SUZUKI JIMNY 2005 3.G Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 141 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-10 POWER STEERING (P/S) SYSTEM (If equipped)

Hydraulic Pressure In P/S Circuit Check

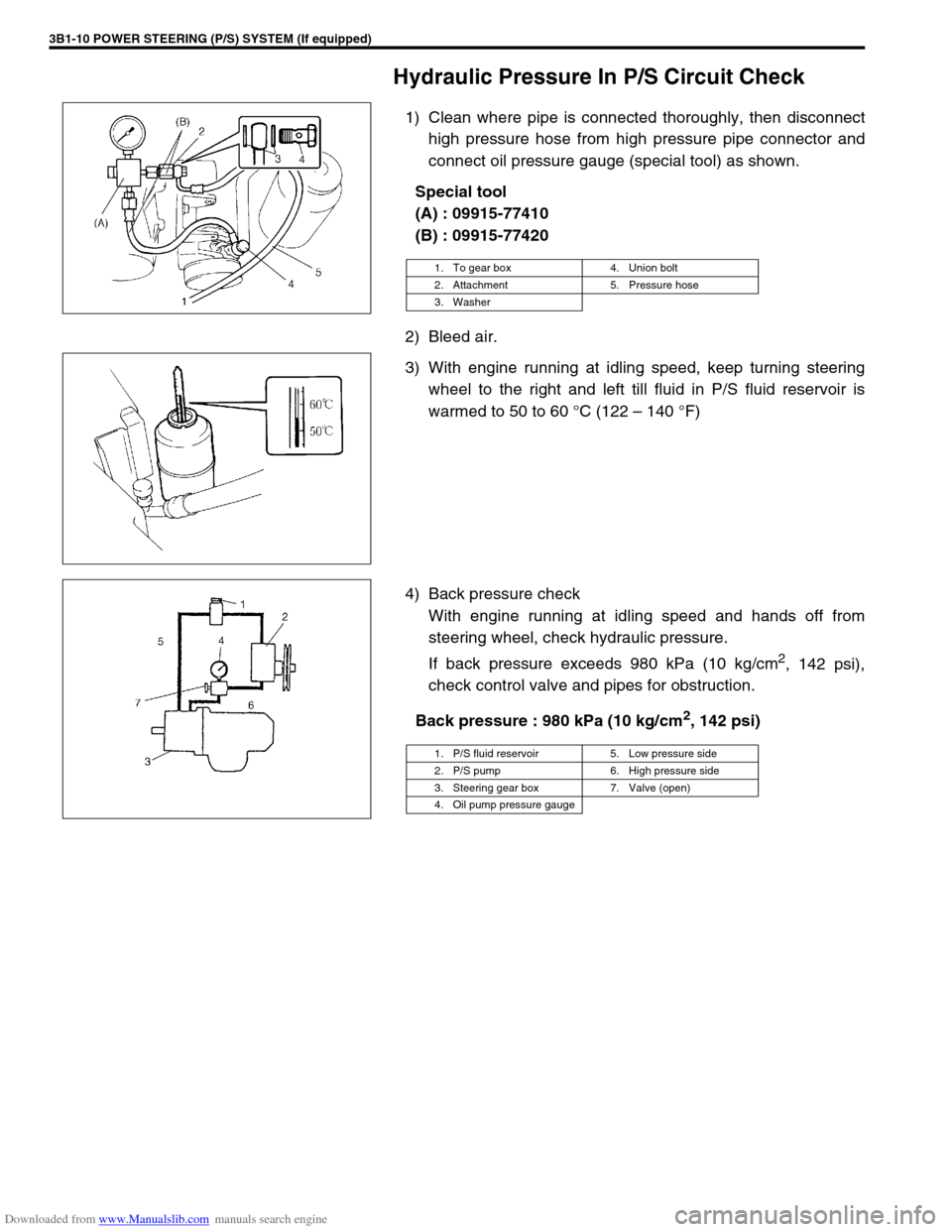

1) Clean where pipe is connected thoroughly, then disconnect

high pressure hose from high pressure pipe connector and

connect oil pressure gauge (special tool) as shown.

Special tool

(A) : 09915-77410

(B) : 09915-77420

2) Bleed air.

