Speed SUZUKI IGNIS 2022 Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2022, Model line: IGNIS, Model: SUZUKI IGNIS 2022Pages: 505, PDF Size: 8.36 MB

Page 376 of 505

7-27INSPECTION AND MAINTENANCE

75RM4-01E

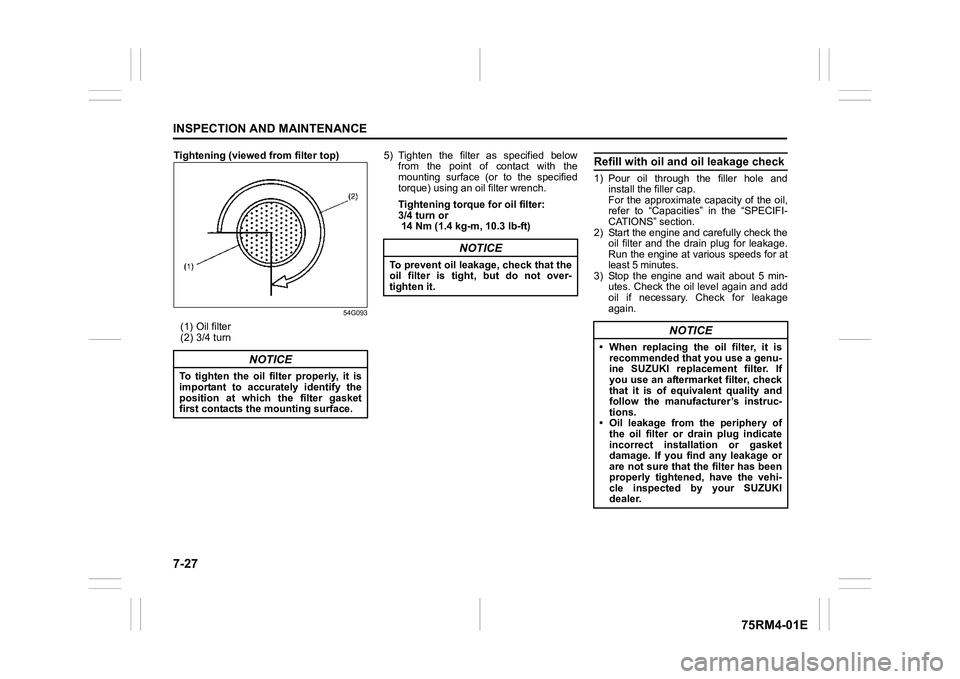

Tightening (viewed from filter top)

54G093

(1) Oil filter

(2) 3/4 turn5) Tighten the filter as specified below

from the point of contact with the

mounting surface (or to the specified

torque) using an oil filter wrench.

Tightening torque for oil filter:

3/4 turn or

14 Nm (1.4 kg -m, 10.3 lb-ft)

Refill with oil and oil leakage check1) Pour oil through the filler hole and

install the filler cap.

For the approximate capacity of the oil,

refer to “Capacities” in the “SPECIFI-

CATIONS” section.

2) Start the engine and carefully check the oil filter and the drain plug for leakage.

Run the engine at various speeds for at

least 5 minutes.

3) Stop the engine and wait about 5 min- utes. Check the oil level again and add

oil if necessary. Check for leakage

again.

NOTICE

To tighten the oil filter properly, it is

important to accurately identify the

position at which the filter gasket

first contacts the mounting surface.

NOTICE

To prevent oil leakage, check that the

oil filter is tight, but do not over-

tighten it.

NOTICE

• When replacing the oil filter, it is recommended that you use a genu-

ine SUZUKI replacement filter. If

you use an aftermarket filter, check

that it is of equi valent quality and

follow the manufacturer’s instruc-

tions.

• Oil leakage from the periphery of the oil filter or drain plug indicate

incorrect installation or gasket

damage. If you find any leakage or

are not sure that the filter has been

properly tightened, have the vehi-

cle inspected by your SUZUKI

dealer.

Page 381 of 505

7-32

INSPECTION AND MAINTENANCE

75RM4-01E

54G106

Spark plug gap “a”

ILZKR6F11:

1.0 – 1.1 mm (0.039 – 0.043 in.)

(For K12M engine model)

Since special procedures, materials and

tools are required, it is recommended that

you trust this job to your authorized

SUZUKI dealer.

