Operation SUZUKI GRAND VITARA 2001 2.G Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 151 of 656

5E2-26 ANTILOCK BRAKE SYSTEM (ABS)

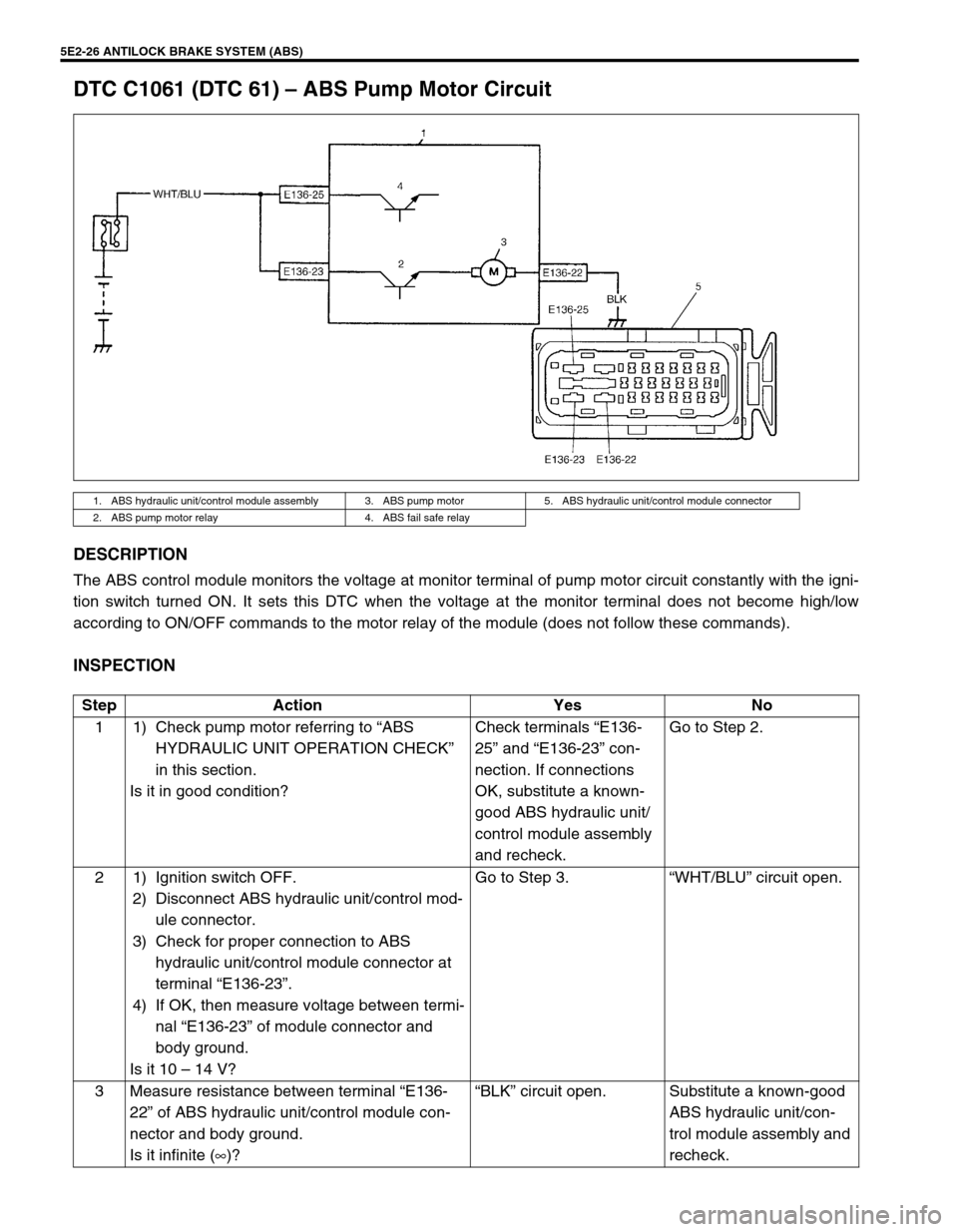

DTC C1061 (DTC 61) – ABS Pump Motor Circuit

DESCRIPTION

The ABS control module monitors the voltage at monitor terminal of pump motor circuit constantly with the igni-

tion switch turned ON. It sets this DTC when the voltage at the monitor terminal does not become high/low

according to ON/OFF commands to the motor relay of the module (does not follow these commands).

INSPECTION

1. ABS hydraulic unit/control module assembly 3. ABS pump motor 5. ABS hydraulic unit/control module connector

2. ABS pump motor relay 4. ABS fail safe relay

Step Action Yes No

1 1) Check pump motor referring to “ABS

HYDRAULIC UNIT OPERATION CHECK”

in this section.

Is it in good condition?Check terminals “E136-

25” and “E136-23” con-

nection. If connections

OK, substitute a known-

good ABS hydraulic unit/

control module assembly

and recheck.Go to Step 2.

2 1) Ignition switch OFF.

2) Disconnect ABS hydraulic unit/control mod-

ule connector.

3) Check for proper connection to ABS

hydraulic unit/control module connector at

terminal “E136-23”.

4) If OK, then measure voltage between termi-

nal “E136-23” of module connector and

body ground.

Is it 10 – 14 V?Go to Step 3.“WHT/BLU” circuit open.

3 Measure resistance between terminal “E136-

22” of ABS hydraulic unit/control module con-

nector and body ground.

Is it infinite (∞)?“BLK” circuit open. Substitute a known-good

ABS hydraulic unit/con-

trol module assembly and

recheck.

Page 154 of 656

ANTILOCK BRAKE SYSTEM (ABS) 5E2-29

On-Vehicle Service

Precautions

When connector are connected to ABS hydraulic unit/control

module assembly, do not disconnect connectors of sensors and

turn ignition switch ON. Then DTC will be set in ABS control mod-

ule.

