Bleed SUZUKI JIMNY 2005 3.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 152 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-21

Tightening Torque Specifications

Required Service Materials

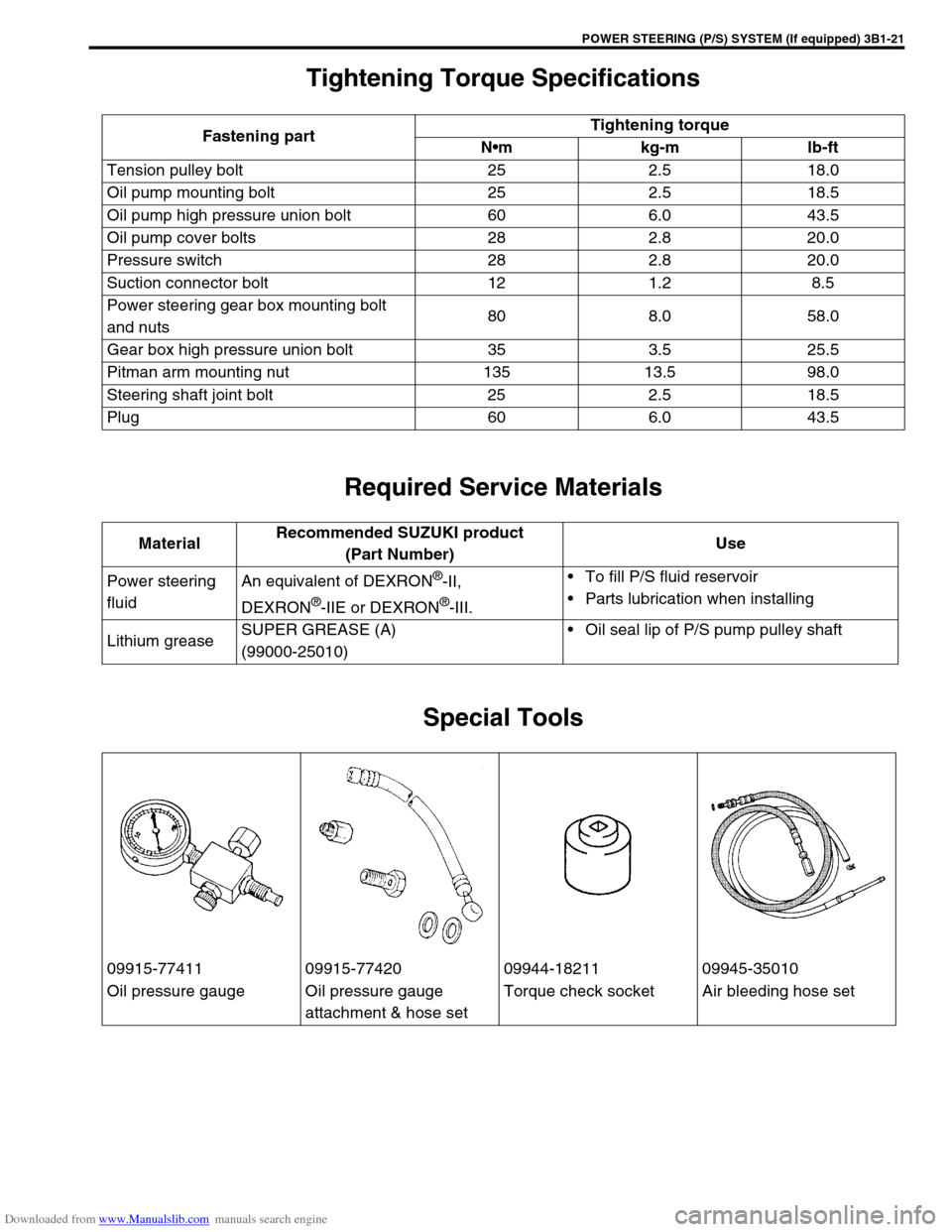

Special Tools

Fastening partTightening torque

Nm kg-m lb-ft

Tension pulley bolt 25 2.5 18.0

Oil pump mounting bolt 25 2.5 18.5

Oil pump high pressure union bolt 60 6.0 43.5

Oil pump cover bolts 28 2.8 20.0

Pressure switch 28 2.8 20.0

Suction connector bolt 12 1.2 8.5

Power steering gear box mounting bolt

and nuts80 8.0 58.0

Gear box high pressure union bolt 35 3.5 25.5

Pitman arm mounting nut 135 13.5 98.0

Steering shaft joint bolt 25 2.5 18.5

Plug 60 6.0 43.5

MaterialRecommended SUZUKI product

(Part Number)Use

Power steering

fluidAn equivalent of DEXRON

®-II,

DEXRON

®-IIE or DEXRON®-III.To fill P/S fluid reservoir

Parts lubrication when installing

Lithium greaseSUPER GREASE (A)