Continuously variable transaxle (CVT) fluidSpecified fluidUse a CVT fluid SUZUKI CVT FLUID

GREEN-2.Fluid level checkYou must check the fluid level with the CVT

fluid at normal ope rating temperature.

To check the fluid level:

1) To warm up the CVT fluid, drive the vehicle for more 5 km. NOTE:

Do not check the fluid level if you have just

driven the vehicle for a long time at high

speed, or if you have driven in city traffic in

hot weather, or if the vehicle has been pull-

ing a trailer. Wait until the fluid cools down

(about 30 minutes), or the fluid level indi-

cation will not be correct.

2) Park your vehicle on level ground.

3) Apply the parking brake and then start

the engine in “P” (Park). Let it idle for

two minutes and keep it running during

the fluid level check.

4) With your foot on the brake pedal,

move the gearshift lever through each

gear, pausing for about three seconds

in each range. Then move it back to the

“P” (Park) position.

NOTICE

When replacing spark plugs, you

should use the brand and type speci-

fied for your vehicle. For the specified

plugs, refer to “SPECIFICATIONS”

section in the end of this book. If you

wish to use a brand of spark plug

other than the specified plugs, con-

sult your SUZUKI dealer.

NOTICE

Driving with too much or too little

fluid can damage the transaxle.

NOTICE

Be sure to use the specified CVT

fluid. Using CVT fluid other than

SUZUKI CVT FLUID GREEN-2 may

damage the CVT of your vehicle.

WA R N I N G

Be sure to depress the brake pedal

when moving the gearshift lever, or

the vehicle can move suddenly.

Page 389 of 505

7-40

INSPECTION AND MAINTENANCE

75RM4-01E

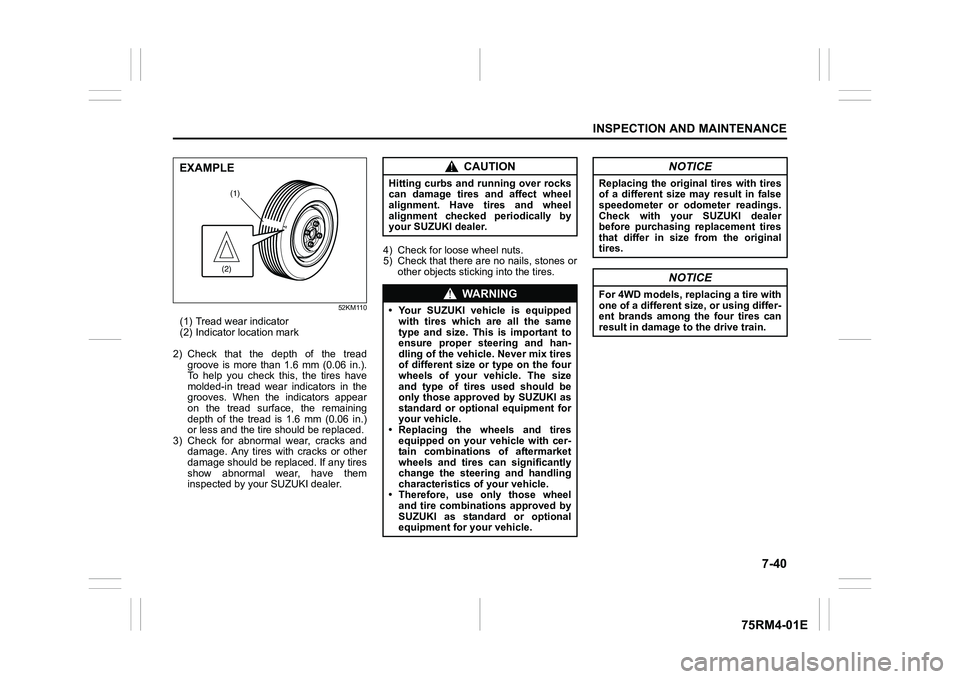

52KM110

(1) Tread wear indicator

(2) Indicator location mark

2) Check that the depth of the tread groove is more than 1.6 mm (0.06 in.).

To help you check this, the tires have

molded-in tread wear indicators in the

grooves. When the indicators appear

on the tread surface, the remaining

depth of the tread is 1.6 mm (0.06 in.)

or less and the tire should be replaced.

