Bleed SUZUKI JIMNY 2005 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 276 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-15

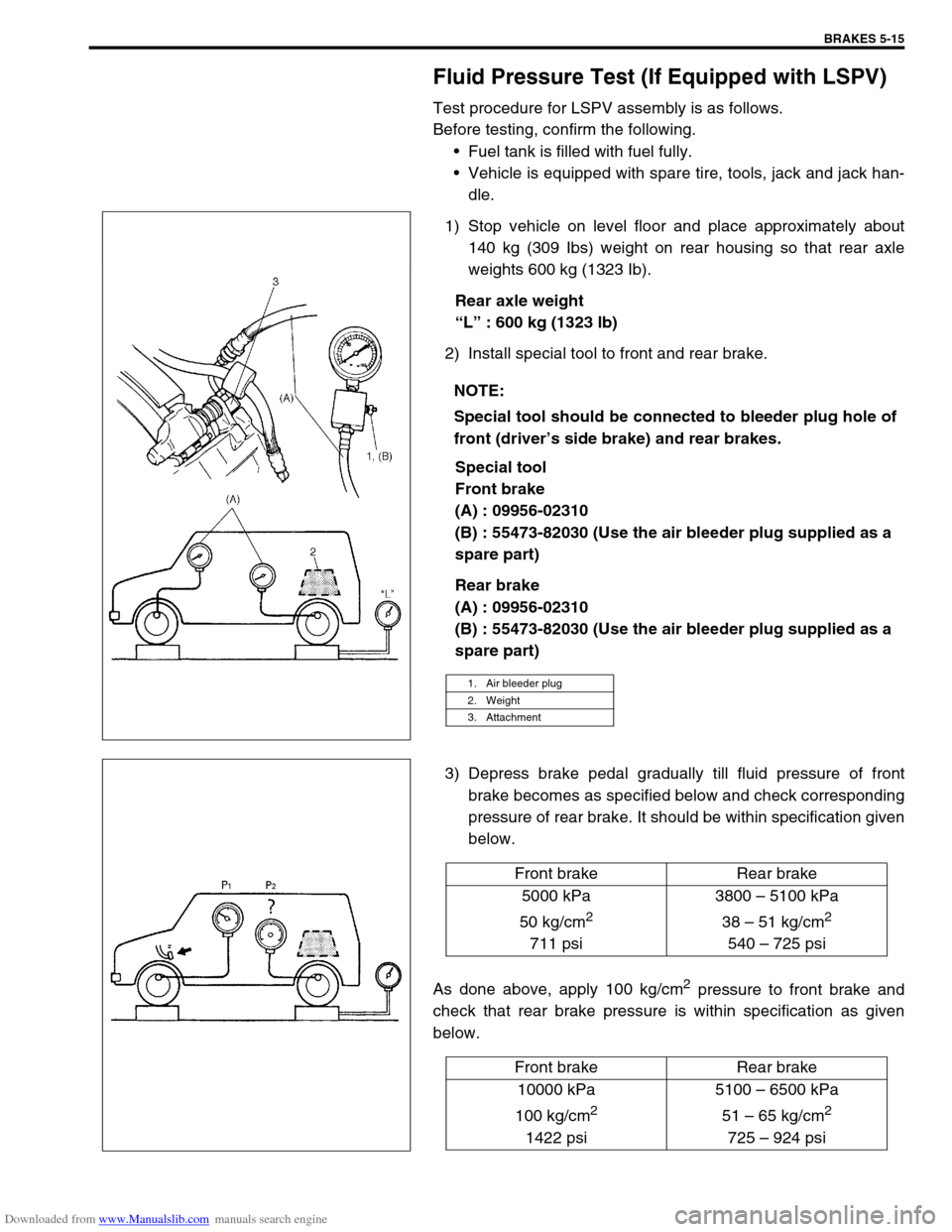

Fluid Pressure Test (If Equipped with LSPV)

Test procedure for LSPV assembly is as follows.

Before testing, confirm the following.

Fuel tank is filled with fuel fully.

Vehicle is equipped with spare tire, tools, jack and jack han-

dle.

1) Stop vehicle on level floor and place approximately about

140 kg (309 Ibs) weight on rear housing so that rear axle

weights 600 kg (1323 Ib).

Rear axle weight

“L” : 600 kg (1323 lb)

2) Install special tool to front and rear brake.

Special tool

Front brake

(A) : 09956-02310

(B) : 55473-82030 (Use the air bleeder plug supplied as a

spare part)

Rear brake

(A) : 09956-02310

(B) : 55473-82030 (Use the air bleeder plug supplied as a

spare part)

3) Depress brake pedal gradually till fluid pressure of front

brake becomes as specified below and check corresponding

pressure of rear brake. It should be within specification given

below.

As done above, apply 100 kg/cm

2 pressure to front brake and

check that rear brake pressure is within specification as given

below.NOTE:

Special tool should be connected to bleeder plug hole of

front (driver’s side brake) and rear brakes.

