Lever SUZUKI JIMNY 2005 3.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 60 of 687

Downloaded from www.Manualslib.com manuals search engine HEATER AND VENTILATION 1A-7

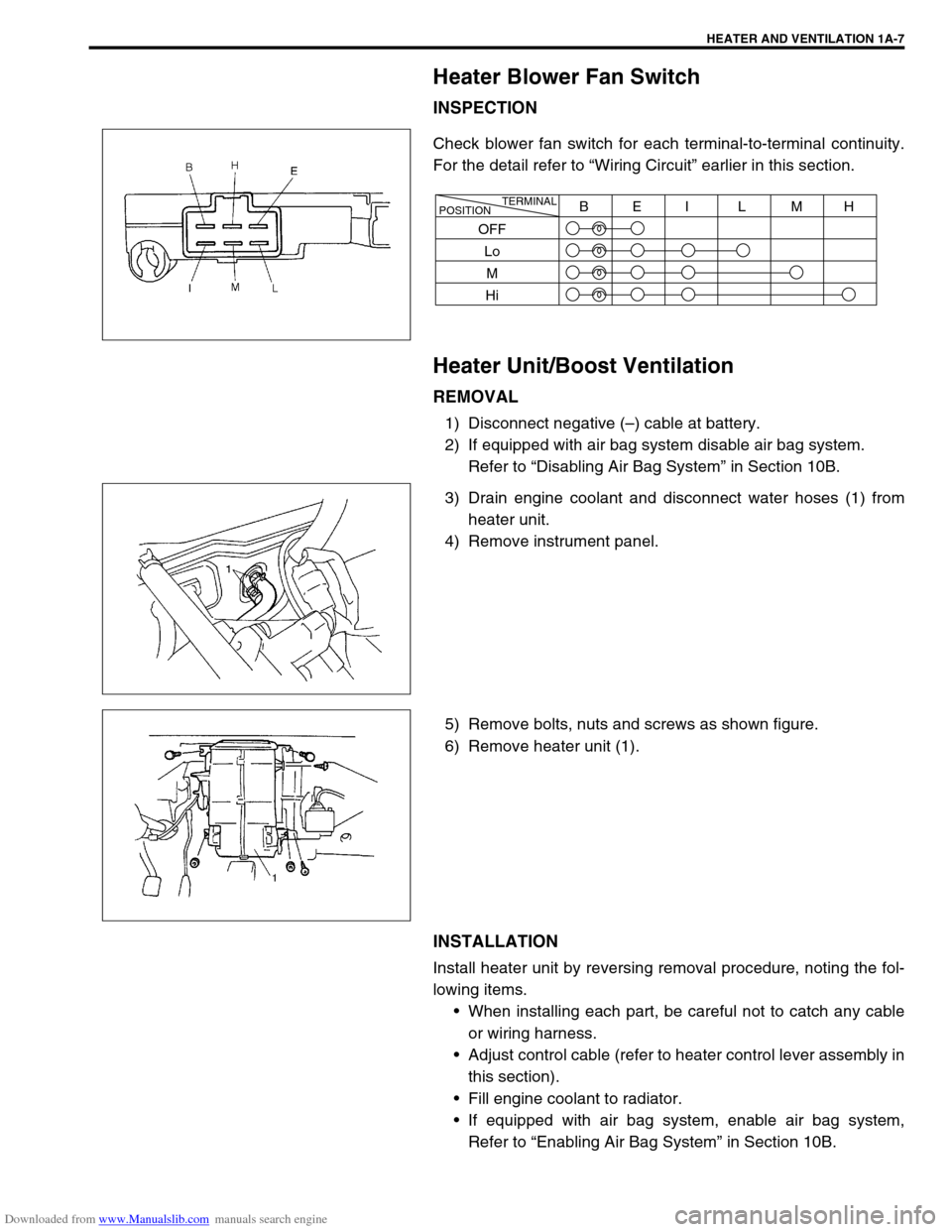

Heater Blower Fan Switch

INSPECTION

Check blower fan switch for each terminal-to-terminal continuity.

For the detail refer to “Wiring Circuit” earlier in this section.

Heater Unit/Boost Ventilation

REMOVAL

1) Disconnect negative (–) cable at battery.

2) If equipped with air bag system disable air bag system.

Refer to “Disabling Air Bag System” in Section 10B.

