Section 8a SUZUKI GRAND VITARA 2001 2.G Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 536 of 656

CRUISE CONTROL SYSTEM 8E-15

Throttle Valve Opening Signal Circuit Check

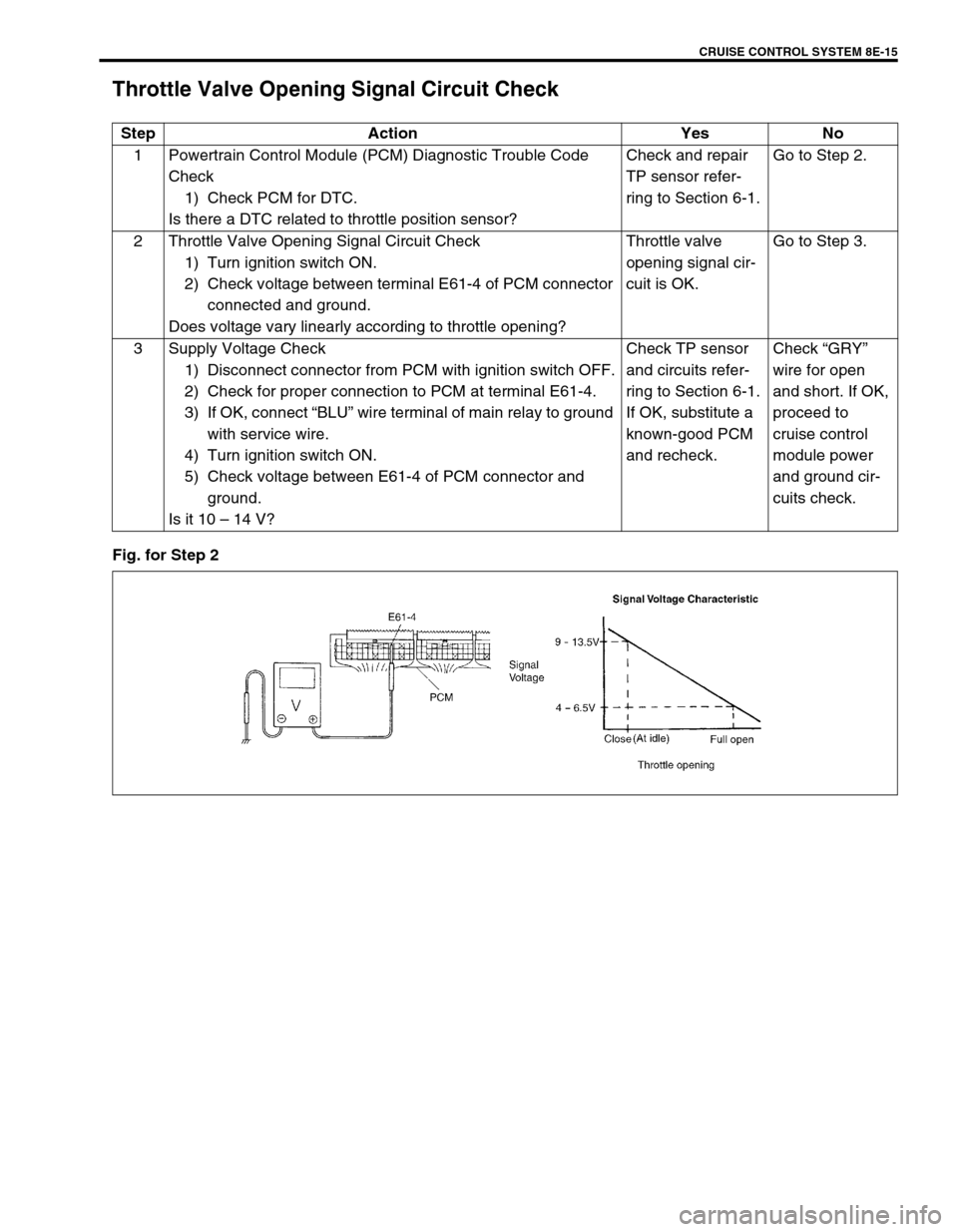

Fig. for Step 2Step Action Yes No

1 Powertrain Control Module (PCM) Diagnostic Trouble Code

Check

1) Check PCM for DTC.

Is there a DTC related to throttle position sensor?Check and repair

TP sensor refer-

ring to Section 6-1.Go to Step 2.

2 Throttle Valve Opening Signal Circuit Check

1) Turn ignition switch ON.

2) Check voltage between terminal E61-4 of PCM connector

connected and ground.

Does voltage vary linearly according to throttle opening?Throttle valve

opening signal cir-

cuit is OK.Go to Step 3.

3 Supply Voltage Check

1) Disconnect connector from PCM with ignition switch OFF.

2) Check for proper connection to PCM at terminal E61-4.

3) If OK, connect “BLU” wire terminal of main relay to ground

with service wire.

4) Turn ignition switch ON.

5) Check voltage between E61-4 of PCM connector and

ground.

Is it 10 – 14 V?Check TP sensor

and circuits refer-

ring to Section 6-1.

If OK, substitute a

known-good PCM

and recheck.Check “GRY”

wire for open

and short. If OK,

proceed to

cruise control

module power

and ground cir-

cuits check.

Page 538 of 656

CRUISE CONTROL SYSTEM 8E-17

Cruise Control Module and Its Circuit Inspection

VOLTAGE CHECK

Check for input or output voltage of control module (voltage between each circuit and body ground) with cruise

control module connector connected.CAUTION:

Cruise control module can not be checked by itself. It is strictly prohibited to connect voltmeter or

ohmmeter to cruise control module with coupler disconnected from it.