(99000-25010)Oil seal lip of P/S pump pulley shaft

09915-77411 09915-77420 09944-18211 09945-35010

Oil pressure gauge Oil pressure gauge

attachment & hose setTorque check socket Air bleeding hose set

Page 232 of 687

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION 3E-13

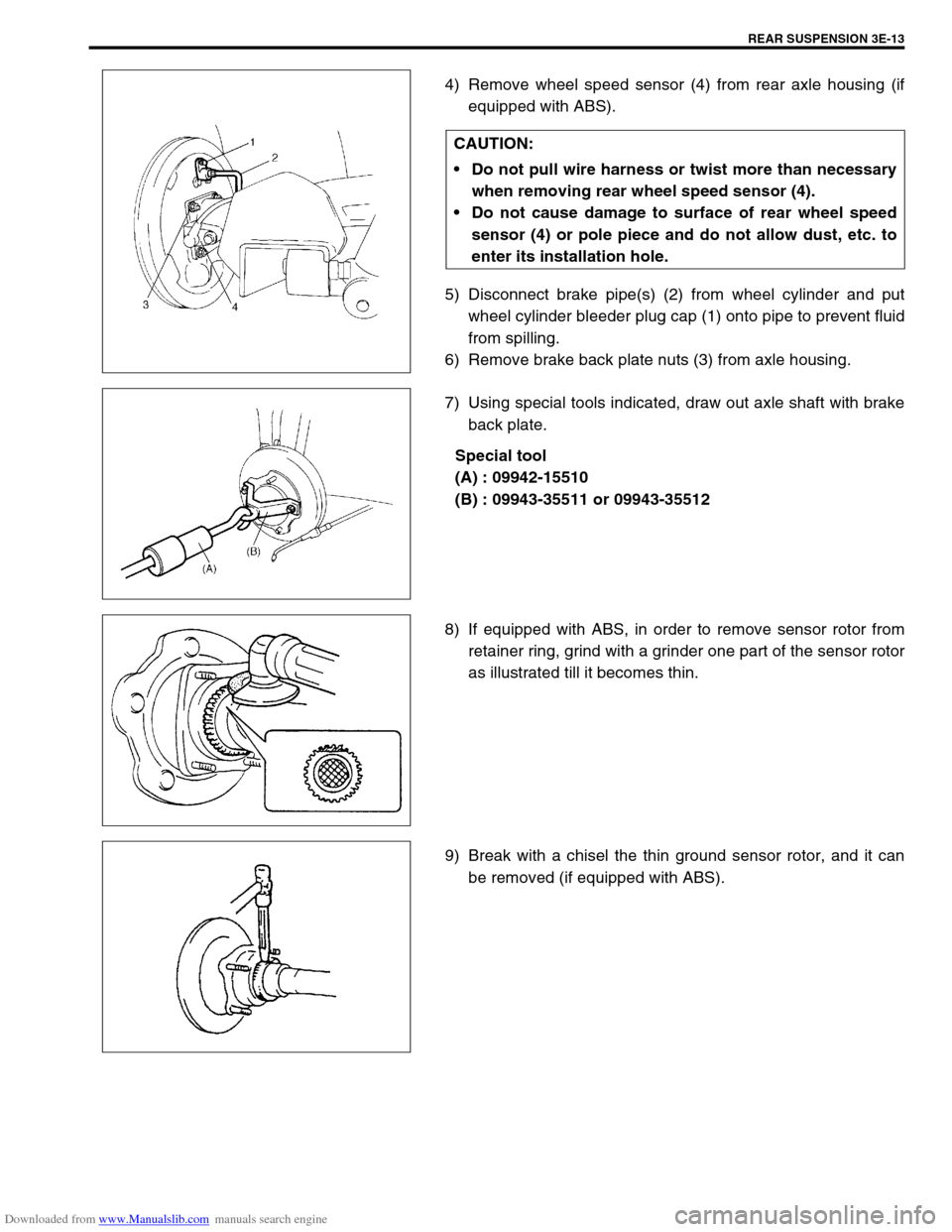

4) Remove wheel speed sensor (4) from rear axle housing (if

equipped with ABS).

5) Disconnect brake pipe(s) (2) from wheel cylinder and put

wheel cylinder bleeder plug cap (1) onto pipe to prevent fluid

from spilling.

6) Remove brake back plate nuts (3) from axle housing.

7) Using special tools indicated, draw out axle shaft with brake

back plate.

Special tool

(A) : 09942-15510

(B) : 09943-35511 or 09943-35512

8) If equipped with ABS, in order to remove sensor rotor from

retainer ring, grind with a grinder one part of the sensor rotor

as illustrated till it becomes thin.

9) Break with a chisel the thin ground sensor rotor, and it can

be removed (if equipped with ABS). CAUTION:

Do not pull wire harness or twist more than necessary

when removing rear wheel speed sensor (4).

Do not cause damage to surface of rear wheel speed

sensor (4) or pole piece and do not allow dust, etc. to

enter its installation hole.

Page 235 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-16 REAR SUSPENSION

