check engine SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 467 of 687

Downloaded from www.Manualslib.com manuals search engine 6-110 ENGINE GENERAL INFORMATION AND DIAGNOSIS

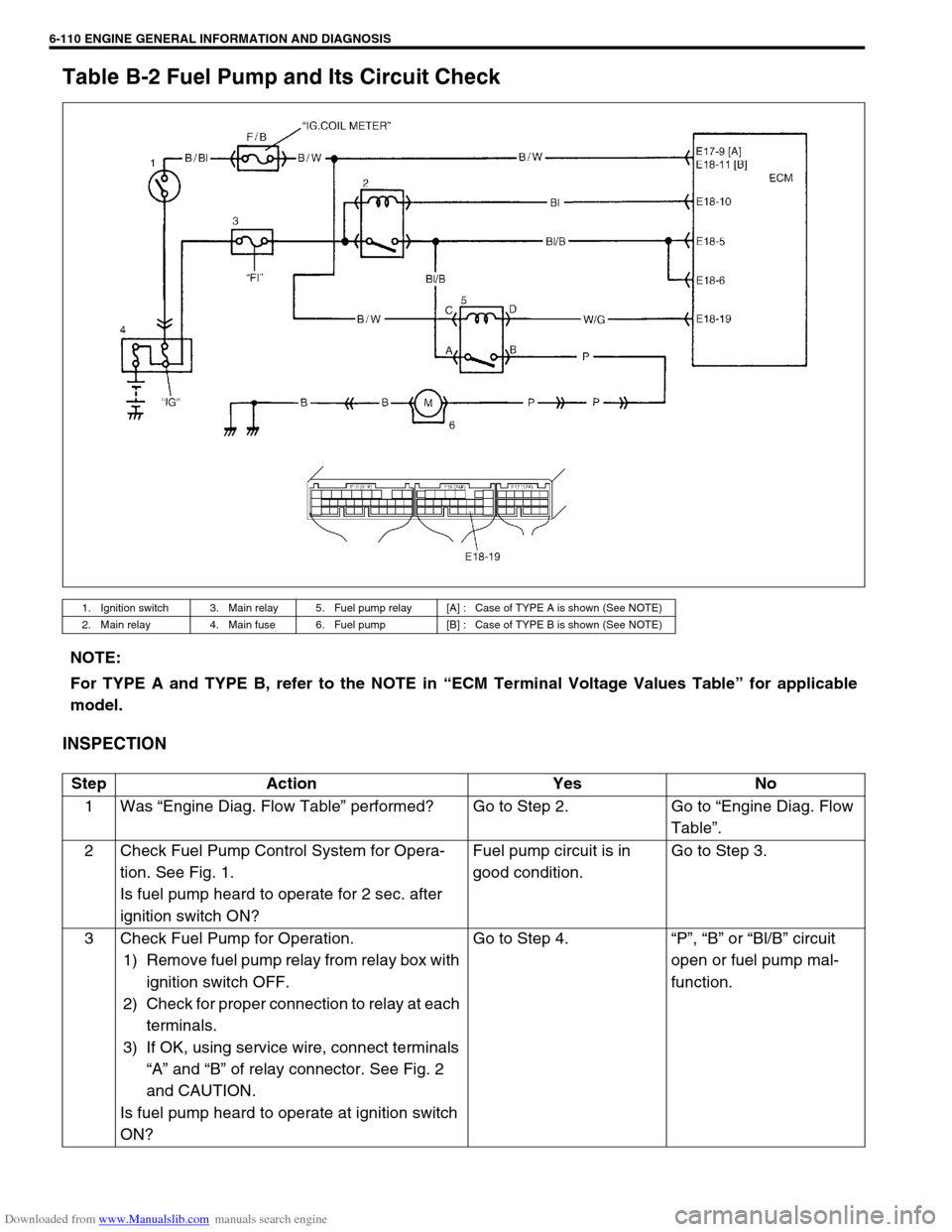

Table B-2 Fuel Pump and Its Circuit Check

INSPECTION

1. Ignition switch 3. Main relay 5. Fuel pump relay [A] : Case of TYPE A is shown (See NOTE)

2. Main relay 4. Main fuse 6. Fuel pump [B] : Case of TYPE B is shown (See NOTE)

NOTE:

For TYPE A and TYPE B, refer to the NOTE in “ECM Terminal Voltage Values Table” for applicable

model.

