pressure SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 14 of 687

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION 0A-9

When disconnecting vacuum hoses, attach a tag

describing the correct installation positions so that the

hoses can be reinstalled correctly.

After servicing fuel, oil, coolant, vacuum, exhaust or

brake systems, check all lines related to the system for

leaks.

For vehicles equipped with fuel injection systems, never

disconnect the fuel line between the fuel pump and

injector without first releasing the fuel pressure, or fuel

can be sprayed out under pressure.

When performing a work that produces a heat exceeding

80°C (176°F) in the vicinity of the electrical parts, remove

the heat sensitive electrical part(s) beforehand.

Use care not to expose connectors and electrical parts

to water which will be a cause of a trouble.

Always be careful not to handle electrical parts (com-

puter, relay, etc.) in a rough manner or drop them.

Page 27 of 687

Downloaded from www.Manualslib.com manuals search engine 0A-22 GENERAL INFORMATION

LLH

LSPVLeft Hand

Load Sensing Proportioning Valve

TTBI

TCC

TCM

TP Sensor

TVV

TWC

2WDThrottle Body Fuel Injection

(Single-Point Fuel Injection, SPI)

Torque Converter Clutch

Transmission Control Module

(A/T Controller, A/T Control Mod-

ule)

Throttle Position Sensor

Thermal Vacuum Valve

(Thermal Vacuum Switching Valve,

TVSV, Bimetal Vacuum Switching

Valve, BVSV)

Three Way Catalytic Converter

(Three Way Catalyst)

2 Wheel Drive MMAF Sensor

MAP Sensor

Max

MFI

Min

MIL

M/TMass Air Flow Sensor

(Air Flow Sensor, AFS, Air Flow

Meter, AFM)

Manifold Absolute Pressure

Sensor (Pressure Sensor, PS)

Maximum

Multiport Fuel Injection

(Multipoint Fuel Injection)

Minimum

Malfunction Indicator Lamp

(“CHECK ENGINE” Light)

Manual Transmission

N NOx Nitrogen Oxides VVIN

VSSVehicle Identification Number

Vehicle Speed Sensor

OOBD

O/D

OHCOn-Board Diagnostic System

(Self-Diagnosis Function)

Overdrive

Over Head CamshaftWWU-OC

WU-TWCWarm Up Oxidation Catalytic

Converter

Warm Up Three Way Catalytic

Converter

PPNP

P/S

PSP Switch

PCM

PCVPark/Neutral Position

Power Steering

Power Steering Pressure Switch

(P/S Pressure Switch)

Powertrain Control Module

Positive Crankcase Ventilation

R RH Right Hand

SSAE

SDM

SFI

SOHCSociety of Automotive Engineers

Sensing and Diagnostic Module

(Air bag controller, Air bag control

module)

