body SUZUKI JIMNY 2005 3.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 610 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-5

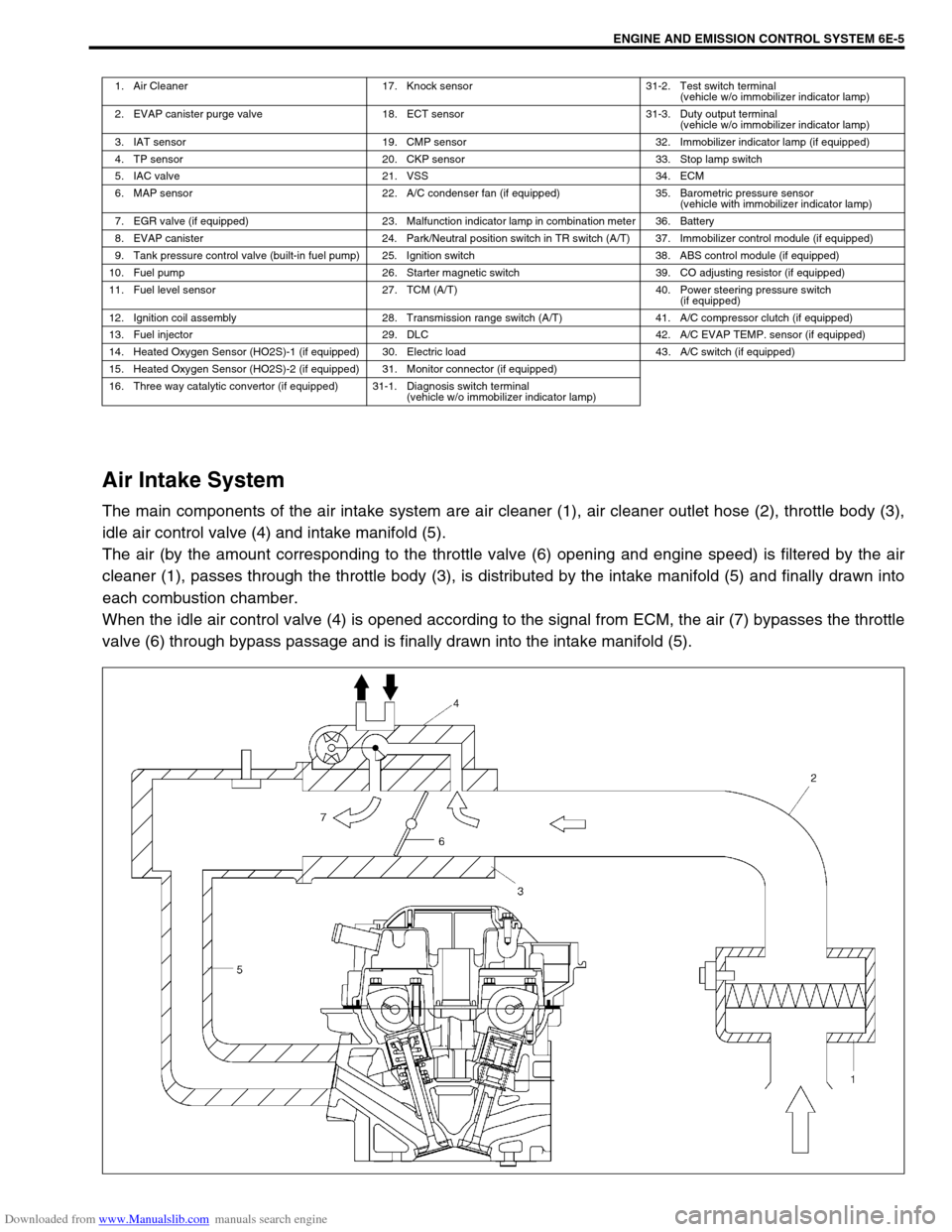

Air Intake System

The main components of the air intake system are air cleaner (1), air cleaner outlet hose (2), throttle body (3),

idle air control valve (4) and intake manifold (5).

