SUZUKI JIMNY 2005 3.G Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 131 of 687

Downloaded from www.Manualslib.com manuals search engine 3B-10 STEERING GEAR BOX (MANUAL TYPE) AND LINKAGE

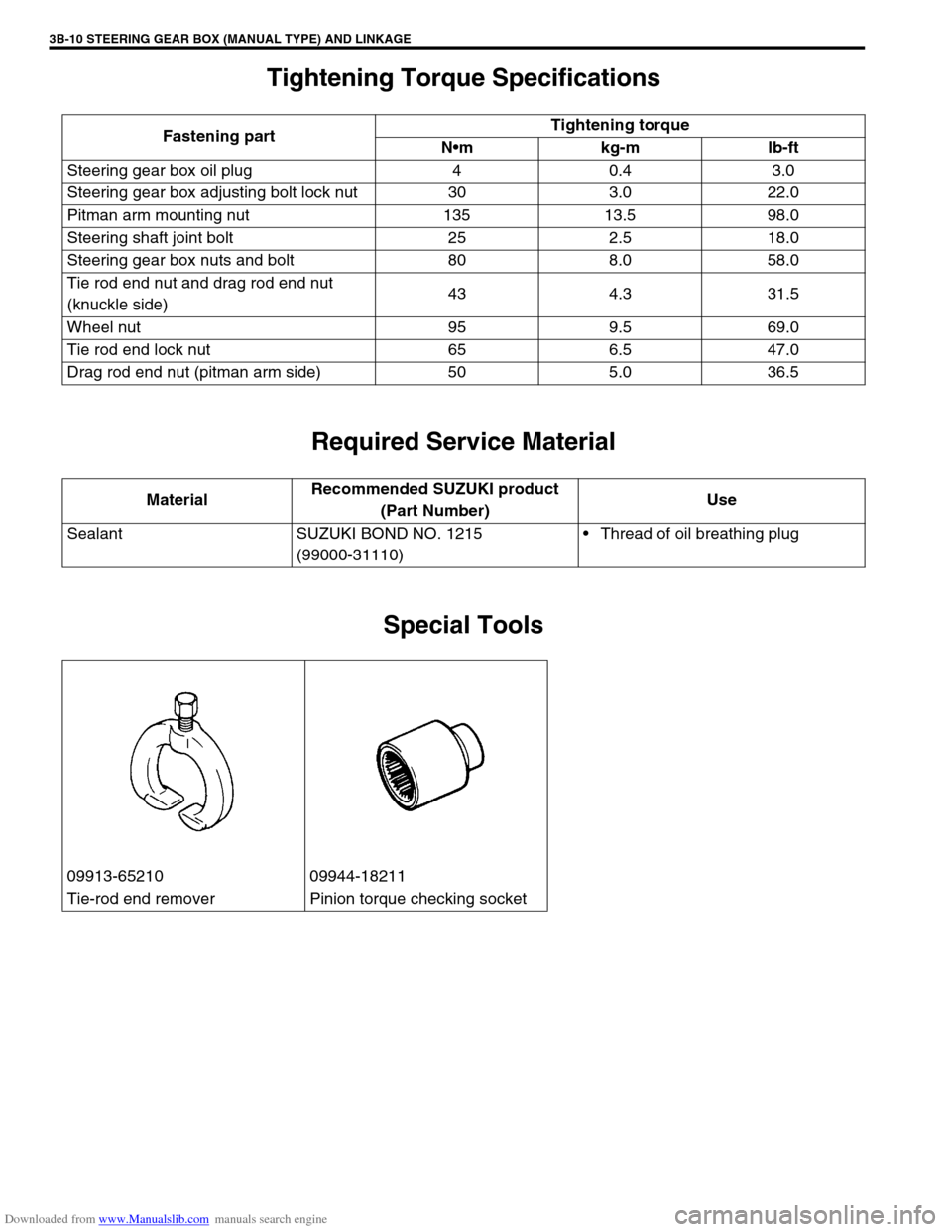

Tightening Torque Specifications

Required Service Material

Special Tools

Fastening partTightening torque

Nm kg-m lb-ft

Steering gear box oil plug 4 0.4 3.0

Steering gear box adjusting bolt lock nut 30 3.0 22.0

Pitman arm mounting nut 135 13.5 98.0

Steering shaft joint bolt 25 2.5 18.0

Steering gear box nuts and bolt 80 8.0 58.0

Tie rod end nut and drag rod end nut

(knuckle side)43 4.3 31.5

Wheel nut 95 9.5 69.0

Tie rod end lock nut 65 6.5 47.0

Drag rod end nut (pitman arm side) 50 5.0 36.5

MaterialRecommended SUZUKI product

(Part Number)Use

Sealant SUZUKI BOND NO. 1215

(99000-31110)Thread of oil breathing plug

09913-65210 09944-18211

Tie-rod end remover Pinion torque checking socket

Page 132 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-1

6F1

6F2

6G

6H

6K

3B1

7D

7E

7F

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3B1

POWER STEERING (P/S) SYSTEM

(If equipped)