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Check Fuel Pump Control System for Opera-

tion. See Fig. 1.

Is fuel pump heard to operate for 2 sec. after

ignition switch ON?Fuel pump circuit is in

good condition.Go to Step 3.

3 Check Fuel Pump for Operation.

1) Remove fuel pump relay from relay box with

ignition switch OFF.

2) Check for proper connection to relay at each

terminals.

3) If OK, using service wire, connect terminals

“A” and “B” of relay connector. See Fig. 2

and CAUTION.

Is fuel pump heard to operate at ignition switch

ON?Go to Step 4.“P”, “B” or “Bl/B” circuit

open or fuel pump mal-

function.

Page 468 of 687

![SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-111

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3 / [C] Fig. 3 for Step 44 Check Fuel Pump Relay for SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-111

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3 / [C] Fig. 3 for Step 44 Check Fuel Pump Relay for](/img/20/7588/w960_7588-467.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-111

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3 / [C] Fig. 3 for Step 44 Check Fuel Pump Relay for Operation.

1) Check resistance between each two termi-

nals of fuel pump relay. See Fig.3.

Fuel pump relay resistance

Between terminals “A” and “B” : Infinity

Between terminals “C” and “D”: 100 – 150

Ω

ΩΩ Ω

2) Check that there is continuity between ter-

minals “A” and “B” when battery is con-

nected to terminals “C” and “D”. See Fig. 3.

Is fuel pump relay in good condition?“W/G” circuit open or poor

E18-19 connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.Replace fuel pump

relay. Step Action Yes No

CAUTION:

Check to make sure that connection is made between correct terminals. Wrong connection can cause

damage to ECM, wire harness, etc.

Page 469 of 687

Downloaded from www.Manualslib.com manuals search engine 6-112 ENGINE GENERAL INFORMATION AND DIAGNOSIS