The air (by the amount corresponding to the throttle valve (6) opening and engine speed) is filtered by the air

cleaner (1), passes through the throttle body (3), is distributed by the intake manifold (5) and finally drawn into

each combustion chamber.

When the idle air control valve (4) is opened according to the signal from ECM, the air (7) bypasses the throttle

valve (6) through bypass passage and is finally drawn into the intake manifold (5).

1. Air Cleaner 17. Knock sensor 31-2. Test switch terminal

(vehicle w/o immobilizer indicator lamp)

2. EVAP canister purge valve 18. ECT sensor 31-3. Duty output terminal

(vehicle w/o immobilizer indicator lamp)

3. IAT sensor 19. CMP sensor 32. Immobilizer indicator lamp (if equipped)

4. TP sensor 20. CKP sensor 33. Stop lamp switch

5. IAC valve 21. VSS 34. ECM

6. MAP sensor 22. A/C condenser fan (if equipped) 35. Barometric pressure sensor

(vehicle with immobilizer indicator lamp)

7. EGR valve (if equipped) 23. Malfunction indicator lamp in combination meter 36. Battery

8. EVAP canister 24. Park/Neutral position switch in TR switch (A/T) 37. Immobilizer control module (if equipped)

9. Tank pressure control valve (built-in fuel pump) 25. Ignition switch 38. ABS control module (if equipped)

10. Fuel pump 26. Starter magnetic switch 39. CO adjusting resistor (if equipped)

11. Fuel level sensor 27. TCM (A/T) 40. Power steering pressure switch

(if equipped)

12. Ignition coil assembly 28. Transmission range switch (A/T) 41. A/C compressor clutch (if equipped)

13. Fuel injector 29. DLC 42. A/C EVAP TEMP. sensor (if equipped)

14. Heated Oxygen Sensor (HO2S)-1 (if equipped) 30. Electric load 43. A/C switch (if equipped)

15. Heated Oxygen Sensor (HO2S)-2 (if equipped) 31. Monitor connector (if equipped)

16. Three way catalytic convertor (if equipped) 31-1. Diagnosis switch terminal

(vehicle w/o immobilizer indicator lamp)

Page 615 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-10 ENGINE AND EMISSION CONTROL SYSTEM