CONTENTS

General Description ......................................3B1-2

Diagnosis .......................................................3B1-3

Diagnosis Table .......................................... 3B1-3

Steering Wheel Play Check ........................ 3B1-5

Steering Force Check ................................. 3B1-5

Power Steering Belt Check ......................... 3B1-6

Power Steering Belt Tension Adjustment .... 3B1-6

Power Steering Fluid Level Check .............. 3B1-6

Idle-Up System Check ................................ 3B1-7

Power Steering Fluid Leakage Check ......... 3B1-7Air Bleeding Procedure ............................... 3B1-8

Hydraulic Pressure In P/S Circuit Check .. 3B1-10

On-Vehicle Service ..................................... 3B1-12

Power Steering Belt .................................. 3B1-12

Power Steering (P/S) Pump ...................... 3B1-12

Power Steering (P/S) Gear Box ................ 3B1-18

Tightening Torque Specifications ............. 3B1-21

Required Service Materials ........................ 3B1-21

Special Tools ............................................... 3B1-21 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and negative cable is disconnected from the battery. Otherwise, the system may

be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

All steering gear fasteners are important attaching parts in that they could affect the performance of

vital parts and systems, and/or could result in major repair expense. They must be replaced with one

of the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified dur-

ing reassembly to assure proper retention of these parts.

Page 133 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-2 POWER STEERING (P/S) SYSTEM (If equipped)

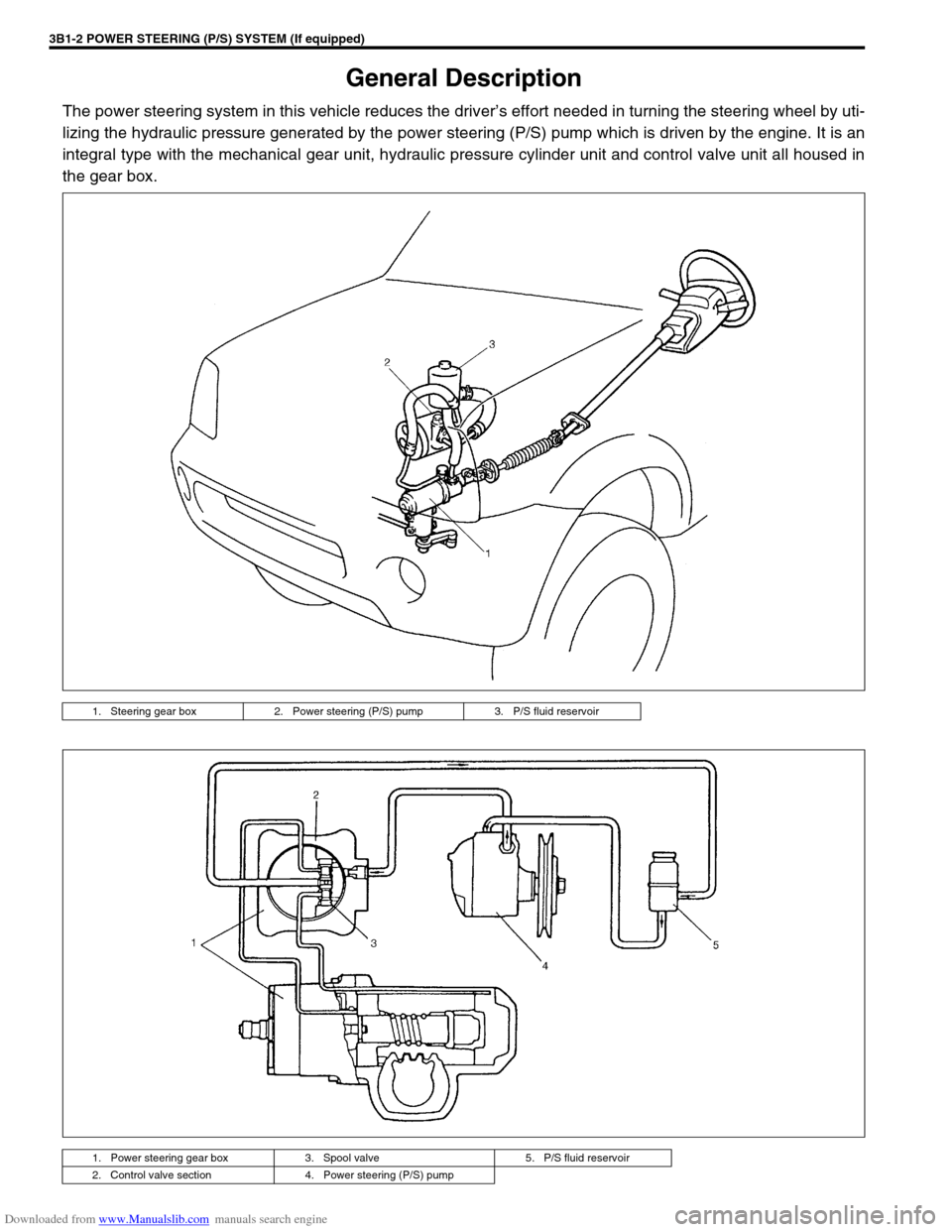

General Description

The power steering system in this vehicle reduces the driver’s effort needed in turning the steering wheel by uti-

lizing the hydraulic pressure generated by the power steering (P/S) pump which is driven by the engine. It is an

integral type with the mechanical gear unit, hydraulic pressure cylinder unit and control valve unit all housed in

the gear box.