Sequential Multiport Fuel Injection

Single Over Head Camshaft

Page 36 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-5

Maintenance Service

Engine

Drive Belt

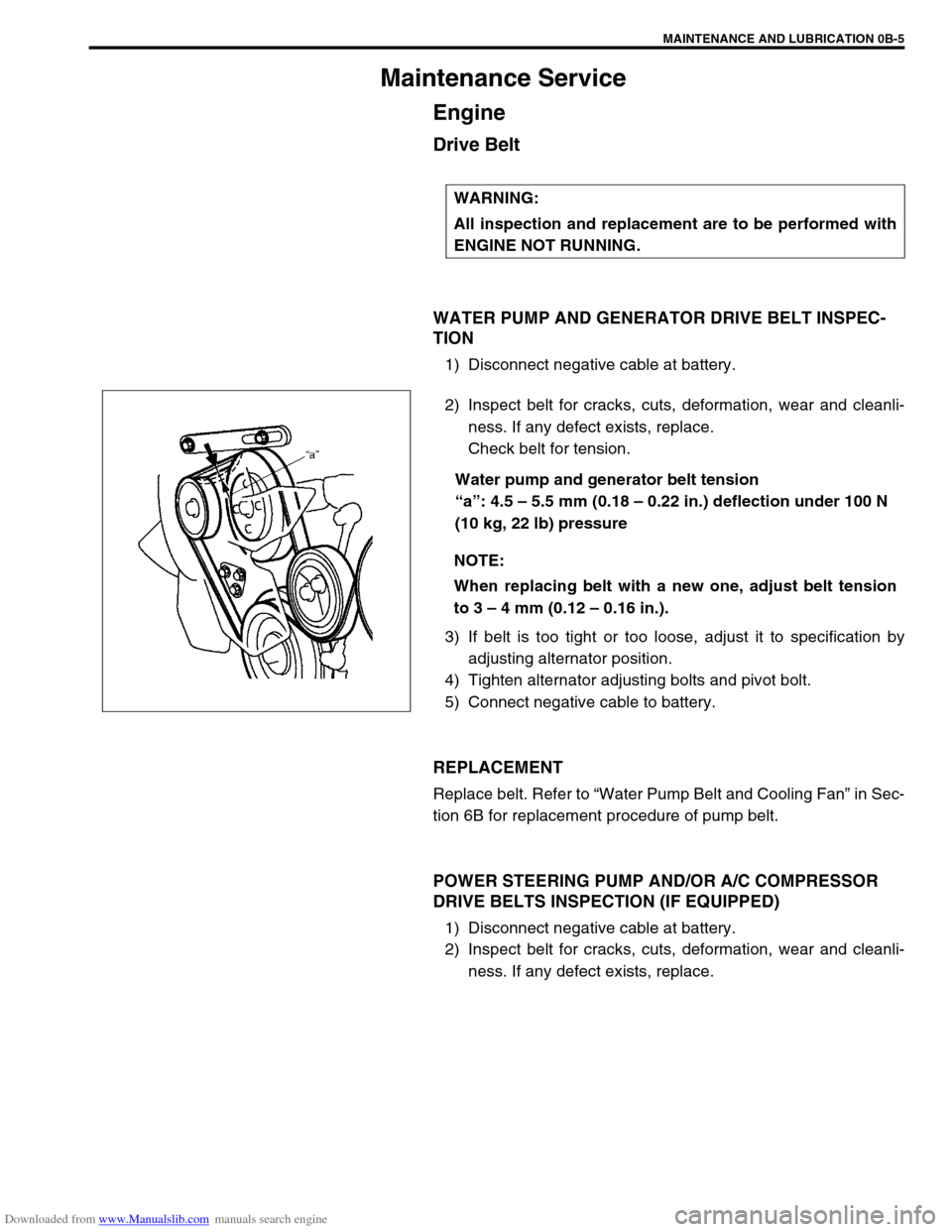

WATER PUMP AND GENERATOR DRIVE BELT INSPEC-

TION

1) Disconnect negative cable at battery.

2) Inspect belt for cracks, cuts, deformation, wear and cleanli-

ness. If any defect exists, replace.

Check belt for tension.

Water pump and generator belt tension

“a”: 4.5 – 5.5 mm (0.18 – 0.22 in.) deflection under 100 N

(10 kg, 22 lb) pressure

3) If belt is too tight or too loose, adjust it to specification by

adjusting alternator position.

4) Tighten alternator adjusting bolts and pivot bolt.

5) Connect negative cable to battery.

REPLACEMENT

Replace belt. Refer to “Water Pump Belt and Cooling Fan” in Sec-

tion 6B for replacement procedure of pump belt.

POWER STEERING PUMP AND/OR A/C COMPRESSOR

DRIVE BELTS INSPECTION (IF EQUIPPED)

1) Disconnect negative cable at battery.

2) Inspect belt for cracks, cuts, deformation, wear and cleanli-

ness. If any defect exists, replace. WARNING:

All inspection and replacement are to be performed with

ENGINE NOT RUNNING.

NOTE:

When replacing belt with a new one, adjust belt tension

to 3 – 4 mm (0.12 – 0.16 in.).

Page 37 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-6 MAINTENANCE AND LUBRICATION

