SUZUKI JIMNY 2005 3.G Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 211 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-38 FRONT SUSPENSION

Front Axle Housing

REMOVAL

1) Hoist vehicle.

2) Remove front wheels.

3) Drain front differential gear oil (for 4WD).

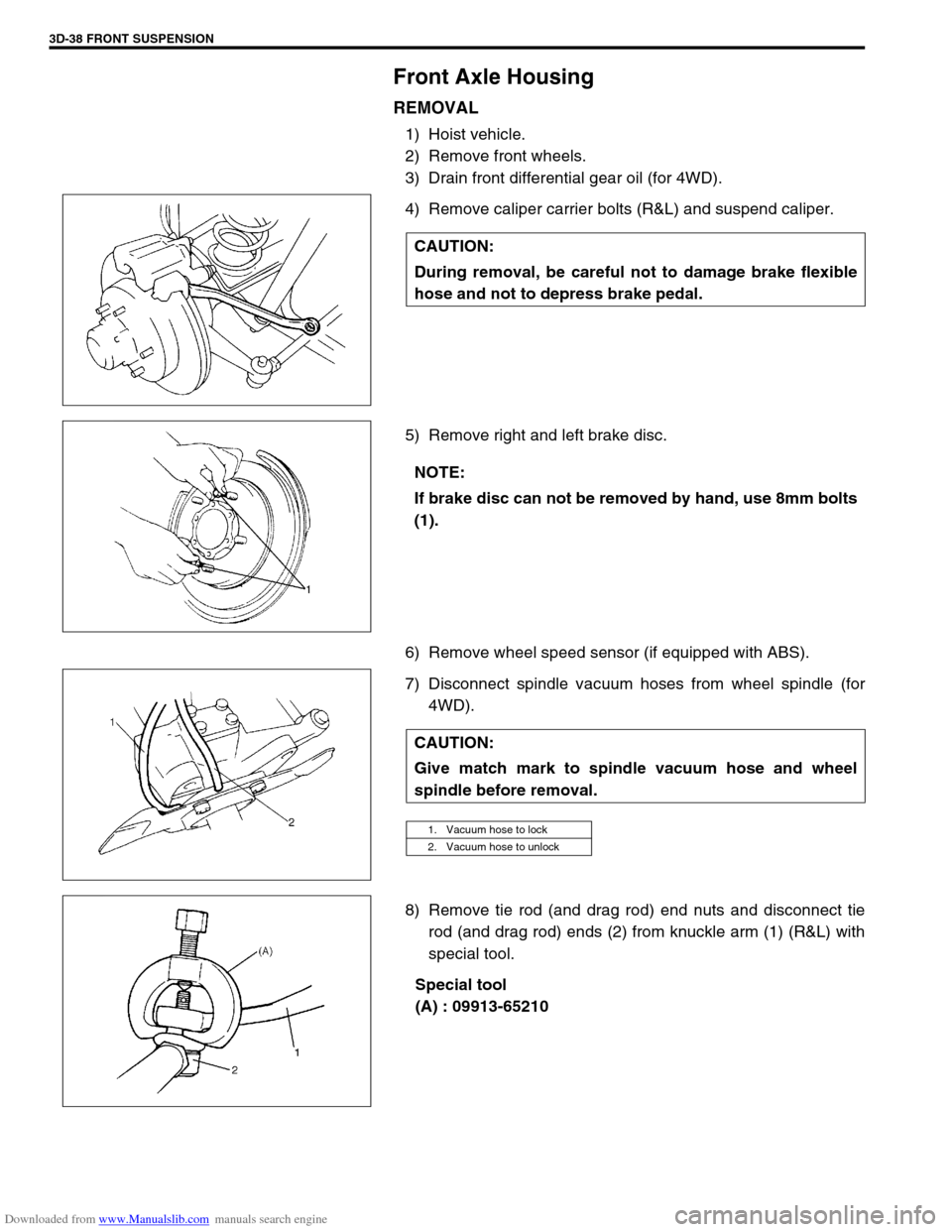

4) Remove caliper carrier bolts (R&L) and suspend caliper.