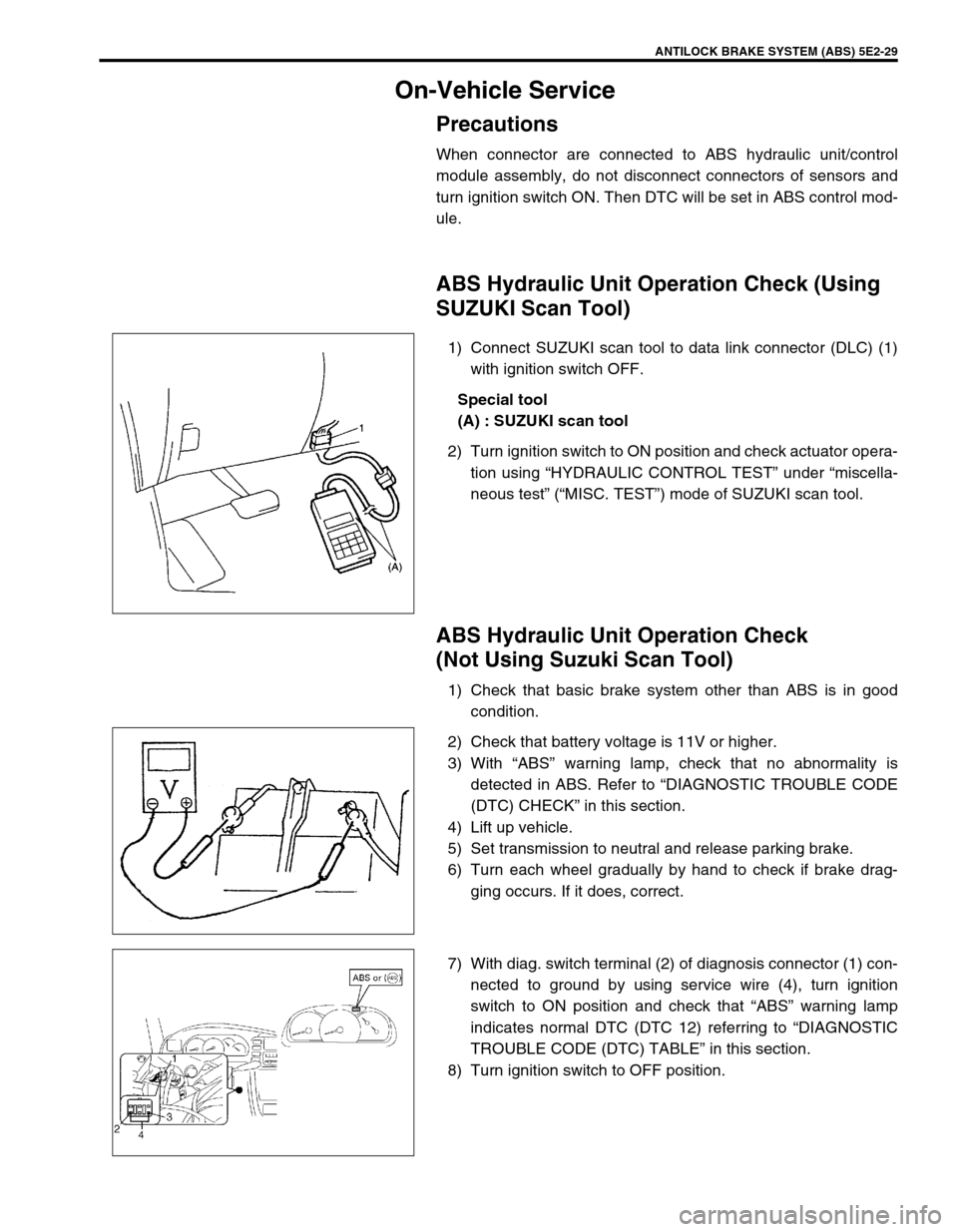

ABS Hydraulic Unit Operation Check (Using

SUZUKI Scan Tool)

1) Connect SUZUKI scan tool to data link connector (DLC) (1)

with ignition switch OFF.

Special tool

(A) : SUZUKI scan tool

2) Turn ignition switch to ON position and check actuator opera-

tion using “HYDRAULIC CONTROL TEST” under “miscella-

neous test” (“MISC. TEST”) mode of SUZUKI scan tool.

ABS Hydraulic Unit Operation Check

(Not Using Suzuki Scan Tool)

1) Check that basic brake system other than ABS is in good

condition.

2) Check that battery voltage is 11V or higher.

3) With “ABS” warning lamp, check that no abnormality is

detected in ABS. Refer to “DIAGNOSTIC TROUBLE CODE

(DTC) CHECK” in this section.

4) Lift up vehicle.

5) Set transmission to neutral and release parking brake.

6) Turn each wheel gradually by hand to check if brake drag-

ging occurs. If it does, correct.

7) With diag. switch terminal (2) of diagnosis connector (1) con-

nected to ground by using service wire (4), turn ignition

switch to ON position and check that “ABS” warning lamp

indicates normal DTC (DTC 12) referring to “DIAGNOSTIC

TROUBLE CODE (DTC) TABLE” in this section.

8) Turn ignition switch to OFF position.

Page 155 of 656

5E2-30 ANTILOCK BRAKE SYSTEM (ABS)

