torque SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 512 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-31

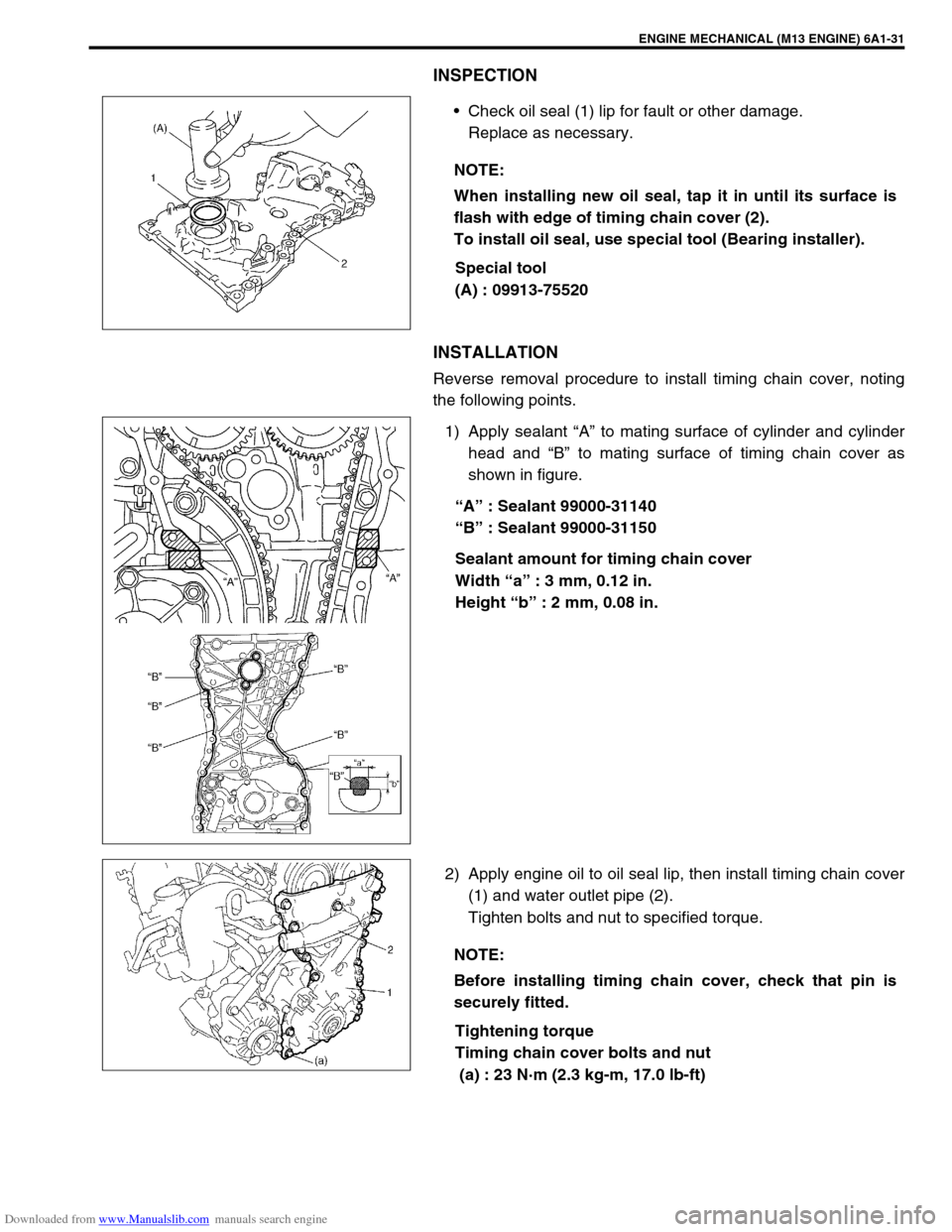

INSPECTION

Check oil seal (1) lip for fault or other damage.

Replace as necessary.

Special tool

(A) : 09913-75520

INSTALLATION

Reverse removal procedure to install timing chain cover, noting

the following points.