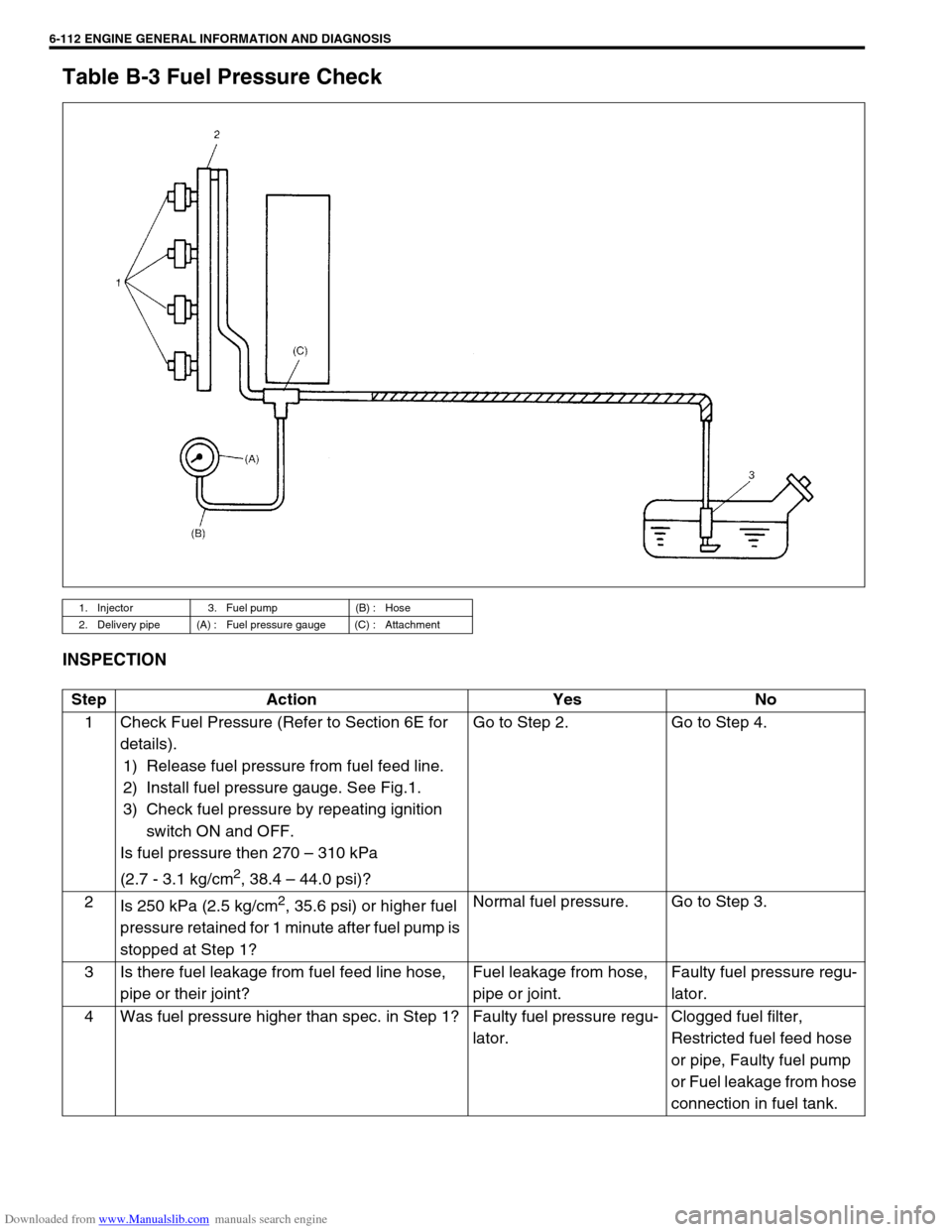

Table B-3 Fuel Pressure Check

INSPECTION

1. Injector 3. Fuel pump (B) : Hose

2. Delivery pipe (A) : Fuel pressure gauge (C) : Attachment

Step Action Yes No

1 Check Fuel Pressure (Refer to Section 6E for

details).

1) Release fuel pressure from fuel feed line.

2) Install fuel pressure gauge. See Fig.1.

3) Check fuel pressure by repeating ignition

switch ON and OFF.

Is fuel pressure then 270 – 310 kPa

(2.7 - 3.1 kg/cm

2, 38.4 – 44.0 psi)?Go to Step 2. Go to Step 4.

2

Is 250 kPa (2.5 kg/cm

2, 35.6 psi) or higher fuel

pressure retained for 1 minute after fuel pump is

stopped at Step 1?Normal fuel pressure. Go to Step 3.

3 Is there fuel leakage from fuel feed line hose,

pipe or their joint?Fuel leakage from hose,

pipe or joint.Faulty fuel pressure regu-

lator.

4 Was fuel pressure higher than spec. in Step 1? Faulty fuel pressure regu-

lator.Clogged fuel filter,

Restricted fuel feed hose

or pipe, Faulty fuel pump

or Fuel leakage from hose

connection in fuel tank.

Page 471 of 687

Downloaded from www.Manualslib.com manuals search engine 6-114 ENGINE GENERAL INFORMATION AND DIAGNOSIS