CIRCUIT NORMAL

VOLTAGECONDITION

Vehicle speed sensor Indicator deflection

repeated between

0 – 1 V and 3 – 5 VIgnition switch ON and cruise main switch ON. Vehicle

hoisted and rear left tire turned slowly with rear right

tire locked.

Stop lamp switch 0 – 2 V Brake pedal released.

10 – 14 V Brake pedal depressed.

Overdrive and TCC off signal

(4 A/T only) 10 – 14 V Ignition switch ON.

CRUISE indicator light 10 – 14 V Ignition switch ON.

Ground––

Brake pedal position switch

(in stop lamp switch) 10 – 14 V Ignition switch ON and brake pedal released.

0 V Ignition switch ON and brake pedal depressed.

Throttle valve opening signal

from PCM (4A/T only)Ignition switch ON.

Voltage varies as specified by graph in “THROTTLE VALVE OPENING SIG-

NAL CIRCUIT CHECK” in this section.

Cruise main switch 7 – 9V Ignition switch ON and cruise main switch released.

3 – 5 V Ignition switch ON and cruise main switch pressed.

CANCEL switch 0 – 1 V Ignition switch ON and CANCEL switch pressed.

COAST SET switch 1 – 2 V Ignition switch ON and COAST SET switch rotated.

RESUME ACCEL switch 2.5 – 4 V Ignition switch ON and RESUME ACCEL switch

rotated.

Clutch pedal position switch

(M/T only)10 – 14 V Ignition switch ON and clutch pedal released.

0 – 1 V Ignition switch ON and clutch pedal depressed fully.

Transmission range switch

(Park/Neutral position switch)

(A/T only)0 V Ignition switch ON and selector lever in “P” or “N”

range.

10 – 14 V Ignition switch ON and selector lever in “R”, “D”, “2” or

“L” range.

Cruise main switch indicator

lamp0 – 1 V Ignition switch ON.

10 – 14 V Ignition switch ON and after input main switch ON sig-

nal.

Page 541 of 656

8E-20 CRUISE CONTROL SYSTEM

Coast/Set, Resume/Accel and Cancel

Switches

These switches are built in the combination switch assembly.

REMOVAL AND INSTALLATION

Refer to “COMBINATION SWITCH” in Section 3C1.

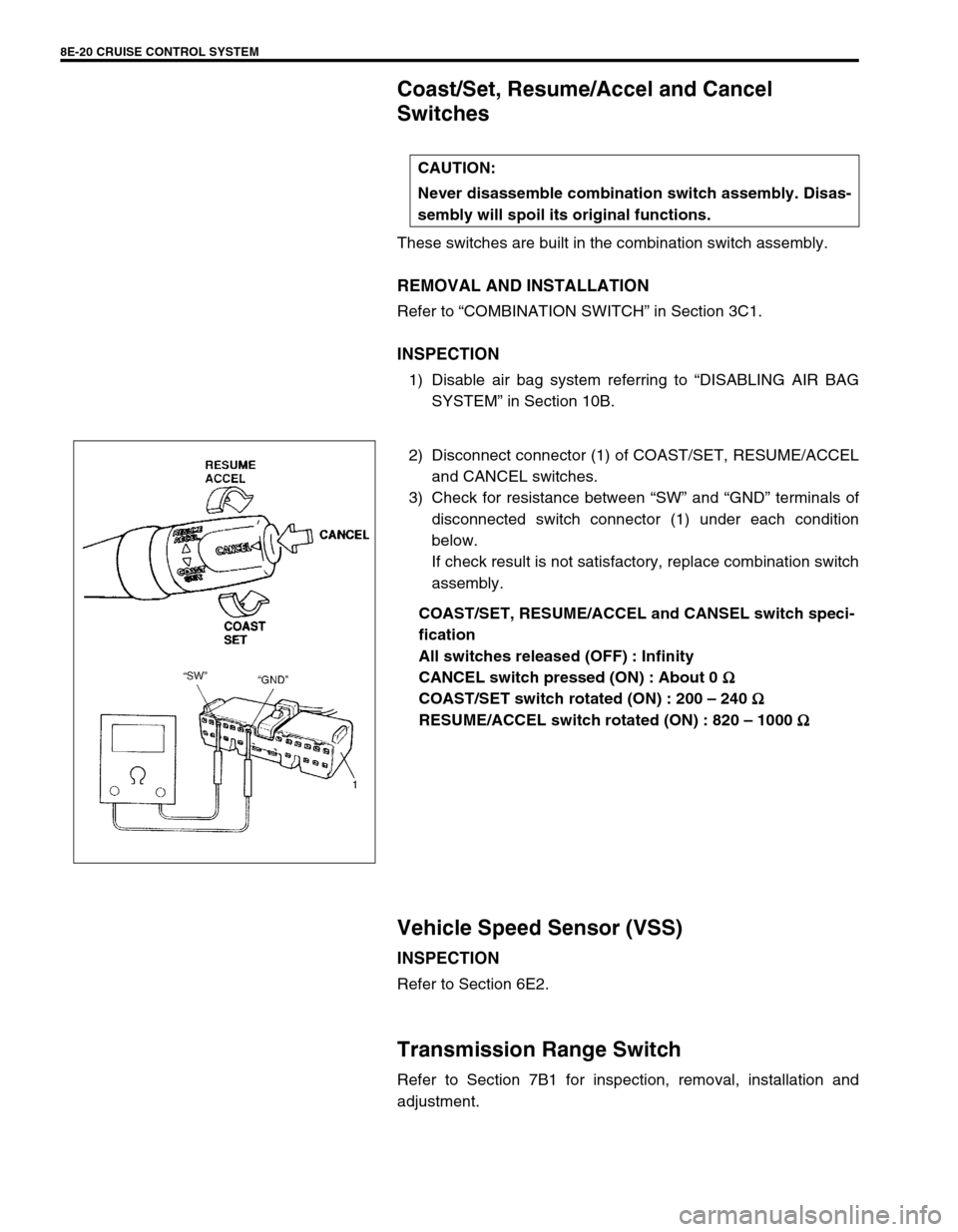

INSPECTION

1) Disable air bag system referring to “DISABLING AIR BAG

SYSTEM” in Section 10B.