1. Steering gear box 2. Power steering (P/S) pump 3. P/S fluid reservoir

1. Power steering gear box 3. Spool valve 5. P/S fluid reservoir

2. Control valve section 4. Power steering (P/S) pump

Page 134 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-3

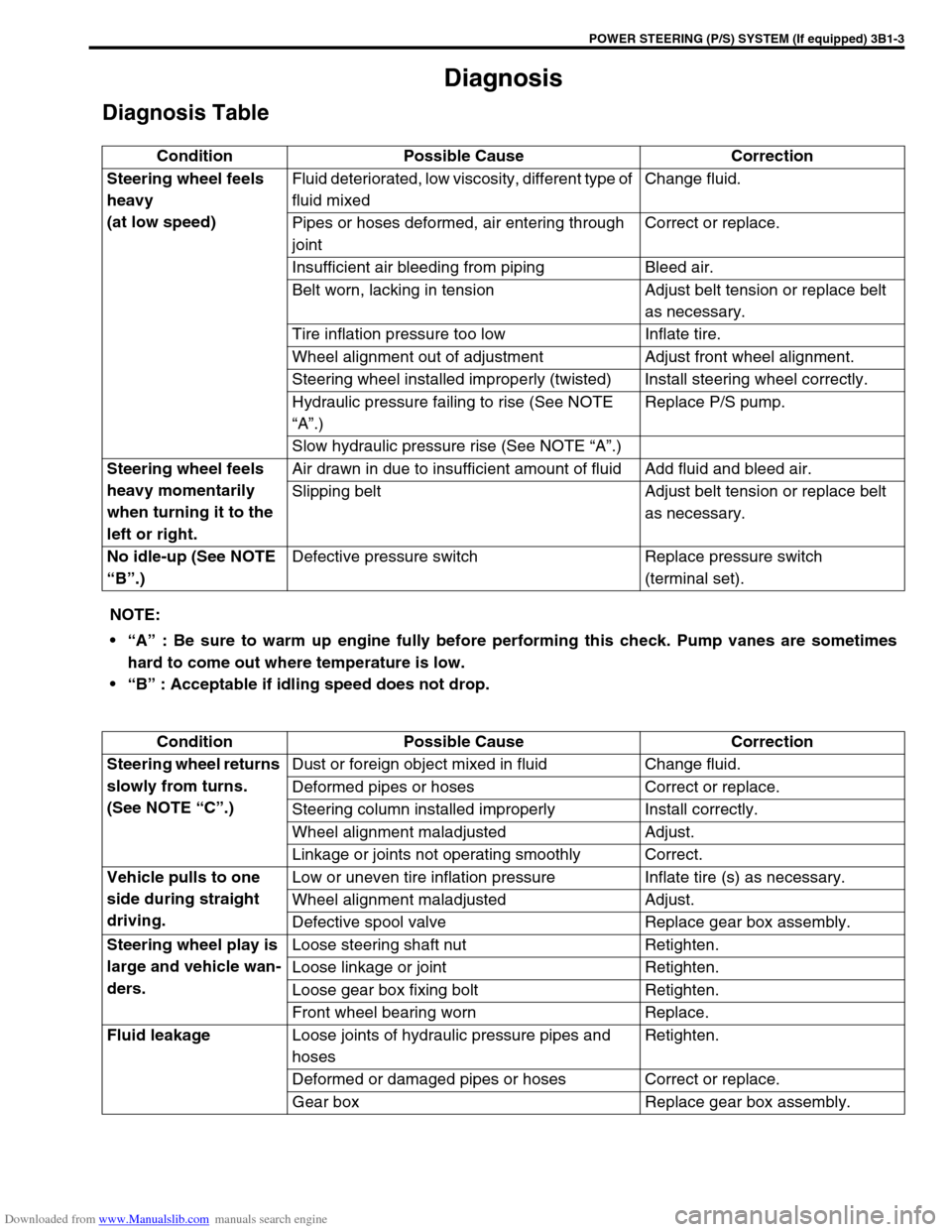

Diagnosis

Diagnosis Table

Condition Possible Cause Correction

Steering wheel feels

heavy

(at low speed)Fluid deteriorated, low viscosity, different type of

fluid mixedChange fluid.

Pipes or hoses deformed, air entering through

jointCorrect or replace.

Insufficient air bleeding from piping Bleed air.

Belt worn, lacking in tension Adjust belt tension or replace belt

as necessary.

Tire inflation pressure too low Inflate tire.

Wheel alignment out of adjustment Adjust front wheel alignment.

Steering wheel installed improperly (twisted) Install steering wheel correctly.

Hydraulic pressure failing to rise (See NOTE

“A”.)Replace P/S pump.

Slow hydraulic pressure rise (See NOTE “A”.)

Steering wheel feels

heavy momentarily

when turning it to the

left or right.Air drawn in due to insufficient amount of fluid Add fluid and bleed air.

Slipping belt Adjust belt tension or replace belt

as necessary.

No idle-up (See NOTE

“B”.)Defective pressure switch Replace pressure switch

(terminal set).

NOTE:

“A” : Be sure to warm up engine fully before performing this check. Pump vanes are sometimes

hard to come out where temperature is low.

“B” : Acceptable if idling speed does not drop.

Condition Possible Cause Correction

Steering wheel returns

slowly from turns.

(See NOTE “C”.)Dust or foreign object mixed in fluid Change fluid.

Deformed pipes or hoses Correct or replace.

