engine SUZUKI GRAND VITARA 2017 Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2017, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2017Pages: 482, PDF Size: 21 MB

Page 380 of 482

7-42

INSPECTION AND MAINTENANCE

54P00-01E

The main fuse, primary fuses and some of the

individual fuses are located in the engine

compartment. If the main fuse blows, no elec-

trical component will function. If a primary fuse

blows, no electrical component in the corre-

sponding load group will function. When

replacing the main fuse, a primary fuse or an

individual fuse, use a genuine SUZUKI

replacement.To remove a fuse, use the fuse puller pro-

vided in the fuse box. The amperage of each

fuse is shown in the back of the fuse box

cover. (9) 30 A Radiator fan 2

(10) 20 A Front fog light

(11) 7.5 A Headlight 2

(12) 25 A Headlight 3

(13) 25 A ESP

® control module

(14) 25 A Headlight

(15) 30 A Back up

(16) 30 A DCDC 2

(17) 40 A Ignition switch

(18) 40 A ESP

® motor

(19) 30 A Starting motor

(20) 7.5 A Transaxle 3

(21) 30 A Fuel heater

(22) 30 A Radiator fan

(23) 30 A Transaxle 2

(24) 40 A HY pump

(25) 30 A DCDC

(26) 30 A FI main (DIESEL)

(27) 20 AFI (GAS)

Fuel pump (DIESEL)

(28) 10 A Air compressor

(29) 15 A Transaxle 1

(30) 30 A Blower fan

(31) 15 A Transaxle 4

(32) 15 A Transaxle 5

(33) 7.5 A Starting signal

(34) 15 A Headlight (Left)

(35) 15 A Headlight high (Left)

(36) 7.5 A FI 2 (DIESEL)

(37) 20 A INJ DRV

(38) 15 A FI

(39) 15 A Headlight (Right)

(40) 15 A Headlight high (Right)

(41) 50 AIgnition switch 2

(DIESEL)

(42) 50 A Battery (DIESEL)

(43) 40 A Sub heater (DIESEL)

(44) 40 A Sub heater 3 (DIESEL)

(45) 40 A Sub heater 2 (DIESEL)

Page 383 of 482

7-45

INSPECTION AND MAINTENANCE

54P00-01E

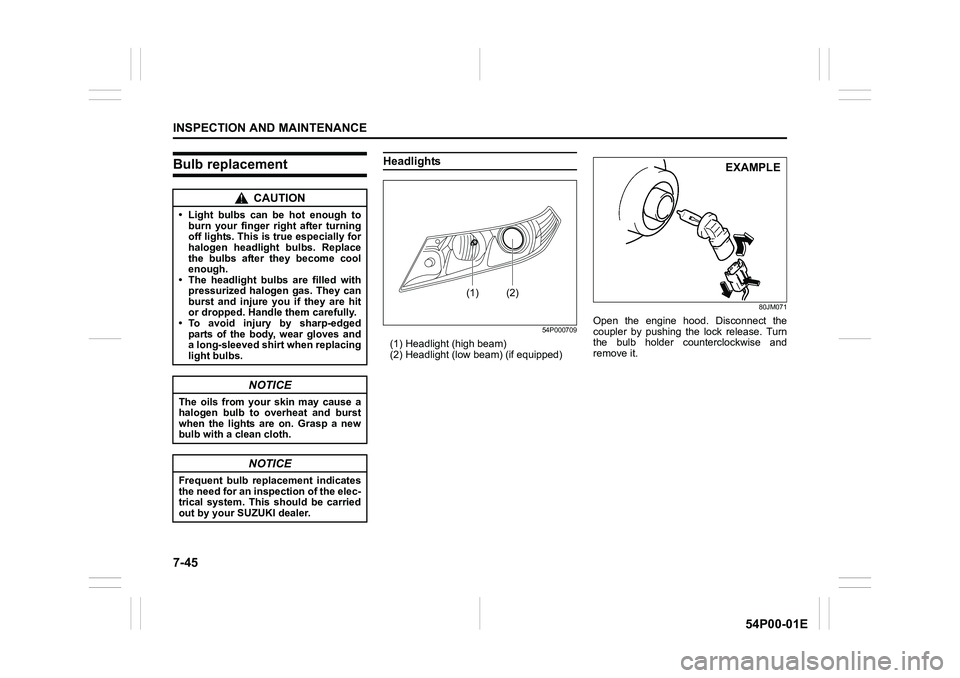

Bulb replacementHeadlights

54P000709

(1) Headlight (high beam)

(2) Headlight (low beam) (if equipped)

80JM071

Open the engine hood. Disconnect the

coupler by pushing the lock release. Turn

the bulb holder counterclockwise and

remove it.