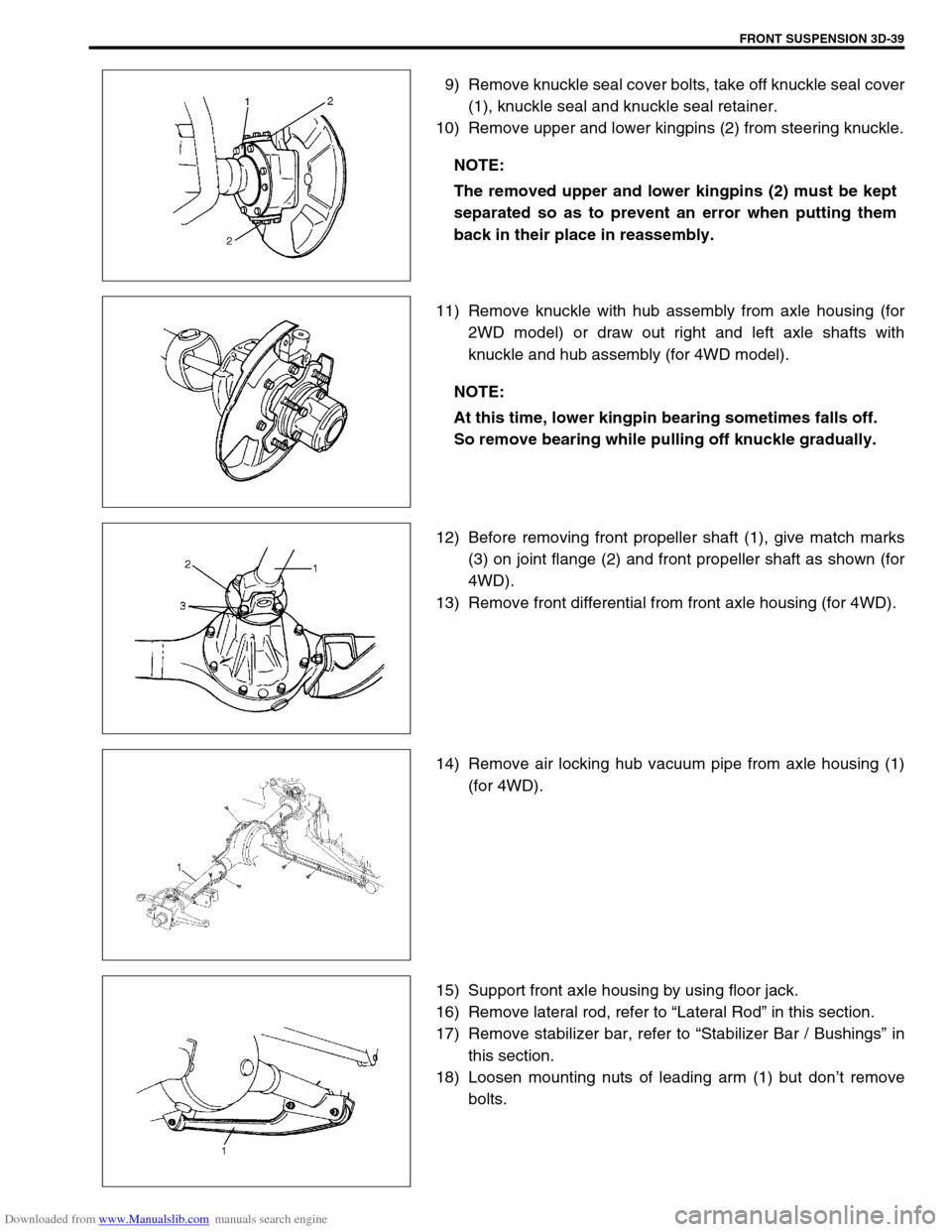

5) Remove right and left brake disc.

6) Remove wheel speed sensor (if equipped with ABS).