Steering column installed improperly Install correctly.

Wheel alignment maladjusted Adjust.

Linkage or joints not operating smoothly Correct.

Vehicle pulls to one

side during straight

driving.Low or uneven tire inflation pressure Inflate tire (s) as necessary.

Wheel alignment maladjusted Adjust.

Defective spool valve Replace gear box assembly.

Steering wheel play is

large and vehicle wan-

ders.Loose steering shaft nut Retighten.

Loose linkage or joint Retighten.

Loose gear box fixing bolt Retighten.

Front wheel bearing worn Replace.

Fluid leakage

Loose joints of hydraulic pressure pipes and

hosesRetighten.

Deformed or damaged pipes or hoses Correct or replace.

Gear box Replace gear box assembly.

Page 135 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-4 POWER STEERING (P/S) SYSTEM (If equipped)

Abnormal noise

(See NOTE “D”.)Air drawn in due to insufficient fluid Replenish fluid.

Air drawn in through pipe or hose joints Retighten or replace.

Belt slipping (loose) Adjust.

Worn belt Replace.

Loose steering linkage Retighten.

Loose gear box fixing bolt Retighten.

Loose pitman arm Retighten.

Pipes or hoses in contact with chassis Correct.

Defective pump vane Replace pump assembly.

Malfunction of flow control valve Replace gear box assembly.

Defective pump shaft bearing Replace pump assembly. Condition Possible Cause Correction

NOTE:

“C” : Turn steering wheel 90° at 35 km/h (22 mile/h) and let it free. If it returns more than 60° then, it

is normal.

“D” : Some hissing noise may be heard through steering column when turning steering wheel with

vehicle halted. It is from operation of the valve in the gear box and indicates nothing abnormal.

Page 136 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-5

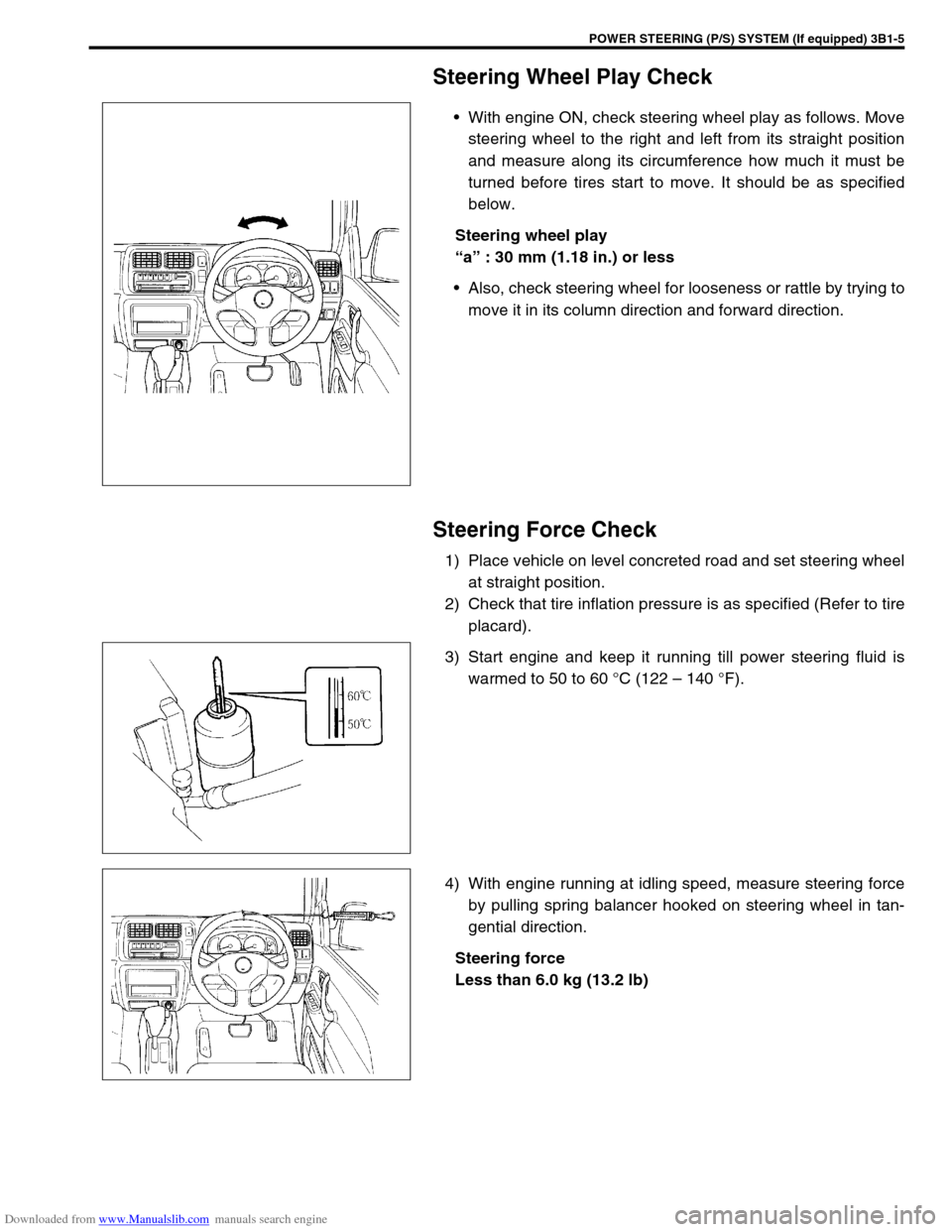

Steering Wheel Play Check

With engine ON, check steering wheel play as follows. Move

steering wheel to the right and left from its straight position

and measure along its circumference how much it must be

turned before tires start to move. It should be as specified

below.