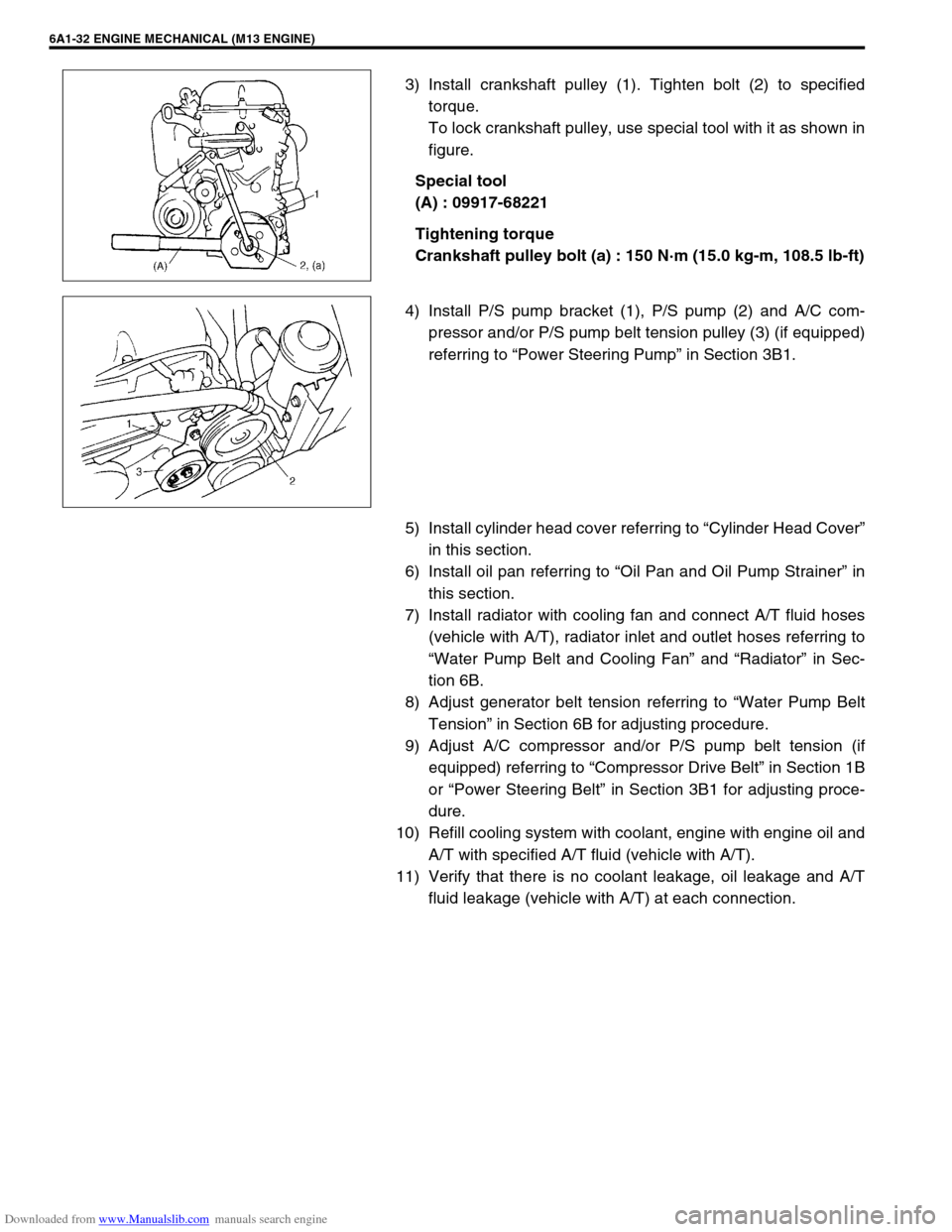

1) Apply sealant “A” to mating surface of cylinder and cylinder

head and “B” to mating surface of timing chain cover as

shown in figure.

“A” : Sealant 99000-31140

“B” : Sealant 99000-31150

Sealant amount for timing chain cover

Width “a” : 3 mm, 0.12 in.

Height “b” : 2 mm, 0.08 in.

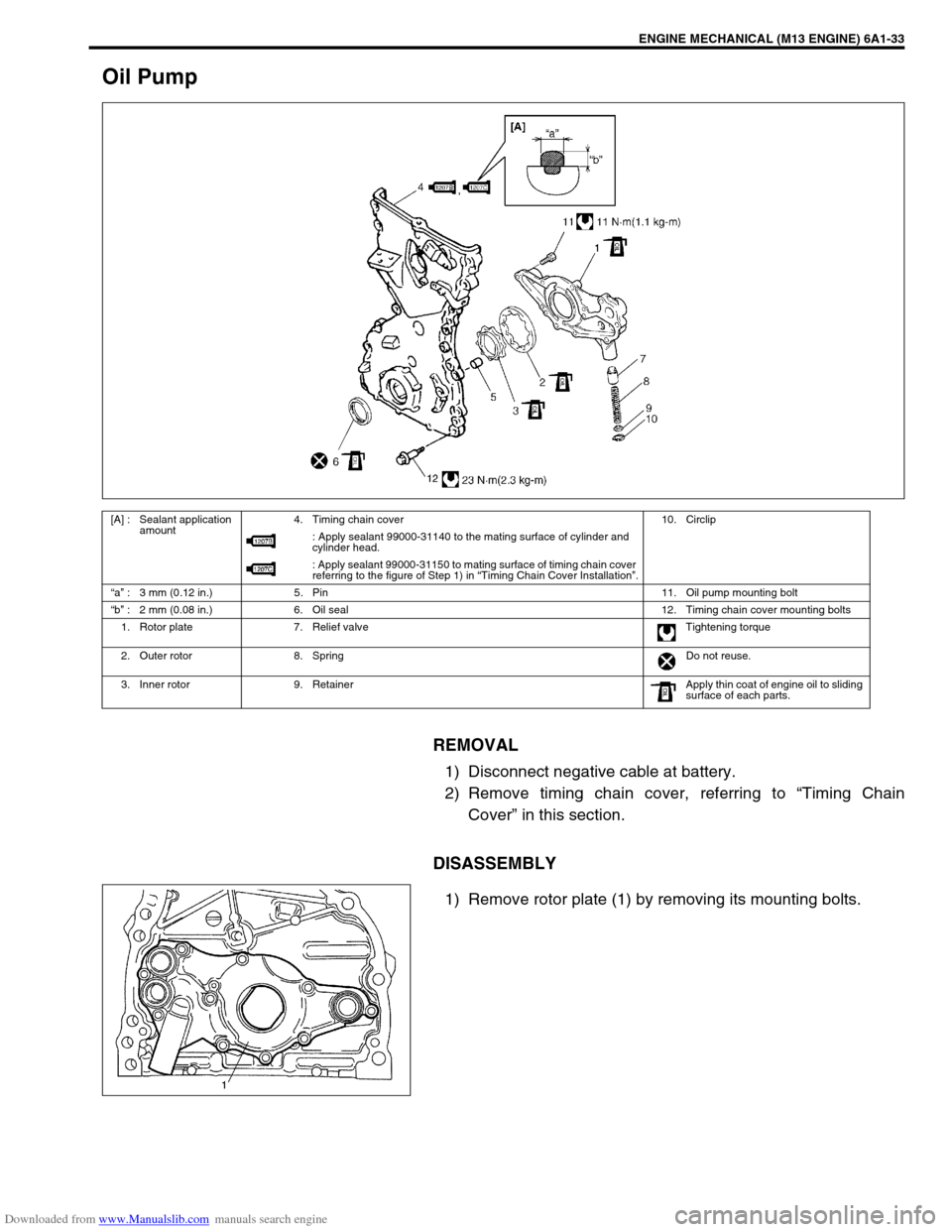

2) Apply engine oil to oil seal lip, then install timing chain cover

(1) and water outlet pipe (2).

Tighten bolts and nut to specified torque.

Tightening torque

Timing chain cover bolts and nut

(a) : 23 N·m (2.3 kg-m, 17.0 lb-ft) NOTE:

When installing new oil seal, tap it in until its surface is

flash with edge of timing chain cover (2).

To install oil seal, use special tool (Bearing installer).

NOTE:

Before installing timing chain cover, check that pin is

securely fitted.