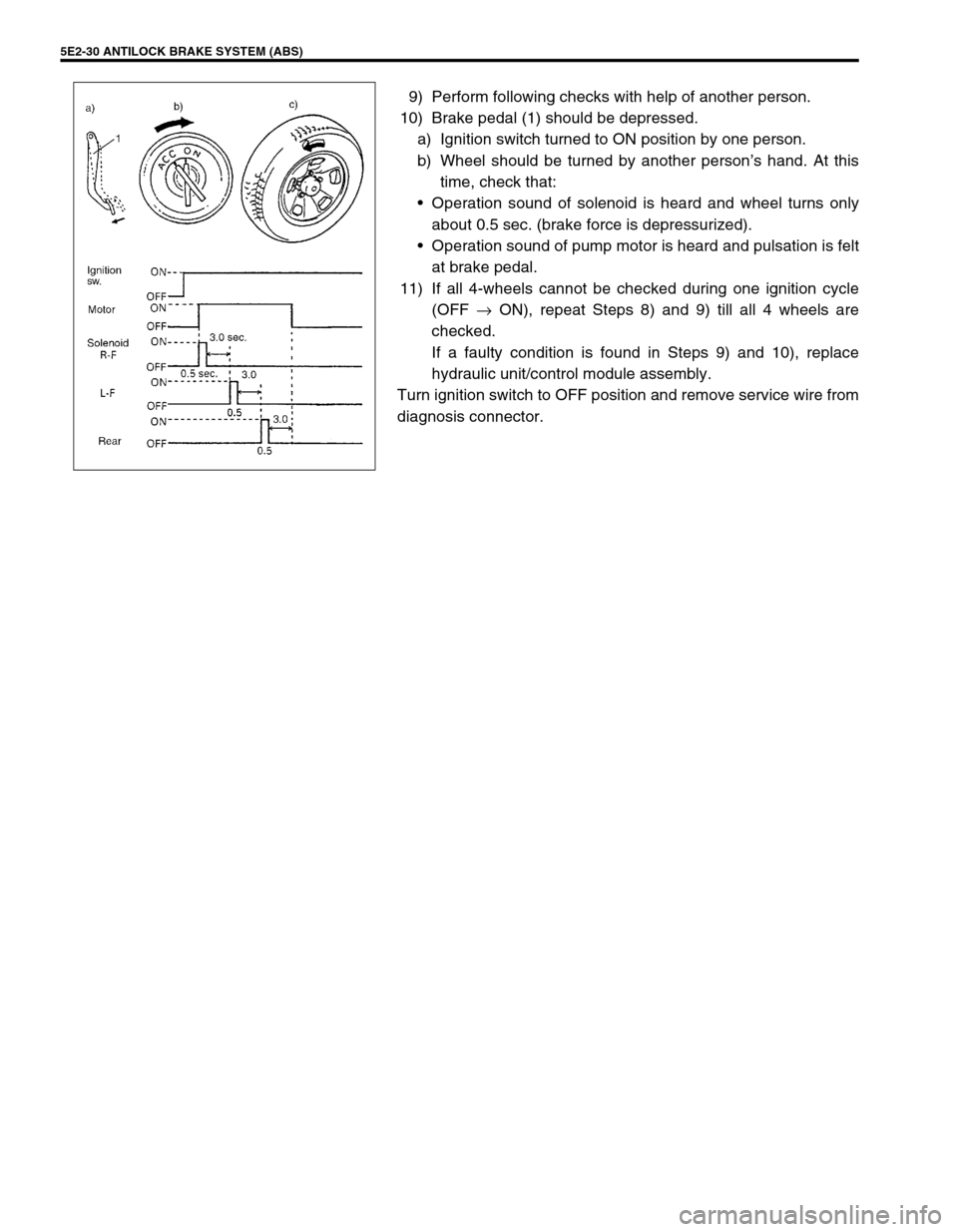

9) Perform following checks with help of another person.

10) Brake pedal (1) should be depressed.

a) Ignition switch turned to ON position by one person.

b) Wheel should be turned by another person’s hand. At this

time, check that:

Operation sound of solenoid is heard and wheel turns only

about 0.5 sec. (brake force is depressurized).

Operation sound of pump motor is heard and pulsation is felt

at brake pedal.

11) If all 4-wheels cannot be checked during one ignition cycle

(OFF → ON), repeat Steps 8) and 9) till all 4 wheels are

checked.

If a faulty condition is found in Steps 9) and 10), replace

hydraulic unit/control module assembly.

Turn ignition switch to OFF position and remove service wire from

diagnosis connector.

Page 157 of 656

5E2-32 ANTILOCK BRAKE SYSTEM (ABS)

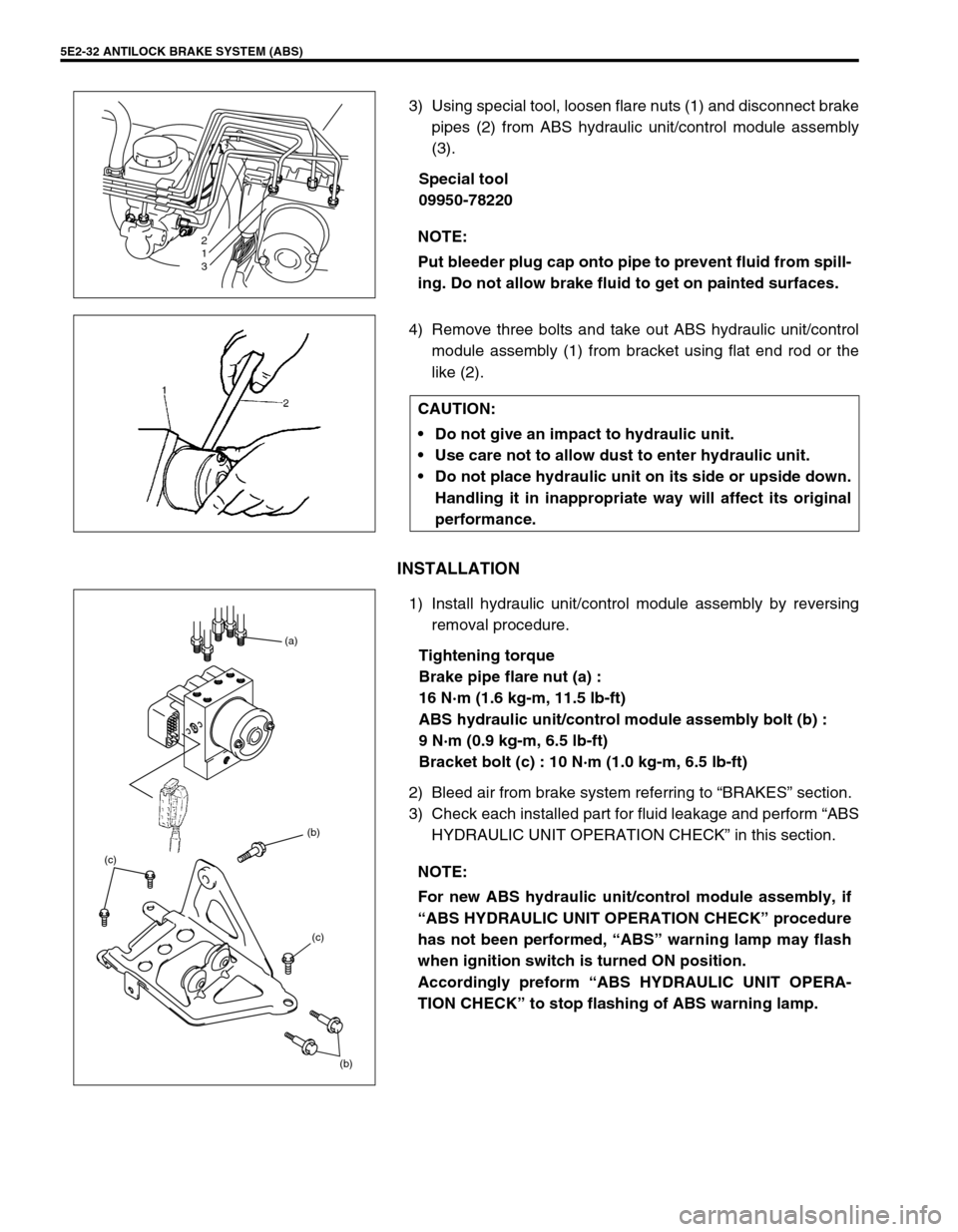

3) Using special tool, loosen flare nuts (1) and disconnect brake

pipes (2) from ABS hydraulic unit/control module assembly

(3).

Special tool

09950-78220

4) Remove three bolts and take out ABS hydraulic unit/control

module assembly (1) from bracket using flat end rod or the

like (2).

INSTALLATION

1) Install hydraulic unit/control module assembly by reversing

removal procedure.

Tightening torque

Brake pipe flare nut (a) :

16 N·m (1.6 kg-m, 11.5 lb-ft)

ABS hydraulic unit/control module assembly bolt (b) :

9 N·m (0.9 kg-m, 6.5 lb-ft)

Bracket bolt (c) : 10 N·m (1.0 kg-m, 6.5 lb-ft)

2) Bleed air from brake system referring to “BRAKES” section.

3) Check each installed part for fluid leakage and perform “ABS

HYDRAULIC UNIT OPERATION CHECK” in this section. NOTE:

Put bleeder plug cap onto pipe to prevent fluid from spill-

ing. Do not allow brake fluid to get on painted surfaces.

2

1

3

CAUTION:

Do not give an impact to hydraulic unit.

Use care not to allow dust to enter hydraulic unit.

