ect SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 602 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE FUEL 6C-7

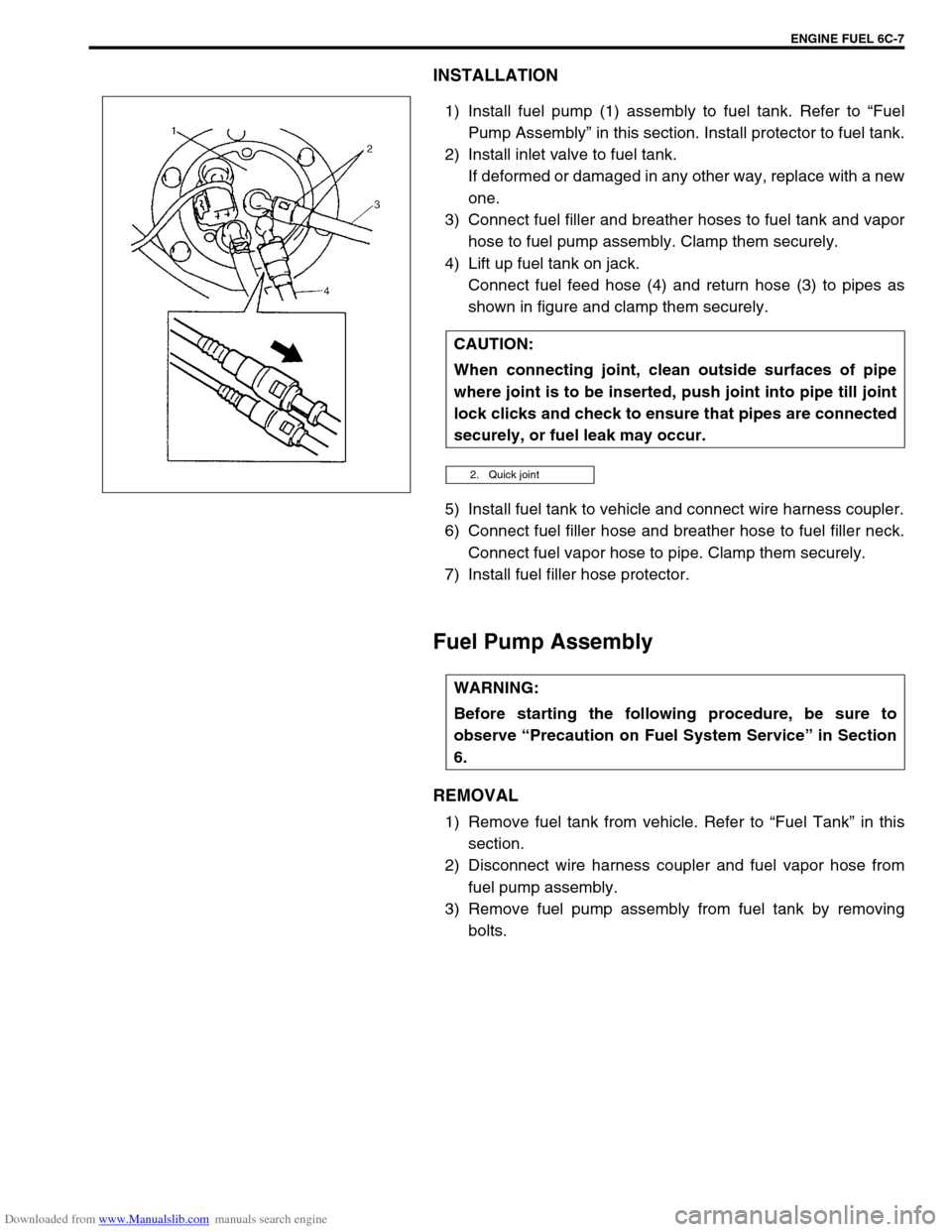

INSTALLATION

1) Install fuel pump (1) assembly to fuel tank. Refer to “Fuel

Pump Assembly” in this section. Install protector to fuel tank.

2) Install inlet valve to fuel tank.

If deformed or damaged in any other way, replace with a new

one.

3) Connect fuel filler and breather hoses to fuel tank and vapor

hose to fuel pump assembly. Clamp them securely.

4) Lift up fuel tank on jack.

Connect fuel feed hose (4) and return hose (3) to pipes as

shown in figure and clamp them securely.

5) Install fuel tank to vehicle and connect wire harness coupler.

6) Connect fuel filler hose and breather hose to fuel filler neck.

