Steering assembly SUZUKI JIMNY 2005 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 166 of 687

Downloaded from www.Manualslib.com manuals search engine STEERING WHEEL AND COLUMN 3C-13

8) If equipped with shift (key) interlock cable (1), remove shift

(key) interlock cable screw (2) and then disconnect its cable

from ignition switch in order a) – c) as shown in the figure.

9) Remove steering column from vehicle.

10) Remove steering column seal (1) from steering column lower

bracket.

INSPECTION

CHECKING PROCEDURE

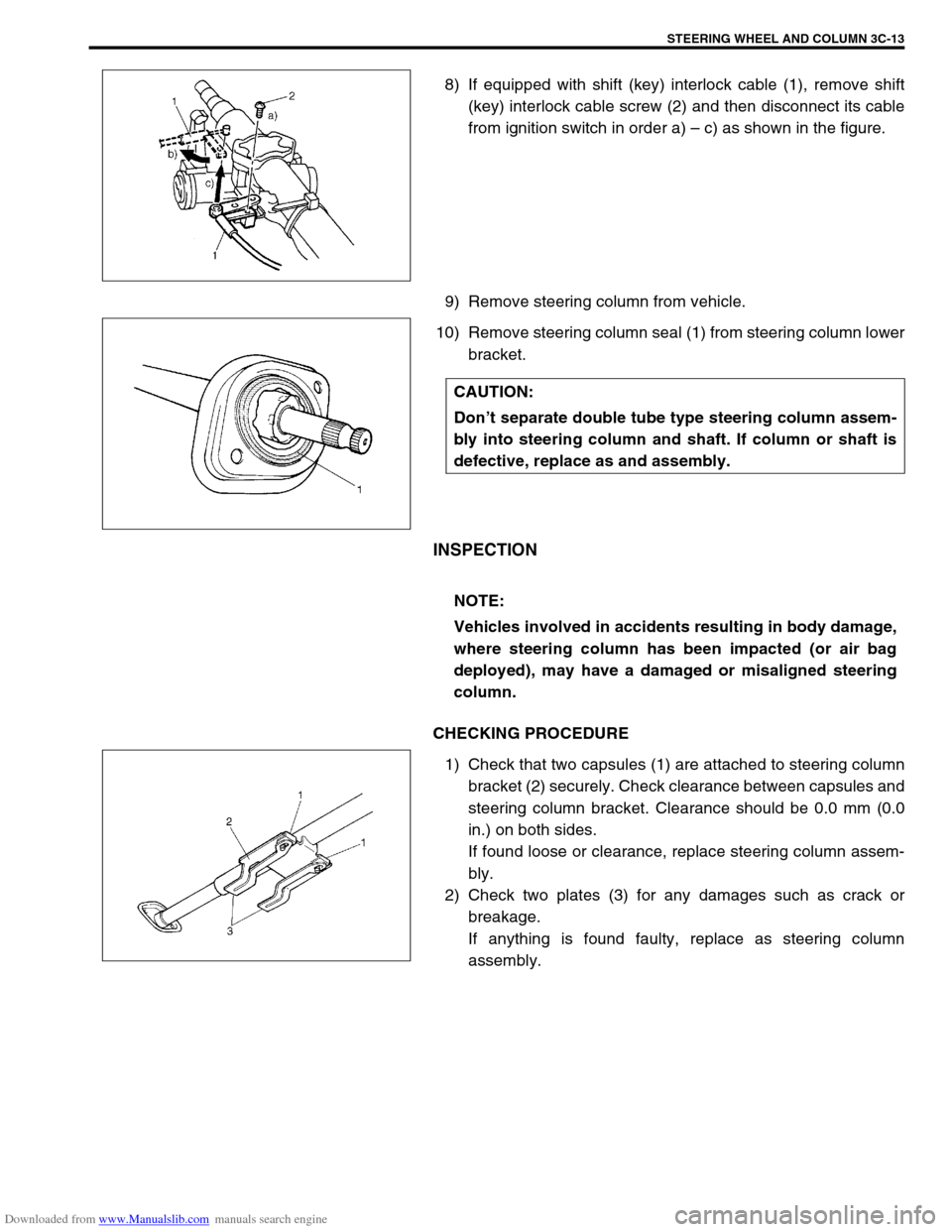

1) Check that two capsules (1) are attached to steering column

bracket (2) securely. Check clearance between capsules and

steering column bracket. Clearance should be 0.0 mm (0.0

in.) on both sides.

If found loose or clearance, replace steering column assem-

bly.

2) Check two plates (3) for any damages such as crack or

breakage.

If anything is found faulty, replace as steering column

assembly.

CAUTION:

Don’t separate double tube type steering column assem-

bly into steering column and shaft. If column or shaft is

defective, replace as and assembly.

NOTE:

Vehicles involved in accidents resulting in body damage,

where steering column has been impacted (or air bag

deployed), may have a damaged or misaligned steering

column.