CAUTION

• Light bulbs can be hot enough to

burn your finger right after turning

off lights. This is true especially for

halogen headlight bulbs. Replace

the bulbs after they become cool

enough.

• The headlight bulbs are filled with

pressurized halogen gas. They can

burst and injure you if they are hit

or dropped. Handle them carefully.

• To avoid injury by sharp-edged

parts of the body, wear gloves and

a long-sleeved shirt when replacing

light bulbs.

NOTICE

The oils from your skin may cause a

halogen bulb to overheat and burst

when the lights are on. Grasp a new

bulb with a clean cloth.

NOTICE

Frequent bulb replacement indicates

the need for an inspection of the elec-

trical system. This should be carried

out by your SUZUKI dealer.

(1) (2)

EXAMPLE

Page 384 of 482

7-46

INSPECTION AND MAINTENANCE

54P00-01E

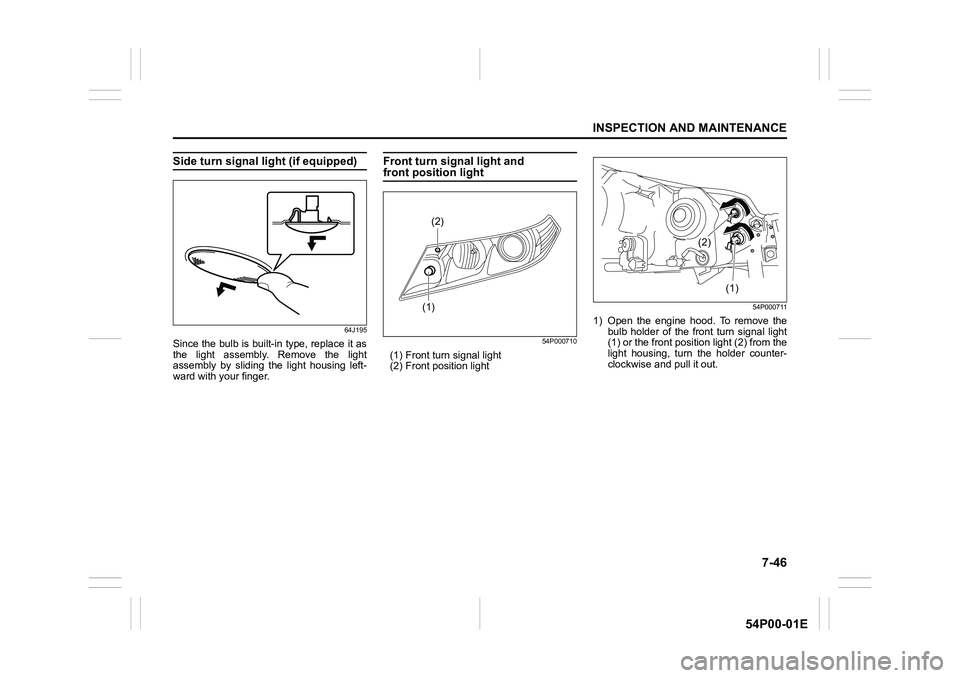

Side turn signal light (if equipped)

64J195

Since the bulb is built-in type, replace it as

the light assembly. Remove the light

assembly by sliding the light housing left-

ward with your finger.

Front turn signal light and front position light

54P000710

(1) Front turn signal light

(2) Front position light

54P000711

1) Open the engine hood. To remove the

bulb holder of the front turn signal light

(1) or the front position light (2) from the

light housing, turn the holder counter-

clockwise and pull it out.