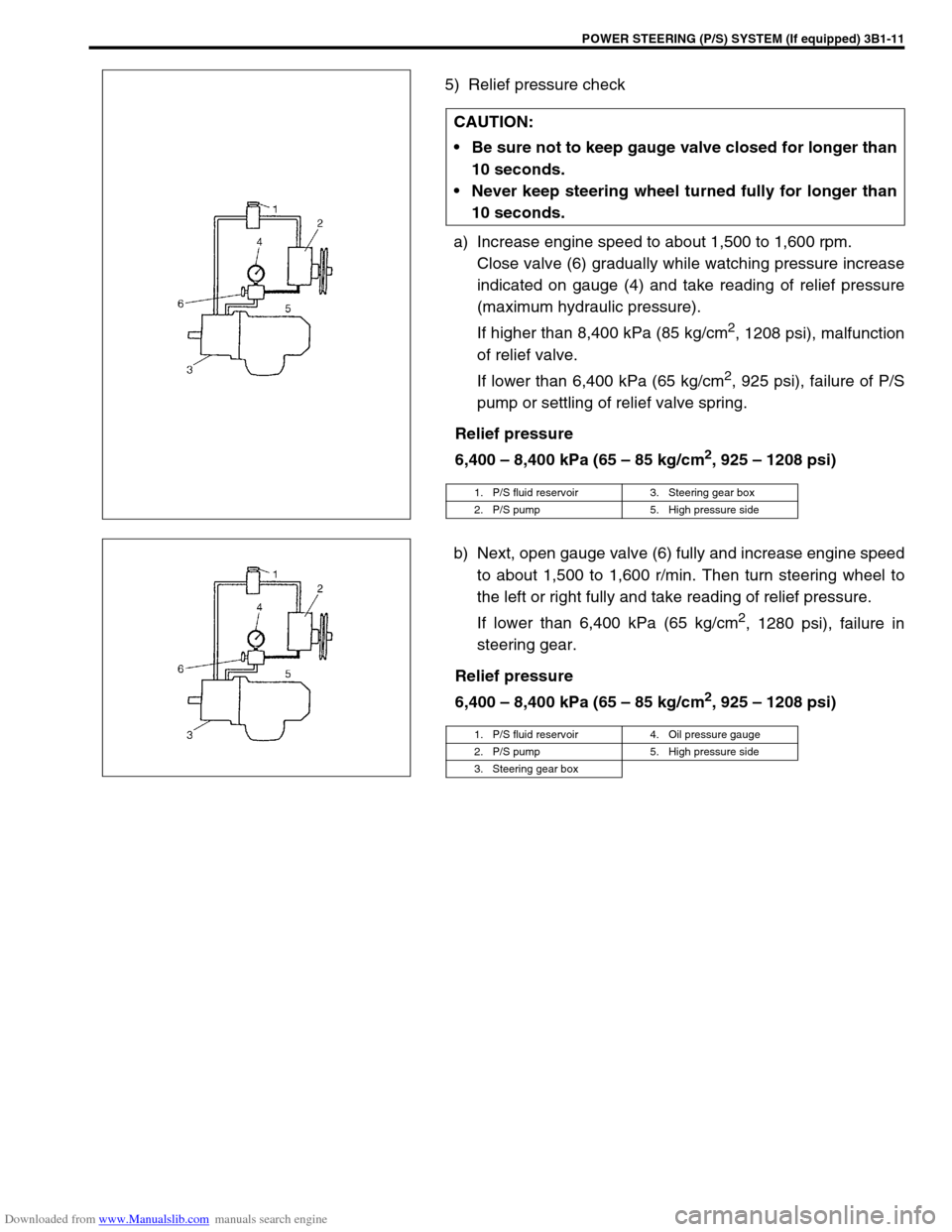

3) With engine running at idling speed, keep turning steering

wheel to the right and left till fluid in P/S fluid reservoir is

warmed to 50 to 60 °C (122 – 140 °F)

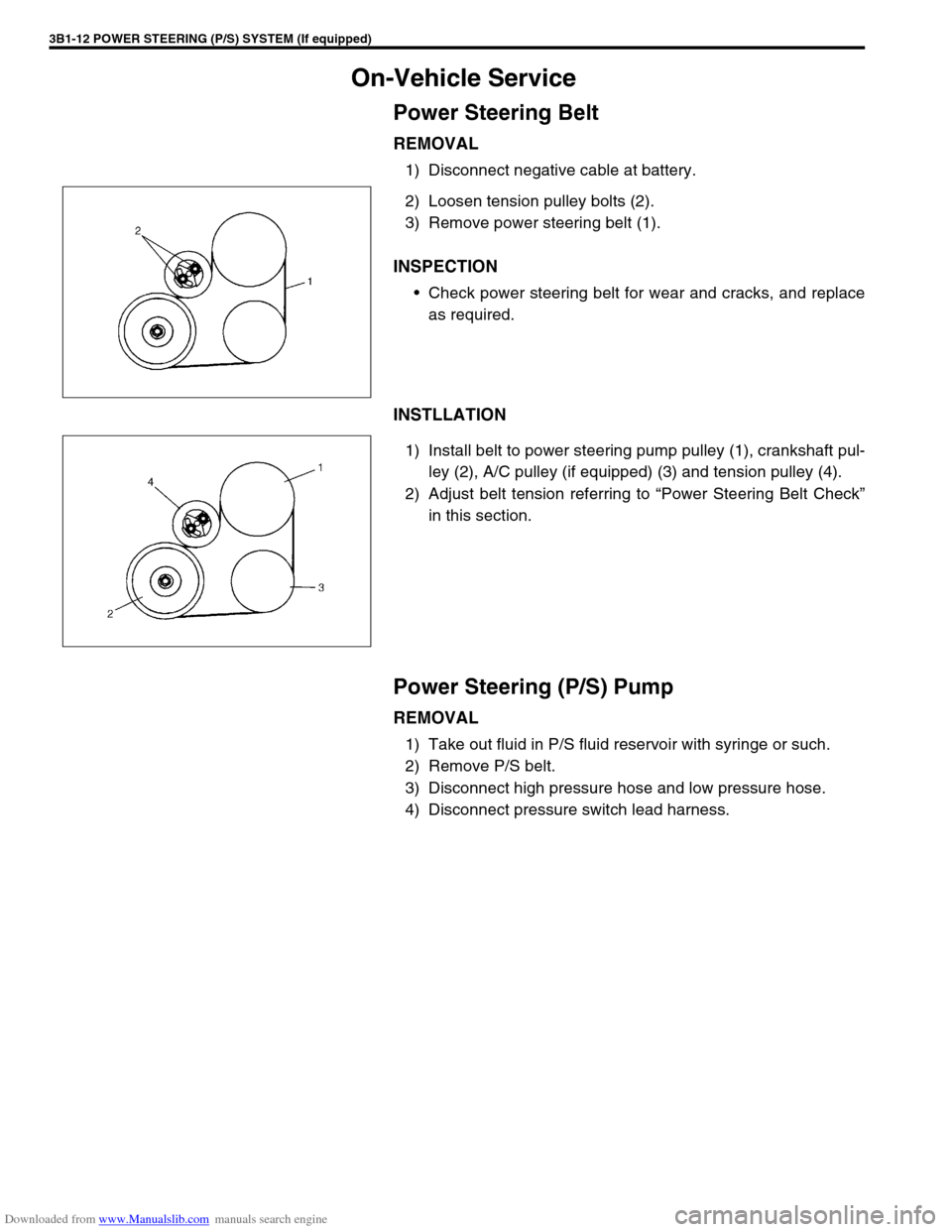

4) Back pressure check

With engine running at idling speed and hands off from

steering wheel, check hydraulic pressure.

If back pressure exceeds 980 kPa (10 kg/cm

2, 142 psi),

check control valve and pipes for obstruction.