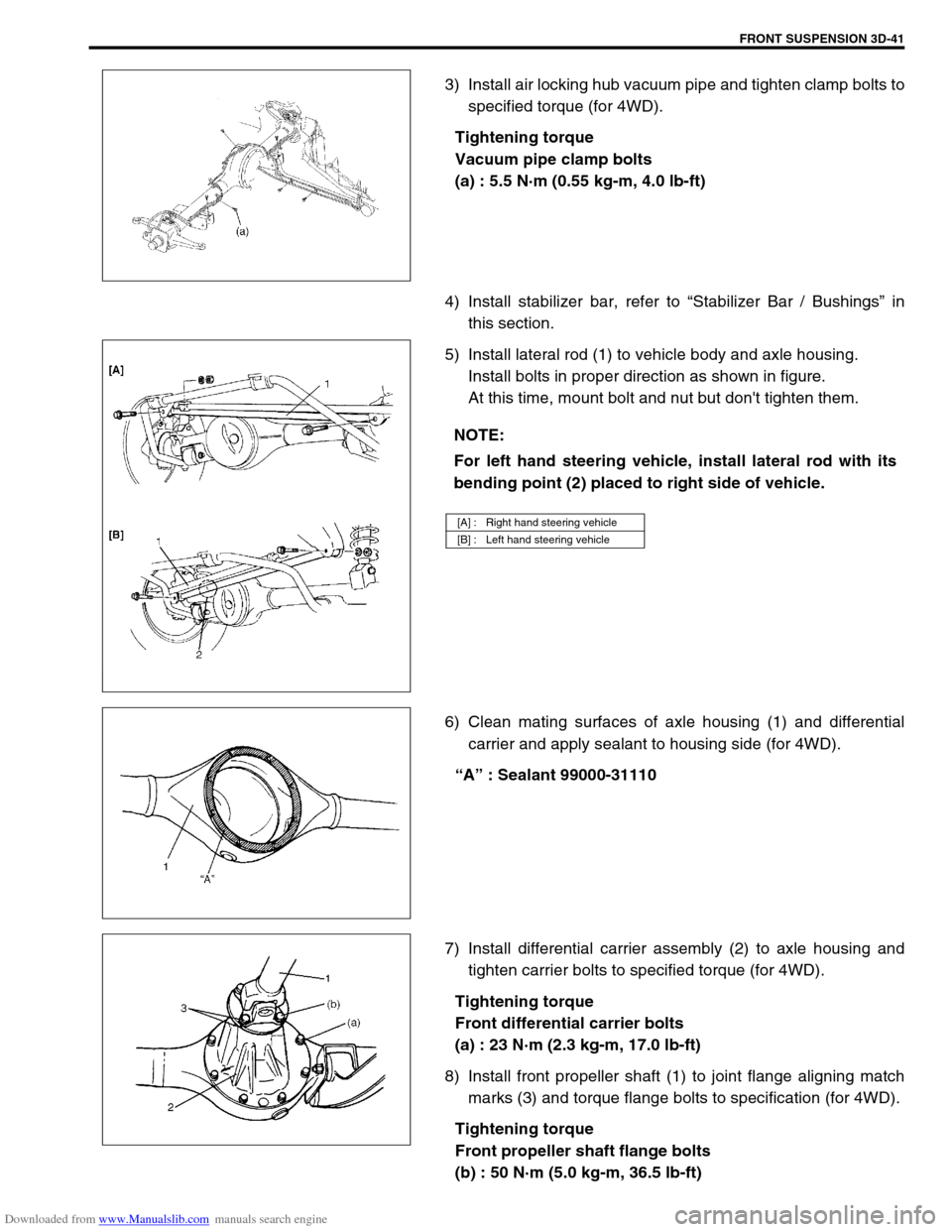

7) Disconnect spindle vacuum hoses from wheel spindle (for

4WD).

