adhesive

2. Glass 5. Primer

3. Molding 6. Ceramic print

“c” “A”

“a”

“b”“d”

6

5

4

Page 548 of 656

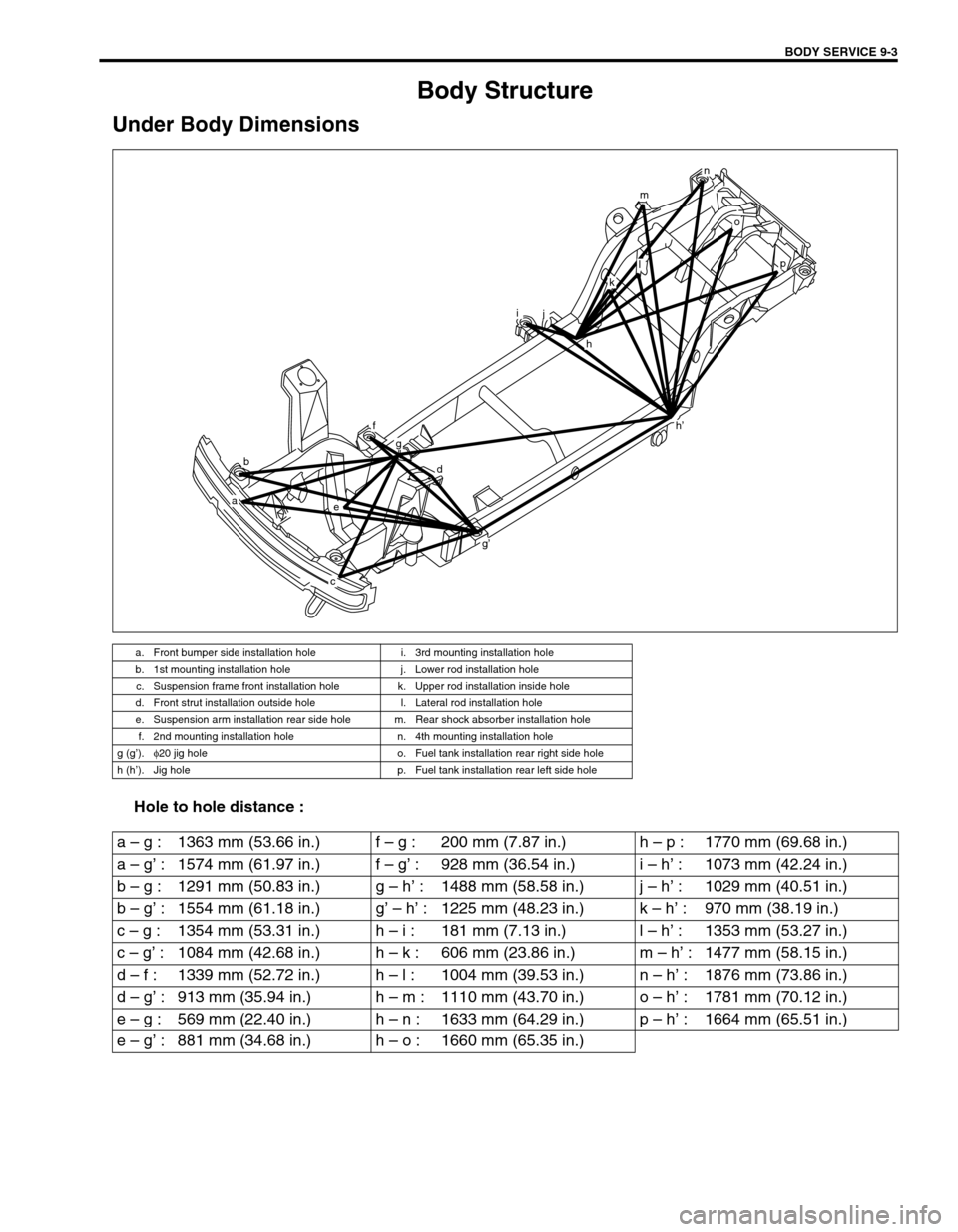

BODY SERVICE 9-3

Body Structure

Under Body Dimensions

Hole to hole distance :