Back pressure : 980 kPa (10 kg/cm

2, 142 psi)

1. To gear box 4. Union bolt

2. Attachment 5. Pressure hose

3. Washer

1. P/S fluid reservoir 5. Low pressure side

2. P/S pump 6. High pressure side

3. Steering gear box 7. Valve (open)

4. Oil pump pressure gauge

Page 142 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-11

5) Relief pressure check

a) Increase engine speed to about 1,500 to 1,600 rpm.

Close valve (6) gradually while watching pressure increase

indicated on gauge (4) and take reading of relief pressure

(maximum hydraulic pressure).

If higher than 8,400 kPa (85 kg/cm

2, 1208 psi), malfunction

of relief valve.

If lower than 6,400 kPa (65 kg/cm

2, 925 psi), failure of P/S

pump or settling of relief valve spring.

Relief pressure

6,400 – 8,400 kPa (65 – 85 kg/cm

2, 925 – 1208 psi)

b) Next, open gauge valve (6) fully and increase engine speed

to about 1,500 to 1,600 r/min. Then turn steering wheel to

the left or right fully and take reading of relief pressure.

If lower than 6,400 kPa (65 kg/cm

2, 1280 psi), failure in

steering gear.

Relief pressure

6,400 – 8,400 kPa (65 – 85 kg/cm

2, 925 – 1208 psi) CAUTION:

Be sure not to keep gauge valve closed for longer than

10 seconds.

Never keep steering wheel turned fully for longer than

10 seconds.

1. P/S fluid reservoir 3. Steering gear box

2. P/S pump 5. High pressure side

1. P/S fluid reservoir 4. Oil pressure gauge

2. P/S pump 5. High pressure side

3. Steering gear box

Page 143 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-12 POWER STEERING (P/S) SYSTEM (If equipped)

On-Vehicle Service

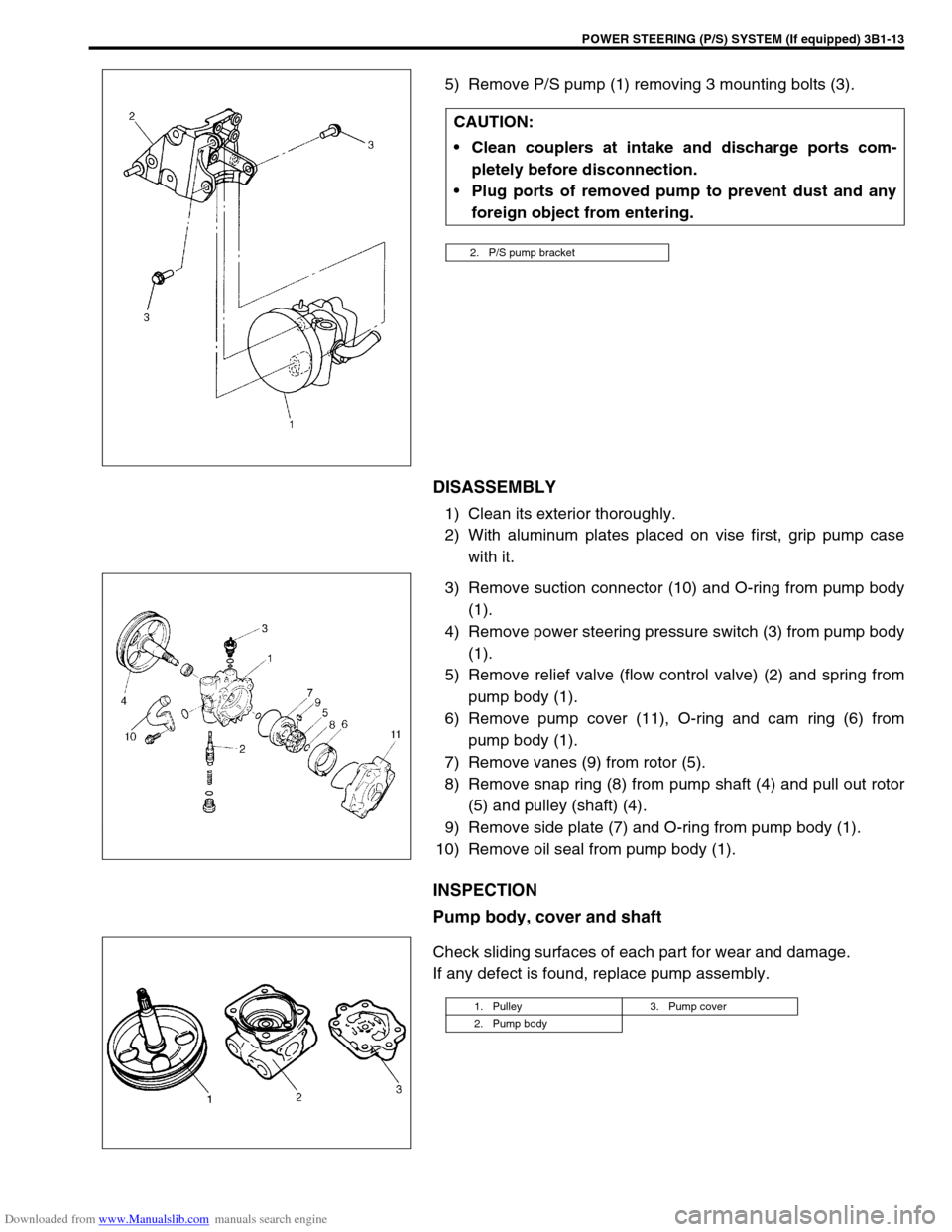

Power Steering Belt

REMOVAL

1) Disconnect negative cable at battery.

2) Loosen tension pulley bolts (2).

3) Remove power steering belt (1).

INSPECTION

Check power steering belt for wear and cracks, and replace

as required.

INSTLLATION

1) Install belt to power steering pump pulley (1), crankshaft pul-

ley (2), A/C pulley (if equipped) (3) and tension pulley (4).

2) Adjust belt tension referring to “Power Steering Belt Check”

in this section.