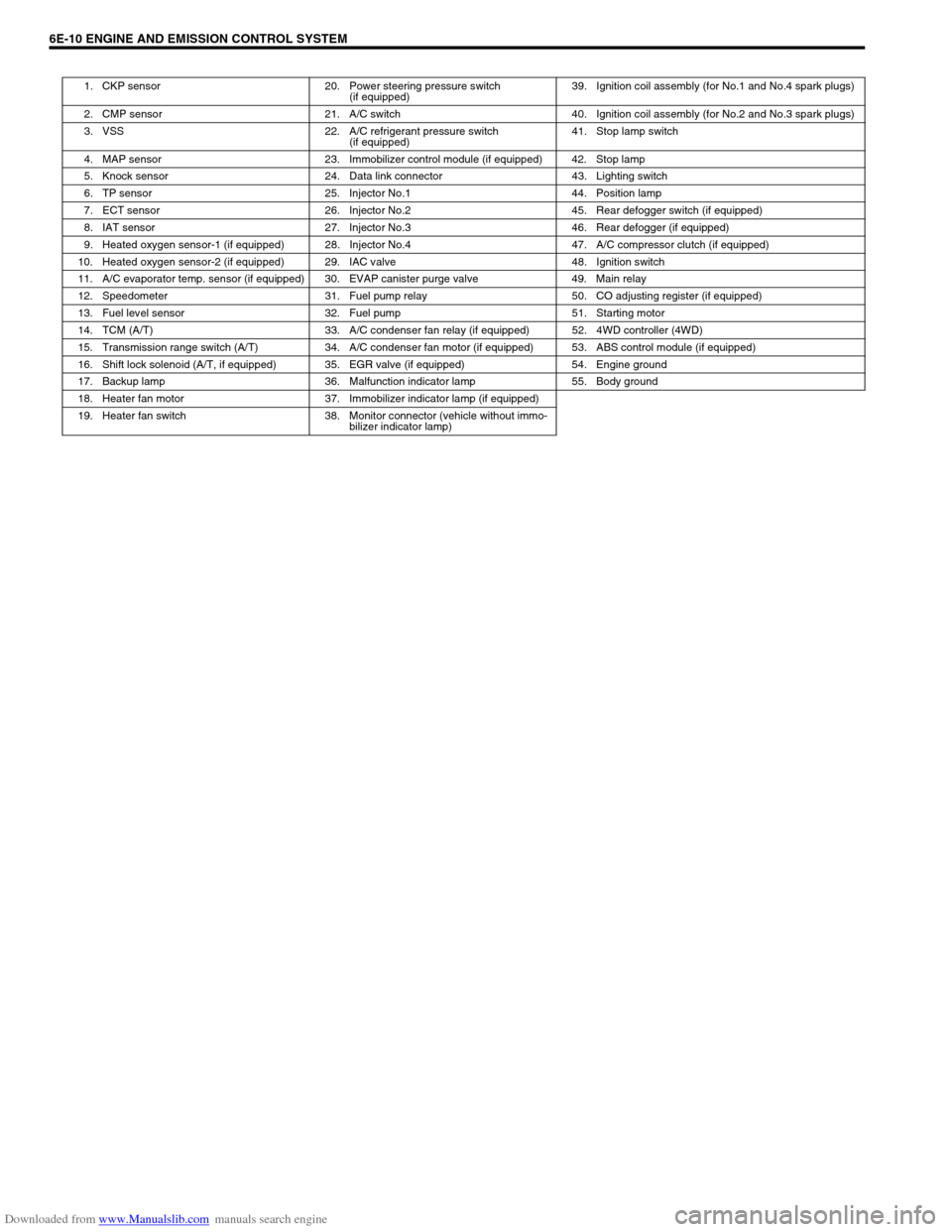

1. CKP sensor 20. Power steering pressure switch

(if equipped)39. Ignition coil assembly (for No.1 and No.4 spark plugs)

2. CMP sensor 21. A/C switch 40. Ignition coil assembly (for No.2 and No.3 spark plugs)

3. VSS 22. A/C refrigerant pressure switch

(if equipped)41. Stop lamp switch

4. MAP sensor 23. Immobilizer control module (if equipped) 42. Stop lamp

5. Knock sensor 24. Data link connector 43. Lighting switch

6. TP sensor 25. Injector No.1 44. Position lamp

7. ECT sensor 26. Injector No.2 45. Rear defogger switch (if equipped)

8. IAT sensor 27. Injector No.3 46. Rear defogger (if equipped)

9. Heated oxygen sensor-1 (if equipped) 28. Injector No.4 47. A/C compressor clutch (if equipped)

10. Heated oxygen sensor-2 (if equipped) 29. IAC valve 48. Ignition switch

11. A/C evaporator temp. sensor (if equipped) 30. EVAP canister purge valve 49. Main relay

12. Speedometer 31. Fuel pump relay 50. CO adjusting register (if equipped)

13. Fuel level sensor 32. Fuel pump 51. Starting motor

14. TCM (A/T) 33. A/C condenser fan relay (if equipped) 52. 4WD controller (4WD)

15. Transmission range switch (A/T) 34. A/C condenser fan motor (if equipped) 53. ABS control module (if equipped)

16. Shift lock solenoid (A/T, if equipped) 35. EGR valve (if equipped) 54. Engine ground

17. Backup lamp 36. Malfunction indicator lamp 55. Body ground

18. Heater fan motor 37. Immobilizer indicator lamp (if equipped)

19. Heater fan switch 38. Monitor connector (vehicle without immo-

bilizer indicator lamp)

Page 617 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-12 ENGINE AND EMISSION CONTROL SYSTEM

1. CKP sensor 20. Power steering pressure switch

(if equipped)39. Ignition coil assembly (for No.1 and No.4 spark plugs)