Connect fuel vapor hose to pipe. Clamp them securely.

7) Install fuel filler hose protector.

Fuel Pump Assembly

REMOVAL

1) Remove fuel tank from vehicle. Refer to “Fuel Tank” in this

section.

2) Disconnect wire harness coupler and fuel vapor hose from

fuel pump assembly.

3) Remove fuel pump assembly from fuel tank by removing

bolts. CAUTION:

When connecting joint, clean outside surfaces of pipe

where joint is to be inserted, push joint into pipe till joint

lock clicks and check to ensure that pipes are connected

securely, or fuel leak may occur.

2. Quick joint

WARNING:

Before starting the following procedure, be sure to

observe “Precaution on Fuel System Service” in Section

6.

Page 603 of 687

Downloaded from www.Manualslib.com manuals search engine 6C-8 ENGINE FUEL

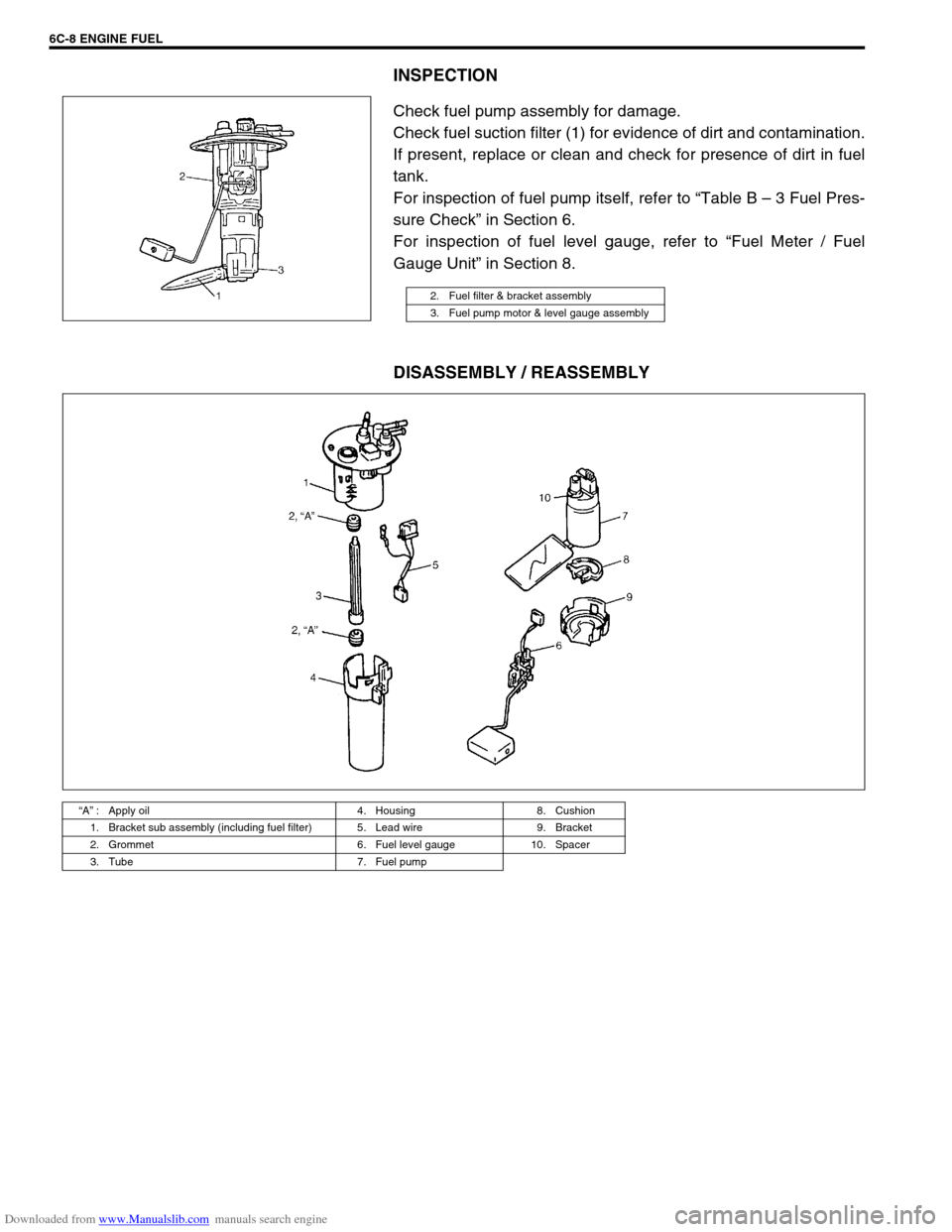

INSPECTION

Check fuel pump assembly for damage.