Power Steering (P/S) Pump

REMOVAL

1) Take out fluid in P/S fluid reservoir with syringe or such.

2) Remove P/S belt.

3) Disconnect high pressure hose and low pressure hose.

4) Disconnect pressure switch lead harness.

Page 144 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-13

5) Remove P/S pump (1) removing 3 mounting bolts (3).

DISASSEMBLY

1) Clean its exterior thoroughly.

2) With aluminum plates placed on vise first, grip pump case

with it.

3) Remove suction connector (10) and O-ring from pump body

(1).

4) Remove power steering pressure switch (3) from pump body

(1).

5) Remove relief valve (flow control valve) (2) and spring from

pump body (1).

6) Remove pump cover (11), O-ring and cam ring (6) from

pump body (1).

7) Remove vanes (9) from rotor (5).

8) Remove snap ring (8) from pump shaft (4) and pull out rotor

(5) and pulley (shaft) (4).

9) Remove side plate (7) and O-ring from pump body (1).

10) Remove oil seal from pump body (1).

INSPECTION

Pump body, cover and shaft

Check sliding surfaces of each part for wear and damage.

If any defect is found, replace pump assembly.CAUTION:

Clean couplers at intake and discharge ports com-

pletely before disconnection.

Plug ports of removed pump to prevent dust and any

foreign object from entering.

2. P/S pump bracket

1. Pulley 3. Pump cover

2. Pump body

Page 145 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-14 POWER STEERING (P/S) SYSTEM (If equipped)

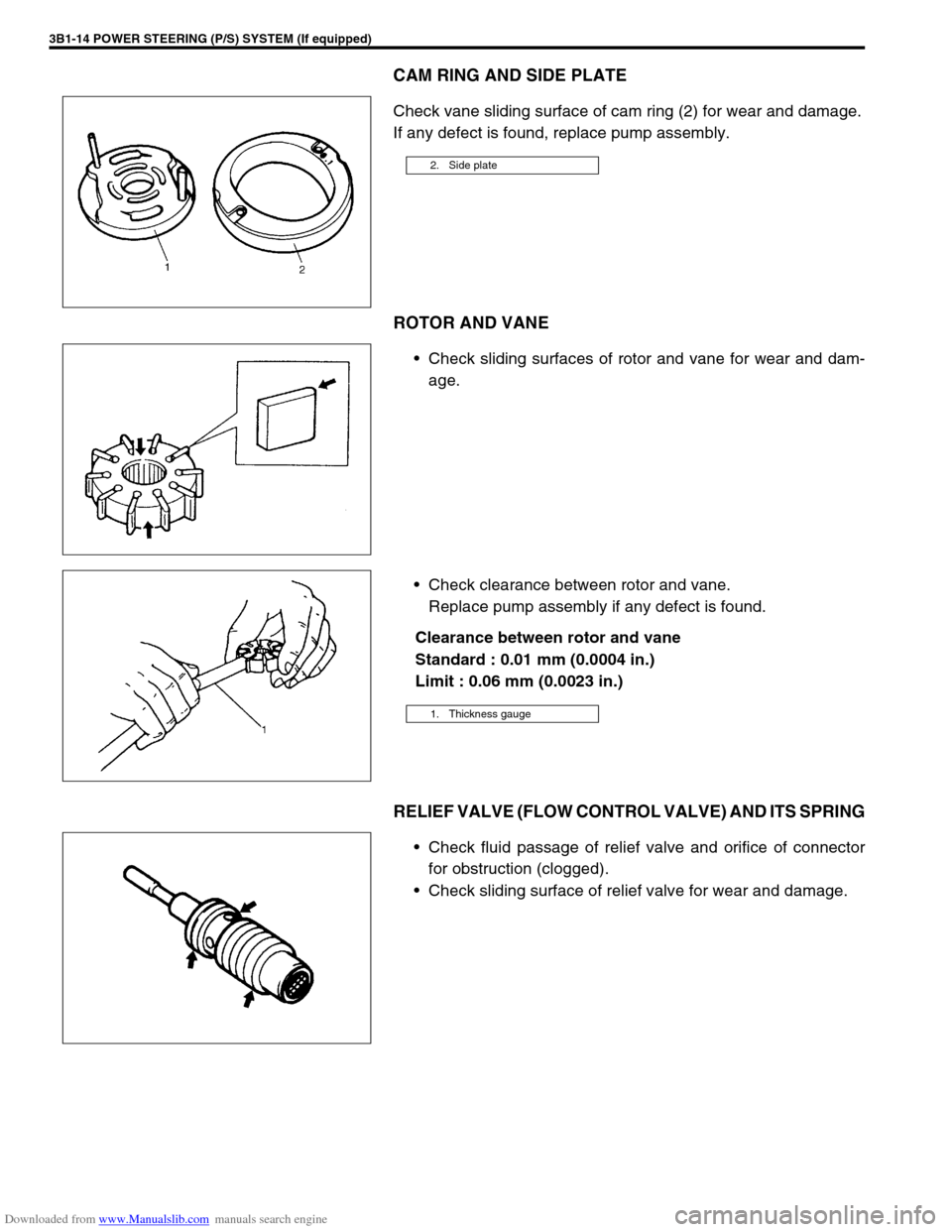

CAM RING AND SIDE PLATE

Check vane sliding surface of cam ring (2) for wear and damage.

If any defect is found, replace pump assembly.