Page 167 of 687

Downloaded from www.Manualslib.com manuals search engine 3C-14 STEERING WHEEL AND COLUMN

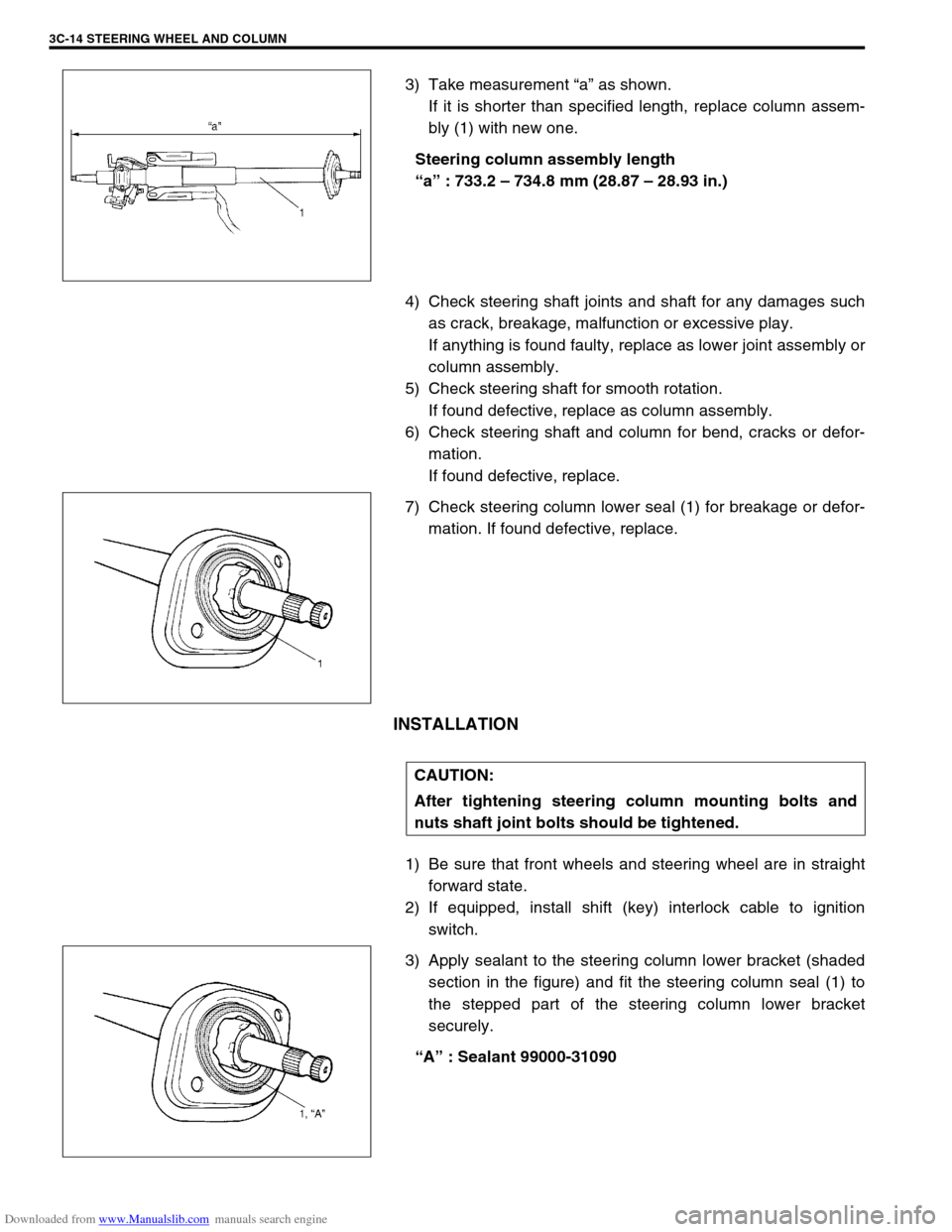

3) Take measurement “a” as shown.

If it is shorter than specified length, replace column assem-

bly (1) with new one.

Steering column assembly length

“a” : 733.2 – 734.8 mm (28.87 – 28.93 in.)

4) Check steering shaft joints and shaft for any damages such

as crack, breakage, malfunction or excessive play.

If anything is found faulty, replace as lower joint assembly or

column assembly.

5) Check steering shaft for smooth rotation.

If found defective, replace as column assembly.

6) Check steering shaft and column for bend, cracks or defor-

mation.

If found defective, replace.

7) Check steering column lower seal (1) for breakage or defor-

mation. If found defective, replace.

INSTALLATION

1) Be sure that front wheels and steering wheel are in straight

forward state.

2) If equipped, install shift (key) interlock cable to ignition

switch.