2) Disconnect connector (1) of COAST/SET, RESUME/ACCEL

and CANCEL switches.

3) Check for resistance between “SW” and “GND” terminals of

disconnected switch connector (1) under each condition

below.

If check result is not satisfactory, replace combination switch

assembly.

COAST/SET, RESUME/ACCEL and CANSEL switch speci-

fication

All switches released (OFF) : Infinity

CANCEL switch pressed (ON) : About 0 Ω

ΩΩ Ω

COAST/SET switch rotated (ON) : 200 – 240 Ω

ΩΩ Ω

RESUME/ACCEL switch rotated (ON) : 820 – 1000 Ω

ΩΩ Ω

Vehicle Speed Sensor (VSS)

INSPECTION

Refer to Section 6E2.

Transmission Range Switch

Refer to Section 7B1 for inspection, removal, installation and

adjustment.CAUTION:

Never disassemble combination switch assembly. Disas-

sembly will spoil its original functions.

Page 543 of 656

8E-22 CRUISE CONTROL SYSTEM

Stop Lamp Switch (with Pedal Position

Switch)

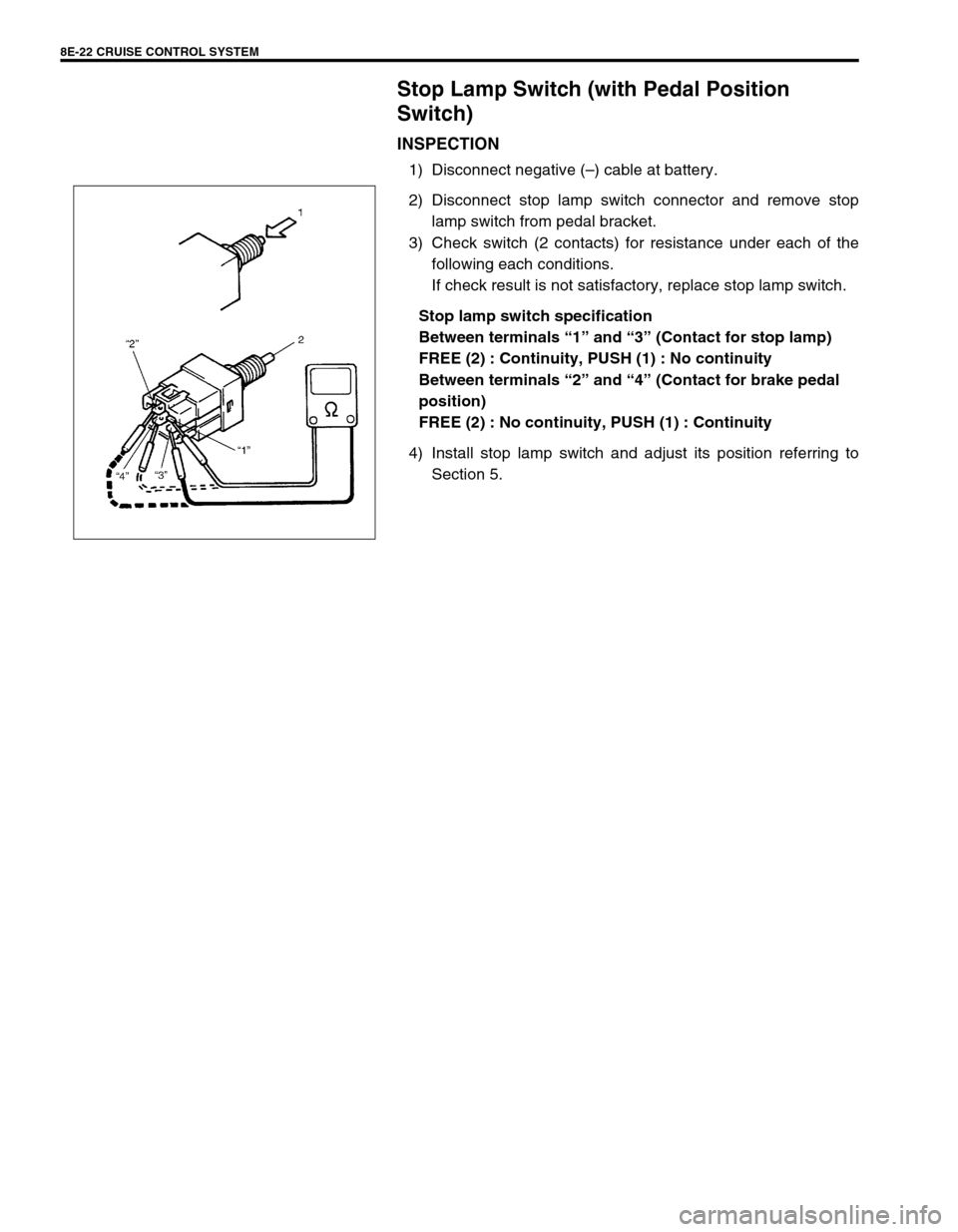

INSPECTION

1) Disconnect negative (–) cable at battery.