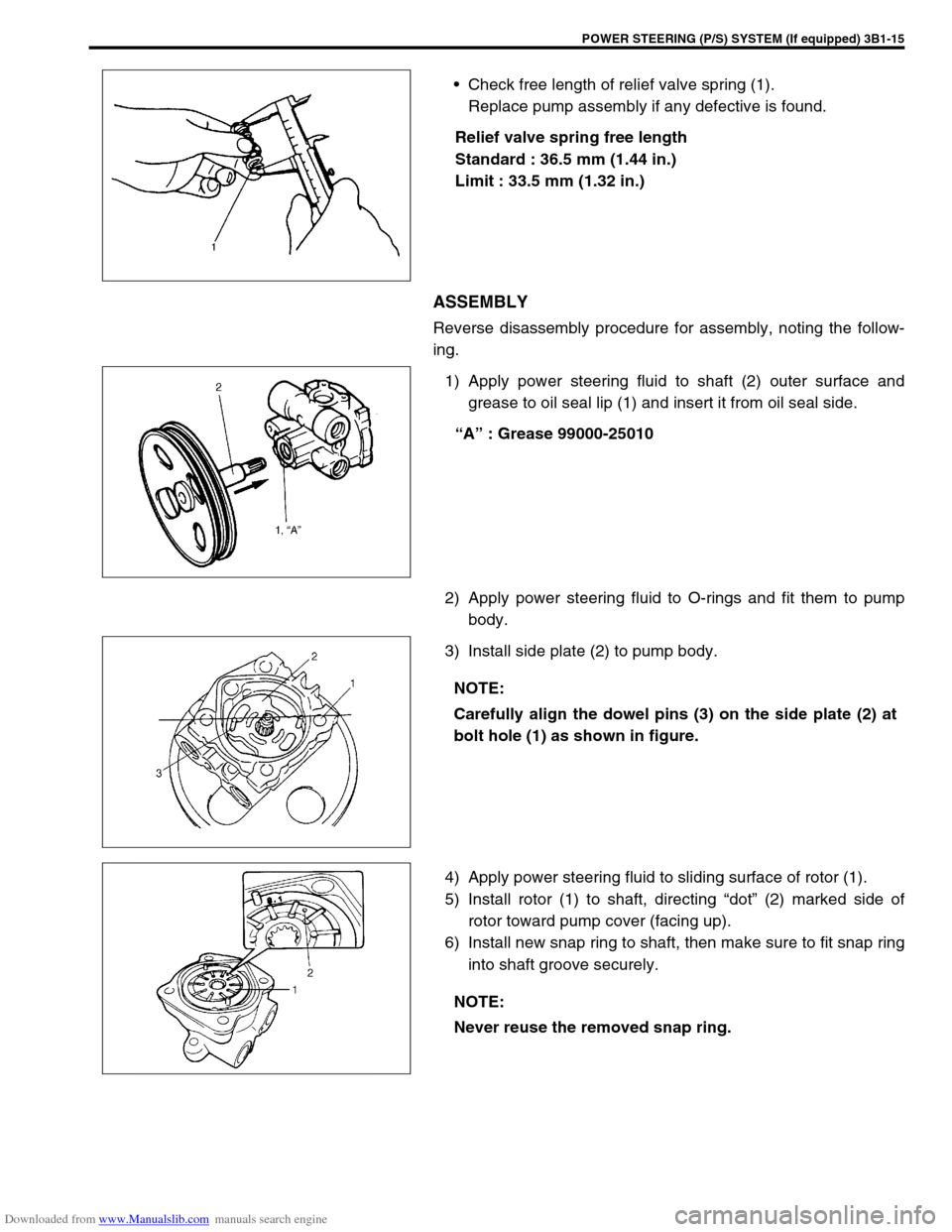

ROTOR AND VANE

Check sliding surfaces of rotor and vane for wear and dam-

age.

Check clearance between rotor and vane.

Replace pump assembly if any defect is found.

Clearance between rotor and vane

Standard : 0.01 mm (0.0004 in.)

Limit : 0.06 mm (0.0023 in.)