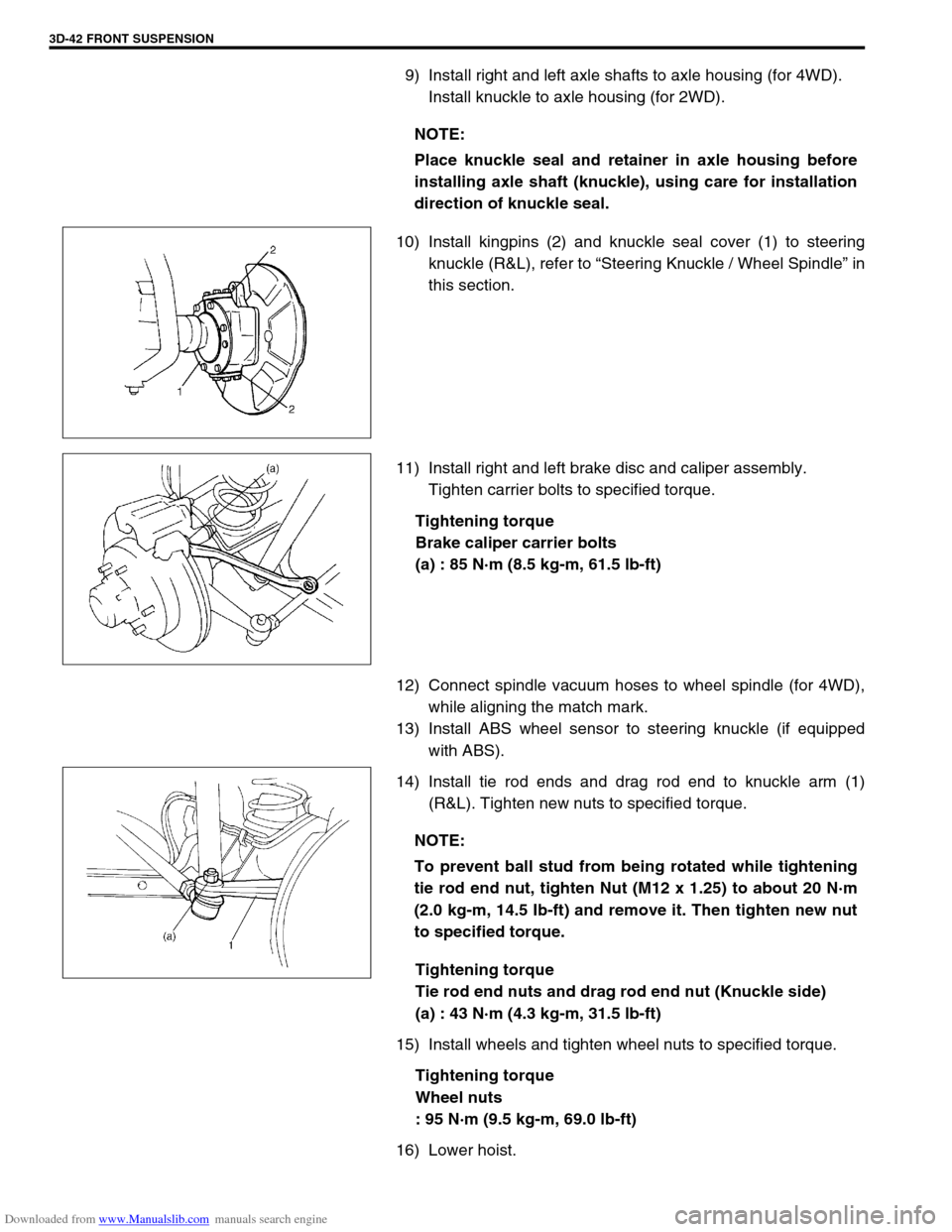

8) Remove tie rod (and drag rod) end nuts and disconnect tie

rod (and drag rod) ends (2) from knuckle arm (1) (R&L) with

special tool.

Special tool

(A) : 09913-65210 CAUTION:

During removal, be careful not to damage brake flexible

hose and not to depress brake pedal.

NOTE:

If brake disc can not be removed by hand, use 8mm bolts

(1).

CAUTION:

Give match mark to spindle vacuum hose and wheel

spindle before removal.

1. Vacuum hose to lock

2. Vacuum hose to unlock

Page 212 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-39

9) Remove knuckle seal cover bolts, take off knuckle seal cover

(1), knuckle seal and knuckle seal retainer.

10) Remove upper and lower kingpins (2) from steering knuckle.

11) Remove knuckle with hub assembly from axle housing (for

2WD model) or draw out right and left axle shafts with

knuckle and hub assembly (for 4WD model).

12) Before removing front propeller shaft (1), give match marks

(3) on joint flange (2) and front propeller shaft as shown (for

4WD).

13) Remove front differential from front axle housing (for 4WD).

14) Remove air locking hub vacuum pipe from axle housing (1)

(for 4WD).

15) Support front axle housing by using floor jack.

16) Remove lateral rod, refer to “Lateral Rod” in this section.

17) Remove stabilizer bar, refer to “Stabilizer Bar / Bushings” in

this section.

