cvt SUZUKI IGNIS 2022 Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2022, Model line: IGNIS, Model: SUZUKI IGNIS 2022Pages: 505, PDF Size: 8.36 MB

Page 377 of 505

7-28

INSPECTION AND MAINTENANCE

75RM4-01E

Engine coolantSelection of coolantTo maintain optimum performance and

durability of your engine, use SUZUKI gen-

uine coolant or equivalent.

NOTE:

If you use the engine coolant other than

the SUZUKI LLC: Super (Blue) for replace-

ment, follow the schedule of SUZUKI LLC:

Standard (Green). To see the detail of the

maintenance schedule, refer to “Periodic

maintenance schedule” in this section.

This type of coolant is the best for cooling

system for the following reasons:

• The coolant helps maintain properengine temperature.

• It gives proper protection against freez- ing and boiling.

• It gives proper protection against corro- sion and rust. Failure to use the proper coolant can dam-

age your cooling system. Your authorized

SUZUKI dealer can help you select the

proper coolant.

Coolant level checkCheck the coolant le

vel at the reservoir

tank, not at the radiator. With the engine

cool, the coolant level should be between

“FULL” and “LOW” marks.Adding coolant

NOTICE

SUZUKI LLC: Super (Blue) coolant;

This coolant is already diluted to the

proper percentage. Do not dilute with

distilled water additionally. Doing so

may result in the possibility of freez-

ing and/or overheating coolant.

NOTICE

To avoid damaging your cooling sys-

tem:

• Always use a high quality ethylene

glycol base non-silicate type cool-

ant diluted with distilled water at

the correct mixture concentration.

• Check that the proper mix is 50/50

coolant to distill ed water and in no

case higher than 70/30. Concentra-

tions greater than 70/30 coolant to

distilled water will cause overheat-

ing conditions.

• Do not use straight coolant nor plain water (except SUZUKI LLC:

Super (Blue)).

• Do not add extra inhibitors or addi- tives. They may not be compatible

with your cooling system.

• Do not mix different types of base coolants. Doing so may result in

accelerated seal wear and/or the

possibility of severe overheating

and extensive engine or CVT (if

equipped) damage.

WA R N I N G

Swallowing engine coolant can cause

severe injury or death. Inhaling cool-

ant mist or vapors or getting coolant

in your eyes could result in severe

injury.

• Do not drink antifreeze or coolantsolution. If swallowed, do not

induce vomiting. Immediately con-

tact a poison control center or a

physician.

• Avoid inhaling coolant mist or hot

vapors. If inhaled, remove to a

fresh air area.

• If coolant gets in the eyes, flush

with water and seek medical atten-

tion.

• Wash thoroughly after handling

coolant.

• Keep engine coolant out of the

reach of children and pets.

Page 381 of 505

7-32

INSPECTION AND MAINTENANCE

75RM4-01E

54G106

Spark plug gap “a”

ILZKR6F11:

1.0 – 1.1 mm (0.039 – 0.043 in.)

(For K12M engine model)

Since special procedures, materials and

tools are required, it is recommended that

you trust this job to your authorized

SUZUKI dealer.

Continuously variable transaxle (CVT) fluidSpecified fluidUse a CVT fluid SUZUKI CVT FLUID

GREEN-2.Fluid level checkYou must check the fluid level with the CVT

fluid at normal ope rating temperature.

To check the fluid level:

1) To warm up the CVT fluid, drive the vehicle for more 5 km. NOTE:

Do not check the fluid level if you have just

driven the vehicle for a long time at high

speed, or if you have driven in city traffic in

hot weather, or if the vehicle has been pull-

ing a trailer. Wait until the fluid cools down

(about 30 minutes), or the fluid level indi-

cation will not be correct.

2) Park your vehicle on level ground.

3) Apply the parking brake and then start

the engine in “P” (Park). Let it idle for

two minutes and keep it running during

the fluid level check.

4) With your foot on the brake pedal,

move the gearshift lever through each

gear, pausing for about three seconds

in each range. Then move it back to the

“P” (Park) position.