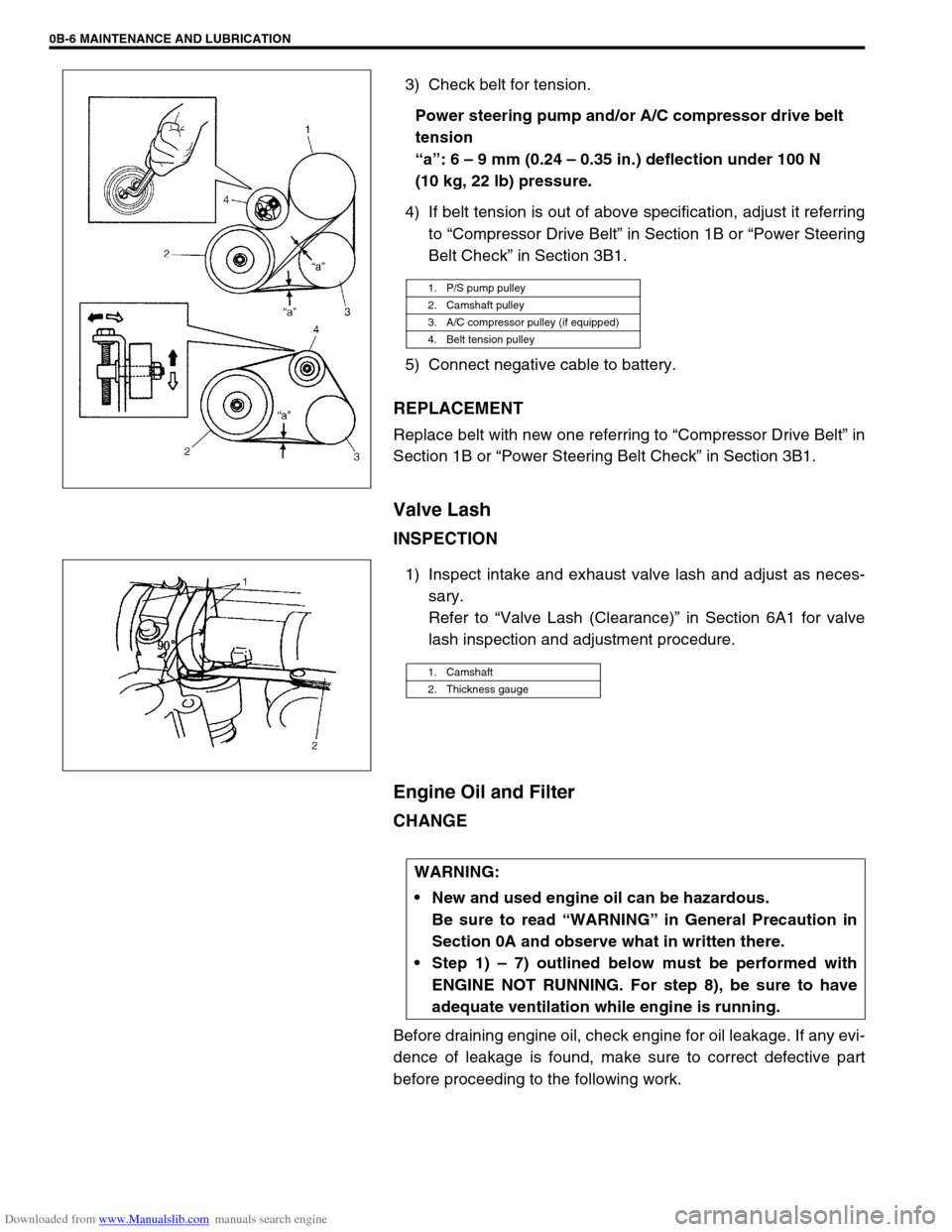

3) Check belt for tension.

Power steering pump and/or A/C compressor drive belt

tension

“a”: 6 – 9 mm (0.24 – 0.35 in.) deflection under 100 N

(10 kg, 22 lb) pressure.

4) If belt tension is out of above specification, adjust it referring

to “Compressor Drive Belt” in Section 1B or “Power Steering

Belt Check” in Section 3B1.

5) Connect negative cable to battery.

REPLACEMENT

Replace belt with new one referring to “Compressor Drive Belt” in

Section 1B or “Power Steering Belt Check” in Section 3B1.

Valve Lash

INSPECTION

1) Inspect intake and exhaust valve lash and adjust as neces-

sary.

Refer to “Valve Lash (Clearance)” in Section 6A1 for valve

lash inspection and adjustment procedure.

Engine Oil and Filter

CHANGE

Before draining engine oil, check engine for oil leakage. If any evi-

dence of leakage is found, make sure to correct defective part

before proceeding to the following work.

1. P/S pump pulley

2. Camshaft pulley

3. A/C compressor pulley (if equipped)

4. Belt tension pulley

1. Camshaft

2. Thickness gauge

WARNING:

New and used engine oil can be hazardous.

Be sure to read “WARNING” in General Precaution in

Section 0A and observe what in written there.

Step 1) – 7) outlined below must be performed with

ENGINE NOT RUNNING. For step 8), be sure to have

adequate ventilation while engine is running.