Do not place hydraulic unit on its side or upside down.

Handling it in inappropriate way will affect its original

performance.

NOTE:

For new ABS hydraulic unit/control module assembly, if

“ABS HYDRAULIC UNIT OPERATION CHECK” procedure

has not been performed, “ABS” warning lamp may flash

when ignition switch is turned ON position.

Accordingly preform “ABS HYDRAULIC UNIT OPERA-

TION CHECK” to stop flashing of ABS warning lamp.

(b) (b) (a)

(c) (c)

Page 164 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-3

General Information

Statement of Cleanliness and Care

An automobile engine is a combination of many machined, honed, polished and lapped surfaces with tolerances

that are measured in the thousands of an millimeter (ten thousands of inch). Accordingly, when any internal

engine parts are serviced, care and cleanliness are important. Throughout this section, it should be understood

that proper cleaning and protection of machined surfaces and friction areas is part of the repair procedure. This

is considered standard shop practice even if not specifically stated.

A liberal coating of engine oil should be applied to friction areas during assembly to protect and lubricate the

surface on initial operation.

Whenever valve train components, pistons, piston rings, connecting rods, rod bearings and crankshaft jour-

nal bearings are removed for service, they should be retained in order. At the time of installation, they should

be installed in the same locations and with the same mating surfaces as when removed.

Battery cables should be disconnected before any major work is performed on the engine. Failure to discon-

nect cables may result in damage to wire harness or other electrical parts.

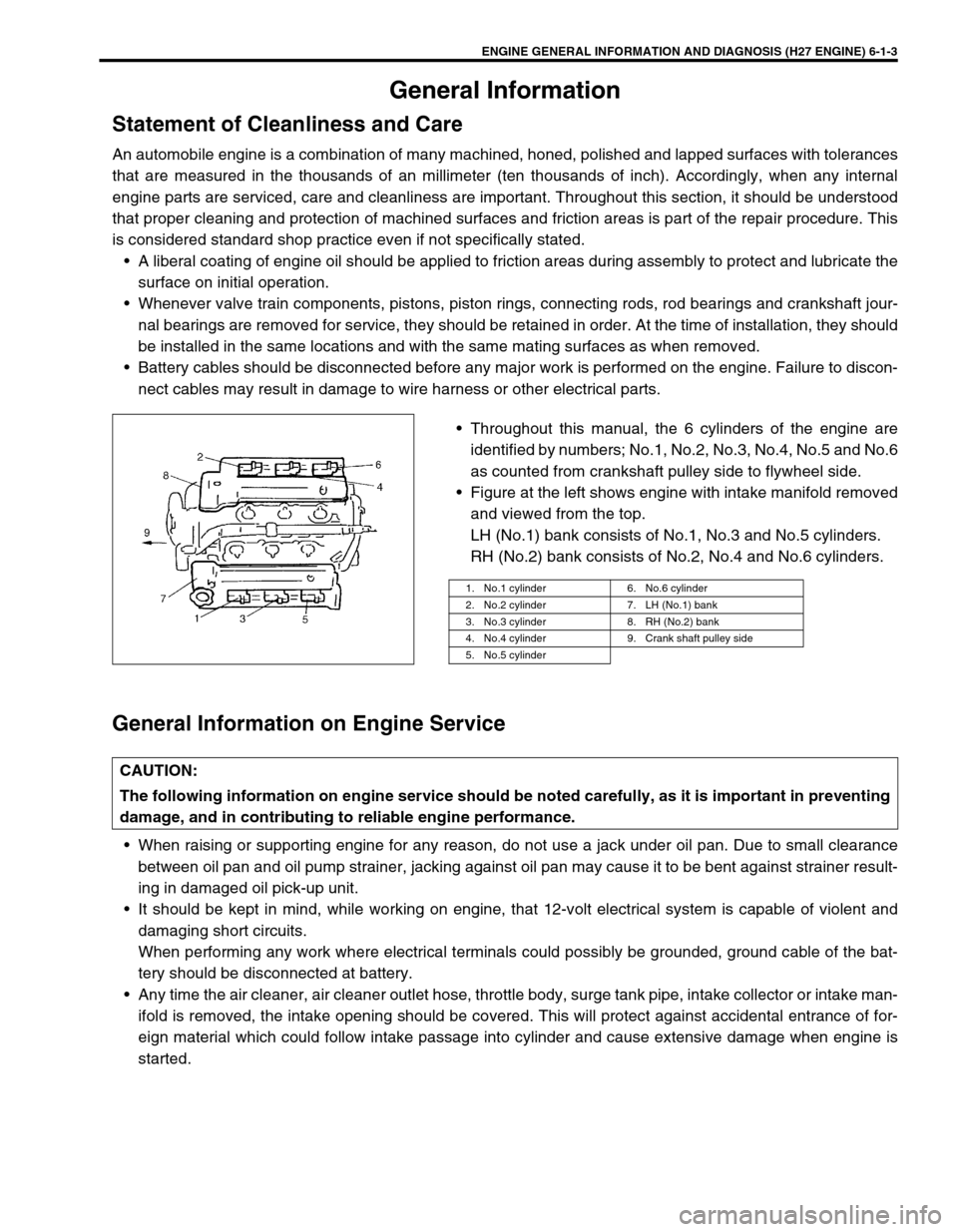

Throughout this manual, the 6 cylinders of the engine are

identified by numbers; No.1, No.2, No.3, No.4, No.5 and No.6

as counted from crankshaft pulley side to flywheel side.

Figure at the left shows engine with intake manifold removed

and viewed from the top.

LH (No.1) bank consists of No.1, No.3 and No.5 cylinders.

RH (No.2) bank consists of No.2, No.4 and No.6 cylinders.

General Information on Engine Service

When raising or supporting engine for any reason, do not use a jack under oil pan. Due to small clearance

between oil pan and oil pump strainer, jacking against oil pan may cause it to be bent against strainer result-

ing in damaged oil pick-up unit.

It should be kept in mind, while working on engine, that 12-volt electrical system is capable of violent and

damaging short circuits.

When performing any work where electrical terminals could possibly be grounded, ground cable of the bat-

tery should be disconnected at battery.

Any time the air cleaner, air cleaner outlet hose, throttle body, surge tank pipe, intake collector or intake man-

ifold is removed, the intake opening should be covered. This will protect against accidental entrance of for-

eign material which could follow intake passage into cylinder and cause extensive damage when engine is

started.

1. No.1 cylinder 6. No.6 cylinder

2. No.2 cylinder 7. LH (No.1) bank

3. No.3 cylinder 8. RH (No.2) bank

4. No.4 cylinder 9. Crank shaft pulley side

5. No.5 cylinder

CAUTION:

The following information on engine service should be noted carefully, as it is important in preventing

damage, and in contributing to reliable engine performance.

Page 167 of 656

6-1-6 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

Engine Diagnosis

General Description

This vehicle is equipped with an engine and emission control system which are under control of ECM (PCM).

