torque SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 589 of 687

Downloaded from www.Manualslib.com manuals search engine 6B-12 ENGINE COOLING

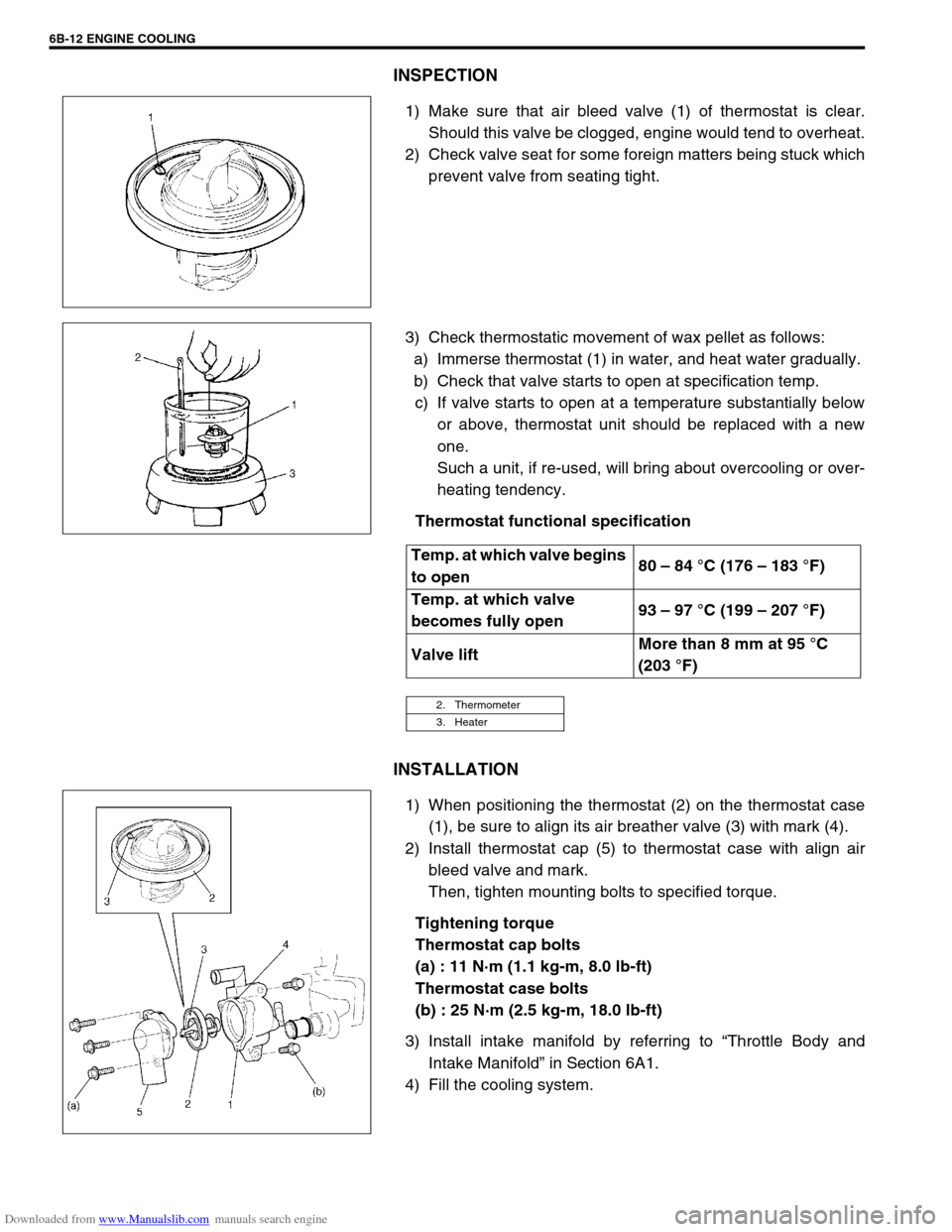

INSPECTION

1) Make sure that air bleed valve (1) of thermostat is clear.