2. CMP sensor 21. A/C switch 40. Ignition coil assembly (for No.2 and No.3 spark plugs)

3. VSS 22. A/C refrigerant pressure switch

(if equipped)41. Stop lamp switch

4. MAP sensor 23. Immobilizer control module (if equipped) 42. Stop lamp

5. Knock sensor 24. Data link connector 43. Lighting switch

6. TP sensor 25. Injector No.1 44. Position lamp

7. ECT sensor 26. Injector No.2 45. Rear defogger switch (if equipped)

8. IAT sensor 27. Injector No.3 46. Rear defogger (if equipped)

9. Heated oxygen sensor-1 (if equipped) 28. Injector No.4 47. A/C compressor clutch (if equipped)

10. Heated oxygen sensor-2 (if equipped) 29. IAC valve 48. Ignition switch

11. A/C evaporator temp. sensor (if equipped) 30. EVAP canister purge valve 49. Main relay

12. Speedometer 31. Fuel pump relay 50. CO adjusting register (if equipped)

13. Fuel level sensor 32. Fuel pump 51. Starting motor

14. TCM (A/T) 33. A/C condenser fan relay (if equipped) 52. 4WD controller (4WD)

15. Transmission range switch (A/T) 34. A/C condenser fan motor (if equipped) 53. ABS control module (if equipped)

16. Shift lock solenoid (A/T, if equipped) 35. EGR valve (if equipped) 54. Engine ground

17. Backup lamp 36. Malfunction indicator lamp 55. Body ground

18. Heater fan motor 37. Immobilizer indicator lamp (if equipped)

19. Heater fan switch 38. Monitor connector (vehicle without immo-

bilizer indicator lamp)