Check fuel suction filter (1) for evidence of dirt and contamination.

If present, replace or clean and check for presence of dirt in fuel

tank.

For inspection of fuel pump itself, refer to “Table B – 3 Fuel Pres-

sure Check” in Section 6.

For inspection of fuel level gauge, refer to “Fuel Meter / Fuel

Gauge Unit” in Section 8.

DISASSEMBLY / REASSEMBLY

2. Fuel filter & bracket assembly

3. Fuel pump motor & level gauge assembly

“A” : Apply oil 4. Housing 8. Cushion

1. Bracket sub assembly (including fuel filter) 5. Lead wire 9. Bracket

2. Grommet 6. Fuel level gauge 10. Spacer

3. Tube 7. Fuel pump

Page 604 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE FUEL 6C-9

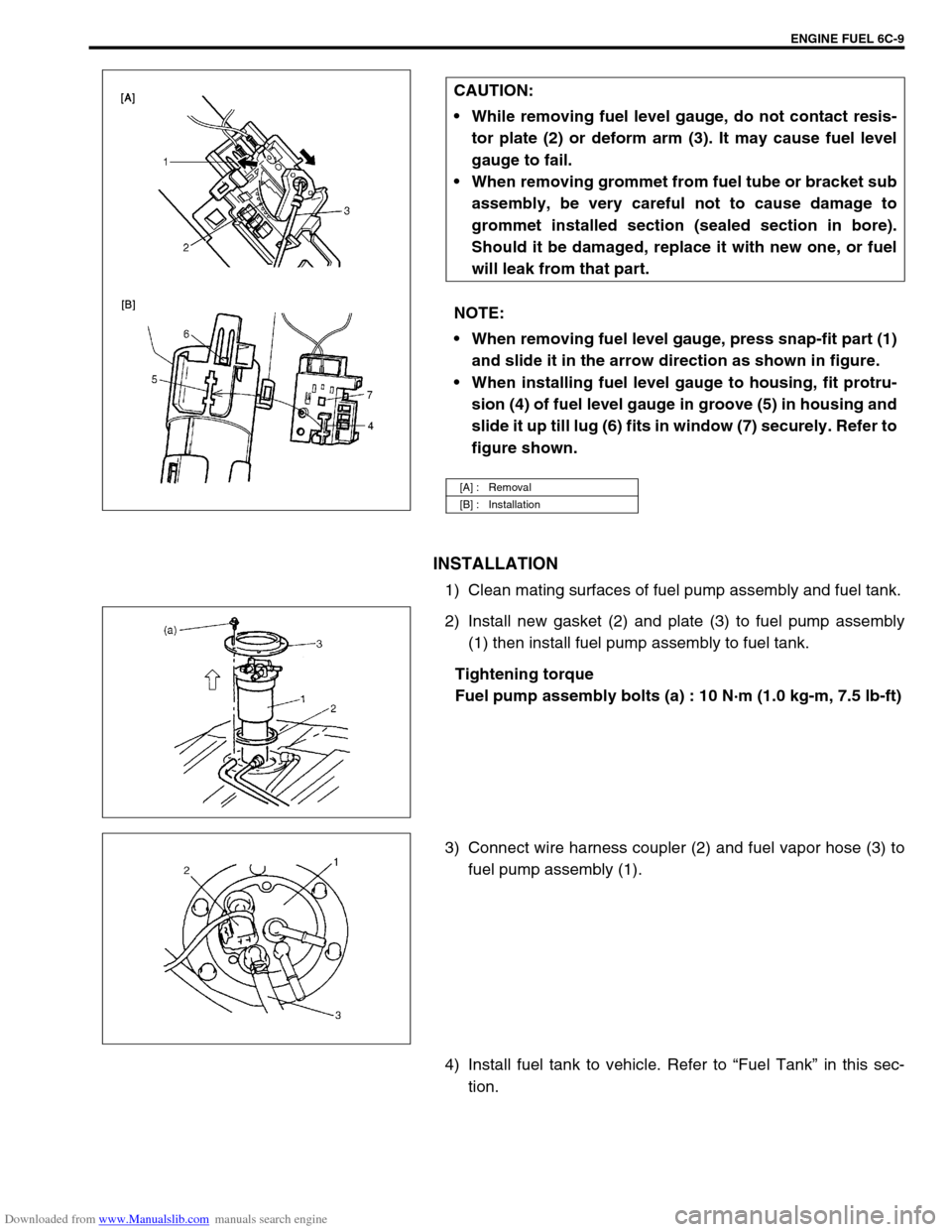

INSTALLATION

1) Clean mating surfaces of fuel pump assembly and fuel tank.