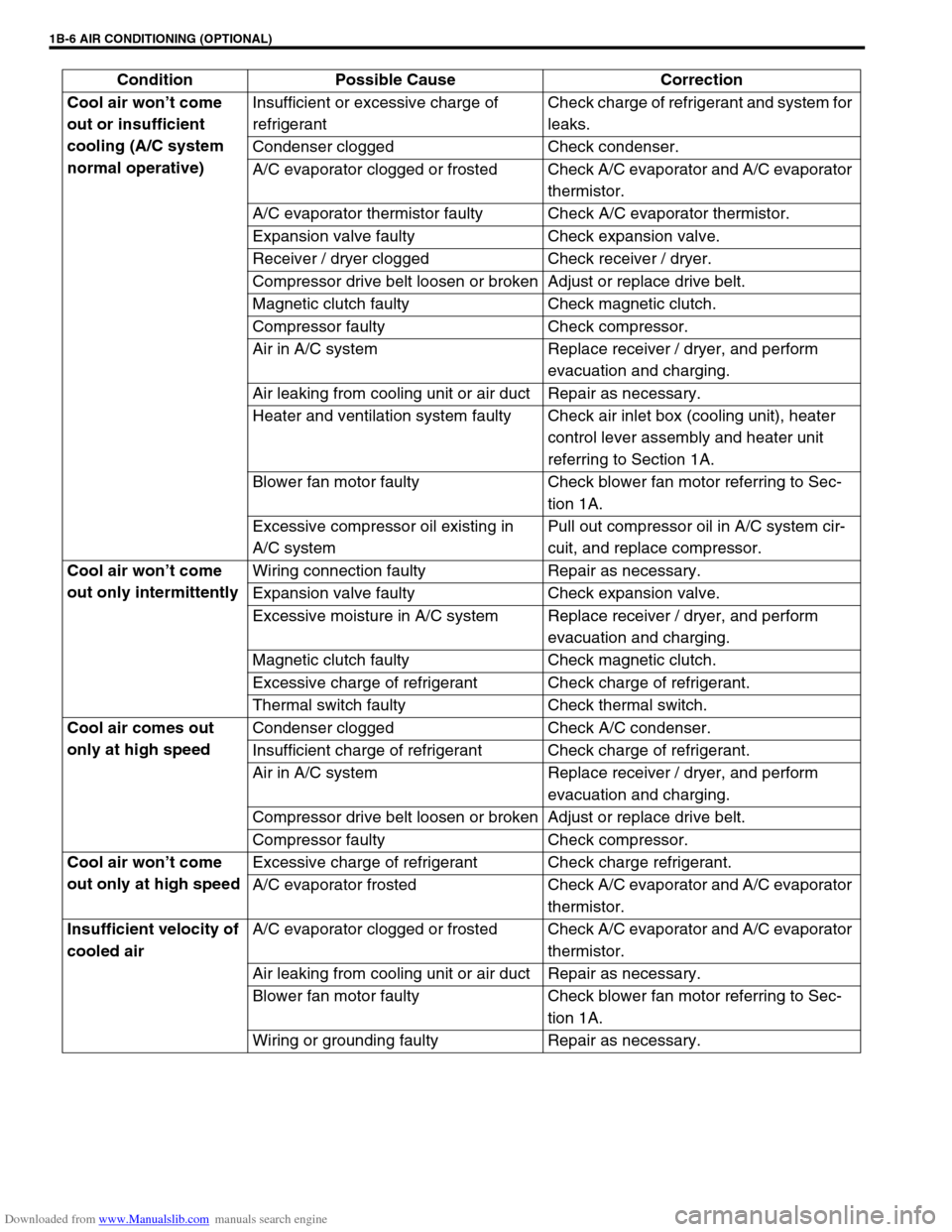

3) Drain engine coolant and disconnect water hoses (1) from

heater unit.

4) Remove instrument panel.

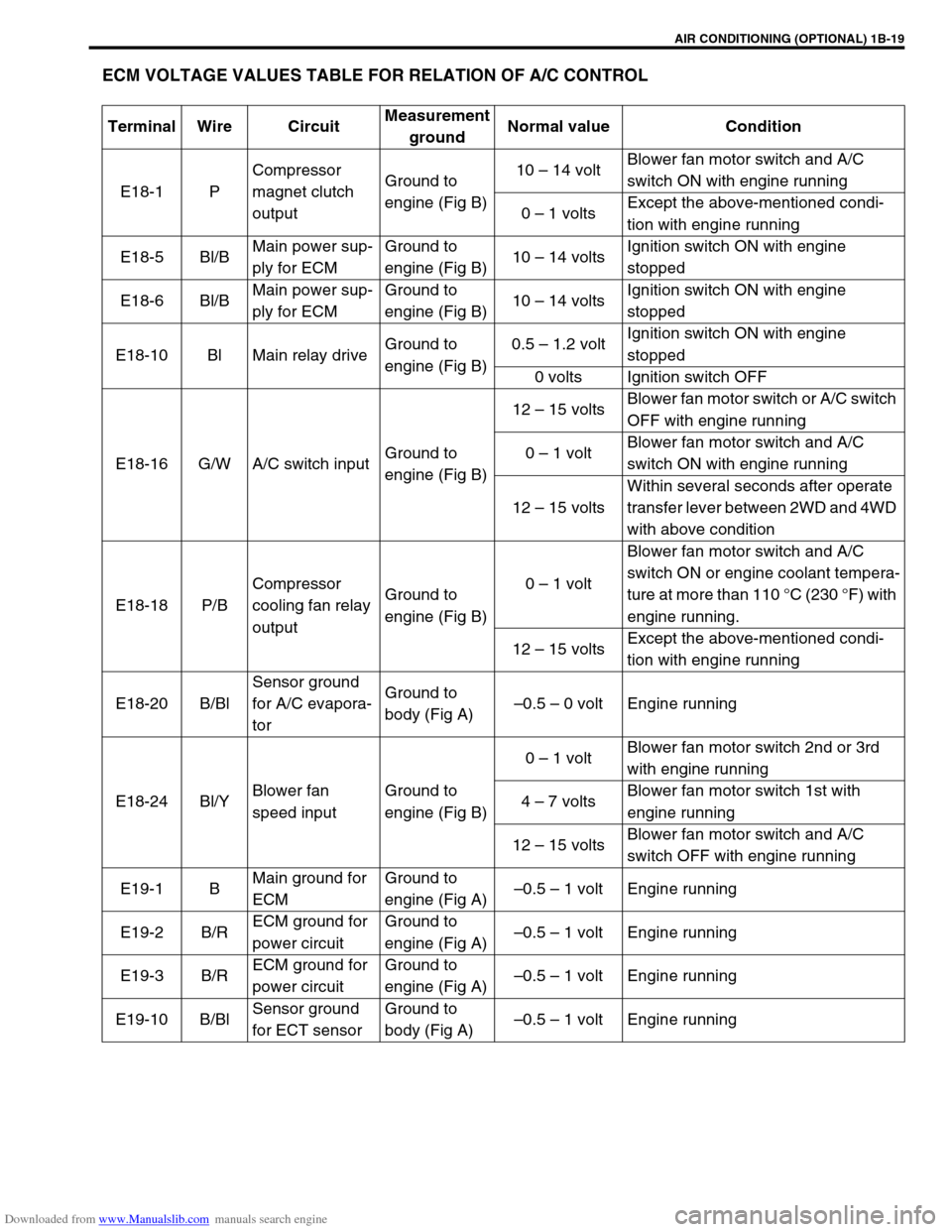

5) Remove bolts, nuts and screws as shown figure.

6) Remove heater unit (1).

INSTALLATION

Install heater unit by reversing removal procedure, noting the fol-

lowing items.

When installing each part, be careful not to catch any cable

or wiring harness.

Adjust control cable (refer to heater control lever assembly in

this section).

Fill engine coolant to radiator.

If equipped with air bag system, enable air bag system,

Refer to “Enabling Air Bag System” in Section 10B.

TERMINAL

POSITIONBEI L MH

OFF

Lo

M

Hi

Page 67 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-6 AIR CONDITIONING (OPTIONAL)

Cool air won’t come

out or insufficient

cooling (A/C system

normal operative)Insufficient or excessive charge of

refrigerantCheck charge of refrigerant and system for

leaks.

Condenser clogged Check condenser.

A/C evaporator clogged or frosted Check A/C evaporator and A/C evaporator

thermistor.

A/C evaporator thermistor faulty Check A/C evaporator thermistor.

Expansion valve faulty Check expansion valve.

Receiver / dryer clogged Check receiver / dryer.

Compressor drive belt loosen or broken Adjust or replace drive belt.