Page 620 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-15

On-Vehicle Service

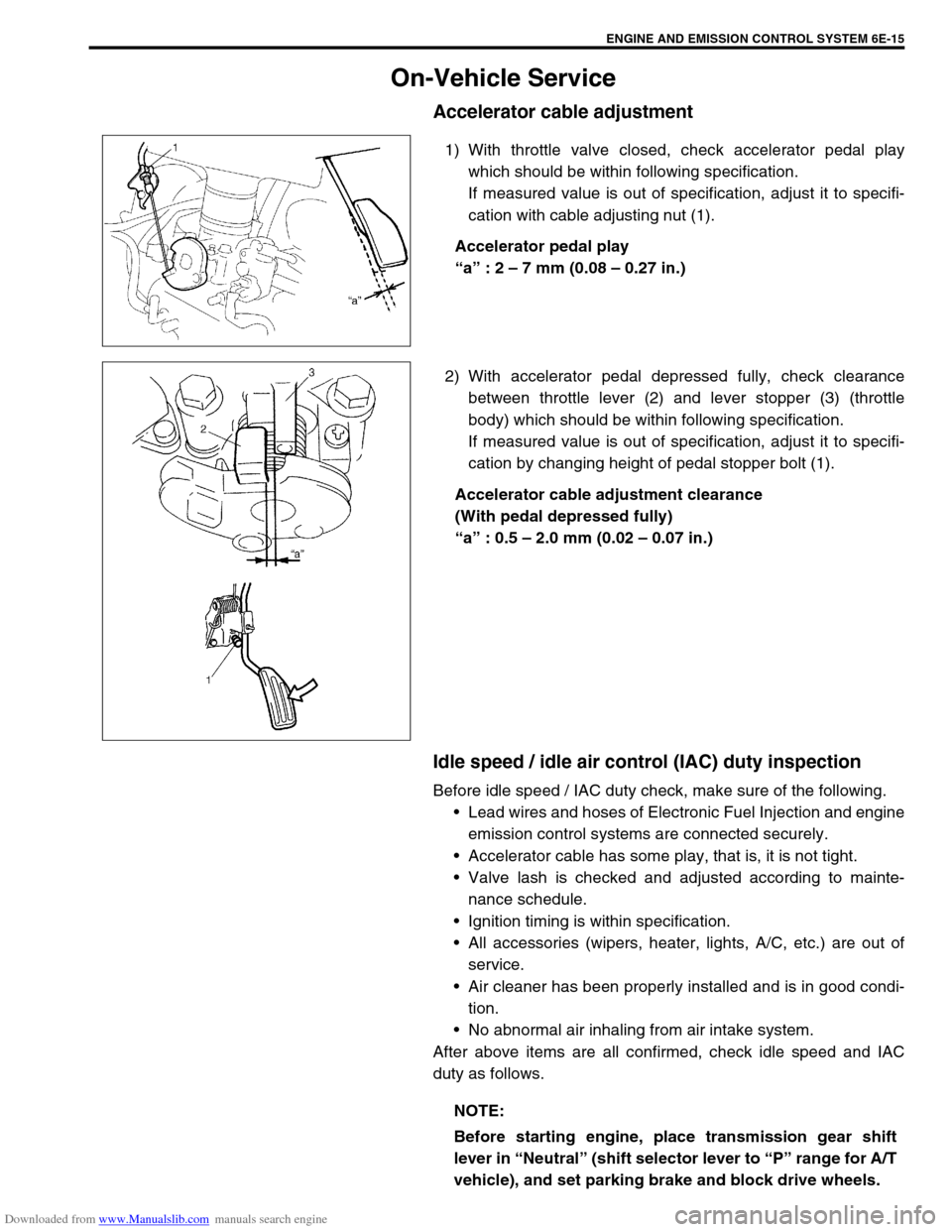

Accelerator cable adjustment

1) With throttle valve closed, check accelerator pedal play

which should be within following specification.

If measured value is out of specification, adjust it to specifi-

cation with cable adjusting nut (1).

Accelerator pedal play

“a” : 2 – 7 mm (0.08 – 0.27 in.)

2) With accelerator pedal depressed fully, check clearance

between throttle lever (2) and lever stopper (3) (throttle

body) which should be within following specification.

If measured value is out of specification, adjust it to specifi-

cation by changing height of pedal stopper bolt (1).

Accelerator cable adjustment clearance

(With pedal depressed fully)

“a” : 0.5 – 2.0 mm (0.02 – 0.07 in.)

Idle speed / idle air control (IAC) duty inspection

Before idle speed / IAC duty check, make sure of the following.

Lead wires and hoses of Electronic Fuel Injection and engine

emission control systems are connected securely.

Accelerator cable has some play, that is, it is not tight.

Valve lash is checked and adjusted according to mainte-

nance schedule.

Ignition timing is within specification.

All accessories (wipers, heater, lights, A/C, etc.) are out of

service.

Air cleaner has been properly installed and is in good condi-

tion.

No abnormal air inhaling from air intake system.

After above items are all confirmed, check idle speed and IAC

duty as follows.

NOTE:

Before starting engine, place transmission gear shift

lever in “Neutral” (shift selector lever to “P” range for A/T

vehicle), and set parking brake and block drive wheels.

Page 623 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-18 ENGINE AND EMISSION CONTROL SYSTEM

Air Intake System

Throttle body

ON-VEHICLE INSPECTION

Check that throttle valve lever (1) moves smoothly.

REMOVAL

1) Disconnect negative cable at battery.

2) Drain cooling system.

3) Disconnect accelerator cable (1) from throttle valve lever.

1. Throttle body 4. Gasket 7. TP sensor screws

2. Throttle body gasket 5. Idle air control valve Tightening torque

3. TP sensor 6. IAC valve screws Do not reuse

Page 624 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-19

4) Disconnect air cleaner outlet NO.2 hose (1) from throttle

body.

5) Disconnect electric connector from TP sensor (1) and IAC

valve (2).

6) Remove throttle body from intake manifold.

7) Disconnect engine coolant hoses from throttle body.

DISASSEMBLY

1) Remove TP sensor and IAC valve from throttle body.

CLEANING

Clean throttle body bore (1) and idle air passage (2) by blowing

compressed air.

REASSEMBLY

1) Install IAC valve to throttle body referring to “Idle Air Control

Valve” in this section.

2) Install TP sensor to throttle body referring to “Throttle Posi-

tion Sensor” in this section for installation.

NOTE:

While disassembling and assembling throttle body, use

special care not to deform levers on throttle valve shaft

or cause damage to any other parts.

NOTE:

TP sensor, idle air control valve or other components

containing rubber must not be placed in a solvent or

cleaner bath. A chemical reaction will cause these parts

to swell, harden or get distorted.