Steering wheel play

“a” : 30 mm (1.18 in.) or less

Also, check steering wheel for looseness or rattle by trying to

move it in its column direction and forward direction.

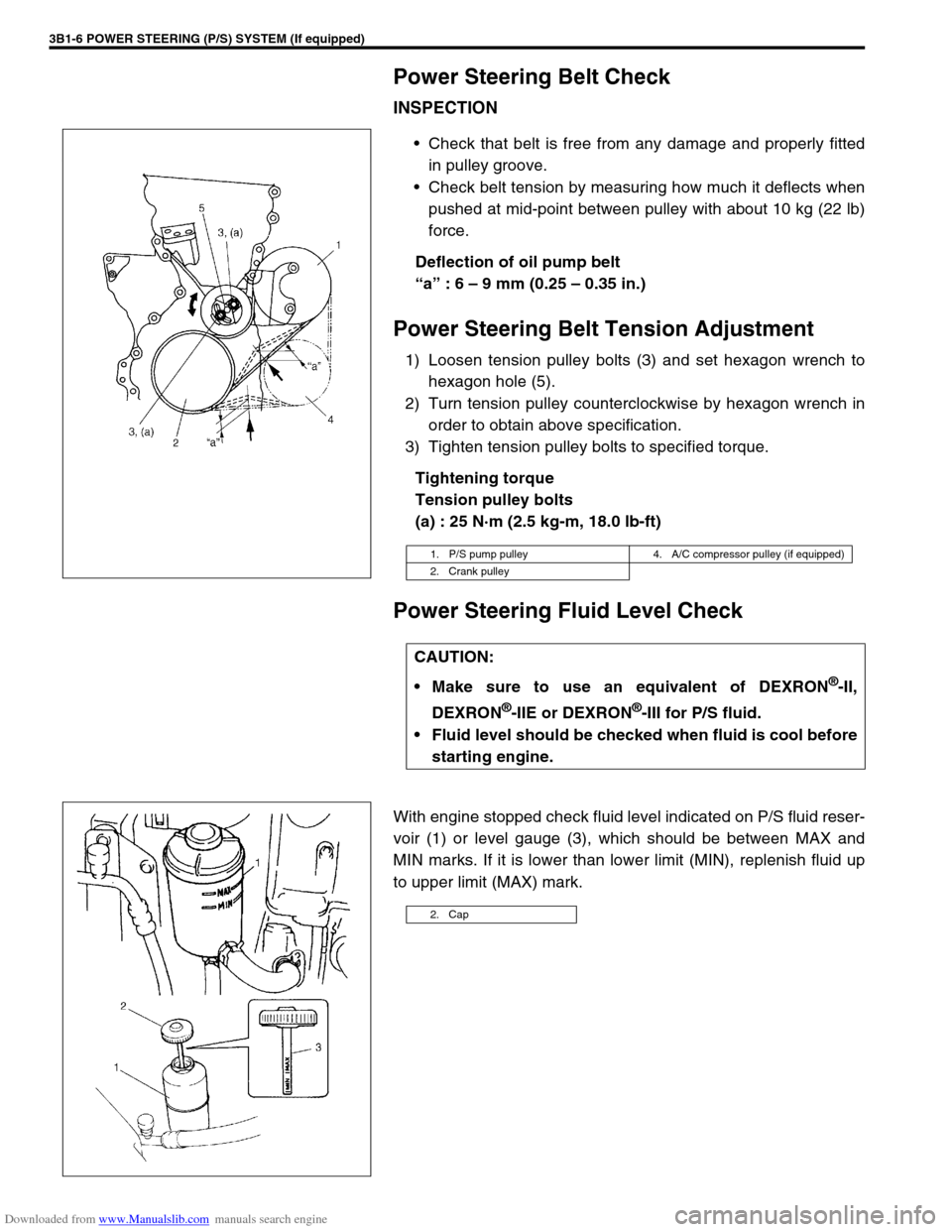

Steering Force Check

1) Place vehicle on level concreted road and set steering wheel

at straight position.

2) Check that tire inflation pressure is as specified (Refer to tire

placard).

3) Start engine and keep it running till power steering fluid is

warmed to 50 to 60 °C (122 – 140 °F).

4) With engine running at idling speed, measure steering force

by pulling spring balancer hooked on steering wheel in tan-

gential direction.