Magnetic clutch faulty Check magnetic clutch.

Compressor faulty Check compressor.

Air in A/C system Replace receiver / dryer, and perform

evacuation and charging.

Air leaking from cooling unit or air duct Repair as necessary.

Heater and ventilation system faulty Check air inlet box (cooling unit), heater

control lever assembly and heater unit

referring to Section 1A.

Blower fan motor faulty Check blower fan motor referring to Sec-

tion 1A.

Excessive compressor oil existing in

A/C systemPull out compressor oil in A/C system cir-

cuit, and replace compressor.

Cool air won’t come

out only intermittentlyWiring connection faulty Repair as necessary.

Expansion valve faulty Check expansion valve.

Excessive moisture in A/C system Replace receiver / dryer, and perform

evacuation and charging.

Magnetic clutch faulty Check magnetic clutch.

Excessive charge of refrigerant Check charge of refrigerant.

Thermal switch faulty Check thermal switch.

Cool air comes out

only at high speedCondenser clogged Check A/C condenser.

Insufficient charge of refrigerant Check charge of refrigerant.

Air in A/C system Replace receiver / dryer, and perform

evacuation and charging.

Compressor drive belt loosen or broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Cool air won’t come

out only at high speedExcessive charge of refrigerant Check charge refrigerant.

A/C evaporator frosted Check A/C evaporator and A/C evaporator

thermistor.

Insufficient velocity of

cooled airA/C evaporator clogged or frosted Check A/C evaporator and A/C evaporator

thermistor.

Air leaking from cooling unit or air duct Repair as necessary.

Blower fan motor faulty Check blower fan motor referring to Sec-

tion 1A.

Wiring or grounding faulty Repair as necessary. Condition Possible Cause Correction

Page 80 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-19

ECM VOLTAGE VALUES TABLE FOR RELATION OF A/C CONTROL

Terminal Wire CircuitMeasurement

groundNormal value Condition

E18-1 PCompressor

magnet clutch

outputGround to

engine (Fig B)10 – 14 voltBlower fan motor switch and A/C

switch ON with engine running

0 – 1 voltsExcept the above-mentioned condi-

tion with engine running

E18-5 Bl/BMain power sup-

ply for ECMGround to

engine (Fig B)10 – 14 voltsIgnition switch ON with engine

stopped

E18-6 Bl/BMain power sup-

ply for ECMGround to

engine (Fig B)10 – 14 voltsIgnition switch ON with engine

stopped

E18-10 Bl Main relay driveGround to

engine (Fig B)0.5 – 1.2 voltIgnition switch ON with engine

stopped

0 volts Ignition switch OFF

E18-16 G/W A/C switch inputGround to

engine (Fig B)12 – 15 voltsBlower fan motor switch or A/C switch

OFF with engine running

0 – 1 voltBlower fan motor switch and A/C

switch ON with engine running

12 – 15 voltsWithin several seconds after operate

transfer lever between 2WD and 4WD

with above condition

E18-18 P/BCompressor

cooling fan relay

outputGround to

engine (Fig B)0 – 1 voltBlower fan motor switch and A/C

switch ON or engine coolant tempera-

ture at more than 110 °C (230 °F) with

engine running.

12 – 15 voltsExcept the above-mentioned condi-

tion with engine running

E18-20 B/BlSensor ground

for A/C evapora-

torGround to

body (Fig A)–0.5 – 0 volt Engine running

E18-24 Bl/YBlower fan

speed inputGround to

engine (Fig B)0 – 1 voltBlower fan motor switch 2nd or 3rd

with engine running

4 – 7 voltsBlower fan motor switch 1st with

engine running

12 – 15 voltsBlower fan motor switch and A/C

switch OFF with engine running

E19-1 BMain ground for

ECMGround to

engine (Fig A)–0.5 – 1 volt Engine running

E19-2 B/RECM ground for

power circuitGround to

engine (Fig A)–0.5 – 1 volt Engine running

E19-3 B/RECM ground for

power circuitGround to

engine (Fig A)–0.5 – 1 volt Engine running

E19-10 B/BlSensor ground

for ECT sensorGround to

body (Fig A)–0.5 – 1 volt Engine running

Page 97 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-36 AIR CONDITIONING (OPTIONAL)