Page 513 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-32 ENGINE MECHANICAL (M13 ENGINE)

3) Install crankshaft pulley (1). Tighten bolt (2) to specified

torque.

To lock crankshaft pulley, use special tool with it as shown in

figure.

Special tool

(A) : 09917-68221

Tightening torque

Crankshaft pulley bolt (a) : 150 N·m (15.0 kg-m, 108.5 lb-ft)

4) Install P/S pump bracket (1), P/S pump (2) and A/C com-

pressor and/or P/S pump belt tension pulley (3) (if equipped)

referring to “Power Steering Pump” in Section 3B1.

5) Install cylinder head cover referring to “Cylinder Head Cover”

in this section.

6) Install oil pan referring to “Oil Pan and Oil Pump Strainer” in

this section.

7) Install radiator with cooling fan and connect A/T fluid hoses

(vehicle with A/T), radiator inlet and outlet hoses referring to

“Water Pump Belt and Cooling Fan” and “Radiator” in Sec-

tion 6B.

8) Adjust generator belt tension referring to “Water Pump Belt

Tension” in Section 6B for adjusting procedure.

9) Adjust A/C compressor and/or P/S pump belt tension (if

equipped) referring to “Compressor Drive Belt” in Section 1B

or “Power Steering Belt” in Section 3B1 for adjusting proce-

dure.

10) Refill cooling system with coolant, engine with engine oil and

A/T with specified A/T fluid (vehicle with A/T).

11) Verify that there is no coolant leakage, oil leakage and A/T

fluid leakage (vehicle with A/T) at each connection.

Page 514 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-33

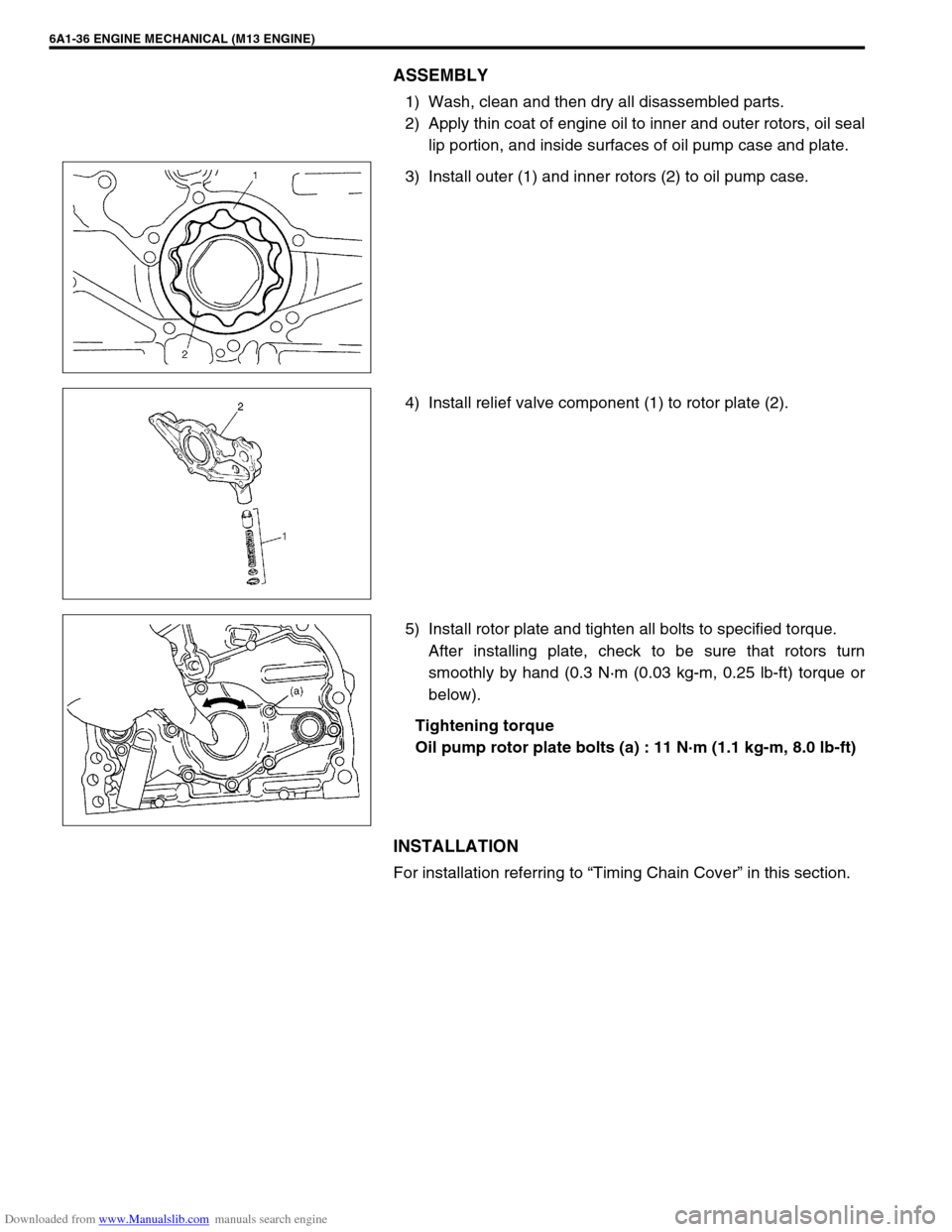

Oil Pump

REMOVAL

1) Disconnect negative cable at battery.

2) Remove timing chain cover, referring to “Timing Chain

Cover” in this section.

DISASSEMBLY

1) Remove rotor plate (1) by removing its mounting bolts.

[A] : Sealant application

amount4. Timing chain cover 10. Circlip

: Apply sealant 99000-31140 to the mating surface of cylinder and

cylinder head.

: Apply sealant 99000-31150 to mating surface of timing chain cover

referring to the figure of Step 1) in “Timing Chain Cover Installation”.

“a” : 3 mm (0.12 in.) 5. Pin 11. Oil pump mounting bolt

“b” : 2 mm (0.08 in.) 6. Oil seal 12. Timing chain cover mounting bolts

1. Rotor plate 7. Relief valve Tightening torque

2. Outer rotor 8. Spring Do not reuse.

3. Inner rotor 9. Retainer Apply thin coat of engine oil to sliding

surface of each parts.