Steering force

Less than 6.0 kg (13.2 lb)

Page 137 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-6 POWER STEERING (P/S) SYSTEM (If equipped)

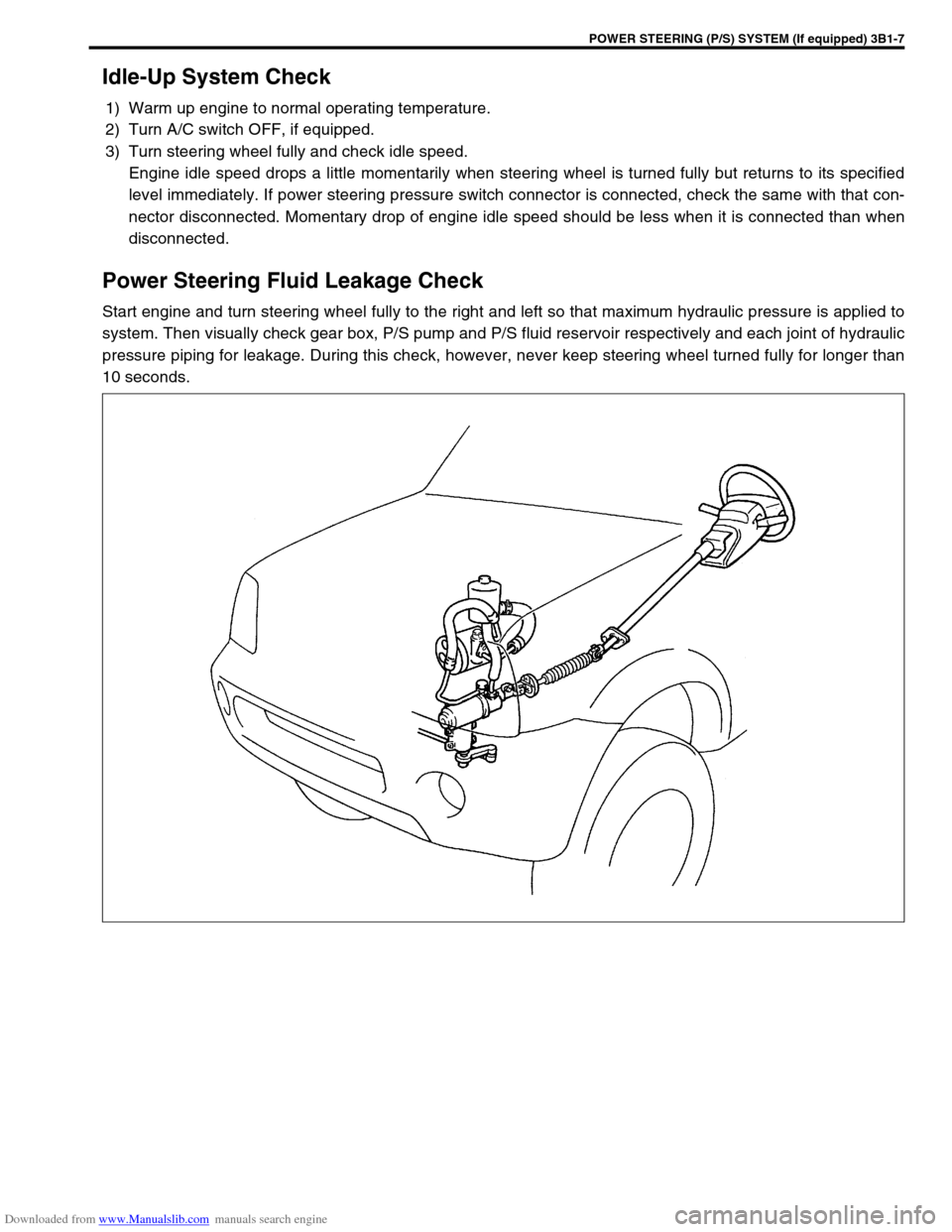

Power Steering Belt Check

INSPECTION

Check that belt is free from any damage and properly fitted

in pulley groove.

Check belt tension by measuring how much it deflects when

pushed at mid-point between pulley with about 10 kg (22 lb)

force.

Deflection of oil pump belt

“a” : 6 – 9 mm (0.25 – 0.35 in.)

Power Steering Belt Tension Adjustment

1) Loosen tension pulley bolts (3) and set hexagon wrench to

hexagon hole (5).

2) Turn tension pulley counterclockwise by hexagon wrench in

order to obtain above specification.

3) Tighten tension pulley bolts to specified torque.

Tightening torque

Tension pulley bolts

(a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

Power Steering Fluid Level Check

With engine stopped check fluid level indicated on P/S fluid reser-

voir (1) or level gauge (3), which should be between MAX and

MIN marks. If it is lower than lower limit (MIN), replenish fluid up

to upper limit (MAX) mark.

1. P/S pump pulley 4. A/C compressor pulley (if equipped)

2. Crank pulley

CAUTION:

Make sure to use an equivalent of DEXRON

®-II,

DEXRON

®-IIE or DEXRON®-III for P/S fluid.

Fluid level should be checked when fluid is cool before

starting engine.

2. Cap

Page 138 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-7

Idle-Up System Check

1) Warm up engine to normal operating temperature.

2) Turn A/C switch OFF, if equipped.

3) Turn steering wheel fully and check idle speed.

Engine idle speed drops a little momentarily when steering wheel is turned fully but returns to its specified

level immediately. If power steering pressure switch connector is connected, check the same with that con-

nector disconnected. Momentary drop of engine idle speed should be less when it is connected than when

disconnected.