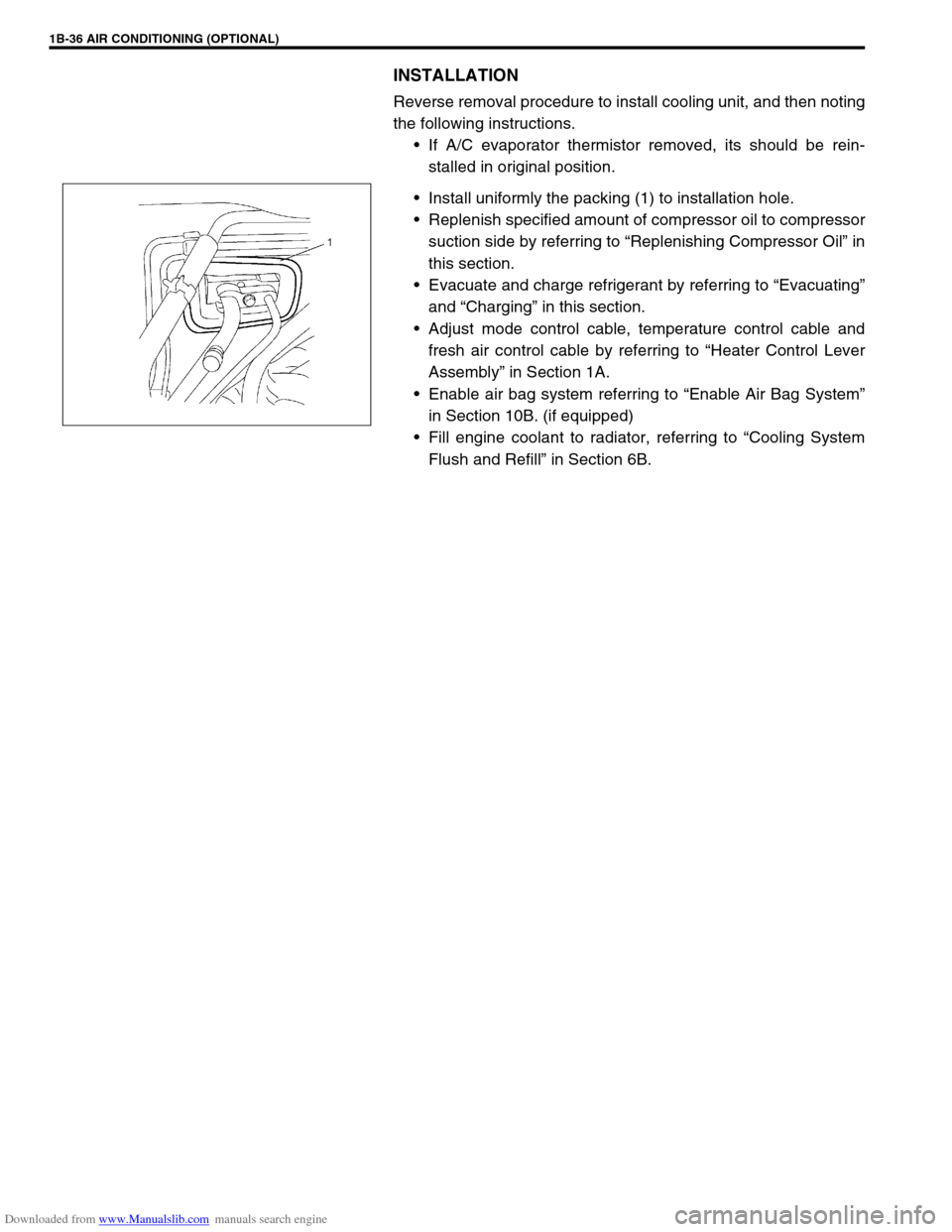

INSTALLATION

Reverse removal procedure to install cooling unit, and then noting

the following instructions.

If A/C evaporator thermistor removed, its should be rein-

stalled in original position.

Install uniformly the packing (1) to installation hole.

Replenish specified amount of compressor oil to compressor

suction side by referring to “Replenishing Compressor Oil” in

this section.

Evacuate and charge refrigerant by referring to “Evacuating”

and “Charging” in this section.

Adjust mode control cable, temperature control cable and

fresh air control cable by referring to “Heater Control Lever

Assembly” in Section 1A.

Enable air bag system referring to “Enable Air Bag System”

in Section 10B. (if equipped)

Fill engine coolant to radiator, referring to “Cooling System

Flush and Refill” in Section 6B.

Page 100 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-39

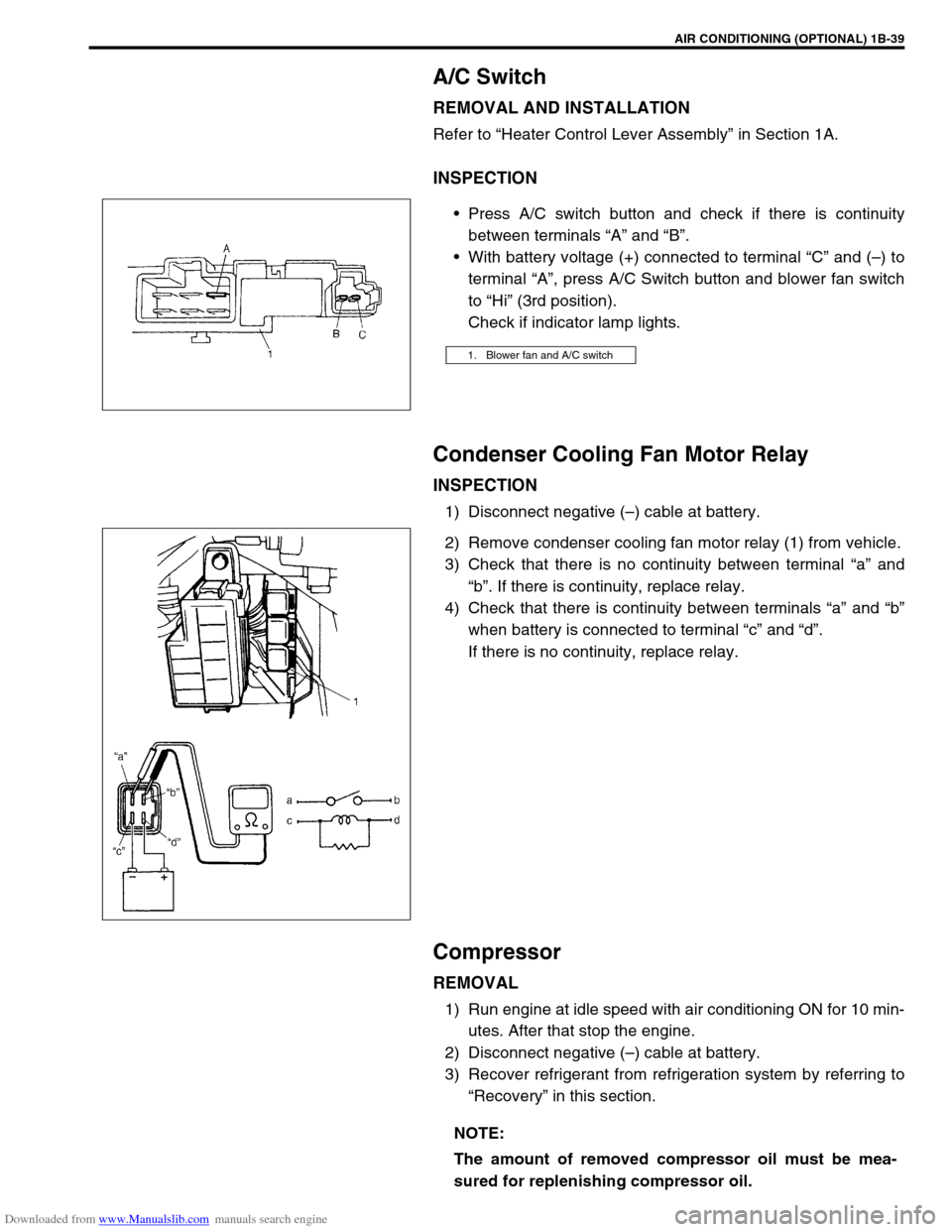

A/C Switch

REMOVAL AND INSTALLATION

Refer to “Heater Control Lever Assembly” in Section 1A.

INSPECTION

Press A/C switch button and check if there is continuity

between terminals “A” and “B”.

With battery voltage (+) connected to terminal “C” and (–) to

terminal “A”, press A/C Switch button and blower fan switch

to “Hi” (3rd position).

Check if indicator lamp lights.