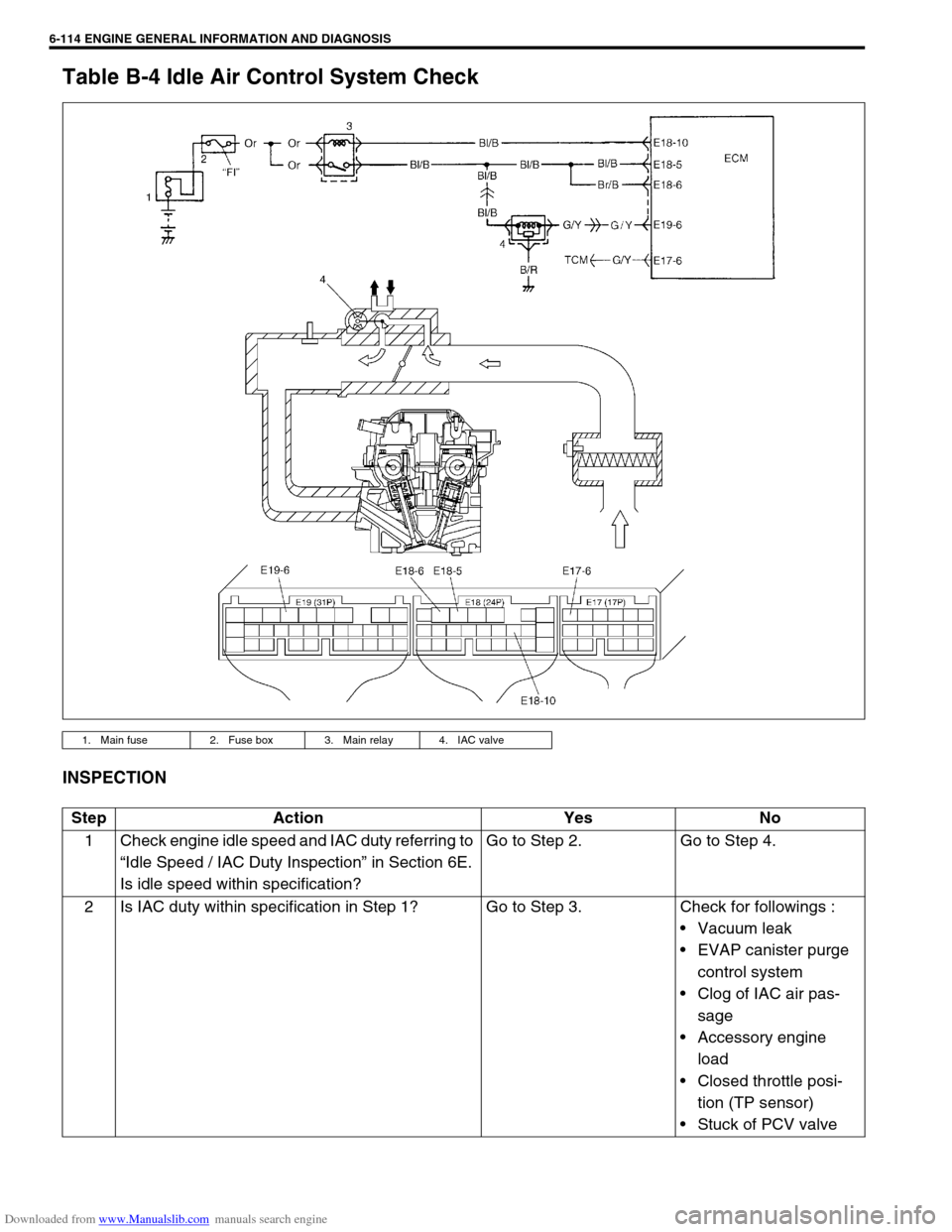

Table B-4 Idle Air Control System Check

INSPECTION

1. Main fuse 2. Fuse box 3. Main relay 4. IAC valve

Step Action Yes No

1 Check engine idle speed and IAC duty referring to

“Idle Speed / IAC Duty Inspection” in Section 6E.

Is idle speed within specification?Go to Step 2. Go to Step 4.

2 Is IAC duty within specification in Step 1? Go to Step 3. Check for followings :

Vacuum leak

EVAP canister purge

control system

Clog of IAC air pas-

sage

Accessory engine

load

Closed throttle posi-

tion (TP sensor)

Stuck of PCV valve

Page 472 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-115

3 Is engine idle speed kept specified speed even

with headlight ON?System is in good condi-

tion.Check IAC system for

operation referring to

Step 3 or Step 4 of DTC

P0505 Diag. Flow Table.