2) Disconnect stop lamp switch connector and remove stop

lamp switch from pedal bracket.

3) Check switch (2 contacts) for resistance under each of the

following each conditions.

If check result is not satisfactory, replace stop lamp switch.

Stop lamp switch specification

Between terminals “1” and “3” (Contact for stop lamp)

FREE (2) : Continuity, PUSH (1) : No continuity

Between terminals “2” and “4” (Contact for brake pedal

position)

FREE (2) : No continuity, PUSH (1) : Continuity

4) Install stop lamp switch and adjust its position referring to

Section 5.

Page 544 of 656

CRUISE CONTROL SYSTEM 8E-23

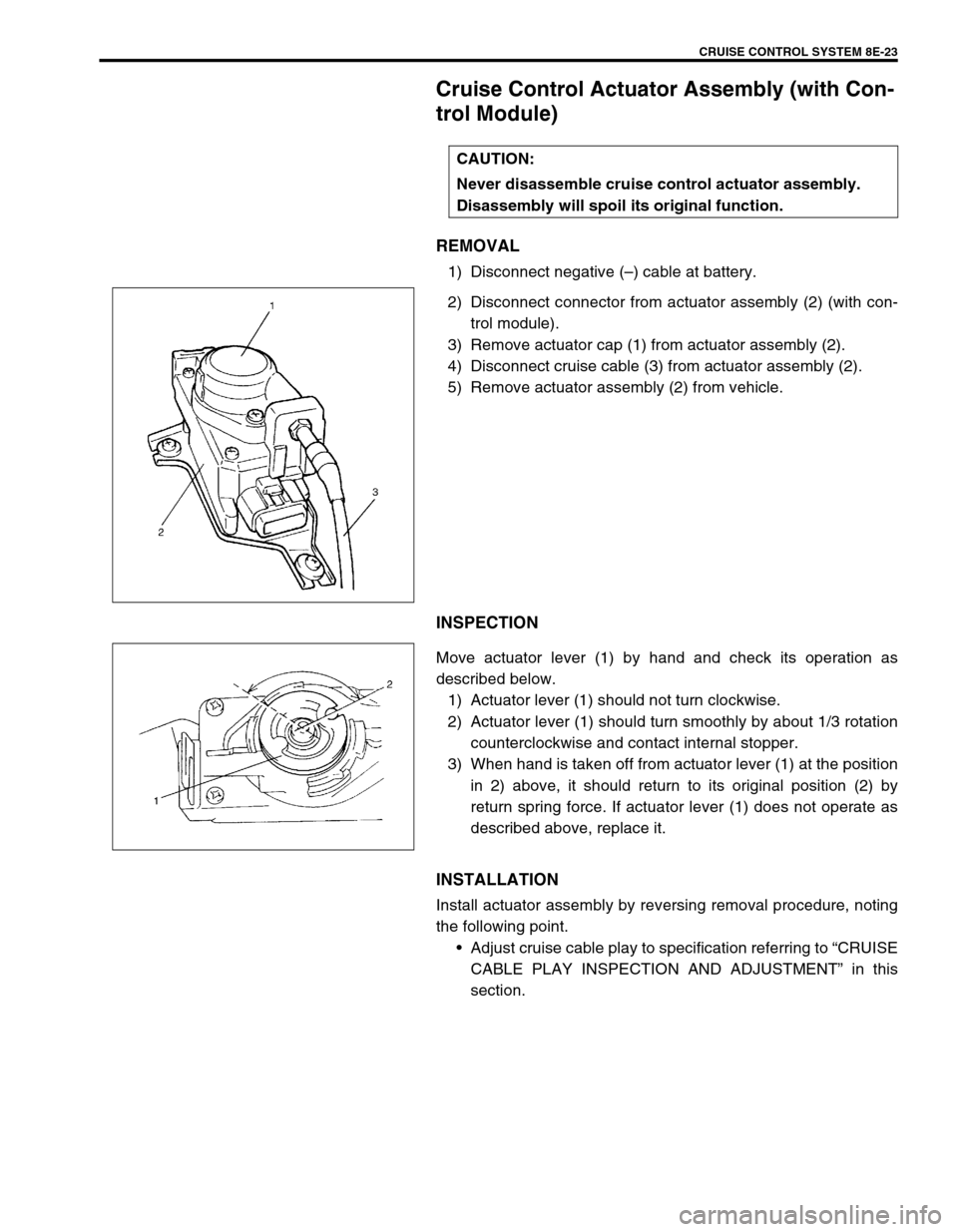

Cruise Control Actuator Assembly (with Con-

trol Module)

REMOVAL

1) Disconnect negative (–) cable at battery.

2) Disconnect connector from actuator assembly (2) (with con-

trol module).

3) Remove actuator cap (1) from actuator assembly (2).

4) Disconnect cruise cable (3) from actuator assembly (2).

5) Remove actuator assembly (2) from vehicle.