Should this valve be clogged, engine would tend to overheat.

2) Check valve seat for some foreign matters being stuck which

prevent valve from seating tight.

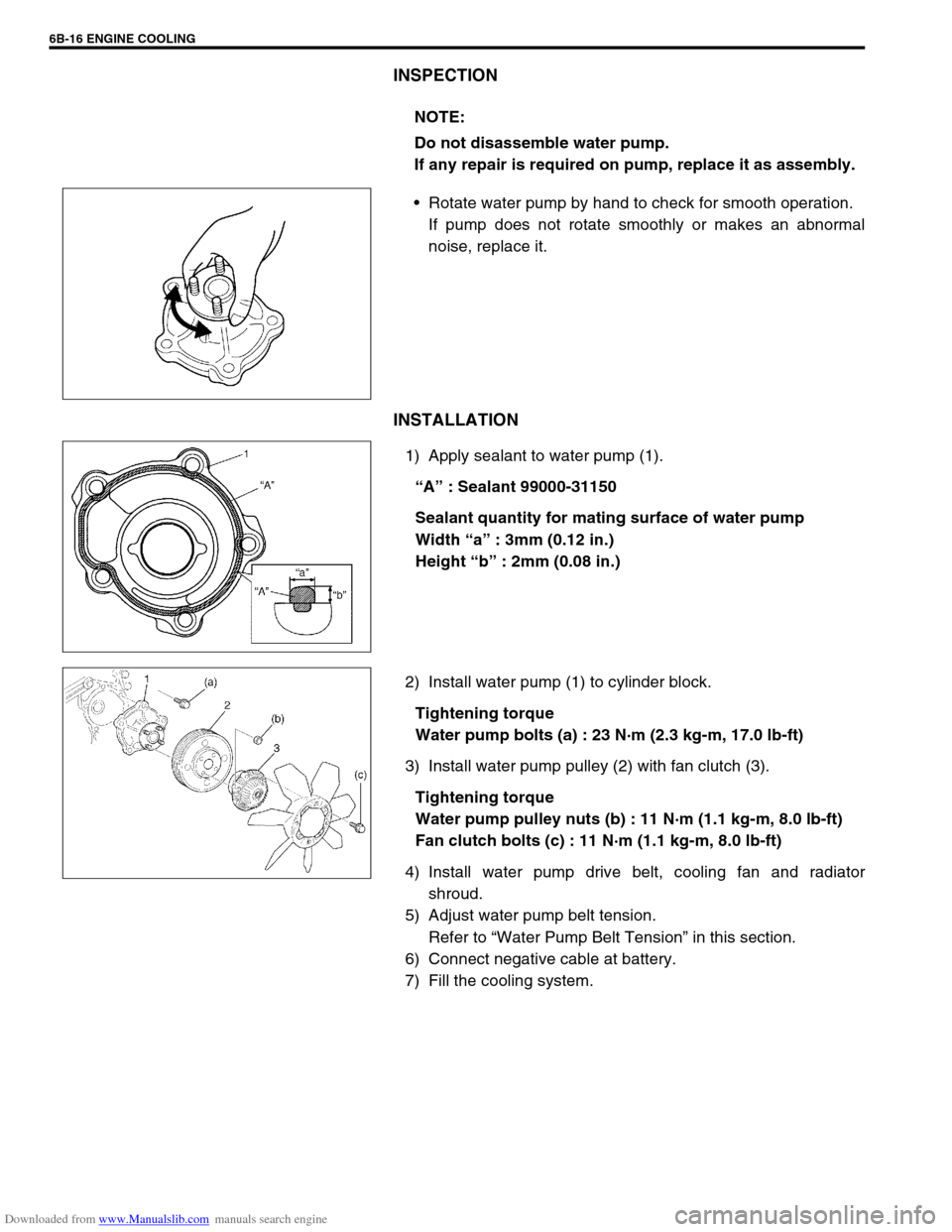

3) Check thermostatic movement of wax pellet as follows:

a) Immerse thermostat (1) in water, and heat water gradually.

b) Check that valve starts to open at specification temp.

c) If valve starts to open at a temperature substantially below

or above, thermostat unit should be replaced with a new

one.