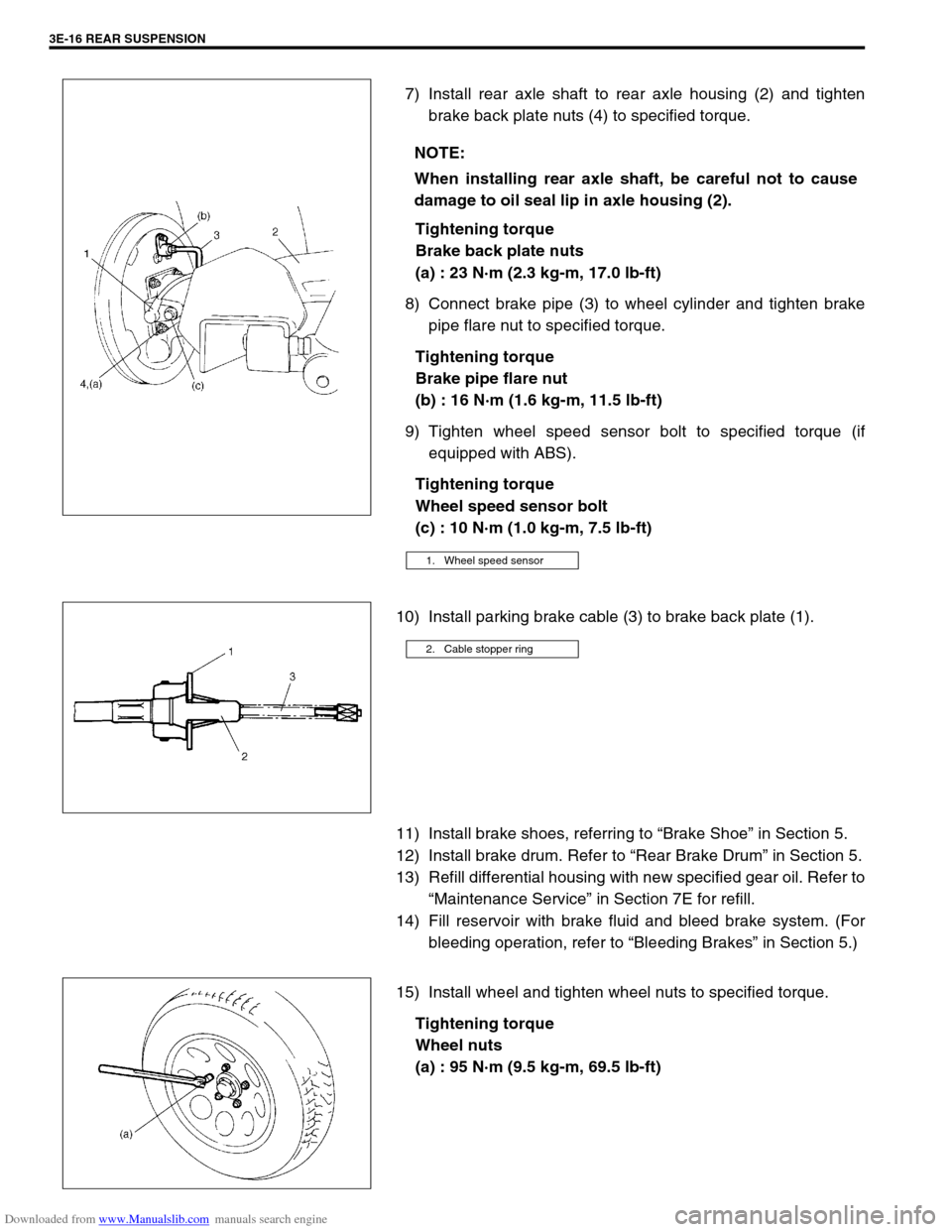

7) Install rear axle shaft to rear axle housing (2) and tighten

brake back plate nuts (4) to specified torque.

Tightening torque

Brake back plate nuts

(a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

8) Connect brake pipe (3) to wheel cylinder and tighten brake

pipe flare nut to specified torque.

Tightening torque

Brake pipe flare nut

(b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

9) Tighten wheel speed sensor bolt to specified torque (if

equipped with ABS).

Tightening torque

Wheel speed sensor bolt

(c) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

10) Install parking brake cable (3) to brake back plate (1).

11) Install brake shoes, referring to “Brake Shoe” in Section 5.

12) Install brake drum. Refer to “Rear Brake Drum” in Section 5.

13) Refill differential housing with new specified gear oil. Refer to

“Maintenance Service” in Section 7E for refill.

14) Fill reservoir with brake fluid and bleed brake system. (For

bleeding operation, refer to “Bleeding Brakes” in Section 5.)

15) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts

(a) : 95 N·m (9.5 kg-m, 69.5 lb-ft) NOTE:

When installing rear axle shaft, be careful not to cause

damage to oil seal lip in axle housing (2).

1. Wheel speed sensor

2. Cable stopper ring

Page 249 of 687

Downloaded from www.Manualslib.com manuals search engine 3F-6 WHEELS AND TIRES

Maintenance and Minor Adjustments

Wheel and Tire

Wheel repairs that use welding, heating, or peening are not approved. All damaged wheels should be replaced.

Studs

If a broken stud is found, see Section 3E (rear) or Section 3D (front) for Note and Replacement procedure.