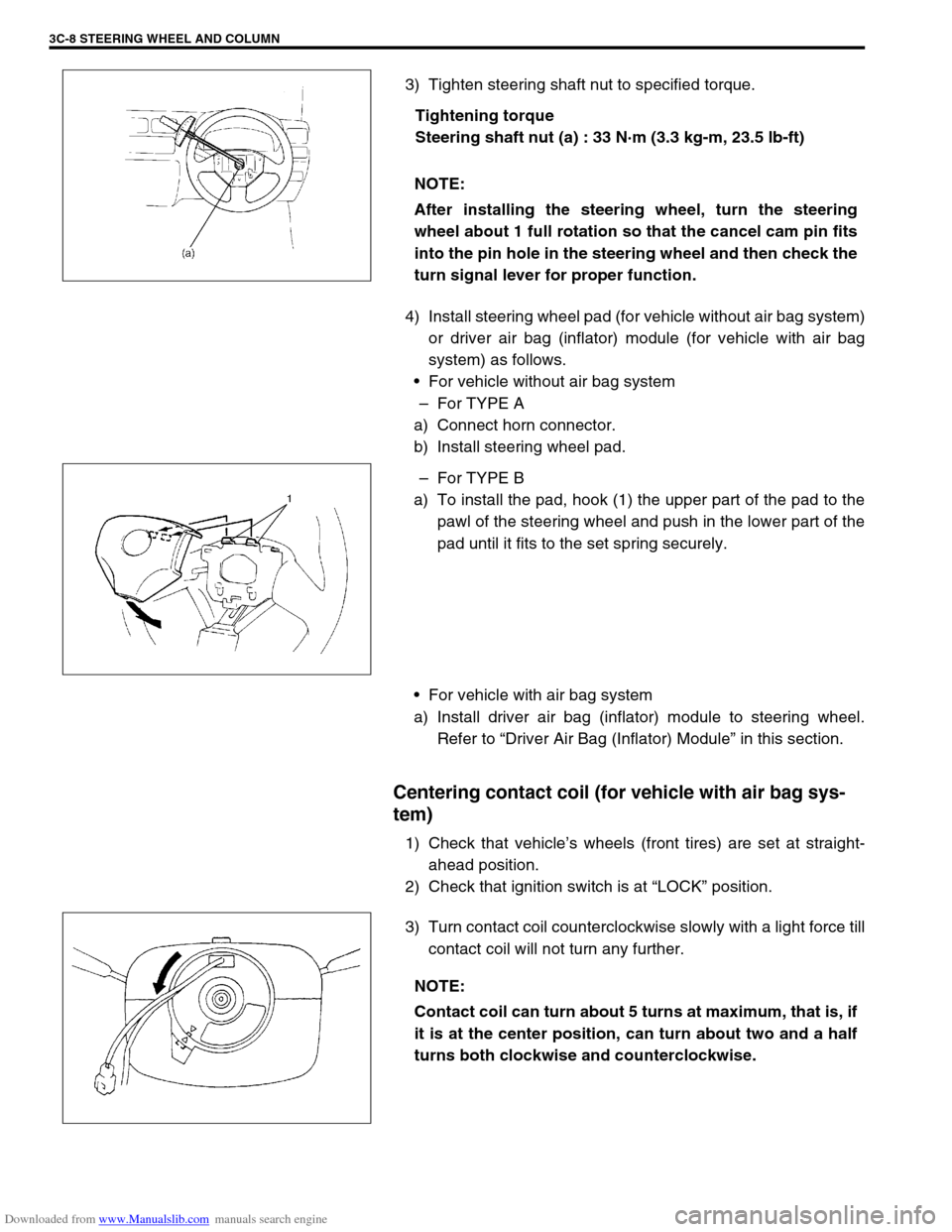

Condenser Cooling Fan Motor Relay

INSPECTION

1) Disconnect negative (–) cable at battery.

2) Remove condenser cooling fan motor relay (1) from vehicle.

3) Check that there is no continuity between terminal “a” and

“b”. If there is continuity, replace relay.

4) Check that there is continuity between terminals “a” and “b”

when battery is connected to terminal “c” and “d”.

If there is no continuity, replace relay.

Compressor

REMOVAL

1) Run engine at idle speed with air conditioning ON for 10 min-

utes. After that stop the engine.

2) Disconnect negative (–) cable at battery.

3) Recover refrigerant from refrigeration system by referring to

“Recovery” in this section.

1. Blower fan and A/C switch

NOTE:

The amount of removed compressor oil must be mea-

sured for replenishing compressor oil.

Page 161 of 687

Downloaded from www.Manualslib.com manuals search engine 3C-8 STEERING WHEEL AND COLUMN