Such a unit, if re-used, will bring about overcooling or over-

heating tendency.

Thermostat functional specification

INSTALLATION

1) When positioning the thermostat (2) on the thermostat case

(1), be sure to align its air breather valve (3) with mark (4).

2) Install thermostat cap (5) to thermostat case with align air

bleed valve and mark.

Then, tighten mounting bolts to specified torque.

Tightening torque

Thermostat cap bolts

(a) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

Thermostat case bolts

(b) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

3) Install intake manifold by referring to “Throttle Body and

Intake Manifold” in Section 6A1.

4) Fill the cooling system.

Temp. at which valve begins

to open80 – 84 °C (176 – 183 °F)

Temp. at which valve

becomes fully open93 – 97 °C (199 – 207 °F)

Valve liftMore than 8 mm at 95 °C

(203 °F)

2. Thermometer

3. Heater

Page 592 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE COOLING 6B-15

Water Pump

COMPONENTS

REMOVAL

1) Drain cooling system.

Refer to Step 6) of “Cooling System Flush and Refill” in this

section.

2) Remove the radiator shroud.

3) Remove radiator referring to “Radiator” in this section.

4) Loosen water pump drive belt tension.

Then remove water pump pulley (2) with fan clutch (3) and

pump drive belt.

5) Remove water pump assembly (1).