1. Air bleeder plug

2. Weight

3. Attachment

Front brake Rear brake

5000 kPa

50 kg/cm

2

711 psi3800 – 5100 kPa

38 – 51 kg/cm

2

540 – 725 psi

Front brake Rear brake

10000 kPa

100 kg/cm

2

1422 psi5100 – 6500 kPa

51 – 65 kg/cm

2

725 – 924 psi

Page 278 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-17

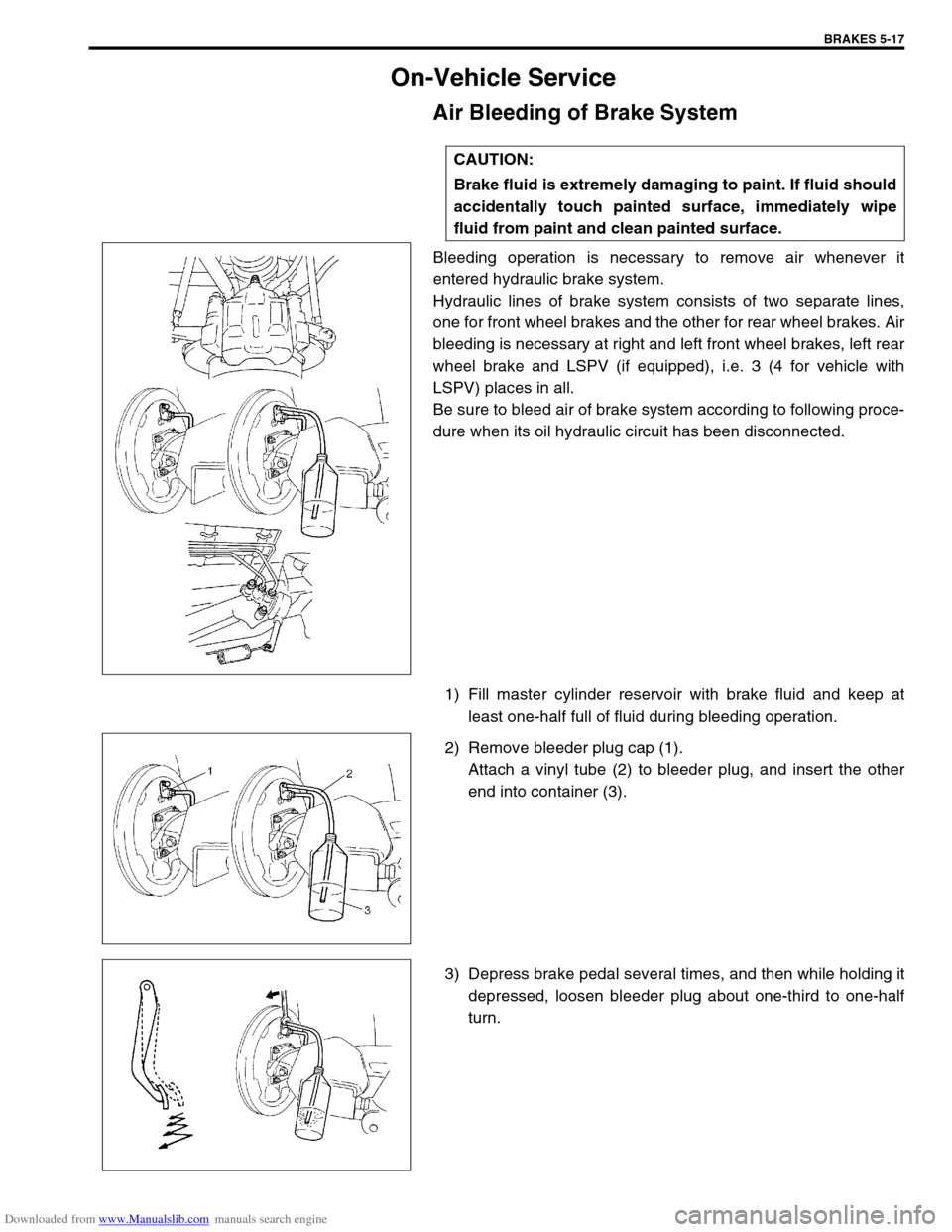

On-Vehicle Service

Air Bleeding of Brake System

Bleeding operation is necessary to remove air whenever it

entered hydraulic brake system.

Hydraulic lines of brake system consists of two separate lines,

one for front wheel brakes and the other for rear wheel brakes. Air

bleeding is necessary at right and left front wheel brakes, left rear

wheel brake and LSPV (if equipped), i.e. 3 (4 for vehicle with

LSPV) places in all.

Be sure to bleed air of brake system according to following proce-

dure when its oil hydraulic circuit has been disconnected.

1) Fill master cylinder reservoir with brake fluid and keep at

least one-half full of fluid during bleeding operation.

2) Remove bleeder plug cap (1).

Attach a vinyl tube (2) to bleeder plug, and insert the other

end into container (3).

3) Depress brake pedal several times, and then while holding it

depressed, loosen bleeder plug about one-third to one-half

turn. CAUTION:

Brake fluid is extremely damaging to paint. If fluid should

accidentally touch painted surface, immediately wipe

fluid from paint and clean painted surface.