The engine and emission control system in this vehicle are controlled by ECM (PCM). ECM (PCM) has an On-

Board Diagnostic system which detects a malfunction in this system and abnormality of those parts that influ-

ence the engine exhaust emission. When diagnosing engine troubles, be sure to have full understanding of the

outline of “ON-BOARD DIAGNOSTIC SYSTEM” and each item in “PRECAUTION IN DIAGNOSING TROUBLE”

and execute diagnosis according to “ENGINE DIAGNOSTIC FLOW TABLE” in this section.

There is a close relationship between the engine mechanical, engine cooling system, ignition system, exhaust

system, etc. and the engine and emission control system in their structure and operation. In case of an engine

trouble, even when the malfunction indicator lamp (MIL) doesn’t turn ON, it should be diagnosed according to

“ENGINE DIAGNOSTIC FLOW TABLE” in this section.

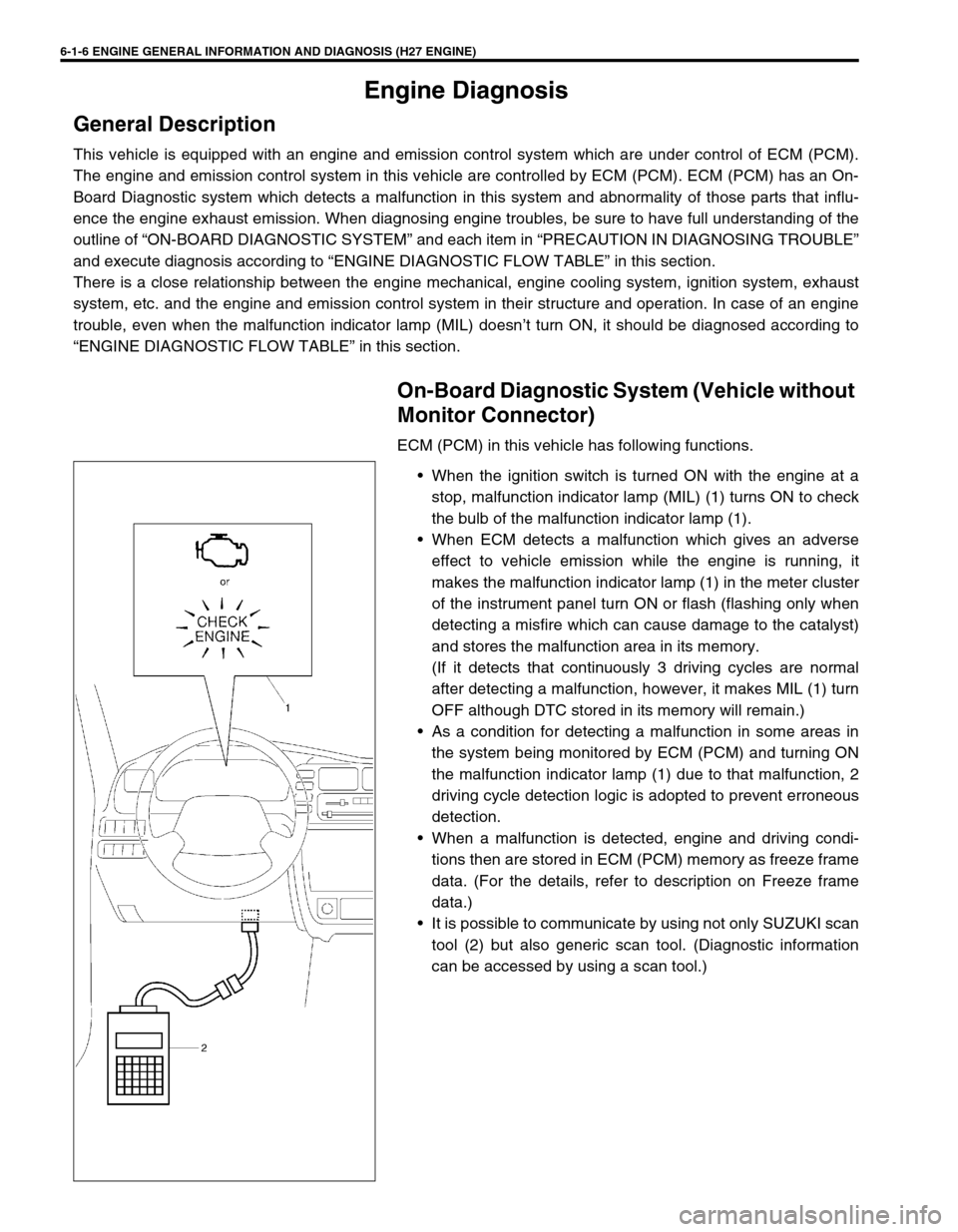

On-Board Diagnostic System (Vehicle without

Monitor Connector)

ECM (PCM) in this vehicle has following functions.

When the ignition switch is turned ON with the engine at a

stop, malfunction indicator lamp (MIL) (1) turns ON to check

the bulb of the malfunction indicator lamp (1).

When ECM detects a malfunction which gives an adverse

effect to vehicle emission while the engine is running, it

makes the malfunction indicator lamp (1) in the meter cluster

of the instrument panel turn ON or flash (flashing only when

detecting a misfire which can cause damage to the catalyst)

and stores the malfunction area in its memory.

(If it detects that continuously 3 driving cycles are normal

after detecting a malfunction, however, it makes MIL (1) turn

OFF although DTC stored in its memory will remain.)

As a condition for detecting a malfunction in some areas in

the system being monitored by ECM (PCM) and turning ON

the malfunction indicator lamp (1) due to that malfunction, 2

driving cycle detection logic is adopted to prevent erroneous

detection.

When a malfunction is detected, engine and driving condi-

tions then are stored in ECM (PCM) memory as freeze frame

data. (For the details, refer to description on Freeze frame

data.)

It is possible to communicate by using not only SUZUKI scan

tool (2) but also generic scan tool. (Diagnostic information

can be accessed by using a scan tool.)

Page 168 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-7

WARM-UP CYCLE

A warm-up cycle means sufficient vehicle operation such that the

coolant temperature has risen by at least 22°C (40°F) from

engine starting and reaches a minimum temperature of 70 °C

(160 °F).

DRIVING CYCLE

A “Driving Cycle” consists of engine startup, driving mode where

a malfunction would be detected if present and engine shutoff.

2 DRIVING CYCLE DETECTION LOGIC

The malfunction detected in the first driving cycle is stored in

ECM (PCM) memory (in the form of pending DTC) but the mal-

function indicator lamp does not light at this time. It lights up at the

second detection of same malfunction also in the next driving

cycle.

PENDING DTC

Pending DTC means a DTC detected and stored temporarily at 1

driving cycle of the DTC which is detected in the 2 driving cycle

detection logic.