(1)(2)

(1) (2)

Page 385 of 482

7-47

INSPECTION AND MAINTENANCE

54P00-01E

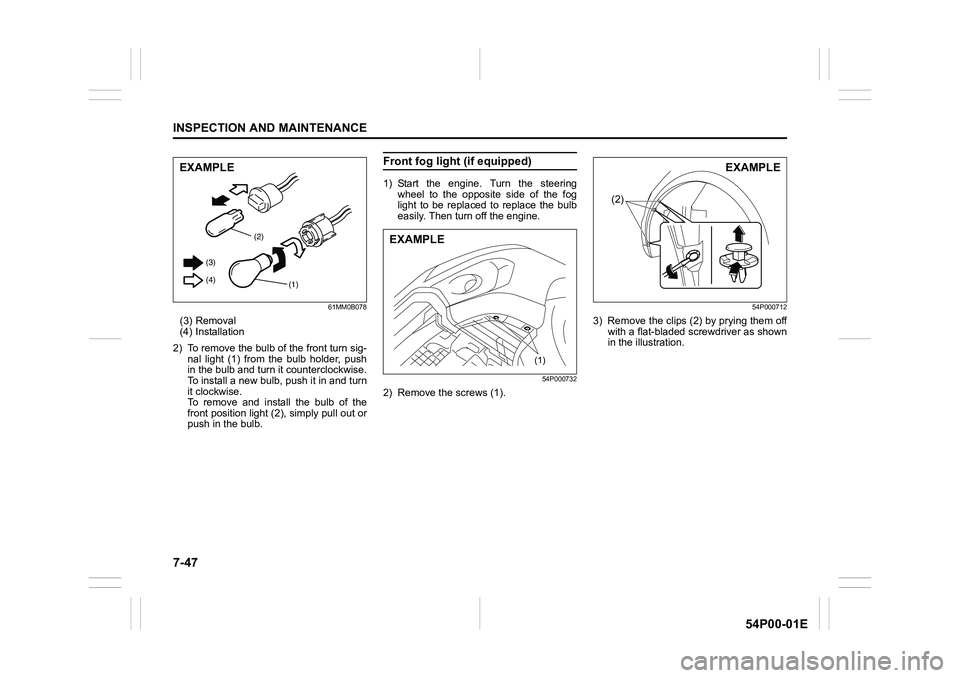

61MM0B078

(3) Removal

(4) Installation

2) To remove the bulb of the front turn sig-

nal light (1) from the bulb holder, push

in the bulb and turn it counterclockwise.

To install a new bulb, push it in and turn

it clockwise.

To remove and install the bulb of the

front position light (2), simply pull out or

push in the bulb.

Front fog light (if equipped)

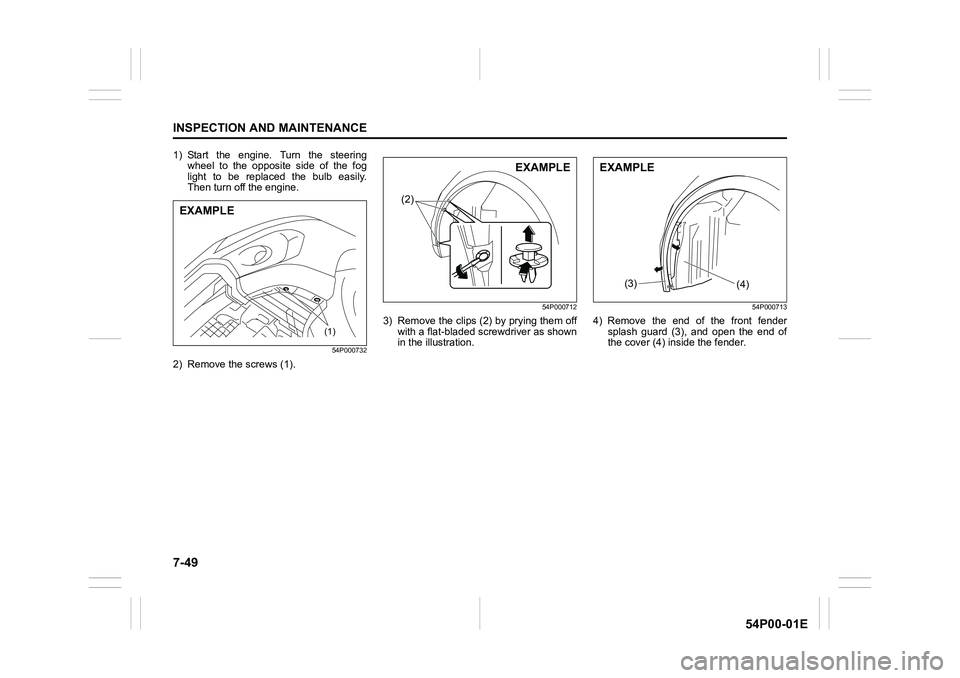

1) Start the engine. Turn the steering

wheel to the opposite side of the fog

light to be replaced to replace the bulb

easily. Then turn off the engine.