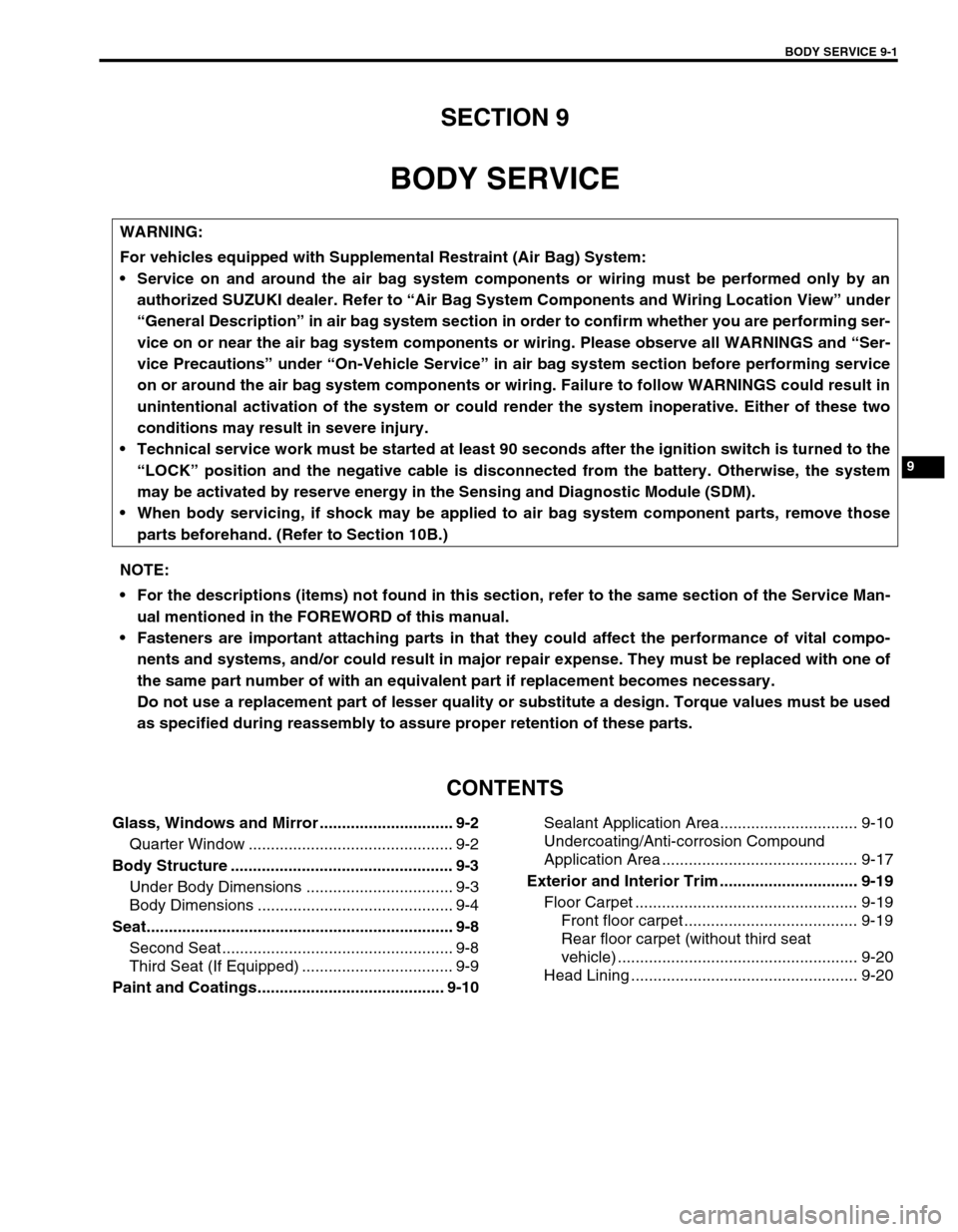

INSPECTION

Move actuator lever (1) by hand and check its operation as

described below.

1) Actuator lever (1) should not turn clockwise.

2) Actuator lever (1) should turn smoothly by about 1/3 rotation

counterclockwise and contact internal stopper.

3) When hand is taken off from actuator lever (1) at the position

in 2) above, it should return to its original position (2) by

return spring force. If actuator lever (1) does not operate as

described above, replace it.

INSTALLATION

Install actuator assembly by reversing removal procedure, noting

the following point.

•Adjust cruise cable play to specification referring to “CRUISE

CABLE PLAY INSPECTION AND ADJUSTMENT” in this

section. CAUTION:

Never disassemble cruise control actuator assembly.

Disassembly will spoil its original function.

Page 545 of 656

8E-24 CRUISE CONTROL SYSTEM

Cruise Cable

REMOVAL

1) Disconnect cruise cable from cruise control arm and accelerator bracket.

2) Remove actuator cap and disconnect cruise cable from actuator.

3) Release cable from all clamps.

4) Remove cable from vehicle.

INSTALLATION

Install cruise cable by reversing removal procedure, noting the following points.

•Refer to the figure for proper clamp location and cable routing.

•Adjust cable play to specification referring to “CRUISE CABLE PLAY INSPECTION AND ADJUSTMENT” in

this section.

1. Actuator cap 4. Cruise cable 7. Clamp at member

2. Actuator assembly 5. Clamp 8. Accelerator pedal

3. Screw 6. Grommet 9. Member

Page 546 of 656

BODY SERVICE 9-1

9

SECTION 9

BODY SERVICE

CONTENTS

Glass, Windows and Mirror .............................. 9-2

Quarter Window .............................................. 9-2

Body Structure .................................................. 9-3

Under Body Dimensions ................................. 9-3

Body Dimensions ............................................ 9-4

Seat..................................................................... 9-8

Second Seat .................................................... 9-8

Third Seat (If Equipped) .................................. 9-9

Paint and Coatings.......................................... 9-10Sealant Application Area............................... 9-10

Undercoating/Anti-corrosion Compound

Application Area ............................................ 9-17

Exterior and Interior Trim ............................... 9-19

Floor Carpet .................................................. 9-19

Front floor carpet ....................................... 9-19

Rear floor carpet (without third seat

vehicle) ...................................................... 9-20

Head Lining ................................................... 9-20

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

When body servicing, if shock may be applied to air bag system component parts, remove those

parts beforehand. (Refer to Section 10B.)