3) Check for abnormal wear, cracks and damage. Any tires with cracks or other

damage should be replaced. If any tires

show abnormal wear, have them

inspected by your SUZUKI dealer. 4) Check for loose wheel nuts.

5) Check that there are no nails, stones or

other objects sticki ng into the tires.

(1)(2)

EXAMPLE

CAUTION

Hitting curbs and running over rocks

can damage tires and affect wheel

alignment. Have tires and wheel

alignment checked periodically by

your SUZUKI dealer.

WA R N I N G

• Your SUZUKI vehicle is equipped

with tires which are all the same

type and size. This is important to

ensure proper steering and han-

dling of the vehicle. Never mix tires

of different size or type on the four

wheels of your vehicle. The size

and type of tires used should be

only those approved by SUZUKI as

standard or optional equipment for

your vehicle.

• Replacing the wheels and tires

equipped on your vehicle with cer-

tain combinations of aftermarket

wheels and tires can significantly

change the steering and handling

characteristics of your vehicle.

• Therefore, use only those wheel

and tire combinations approved by

SUZUKI as standard or optional

equipment for your vehicle.

NOTICE

Replacing the original tires with tires

of a different size may result in false

speedometer or odometer readings.

Check with your SUZUKI dealer

before purchasing replacement tires

that differ in size from the original

tires.

NOTICE

For 4WD models, replacing a tire with

one of a different size, or using differ-

ent brands among the four tires can

result in damage to the drive train.

Page 415 of 505

8-6

EMERGENCY SERVICE

75RM4-01E

IMPORTANT

The flat tire repair kit cannot be used in

the following cases. Consult a SUZUKI

dealer or a roadside assistance service.

• Cuts or piercing in the tire treadlarger than approx. 4 mm.

• Cuts in the tire side wall.

• Tire damage caused by driving with considerably reduced tire pressure or

even with deflated tire.

• The tire bead completely unseated outside of the rim.

• The rim damaged.

Small punctures in the tire tread,

caused by a nail or a screw, can be

sealed with the flat tire repair kit.

Do not remove nails or screws from the

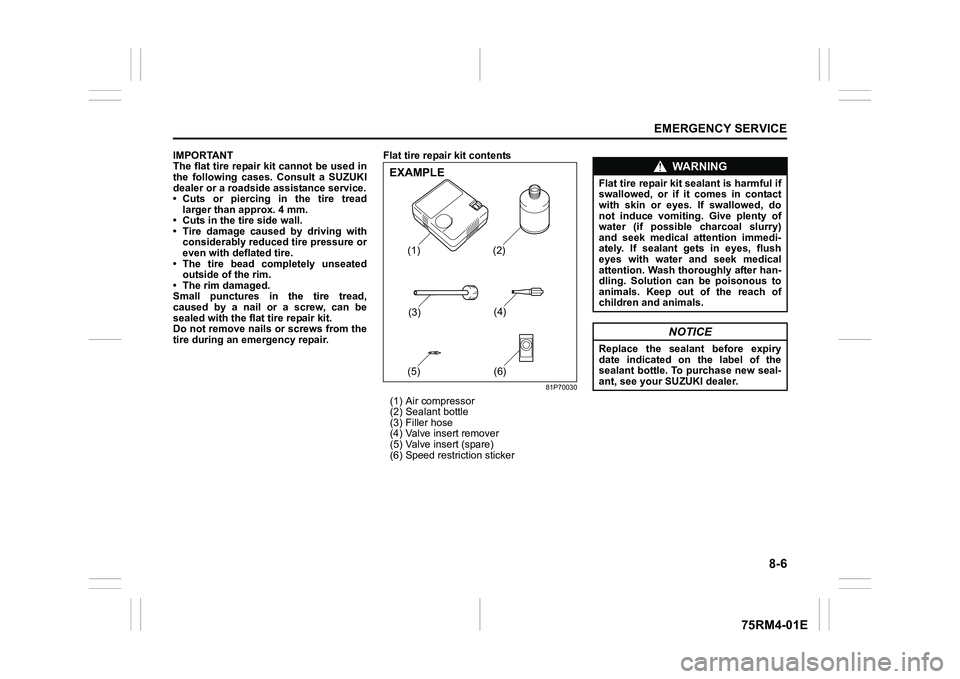

tire during an e mergency repair. Flat tire repair kit contents

81P70030

(1) Air compressor

(2) Sealant bottle

(3) Filler hose

(4) Valve insert remover

(5) Valve insert (spare)

(6) Speed restriction sticker

(1)(3)

(4)

(5)

(6)(2)

EXAMPLE

WA R N I N G

Flat tire repair kit sealant is harmful if

swallowed, or if it comes in contact

with skin or eyes. If swallowed, do

not induce vomiting. Give plenty of

water (if possible charcoal slurry)

and seek medical attention immedi-

ately. If sealant gets in eyes, flush

eyes with water and seek medical

attention. Wash thoroughly after han-

dling. Solution can be poisonous to

animals. Keep out of the reach of

children and animals.