1. Water pump 4. Radiator cooling fan 7. Radiator cooling fan mounting bolt

2. Water pump pulley 5. Water pump mounting bolts Tightening Torque

3. Radiator cooling fan clutch 6. Water pump pulley and fan clutch mounting nuts

1. Drain plug

Page 593 of 687

Downloaded from www.Manualslib.com manuals search engine 6B-16 ENGINE COOLING

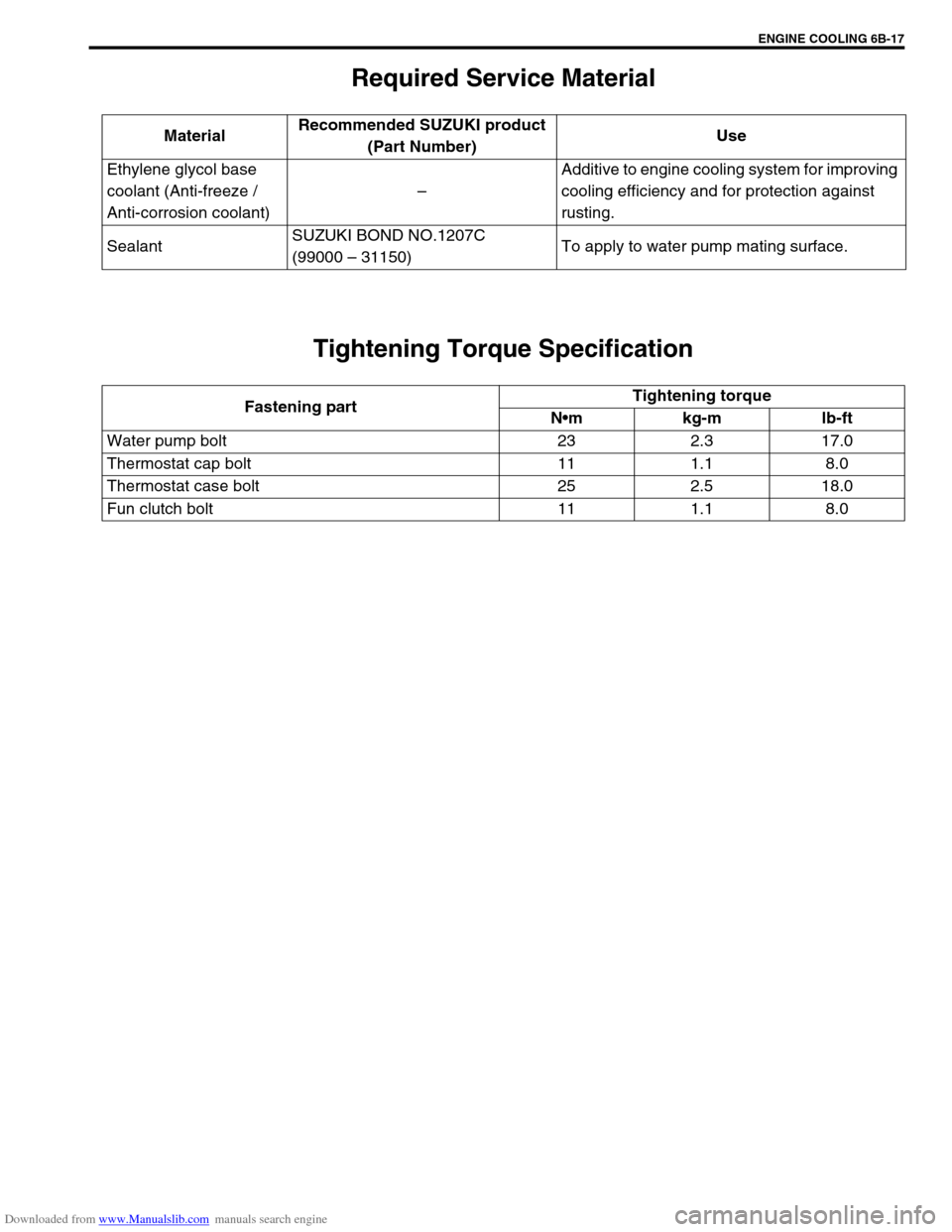

INSPECTION

Rotate water pump by hand to check for smooth operation.

If pump does not rotate smoothly or makes an abnormal

noise, replace it.

INSTALLATION

1) Apply sealant to water pump (1).

“A” : Sealant 99000-31150

Sealant quantity for mating surface of water pump

Width “a” : 3mm (0.12 in.)

Height “b” : 2mm (0.08 in.)

2) Install water pump (1) to cylinder block.

Tightening torque

Water pump bolts (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

3) Install water pump pulley (2) with fan clutch (3).

Tightening torque

Water pump pulley nuts (b) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

Fan clutch bolts (c) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

4) Install water pump drive belt, cooling fan and radiator

shroud.

5) Adjust water pump belt tension.

Refer to “Water Pump Belt Tension” in this section.

6) Connect negative cable at battery.

7) Fill the cooling system.NOTE:

Do not disassemble water pump.

If any repair is required on pump, replace it as assembly.

Page 594 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE COOLING 6B-17

Required Service Material

Tightening Torque Specification

MaterialRecommended SUZUKI product

(Part Number)Use

Ethylene glycol base

coolant (Anti-freeze /

Anti-corrosion coolant)–Additive to engine cooling system for improving

cooling efficiency and for protection against

rusting.

SealantSUZUKI BOND NO.1207C

(99000 – 31150)To apply to water pump mating surface.