18) Loosen mounting nuts of leading arm (1) but don’t remove

bolts. NOTE:

The removed upper and lower kingpins (2) must be kept

separated so as to prevent an error when putting them

back in their place in reassembly.

NOTE:

At this time, lower kingpin bearing sometimes falls off.

So remove bearing while pulling off knuckle gradually.

Page 213 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-40 FRONT SUSPENSION

19) Lower floor jack until tension of suspension coil spring

becomes a little loose and remove right and left sides lower

mounting bolt of shock absorber (1).

20) Remove front mounting bolts of leading arm.

21) Lower front axle housing gradually.

22) Remove axle housing.

INSTALLATION

1) Place rear axle housing on floor jack. Then install leading

arm front mounting bolts (right & left) in proper direction as

shown. At this time, mount nuts but don’t tighten them.

2) Install lower part of shock absorber (1) to right and left sides

of axle housing and install bolts (2) in proper direction as

shown in figure. At this time, mount nuts (3) but don’t tighten

them.

A : Body outside

Page 214 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-41

3) Install air locking hub vacuum pipe and tighten clamp bolts to

specified torque (for 4WD).

Tightening torque

Vacuum pipe clamp bolts

(a) : 5.5 N·m (0.55 kg-m, 4.0 lb-ft)

4) Install stabilizer bar, refer to “Stabilizer Bar / Bushings” in

this section.

5) Install lateral rod (1) to vehicle body and axle housing.

Install bolts in proper direction as shown in figure.

At this time, mount bolt and nut but don't tighten them.

6) Clean mating surfaces of axle housing (1) and differential

carrier and apply sealant to housing side (for 4WD).

“A” : Sealant 99000-31110

7) Install differential carrier assembly (2) to axle housing and

tighten carrier bolts to specified torque (for 4WD).

Tightening torque

Front differential carrier bolts

(a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

8) Install front propeller shaft (1) to joint flange aligning match

marks (3) and torque flange bolts to specification (for 4WD).

Tightening torque

Front propeller shaft flange bolts

(b) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

NOTE:

For left hand steering vehicle, install lateral rod with its

bending point (2) placed to right side of vehicle.

[A] : Right hand steering vehicle

[B] : Left hand steering vehicle

Page 215 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-42 FRONT SUSPENSION

9) Install right and left axle shafts to axle housing (for 4WD).

Install knuckle to axle housing (for 2WD).

10) Install kingpins (2) and knuckle seal cover (1) to steering

knuckle (R&L), refer to “Steering Knuckle / Wheel Spindle” in

this section.

11) Install right and left brake disc and caliper assembly.

Tighten carrier bolts to specified torque.

Tightening torque

Brake caliper carrier bolts

(a) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

12) Connect spindle vacuum hoses to wheel spindle (for 4WD),

while aligning the match mark.

13) Install ABS wheel sensor to steering knuckle (if equipped

with ABS).

14) Install tie rod ends and drag rod end to knuckle arm (1)

(R&L). Tighten new nuts to specified torque.

Tightening torque

Tie rod end nuts and drag rod end nut (Knuckle side)

(a) : 43 N·m (4.3 kg-m, 31.5 lb-ft)

15) Install wheels and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts

: 95 N·m (9.5 kg-m, 69.0 lb-ft)

16) Lower hoist.NOTE:

Place knuckle seal and retainer in axle housing before

installing axle shaft (knuckle), using care for installation

direction of knuckle seal.

NOTE:

To prevent ball stud from being rotated while tightening

tie rod end nut, tighten Nut (M12 x 1.25) to about 20 N·m

(2.0 kg-m, 14.5 Ib-ft) and remove it. Then tighten new nut

to specified torque.

Page 216 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-43

17) Tighten lateral rod (1) mounting bolt and nut to specified

torque.

Tightening torque

Lateral rod bolt and nut

(a) : 90 N·m (9.0 kg-m, 65.0 lb-ft)

18) Tighten right and left shock absorber lower mounting nuts

and leading arm mounting nuts to specified torque.

Tightening torque

Shock absorber lower nuts and leading arm nuts

(a) : 90 N·m (9.0 kg-m, 65.0 lb-ft)

19) Refill front axle (differential) housing with new specified gear

oil. Refer to “Maintenance Service” in Section 7E for refill.