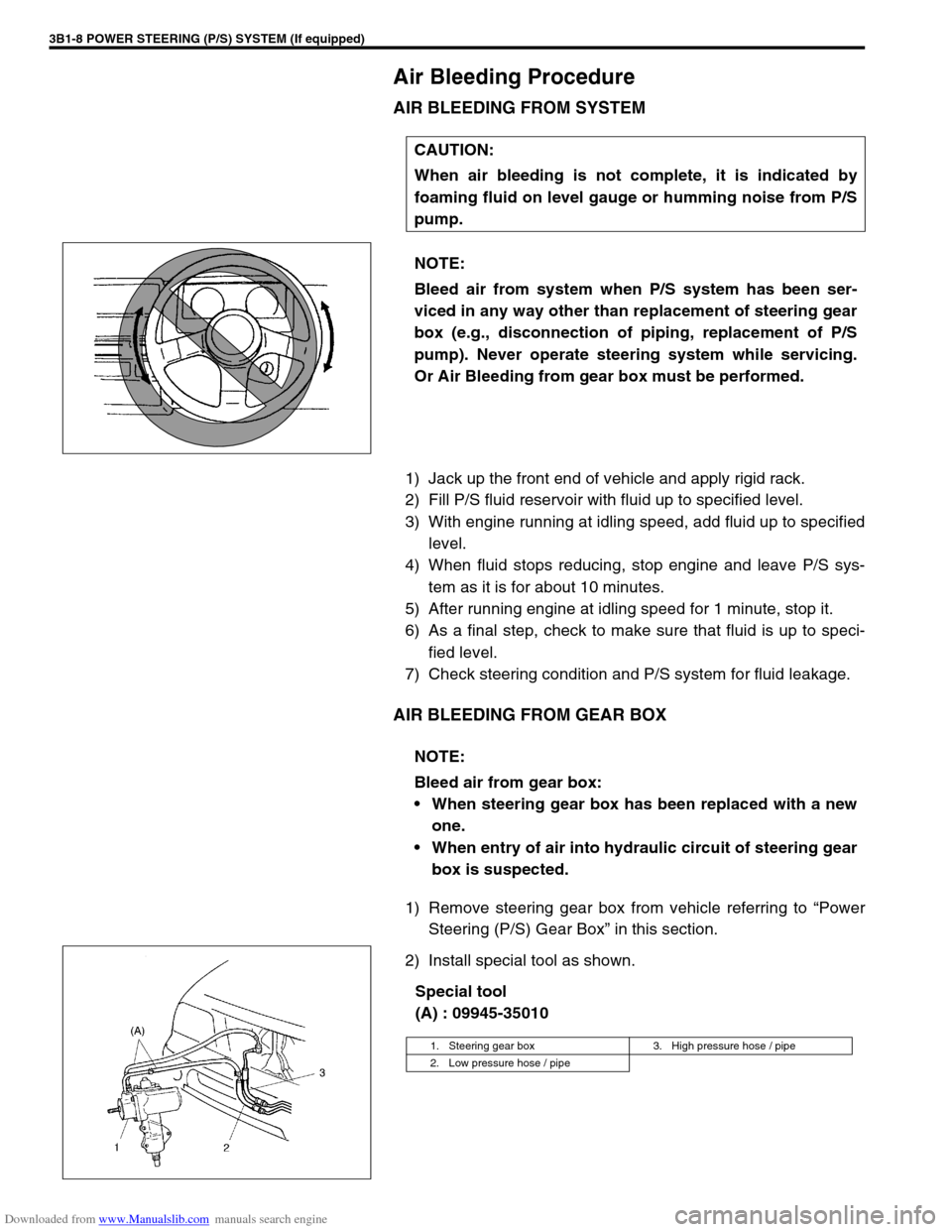

Power Steering Fluid Leakage Check

Start engine and turn steering wheel fully to the right and left so that maximum hydraulic pressure is applied to

system. Then visually check gear box, P/S pump and P/S fluid reservoir respectively and each joint of hydraulic

pressure piping for leakage. During this check, however, never keep steering wheel turned fully for longer than

10 seconds.

Page 139 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-8 POWER STEERING (P/S) SYSTEM (If equipped)

Air Bleeding Procedure

AIR BLEEDING FROM SYSTEM

1) Jack up the front end of vehicle and apply rigid rack.

2) Fill P/S fluid reservoir with fluid up to specified level.

3) With engine running at idling speed, add fluid up to specified

level.

4) When fluid stops reducing, stop engine and leave P/S sys-

tem as it is for about 10 minutes.

5) After running engine at idling speed for 1 minute, stop it.

6) As a final step, check to make sure that fluid is up to speci-

fied level.

7) Check steering condition and P/S system for fluid leakage.

AIR BLEEDING FROM GEAR BOX

1) Remove steering gear box from vehicle referring to “Power

Steering (P/S) Gear Box” in this section.

2) Install special tool as shown.

Special tool

(A) : 09945-35010 CAUTION:

When air bleeding is not complete, it is indicated by

foaming fluid on level gauge or humming noise from P/S

pump.

NOTE:

Bleed air from system when P/S system has been ser-

viced in any way other than replacement of steering gear

box (e.g., disconnection of piping, replacement of P/S

pump). Never operate steering system while servicing.

Or Air Bleeding from gear box must be performed.

NOTE:

Bleed air from gear box:

When steering gear box has been replaced with a new

one.

When entry of air into hydraulic circuit of steering gear

box is suspected.

1. Steering gear box 3. High pressure hose / pipe

2. Low pressure hose / pipe

Page 140 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-9

3) After running engine at idling speed for 3 to 5 seconds, stop

it and add fluid up to specified level. Repeat this step a few

times.