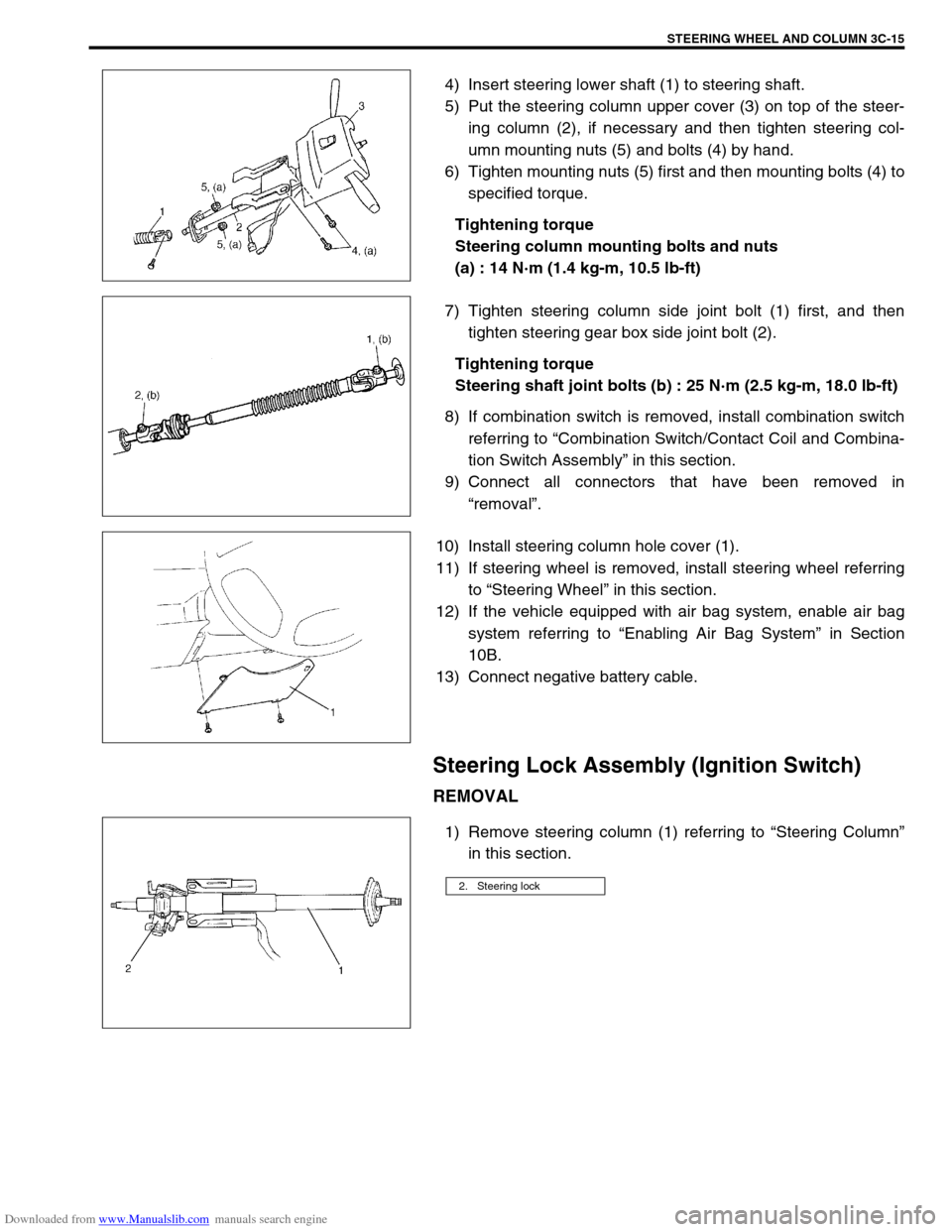

3) Apply sealant to the steering column lower bracket (shaded

section in the figure) and fit the steering column seal (1) to

the stepped part of the steering column lower bracket

securely.

“A” : Sealant 99000-31090

CAUTION:

After tightening steering column mounting bolts and

nuts shaft joint bolts should be tightened.

Page 168 of 687

Downloaded from www.Manualslib.com manuals search engine STEERING WHEEL AND COLUMN 3C-15