Page 44 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-13

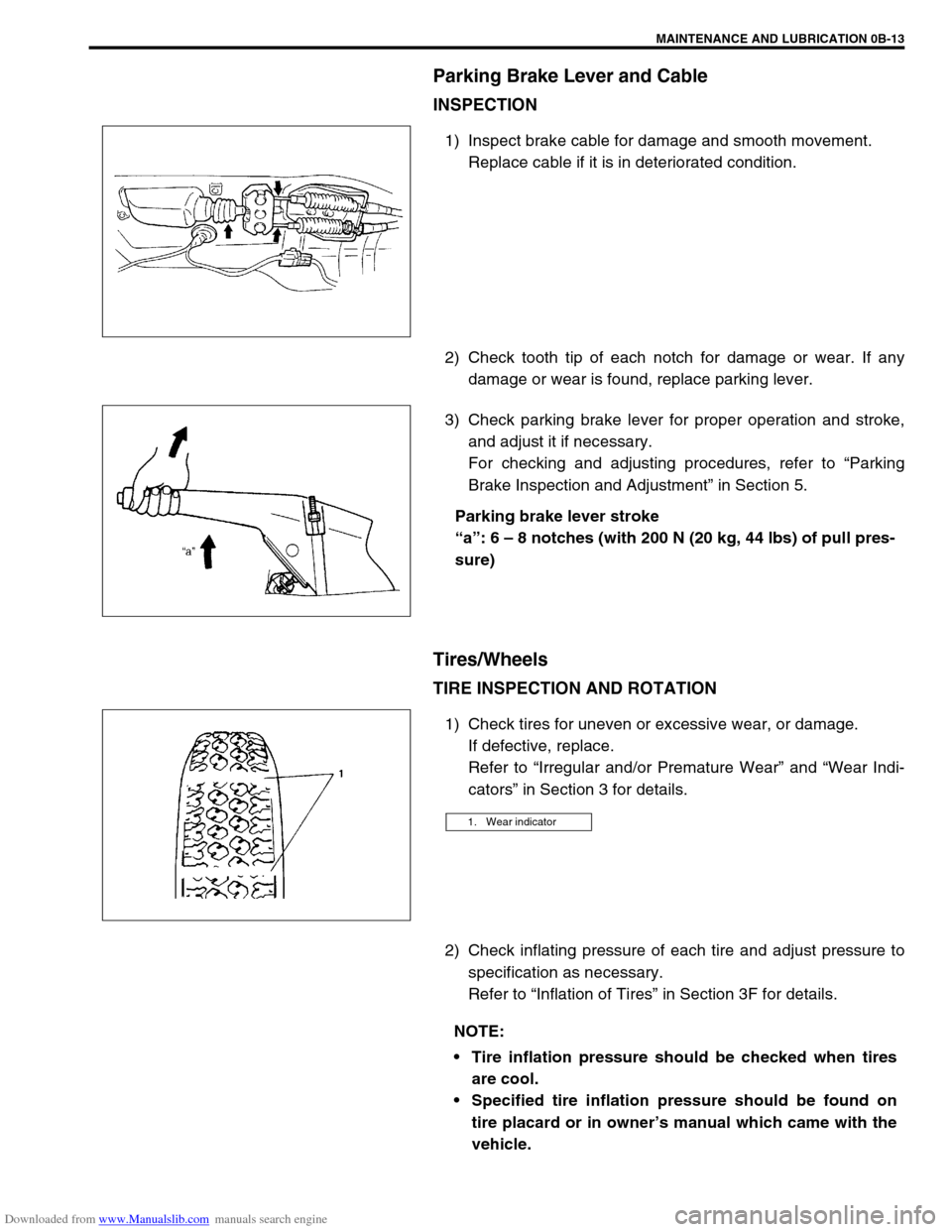

Parking Brake Lever and Cable

INSPECTION

1) Inspect brake cable for damage and smooth movement.

Replace cable if it is in deteriorated condition.

2) Check tooth tip of each notch for damage or wear. If any

damage or wear is found, replace parking lever.

3) Check parking brake lever for proper operation and stroke,

and adjust it if necessary.

For checking and adjusting procedures, refer to “Parking

Brake Inspection and Adjustment” in Section 5.

Parking brake lever stroke

“a”: 6 – 8 notches (with 200 N (20 kg, 44 lbs) of pull pres-

sure)

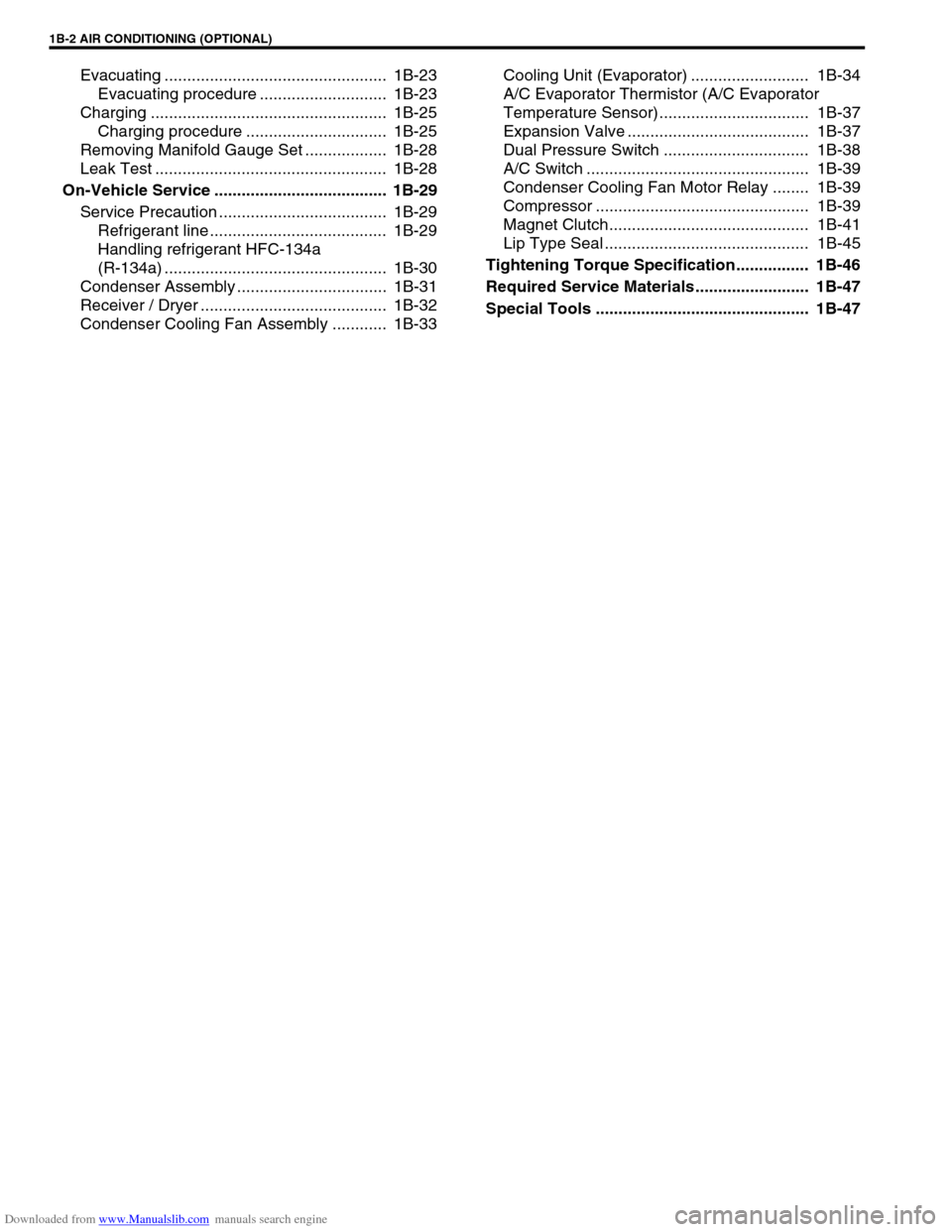

Tires/Wheels

TIRE INSPECTION AND ROTATION

1) Check tires for uneven or excessive wear, or damage.

If defective, replace.

Refer to “Irregular and/or Premature Wear” and “Wear Indi-

cators” in Section 3 for details.