Page 279 of 687

Downloaded from www.Manualslib.com manuals search engine 5-18 BRAKES

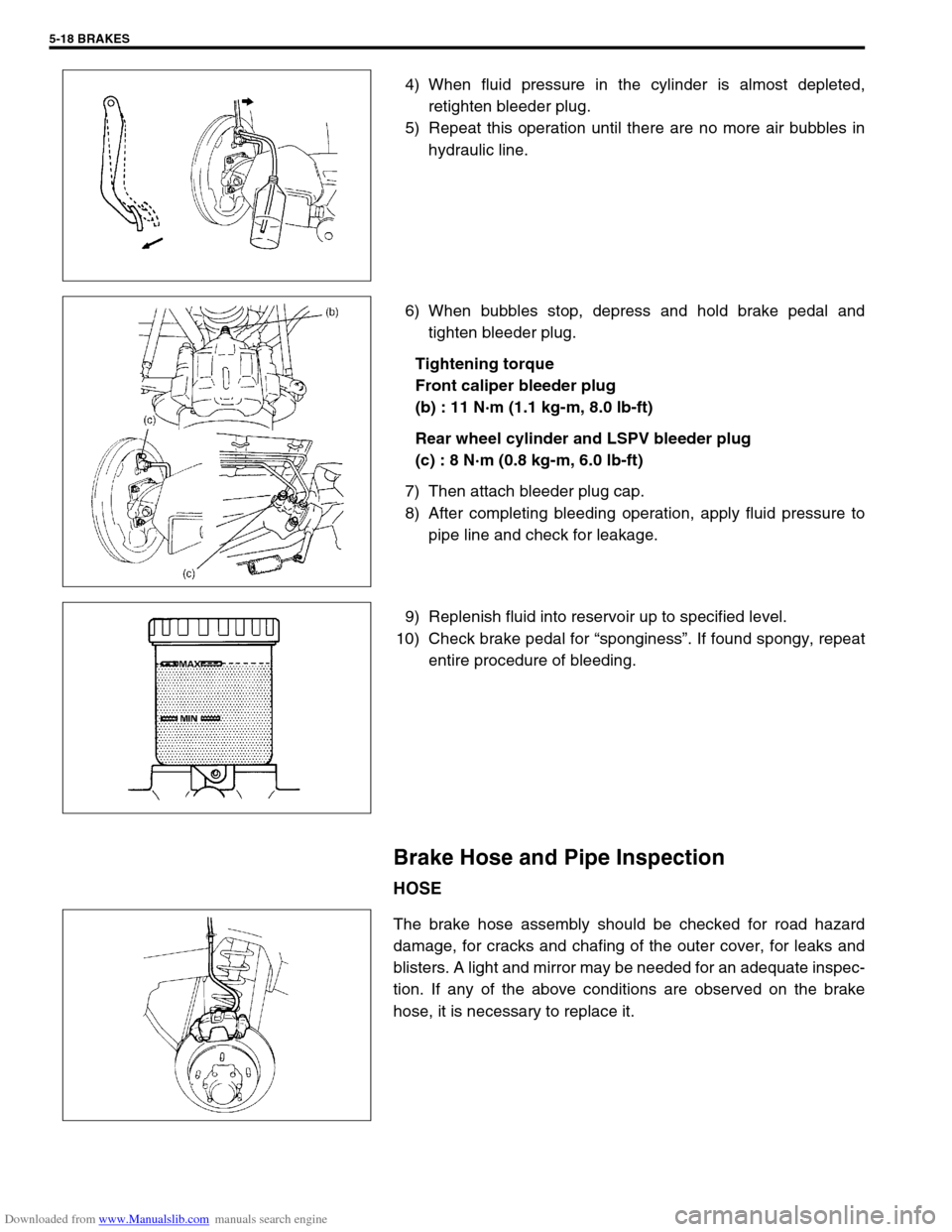

4) When fluid pressure in the cylinder is almost depleted,

retighten bleeder plug.

5) Repeat this operation until there are no more air bubbles in

hydraulic line.

6) When bubbles stop, depress and hold brake pedal and

tighten bleeder plug.

Tightening torque

Front caliper bleeder plug

(b) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

Rear wheel cylinder and LSPV bleeder plug

(c) : 8 N·m (0.8 kg-m, 6.0 lb-ft)

7) Then attach bleeder plug cap.

8) After completing bleeding operation, apply fluid pressure to

pipe line and check for leakage.

9) Replenish fluid into reservoir up to specified level.

10) Check brake pedal for “sponginess”. If found spongy, repeat

entire procedure of bleeding.

Brake Hose and Pipe Inspection

HOSE

The brake hose assembly should be checked for road hazard

damage, for cracks and chafing of the outer cover, for leaks and

blisters. A light and mirror may be needed for an adequate inspec-

tion. If any of the above conditions are observed on the brake

hose, it is necessary to replace it.

Page 280 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-19

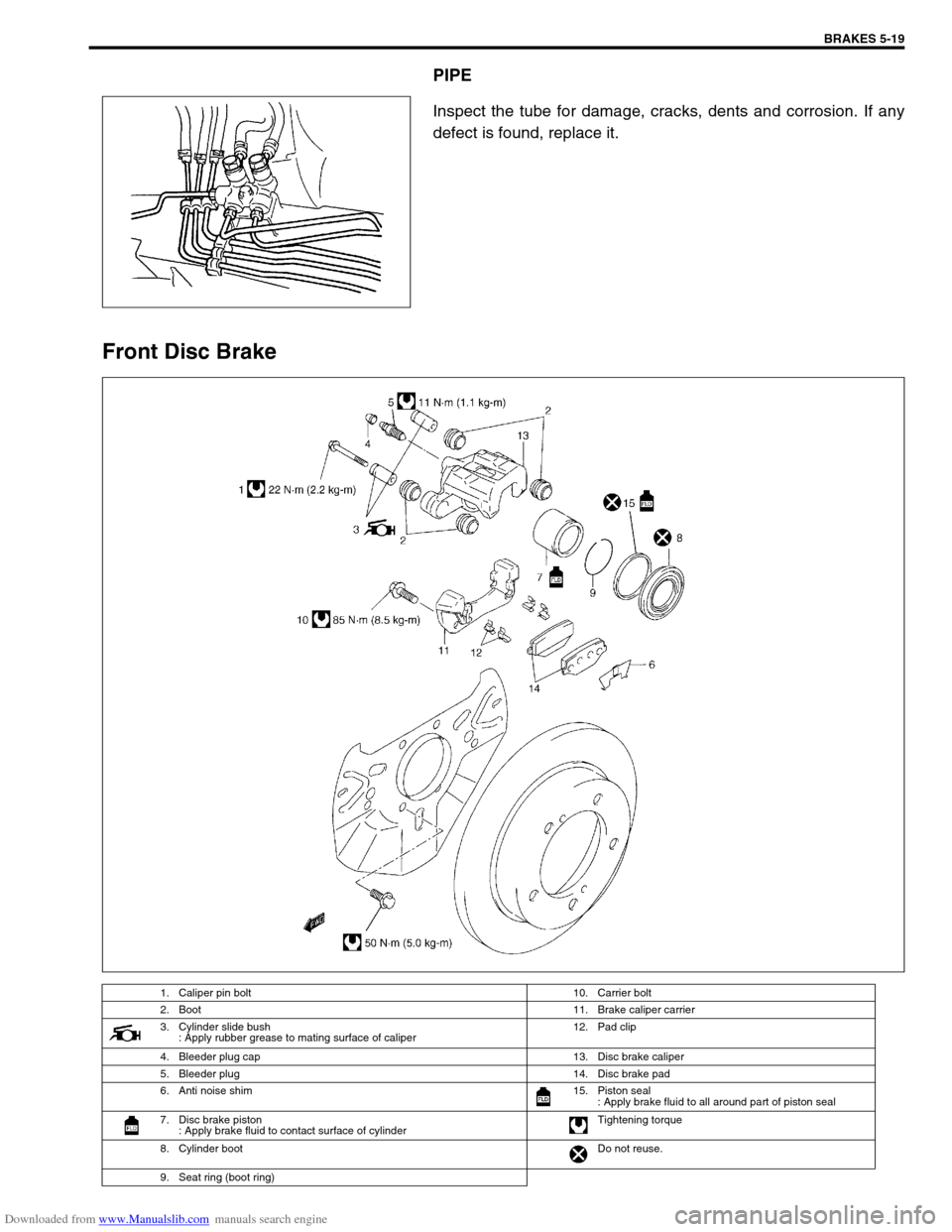

PIPE

Inspect the tube for damage, cracks, dents and corrosion. If any

defect is found, replace it.