Page 517 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-36 ENGINE MECHANICAL (M13 ENGINE)

ASSEMBLY

1) Wash, clean and then dry all disassembled parts.

2) Apply thin coat of engine oil to inner and outer rotors, oil seal

lip portion, and inside surfaces of oil pump case and plate.

3) Install outer (1) and inner rotors (2) to oil pump case.

4) Install relief valve component (1) to rotor plate (2).

5) Install rotor plate and tighten all bolts to specified torque.

After installing plate, check to be sure that rotors turn

smoothly by hand (0.3 N·m (0.03 kg-m, 0.25 lb-ft) torque or

below).

Tightening torque

Oil pump rotor plate bolts (a) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

INSTALLATION

For installation referring to “Timing Chain Cover” in this section.

Page 518 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-37

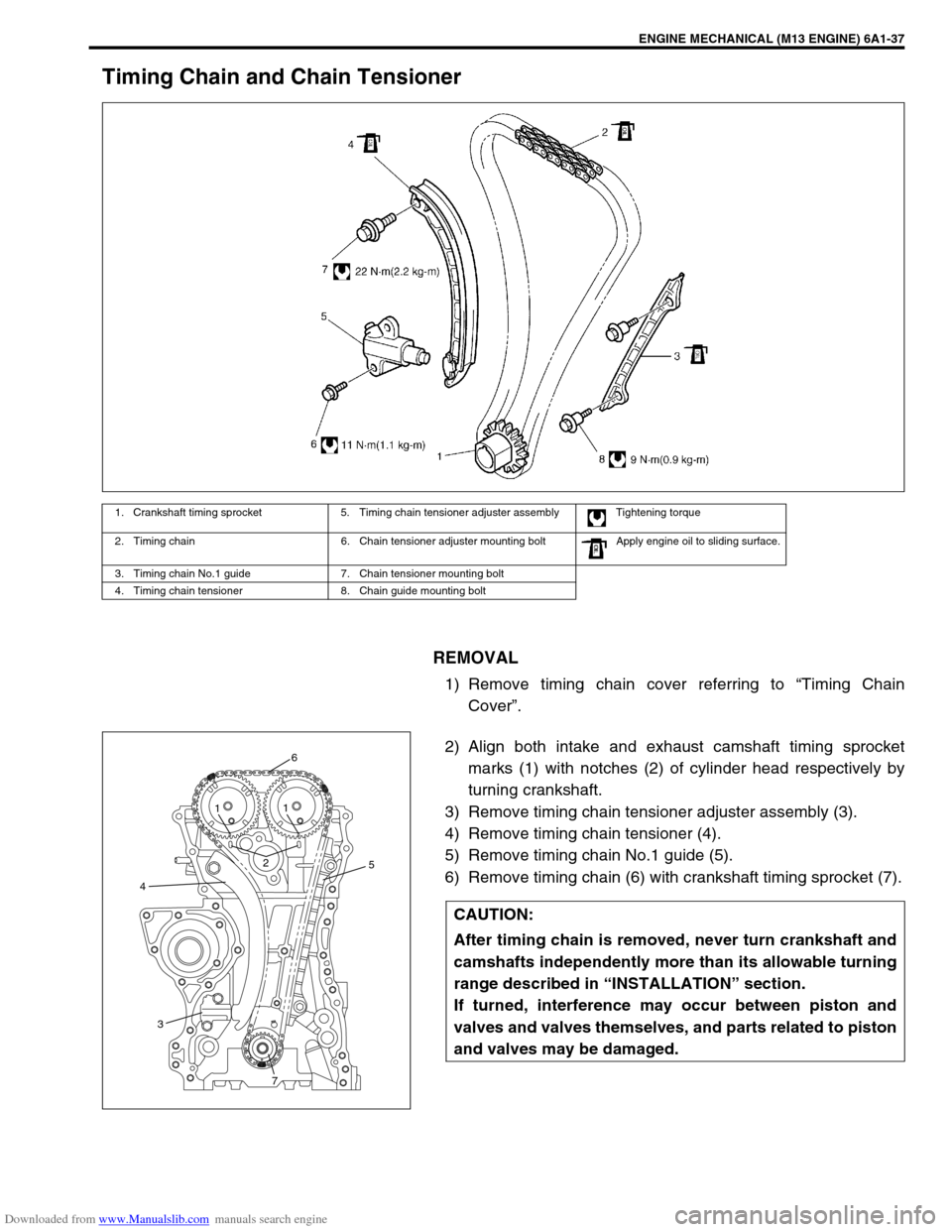

Timing Chain and Chain Tensioner

REMOVAL

1) Remove timing chain cover referring to “Timing Chain

Cover”.

2) Align both intake and exhaust camshaft timing sprocket

marks (1) with notches (2) of cylinder head respectively by

turning crankshaft.

3) Remove timing chain tensioner adjuster assembly (3).

4) Remove timing chain tensioner (4).

5) Remove timing chain No.1 guide (5).

6) Remove timing chain (6) with crankshaft timing sprocket (7).

1. Crankshaft timing sprocket 5. Timing chain tensioner adjuster assembly Tightening torque

2. Timing chain 6. Chain tensioner adjuster mounting bolt Apply engine oil to sliding surface.

3. Timing chain No.1 guide 7. Chain tensioner mounting bolt

4. Timing chain tensioner 8. Chain guide mounting bolt

CAUTION:

After timing chain is removed, never turn crankshaft and

camshafts independently more than its allowable turning

range described in “INSTALLATION” section.

If turned, interference may occur between piston and

valves and valves themselves, and parts related to piston

and valves may be damaged.