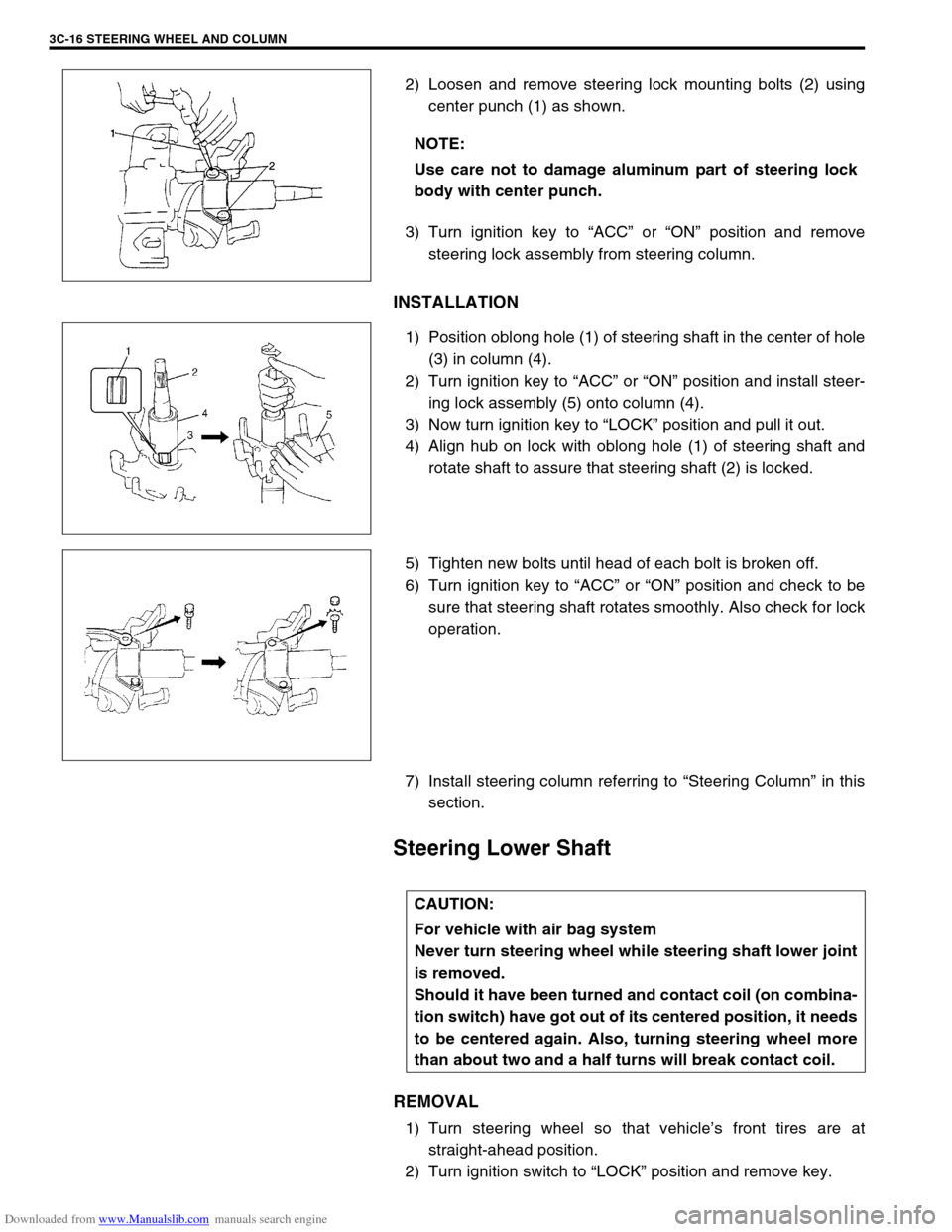

4) Insert steering lower shaft (1) to steering shaft.

5) Put the steering column upper cover (3) on top of the steer-

ing column (2), if necessary and then tighten steering col-

umn mounting nuts (5) and bolts (4) by hand.

6) Tighten mounting nuts (5) first and then mounting bolts (4) to

specified torque.

Tightening torque

Steering column mounting bolts and nuts

(a) : 14 N·m (1.4 kg-m, 10.5 lb-ft)

7) Tighten steering column side joint bolt (1) first, and then

tighten steering gear box side joint bolt (2).

Tightening torque

Steering shaft joint bolts (b) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

8) If combination switch is removed, install combination switch

referring to “Combination Switch/Contact Coil and Combina-

tion Switch Assembly” in this section.

9) Connect all connectors that have been removed in

“removal”.

10) Install steering column hole cover (1).

11) If steering wheel is removed, install steering wheel referring

to “Steering Wheel” in this section.

12) If the vehicle equipped with air bag system, enable air bag

system referring to “Enabling Air Bag System” in Section

10B.

13) Connect negative battery cable.

Steering Lock Assembly (Ignition Switch)

REMOVAL

1) Remove steering column (1) referring to “Steering Column”

in this section.

2. Steering lock

Page 169 of 687

Downloaded from www.Manualslib.com manuals search engine 3C-16 STEERING WHEEL AND COLUMN

2) Loosen and remove steering lock mounting bolts (2) using

center punch (1) as shown.

3) Turn ignition key to “ACC” or “ON” position and remove

steering lock assembly from steering column.

INSTALLATION

1) Position oblong hole (1) of steering shaft in the center of hole

(3) in column (4).

2) Turn ignition key to “ACC” or “ON” position and install steer-

ing lock assembly (5) onto column (4).

3) Now turn ignition key to “LOCK” position and pull it out.

4) Align hub on lock with oblong hole (1) of steering shaft and

rotate shaft to assure that steering shaft (2) is locked.

5) Tighten new bolts until head of each bolt is broken off.

6) Turn ignition key to “ACC” or “ON” position and check to be

sure that steering shaft rotates smoothly. Also check for lock

operation.

7) Install steering column referring to “Steering Column” in this

section.

Steering Lower Shaft

REMOVAL

1) Turn steering wheel so that vehicle’s front tires are at

straight-ahead position.

2) Turn ignition switch to “LOCK” position and remove key. NOTE:

Use care not to damage aluminum part of steering lock

body with center punch.

CAUTION:

For vehicle with air bag system

Never turn steering wheel while steering shaft lower joint

is removed.

Should it have been turned and contact coil (on combina-

tion switch) have got out of its centered position, it needs

to be centered again. Also, turning steering wheel more

than about two and a half turns will break contact coil.

Page 170 of 687

Downloaded from www.Manualslib.com manuals search engine STEERING WHEEL AND COLUMN 3C-17