Front Disc Brake

1. Caliper pin bolt 10. Carrier bolt

2. Boot11. Brake caliper carrier

3. Cylinder slide bush

: Apply rubber grease to mating surface of caliper12. Pad clip

4. Bleeder plug cap 13. Disc brake caliper

5. Bleeder plug 14. Disc brake pad

6. Anti noise shim 15. Piston seal

: Apply brake fluid to all around part of piston seal

7. Disc brake piston

: Apply brake fluid to contact surface of cylinderTightening torque

8. Cylinder bootDo not reuse.

9. Seat ring (boot ring)

Page 283 of 687

Downloaded from www.Manualslib.com manuals search engine 5-22 BRAKES

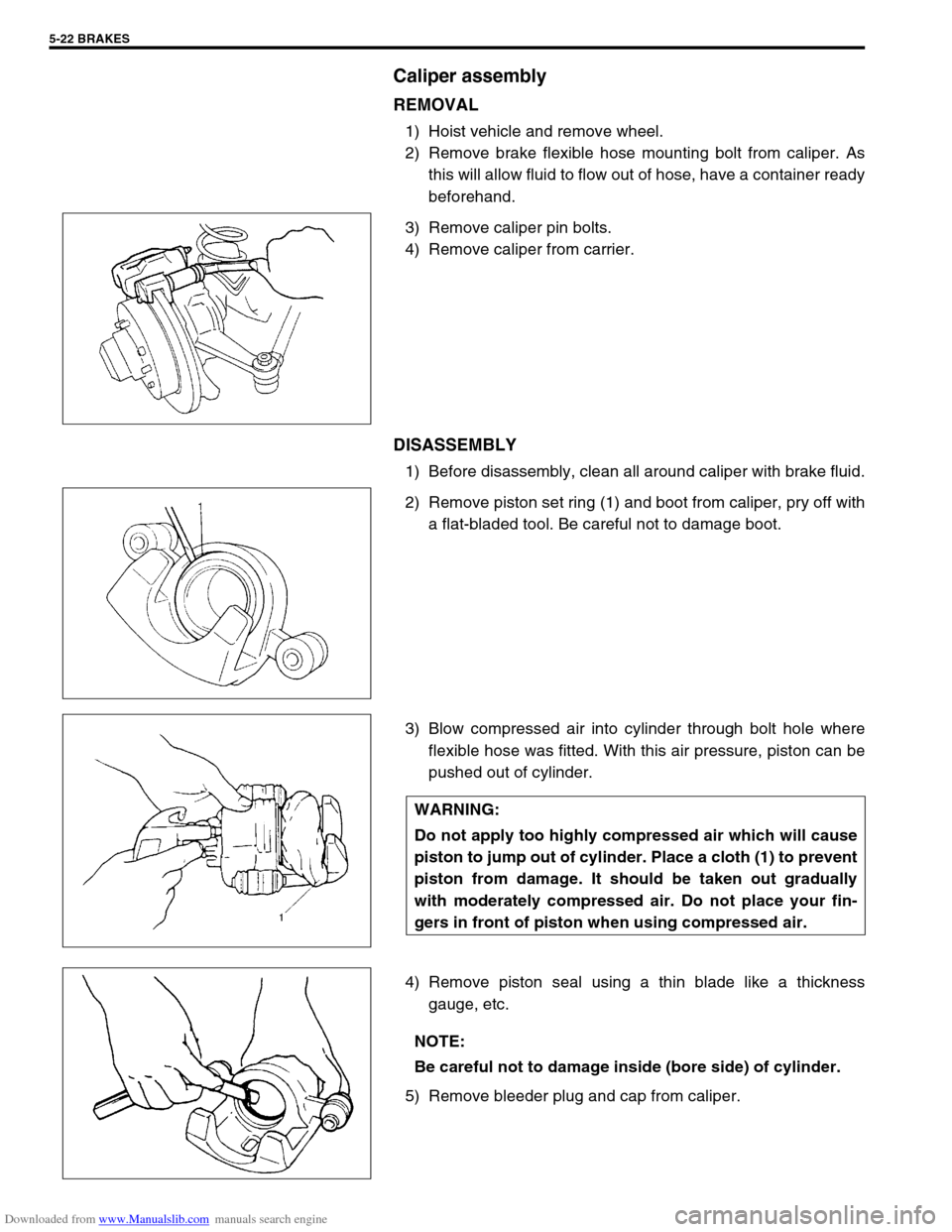

Caliper assembly

REMOVAL

1) Hoist vehicle and remove wheel.

2) Remove brake flexible hose mounting bolt from caliper. As

this will allow fluid to flow out of hose, have a container ready

beforehand.

3) Remove caliper pin bolts.

4) Remove caliper from carrier.