20) Confirm front end (wheel) alignment referring to “Preliminary

Checks Prior to Adjusting Front Alignment” in Section 3A. NOTE:

When tightening bolt and nut, be sure that vehicle is off

hoist and in non loaded condition.

NOTE:

When tightening these nuts, be sure that vehicle is off

hoist and in non loaded condition.

1. Shock absorber

2. Leading arm

Page 217 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-44 FRONT SUSPENSION

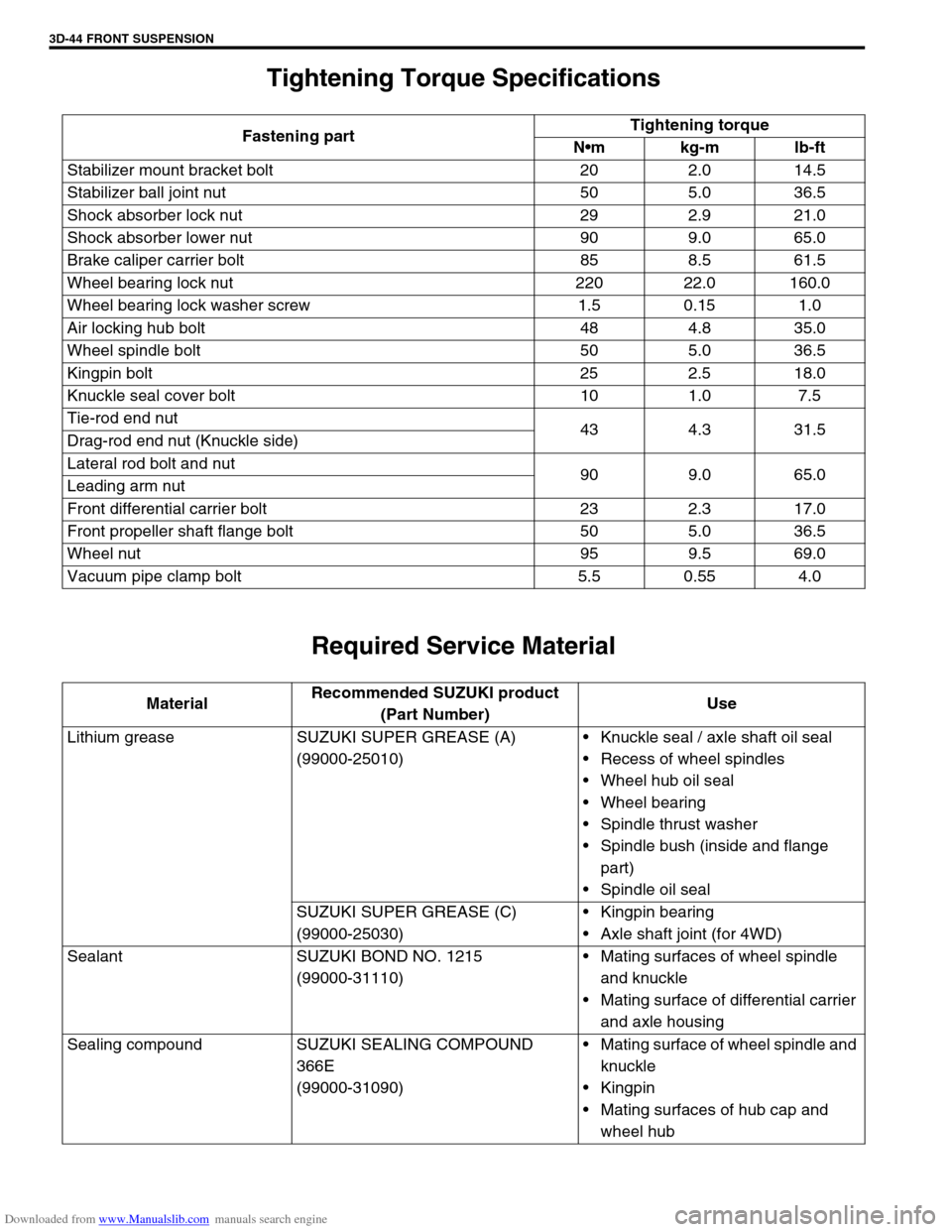

Tightening Torque Specifications

Required Service Material

Fastening partTightening torque

Nm kg-m lb-ft

Stabilizer mount bracket bolt 20 2.0 14.5

Stabilizer ball joint nut 50 5.0 36.5

Shock absorber lock nut 29 2.9 21.0

Shock absorber lower nut 90 9.0 65.0

Brake caliper carrier bolt 85 8.5 61.5

Wheel bearing lock nut 220 22.0 160.0

Wheel bearing lock washer screw 1.5 0.15 1.0

Air locking hub bolt 48 4.8 35.0

Wheel spindle bolt 50 5.0 36.5

Kingpin bolt 25 2.5 18.0

Knuckle seal cover bolt 10 1.0 7.5

Tie-rod end nut

43 4.3 31.5

Drag-rod end nut (Knuckle side)

Lateral rod bolt and nut

90 9.0 65.0

Leading arm nut

Front differential carrier bolt 23 2.3 17.0

Front propeller shaft flange bolt 50 5.0 36.5

Wheel nut 95 9.5 69.0

Vacuum pipe clamp bolt 5.5 0.55 4.0

MaterialRecommended SUZUKI product

(Part Number)Use

Lithium grease SUZUKI SUPER GREASE (A)

(99000-25010)Knuckle seal / axle shaft oil seal

Recess of wheel spindles

Wheel hub oil seal

Wheel bearing

Spindle thrust washer

Spindle bush (inside and flange

part)

Spindle oil seal

SUZUKI SUPER GREASE (C)

(99000-25030)Kingpin bearing

Axle shaft joint (for 4WD)