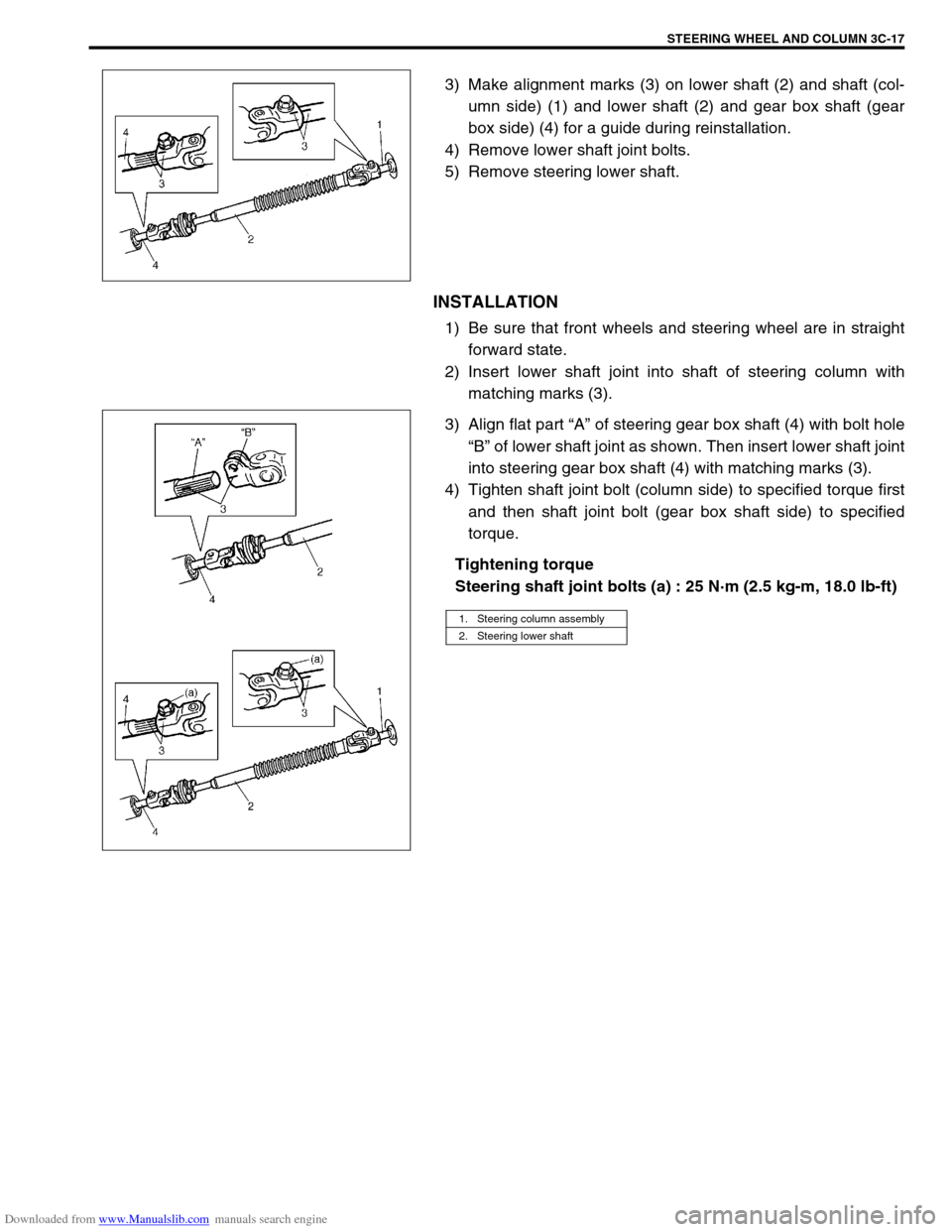

3) Make alignment marks (3) on lower shaft (2) and shaft (col-

umn side) (1) and lower shaft (2) and gear box shaft (gear

box side) (4) for a guide during reinstallation.

4) Remove lower shaft joint bolts.

5) Remove steering lower shaft.

INSTALLATION

1) Be sure that front wheels and steering wheel are in straight

forward state.

2) Insert lower shaft joint into shaft of steering column with

matching marks (3).

3) Align flat part “A” of steering gear box shaft (4) with bolt hole

“B” of lower shaft joint as shown. Then insert lower shaft joint

into steering gear box shaft (4) with matching marks (3).

4) Tighten shaft joint bolt (column side) to specified torque first

and then shaft joint bolt (gear box shaft side) to specified

torque.

Tightening torque

Steering shaft joint bolts (a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

1. Steering column assembly

2. Steering lower shaft

Page 171 of 687

Downloaded from www.Manualslib.com manuals search engine 3C-18 STEERING WHEEL AND COLUMN