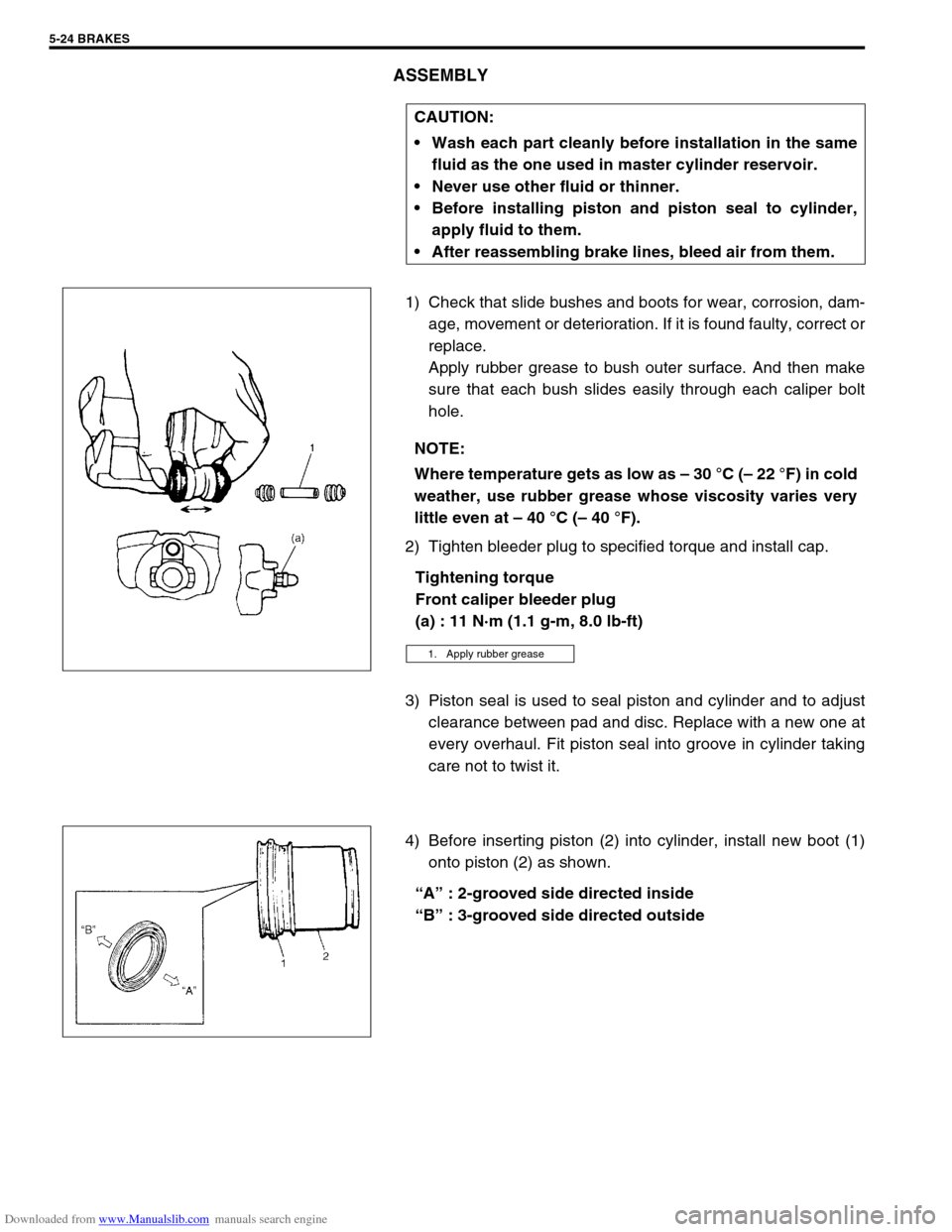

DISASSEMBLY

1) Before disassembly, clean all around caliper with brake fluid.

2) Remove piston set ring (1) and boot from caliper, pry off with

a flat-bladed tool. Be careful not to damage boot.

3) Blow compressed air into cylinder through bolt hole where

flexible hose was fitted. With this air pressure, piston can be

pushed out of cylinder.

4) Remove piston seal using a thin blade like a thickness

gauge, etc.

5) Remove bleeder plug and cap from caliper.

WARNING:

Do not apply too highly compressed air which will cause

piston to jump out of cylinder. Place a cloth (1) to prevent

piston from damage. It should be taken out gradually

with moderately compressed air. Do not place your fin-

gers in front of piston when using compressed air.

NOTE:

Be careful not to damage inside (bore side) of cylinder.