Page 625 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-20 ENGINE AND EMISSION CONTROL SYSTEM

INSTALLATION

1) Clean mating surfaces and install throttle body gasket to

intake manifold.

Use new gasket.

2) Connect engine coolant hoses.

3) Install throttle body (1) to intake manifold.

4) Connect connectors to TP sensor (2) and IAC valve (3)

securely.

5) Install air cleaner outlet No.2 hose (1) and pipe.

6) Connect accelerator cable and adjust cable play to specifica-

tion.

7) Refill cooling system.

8) Connect negative cable at battery.

Page 626 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-21

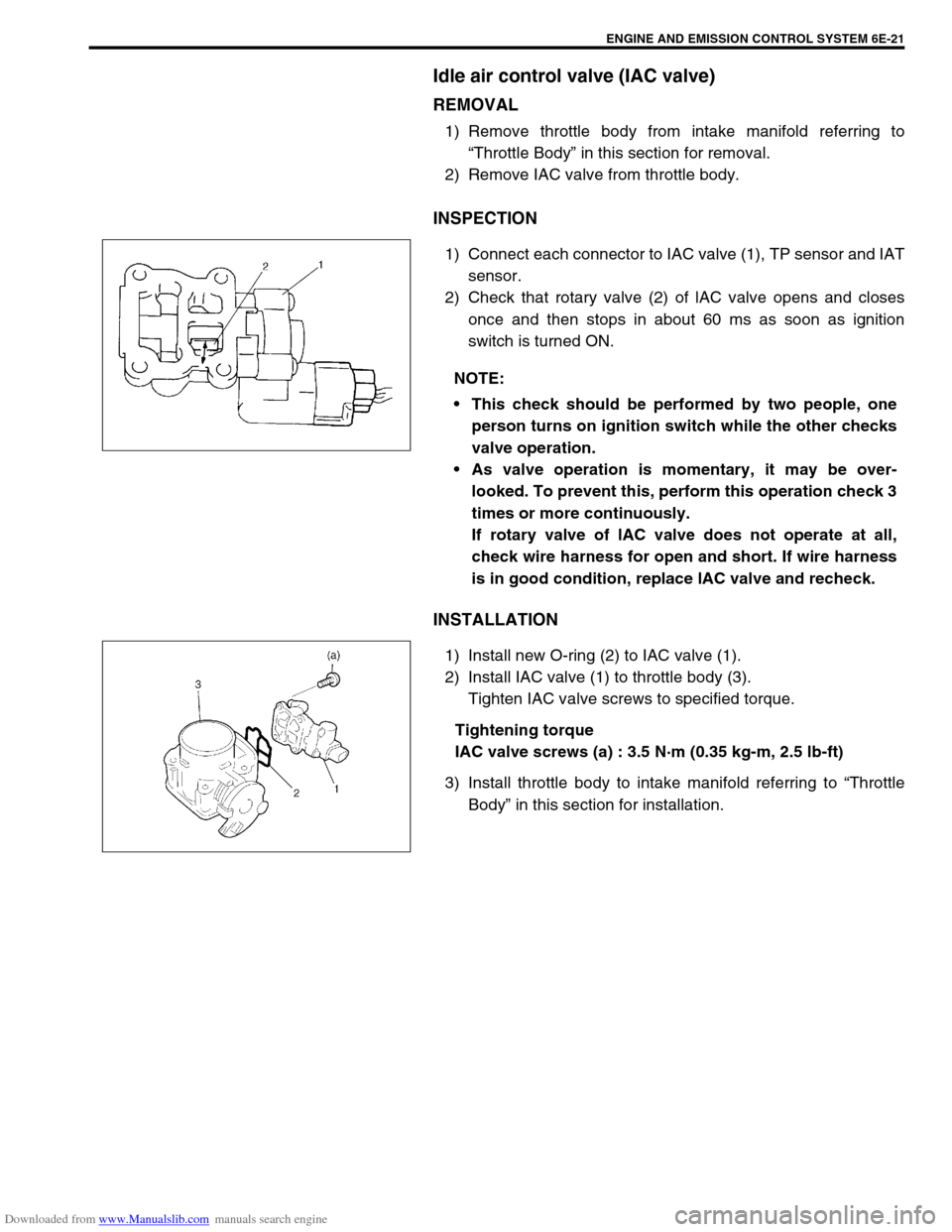

Idle air control valve (IAC valve)

REMOVAL

1) Remove throttle body from intake manifold referring to

“Throttle Body” in this section for removal.