NOTICE

When replacing spark plugs, you

should use the brand and type speci-

fied for your vehicle. For the specified

plugs, refer to “SPECIFICATIONS”

section in the end of this book. If you

wish to use a brand of spark plug

other than the specified plugs, con-

sult your SUZUKI dealer.

NOTICE

Driving with too much or too little

fluid can damage the transaxle.

NOTICE

Be sure to use the specified CVT

fluid. Using CVT fluid other than

SUZUKI CVT FLUID GREEN-2 may

damage the CVT of your vehicle.

WA R N I N G

Be sure to depress the brake pedal

when moving the gearshift lever, or

the vehicle can move suddenly.

Page 382 of 505

7-33INSPECTION AND MAINTENANCE

75RM4-01E

75F086

81PN159 75RM370

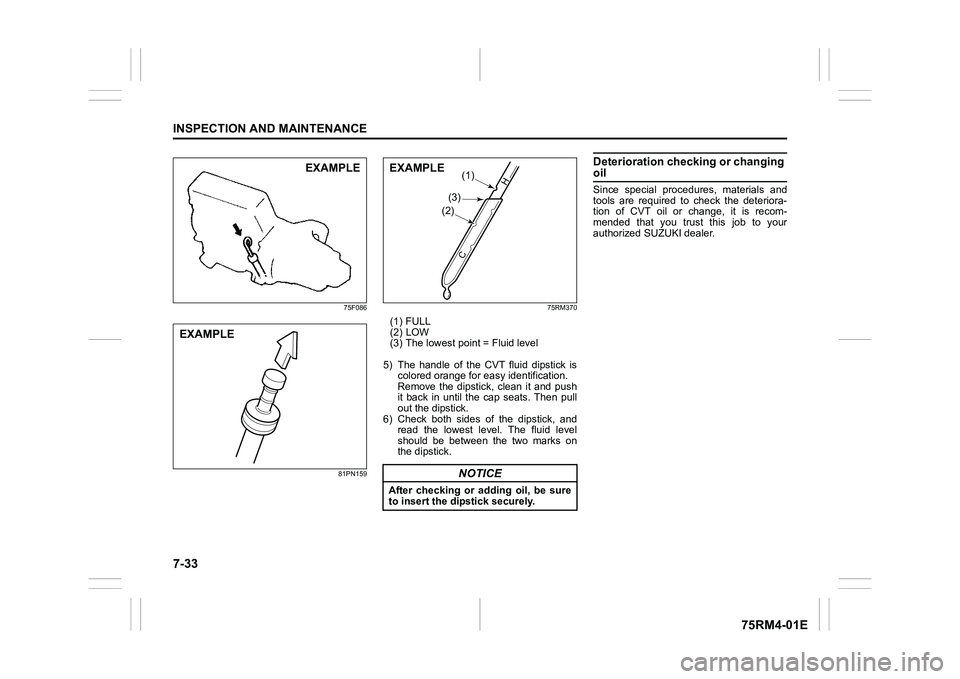

(1) FULL

(2) LOW

(3) The lowest point = Fluid level

5) The handle of the CVT fluid dipstick is colored orange for ea sy identification.

Remove the dipstick, clean it and push

it back in until the cap seats. Then pull

out the dipstick.

6) Check both sides of the dipstick, and read the lowest level. The fluid level

should be between the two marks on

the dipstick.

Deterioration checking or changing oilSince special procedures, materials and

tools are required to check the deteriora-

tion of CVT oil or change, it is recom-

mended that you trust this job to your

authorized SUZUKI dealer.

EXAMPLE

EXAMPLE

NOTICE

After checking or adding oil, be sure

to insert the di pstick securely.