Fastening partTightening torque

Nm kg-m lb-ft

Water pump bolt 23 2.3 17.0

Thermostat cap bolt 11 1.1 8.0

Thermostat case bolt 25 2.5 18.0

Fun clutch bolt 11 1.1 8.0

Page 596 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE FUEL 6C-1

6F1

7A

7A1

7A

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

6G

6C

6K

9

10

10A

10B

SECTION 6C

ENGINE FUEL

CONTENTS

General Description ....................................... 6C-2

Fuel System ................................................. 6C-2

Fuel Tank ..................................................... 6C-2

Fuel Pump Assembly ................................... 6C-3

Fuel Filler Cap .............................................. 6C-3

On-Vehicle Service......................................... 6C-4Fuel Lines .................................................... 6C-4

Fuel Filler Cap.............................................. 6C-4

Fuel Tank ..................................................... 6C-4

Fuel Pump Assembly ................................... 6C-7

Tightening Torque Specification ................ 6C-10

Special Tool .................................................. 6C-10

CAUTION:

For vehicles with a catalytic converter, be sure to use unleaded fuel only. Use of leaded and/or low

lead fuel can result in engine damage and reduce the effectiveness of the emission control system.

Page 597 of 687

Downloaded from www.Manualslib.com manuals search engine 6C-2 ENGINE FUEL

General Description

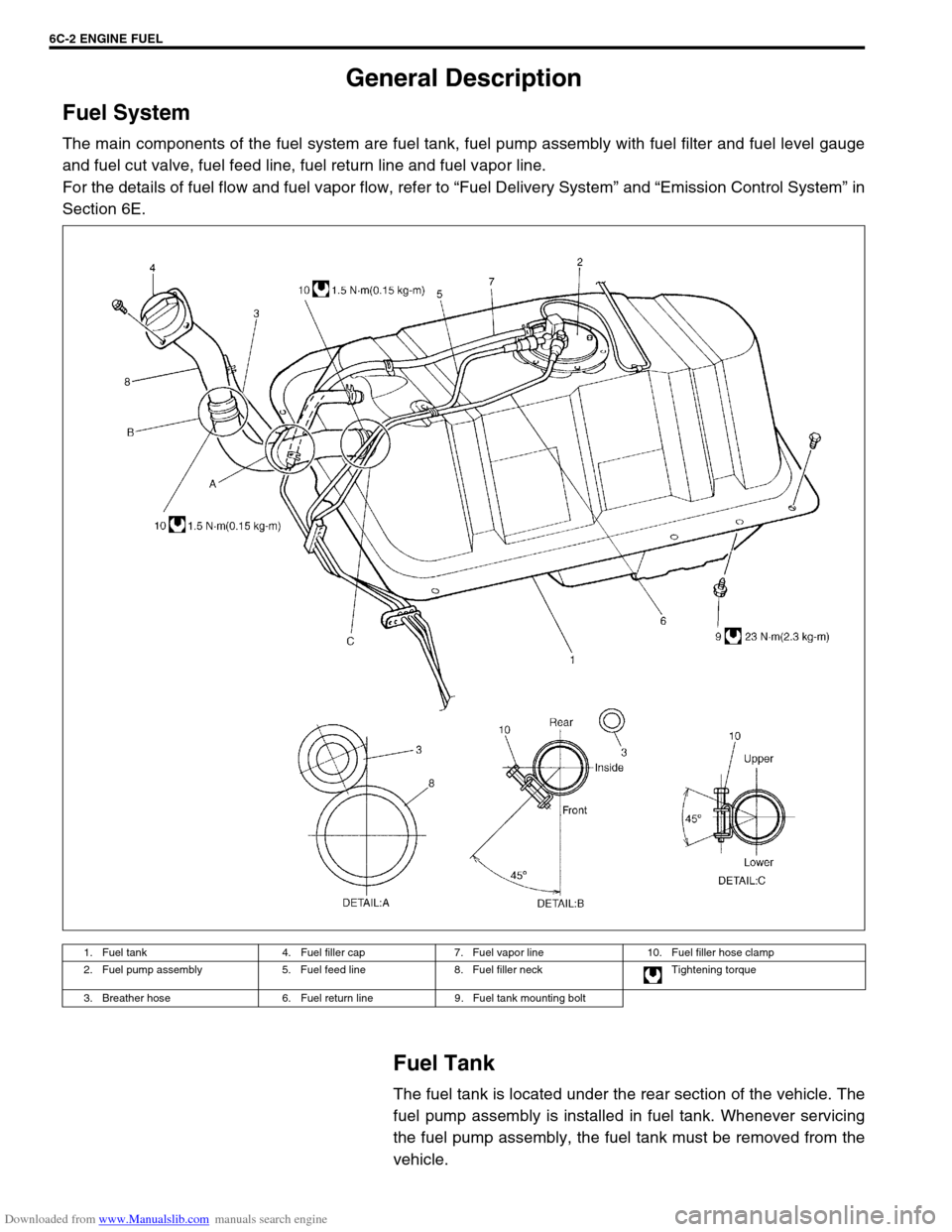

Fuel System

The main components of the fuel system are fuel tank, fuel pump assembly with fuel filter and fuel level gauge

and fuel cut valve, fuel feed line, fuel return line and fuel vapor line.

For the details of fuel flow and fuel vapor flow, refer to “Fuel Delivery System” and “Emission Control System” in

Section 6E.

Fuel Tank

The fuel tank is located under the rear section of the vehicle. The

fuel pump assembly is installed in fuel tank. Whenever servicing

the fuel pump assembly, the fuel tank must be removed from the

vehicle.