2) Remove IAC valve from throttle body.

INSPECTION

1) Connect each connector to IAC valve (1), TP sensor and IAT

sensor.

2) Check that rotary valve (2) of lAC valve opens and closes

once and then stops in about 60 ms as soon as ignition

switch is turned ON.

INSTALLATION

1) Install new O-ring (2) to IAC valve (1).

2) Install IAC valve (1) to throttle body (3).

Tighten IAC valve screws to specified torque.

Tightening torque

IAC valve screws (a) : 3.5 N·m (0.35 kg-m, 2.5 lb-ft)

3) Install throttle body to intake manifold referring to “Throttle

Body” in this section for installation. NOTE:

This check should be performed by two people, one

person turns on ignition switch while the other checks

valve operation.

As valve operation is momentary, it may be over-

looked. To prevent this, perform this operation check 3

times or more continuously.

If rotary valve of lAC valve does not operate at all,

check wire harness for open and short. If wire harness

is in good condition, replace lAC valve and recheck.

Page 628 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-23

6) Start engine and warm it up to normal operating tempera-

ture.

7) Measure fuel pressure at idling.

If measured pressure doesn’t satisfy specification, refer to

“Diagnostic Flow Table B-3” in Section 6 and check each

possibly defective part. Replace if found defective.

8) After checking fuel pressure, remove fuel pressure gauge.

9) Remove special tools from fuel delivery pipe.

10) Connect fuel feed hose to fuel delivery pipe and clamp it

securely.

11) With engine “OFF” and ignition switch “ON”, check for fuel

leaks.

Fuel pump

ON-VEHICLE INSPECTION

1) Remove filler cap and turn ON ignition switch (2). Then fuel

pump operating sound should be heard from fuel filler (1) for

about 2 seconds and stop. Be sure to reinstall fuel filler cap

after checking.

If above check result is not satisfactory, advance to “Diag-

nostic Flow Table B-2” in Section 6.

2) Turn OFF ignition switch and leave over 10 minutes as it is.CAUTION:

As fuel feed line is still under high fuel pressure, make

sure to release fuel pressure according to following pro-

cedures.

Place fuel container under joint.

Cover joint with rag and loosen joint nut slowly to

release fuel pressure gradually.

CAUTION:

When fuel filler cap is removed in any procedure, work

must be done in a well-ventilated area, keep away from

any open flames and without smoking.

NOTE:

The fuel pressure regulator is the one body with the fuel

pump assembly so individual inspection of it is impossi-

ble.

Page 629 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-24 ENGINE AND EMISSION CONTROL SYSTEM

3) Fuel pressure should be felt at fuel feed hose (1) for 2 sec-

onds after ignition switch ON.

If fuel pressure is not felt, advance to “Diagnostic Flow Table

B-3” in Section 6.

REMOVAL

Remove fuel tank from body according to procedure described in

“Fuel Tank” of Section 6C and remove fuel pump from fuel tank.

INSPECTION

Check fuel pump filter for evidence of dirt and contamination. If

present, clean and check for presence of dirt in fuel tank.

INSTALLATION

1) Install fuel pump to its bracket.

2) Install fuel pump to fuel tank and then install fuel tank to

body according to procedure described in “Fuel Tank” of

Section 6C.