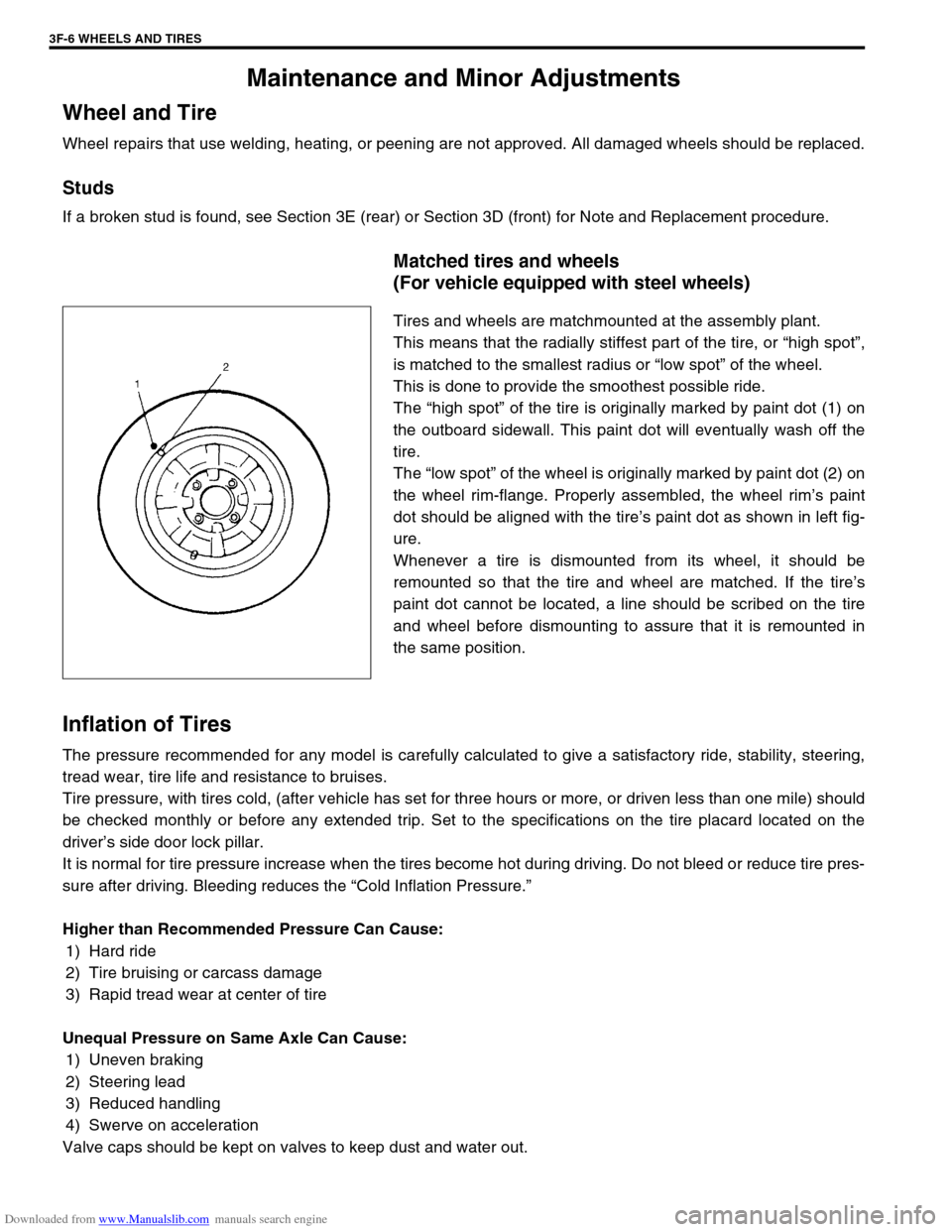

Matched tires and wheels

(For vehicle equipped with steel wheels)

Tires and wheels are matchmounted at the assembly plant.

This means that the radially stiffest part of the tire, or “high spot”,

is matched to the smallest radius or “low spot” of the wheel.

This is done to provide the smoothest possible ride.

The “high spot” of the tire is originally marked by paint dot (1) on

the outboard sidewall. This paint dot will eventually wash off the

tire.

The “low spot” of the wheel is originally marked by paint dot (2) on

the wheel rim-flange. Properly assembled, the wheel rim’s paint

dot should be aligned with the tire’s paint dot as shown in left fig-

ure.

Whenever a tire is dismounted from its wheel, it should be

remounted so that the tire and wheel are matched. If the tire’s

paint dot cannot be located, a line should be scribed on the tire

and wheel before dismounting to assure that it is remounted in

the same position.

Inflation of Tires

The pressure recommended for any model is carefully calculated to give a satisfactory ride, stability, steering,

tread wear, tire life and resistance to bruises.

Tire pressure, with tires cold, (after vehicle has set for three hours or more, or driven less than one mile) should

be checked monthly or before any extended trip. Set to the specifications on the tire placard located on the

driver’s side door lock pillar.

It is normal for tire pressure increase when the tires become hot during driving. Do not bleed or reduce tire pres-

sure after driving. Bleeding reduces the “Cold Inflation Pressure.”

Higher than Recommended Pressure Can Cause:

1) Hard ride

2) Tire bruising or carcass damage

3) Rapid tread wear at center of tire

Unequal Pressure on Same Axle Can Cause:

1) Uneven braking

2) Steering lead

3) Reduced handling

4) Swerve on acceleration

Valve caps should be kept on valves to keep dust and water out.

Page 262 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

5

9

10

10A

10B

9

10

10A

10B

SECTION 5

BRAKES

CONTENTS

General Description ......................................... 5-3

Diagnosis .......................................................... 5-4

Road Testing Brakes ...................................... 5-4

Brake Fluid Leaks .......................................... 5-4

Substandard or Contaminated Brake Fluid .... 5-4

Diagnosis Table ............................................. 5-5

Brake Pedal Free Height Adjustment ............. 5-8

Brake Pedal Play Check ................................ 5-8

Stop Light Switch Adjustment ........................ 5-8

Excessive Pedal Travel Check ....................... 5-9

Front Brake Disc Check ................................. 5-9

Front Brake Pad Check .................................. 5-9

Rear Brake Shoe Check .............................. 5-10

Master Cylinder and Brake Fluid Level

Check ........................................................... 5-10

Rear Drum Brake Shoe Adjustment ............. 5-11

Parking Brake Inspection and Adjustment ... 5-11

Booster Operation Check ............................. 5-12Fluid Pressure Test

(If Equipped with LSPV) ............................... 5-15

On-Vehicle Service ........................................ 5-17

Air Bleeding of Brake System ...................... 5-17

Brake Hose and Pipe Inspection.................. 5-18

Front Disc Brake .......................................... 5-19

Brake pad ................................................. 5-20

Caliper assembly...................................... 5-22

Brake Disc.................................................... 5-26

Rear Brake ................................................... 5-29

Brake drum............................................... 5-29

Brake shoe ............................................... 5-32

Wheel Cylinder............................................. 5-33

Brake back plate ...................................... 5-34

Master Cylinder .............................................. 5-36

Master Cylinder Reservoir ........................... 5-36

Master Cylinder Assembly ........................... 5-37 WARNING:

For lifting point of vehicle, refer to Section 0A.

WARNING:

For vehicles equipped with Supplement Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

When inspecting and servicing vehicle equipped with ABS, be sure to refer to section 5E first.

All brake fasteners are important attaching parts in that they could affect the performance of vital

parts and systems, and/or could result in major repair expense. They must be replaced with one of

same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified

during reassembly to assure proper retention of all parts. There is to be no welding as it may result

in extensive damage and weakening of the metal.