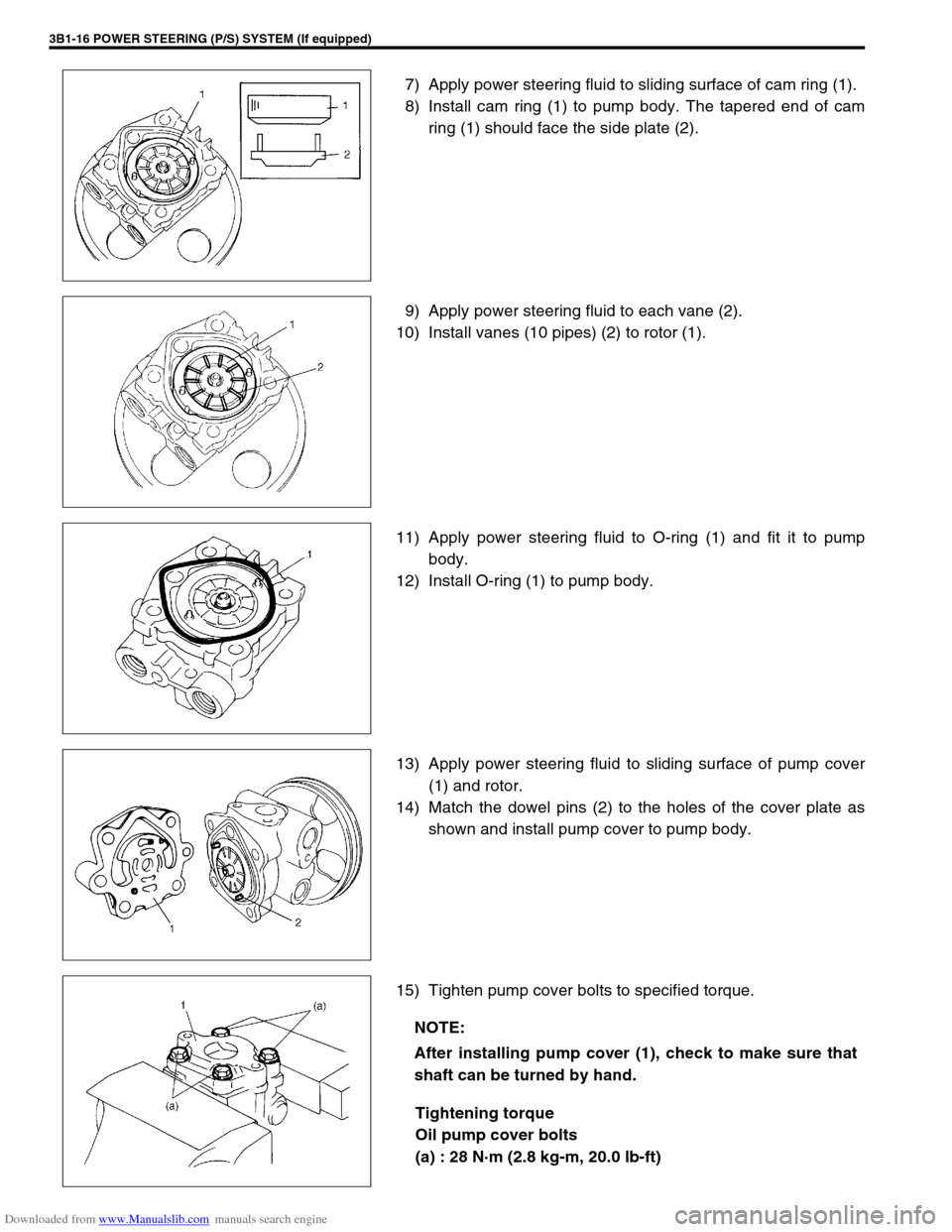

RELIEF VALVE (FLOW CONTROL VALVE) AND ITS SPRING

Check fluid passage of relief valve and orifice of connector

for obstruction (clogged).

Check sliding surface of relief valve for wear and damage.

2. Side plate

1. Thickness gauge

Page 146 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-15

Check free length of relief valve spring (1).

Replace pump assembly if any defective is found.

Relief valve spring free length

Standard : 36.5 mm (1.44 in.)

Limit : 33.5 mm (1.32 in.)

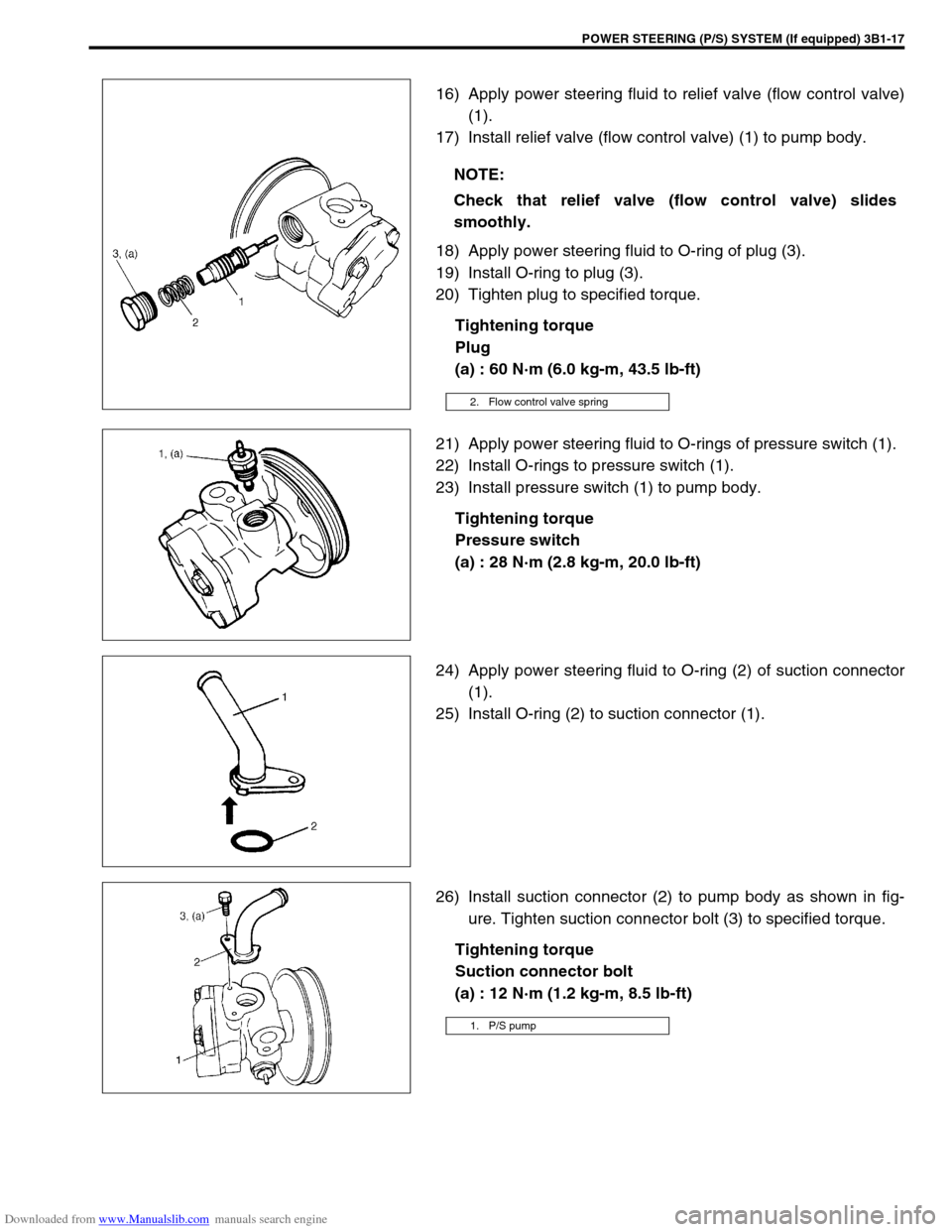

ASSEMBLY

Reverse disassembly procedure for assembly, noting the follow-

ing.

1) Apply power steering fluid to shaft (2) outer surface and

grease to oil seal lip (1) and insert it from oil seal side.

“A” : Grease 99000-25010

2) Apply power steering fluid to O-rings and fit them to pump

body.

3) Install side plate (2) to pump body.

4) Apply power steering fluid to sliding surface of rotor (1).

5) Install rotor (1) to shaft, directing “dot” (2) marked side of

rotor toward pump cover (facing up).

6) Install new snap ring to shaft, then make sure to fit snap ring

into shaft groove securely.

NOTE:

Carefully align the dowel pins (3) on the side plate (2) at

bolt hole (1) as shown in figure.