NOTE:

For the descriptions (items) not found in this section, refer to the same section of the Service Man-

ual mentioned in the FOREWORD of this manual.

Fasteners are important attaching parts in that they could affect the performance of vital compo-

nents and systems, and/or could result in major repair expense. They must be replaced with one of

the same part number of with an equivalent part if replacement becomes necessary.

Do not use a replacement part of lesser quality or substitute a design. Torque values must be used

as specified during reassembly to assure proper retention of these parts.

Page 547 of 656

9-2 BODY SERVICE

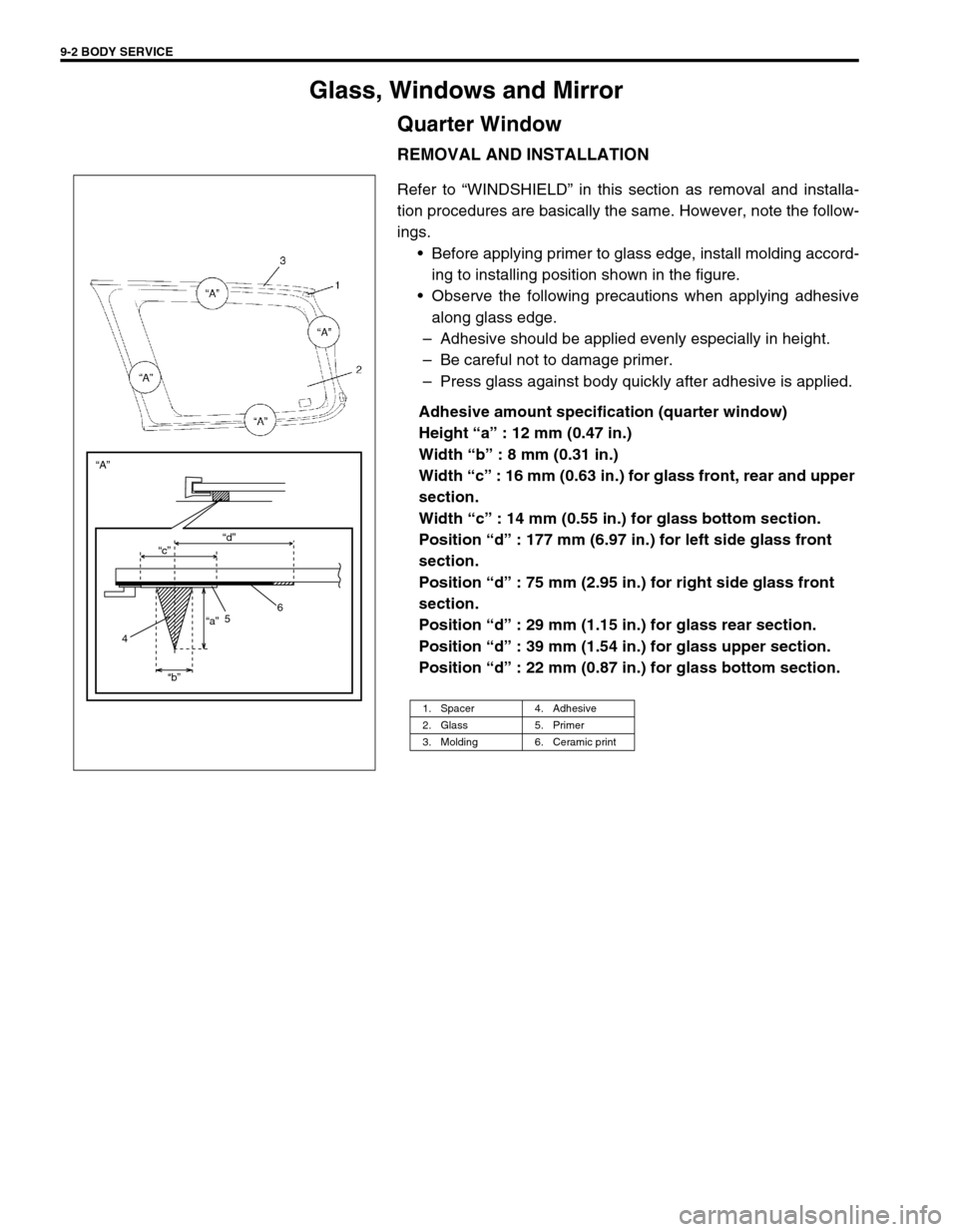

Glass, Windows and Mirror

Quarter Window

REMOVAL AND INSTALLATION

Refer to “WINDSHIELD” in this section as removal and installa-

tion procedures are basically the same. However, note the follow-

ings.

•Before applying primer to glass edge, install molding accord-

ing to installing position shown in the figure.

•Observe the following precautions when applying adhesive

along glass edge.

–Adhesive should be applied evenly especially in height.

–Be careful not to damage primer.

–Press glass against body quickly after adhesive is applied.

Adhesive amount specification (quarter window)

Height “a” : 12 mm (0.47 in.)

Width “b” : 8 mm (0.31 in.)

Width “c” : 16 mm (0.63 in.) for glass front, rear and upper

section.

Width “c” : 14 mm (0.55 in.) for glass bottom section.

Position “d” : 177 mm (6.97 in.) for left side glass front

section.

Position “d” : 75 mm (2.95 in.) for right side glass front

section.

Position “d” : 29 mm (1.15 in.) for glass rear section.