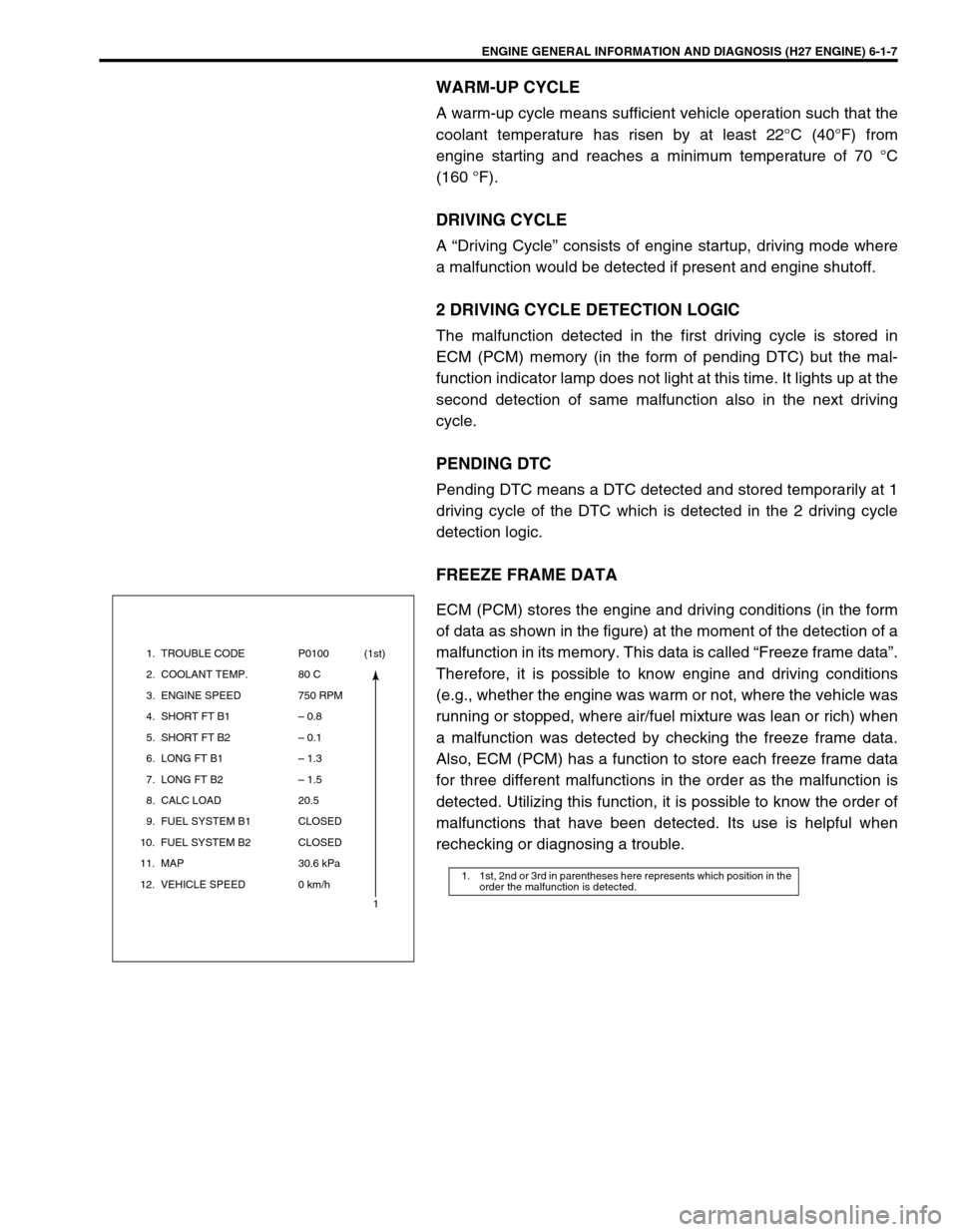

FREEZE FRAME DATA

ECM (PCM) stores the engine and driving conditions (in the form

of data as shown in the figure) at the moment of the detection of a

malfunction in its memory. This data is called “Freeze frame data”.

Therefore, it is possible to know engine and driving conditions

(e.g., whether the engine was warm or not, where the vehicle was

running or stopped, where air/fuel mixture was lean or rich) when

a malfunction was detected by checking the freeze frame data.

Also, ECM (PCM) has a function to store each freeze frame data

for three different malfunctions in the order as the malfunction is

detected. Utilizing this function, it is possible to know the order of

malfunctions that have been detected. Its use is helpful when

rechecking or diagnosing a trouble.

1. 1st, 2nd or 3rd in parentheses here represents which position in the

order the malfunction is detected.

1. TROUBLE CODE

2. COOLANT TEMP.

3. ENGINE SPEED

4. SHORT FT B1

5. SHORT FT B2

6. LONG FT B1

7. LONG FT B2

8. CALC LOAD

9. FUEL SYSTEM B1

10. FUEL SYSTEM B2

11. MAP

12. VEHICLE SPEEDP0100

80 C

750 RPM

– 0.8

– 0.1

– 1.3

– 1.5

20.5

CLOSED

CLOSED

30.6 kPa

0 km/h(1st)

1

Page 174 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-13

STEP 2. DIAGNOSTIC TROUBLE CODE (DTC)/FREEZE FRAME DATA CHECK

First, check DTC, referring to “DIAGNOSTIC TROUBLE CODE CHECK” in this section. If DTC is indicated,

record DTC and freeze frame data.

After that clear DTC referring to “DIAGNOSTIC TROUBLE CODE CLEARANCE” in this section. DTC indicates

malfunction that occurred in the system but does not indicate whether it exists now or it occurred in the past and

the normal condition has been restored now. To check which case applies, check the symptom in question

according to Step 5 and recheck DTC according to Step 6, 7.

Attempt to diagnose a trouble based on DTC in this step only or failure to clear the DTC (including pending DTC)

in this step will lead to incorrect diagnosis, trouble diagnosis of a normal circuit or difficulty in troubleshooting.

STEP 3. and 4. VISUAL INSPECTION

Be sure to perform visual check of the following items that support proper function of the engine.

STEP 5. TROUBLE SYMPTOM CONFIRMATION

Based on information obtained in Step 1 “CUSTOMER COMPLAINT ANALYSIS” and Step 2 “DTC/FREEZE

FRAME DATA CHECK”, confirm trouble symptoms. Also, reconfirm DTC according to “DTC CONFIRMATION

PROCEDURE” described in each “DTC FLOW TABLE”.NOTE:

For A/T vehicle, if only DTC P0705, P0715, P0720, P0741, P0743, P0751, P0753, P0756, P0758, or P1875

is indicated in this step, proceed to “DIAGNOSIS” in SECTION 7B1.