4 Was idle speed higher than specification in Step

1?Go to Step 5. Go to Step 8.

5 Check A/C (input) signal circuit referring to Step 1

of Table B-5 A/C Signal Circuit Check, if

equipped. (A/C signal can be also checked by

using SUZUKI scan tool.)

Is it in good condition?Go to Step 6. Repair or replace A/C

signal circuit or A/C sys-

tem.

6 Check IAC system referring to Step 2 to Step 4 of

DTC P0505 Diag. Flow Table.

Is check result satisfactory?Go to Step 7. Go to Step 5 of DTC

P0505 Diag. Flow Table.

7 Was IAC duty less than about 3% (or more than

about 97% for OFF duty meter) in Step 1 of this

table?Check abnormal air

inhaling from air intake

system, PCV valve and

EVAP canister purge

control system.Check TP sensor

(closed throttle position)

and ECT sensor for per-

formance.

If sensors are OK, sub-

stitute a known-good

ECM.

8 Is SUZUKI scan tool available? Go to Step 9. Go to Step 10.

9 Check PNP signal (“D” range signal).

1) Connect SUZUKI scan tool to DLC with igni-

tion switch OFF.

2) Turn ignition switch ON and check PNP signal

(“P/N” and “D” range) on display when shifting

selector lever to each range. See Table 1.

Is check result satisfactory?Go to Step 11. Repair or replace.

10 Check PNP signal (“D” range signal).

1) Turn ignition switch ON.

2) Check voltage at terminal E17-6 of ECM con-

nector connected. See Fig. 1 and Table 1.

Is check result satisfactory?Go to Step 11. Repair or replace.

11 Check IAC system referring to Step 2 to Step 4 of

DTC P0505 Diag. Flow Table.

Is check result satisfactory?Go to Step 12. Go to Step 5 of DTC

P0505 Diag. Flow Table.

12 Was IAC duty more than about 30% or ✱40% (or

less than 70% or ✱60% for OFF duty meter) in

Step 1 of this table? See NOTE.Check parts or system

which can cause engine

low idle.

Accessory engine load

Clog of air passage

Etc.Substitute a known-good

ECM and recheck. Step Action Yes No

NOTE:

Duty value with (

✱

✱✱ ✱) are applicable to vehicle used at high altitude (higher than 2000 m or 6560 ft).