45

6

21

1

3

7

Page 520 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-39

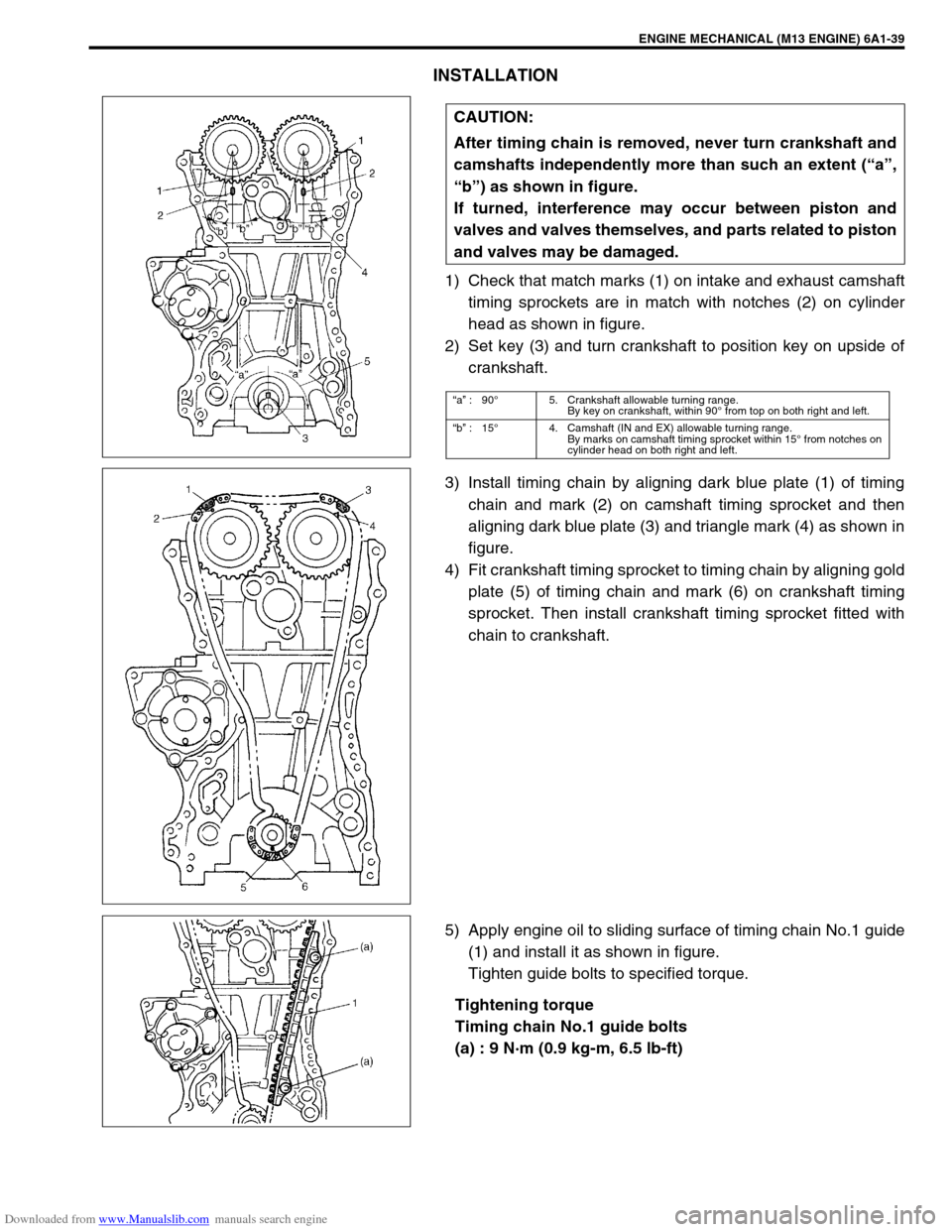

INSTALLATION

1) Check that match marks (1) on intake and exhaust camshaft

timing sprockets are in match with notches (2) on cylinder

head as shown in figure.

2) Set key (3) and turn crankshaft to position key on upside of

crankshaft.

3) Install timing chain by aligning dark blue plate (1) of timing

chain and mark (2) on camshaft timing sprocket and then

aligning dark blue plate (3) and triangle mark (4) as shown in

figure.

4) Fit crankshaft timing sprocket to timing chain by aligning gold

plate (5) of timing chain and mark (6) on crankshaft timing

sprocket. Then install crankshaft timing sprocket fitted with

chain to crankshaft.

5) Apply engine oil to sliding surface of timing chain No.1 guide

(1) and install it as shown in figure.

Tighten guide bolts to specified torque.

Tightening torque

Timing chain No.1 guide bolts

(a) : 9 N·m (0.9 kg-m, 6.5 lb-ft) CAUTION:

After timing chain is removed, never turn crankshaft and

camshafts independently more than such an extent (“a”,

“b”) as shown in figure.

If turned, interference may occur between piston and

valves and valves themselves, and parts related to piston

and valves may be damaged.

“a” :90°5. Crankshaft allowable turning range.

By key on crankshaft, within 90° from top on both right and left.

“b” :15°4. Camshaft (IN and EX) allowable turning range.

By marks on camshaft timing sprocket within 15° from notches on

cylinder head on both right and left.

Page 521 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-40 ENGINE MECHANICAL (M13 ENGINE)