NOTE:

Never reuse the removed snap ring.

Page 147 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-16 POWER STEERING (P/S) SYSTEM (If equipped)

7) Apply power steering fluid to sliding surface of cam ring (1).

8) Install cam ring (1) to pump body. The tapered end of cam

ring (1) should face the side plate (2).

9) Apply power steering fluid to each vane (2).

10) Install vanes (10 pipes) (2) to rotor (1).

11) Apply power steering fluid to O-ring (1) and fit it to pump

body.

12) Install O-ring (1) to pump body.

13) Apply power steering fluid to sliding surface of pump cover

(1) and rotor.

14) Match the dowel pins (2) to the holes of the cover plate as

shown and install pump cover to pump body.

15) Tighten pump cover bolts to specified torque.

Tightening torque

Oil pump cover bolts

(a) : 28 N·m (2.8 kg-m, 20.0 lb-ft)

NOTE:

After installing pump cover (1), check to make sure that

shaft can be turned by hand.

Page 148 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-17

16) Apply power steering fluid to relief valve (flow control valve)

(1).

17) Install relief valve (flow control valve) (1) to pump body.

18) Apply power steering fluid to O-ring of plug (3).

19) Install O-ring to plug (3).

20) Tighten plug to specified torque.

Tightening torque

Plug

(a) : 60 N·m (6.0 kg-m, 43.5 lb-ft)

21) Apply power steering fluid to O-rings of pressure switch (1).

22) Install O-rings to pressure switch (1).

23) Install pressure switch (1) to pump body.

Tightening torque

Pressure switch

(a) : 28 N·m (2.8 kg-m, 20.0 lb-ft)

24) Apply power steering fluid to O-ring (2) of suction connector

(1).

25) Install O-ring (2) to suction connector (1).

26) Install suction connector (2) to pump body as shown in fig-

ure. Tighten suction connector bolt (3) to specified torque.

Tightening torque

Suction connector bolt

(a) : 12 N·m (1.2 kg-m, 8.5 lb-ft) NOTE:

Check that relief valve (flow control valve) slides

smoothly.

2. Flow control valve spring

1. P/S pump

Page 149 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-18 POWER STEERING (P/S) SYSTEM (If equipped)

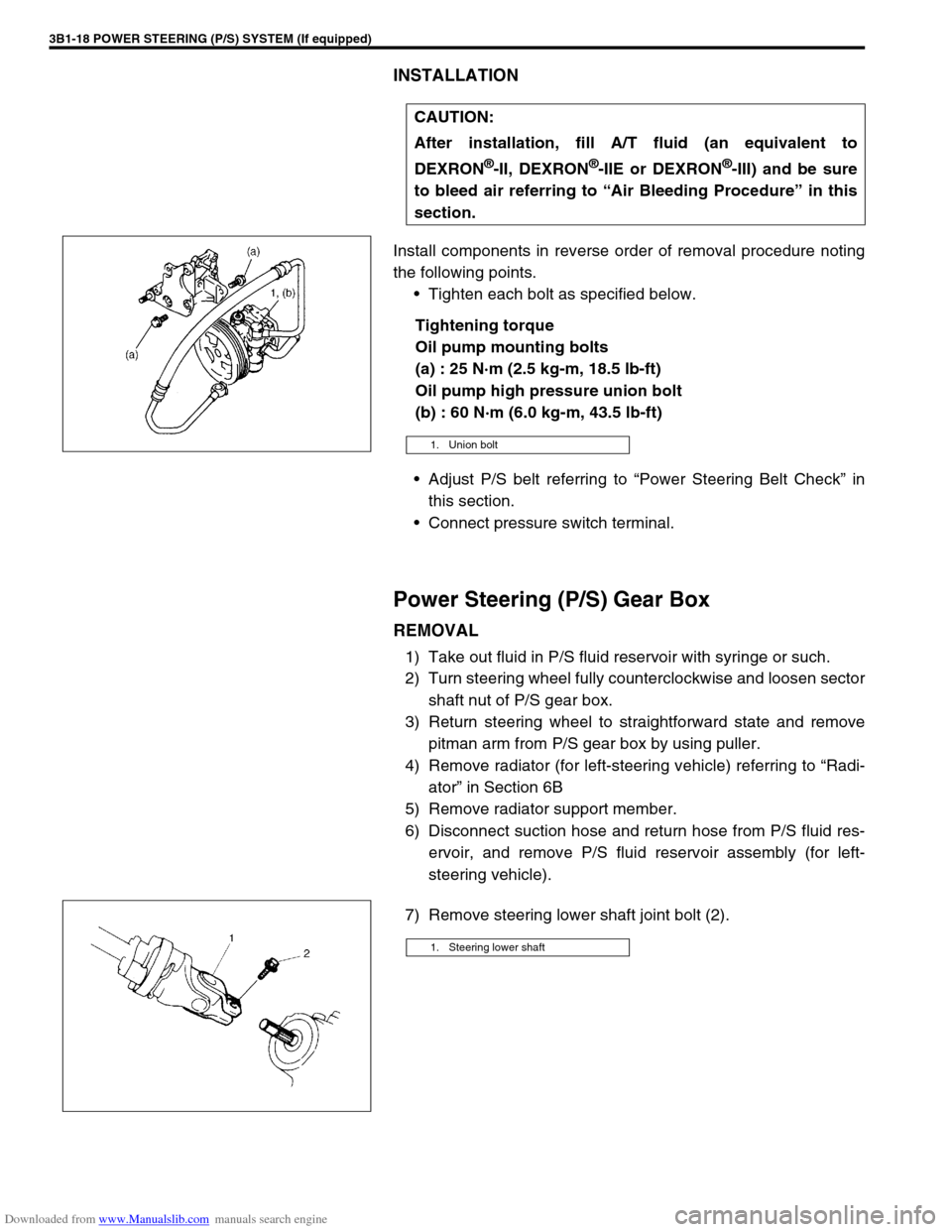

INSTALLATION

Install components in reverse order of removal procedure noting

the following points.

Tighten each bolt as specified below.