54P000732

2) Remove the screws (1).

54P000712

3) Remove the clips (2) by prying them off

with a flat-bladed screwdriver as shown

in the illustration.

(2)

(1) (3)

(4)

EXAMPLE

(1)

EXAMPLE

(2)

EXAMPLE

Page 387 of 482

7-49

INSPECTION AND MAINTENANCE

54P00-01E

1) Start the engine. Turn the steering

wheel to the opposite side of the fog

light to be replaced the bulb easily.

Then turn off the engine.

54P000732

2) Remove the screws (1).

54P000712

3) Remove the clips (2) by prying them off

with a flat-bladed screwdriver as shown

in the illustration.

54P000713

4) Remove the end of the front fender

splash guard (3), and open the end of

the cover (4) inside the fender.(1)

EXAMPLE

(2)

EXAMPLE

(3)(4)

EXAMPLE

Page 397 of 482

7-59

INSPECTION AND MAINTENANCE

54P00-01E

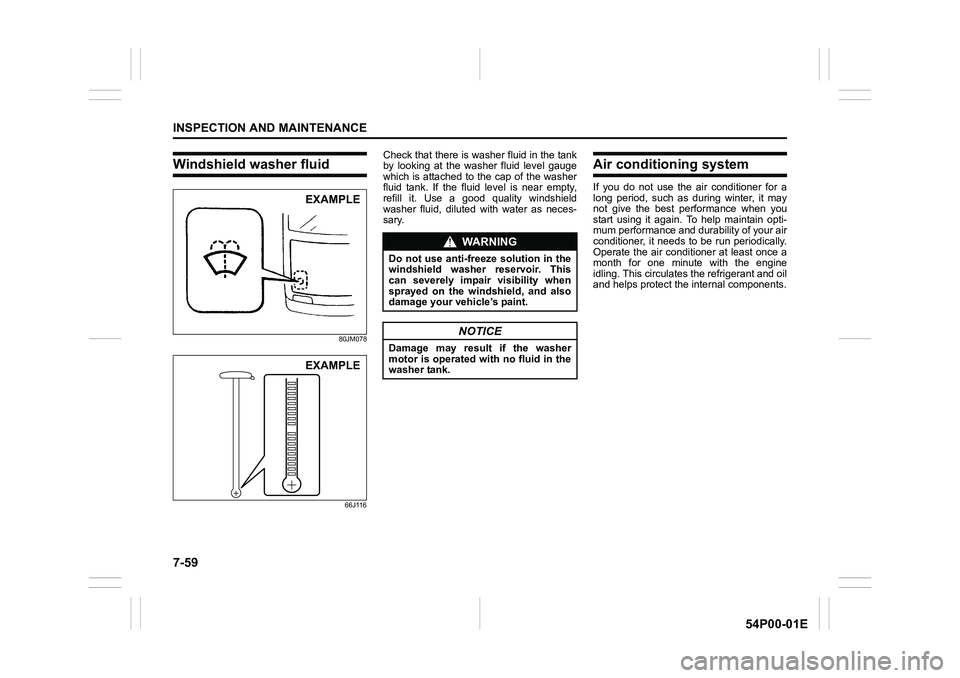

Windshield washer fluid

80JM078

66J116

Check that there is washer fluid in the tank

by looking at the washer fluid level gauge

which is attached to the cap of the washer

fluid tank. If the fluid level is near empty,

refill it. Use a good quality windshield

washer fluid, diluted with water as neces-

sary.Air conditioning system

If you do not use the air conditioner for a

long period, such as during winter, it may

not give the best performance when you

start using it again. To help maintain opti-

mum performance and durability of your air

conditioner, it needs to be run periodically.

Operate the air conditioner at least once a

month for one minute with the engine

idling. This circulates the refrigerant and oil

and helps protect the internal components.