Page 264 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-3

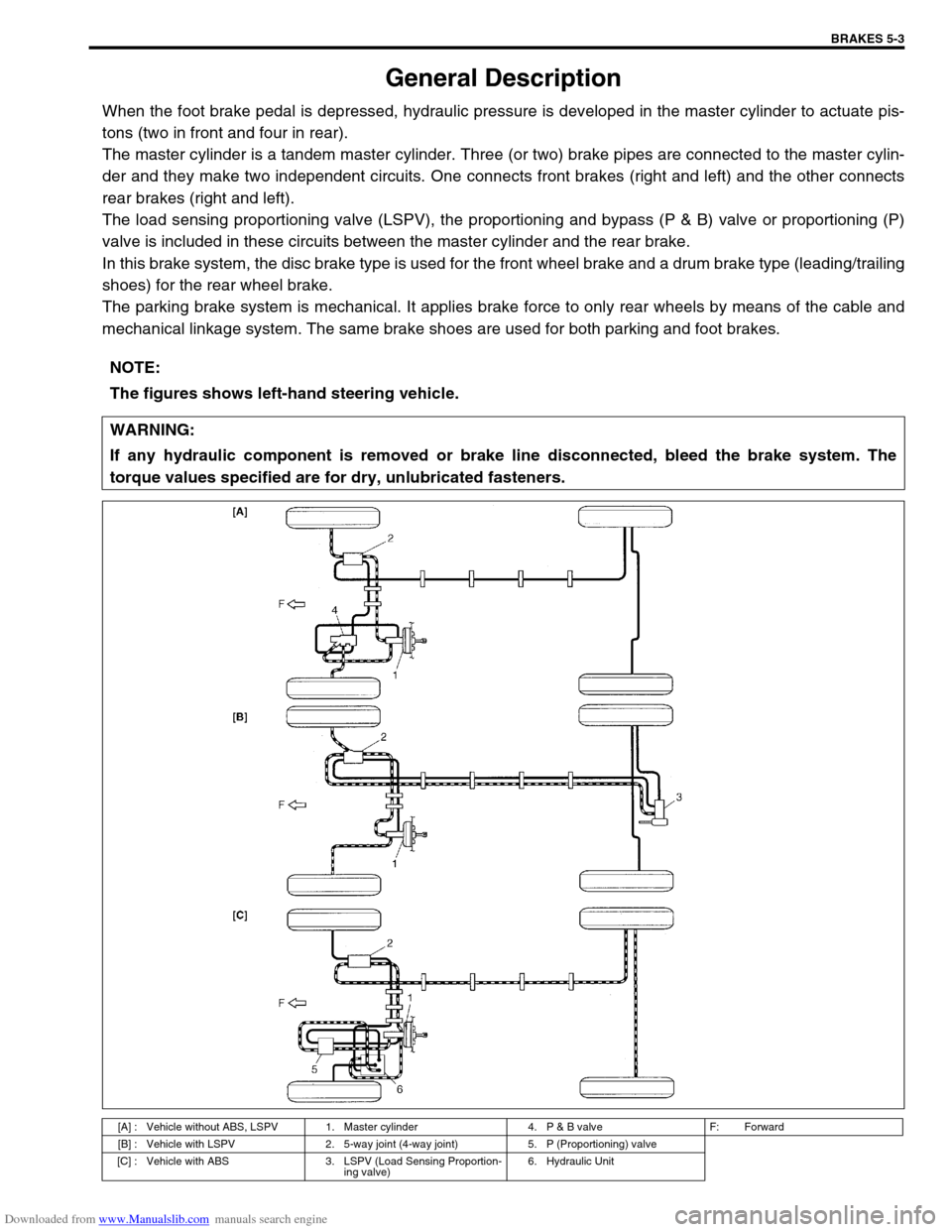

General Description

When the foot brake pedal is depressed, hydraulic pressure is developed in the master cylinder to actuate pis-

tons (two in front and four in rear).

The master cylinder is a tandem master cylinder. Three (or two) brake pipes are connected to the master cylin-

der and they make two independent circuits. One connects front brakes (right and left) and the other connects

rear brakes (right and left).

The load sensing proportioning valve (LSPV), the proportioning and bypass (P & B) valve or proportioning (P)

valve is included in these circuits between the master cylinder and the rear brake.

In this brake system, the disc brake type is used for the front wheel brake and a drum brake type (leading/trailing

shoes) for the rear wheel brake.

The parking brake system is mechanical. It applies brake force to only rear wheels by means of the cable and

mechanical linkage system. The same brake shoes are used for both parking and foot brakes.

NOTE:

The figures shows left-hand steering vehicle.

WARNING:

If any hydraulic component is removed or brake line disconnected, bleed the brake system. The

torque values specified are for dry, unlubricated fasteners.

[A] : Vehicle without ABS, LSPV 1. Master cylinder 4. P & B valve F: Forward

[B] : Vehicle with LSPV 2. 5-way joint (4-way joint) 5. P (Proportioning) valve

[C] : Vehicle with ABS 3. LSPV (Load Sensing Proportion-

ing valve)6. Hydraulic Unit

Page 265 of 687

Downloaded from www.Manualslib.com manuals search engine 5-4 BRAKES

Diagnosis

Road Testing Brakes

Brakes should be tested on dry, clean, smooth and reasonably level roadway which is not crowned. Road test

brakes by making brake applications with both light and heavy pedal forces at various speeds to determine if the

vehicle stops evenly and effectively.

Also drive vehicle to see if it leads to one side or the other without brake application. If it does, check the tire

pressure, front end alignment and front suspension attachments for looseness. See diagnosis table for other

causes.

Brake Fluid Leaks

Check the master cylinder fluid levels. While a slight drop in reservoir level does result from normal lining wear,

an abnormally low level indicates a leak in the system. In such a case, check the entire brake system for leak-

age. If even a slight evidence of leakage is noted, the cause should be corrected or defective parts should be

replaced.

If fluid level is lower than the minimum level of reservoir, refilling is necessary. Fill reservoir with specified brake

fluid.

Brake fluid: Refer to reservoir tank cap.

Substandard or Contaminated Brake Fluid

Improper brake fluid, mineral oil or water in the fluid may cause the brake fluid to boil or the rubber components

in the hydraulic system to deteriorate.

If primary piston cups are swollen, then rubber parts have deteriorated. This deterioration may also be evi-

denced by swollen wheel cylinder piston cups on the drum brake wheels.

If deterioration of rubber is evident, disassemble all hydraulic parts and wash with alcohol. Dry these parts with

compressed air before assembly to keep alcohol out of the system. Replace all rubber parts in the system,

including hoses. Also, when working on the brake mechanisms, check for fluid on the linings. If excessive fluid is

found, replace the linings.

If master cylinder piston seals are satisfactory, check for leakage or excessive heat conditions. If condition is not

found, drain fluid, flush with brake fluid, refill and bleed the system.