(3)

(1)

(2)

C

H

�(�Ο�Ν�0�3�/�(

Page 395 of 505

7-46

INSPECTION AND MAINTENANCE

75RM4-01E

*1: Models with ENG A-STOP

*2: CVT models with ENG A-STOP

*3: Auto Gear Shift models

*4: Models with Auto-on headlight system

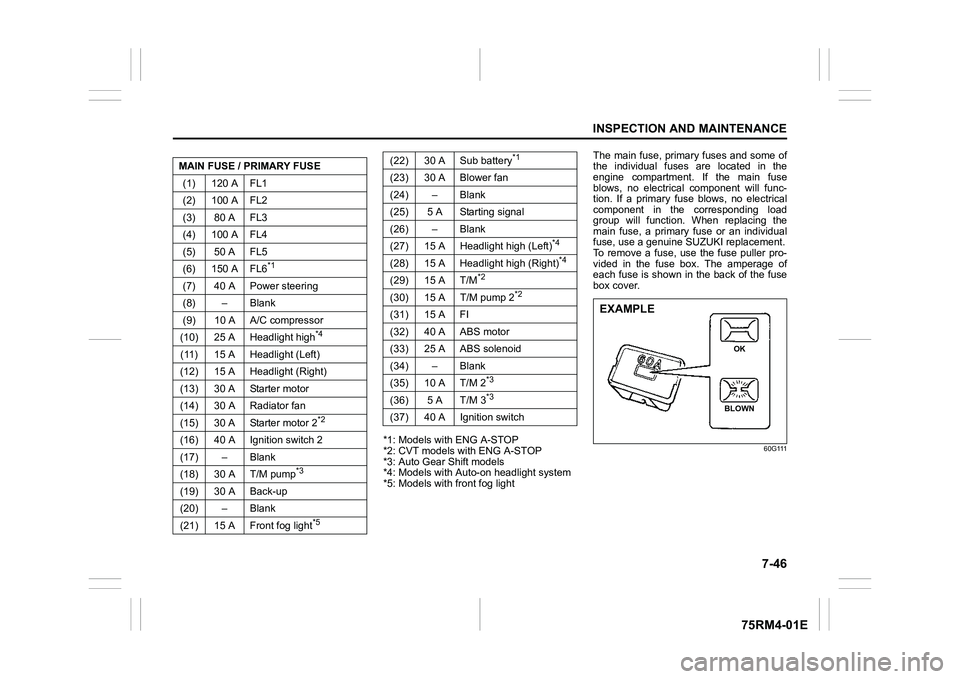

*5: Models with front fog light The main fuse, primary fuses and some of

the individual fuses are located in the

engine compartment. If the main fuse

blows, no electrical component will func-

tion. If a primary fuse blows, no electrical

component in the corresponding load

group will function. When replacing the

main fuse, a primary fuse or an individual

fuse, use a genuine S

UZUKI replacement.

To remove a fuse, use the fuse puller pro-

vided in the fuse box. The amperage of

each fuse is shown in the back of the fuse

box cover.

60G111

MAIN FUSE / PRIMARY FUSE

(1) 120 A FL1

(2) 100 A FL2

(3) 80 A FL3

(4) 100 A FL4

(5) 50 A FL5

(6) 150 A FL6

*1

(7) 40 A Power steering

(8) – Blank

(9) 10 A A/C compressor

(10) 25 A Headlight high

*4

(11) 15 A Headlight (Left)

(12) 15 A Headlight (Right)

(13) 30 A Starter motor

(14) 30 A Radiator fan

(15) 30 A Starter motor 2

*2

(16) 40 A Ignition switch 2

(17) – Blank

(18) 30 A T/M pump

*3

(19) 30 A Back-up

(20) – Blank

(21) 15 A Front fog light

*5

(22) 30 A Sub battery

*1

(23) 30 A Blower fan

(24) – Blank

(25) 5 A Starting signal

(26) – Blank

(27) 15 A Headlight high (Left)

*4

(28) 15 A Headlight high (Right)