2) Check inflating pressure of each tire and adjust pressure to

specification as necessary.

Refer to “Inflation of Tires” in Section 3F for details.

1. Wear indicator

NOTE:

Tire inflation pressure should be checked when tires

are cool.

Specified tire inflation pressure should be found on

tire placard or in owner’s manual which came with the

vehicle.

Page 63 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-2 AIR CONDITIONING (OPTIONAL)

Evacuating ................................................. 1B-23

Evacuating procedure ............................ 1B-23

Charging .................................................... 1B-25

Charging procedure ............................... 1B-25

Removing Manifold Gauge Set .................. 1B-28

Leak Test ................................................... 1B-28

On-Vehicle Service ...................................... 1B-29

Service Precaution ..................................... 1B-29

Refrigerant line ....................................... 1B-29

Handling refrigerant HFC-134a

(R-134a) ................................................. 1B-30

Condenser Assembly ................................. 1B-31

Receiver / Dryer ......................................... 1B-32

Condenser Cooling Fan Assembly ............ 1B-33Cooling Unit (Evaporator) .......................... 1B-34

A/C Evaporator Thermistor (A/C Evaporator

Temperature Sensor)................................. 1B-37

Expansion Valve ........................................ 1B-37

Dual Pressure Switch ................................ 1B-38

A/C Switch ................................................. 1B-39

Condenser Cooling Fan Motor Relay ........ 1B-39

Compressor ............................................... 1B-39

Magnet Clutch............................................ 1B-41

Lip Type Seal ............................................. 1B-45

Tightening Torque Specification................ 1B-46

Required Service Materials ......................... 1B-47

Special Tools ............................................... 1B-47

Page 64 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-3

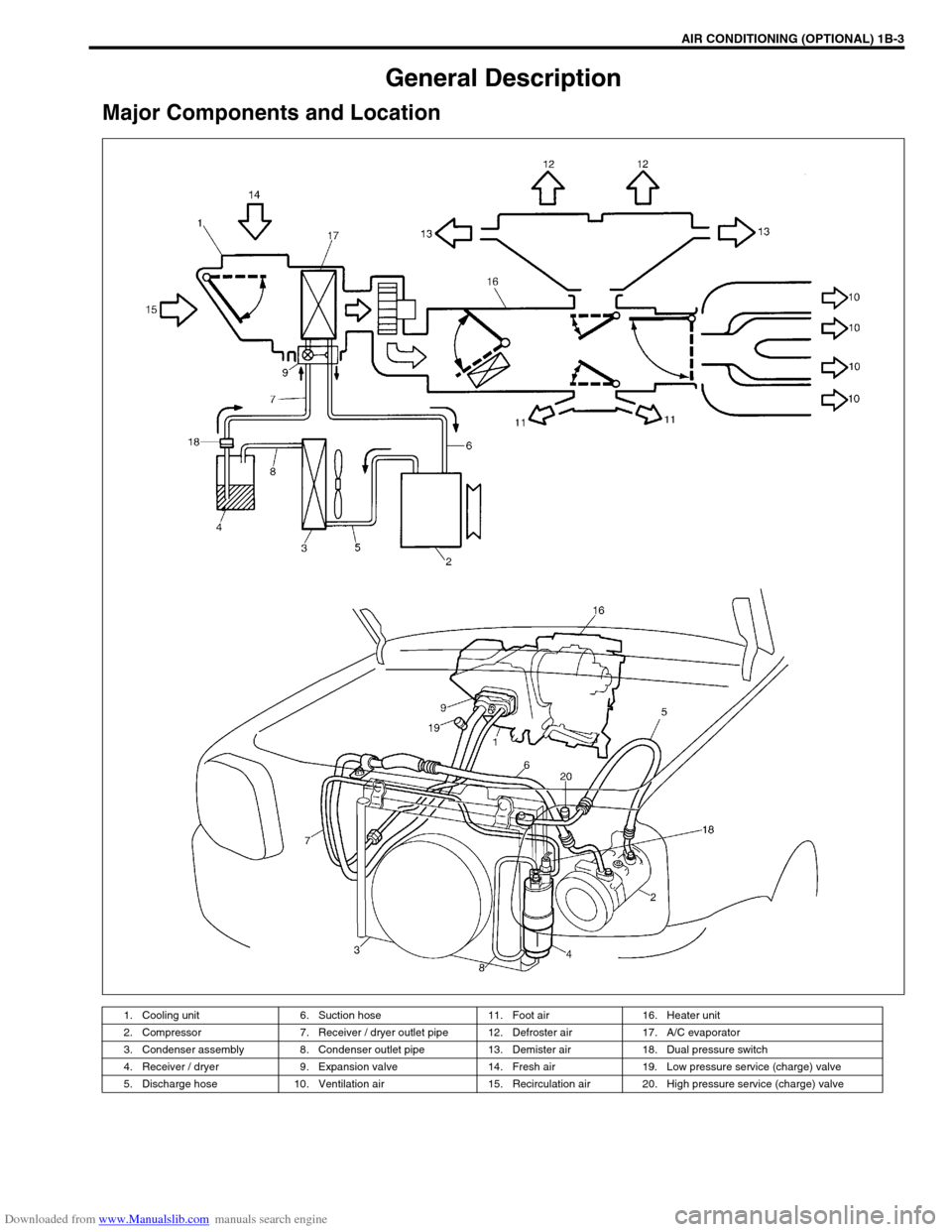

General Description

Major Components and Location

1. Cooling unit 6. Suction hose 11. Foot air 16. Heater unit

2. Compressor 7. Receiver / dryer outlet pipe 12. Defroster air 17. A/C evaporator

3. Condenser assembly 8. Condenser outlet pipe 13. Demister air 18. Dual pressure switch

4. Receiver / dryer 9. Expansion valve 14. Fresh air 19. Low pressure service (charge) valve

5. Discharge hose 10. Ventilation air 15. Recirculation air 20. High pressure service (charge) valve

Page 65 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-4 AIR CONDITIONING (OPTIONAL)