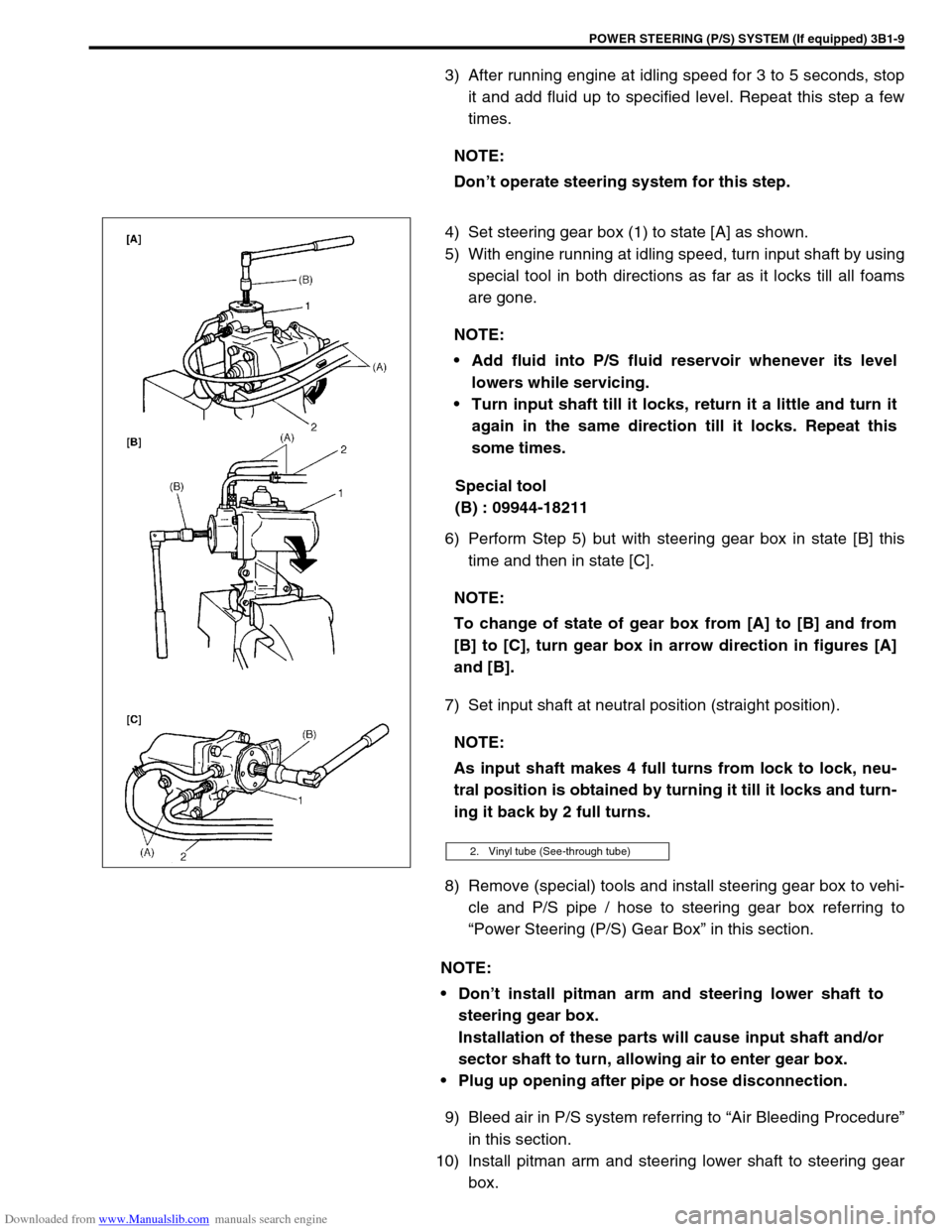

4) Set steering gear box (1) to state [A] as shown.

5) With engine running at idling speed, turn input shaft by using

special tool in both directions as far as it locks till all foams

are gone.

Special tool

(B) : 09944-18211

6) Perform Step 5) but with steering gear box in state [B] this

time and then in state [C].

7) Set input shaft at neutral position (straight position).

8) Remove (special) tools and install steering gear box to vehi-

cle and P/S pipe / hose to steering gear box referring to

“Power Steering (P/S) Gear Box” in this section.

9) Bleed air in P/S system referring to “Air Bleeding Procedure”

in this section.

10) Install pitman arm and steering lower shaft to steering gear

box. NOTE:

Don’t operate steering system for this step.

NOTE:

Add fluid into P/S fluid reservoir whenever its level

lowers while servicing.

Turn input shaft till it locks, return it a little and turn it

again in the same direction till it locks. Repeat this

some times.

NOTE:

To change of state of gear box from [A] to [B] and from

[B] to [C], turn gear box in arrow direction in figures [A]

and [B].

NOTE:

As input shaft makes 4 full turns from lock to lock, neu-

tral position is obtained by turning it till it locks and turn-

ing it back by 2 full turns.

2. Vinyl tube (See-through tube)

NOTE:

Don’t install pitman arm and steering lower shaft to

steering gear box.

Installation of these parts will cause input shaft and/or

sector shaft to turn, allowing air to enter gear box.

Plug up opening after pipe or hose disconnection.