*4

(29) 15 A T/M

*2

(30) 15 A T/M pump 2

*2

(31) 15 A FI

(32) 40 A ABS motor

(33) 25 A ABS solenoid

(34) – Blank

(35) 10 A T/M 2

*3

(36) 5 A T/M 3

*3

(37) 40 A Ignition switch

EXAMPLE

BLOWN OK

Page 410 of 505

8-1EMERGENCY SERVICE

75RM4-01E

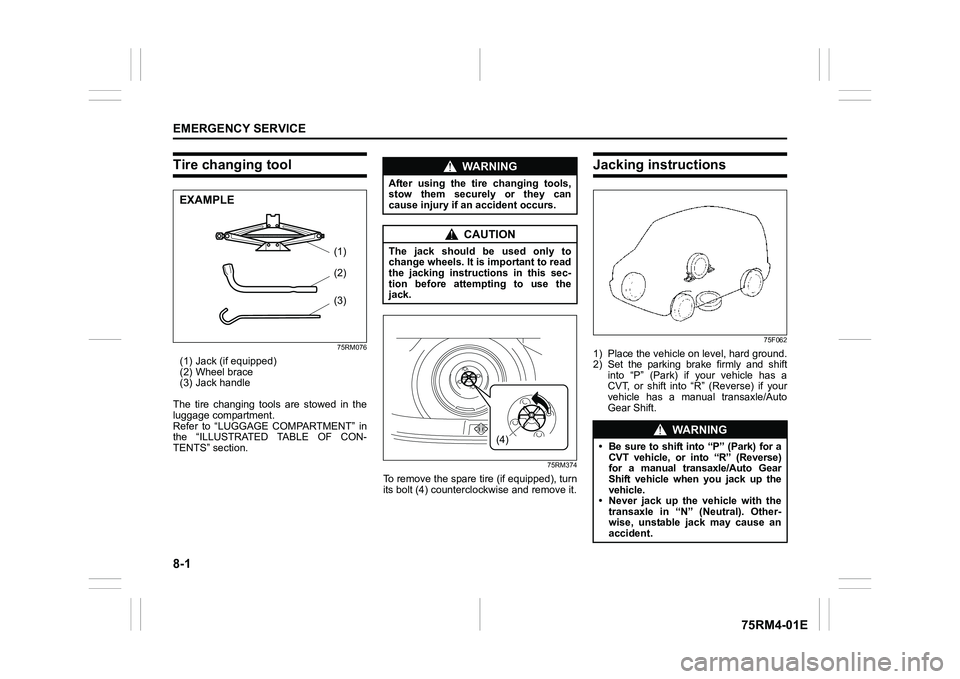

Tire changing tool

75RM076

(1) Jack (if equipped)

(2) Wheel brace

(3) Jack handle

The tire changing tools are stowed in the

luggage compartment.

Refer to “LUGGAGE COMPARTMENT” in

the “ILLUSTRATED TABLE OF CON-

TENTS” section.

75RM374

To remove the spare tire (if equipped), turn

its bolt (4) countercl ockwise and remove it.

Jacking instructions

75F062

1) Place the vehicle on level, hard ground.

2) Set the parking brake firmly and shift into “P” (Park) if your vehicle has a

CVT, or shift into “R” (Reverse) if your

vehicle has a manual transaxle/Auto

Gear Shift.

(3)(2)

(1)

EXAMPLE

WA R N I N G

After using the tire changing tools,

stow them securely or they can

cause injury if an accident occurs.

CAUTION

The jack should be used only to

change wheels. It is important to read

the jacking instructions in this sec-

tion before attempting to use the

jack.

(4)

�:�Ν �5 �1 �, �1 �*

�

Page 413 of 505

8-4

EMERGENCY SERVICE

75RM4-01E

NOTE:

For more details, contact an authorized

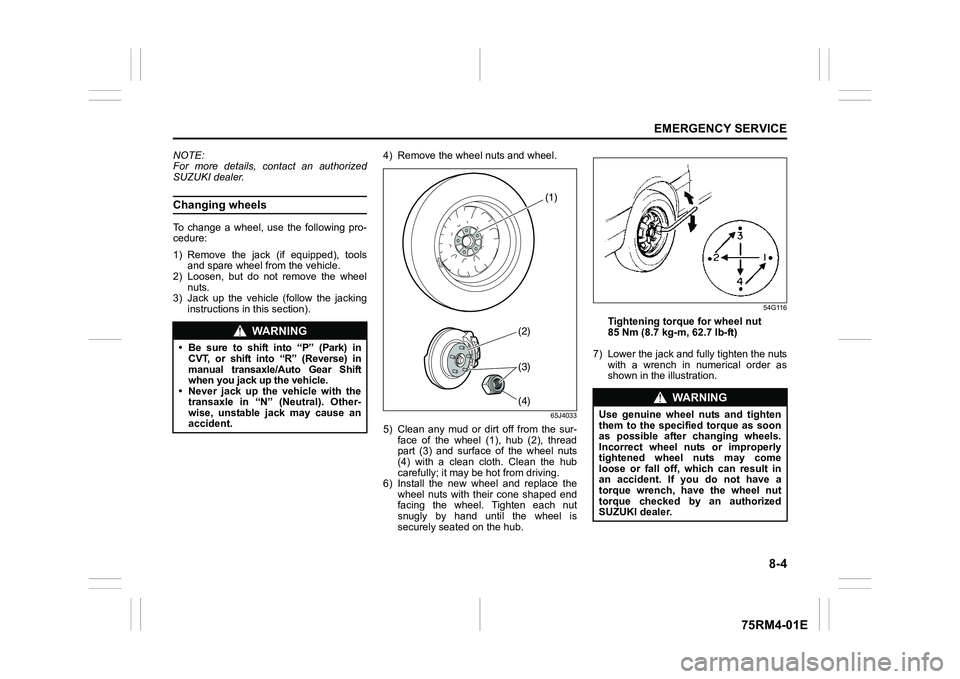

SUZUKI dealer.Changing wheelsTo change a wheel, use the following pro-

cedure:

1) Remove the jack (if equipped), toolsand spare wheel from the vehicle.

2) Loosen, but do not remove the wheel

nuts.

3) Jack up the vehicle (follow the jacking instructions in this section). 4) Remove the wheel nuts and wheel.

65J4033

5) Clean any mud or dirt off from the sur-

face of the wheel (1), hub (2), thread

part (3) and surface of the wheel nuts

(4) with a clean cloth. Clean the hub

carefully; it m ay be hot from driving.

6) Install the new wheel and replace the

wheel nuts with their cone shaped end

facing the wheel. Tighten each nut

snugly by hand until the wheel is

securely seated on the hub.

54G116

Tightening torque for wheel nut

85 Nm (8.7 kg-m, 62.7 lb-ft)

7) Lower the jack and fully tighten the nuts with a wrench in numerical order as

shown in the illustration.

WA R N I N G

• Be sure to shift into “P” (Park) inCVT, or shift into “R” (Reverse) in

manual transaxle/Auto Gear Shift

when you jack up the vehicle.• Never jack up the vehicle with the

transaxle in “N” (Neutral). Other-

wise, unstable jack may cause an

accident.

(2)(4)

(1)

(3)

WA R N I N G

Use genuine wheel nuts and tighten

them to the specified torque as soon

as possible after changing wheels.

Incorrect wheel nut s or improperly

tightened wheel nuts may come

loose or fall off, which can result in

an accident. If you do not have a

torque wrench, have the wheel nut

torque checked by an authorized

SUZUKI dealer.