INSPECTION ITEM REFERRING SECTION

• Engine oil - - - - - level, leakage

• Engine coolant - - - - - level, leakage

• Fuel - - - - - level, leakage

• A/T fluid - - - - - level, leakage

• Air cleaner element - - - - - dirt, clogging

• Battery - - - - - fluid level, corrosion of terminal

• Water pump belt and/or cooling fan belt - - - - - tension, damage

• Accelerator cable - - - - - play, installation

• A/T throttle cable - - - - - play, installation

• Vacuum hoses of air intake system

- - - - - disconnection, looseness, deterioration, bend

• Connectors of electric wire harness - - - - - disconnection, friction

• Fuses - - - - - burning

• Parts - - - - - installation, bolt - - - - - looseness

• Parts - - - - - deformation

• Other parts that can be checked visually

• Also check following items at engine start, if possible

– Malfunction indicator lamp - - - - - operation

– Charge warning lamp - - - - - operation

– Engine oil pressure warning lamp - - - - - operation

– Engine coolant temp. meter - - - - - operation

– Fuel lever meter - - - - - operation

– Abnormal air being inhaled from air intake system

– Exhaust system - - - - - leakage of exhaust gas, noise

– Other parts that can be checked visuallySECTION 0B

SECTION 0B

SECTION 0B

SECTION 0B

SECTION 0B

SECTION 0B

SECTION 6C

SECTION 6E2

SECTION 6E2

SECTION 6A2

SECTION 8

SECTION 6-1

SECTION 6H

SECTION 8/6A2

SECTION 8

SECTION 8

Page 182 of 656

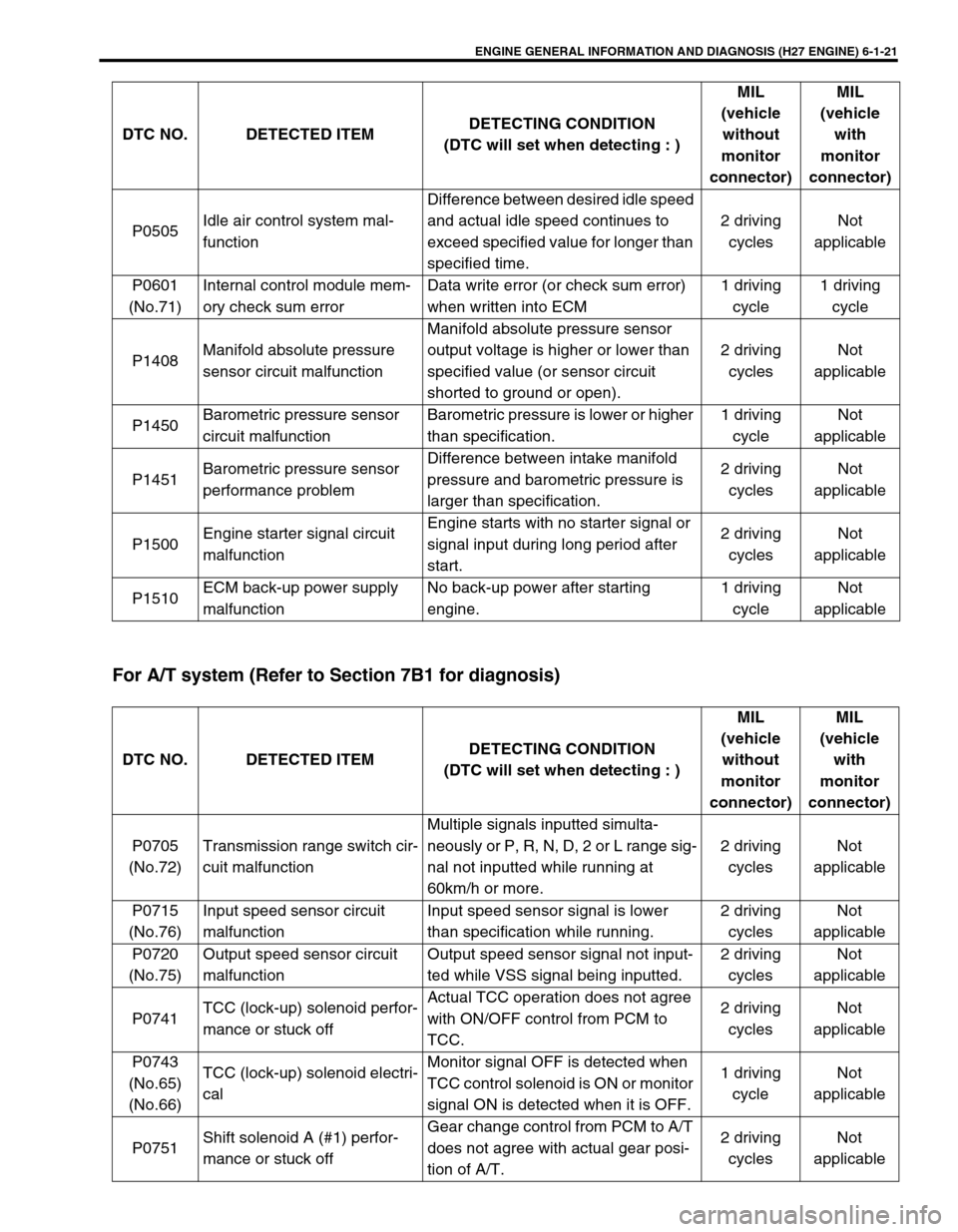

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-21

For A/T system (Refer to Section 7B1 for diagnosis)

P0505Idle air control system mal-

functionDifference between desired idle speed

and actual idle speed continues to

exceed specified value for longer than

specified time.2 driving

cyclesNot

applicable

P0601

(No.71)Internal control module mem-

ory check sum errorData write error (or check sum error)

when written into ECM1 driving

cycle1 driving

cycle

P1408Manifold absolute pressure

sensor circuit malfunctionManifold absolute pressure sensor

output voltage is higher or lower than

specified value (or sensor circuit

shorted to ground or open).2 driving

cyclesNot

applicable

P1450Barometric pressure sensor

circuit malfunctionBarometric pressure is lower or higher

than specification.1 driving

cycleNot

applicable

P1451Barometric pressure sensor

performance problemDifference between intake manifold

pressure and barometric pressure is

larger than specification.2 driving

cyclesNot

applicable

P1500Engine starter signal circuit

malfunctionEngine starts with no starter signal or

signal input during long period after

start.2 driving

cyclesNot

applicable

P1510ECM back-up power supply

malfunctionNo back-up power after starting

engine.1 driving

cycleNot

applicable DTC NO. DETECTED ITEMDETECTING CONDITION

(DTC will set when detecting : )MIL

(vehicle

without

monitor

connector)MIL

(vehicle

with

monitor

connector)

DTC NO. DETECTED ITEMDETECTING CONDITION

(DTC will set when detecting : )MIL

(vehicle

without

monitor

connector)MIL

(vehicle

with

monitor

connector)