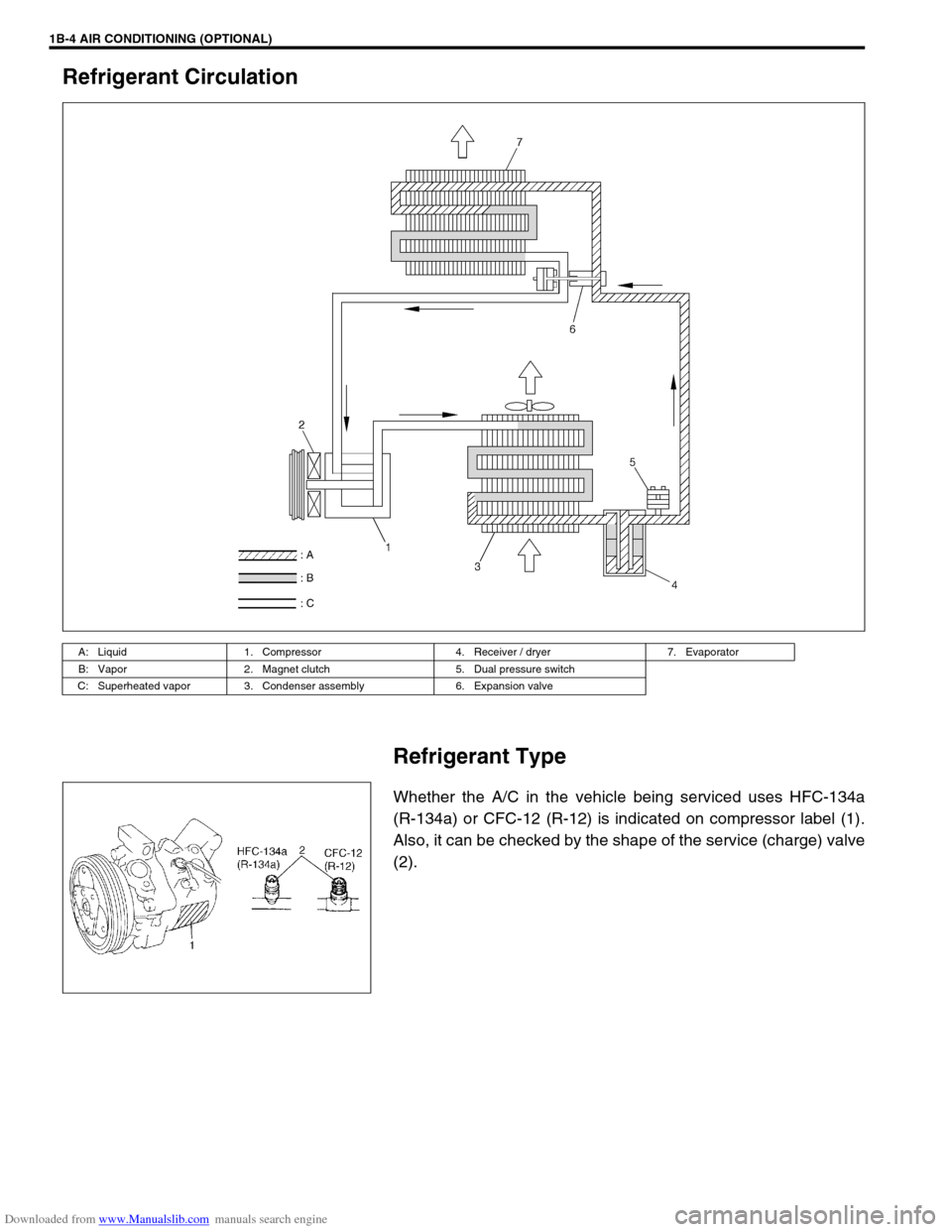

Refrigerant Circulation

Refrigerant Type

Whether the A/C in the vehicle being serviced uses HFC-134a

(R-134a) or CFC-12 (R-12) is indicated on compressor label (1).

Also, it can be checked by the shape of the service (charge) valve

(2).