Page 416 of 505

8-7EMERGENCY SERVICE

75RM4-01E

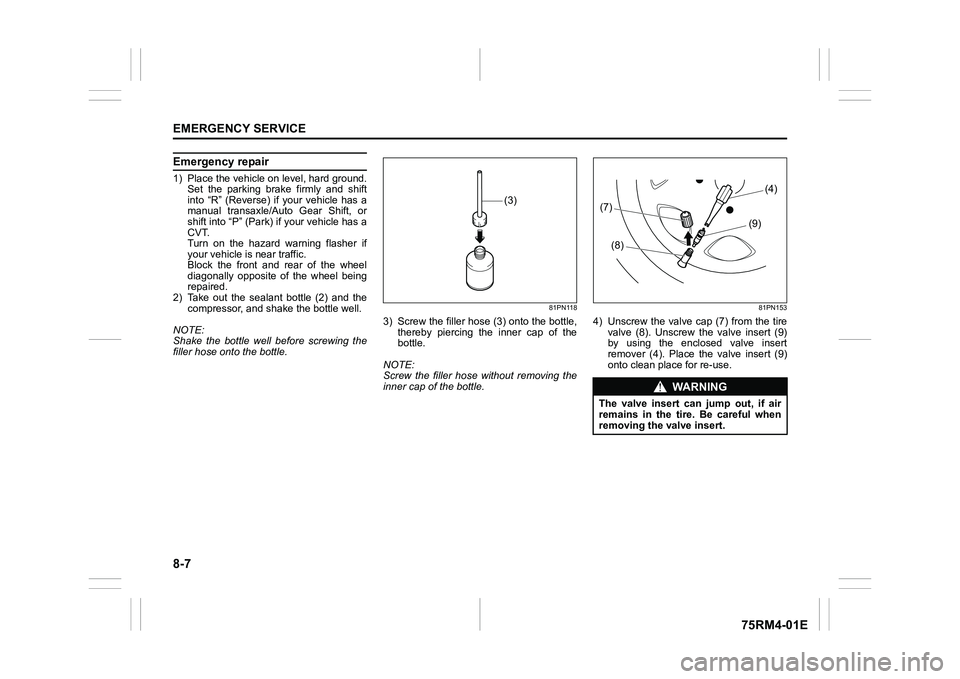

Emergency repair1) Place the vehicle on level, hard ground.

Set the parking brake firmly and shift

into “R” (Reverse) if your vehicle has a

manual transaxle/Auto Gear Shift, or

shift into “P” (Park) if your vehicle has a

CVT.

Turn on the hazard warning flasher if

your vehicle is near traffic.

Block the front and rear of the wheel

diagonally opposite of the wheel being

repaired.

2) Take out the sealant bottle (2) and the compressor, and shake the bottle well.

NOTE:

Shake the bottle well before screwing the

filler hose onto the bottle.

81PN118

3) Screw the filler hose (3) onto the bottle, thereby piercing the inner cap of the

bottle.

NOTE:

Screw the filler hose without removing the

inner cap of the bottle.

81PN153

4) Unscrew the valve cap (7) from the tire valve (8). Unscrew the valve insert (9)

by using the enclosed valve insert

remover (4). Place the valve insert (9)

onto clean place for re-use.

(3)

WA R N I N G

The valve insert can jump out, if air

remains in the tire. Be careful when

removing the valve insert.(7)

(8) (9)(4)

Page 419 of 505

8-10

EMERGENCY SERVICE

75RM4-01E

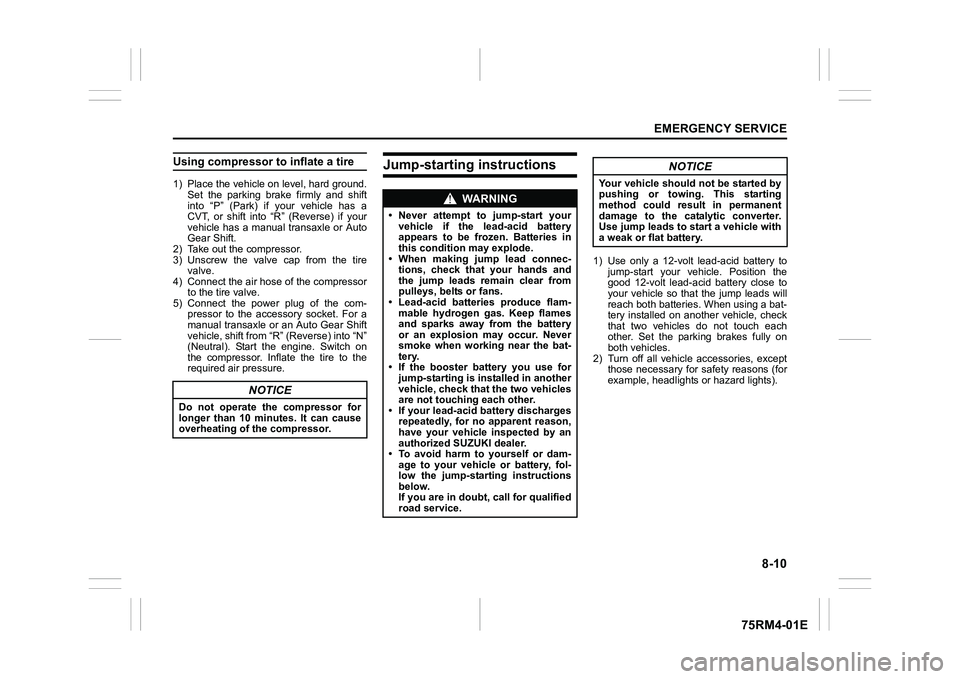

Using compressor to inflate a tire1) Place the vehicle on level, hard ground.