Tightening torque

Oil pump mounting bolts

(a) : 25 N·m (2.5 kg-m, 18.5 lb-ft)

Oil pump high pressure union bolt

(b) : 60 N·m (6.0 kg-m, 43.5 lb-ft)

Adjust P/S belt referring to “Power Steering Belt Check” in

this section.

Connect pressure switch terminal.

Power Steering (P/S) Gear Box

REMOVAL

1) Take out fluid in P/S fluid reservoir with syringe or such.

2) Turn steering wheel fully counterclockwise and loosen sector

shaft nut of P/S gear box.

3) Return steering wheel to straightforward state and remove

pitman arm from P/S gear box by using puller.

4) Remove radiator (for left-steering vehicle) referring to “Radi-

ator” in Section 6B

5) Remove radiator support member.

6) Disconnect suction hose and return hose from P/S fluid res-

ervoir, and remove P/S fluid reservoir assembly (for left-

steering vehicle).

7) Remove steering lower shaft joint bolt (2).CAUTION:

After installation, fill A/T fluid (an equivalent to

DEXRON

®-II, DEXRON®-IIE or DEXRON®-III) and be sure

to bleed air referring to “Air Bleeding Procedure” in this

section.

1. Union bolt

1. Steering lower shaft

Page 150 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-19

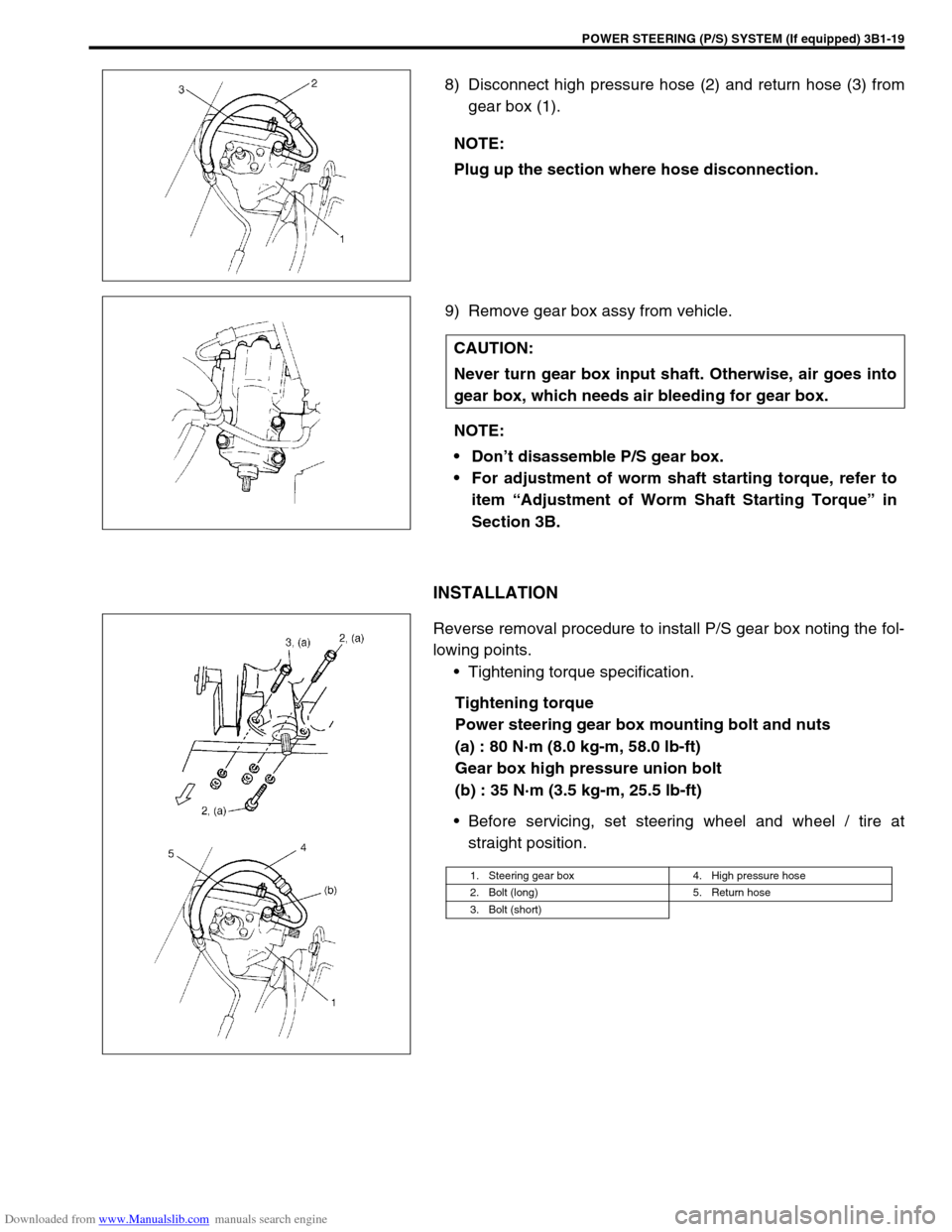

8) Disconnect high pressure hose (2) and return hose (3) from

gear box (1).

9) Remove gear box assy from vehicle.

INSTALLATION

Reverse removal procedure to install P/S gear box noting the fol-

lowing points.

Tightening torque specification.

Tightening torque

Power steering gear box mounting bolt and nuts

(a) : 80 N·m (8.0 kg-m, 58.0 lb-ft)

Gear box high pressure union bolt

(b) : 35 N·m (3.5 kg-m, 25.5 lb-ft)

Before servicing, set steering wheel and wheel / tire at

straight position. NOTE:

Plug up the section where hose disconnection.

CAUTION:

Never turn gear box input shaft. Otherwise, air goes into

gear box, which needs air bleeding for gear box.

NOTE:

Don’t disassemble P/S gear box.

For adjustment of worm shaft starting torque, refer to

item “Adjustment of Worm Shaft Starting Torque” in

Section 3B.

1. Steering gear box 4. High pressure hose

2. Bolt (long) 5. Return hose

3. Bolt (short)