EXAMPLE

EXAMPLE

WA R N I N G

Do not use anti-freeze solution in the

windshield washer reservoir. This

can severely impair visibility when

sprayed on the windshield, and also

damage your vehicle’s paint.

NOTICE

Damage may result if the washer

motor is operated with no fluid in the

washer tank.

Page 400 of 482

EMERGENCY SERVICE

8

54P00-01E

60G411

EMERGENCY SERVICE

Tire changing tool ............................................................... 8-1

Jacking instructions ........................................................... 8-1

Flat tire repair kit (if equipped) .......................................... 8-5

Jump-starting instructions ................................................. 8-8

Towing .................................................................................. 8-10

Engine trouble: Starter does not operate ......................... 8-11

Engine trouble: Flooded engine ........................................ 8-11

Engine trouble: Overheating .............................................. 8-12

Page 402 of 482

8-2

EMERGENCY SERVICE

54P00-01E

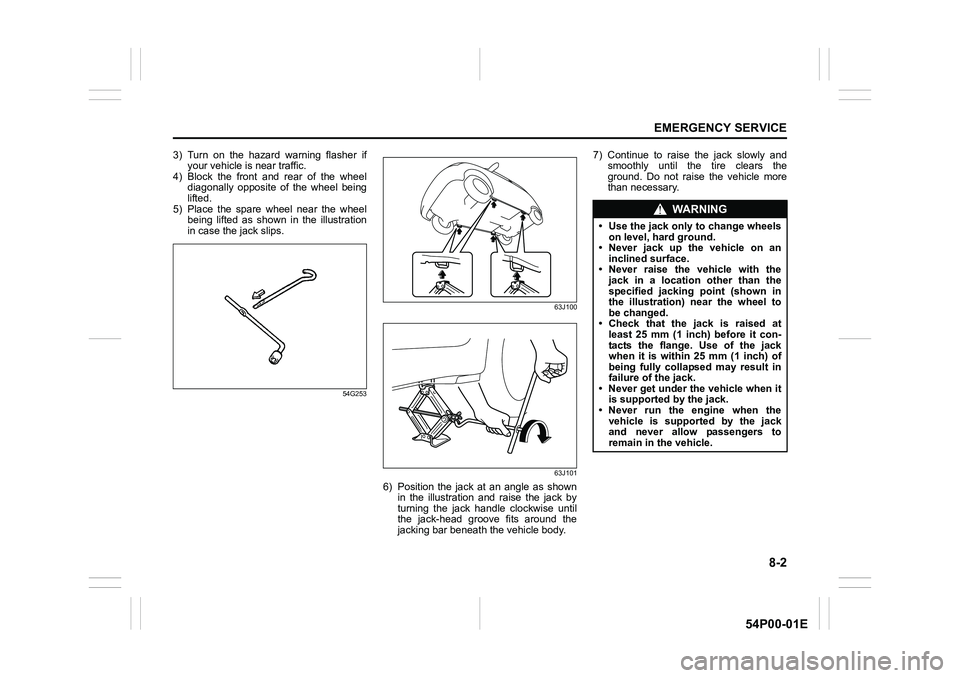

3) Turn on the hazard warning flasher if

your vehicle is near traffic.

4) Block the front and rear of the wheel

diagonally opposite of the wheel being

lifted.

5) Place the spare wheel near the wheel

being lifted as shown in the illustration

in case the jack slips.

54G25363J100

63J101

6) Position the jack at an angle as shown

in the illustration and raise the jack by

turning the jack handle clockwise until

the jack-head groove fits around the

jacking bar beneath the vehicle body.7) Continue to raise the jack slowly and

smoothly until the tire clears the

ground. Do not raise the vehicle more

than necessary.

WA R N I N G

• Use the jack only to change wheels

on level, hard ground.

• Never jack up the vehicle on an

inclined surface.

• Never raise the vehicle with the

jack in a location other than the

specified jacking point (shown in

the illustration) near the wheel to

be changed.

• Check that the jack is raised at

least 25 mm (1 inch) before it con-

tacts the flange. Use of the jack

when it is within 25 mm (1 inch) of

being fully collapsed may result in

failure of the jack.

• Never get under the vehicle when it

is supported by the jack.

• Never run the engine when the

vehicle is supported by the jack

and never allow passengers to

remain in the vehicle.