Page 285 of 687

Downloaded from www.Manualslib.com manuals search engine 5-24 BRAKES

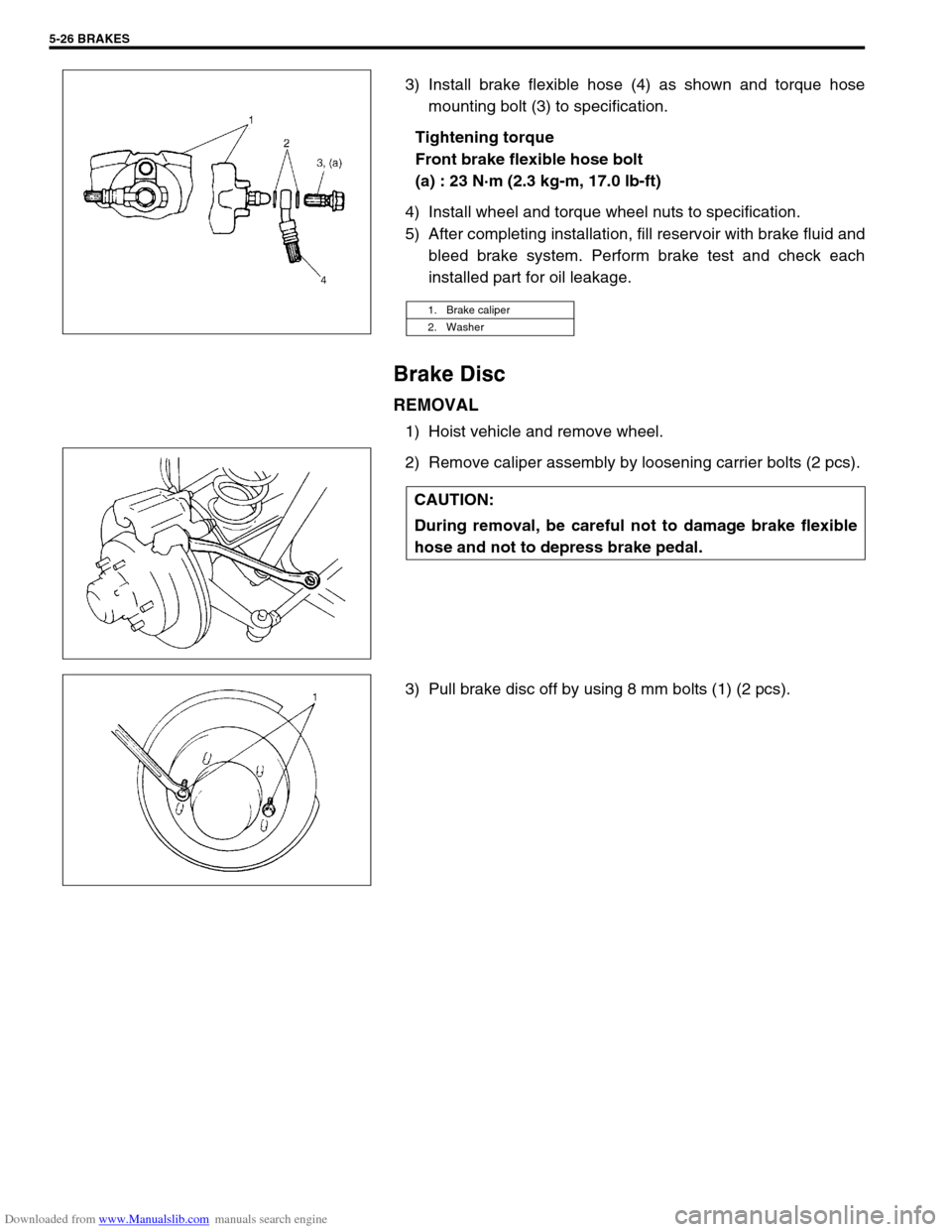

ASSEMBLY

1) Check that slide bushes and boots for wear, corrosion, dam-

age, movement or deterioration. If it is found faulty, correct or

replace.

Apply rubber grease to bush outer surface. And then make

sure that each bush slides easily through each caliper bolt

hole.

2) Tighten bleeder plug to specified torque and install cap.

Tightening torque

Front caliper bleeder plug

(a) : 11 N·m (1.1 g-m, 8.0 lb-ft)

3) Piston seal is used to seal piston and cylinder and to adjust

clearance between pad and disc. Replace with a new one at

every overhaul. Fit piston seal into groove in cylinder taking

care not to twist it.

4) Before inserting piston (2) into cylinder, install new boot (1)

onto piston (2) as shown.

“A” : 2-grooved side directed inside

“B” : 3-grooved side directed outside CAUTION:

Wash each part cleanly before installation in the same

fluid as the one used in master cylinder reservoir.

Never use other fluid or thinner.

Before installing piston and piston seal to cylinder,

apply fluid to them.

After reassembling brake lines, bleed air from them.

NOTE:

Where temperature gets as low as – 30 °C (– 22 °F) in cold

weather, use rubber grease whose viscosity varies very

little even at – 40 °C (– 40 °F).

1. Apply rubber grease

Page 287 of 687

Downloaded from www.Manualslib.com manuals search engine 5-26 BRAKES

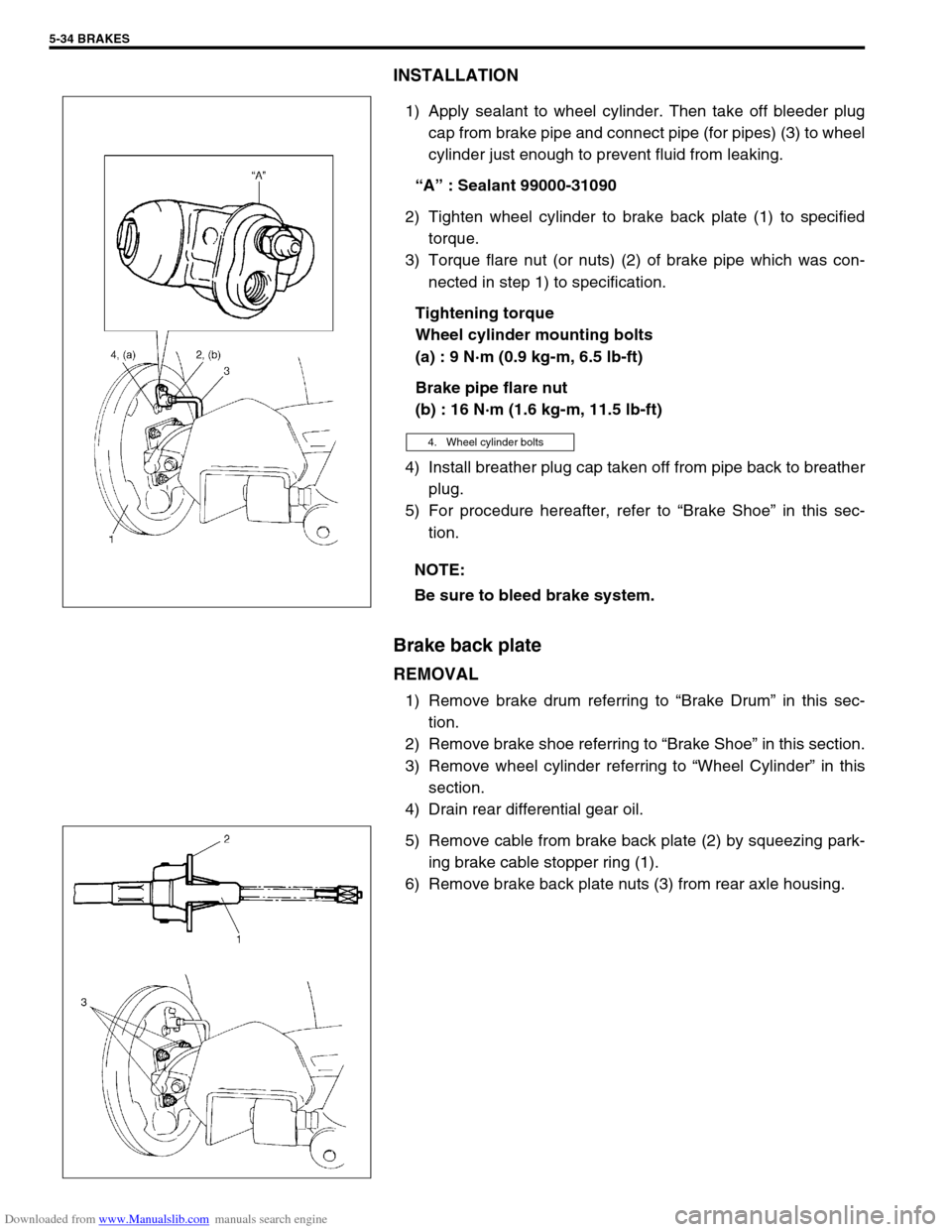

3) Install brake flexible hose (4) as shown and torque hose

mounting bolt (3) to specification.