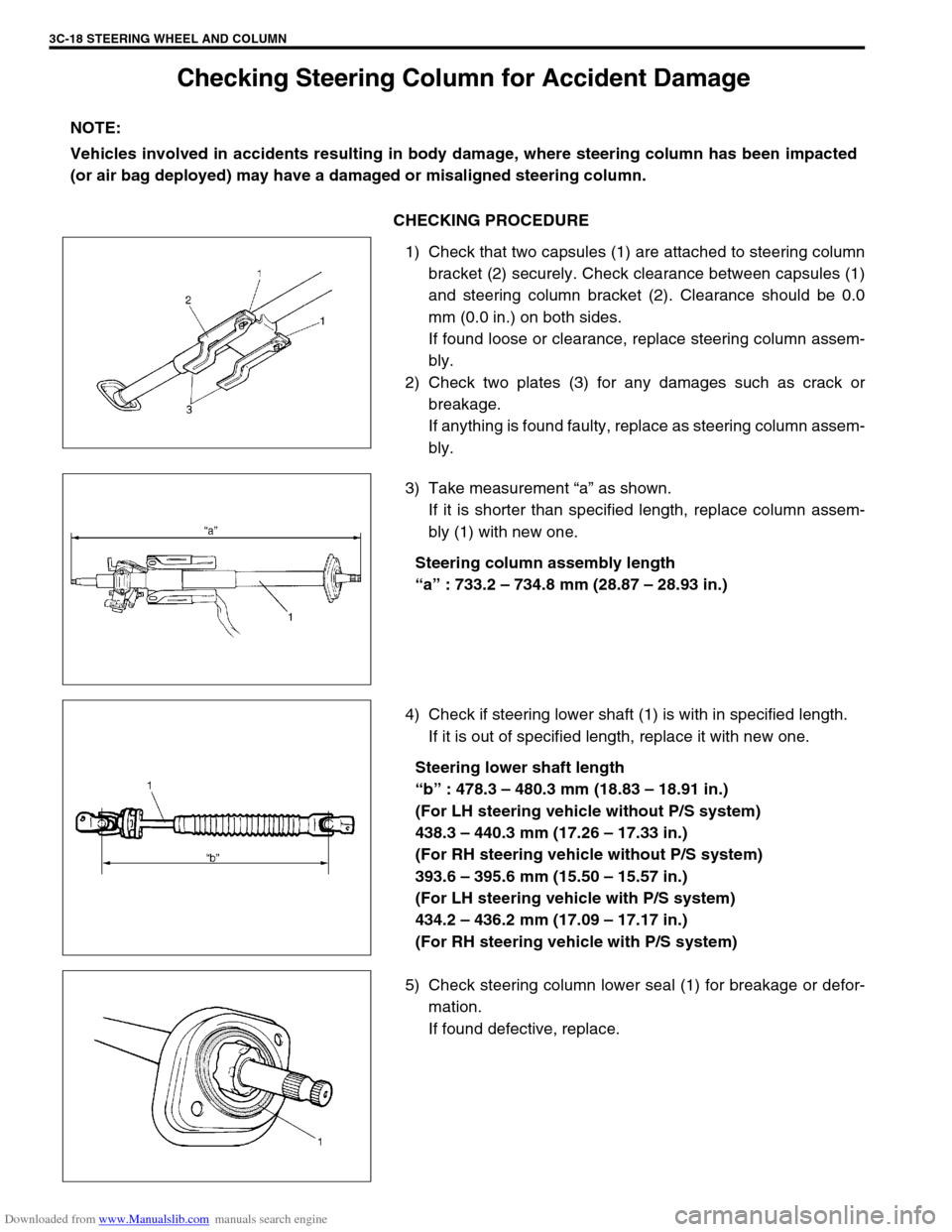

Checking Steering Column for Accident Damage

CHECKING PROCEDURE

1) Check that two capsules (1) are attached to steering column

bracket (2) securely. Check clearance between capsules (1)

and steering column bracket (2). Clearance should be 0.0

mm (0.0 in.) on both sides.

If found loose or clearance, replace steering column assem-

bly.

2) Check two plates (3) for any damages such as crack or

breakage.

If anything is found faulty, replace as steering column assem-

bly.

3) Take measurement “a” as shown.

If it is shorter than specified length, replace column assem-

bly (1) with new one.

Steering column assembly length

“a” : 733.2 – 734.8 mm (28.87 – 28.93 in.)

4) Check if steering lower shaft (1) is with in specified length.

If it is out of specified length, replace it with new one.

Steering lower shaft length

“b” : 478.3 – 480.3 mm (18.83 – 18.91 in.)

(For LH steering vehicle without P/S system)

438.3 – 440.3 mm (17.26 – 17.33 in.)

(For RH steering vehicle without P/S system)

393.6 – 395.6 mm (15.50 – 15.57 in.)

(For LH steering vehicle with P/S system)

434.2 – 436.2 mm (17.09 – 17.17 in.)

(For RH steering vehicle with P/S system)

5) Check steering column lower seal (1) for breakage or defor-

mation.

If found defective, replace. NOTE:

Vehicles involved in accidents resulting in body damage, where steering column has been impacted

(or air bag deployed) may have a damaged or misaligned steering column.

Page 172 of 687

Downloaded from www.Manualslib.com manuals search engine STEERING WHEEL AND COLUMN 3C-19