The system must be flushed if there is any doubt as to the grade of fluid in the system or if fluid has been used

which contained parts that have been subjected to contaminated fluid.CAUTION:

Since brake system of this vehicle is factory-filled with brake fluid indicated on reservoir tank cap, do

not use or mix different type of fluid when refilling; otherwise serious damage will occur.

Do not use old or used brake fluid, or any fluid from a unsealed container.

Page 266 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-5

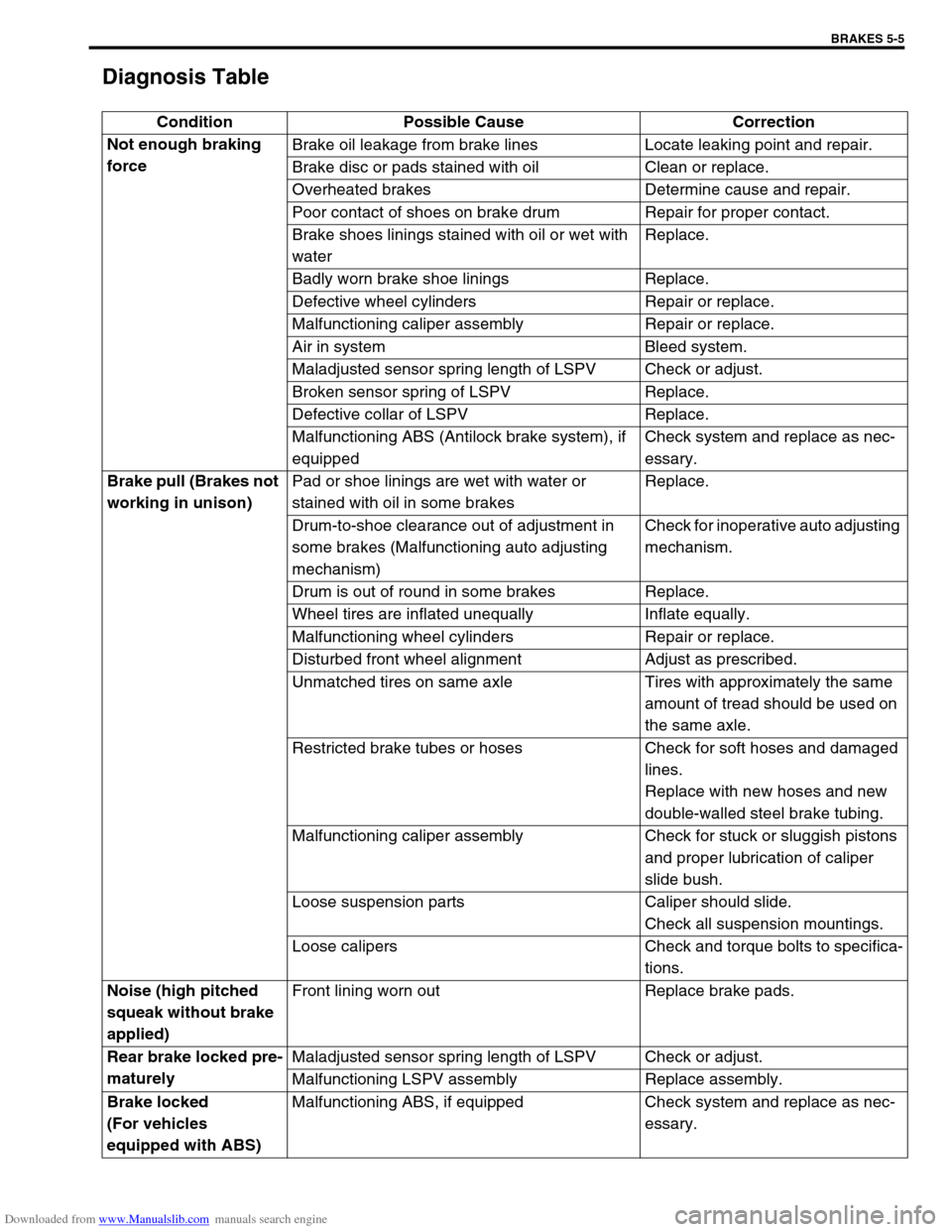

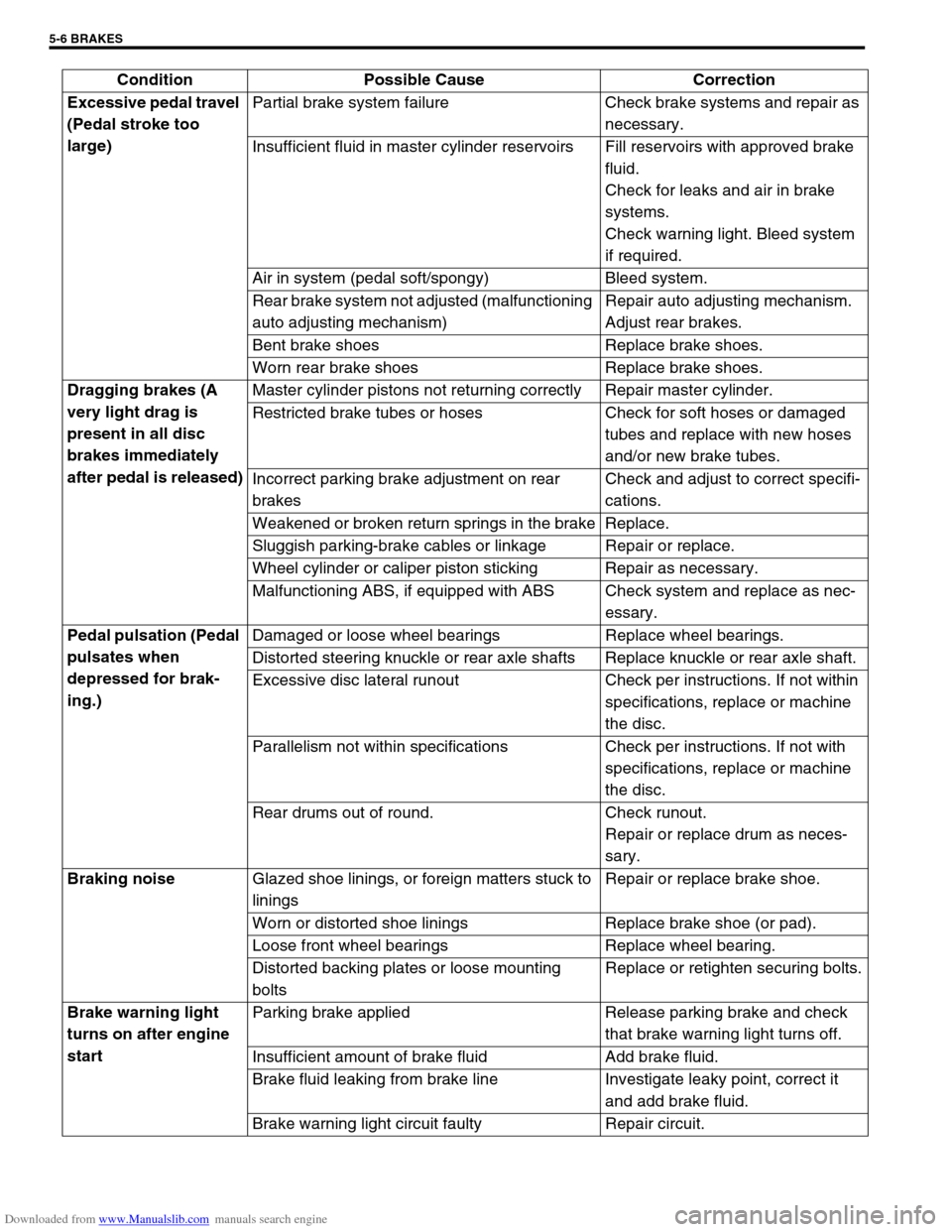

Diagnosis Table

Condition Possible Cause Correction

Not enough braking

forceBrake oil leakage from brake lines Locate leaking point and repair.

Brake disc or pads stained with oil Clean or replace.

Overheated brakes Determine cause and repair.

Poor contact of shoes on brake drum Repair for proper contact.

Brake shoes linings stained with oil or wet with

waterReplace.

Badly worn brake shoe linings Replace.

Defective wheel cylinders Repair or replace.

Malfunctioning caliper assembly Repair or replace.

Air in system Bleed system.

Maladjusted sensor spring length of LSPV Check or adjust.

Broken sensor spring of LSPV Replace.

Defective collar of LSPV Replace.

Malfunctioning ABS (Antilock brake system), if

equippedCheck system and replace as nec-

essary.

Brake pull (Brakes not

working in unison)Pad or shoe linings are wet with water or

stained with oil in some brakesReplace.

Drum-to-shoe clearance out of adjustment in

some brakes (Malfunctioning auto adjusting

mechanism)Check for inoperative auto adjusting

mechanism.

Drum is out of round in some brakes Replace.

Wheel tires are inflated unequally Inflate equally.

Malfunctioning wheel cylinders Repair or replace.

Disturbed front wheel alignment Adjust as prescribed.

Unmatched tires on same axle Tires with approximately the same

amount of tread should be used on

the same axle.

Restricted brake tubes or hoses Check for soft hoses and damaged

lines.

Replace with new hoses and new

double-walled steel brake tubing.

Malfunctioning caliper assembly Check for stuck or sluggish pistons

and proper lubrication of caliper

slide bush.

Loose suspension parts Caliper should slide.

Check all suspension mountings.