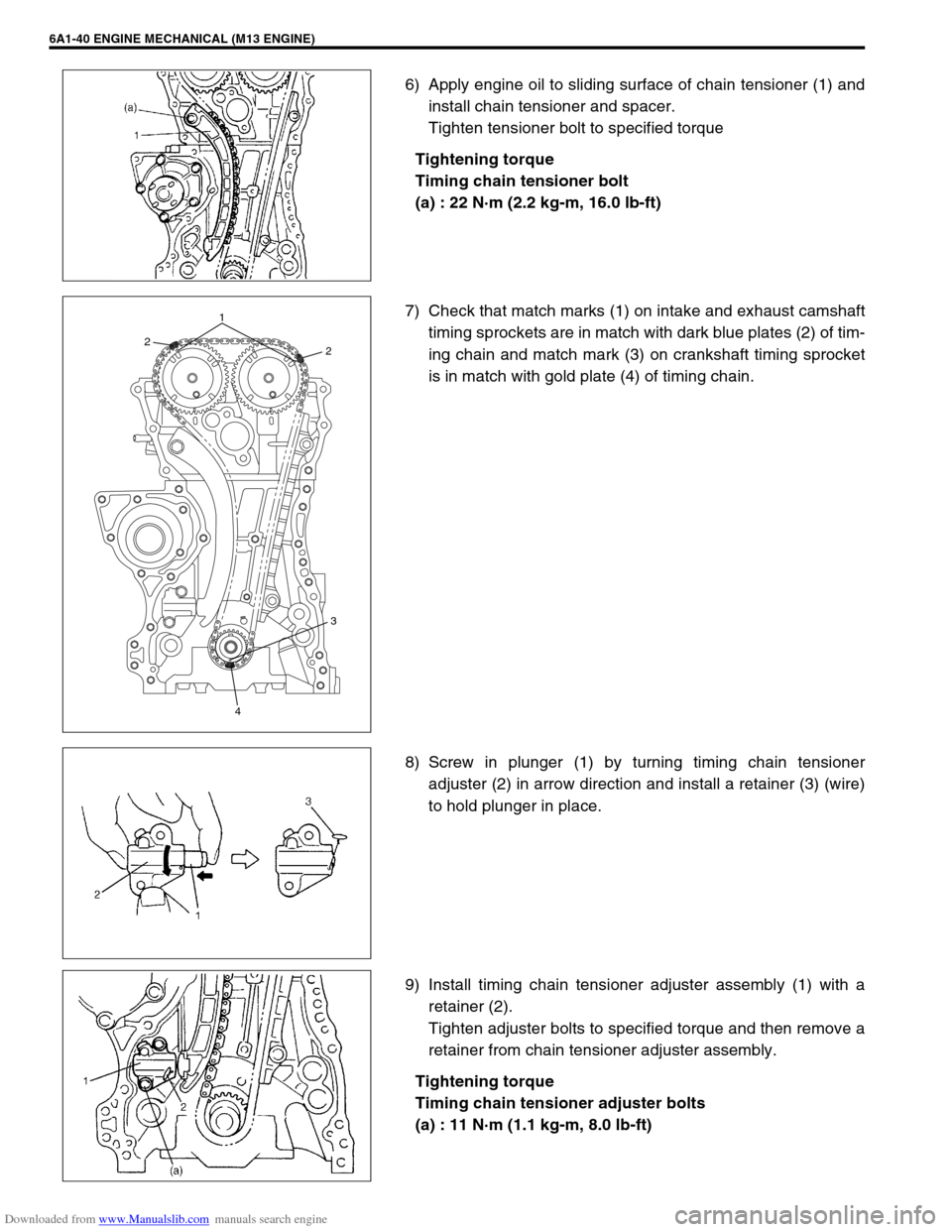

6) Apply engine oil to sliding surface of chain tensioner (1) and

install chain tensioner and spacer.

Tighten tensioner bolt to specified torque

Tightening torque

Timing chain tensioner bolt

(a) : 22 N·m (2.2 kg-m, 16.0 lb-ft)

7) Check that match marks (1) on intake and exhaust camshaft

timing sprockets are in match with dark blue plates (2) of tim-

ing chain and match mark (3) on crankshaft timing sprocket

is in match with gold plate (4) of timing chain.

8) Screw in plunger (1) by turning timing chain tensioner

adjuster (2) in arrow direction and install a retainer (3) (wire)

to hold plunger in place.

9) Install timing chain tensioner adjuster assembly (1) with a

retainer (2).

Tighten adjuster bolts to specified torque and then remove a

retainer from chain tensioner adjuster assembly.

Tightening torque

Timing chain tensioner adjuster bolts

(a) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

221

3

4

Page 523 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-42 ENGINE MECHANICAL (M13 ENGINE)