Sealant SUZUKI BOND NO. 1215

(99000-31110)Mating surfaces of wheel spindle

and knuckle

Mating surface of differential carrier

and axle housing

Sealing compound SUZUKI SEALING COMPOUND

366E

(99000-31090)Mating surface of wheel spindle and

knuckle

Kingpin

Mating surfaces of hub cap and

wheel hub

Page 218 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-45

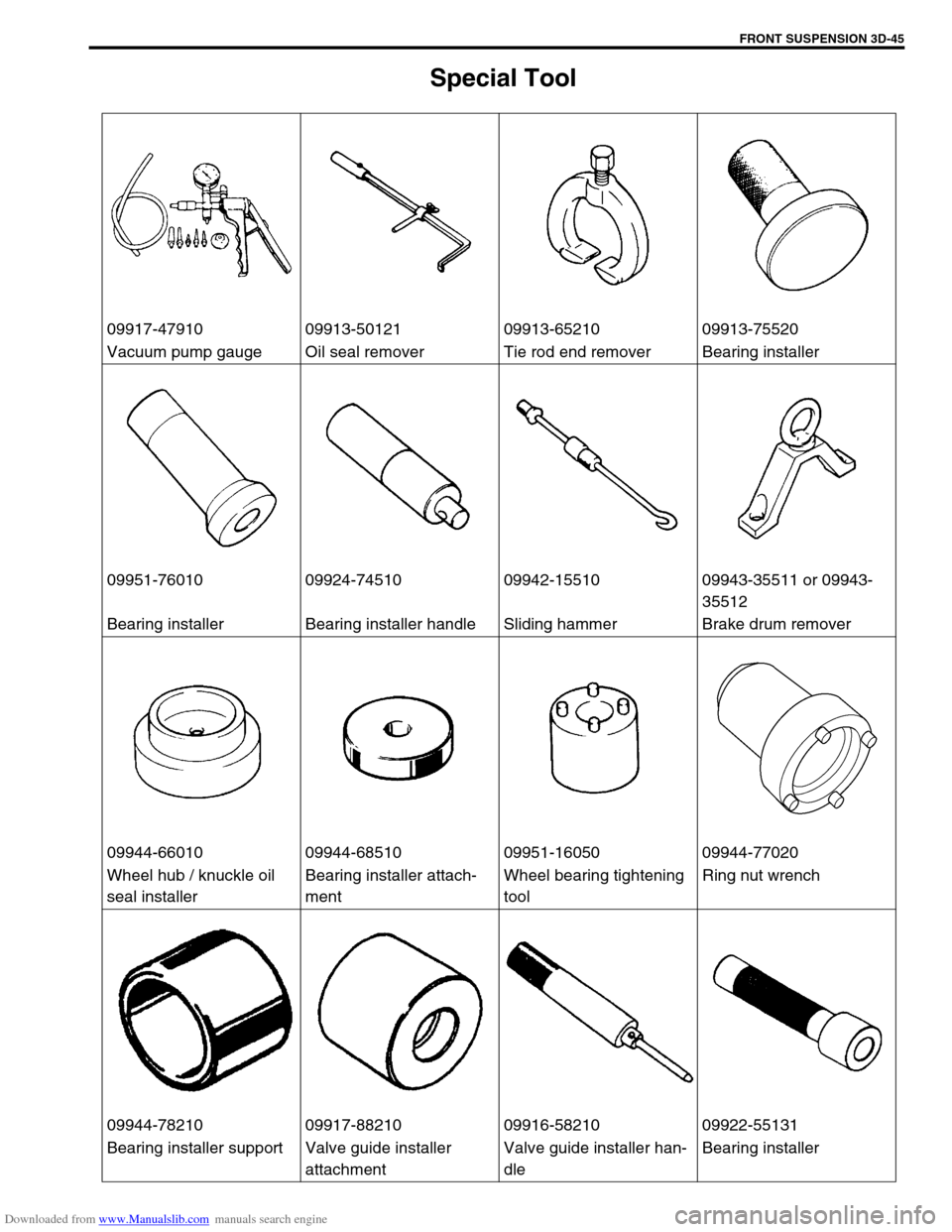

Special Tool

09917-47910 09913-50121 09913-65210 09913-75520

Vacuum pump gauge Oil seal remover Tie rod end remover Bearing installer

09951-76010 09924-74510 09942-15510 09943-35511 or 09943-

35512

Bearing installer Bearing installer handle Sliding hammer Brake drum remover

09944-66010 09944-68510 09951-16050 09944-77020

Wheel hub / knuckle oil

seal installerBearing installer attach-

mentWheel bearing tightening

toolRing nut wrench

09944-78210 09917-88210 09916-58210 09922-55131

Bearing installer support Valve guide installer

attachmentValve guide installer han-

dleBearing installer

Page 219 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-46 FRONT SUSPENSION

09944-66020 09913-85210 09951-16030 09951-26010

Bearing installer Oil seal installer Bush remover Bush remover plate

Page 220 of 687

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION 3E-1

6F1

6F2

6G

1A

6K

7A

7A1

7B1

3E

8A

8B

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3E

REAR SUSPENSION

CONTENTS

General Description ....................................... 3E-2

Diagnosis ........................................................ 3E-3

Diagnosis Table ........................................... 3E-3

Rear Shock Absorber Check ........................ 3E-3

Trailing Arm, Lateral Rod, Axle Housing

and Coil Spring Check ................................. 3E-3

Trailing Arm and Lateral Rod Bush Check ... 3E-3