NOTICE

Replace the sealant before expiry

date indicated on the label of the

sealant bottle. To purchase new seal-

ant, see your SUZUKI dealer.

Page 418 of 505

8-9EMERGENCY SERVICE

75RM4-01E

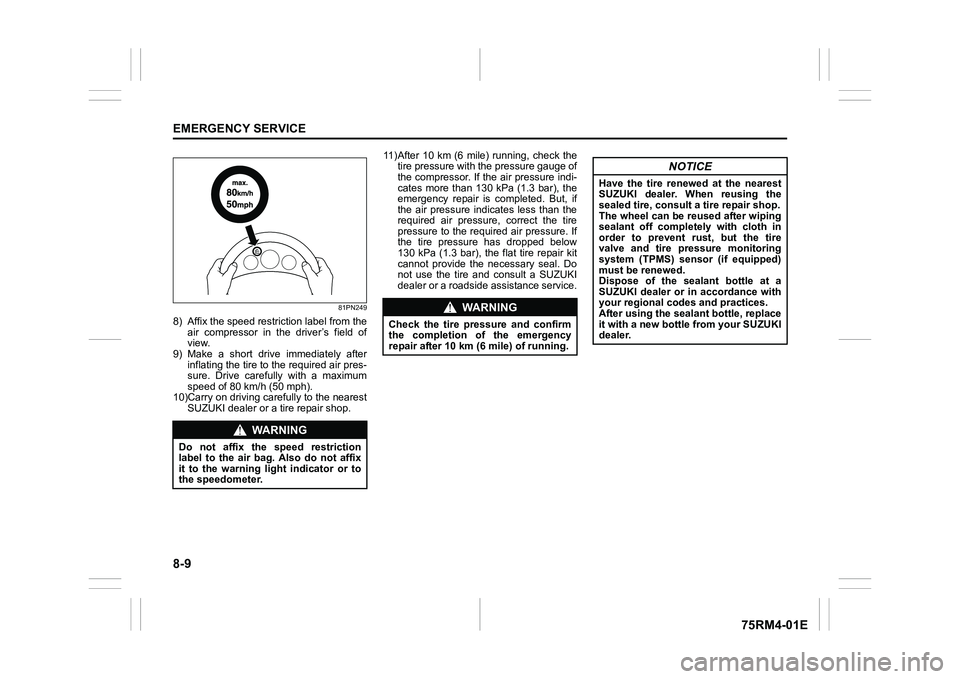

81PN249

8) Affix the speed restriction label from theair compressor in the driver’s field of

view.

9) Make a short drive immediately after inflating the tire to the required air pres-

sure. Drive carefully with a maximum

speed of 80 km/h (50 mph).

10)Carry on driving carefully to the nearest

SUZUKI dealer or a tire repair shop. 11)After 10 km (6 mile) running, check the

tire pressure with the pressure gauge of

the compressor. If the air pressure indi-

cates more than 130 kPa (1.3 bar), the

emergency repair is completed. But, if

the air pressure indicates less than the

required air pressure, correct the tire

pressure to the required air pressure. If

the tire pressure has dropped below

130 kPa (1.3 bar), the flat tire repair kit

cannot provide the necessary seal. Do

not use the tire and consult a SUZUKI

dealer or a roadside assistance service.

WA R N I N G

Do not affix the speed restriction

label to the air bag. Also do not affix

it to the warning light indicator or to

the speedometer.

WA R N I N G

Check the tire pressure and confirm

the completion o f the emergency

repair after 10 km (6 mile) of running.

NOTICE

Have the tire renewed at the nearest

SUZUKI dealer. When reusing the

sealed tire, consult a tire repair shop.