Position “d” : 39 mm (1.54 in.) for glass upper section.

Position “d” : 22 mm (0.87 in.) for glass bottom section.

1. Spacer 4. Adhesive

2. Glass 5. Primer

3. Molding 6. Ceramic print

“c” “A”

“a”

“b”“d”

6

5

4

Page 550 of 656

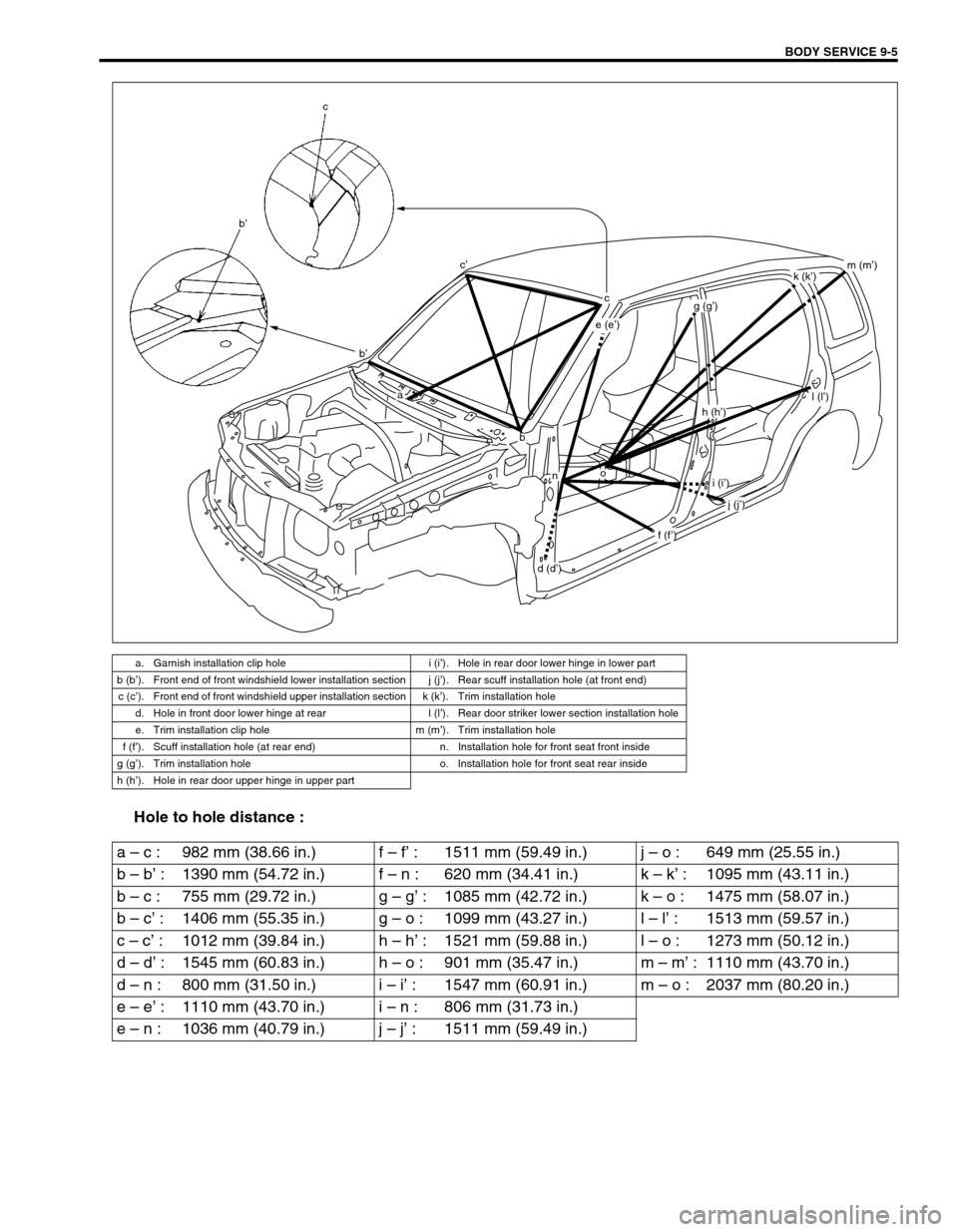

BODY SERVICE 9-5

Hole to hole distance :

a. Garnish installation clip hole i (i’). Hole in rear door lower hinge in lower part

b (b’). Front end of front windshield lower installation section j (j’). Rear scuff installation hole (at front end)

c (c’). Front end of front windshield upper installation section k (k’). Trim installation hole

d. Hole in front door lower hinge at rear l (l’). Rear door striker lower section installation hole

e. Trim installation clip hole m (m’). Trim installation hole

f (f’). Scuff installation hole (at rear end) n. Installation hole for front seat front inside

g (g’). Trim installation hole o. Installation hole for front seat rear inside

h (h’). Hole in rear door upper hinge in upper part

c

b’

c’

b’

a

b

on

e (e’)

cg (g’)

h (h’)

i (i’)

j (j’)

l (l’)

m (m’)k (k’)

f (f’)

d (d’)

a – c : 982 mm (38.66 in.) f – f’ : 1511 mm (59.49 in.) j – o : 649 mm (25.55 in.)

b – b’ : 1390 mm (54.72 in.) f – n : 620 mm (34.41 in.) k – k’ : 1095 mm (43.11 in.)

b – c : 755 mm (29.72 in.) g – g’ : 1085 mm (42.72 in.) k – o : 1475 mm (58.07 in.)

b – c’ : 1406 mm (55.35 in.) g – o : 1099 mm (43.27 in.) l – l’ : 1513 mm (59.57 in.)

c – c’ : 1012 mm (39.84 in.) h – h’ : 1521 mm (59.88 in.) l – o : 1273 mm (50.12 in.)

d – d’ : 1545 mm (60.83 in.) h – o : 901 mm (35.47 in.) m – m’ : 1110 mm (43.70 in.)

d – n : 800 mm (31.50 in.) i – i’ : 1547 mm (60.91 in.) m – o : 2037 mm (80.20 in.)

e – e’ : 1110 mm (43.70 in.) i – n : 806 mm (31.73 in.)

e – n : 1036 mm (40.79 in.) j – j’ : 1511 mm (59.49 in.)