P0705

(No.72)Transmission range switch cir-

cuit malfunctionMultiple signals inputted simulta-

neously or P, R, N, D, 2 or L range sig-

nal not inputted while running at

60km/h or more.2 driving

cyclesNot

applicable

P0715

(No.76)Input speed sensor circuit

malfunctionInput speed sensor signal is lower

than specification while running.2 driving

cyclesNot

applicable

P0720

(No.75)Output speed sensor circuit

malfunctionOutput speed sensor signal not input-

ted while VSS signal being inputted.2 driving

cyclesNot

applicable

P0741TCC (lock-up) solenoid perfor-

mance or stuck offActual TCC operation does not agree

with ON/OFF control from PCM to

TCC.2 driving

cyclesNot

applicable

P0743

(No.65)

(No.66)TCC (lock-up) solenoid electri-

calMonitor signal OFF is detected when

TCC control solenoid is ON or monitor

signal ON is detected when it is OFF.1 driving

cycleNot

applicable

P0751Shift solenoid A (#1) perfor-

mance or stuck offGear change control from PCM to A/T

does not agree with actual gear posi-

tion of A/T.2 driving

cyclesNot

applicable

Page 184 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-23

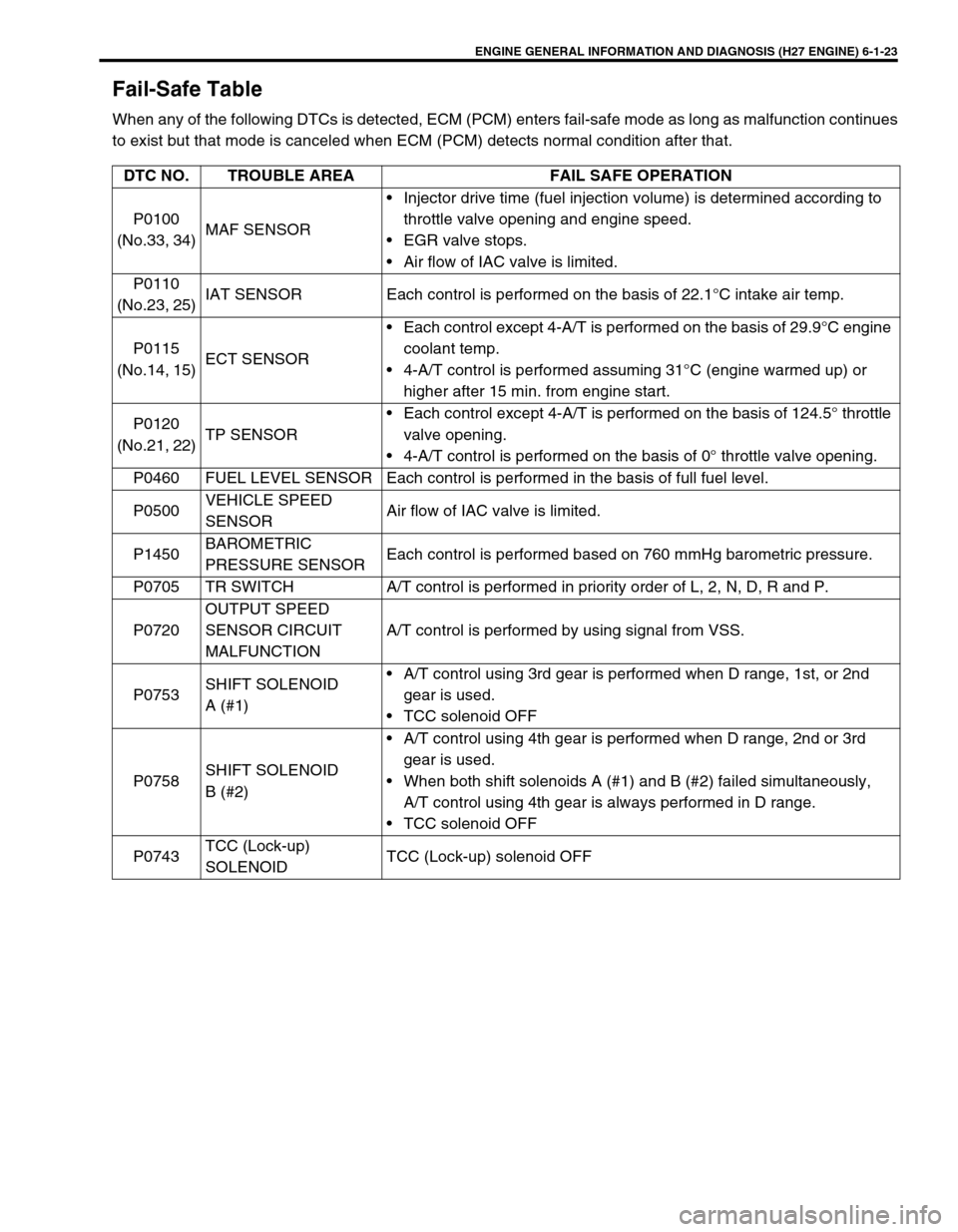

Fail-Safe Table

When any of the following DTCs is detected, ECM (PCM) enters fail-safe mode as long as malfunction continues

to exist but that mode is canceled when ECM (PCM) detects normal condition after that.

DTC NO. TROUBLE AREA FAIL SAFE OPERATION

P0100

(No.33, 34)MAF SENSOR• Injector drive time (fuel injection volume) is determined according to

throttle valve opening and engine speed.

• EGR valve stops.

• Air flow of IAC valve is limited.

P0110

(No.23, 25)IAT SENSOR Each control is performed on the basis of 22.1°C intake air temp.

P0115

(No.14, 15)ECT SENSOR• Each control except 4-A/T is performed on the basis of 29.9°C engine

coolant temp.

• 4-A/T control is performed assuming 31°C (engine warmed up) or

higher after 15 min. from engine start.

P0120

(No.21, 22)TP SENSOR• Each control except 4-A/T is performed on the basis of 124.5° throttle

valve opening.

• 4-A/T control is performed on the basis of 0° throttle valve opening.

P0460 FUEL LEVEL SENSOR Each control is performed in the basis of full fuel level.

P0500VEHICLE SPEED

SENSORAir flow of IAC valve is limited.

P1450BAROMETRIC

PRESSURE SENSOREach control is performed based on 760 mmHg barometric pressure.

P0705 TR SWITCH A/T control is performed in priority order of L, 2, N, D, R and P.

P0720OUTPUT SPEED

SENSOR CIRCUIT

MALFUNCTIONA/T control is performed by using signal from VSS.

P0753SHIFT SOLENOID

A (#1)• A/T control using 3rd gear is performed when D range, 1st, or 2nd

gear is used.

• TCC solenoid OFF

P0758SHIFT SOLENOID

B (#2)• A/T control using 4th gear is performed when D range, 2nd or 3rd

gear is used.

• When both shift solenoids A (#1) and B (#2) failed simultaneously,

A/T control using 4th gear is always performed in D range.

• TCC solenoid OFF

P0743TCC (Lock-up)

SOLENOIDTCC (Lock-up) solenoid OFF