The wheel can be reused after wiping

sealant off completely with cloth in

order to prevent rust, but the tire

valve and tire pressure monitoring

system (TPMS) sensor (if equipped)

must be renewed.

Dispose of the sealant bottle at a

SUZUKI dealer or in accordance with

your regional codes and practices.

After using the seal ant bottle, replace

it with a new bottle from your SUZUKI

dealer.

Page 420 of 505

8-11EMERGENCY SERVICE

75RM4-01E

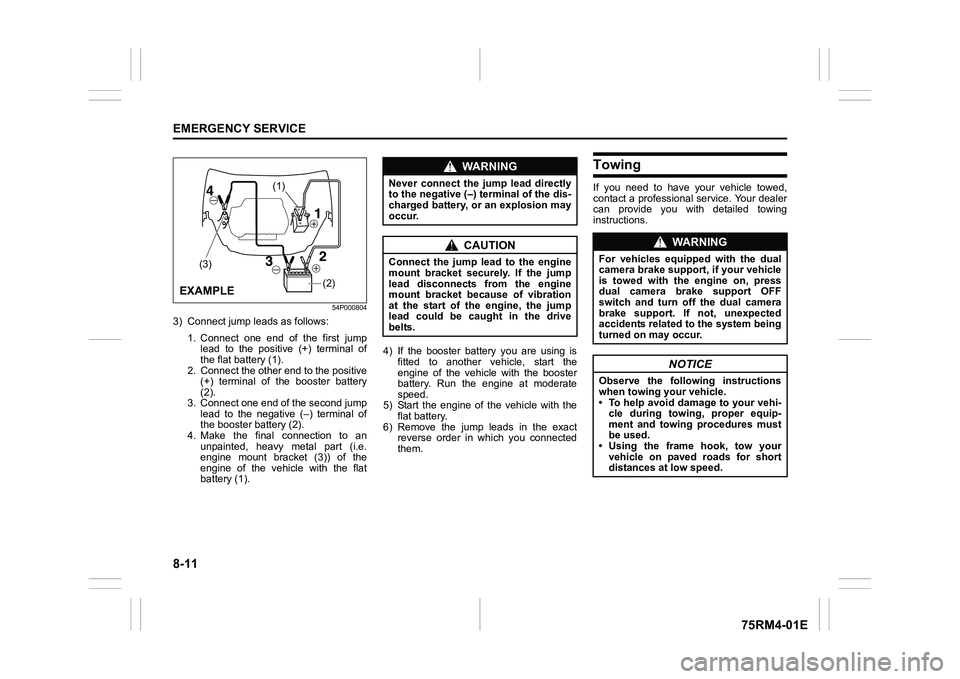

54P000804

3) Connect jump leads as follows:1. Connect one end of the first jumplead to the positive (+) terminal of

the flat battery (1).

2. Connect the other end to the positive (+) terminal of the booster battery

(2).

3. Connect one end of the second jump lead to the negative (–) terminal of

the booster battery (2).

4. Make the final connection to an unpainted, heavy metal part (i.e.

engine mount bracket (3)) of the

engine of the vehicle with the flat

battery (1). 4) If the booster battery you are using is

fitted to another vehicle, start the

engine of the vehicle with the booster

battery. Run the engine at moderate

speed.

5) Start the engine of the vehicle with the flat battery.

6) Remove the jump leads in the exact reverse order in which you connected

them.

TowingIf you need to have your vehicle towed,

contact a professional service. Your dealer

can provide you with detailed towing

instructions.

(2)

(1)

(3)

EXAMPLE

WA R N I N G

Never connect the jump lead directly

to the negative (–) terminal of the dis-

charged battery, or an explosion may

occur.

CAUTION

Connect the jump l ead to the engine

mount bracket securely. If the jump

lead disconnects from the engine

mount bracket because of vibration

at the start of the engine, the jump

lead could be caught in the drive

belts.

WA R N I N G

For vehicles equipped with the dual

camera brake support, if your vehicle

is towed with the engine on, press

dual camera brake support OFF

switch and turn off the dual camera

brake support. If not, unexpected

accidents related to the system being

turned on may occur.

NOTICE

Observe the following instructions

when towing your vehicle.

• To help avoid damage to your vehi- cle during towing, proper equip-

ment and towing procedures must

be used.

• Using the frame hook, tow your

vehicle on paved roads for short

distances at low speed.