Set the parking brake firmly and shift

into “P” (Park) if your vehicle has a

CVT, or shift into “R” (Reverse) if your

vehicle has a manual transaxle or Auto

Gear Shift.

2) Take out the compressor.

3) Unscrew the valve cap from the tire valve.

4) Connect the air ho se of the compressor

to the tire valve.

5) Connect the power plug of the com- pressor to the accessory socket. For a

manual transaxle or an Auto Gear Shift

vehicle, shift from “R” (Reverse) into “N”

(Neutral). Start the engine. Switch on

the compressor. Inflate the tire to the

required air pressure.

Jump-starting instructions

1) Use only a 12-volt lead-acid battery to

jump-start your vehicle. Position the

good 12-volt lead-acid battery close to

your vehicle so that the jump leads will

reach both batteries. When using a bat-

tery installed on another vehicle, check

that two vehicles do not touch each

other. Set the parking brakes fully on

both vehicles.

2) Turn off all vehicle accessories, except those necessary for safety reasons (for

example, headlights or hazard lights).

NOTICE

Do not operate the compressor for

longer than 10 minutes. It can cause

overheating of the compressor.

WA R N I N G

• Never attempt to jump-start your

vehicle if the lead-acid battery

appears to be frozen. Batteries in

this condition may explode.

• When making jump lead connec- tions, check that your hands and

the jump leads remain clear from

pulleys, belts or fans.

• Lead-acid batteries produce flam-

mable hydrogen gas. Keep flames

and sparks away from the battery

or an explosion may occur. Never

smoke when working near the bat-

tery.

• If the booster ba ttery you use for

jump-starting is installed in another

vehicle, check that the two vehicles

are not touching each other.

• If your lead-acid battery discharges repeatedly, for no apparent reason,

have your vehicle inspected by an

authorized SUZUKI dealer.

• To avoid harm to yourself or dam- age to your vehicle or battery, fol-

low the jump-starting instructions

below.

If you are in doubt, call for qualified

road service.

NOTICE

Your vehicle should not be started by

pushing or towing. This starting

method could result in permanent

damage to the catalytic converter.

Use jump leads to start a vehicle with

a weak or flat battery.

Page 421 of 505

8-12

EMERGENCY SERVICE

75RM4-01E

2-wheel drive (2WD) CVTCVT vehicles may be towed using either of

the following methods.

1) From the front, with the front wheelslifted and the rear wheels on the

ground. Before towing, make sure that

the parking brak e is released.

2) From the rear, with the rear wheels

lifted and a dolly under the front wheels.

2-wheel drive (2WD) manual tran-saxle or Auto Gear ShiftManual transaxle vehicles or Auto Gear

Shift vehicles may be towed using either of

the following methods.

1) From the front, with the front wheelslifted and the rear wheels on the

ground. Before towing, check that the

parking brake is released.

2) From the rear, with the rear wheels

lifted and the front wheels on the

ground, provided the steering and

drivetrain are in operational condition.

Before towing, check that transaxle is in

neutral, the steering wheel is unlocked

(vehicle without keyl ess push start sys-

tem - the ignition key should be in

“ACC” position) (vehicle with keyless

push start system - the ignition mode is

ACC), and the steering wheel is

secured with a clamping device

designed for towing service.

4-wheel drive (4WD)Your vehicle should be towed under one of

the following conditions:

1) With all four wheels on a flat-bed truck.

2) With the front or rear wheels lifted and a dolly under the other wheels.

NOTICE

Towing your vehicle with the front

wheels on the ground can result in

damage to the CVT.

NOTICE

The steering column is not strong

enough to withstand shocks trans-

mitted from the fr ont wheels during

towing. Always unlock the steering

wheel before towing.

NOTICE

After shifting the Auto Gear Shift

gearshift lever to the “N” position,

always check the gear position indi-

cator in the instrument cluster shows

the “N” position to make sure that the

transaxle is disengaged.