1. Fuel tank 4. Fuel filler cap 7. Fuel vapor line 10. Fuel filler hose clamp

2. Fuel pump assembly 5. Fuel feed line 8. Fuel filler neck Tightening torque

3. Breather hose 6. Fuel return line 9. Fuel tank mounting bolt

Page 604 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE FUEL 6C-9

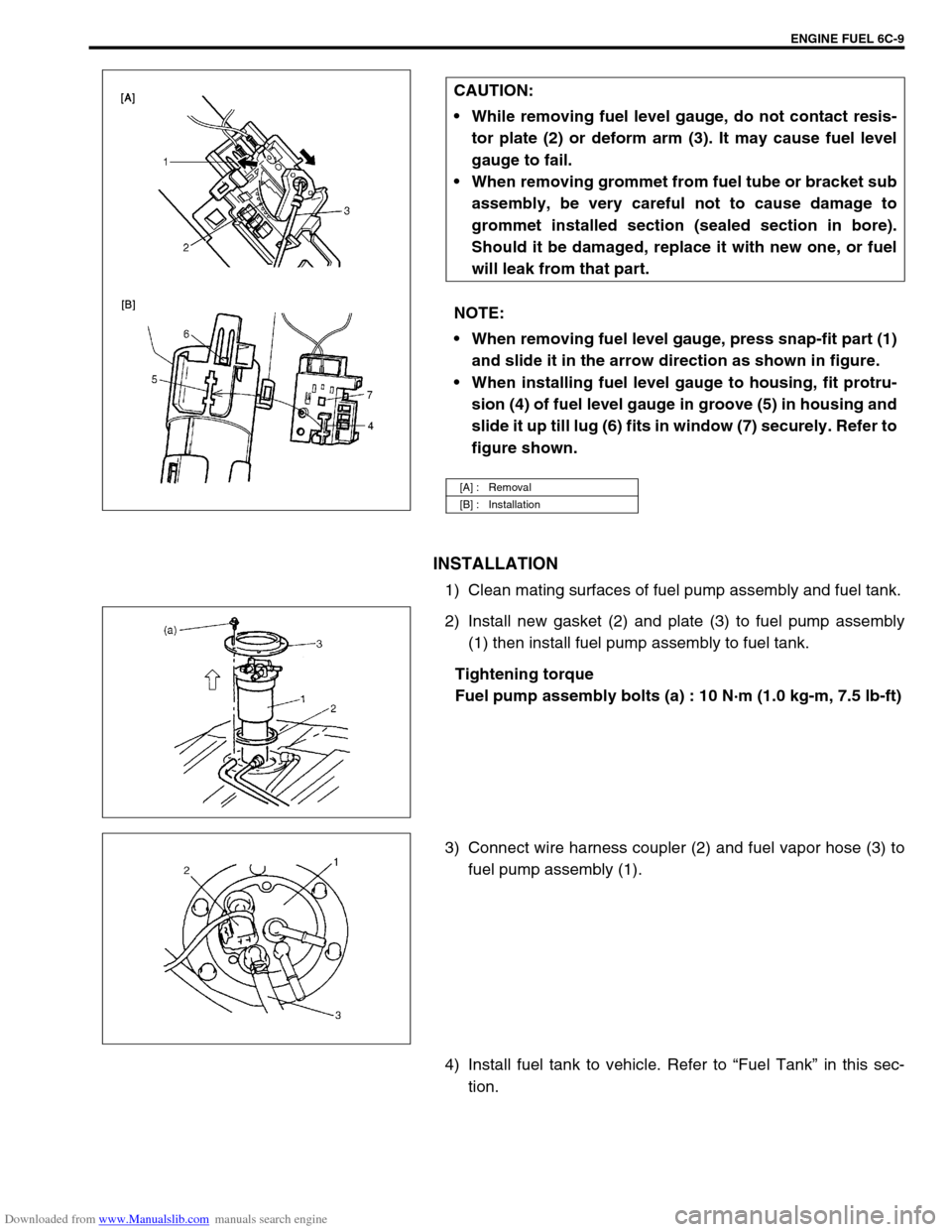

INSTALLATION

1) Clean mating surfaces of fuel pump assembly and fuel tank.

2) Install new gasket (2) and plate (3) to fuel pump assembly

(1) then install fuel pump assembly to fuel tank.

Tightening torque

Fuel pump assembly bolts (a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

3) Connect wire harness coupler (2) and fuel vapor hose (3) to

fuel pump assembly (1).

4) Install fuel tank to vehicle. Refer to “Fuel Tank” in this sec-

tion. CAUTION:

While removing fuel level gauge, do not contact resis-

tor plate (2) or deform arm (3). It may cause fuel level

gauge to fail.

When removing grommet from fuel tube or bracket sub

assembly, be very careful not to cause damage to

grommet installed section (sealed section in bore).

Should it be damaged, replace it with new one, or fuel

will leak from that part.

NOTE:

When removing fuel level gauge, press snap-fit part (1)

and slide it in the arrow direction as shown in figure.

When installing fuel level gauge to housing, fit protru-