Page 422 of 505

8-13EMERGENCY SERVICE

75RM4-01E

Engine trouble: Starter does not operate1) Try turning the ignition switch to“START” position or try pressing the

engine switch to change the ignition

mode to START with the headlights

turned on to determine the lead-acid

battery condition. If the headlights go

excessively dim or go off, it usually

means that either the lead-acid battery

is flat or the battery terminal contact is

poor. Recharge the lead-acid battery or

correct battery terminal contact as nec-

essary.

2) If the headlights remain bright, check the fuses. If the reas on for failure of the

starter is not obvious, there may be a

major electrical problem. Have the vehi-

cle inspected by your authorized

SUZUKI dealer.

Engine trouble: Flooded engine(Vehicle without keyless push start sys-

tem)

If the engine is flooded with gasoline, it

may be hard to start. If this happens, press

the accelerator pedal all the way to the

floor and hold it there while cranking the

engine.

• Do not operate the starter motor for more than 12 seconds.

(Vehicle with keyless push start system)

If the engine is flooded with gasoline, it

may be hard to start. If this happens, press

the accelerator pedal all the way to the

floor and hold it there while cranking the

engine.

• Do not operate the starter motor for more than 12 seconds.

NOTE:

If the engine refuses to start, the starter

motor automatically stops after a certain

period of time. After the starter motor has

automatically stopped or if there is any-

thing abnormal in the engine starting sys-

tem, the starter motor runs only while the

engine switch is held pressed.

Engine trouble: OverheatingThe engine could overheat temporarily

under severe driving conditions. If the high

engine coolant temperature warning light

comes on as overheating during driving:

1) Turn off the air conditioner, if equipped.

2) Take the vehicle to a safe place and park.

3) Let the engine run at the normal idle speed for a few minutes until the high

engine coolant temperature warning

light goes off.

WA R N I N G

If you see or hear escaping steam,

stop the vehicle in a safe place and

immediately turn off the engine to

cool it. Do not open the hood when

steam is present. When the steam

can no longer be seen or heard, open

the hood to see if the coolant is still

boiling. If it is, you must wait until it

stops boiling before you proceed.

Page 436 of 505

11-4SPECIFICATIONS

75RM4-01E

*1 If you cannot prepare tires with the specified load index rate and speed symbol, prepare tires with higher load index rate a nd speed

symbol.

*2 If you prepare snow tires;

• Check that they are tires of the same size, structure and load capacity as the originally installed tires.

• Mount the snow tires on all four wheels.

• Understand that the maximum pe rmissible speed of snow tires is generally less than the originally installed tires.

Consult your SUZUKI dealer or su pplier for further information.

ITEM: Wheels and tires

Tire size, front and rear

175/65R15 84H

*1, 175/60R16 82H

*1

Rim size 175/65R15 tire: 15X5J

175/60R16 tire: 16X5J

Tire pressures For the specified tire pressure, see the tire information label located

on the driver’s door lock pillar.

Recommended snow chain (for Euro pe) Radial thickness: 10 mm, axi al thickness: 10 mm

Recommended snow tire 175/65R15

*2 or 175/60R16

*2

Page 440 of 505

12-1SUPPLEMENT

75RM4-01E

For AustraliaBuilt dateBuilt date is located on Vehicle Identifica-

tion plate.

“Built date” means – the calendar month

and the year in which the body shell and

power train sub-assemblies are conjoined

and the vehicle is driven or moved from the

production line.Temporary-use spare tire (compact spare tire)Temporary Spare Tires fitted to this vehicle

must have a maximum load rating of not

less than 775 kg, or a load index of “99”

and a speed category symbol of not less

than “M” (130 km/h).

Drive with caution when the Temporary-

Use Spare Unit is fitted. Reinstall standard

unit as soon as possible.