Page 551 of 656

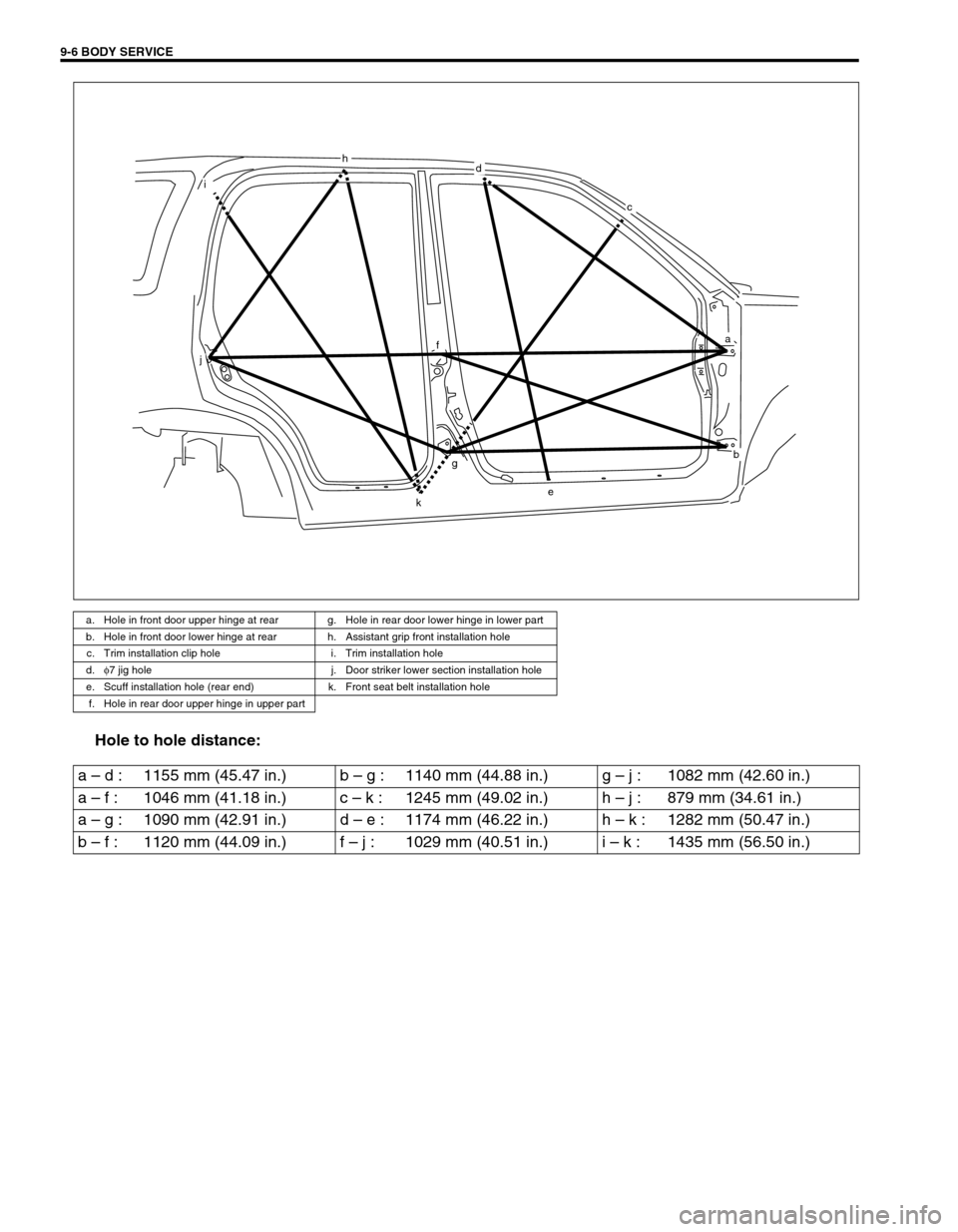

9-6 BODY SERVICE

Hole to hole distance:

a. Hole in front door upper hinge at rear g. Hole in rear door lower hinge in lower part

b. Hole in front door lower hinge at rear h. Assistant grip front installation hole

c. Trim installation clip hole i. Trim installation hole

d.φ

7 jig hole j. Door striker lower section installation hole

e. Scuff installation hole (rear end) k. Front seat belt installation hole

f. Hole in rear door upper hinge in upper part

hd

c

f

i

j

ke

gb

a

a – d : 1155 mm (45.47 in.) b – g : 1140 mm (44.88 in.) g – j : 1082 mm (42.60 in.)

a – f : 1046 mm (41.18 in.) c – k : 1245 mm (49.02 in.) h – j : 879 mm (34.61 in.)

a – g : 1090 mm (42.91 in.) d – e : 1174 mm (46.22 in.) h – k : 1282 mm (50.47 in.)

b – f : 1120 mm (44.09 in.) f – j : 1029 mm (40.51 in.) i – k : 1435 mm (56.50 in.)