Loose calipers Check and torque bolts to specifica-

tions.

Noise (high pitched

squeak without brake

applied)Front lining worn out Replace brake pads.

Rear brake locked pre-

maturelyMaladjusted sensor spring length of LSPV Check or adjust.

Malfunctioning LSPV assembly Replace assembly.

Brake locked

(For vehicles

equipped with ABS)Malfunctioning ABS, if equipped Check system and replace as nec-

essary.

Page 267 of 687

Downloaded from www.Manualslib.com manuals search engine 5-6 BRAKES

Excessive pedal travel

(Pedal stroke too

large)Partial brake system failure Check brake systems and repair as

necessary.

Insufficient fluid in master cylinder reservoirs Fill reservoirs with approved brake

fluid.

Check for leaks and air in brake

systems.

Check warning light. Bleed system

if required.

Air in system (pedal soft/spongy) Bleed system.

Rear brake system not adjusted (malfunctioning

auto adjusting mechanism)Repair auto adjusting mechanism.

Adjust rear brakes.

Bent brake shoes Replace brake shoes.

Worn rear brake shoes Replace brake shoes.

Dragging brakes (A

very light drag is

present in all disc

brakes immediately

after pedal is released)Master cylinder pistons not returning correctly Repair master cylinder.

Restricted brake tubes or hoses Check for soft hoses or damaged

tubes and replace with new hoses

and/or new brake tubes.

Incorrect parking brake adjustment on rear

brakesCheck and adjust to correct specifi-

cations.

Weakened or broken return springs in the brake Replace.

Sluggish parking-brake cables or linkage Repair or replace.

Wheel cylinder or caliper piston sticking Repair as necessary.

Malfunctioning ABS, if equipped with ABS Check system and replace as nec-

essary.

Pedal pulsation (Pedal

pulsates when

depressed for brak-

ing.) Damaged or loose wheel bearings Replace wheel bearings.

Distorted steering knuckle or rear axle shafts Replace knuckle or rear axle shaft.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine

the disc.

Parallelism not within specifications Check per instructions. If not with

specifications, replace or machine

the disc.

Rear drums out of round. Check runout.

Repair or replace drum as neces-

sary.

Braking noise

Glazed shoe linings, or foreign matters stuck to

liningsRepair or replace brake shoe.