Child restraint

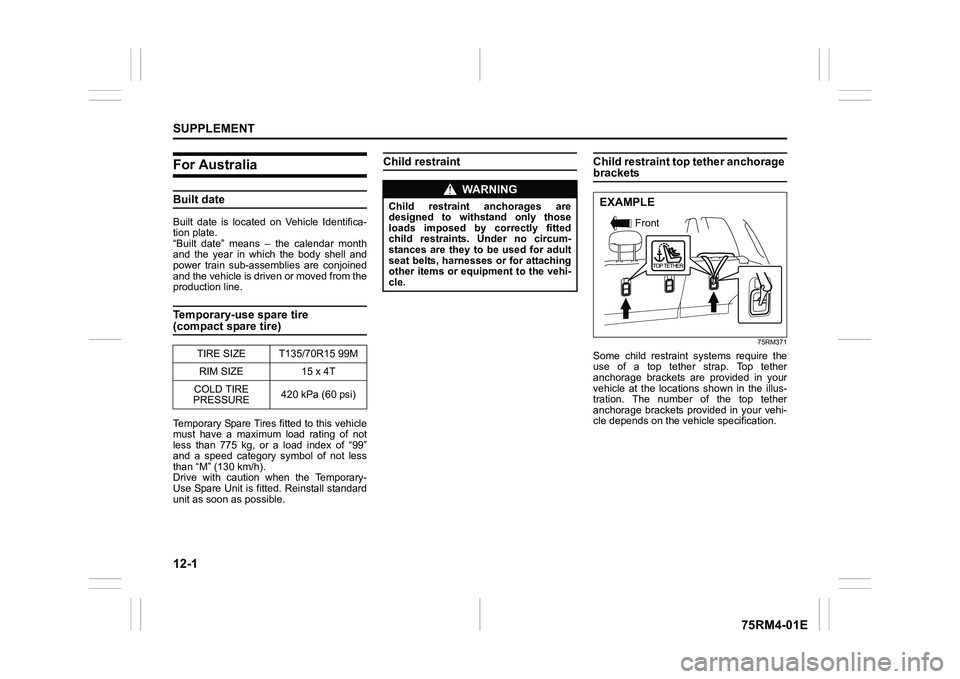

Child restraint top tether anchorage brackets

75RM371

Some child restraint systems require the

use of a top tether strap. Top tether

anchorage brackets are provided in your

vehicle at the locations shown in the illus-

tration. The number of the top tether

anchorage brackets provided in your vehi-

cle depends on the v ehicle specification.

TIRE SIZE T135/70R15 99M

RIM SIZE 15 x 4T

COLD TIRE

PRESSURE 420 kPa (60 psi)

WA R N I N G

Child restraint anchorages are

designed to withstand only those

loads imposed by correctly fitted

child restraints. Under no circum-

stances are they to be used for adult

seat belts, harnesses or for attaching

other items or equipment to the vehi-

cle.

EXAMPLE

Front

Page 442 of 505

12-3SUPPLEMENT

75RM4-01E

Seat belt warningFollow this warning as well as the instruc-

tion for seat belt in this book.In the case where a “Seat Belt Assembly”

incorporates an “ Automatic Length Adjust-

ing and Locking Retractor ” or an “Emer-

gency Locking Retractor ”.

For GCC countriesTechnical data

1.2L

Max power : 61kW/6000 rpm

Max torque : 113Nm/4200 rpm

Max speed : 170km/h (2WD M/T)

160km/h (2WD CVT)

WA R N I N G

Seat belts are designed to bear upon

the bony structure of the body, and

should be worn low across the front

of the pelvis or the pelvis, chest and

shoulders, as applicable; wearing the

lap section of the belt across the

abdominal area must be avoided.

• Seat belts should be adjusted as

firmly as possible, consistent with

comfort, to provide the protection

for which they have been designed.

A slack belt will greatly reduce the

protection afforded to the wearer.

• Care should be taken to avoid con-

tamination of the webbing with pol-

ishes, oils and chemicals, and

particularly battery acid. Cleaning

may safely be carried out using

mild soap and water. The belt

should be replaced if webbing

becomes frayed, contaminated or

damaged. (Continued)

WA R N I N G

(Continued)

• It is essential to replace the entire

assembly after it has been worn in

a severe impact even if damage to

the assembly is not obvious.

• Belts should not be worn with straps twisted.

• Each belt assembly must only be

used by one occupant; it is danger-

ous to put a belt around a child

being carried on the occupant’s

lap.

WA R N I N G

• No modifications or additionsshould be made by the user which

will either prevent the seat belt

adjusting devices from operating to

remove slack, or prevent the seat

belt assembly from being adjusted

to remove slack.

• Referring to the SEAT BELT instruction in this book, adjust the

seat belt so that the lap and sash

portions of the Seat Belt Assembly

fit as firmly as possible consistent

with comfort.