A: Liquid 1. Compressor 4. Receiver / dryer 7. Evaporator

B: Vapor 2. Magnet clutch 5. Dual pressure switch

C: Superheated vapor 3. Condenser assembly 6. Expansion valve

Page 66 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-5

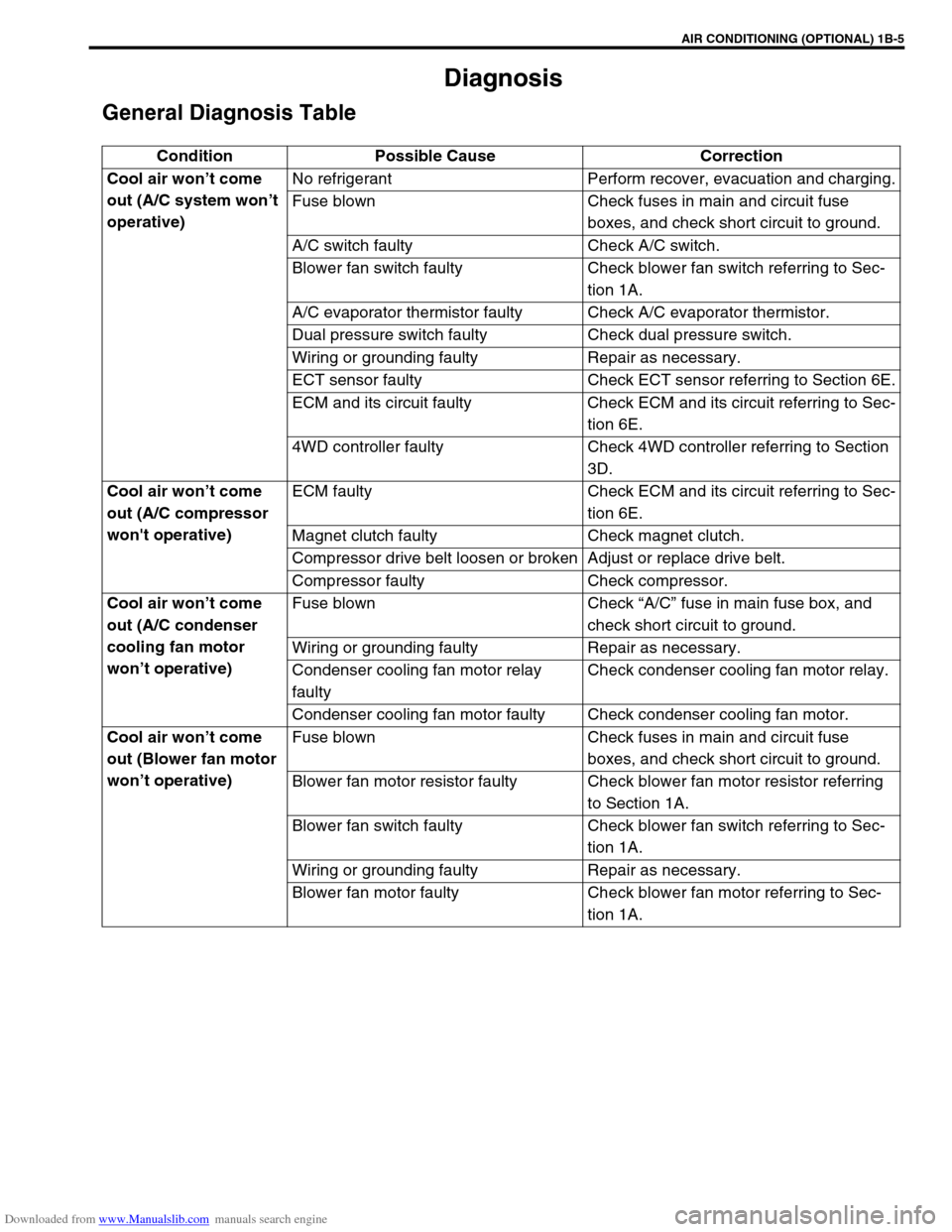

Diagnosis

General Diagnosis Table

Condition Possible Cause Correction

Cool air won’t come

out (A/C system won’t

operative)No refrigerant Perform recover, evacuation and charging.

Fuse blown Check fuses in main and circuit fuse

boxes, and check short circuit to ground.

A/C switch faulty Check A/C switch.

Blower fan switch faulty Check blower fan switch referring to Sec-

tion 1A.

A/C evaporator thermistor faulty Check A/C evaporator thermistor.

Dual pressure switch faulty Check dual pressure switch.

Wiring or grounding faulty Repair as necessary.

ECT sensor faulty Check ECT sensor referring to Section 6E.

ECM and its circuit faulty Check ECM and its circuit referring to Sec-

tion 6E.

4WD controller faulty Check 4WD controller referring to Section

3D.

Cool air won’t come

out (A/C compressor

won't operative)ECM faulty Check ECM and its circuit referring to Sec-

tion 6E.

Magnet clutch faulty Check magnet clutch.

Compressor drive belt loosen or broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Cool air won’t come

out (A/C condenser

cooling fan motor

won’t operative)Fuse blown Check “A/C” fuse in main fuse box, and

check short circuit to ground.

Wiring or grounding faulty Repair as necessary.

Condenser cooling fan motor relay

faultyCheck condenser cooling fan motor relay.

Condenser cooling fan motor faulty Check condenser cooling fan motor.

Cool air won’t come

out (Blower fan motor

won’t operative)Fuse blown Check fuses in main and circuit fuse

boxes, and check short circuit to ground.

Blower fan motor resistor faulty Check blower fan motor resistor referring

to Section 1A.

Blower fan switch faulty Check blower fan switch referring to Sec-

tion 1A.

Wiring or grounding faulty Repair as necessary.

Blower fan motor faulty Check blower fan motor referring to Sec-

tion 1A.