Tightening torque

Front brake flexible hose bolt

(a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

4) Install wheel and torque wheel nuts to specification.

5) After completing installation, fill reservoir with brake fluid and

bleed brake system. Perform brake test and check each

installed part for oil leakage.

Brake Disc

REMOVAL

1) Hoist vehicle and remove wheel.

2) Remove caliper assembly by loosening carrier bolts (2 pcs).

3) Pull brake disc off by using 8 mm bolts (1) (2 pcs).

1. Brake caliper

2. Washer

CAUTION:

During removal, be careful not to damage brake flexible

hose and not to depress brake pedal.

Page 295 of 687

Downloaded from www.Manualslib.com manuals search engine 5-34 BRAKES

INSTALLATION

1) Apply sealant to wheel cylinder. Then take off bleeder plug

cap from brake pipe and connect pipe (for pipes) (3) to wheel

cylinder just enough to prevent fluid from leaking.

“A” : Sealant 99000-31090

2) Tighten wheel cylinder to brake back plate (1) to specified

torque.

3) Torque flare nut (or nuts) (2) of brake pipe which was con-

nected in step 1) to specification.

Tightening torque

Wheel cylinder mounting bolts

(a) : 9 N·m (0.9 kg-m, 6.5 lb-ft)

Brake pipe flare nut

(b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

4) Install breather plug cap taken off from pipe back to breather

plug.

5) For procedure hereafter, refer to “Brake Shoe” in this sec-

tion.

Brake back plate

REMOVAL

1) Remove brake drum referring to “Brake Drum” in this sec-

tion.

2) Remove brake shoe referring to “Brake Shoe” in this section.

3) Remove wheel cylinder referring to “Wheel Cylinder” in this

section.

4) Drain rear differential gear oil.

5) Remove cable from brake back plate (2) by squeezing park-

ing brake cable stopper ring (1).

6) Remove brake back plate nuts (3) from rear axle housing.

4. Wheel cylinder bolts

NOTE:

Be sure to bleed brake system.

Page 299 of 687

Downloaded from www.Manualslib.com manuals search engine 5-38 BRAKES

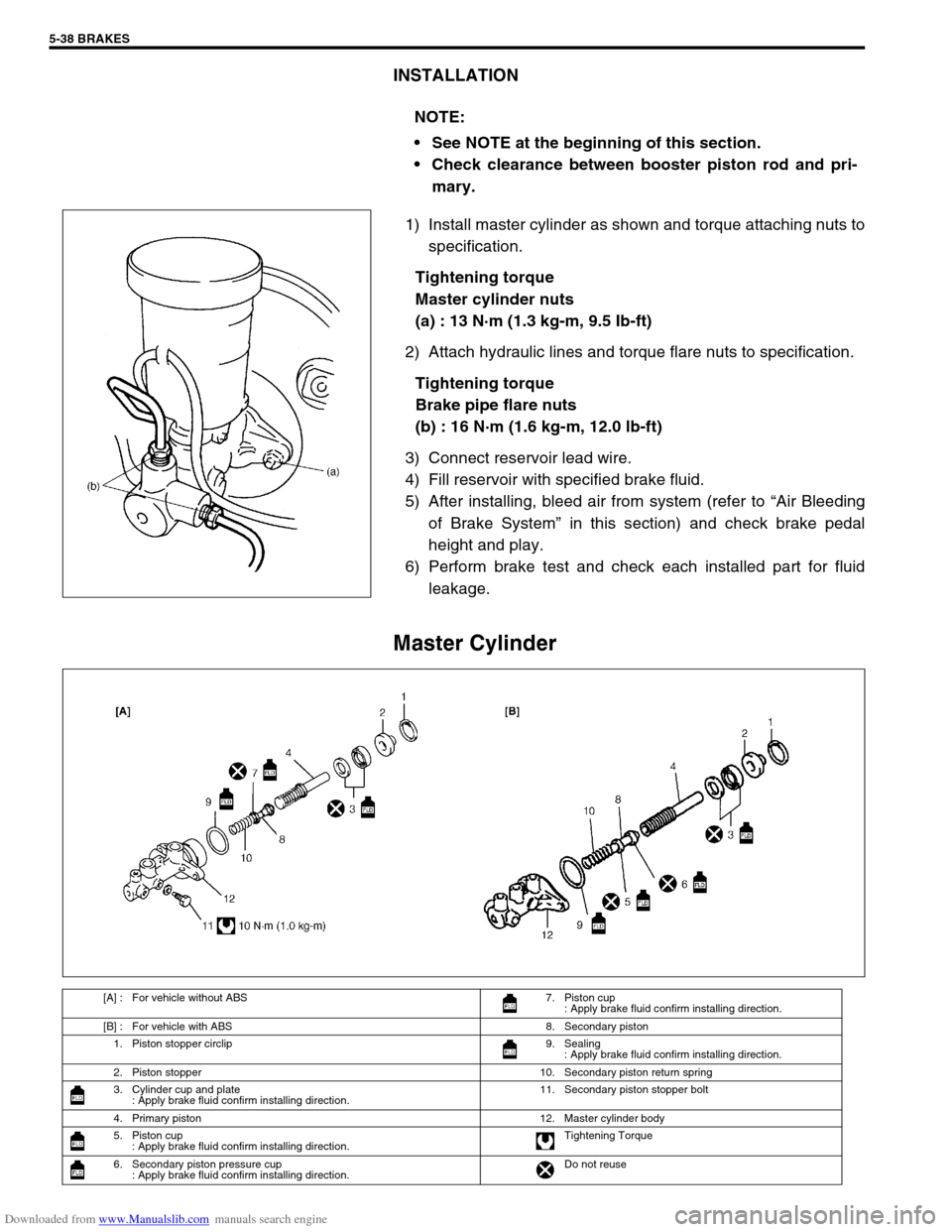

INSTALLATION

1) Install master cylinder as shown and torque attaching nuts to

specification.

Tightening torque

Master cylinder nuts

(a) : 13 N·m (1.3 kg-m, 9.5 Ib-ft)

2) Attach hydraulic lines and torque flare nuts to specification.

Tightening torque

Brake pipe flare nuts

(b) : 16 N·m (1.6 kg-m, 12.0 lb-ft)

3) Connect reservoir lead wire.