Page 404 of 482

8-4

EMERGENCY SERVICE

54P00-01E

NOTE:

For more details, contact an authorized

SUZUKI dealer.

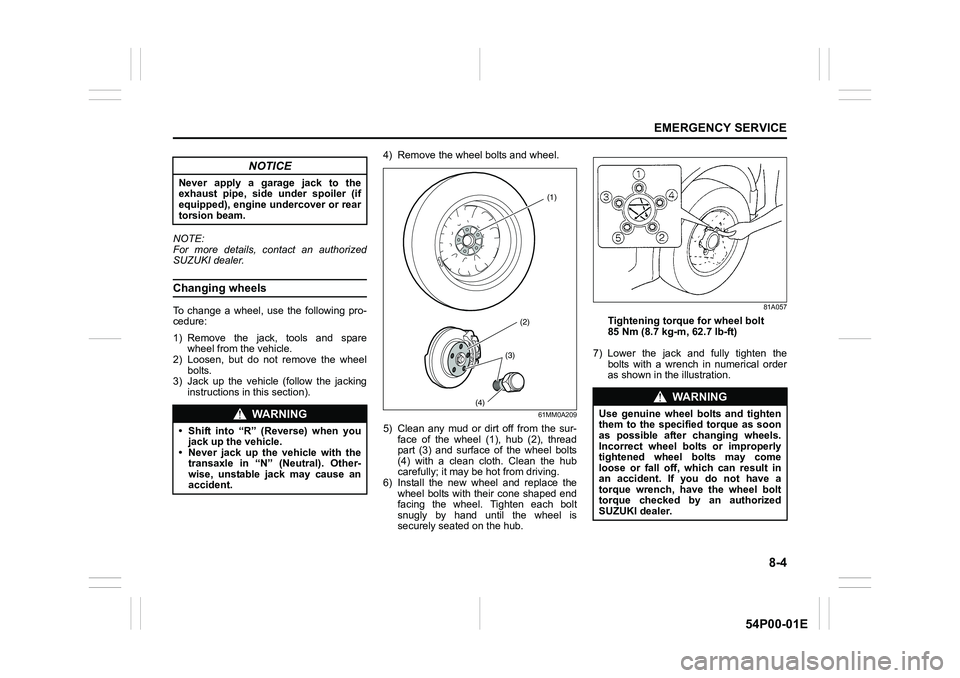

Changing wheels

To change a wheel, use the following pro-

cedure:

1) Remove the jack, tools and spare

wheel from the vehicle.

2) Loosen, but do not remove the wheel

bolts.

3) Jack up the vehicle (follow the jacking

instructions in this section).4) Remove the wheel bolts and wheel.

61MM0A209

5) Clean any mud or dirt off from the sur-

face of the wheel (1), hub (2), thread

part (3) and surface of the wheel bolts

(4) with a clean cloth. Clean the hub

carefully; it may be hot from driving.

6) Install the new wheel and replace the

wheel bolts with their cone shaped end

facing the wheel. Tighten each bolt

snugly by hand until the wheel is

securely seated on the hub.

81A057

Tightening torque for wheel bolt

85 Nm (8.7 kg-m, 62.7 lb-ft)

7) Lower the jack and fully tighten the

bolts with a wrench in numerical order

as shown in the illustration.

NOTICE

Never apply a garage jack to the

exhaust pipe, side under spoiler (if

equipped), engine undercover or rear

torsion beam.

WA R N I N G

• Shift into “R” (Reverse) when you

jack up the vehicle.

• Never jack up the vehicle with the

transaxle in “N” (Neutral). Other-

wise, unstable jack may cause an

accident.

(2)

(4)

(1)

(3)

WA R N I N G

Use genuine wheel bolts and tighten

them to the specified torque as soon

as possible after changing wheels.

Incorrect wheel bolts or improperly

tightened wheel bolts may come

loose or fall off, which can result in

an accident. If you do not have a

torque wrench, have the wheel bolt

torque checked by an authorized

SUZUKI dealer.