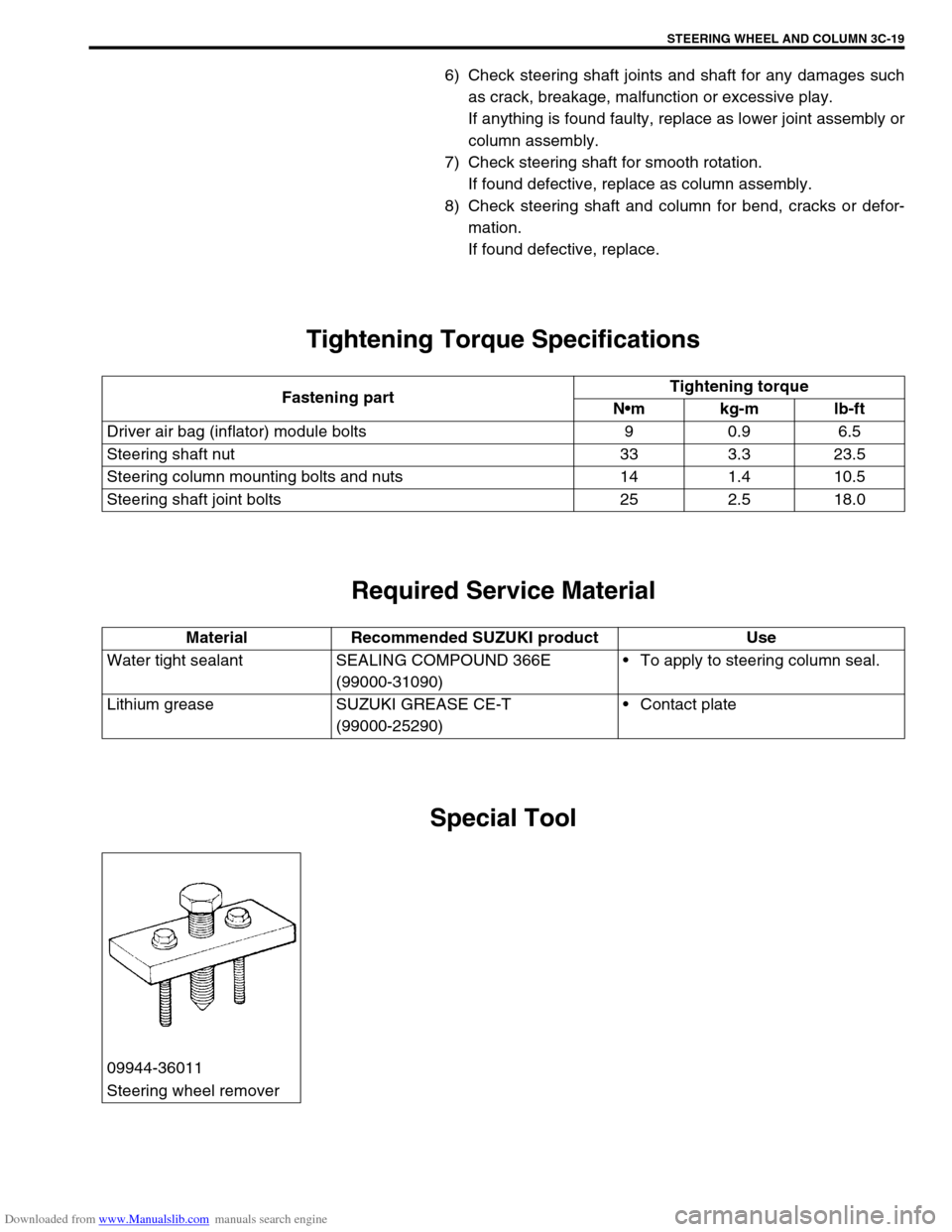

6) Check steering shaft joints and shaft for any damages such

as crack, breakage, malfunction or excessive play.

If anything is found faulty, replace as lower joint assembly or

column assembly.

7) Check steering shaft for smooth rotation.

If found defective, replace as column assembly.

8) Check steering shaft and column for bend, cracks or defor-

mation.

If found defective, replace.

Tightening Torque Specifications

Required Service Material

Special Tool

Fastening partTightening torque

Nm kg-m lb-ft

Driver air bag (inflator) module bolts 9 0.9 6.5

Steering shaft nut 33 3.3 23.5

Steering column mounting bolts and nuts 14 1.4 10.5

Steering shaft joint bolts 25 2.5 18.0

Material Recommended SUZUKI product Use

Water tight sealant SEALING COMPOUND 366E

(99000-31090)To apply to steering column seal.