Page 474 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-117

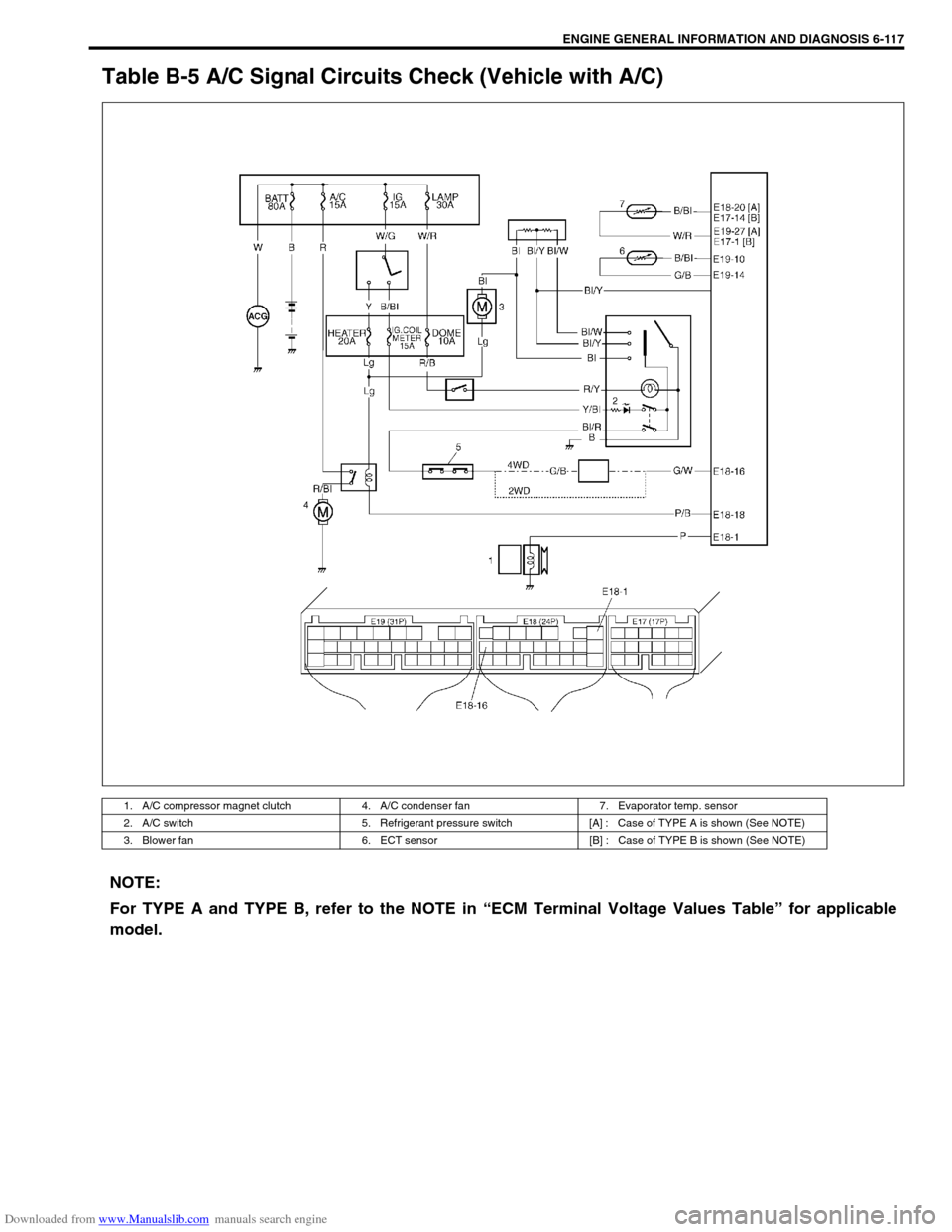

Table B-5 A/C Signal Circuits Check (Vehicle with A/C)

1. A/C compressor magnet clutch 4. A/C condenser fan 7. Evaporator temp. sensor

2. A/C switch 5. Refrigerant pressure switch [A] : Case of TYPE A is shown (See NOTE)

3. Blower fan 6. ECT sensor [B] : Case of TYPE B is shown (See NOTE)

NOTE:

For TYPE A and TYPE B, refer to the NOTE in “ECM Terminal Voltage Values Table” for applicable

model.

Page 475 of 687

Downloaded from www.Manualslib.com manuals search engine 6-118 ENGINE GENERAL INFORMATION AND DIAGNOSIS

INSPECTION

Fig. 1 for Step 1Step Action Yes No

1 Check evaporator temp. sensor.

1) Disconnect ECM connectors with ignition

switch at OFF position.

2) Check resistance between E19-14 terminal

and E19-10 terminal.

Reference value

(Refer to characteristic curve below)

ECT sensor resistance

At 0°C 6.3 – 6.9 k

Ω

ΩΩ Ω

At 25°C 1.8 – 2.2 k

Ω

ΩΩ Ω

Is it within specification?Go to Step 2. Faulty A/C evaporator

thermistor or its circuit.

2 Check A/C switch circuit.

1) Check voltage at E18-16 terminal under

each condition given below.

A/C switch signal specification

Ignition switch ON A/C switch OFF

: 10 – 14 V

Ignition switch ON A/C switch ON

: 0 – 1 V

Is check result satisfactory?Go to Step 3.“G/W” wire open or short

Poor E18-16 terminal con-

nection

If wire and connection are

OK, substitute a known-

good ECM and recheck.

Go to Step 3.

3 Check A/C compressor signal.

1) Check voltage at E18-1 terminal under each

condition given below. See NOTE.