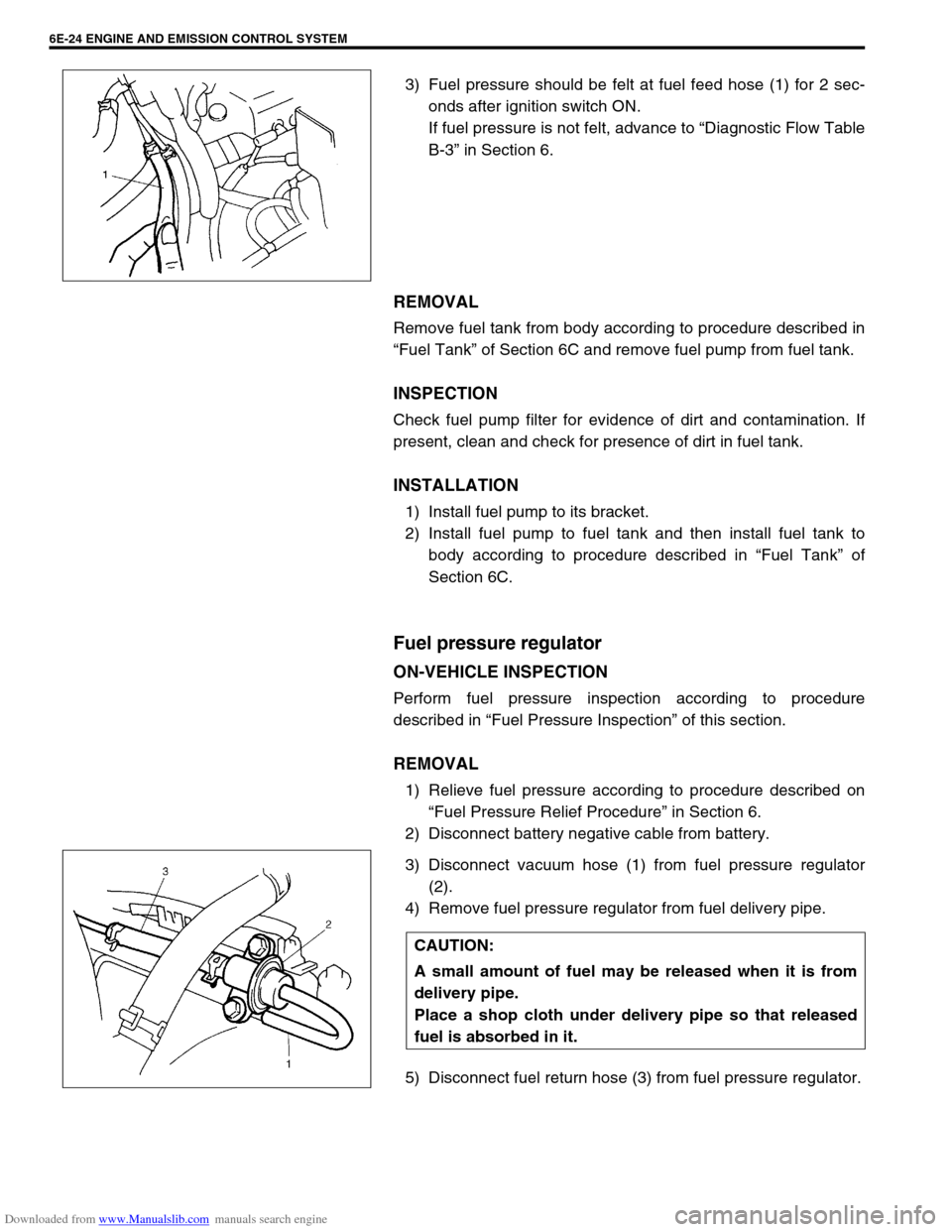

Fuel pressure regulator

ON-VEHICLE INSPECTION

Perform fuel pressure inspection according to procedure

described in “Fuel Pressure Inspection” of this section.

REMOVAL

1) Relieve fuel pressure according to procedure described on

“Fuel Pressure Relief Procedure” in Section 6.

2) Disconnect battery negative cable from battery.

3) Disconnect vacuum hose (1) from fuel pressure regulator

(2).

4) Remove fuel pressure regulator from fuel delivery pipe.

5) Disconnect fuel return hose (3) from fuel pressure regulator.

CAUTION:

A small amount of fuel may be released when it is from

delivery pipe.

Place a shop cloth under delivery pipe so that released

fuel is absorbed in it.