a. Front bumper side installation hole i. 3rd mounting installation hole

b. 1st mounting installation hole j. Lower rod installation hole

c. Suspension frame front installation hole k. Upper rod installation inside hole

d. Front strut installation outside hole l. Lateral rod installation hole

e. Suspension arm installation rear side hole m. Rear shock absorber installation hole

f. 2nd mounting installation hole n. 4th mounting installation hole

g (g’).φ

20 jig hole o. Fuel tank installation rear right side hole

h (h’). Jig hole p. Fuel tank installation rear left side hole

b

a

h’

e

f

g

d

g’

c

ij

h

o

p

n

m

l

k

a – g : 1363 mm (53.66 in.) f – g : 200 mm (7.87 in.) h – p : 1770 mm (69.68 in.)

a – g’ : 1574 mm (61.97 in.) f – g’ : 928 mm (36.54 in.) i – h’ : 1073 mm (42.24 in.)

b – g : 1291 mm (50.83 in.) g – h’ : 1488 mm (58.58 in.) j – h’ : 1029 mm (40.51 in.)

b – g’ : 1554 mm (61.18 in.) g’ – h’ : 1225 mm (48.23 in.) k – h’ : 970 mm (38.19 in.)

c – g : 1354 mm (53.31 in.) h – i : 181 mm (7.13 in.) l – h’ : 1353 mm (53.27 in.)

c – g’ : 1084 mm (42.68 in.) h – k : 606 mm (23.86 in.) m – h’ : 1477 mm (58.15 in.)

d – f : 1339 mm (52.72 in.) h – l : 1004 mm (39.53 in.) n – h’ : 1876 mm (73.86 in.)

d – g’ : 913 mm (35.94 in.) h – m : 1110 mm (43.70 in.) o – h’ : 1781 mm (70.12 in.)

e – g : 569 mm (22.40 in.) h – n : 1633 mm (64.29 in.) p – h’ : 1664 mm (65.51 in.)

e – g’ : 881 mm (34.68 in.) h – o : 1660 mm (65.35 in.)