Worn or distorted shoe linings Replace brake shoe (or pad).

Loose front wheel bearings Replace wheel bearing.

Distorted backing plates or loose mounting

boltsReplace or retighten securing bolts.

Brake warning light

turns on after engine

startParking brake applied Release parking brake and check

that brake warning light turns off.

Insufficient amount of brake fluid Add brake fluid.

Brake fluid leaking from brake line Investigate leaky point, correct it

and add brake fluid.

Brake warning light circuit faulty Repair circuit. Condition Possible Cause Correction

Page 270 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-9

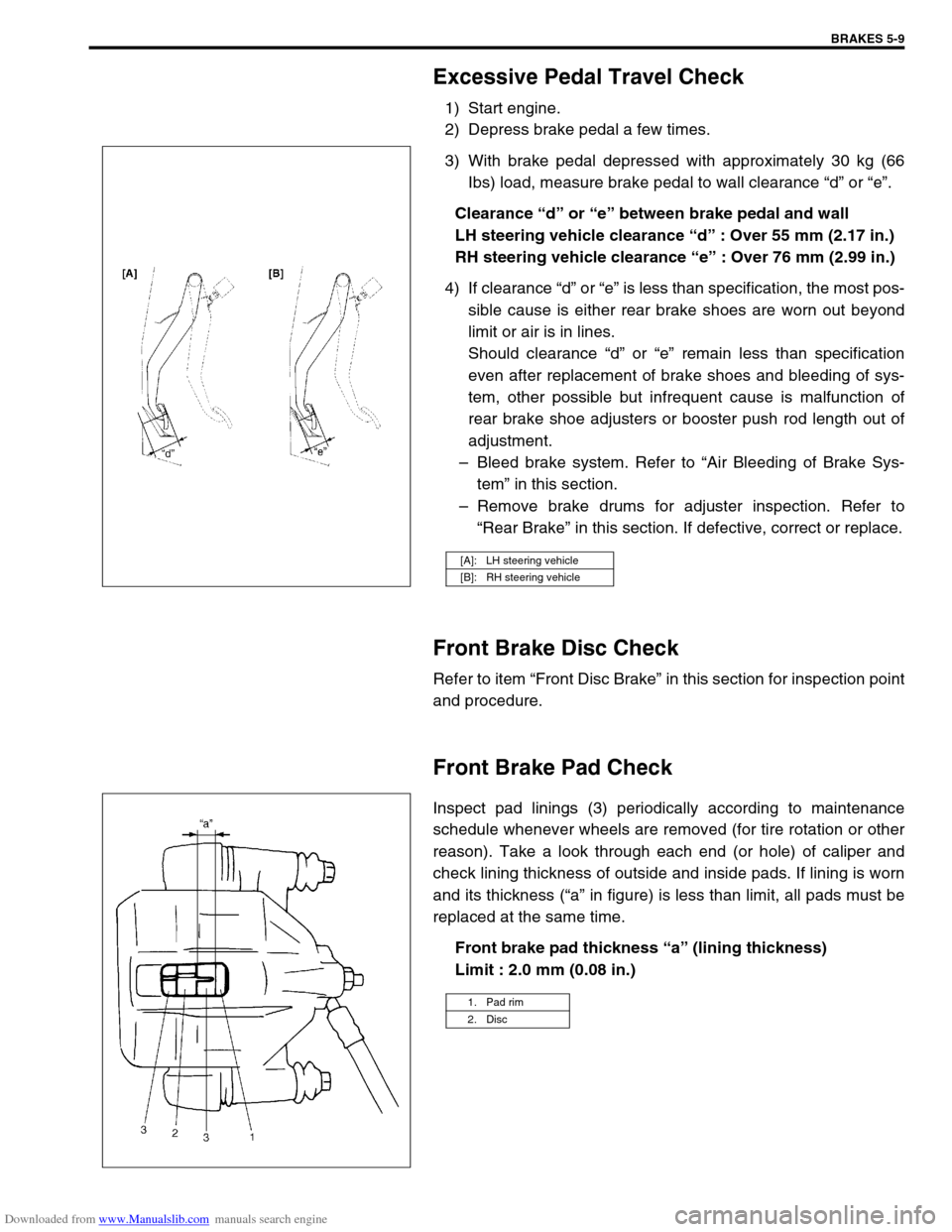

Excessive Pedal Travel Check

1) Start engine.

2) Depress brake pedal a few times.

3) With brake pedal depressed with approximately 30 kg (66

Ibs) load, measure brake pedal to wall clearance “d” or “e”.

Clearance “d” or “e” between brake pedal and wall

LH steering vehicle clearance “d” : Over 55 mm (2.17 in.)

RH steering vehicle clearance “e” : Over 76 mm (2.99 in.)

4) If clearance “d” or “e” is less than specification, the most pos-

sible cause is either rear brake shoes are worn out beyond

limit or air is in lines.

Should clearance “d” or “e” remain less than specification

even after replacement of brake shoes and bleeding of sys-

tem, other possible but infrequent cause is malfunction of

rear brake shoe adjusters or booster push rod length out of

adjustment.

–Bleed brake system. Refer to “Air Bleeding of Brake Sys-

tem” in this section.

–Remove brake drums for adjuster inspection. Refer to

“Rear Brake” in this section. If defective, correct or replace.

Front Brake Disc Check

Refer to item “Front Disc Brake” in this section for inspection point

and procedure.

Front Brake Pad Check

Inspect pad linings (3) periodically according to maintenance

schedule whenever wheels are removed (for tire rotation or other

reason). Take a look through each end (or hole) of caliper and

check lining thickness of outside and inside pads. If lining is worn

and its thickness (“a” in figure) is less than limit, all pads must be

replaced at the same time.

Front brake pad thickness “a” (lining thickness)

Limit : 2.0 mm (0.08 in.)

[A]: LH steering vehicle

[B]: RH steering vehicle

1. Pad rim

2. Disc