Page 407 of 482

8-7

EMERGENCY SERVICE

54P00-01E

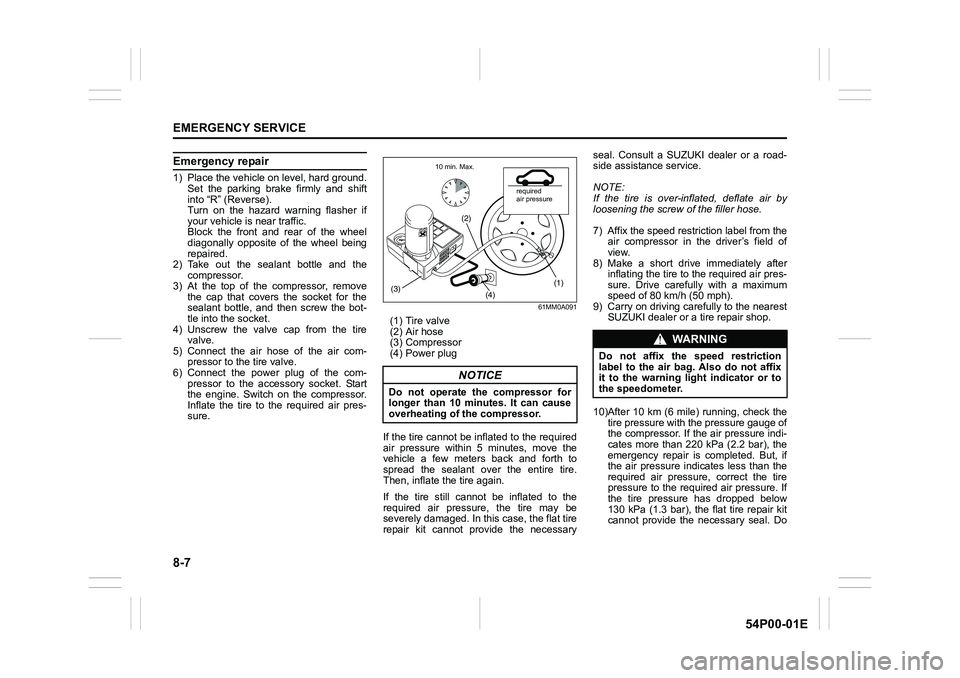

Emergency repair

1) Place the vehicle on level, hard ground.

Set the parking brake firmly and shift

into “R” (Reverse).

Turn on the hazard warning flasher if

your vehicle is near traffic.

Block the front and rear of the wheel

diagonally opposite of the wheel being

repaired.

2) Take out the sealant bottle and the

compressor.

3) At the top of the compressor, remove

the cap that covers the socket for the

sealant bottle, and then screw the bot-

tle into the socket.

4) Unscrew the valve cap from the tire

valve.

5) Connect the air hose of the air com-

pressor to the tire valve.

6) Connect the power plug of the com-

pressor to the accessory socket. Start

the engine. Switch on the compressor.

Inflate the tire to the required air pres-

sure.

61MM0A091

(1) Tire valve

(2) Air hose

(3) Compressor

(4) Power plug

If the tire cannot be inflated to the required

air pressure within 5 minutes, move the

vehicle a few meters back and forth to

spread the sealant over the entire tire.

Then, inflate the tire again.

If the tire still cannot be inflated to the

required air pressure, the tire may be

severely damaged. In this case, the flat tire

repair kit cannot provide the necessaryseal. Consult a SUZUKI dealer or a road-

side assistance service.

NOTE:

If the tire is over-inflated, deflate air by

loosening the screw of the filler hose.

7) Affix the speed restriction label from the

air compressor in the driver’s field of

view.

8) Make a short drive immediately after

inflating the tire to the required air pres-

sure. Drive carefully with a maximum

speed of 80 km/h (50 mph).

9) Carry on driving carefully to the nearest

SUZUKI dealer or a tire repair shop.

10)After 10 km (6 mile) running, check the

tire pressure with the pressure gauge of

the compressor. If the air pressure indi-

cates more than 220 kPa (2.2 bar), the

emergency repair is completed. But, if

the air pressure indicates less than the

required air pressure, correct the tire

pressure to the required air pressure. If

the tire pressure has dropped below

130 kPa (1.3 bar), the flat tire repair kit

cannot provide the necessary seal. Do

NOTICE

Do not operate the compressor for

longer than 10 minutes. It can cause

overheating of the compressor.

(1)

(4)

(2)

(3)

required

air pressure 10 min. Max.

WA R N I N G

Do not affix the speed restriction

label to the air bag. Also do not affix

it to the warning light indicator or to

the speedometer.