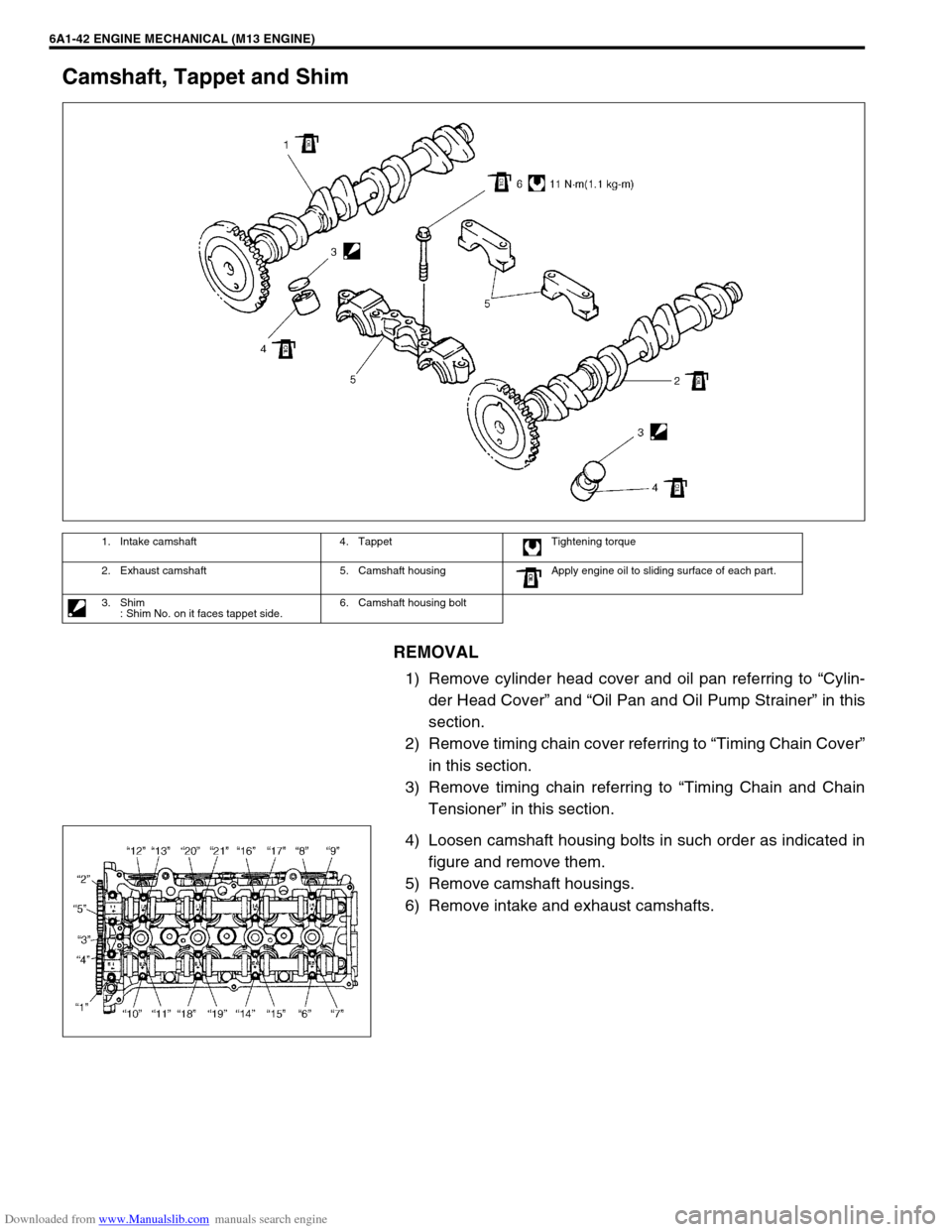

Camshaft, Tappet and Shim

REMOVAL

1) Remove cylinder head cover and oil pan referring to “Cylin-

der Head Cover” and “Oil Pan and Oil Pump Strainer” in this

section.

2) Remove timing chain cover referring to “Timing Chain Cover”

in this section.

3) Remove timing chain referring to “Timing Chain and Chain

Tensioner” in this section.

4) Loosen camshaft housing bolts in such order as indicated in

figure and remove them.

5) Remove camshaft housings.

6) Remove intake and exhaust camshafts.

1. Intake camshaft 4. Tappet Tightening torque

2. Exhaust camshaft 5. Camshaft housing Apply engine oil to sliding surface of each part.

3. Shim

: Shim No. on it faces tappet side.6. Camshaft housing bolt

Page 525 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-44 ENGINE MECHANICAL (M13 ENGINE)

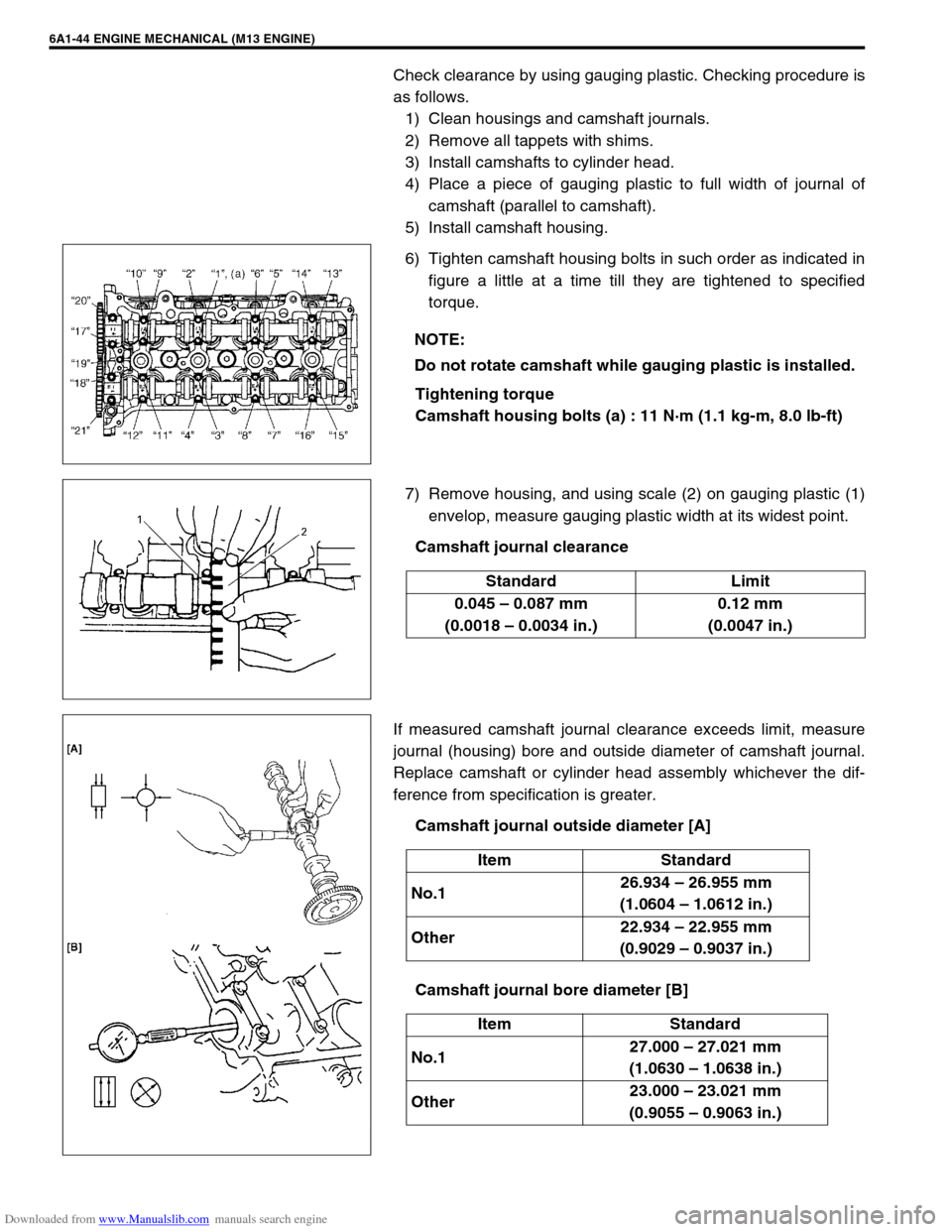

Check clearance by using gauging plastic. Checking procedure is

as follows.

1) Clean housings and camshaft journals.

2) Remove all tappets with shims.

3) Install camshafts to cylinder head.

4) Place a piece of gauging plastic to full width of journal of

camshaft (parallel to camshaft).

5) Install camshaft housing.

6) Tighten camshaft housing bolts in such order as indicated in

figure a little at a time till they are tightened to specified

torque.