A/C compressor signal specification

While engine running, A/C switch OFF

: 0 V

While engine running, A/C switch ON

: 10 – 14 V

Is check result satisfactory?A/C control system cir-

cuits are in good condi-

tion.“P” wire open or short

Poor E18-1 terminal con-

nection

If wire and connection are

OK, substitute a known-

good ECM and recheck.

NOTE:

When A/C evaporator thermistor temp. is below 2.5 °C (36.5 °F), A/C remain OFF (E18-1 terminal volt-

age become 0 – 1 V). This condition is not abnormal.

Page 476 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-119

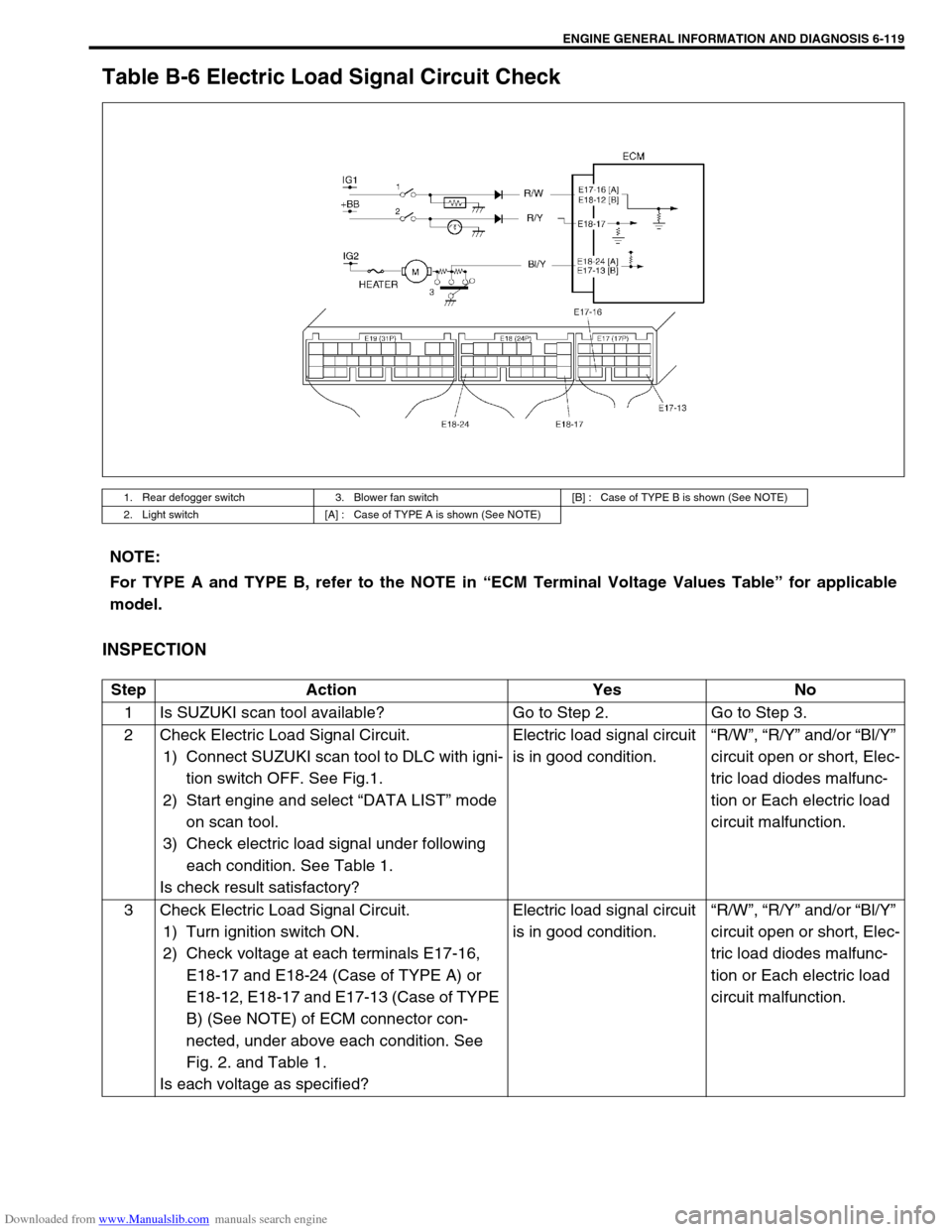

Table B-6 Electric Load Signal Circuit Check

INSPECTION

1. Rear defogger switch 3. Blower fan switch [B] : Case of TYPE B is shown (See NOTE)

2. Light switch [A] : Case of TYPE A is shown (See NOTE)

NOTE:

For TYPE A and TYPE B, refer to the NOTE in “ECM Terminal Voltage Values Table” for applicable

model.

Step Action Yes No

1 Is SUZUKI scan tool available? Go to Step 2. Go to Step 3.

2 Check Electric Load Signal Circuit.

1) Connect SUZUKI scan tool to DLC with igni-

tion switch OFF. See Fig.1.

2) Start engine and select “DATA LIST” mode

on scan tool.

3) Check electric load signal under following

each condition. See Table 1.

Is check result satisfactory?Electric load signal circuit

is in good condition.“R/W”, “R/Y” and/or “Bl/Y”

circuit open or short, Elec-

tric load diodes malfunc-

tion or Each electric load

circuit malfunction.

3 Check Electric Load Signal Circuit.

1) Turn ignition switch ON.

2) Check voltage at each terminals E17-16,

E18-17 and E18-24 (Case of TYPE A) or

E18-12, E18-17 and E17-13 (Case of TYPE

B) (See NOTE) of ECM connector con-

nected, under above each condition. See

Fig. 2. and Table 1.

Is each voltage as specified?Electric load signal circuit

is in good condition.“R/W”, “R/Y” and/or “Bl/Y”

circuit open or short, Elec-

tric load diodes malfunc-

tion or Each electric load

circuit malfunction.

Page 478 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-121

TAble B-7 A/C Condenser Fan Control System Check

INSPECTION

Step Action Yes No

1 Check Fan Control System.

1) Connect scan tool to DLC with ignition switch OFF. See

Fig. 1.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Warm up engine until coolant temp. is 110 °C, 230 °F or

higher and A/C switch turn OFF. (If engine coolant temp.

does not rise, check engine cooling system or ECT sen-

sor.)

Is A/C condenser fan started when engine coolant temp.

reached above temp.?A/C condenser fan con-

trol system is in good

condition.Go to Step 2.

2 Check A/C Condenser Fan Relay and Its Circuit.

1) Check DTC and pending DTC with scan tool.

Is DTC P0481 displayed?Go to DTC P0481 Diag.

Flow Table.Go to Step 3.

3 Check A/C Condenser Fan Relay (1).

1) Turn ignition switch OFF and remove A/C condenser fan

relay.

2) Check for proper connection to relay at terminals “A”

and “B”.

3) If OK, check that there is continuity between “A” and “B”

when battery is connected to terminals “C” and “D”. See

Fig. 2.

Is check result satisfactory?Go to Step 4. Replace A/C

condenser fan

relay.

Page 479 of 687

![SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6-122 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 1 / [B] Fig. 2 for Step 3

Fig. 3 for Step 44 Check A/C Condenser Fan (1).

1) SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6-122 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 1 / [B] Fig. 2 for Step 3

Fig. 3 for Step 44 Check A/C Condenser Fan (1).

1)](/img/20/7588/w960_7588-478.png)

Downloaded from www.Manualslib.com manuals search engine 6-122 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 1 / [B] Fig. 2 for Step 3

Fig. 3 for Step 44 Check A/C Condenser Fan (1).

1) Turn ignition switch OFF.

2) Disconnect fan motor connector (2).

3) Check for proper connection to motor at “R/Bl” and “B”

terminals.

4) If OK, connect battery to motor and check for operation.

See Fig. 3.

Is it in good condition?“R”, “R/Bl” or “B” circuit

open.Replace A/C

condenser fan

motor. Step Action Yes No