If the transaxle cannot be put in neu-

tral, turn the key from the “LOCK” to

the “ON” position or press the engine

switch to change the ignition mode to

ON, and move the Auto Gear Shift

gearshift lever from “N” to “D”, “M”

or “R”, then back to “N” again. Then

turn the key from the “ON” to the

“LOCK” position or press the engine

switch to change the ignition mode to

LOCK (OFF). These procedures may

help put the transaxle in neutral. If

the transaxle still cannot be put in

neutral, you cannot tow the vehicle

without using a towing dolly.

Page 433 of 505

11-1

SPECIFICATIONS

75RM4-01E

11

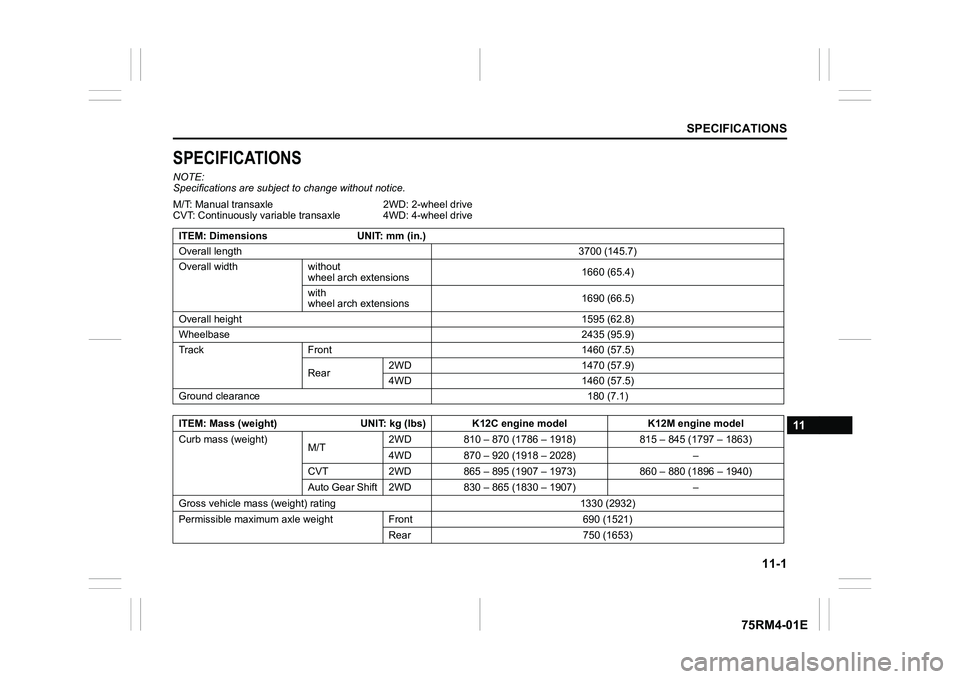

SPECIFICATIONSNOTE:

Specifications are subject to change without notice.

M/T: Manual transaxle

CVT: Continuously variable transaxle 2WD: 2-wheel drive

4WD: 4-wheel drive

ITEM: Dimensions UNIT: mm (in.)

Overall length 3700 (145.7)

Overall width without wheel arch extensions 1660 (65.4)

with

wheel arch extensions 1690 (66.5)

Overall height 1595 (62.8)

Wheelbase 2435 (95.9)

Track Front 1460 (57.5)

Rear2WD 1470 (57.9)

4WD 1460 (57.5)

Ground clearance 180 (7.1)

ITEM: Mass (weight) UNIT: kg (lbs) K12C engine model K12M engine m odel

Curb mass (weight) M/T2WD 810 – 870 (1786 – 1918)

815 – 845 (1797 – 1863)

4WD 870 – 920 (1918 – 2028) –

CVT 2WD 865 – 895 ( 1907 – 1973) 860 – 880 (1896 – 1940)

Auto Gear Shift 2WD 8 30 – 865 (1830 – 1907) –

Gross vehicle mass (wei ght) rating 1330 (2932)

Permissible maximum axle weight Front 690 (1521) Rear 750 (1653)