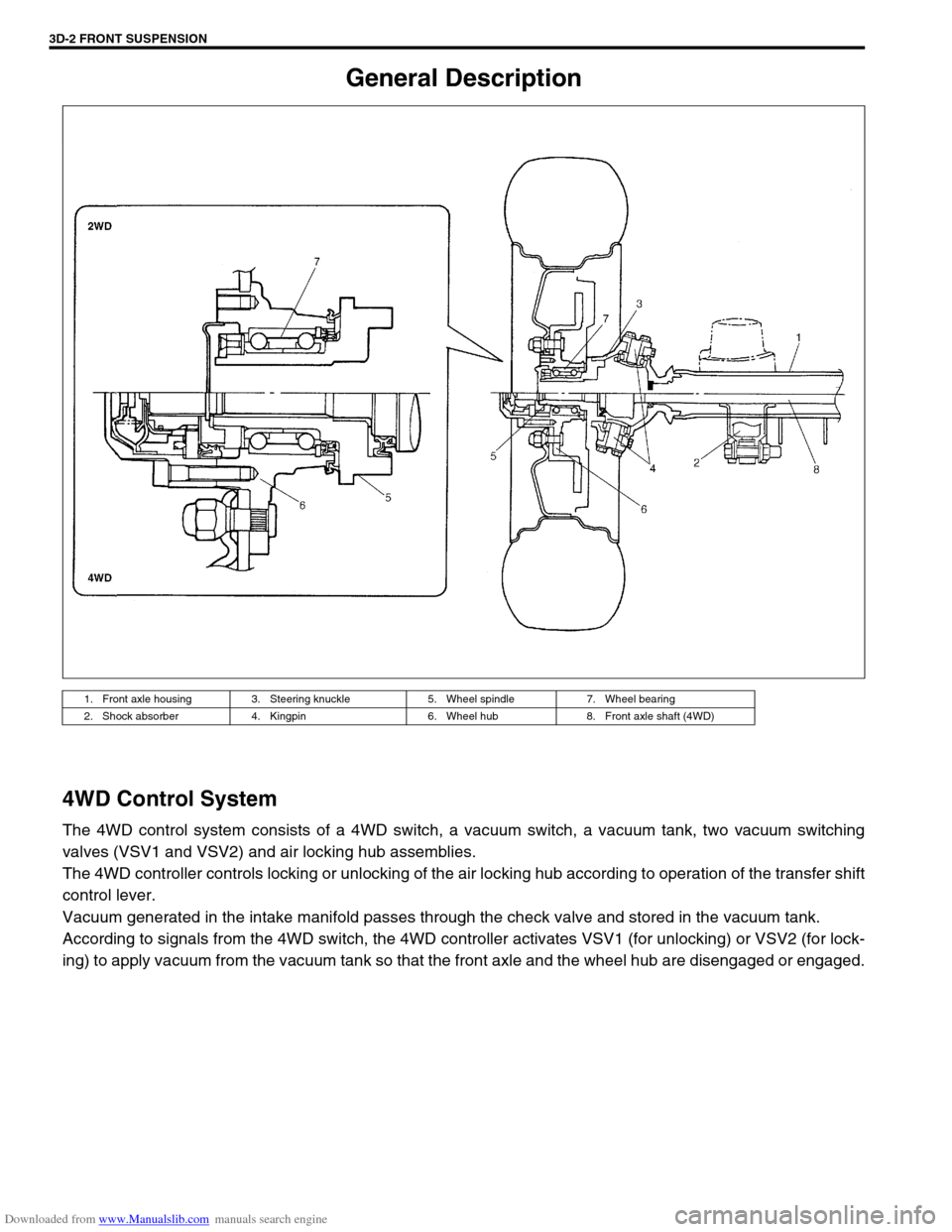

3) Tighten steering shaft nut to specified torque.

Tightening torque

Steering shaft nut (a) : 33 N·m (3.3 kg-m, 23.5 lb-ft)

4) Install steering wheel pad (for vehicle without air bag system)

or driver air bag (inflator) module (for vehicle with air bag

system) as follows.

For vehicle without air bag system

–For TYPE A

a) Connect horn connector.

b) Install steering wheel pad.

–For TYPE B

a) To install the pad, hook (1) the upper part of the pad to the

pawl of the steering wheel and push in the lower part of the

pad until it fits to the set spring securely.

For vehicle with air bag system

a) Install driver air bag (inflator) module to steering wheel.

Refer to “Driver Air Bag (Inflator) Module” in this section.

Centering contact coil (for vehicle with air bag sys-

tem)

1) Check that vehicle’s wheels (front tires) are set at straight-

ahead position.

2) Check that ignition switch is at “LOCK” position.

3) Turn contact coil counterclockwise slowly with a light force till

contact coil will not turn any further. NOTE:

After installing the steering wheel, turn the steering

wheel about 1 full rotation so that the cancel cam pin fits

into the pin hole in the steering wheel and then check the

turn signal lever for proper function.

NOTE:

Contact coil can turn about 5 turns at maximum, that is, if

it is at the center position, can turn about two and a half

turns both clockwise and counterclockwise.

Page 175 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-2 FRONT SUSPENSION

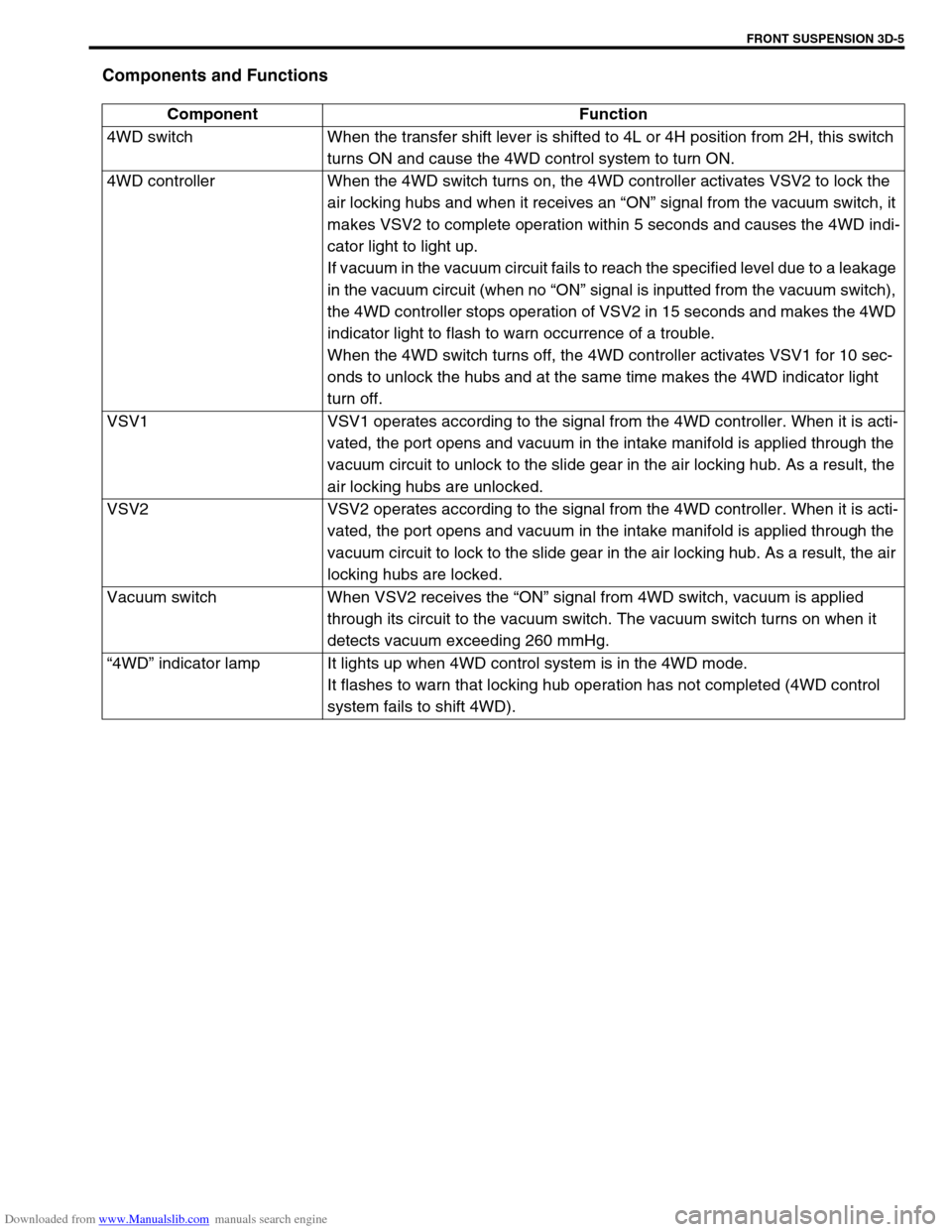

General Description

4WD Control System

The 4WD control system consists of a 4WD switch, a vacuum switch, a vacuum tank, two vacuum switching

valves (VSV1 and VSV2) and air locking hub assemblies.