4) Fill reservoir with specified brake fluid.

5) After installing, bleed air from system (refer to “Air Bleeding

of Brake System” in this section) and check brake pedal

height and play.

6) Perform brake test and check each installed part for fluid

leakage.

Master Cylinder

NOTE:

See NOTE at the beginning of this section.

Check clearance between booster piston rod and pri-

mary.

[A] : For vehicle without ABS 7. Piston cup

: Apply brake fluid confirm installing direction.

[B] : For vehicle with ABS 8. Secondary piston

1. Piston stopper circlip 9. Sealing

: Apply brake fluid confirm installing direction.

2. Piston stopper 10. Secondary piston return spring

3. Cylinder cup and plate

: Apply brake fluid confirm installing direction.11. Secondary piston stopper bolt

4. Primary piston 12. Master cylinder body

5. Piston cup

: Apply brake fluid confirm installing direction.Tightening Torque

6. Secondary piston pressure cup

: Apply brake fluid confirm installing direction.Do not reuse

Page 303 of 687

Downloaded from www.Manualslib.com manuals search engine 5-42 BRAKES

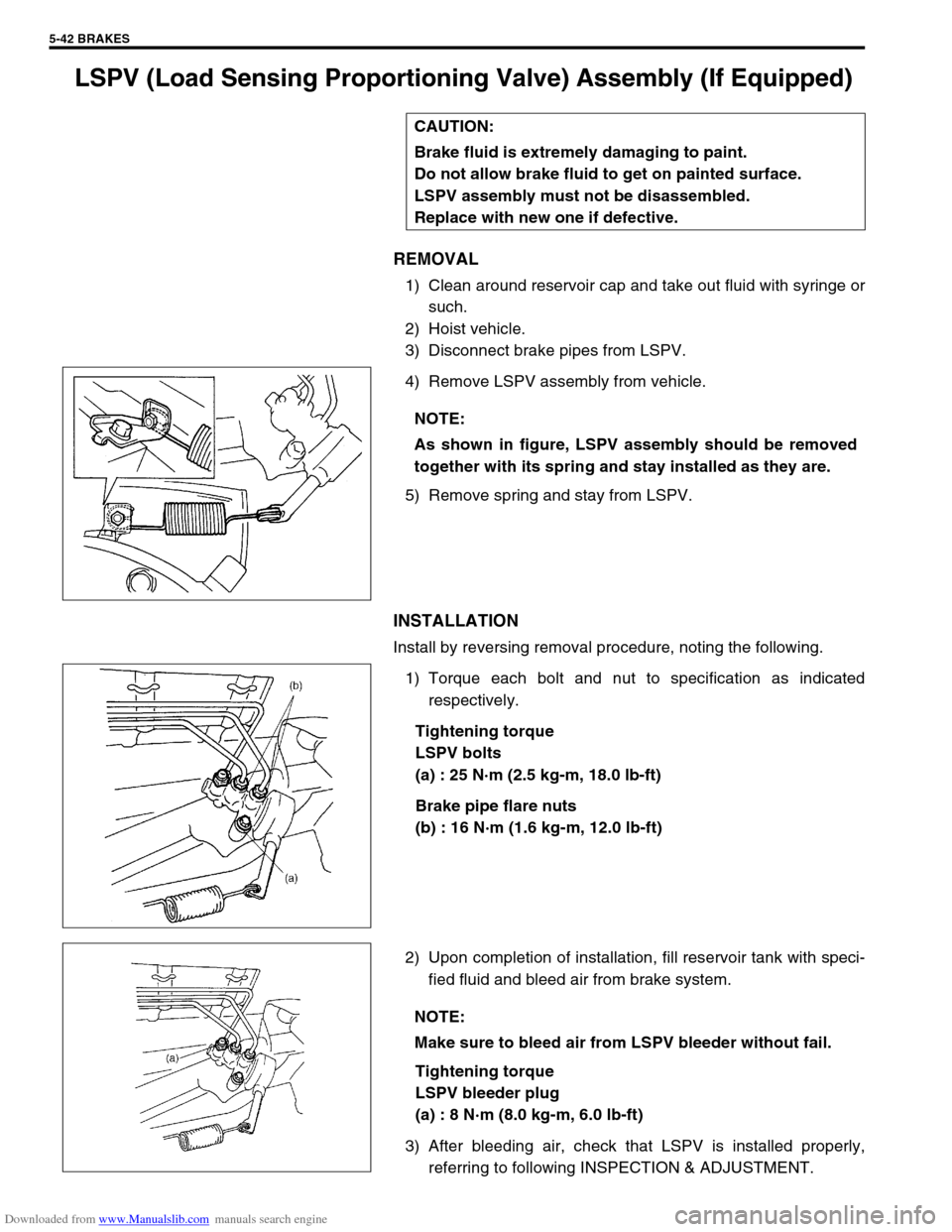

LSPV (Load Sensing Proportioning Valve) Assembly (If Equipped)

REMOVAL

1) Clean around reservoir cap and take out fluid with syringe or

such.

2) Hoist vehicle.

3) Disconnect brake pipes from LSPV.

4) Remove LSPV assembly from vehicle.

5) Remove spring and stay from LSPV.

INSTALLATION

Install by reversing removal procedure, noting the following.

1) Torque each bolt and nut to specification as indicated

respectively.

Tightening torque

LSPV bolts

(a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

Brake pipe flare nuts

(b) : 16 N·m (1.6 kg-m, 12.0 lb-ft)

2) Upon completion of installation, fill reservoir tank with speci-

fied fluid and bleed air from brake system.

Tightening torque

LSPV bleeder plug

(a) : 8 N·m (8.0 kg-m, 6.0 lb-ft)

3) After bleeding air, check that LSPV is installed properly,

referring to following INSPECTION & ADJUSTMENT. CAUTION:

Brake fluid is extremely damaging to paint.

Do not allow brake fluid to get on painted surface.

LSPV assembly must not be disassembled.

Replace with new one if defective.

NOTE:

As shown in figure, LSPV assembly should be removed

together with its spring and stay installed as they are.

NOTE:

Make sure to bleed air from LSPV bleeder without fail.