Lithium grease SUZUKI GREASE CE-T

(99000-25290)Contact plate

09944-36011

Steering wheel remover

Page 174 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-1

6F1

6F2

6G

1A

6K

7A

7A1

3D

7F

8A

8A

8B

8C

8D

8E

9

10

10A

10B

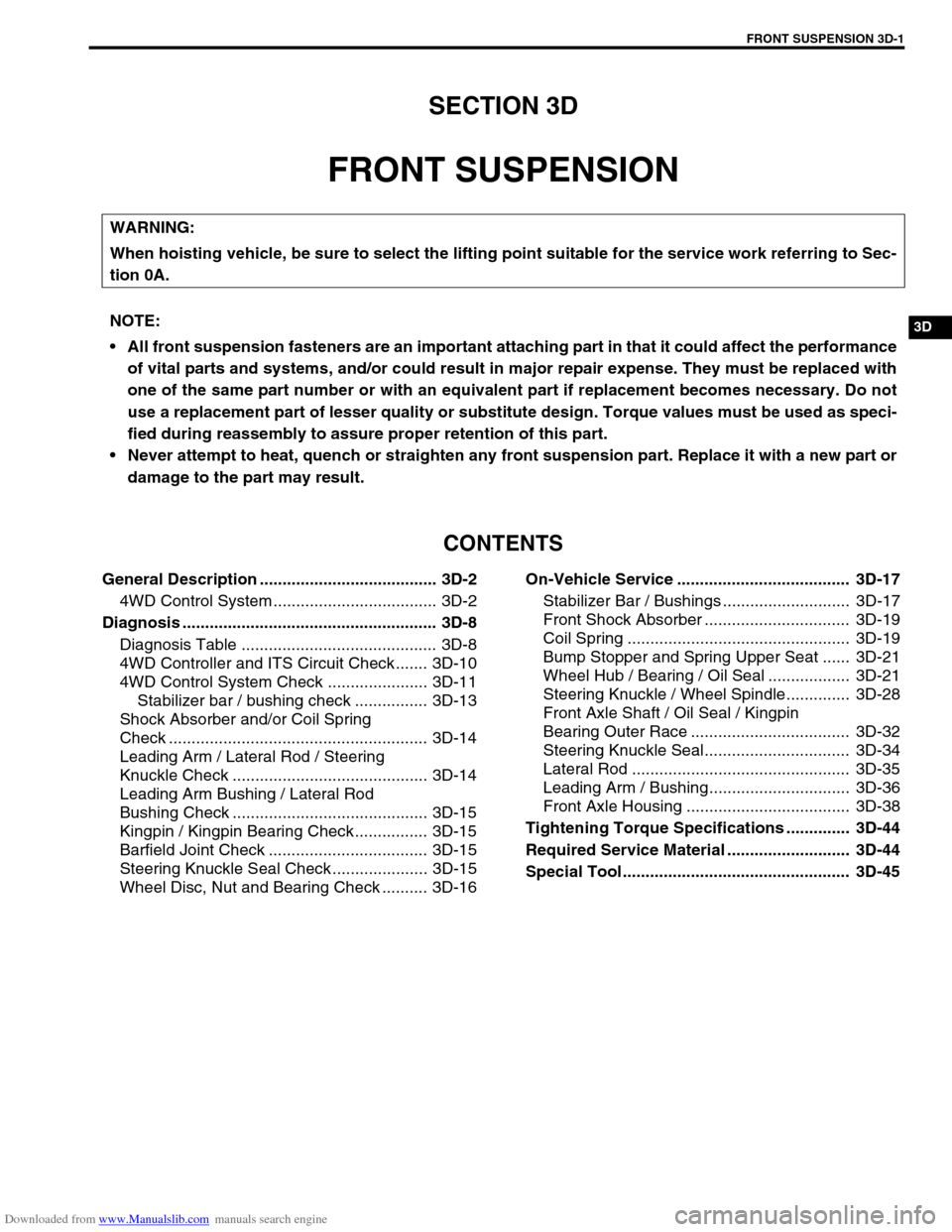

SECTION 3D

FRONT SUSPENSION

CONTENTS

General Description ....................................... 3D-2

4WD Control System .................................... 3D-2

Diagnosis ........................................................ 3D-8

Diagnosis Table ........................................... 3D-8

4WD Controller and ITS Circuit Check ....... 3D-10

4WD Control System Check ...................... 3D-11

Stabilizer bar / bushing check ................ 3D-13

Shock Absorber and/or Coil Spring

Check ......................................................... 3D-14

Leading Arm / Lateral Rod / Steering

Knuckle Check ........................................... 3D-14

Leading Arm Bushing / Lateral Rod

Bushing Check ........................................... 3D-15

Kingpin / Kingpin Bearing Check ................ 3D-15

Barfield Joint Check ................................... 3D-15

Steering Knuckle Seal Check ..................... 3D-15

Wheel Disc, Nut and Bearing Check .......... 3D-16On-Vehicle Service ...................................... 3D-17

Stabilizer Bar / Bushings ............................ 3D-17

Front Shock Absorber ................................ 3D-19

Coil Spring ................................................. 3D-19

Bump Stopper and Spring Upper Seat ...... 3D-21

Wheel Hub / Bearing / Oil Seal .................. 3D-21

Steering Knuckle / Wheel Spindle.............. 3D-28

Front Axle Shaft / Oil Seal / Kingpin

Bearing Outer Race ................................... 3D-32

Steering Knuckle Seal................................ 3D-34

Lateral Rod ................................................ 3D-35

Leading Arm / Bushing............................... 3D-36

Front Axle Housing .................................... 3D-38

Tightening Torque Specifications .............. 3D-44

Required Service Material ........................... 3D-44

Special Tool .................................................. 3D-45

WARNING:

When hoisting vehicle, be sure to select the lifting point suitable for the service work referring to Sec-

tion 0A.

NOTE:

All front suspension fasteners are an important attaching part in that it could affect the performance

of vital parts and systems, and/or could result in major repair expense. They must be replaced with

one of the same part number or with an equivalent part if replacement becomes necessary. Do not

use a replacement part of lesser quality or substitute design. Torque values must be used as speci-

fied during reassembly to assure proper retention of this part.

Never attempt to heat, quench or straighten any front suspension part. Replace it with a new part or

damage to the part may result.

Page 187 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-14 FRONT SUSPENSION

Shock Absorber and/or Coil Spring Check

1) Inspect shock absorber for oil leakage. If shock absorber is

found faulty, replace it as an assembly unit, because it can

not be disassembled.

2) Shock absorber function check

Check and adjust tire pressures as specified.

Bounce body three or four times continuously by pushing

front end on the side with shock absorber to be checked.

Apply the same amount of force at each push and note

shock absorber resistance both when pushed and rebound-

ing.

Also, note how many times vehicle body rebounds before

coming to stop after hands are off. Do the same for shock

absorber on the other side.

Compare shock absorber resistance and number of rebound

on the right with those on the left.

And they must be equal in both. With proper shock absorber,

body should come to stop the moment hands are off or after

only one or two small rebounds. If shock absorbers are sus-

pected, compare them with known good vehicle or shock

absorber.

3) Inspect for damage or deformation.

4) Inspect for cracks or deformation in spring seat.

5) Inspect for deterioration of bump stopper.

6) Inspect shock absorber mount for wear, cracks or deforma-

tion.Replace any parts found defective in steps 2) – 6).

Leading Arm / Lateral Rod / Steering Knuckle

Check

Inspect for cracks, deformation or damage.

Page 201 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-28 FRONT SUSPENSION

Steering Knuckle / Wheel Spindle

REMOVAL

1) Hoist vehicle and remove wheel.

2) Remove wheel hub assembly, refer to “Wheel Hub / Bearing /

Oil Seal” in this section.

3) Disconnect spindle vacuum hoses (1) from wheel spindle (for

4WD).

4) Remove disc dust cover (1) and wheel spindle (2).

5) Remove tie rod end (and drag rod end) nut(s) and discon-

nect tie rod end (and drag rod end) (2) from steering knuckle

(1) with special tool.

Special tool

(A) : 09913-65210

6) Remove knuckle seal cover bolts. Then remove knuckle seal

cover (1), knuckle seal and knuckle seal retainer from

knuckle. CAUTION:

Give match mark to each spindle vacuum hoses before

removing hose.