Page 549 of 656

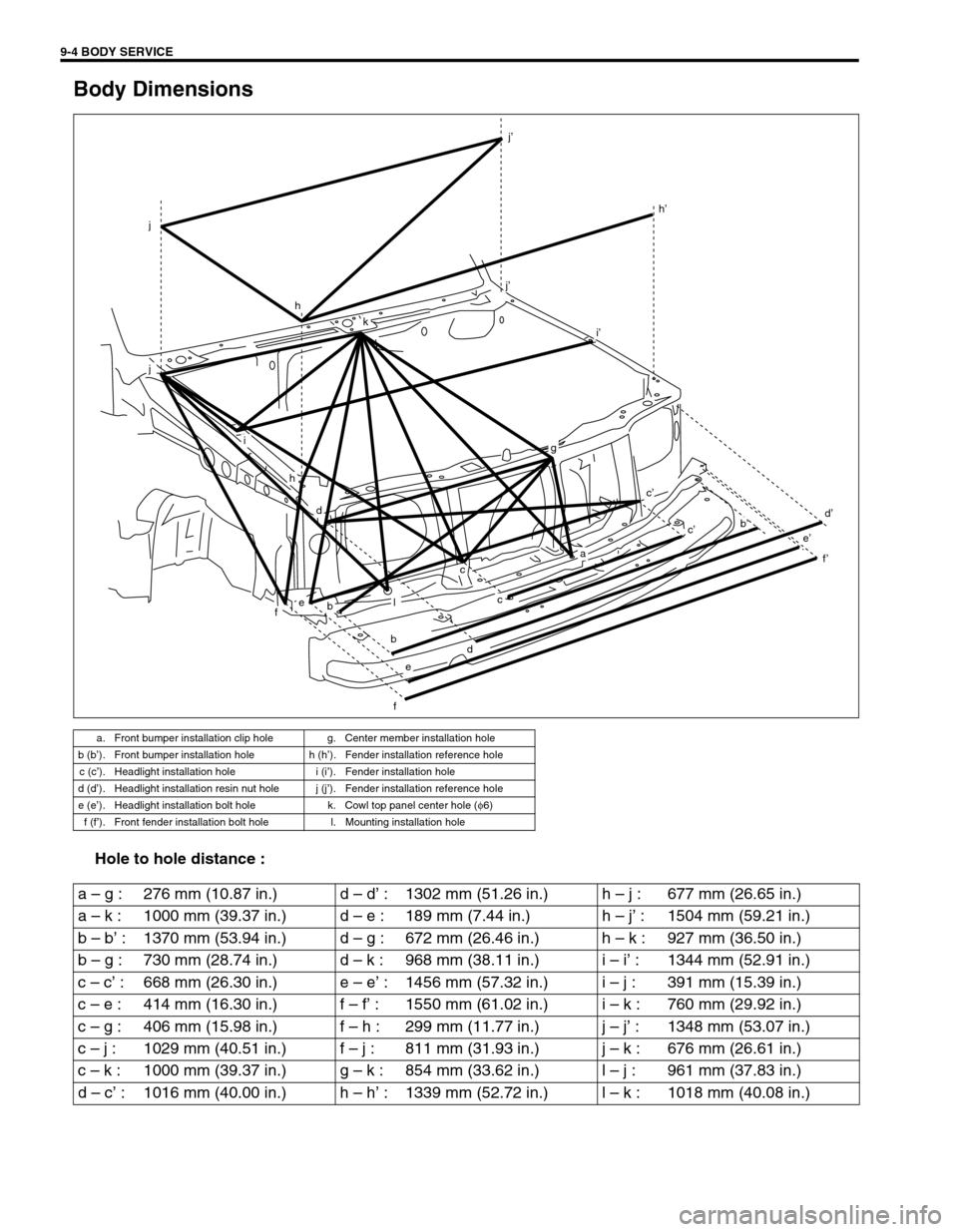

9-4 BODY SERVICE

Body Dimensions

Hole to hole distance :

a. Front bumper installation clip hole g. Center member installation hole

b (b’). Front bumper installation hole h (h’). Fender installation reference hole

c (c’). Headlight installation hole i (i’). Fender installation hole

d (d’). Headlight installation resin nut hole j (j’). Fender installation reference hole

e (e’). Headlight installation bolt hole k. Cowl top panel center hole (φ

6)

f (f’). Front fender installation bolt hole l. Mounting installation hole

k

j’

j’

h’

j

j

i

h

h

febl

c

c

g

a

c’

i’

db’c’

d’

f’

e’

f

e

bd

a – g : 276 mm (10.87 in.) d – d’ : 1302 mm (51.26 in.) h – j : 677 mm (26.65 in.)

a – k : 1000 mm (39.37 in.) d – e : 189 mm (7.44 in.) h – j’ : 1504 mm (59.21 in.)

b – b’ : 1370 mm (53.94 in.) d – g : 672 mm (26.46 in.) h – k : 927 mm (36.50 in.)

b – g : 730 mm (28.74 in.) d – k : 968 mm (38.11 in.) i – i’ : 1344 mm (52.91 in.)

c – c’ : 668 mm (26.30 in.) e – e’ : 1456 mm (57.32 in.) i – j : 391 mm (15.39 in.)

c – e : 414 mm (16.30 in.) f – f’ : 1550 mm (61.02 in.) i – k : 760 mm (29.92 in.)

c – g : 406 mm (15.98 in.) f – h : 299 mm (11.77 in.) j – j’ : 1348 mm (53.07 in.)

c – j : 1029 mm (40.51 in.) f – j : 811 mm (31.93 in.) j – k : 676 mm (26.61 in.)

c – k : 1000 mm (39.37 in.) g – k : 854 mm (33.62 in.) l – j : 961 mm (37.83 in.)

d – c’ : 1016 mm (40.00 in.) h – h’ : 1339 mm (52.72 in.) l – k : 1018 mm (40.08 in.)