Tightening torque

Camshaft housing bolts (a) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

7) Remove housing, and using scale (2) on gauging plastic (1)

envelop, measure gauging plastic width at its widest point.

Camshaft journal clearance

If measured camshaft journal clearance exceeds limit, measure

journal (housing) bore and outside diameter of camshaft journal.

Replace camshaft or cylinder head assembly whichever the dif-

ference from specification is greater.

Camshaft journal outside diameter [A]

Camshaft journal bore diameter [B] NOTE:

Do not rotate camshaft while gauging plastic is installed.

Standard Limit

0.045 – 0.087 mm

(0.0018 – 0.0034 in.)0.12 mm

(0.0047 in.)

Item Standard

No.126.934 – 26.955 mm

(1.0604 – 1.0612 in.)

Other22.934 – 22.955 mm

(0.9029 – 0.9037 in.)

Item Standard

No.127.000 – 27.021 mm

(1.0630 – 1.0638 in.)

Other23.000 – 23.021 mm

(0.9055 – 0.9063 in.)

Page 528 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-47

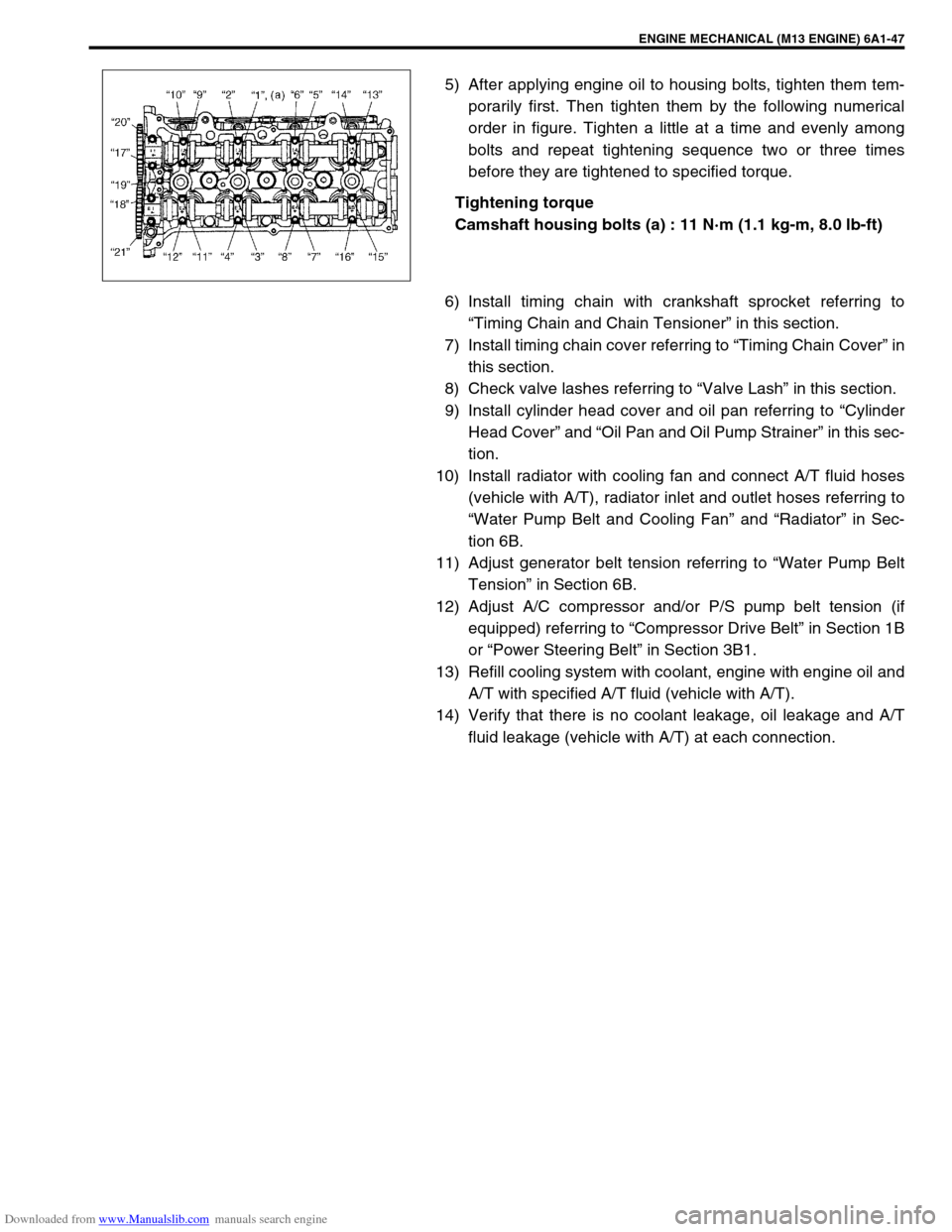

5) After applying engine oil to housing bolts, tighten them tem-

porarily first. Then tighten them by the following numerical

order in figure. Tighten a little at a time and evenly among

bolts and repeat tightening sequence two or three times

before they are tightened to specified torque.

Tightening torque

Camshaft housing bolts (a) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

6) Install timing chain with crankshaft sprocket referring to

“Timing Chain and Chain Tensioner” in this section.

7) Install timing chain cover referring to “Timing Chain Cover” in

this section.

8) Check valve lashes referring to “Valve Lash” in this section.

9) Install cylinder head cover and oil pan referring to “Cylinder

Head Cover” and “Oil Pan and Oil Pump Strainer” in this sec-

tion.

10) Install radiator with cooling fan and connect A/T fluid hoses

(vehicle with A/T), radiator inlet and outlet hoses referring to

“Water Pump Belt and Cooling Fan” and “Radiator” in Sec-

tion 6B.

11) Adjust generator belt tension referring to “Water Pump Belt

Tension” in Section 6B.

12) Adjust A/C compressor and/or P/S pump belt tension (if

equipped) referring to “Compressor Drive Belt” in Section 1B

or “Power Steering Belt” in Section 3B1.

13) Refill cooling system with coolant, engine with engine oil and

A/T with specified A/T fluid (vehicle with A/T).

14) Verify that there is no coolant leakage, oil leakage and A/T

fluid leakage (vehicle with A/T) at each connection.