sion (4) of fuel level gauge in groove (5) in housing and

slide it up till lug (6) fits in window (7) securely. Refer to

figure shown.

[A] : Removal

[B] : Installation

Page 605 of 687

Downloaded from www.Manualslib.com manuals search engine 6C-10 ENGINE FUEL

Tightening Torque Specification

Special Tool

Fastening partTightening torque

Nm kg-m lb-ft

Fuel pump assembly bolt 10 1.0 7.5

09919-47020

Quick joint remover

Page 607 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-2 ENGINE AND EMISSION CONTROL SYSTEM

EGR system (If equipped) ...................... 6E-38

Evaporative emission (EVAP) control

system .................................................... 6E-39

PCV system ........................................... 6E-41Special Tools ............................................... 6E-42

Tightening Torque Specifications .............. 6E-43

Page 623 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-18 ENGINE AND EMISSION CONTROL SYSTEM

Air Intake System

Throttle body

ON-VEHICLE INSPECTION

Check that throttle valve lever (1) moves smoothly.

REMOVAL

1) Disconnect negative cable at battery.

2) Drain cooling system.

3) Disconnect accelerator cable (1) from throttle valve lever.

1. Throttle body 4. Gasket 7. TP sensor screws

2. Throttle body gasket 5. Idle air control valve Tightening torque

3. TP sensor 6. IAC valve screws Do not reuse