The 4WD controller controls locking or unlocking of the air locking hub according to operation of the transfer shift

control lever.

Vacuum generated in the intake manifold passes through the check valve and stored in the vacuum tank.

According to signals from the 4WD switch, the 4WD controller activates VSV1 (for unlocking) or VSV2 (for lock-

ing) to apply vacuum from the vacuum tank so that the front axle and the wheel hub are disengaged or engaged.

1. Front axle housing 3. Steering knuckle 5. Wheel spindle 7. Wheel bearing

2. Shock absorber 4. Kingpin 6. Wheel hub 8. Front axle shaft (4WD)

Page 178 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-5

Components and Functions

Component Function

4WD switch When the transfer shift lever is shifted to 4L or 4H position from 2H, this switch

turns ON and cause the 4WD control system to turn ON.

4WD controller When the 4WD switch turns on, the 4WD controller activates VSV2 to lock the

air locking hubs and when it receives an “ON” signal from the vacuum switch, it

makes VSV2 to complete operation within 5 seconds and causes the 4WD indi-

cator light to light up.

If vacuum in the vacuum circuit fails to reach the specified level due to a leakage

in the vacuum circuit (when no “ON” signal is inputted from the vacuum switch),

the 4WD controller stops operation of VSV2 in 15 seconds and makes the 4WD

indicator light to flash to warn occurrence of a trouble.

When the 4WD switch turns off, the 4WD controller activates VSV1 for 10 sec-

onds to unlock the hubs and at the same time makes the 4WD indicator light

turn off.

VSV1 VSV1 operates according to the signal from the 4WD controller. When it is acti-

vated, the port opens and vacuum in the intake manifold is applied through the

vacuum circuit to unlock to the slide gear in the air locking hub. As a result, the

air locking hubs are unlocked.

VSV2 VSV2 operates according to the signal from the 4WD controller. When it is acti-

vated, the port opens and vacuum in the intake manifold is applied through the

vacuum circuit to lock to the slide gear in the air locking hub. As a result, the air

locking hubs are locked.

Vacuum switch When VSV2 receives the “ON” signal from 4WD switch, vacuum is applied

through its circuit to the vacuum switch. The vacuum switch turns on when it

detects vacuum exceeding 260 mmHg.

“4WD” indicator lamp It lights up when 4WD control system is in the 4WD mode.

It flashes to warn that locking hub operation has not completed (4WD control

system fails to shift 4WD).

Page 179 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-6 FRONT SUSPENSION

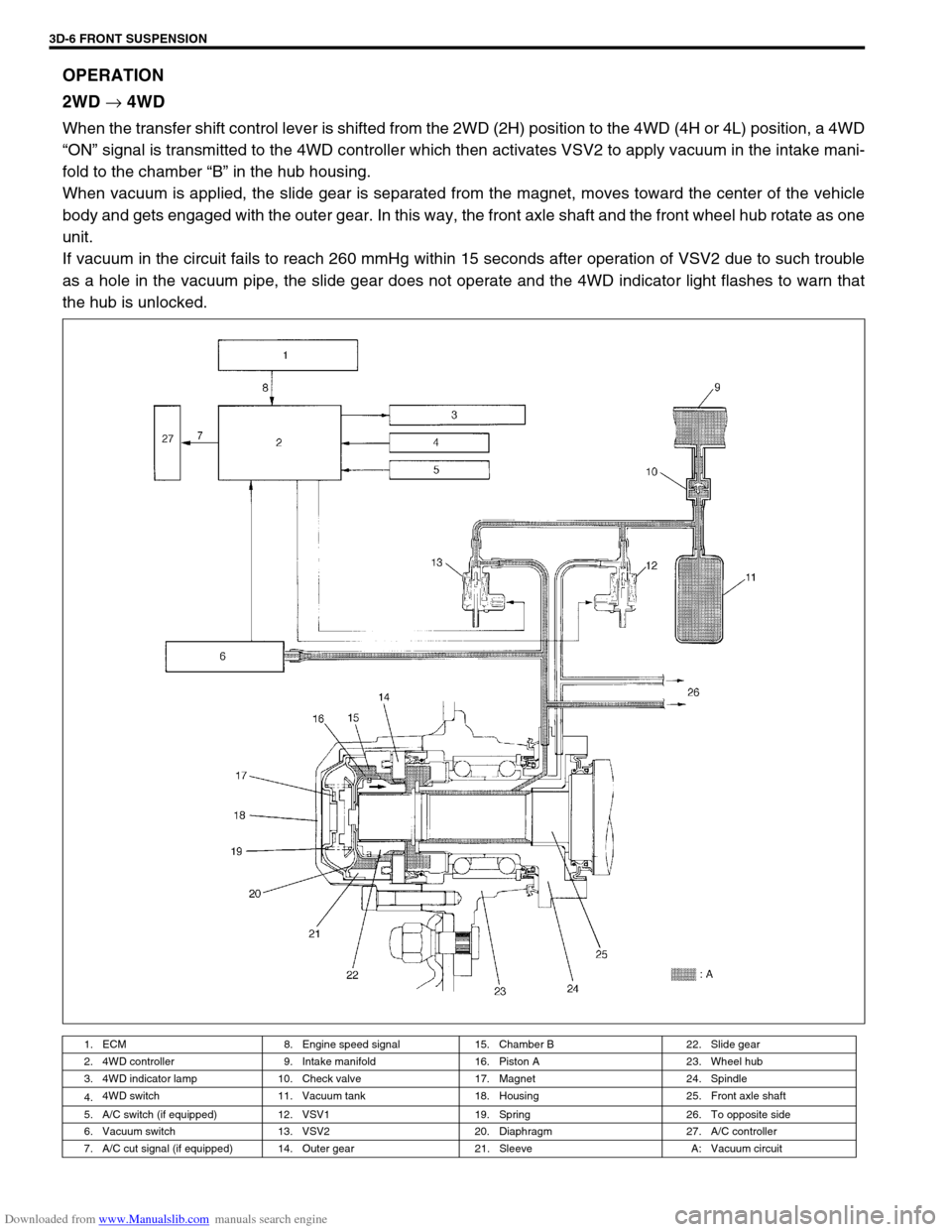

OPERATION

2WD

→ 4WD

When the transfer shift control lever is shifted from the 2WD (2H) position to the 4WD (4H or 4L) position, a 4WD

“ON” signal is transmitted to the 4WD controller which then activates VSV2 to apply vacuum in the intake mani-

fold to the chamber “B” in the hub housing.