Page 68 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-7

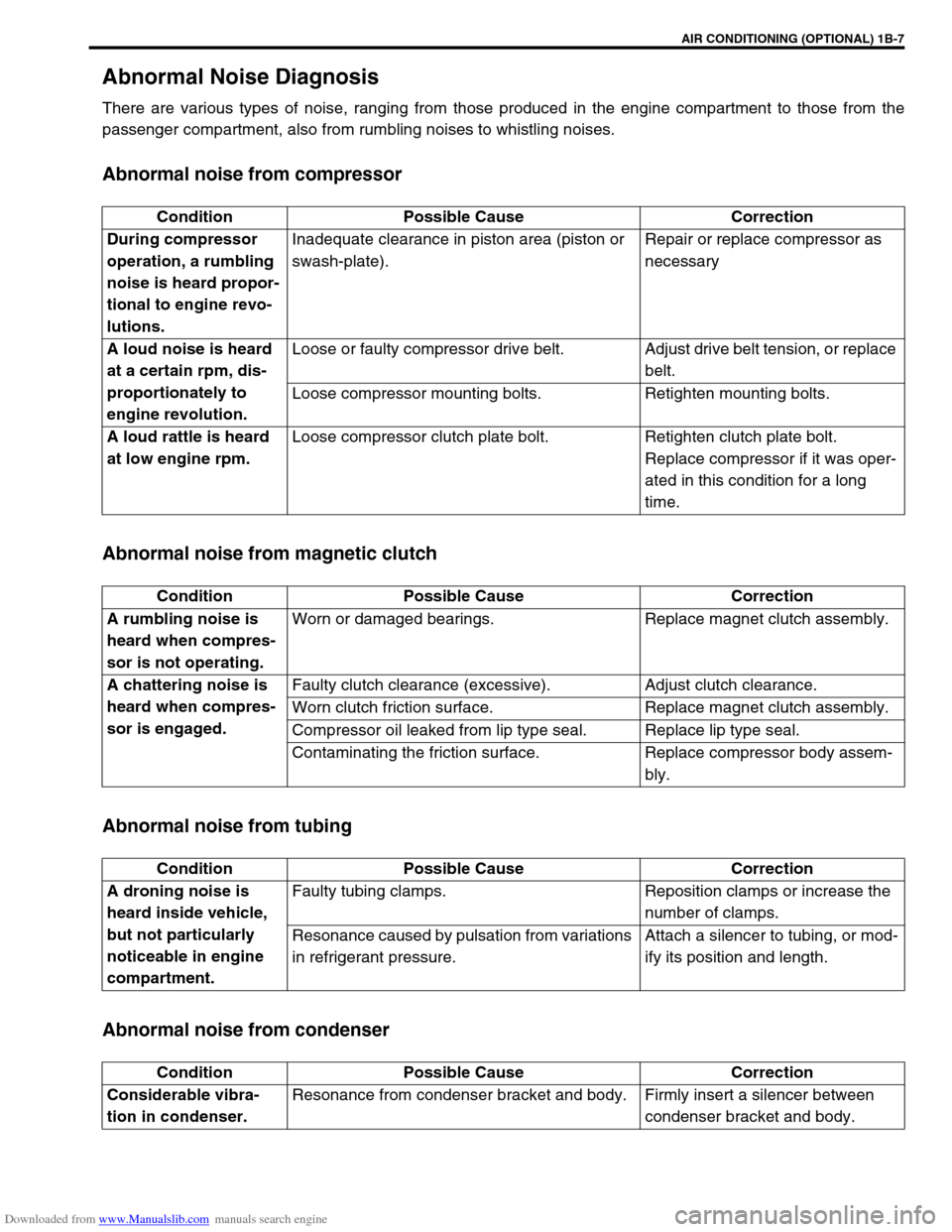

Abnormal Noise Diagnosis

There are various types of noise, ranging from those produced in the engine compartment to those from the

passenger compartment, also from rumbling noises to whistling noises.

Abnormal noise from compressor

Abnormal noise from magnetic clutch

Abnormal noise from tubing

Abnormal noise from condenser

Condition Possible Cause Correction

During compressor

operation, a rumbling

noise is heard propor-

tional to engine revo-

lutions.Inadequate clearance in piston area (piston or

swash-plate).Repair or replace compressor as

necessary

A loud noise is heard

at a certain rpm, dis-

proportionately to

engine revolution.Loose or faulty compressor drive belt. Adjust drive belt tension, or replace

belt.

Loose compressor mounting bolts. Retighten mounting bolts.

A loud rattle is heard

at low engine rpm.Loose compressor clutch plate bolt. Retighten clutch plate bolt.

Replace compressor if it was oper-

ated in this condition for a long

time.

Condition Possible Cause Correction

A rumbling noise is

heard when compres-

sor is not operating.Worn or damaged bearings. Replace magnet clutch assembly.

A chattering noise is

heard when compres-

sor is engaged.Faulty clutch clearance (excessive). Adjust clutch clearance.

Worn clutch friction surface. Replace magnet clutch assembly.

Compressor oil leaked from lip type seal. Replace lip type seal.

Contaminating the friction surface. Replace compressor body assem-

bly.

Condition Possible Cause Correction

A droning noise is

heard inside vehicle,

but not particularly

noticeable in engine

compartment.Faulty tubing clamps. Reposition clamps or increase the

number of clamps.

Resonance caused by pulsation from variations

in refrigerant pressure.Attach a silencer to tubing, or mod-

ify its position and length.

Condition Possible Cause Correction

Considerable vibra-

tion in condenser.Resonance from condenser bracket and body. Firmly insert a silencer between

condenser bracket and body.