Rear Suspension Fasteners ......................... 3E-4

Bearing Retainer and Axle Shaft Oil Seal

Check ........................................................... 3E-4

Bump Stopper and Spring Rubber Seat

Check ........................................................... 3E-4

Wheel Disc, Nut and Bearing Check ............ 3E-4On-Vehicle Service ........................................ 3E-5

Rear Shock Absorber................................... 3E-5

Coil Spring ................................................... 3E-6

Bump Stopper .............................................. 3E-9

Lateral Rod .................................................. 3E-9

Trailing Arm / Bushing................................ 3E-10

Rear Axle Shaft and Wheel Bearing .......... 3E-12

Rear Axle Shaft Inner Oil Seal ................... 3E-17

Rear Axle Housing ..................................... 3E-18

Tightening Torque Specifications .............. 3E-22

Required Service Materials ......................... 3E-22

Special Tools ................................................ 3E-23

WARNING:

When hoisting vehicle, be sure to select the lifting point suitable for the service work referring to Sec-

tion 0A.

NOTE:

All suspension fasteners are an important attaching part in that it could affect the performance of

vital parts and systems, and/or could result in major repair expense. They must be replaced with

one of the same part number or with an equivalent part if replacement becomes necessary. Do not

use a replacement part of lesser quality or substitute design. Torque values must be used as speci-

fied during reassembly to assure proper retention of this part.

Never attempt to heat, quench or straighten any suspension part. Replace it with a new part, or

damage to the part may result.