When vacuum is applied, the slide gear is separated from the magnet, moves toward the center of the vehicle

body and gets engaged with the outer gear. In this way, the front axle shaft and the front wheel hub rotate as one

unit.

If vacuum in the circuit fails to reach 260 mmHg within 15 seconds after operation of VSV2 due to such trouble

as a hole in the vacuum pipe, the slide gear does not operate and the 4WD indicator light flashes to warn that

the hub is unlocked.

1. ECM 8. Engine speed signal 15. Chamber B 22. Slide gear

2. 4WD controller 9. Intake manifold 16. Piston A 23. Wheel hub

3. 4WD indicator lamp 10. Check valve 17. Magnet 24. Spindle

4.4WD switch 11. Vacuum tank 18. Housing 25. Front axle shaft

5. A/C switch (if equipped) 12. VSV1 19. Spring 26. To opposite side

6. Vacuum switch 13. VSV2 20. Diaphragm 27. A/C controller

7. A/C cut signal (if equipped) 14. Outer gear 21. Sleeve A: Vacuum circuit

Page 180 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-7

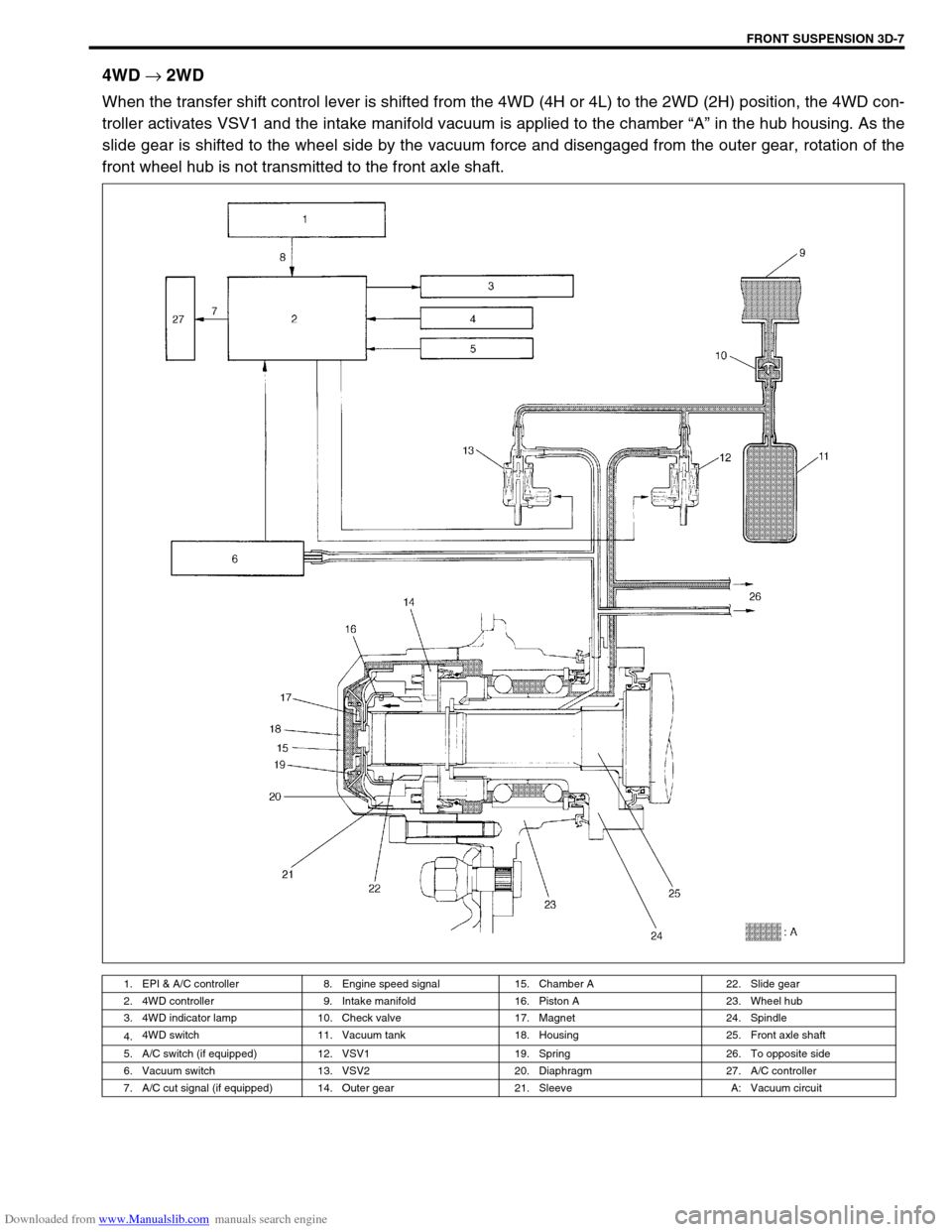

4WD

→ 2WD

When the transfer shift control lever is shifted from the 4WD (4H or 4L) to the 2WD (2H) position, the 4WD con-

troller activates VSV1 and the intake manifold vacuum is applied to the chamber “A” in the hub housing. As the

slide gear is shifted to the wheel side by the vacuum force and disengaged from the outer gear, rotation of the

front wheel hub is not transmitted to the front axle shaft.

1. EPI & A/C controller 8. Engine speed signal 15. Chamber A 22. Slide gear

2. 4WD controller 9. Intake manifold 16. Piston A 23. Wheel hub

3. 4WD indicator lamp 10. Check valve 17. Magnet 24. Spindle

4.4WD switch 11. Vacuum tank 18. Housing 25. Front axle shaft

5. A/C switch (if equipped) 12. VSV1 19. Spring 26. To opposite side

6. Vacuum switch 13. VSV2 20. Diaphragm 27. A/C controller

7. A/C cut signal (if equipped) 14. Outer gear 21. Sleeve A: Vacuum circuit