2) Install new gasket (2) and plate (3) to fuel pump assembly

(1) then install fuel pump assembly to fuel tank.

Tightening torque

Fuel pump assembly bolts (a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

3) Connect wire harness coupler (2) and fuel vapor hose (3) to

fuel pump assembly (1).

4) Install fuel tank to vehicle. Refer to “Fuel Tank” in this sec-

tion. CAUTION:

While removing fuel level gauge, do not contact resis-

tor plate (2) or deform arm (3). It may cause fuel level

gauge to fail.

When removing grommet from fuel tube or bracket sub

assembly, be very careful not to cause damage to

grommet installed section (sealed section in bore).

Should it be damaged, replace it with new one, or fuel

will leak from that part.

NOTE:

When removing fuel level gauge, press snap-fit part (1)

and slide it in the arrow direction as shown in figure.

When installing fuel level gauge to housing, fit protru-

sion (4) of fuel level gauge in groove (5) in housing and

slide it up till lug (6) fits in window (7) securely. Refer to

figure shown.

[A] : Removal

[B] : Installation

Page 606 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-1

6F1

6F2

6G

7C1

7D

7E

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

6H

6E

10

10A

10B

SECTION 6E

ENGINE AND EMISSION CONTROL SYSTEM

CONTENTS

General Description ....................................... 6E-3

Air Intake System ......................................... 6E-5

Fuel Delivery System ................................... 6E-6

Fuel pump ................................................ 6E-6

Electronic Control System ............................ 6E-7

Engine & emission control input / output

table.......................................................... 6E-8

On-Vehicle Service....................................... 6E-15

Accelerator cable adjustment ................. 6E-15

Idle speed / idle air control (IAC) duty

inspection ............................................... 6E-15

Idle mixture inspection / adjustment

(vehicle without heated oxygen

sensor) ................................................... 6E-17

Air Intake System ....................................... 6E-18

Throttle body .......................................... 6E-18

Idle air control valve (IAC valve)............. 6E-21

Fuel Delivery System ................................. 6E-22

Fuel pressure inspection ........................ 6E-22

Fuel pump .............................................. 6E-23

Fuel pressure regulator .......................... 6E-24

Fuel injector ............................................ 6E-25

Electronic Control System .......................... 6E-29Engine control module (ECM) ................ 6E-29

Manifold absolute pressure sensor (MAP

sensor) ................................................... 6E-29

Throttle position sensor (TP sensor) ...... 6E-30

Intake air temperature sensor

(IAT sensor) ........................................... 6E-31

Engine coolant temperature sensor

(ECT sensor) .......................................... 6E-32

Heated oxygen sensor

(Sensor-1 and sensor-2) ........................ 6E-33

Camshaft position sensor....................... 6E-34

Crankshaft position sensor..................... 6E-35

Vehicle speed sensor (VSS) .................. 6E-36

Fuel level sensor (GAUGE).................... 6E-36

Knock sensor ......................................... 6E-36

Main relay, fuel pump relay and A/C

condenser fan control relay .................... 6E-36

Fuel cut operation .................................. 6E-37

A/C condenser fan control system ......... 6E-37

A/C condenser fan ................................. 6E-37

Output signals of throttle valve opening

and engine coolant temp.

(Vehicle with A/T only) ........................... 6E-38

Emission Control System ........................... 6E-38 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Whether following systems (parts) are used in the particular vehicle or not depends on specifications.

Be sure to bear this in mind when performing service work.

EGR valve

Heated oxygen sensor (s) or CO adjusting resistor

Three way catalytic converter (TWC) and warm up three-way catalytic converter (WU-TWC)

Page 608 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-3

General Description

The engine and emission control system is divided into 4 major sub-systems: air intake system, fuel delivery

system, electronic control system and emission control system.

Air intake system includes air cleaner, throttle body, IAC valve and intake manifold.

Fuel delivery system includes fuel pump, delivery pipe, fuel pressure regulator, etc. Electronic control system

includes ECM, various sensors and controlled devices.

Emission control system includes EGR, EVAP and PCV system.

Page 610 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-5

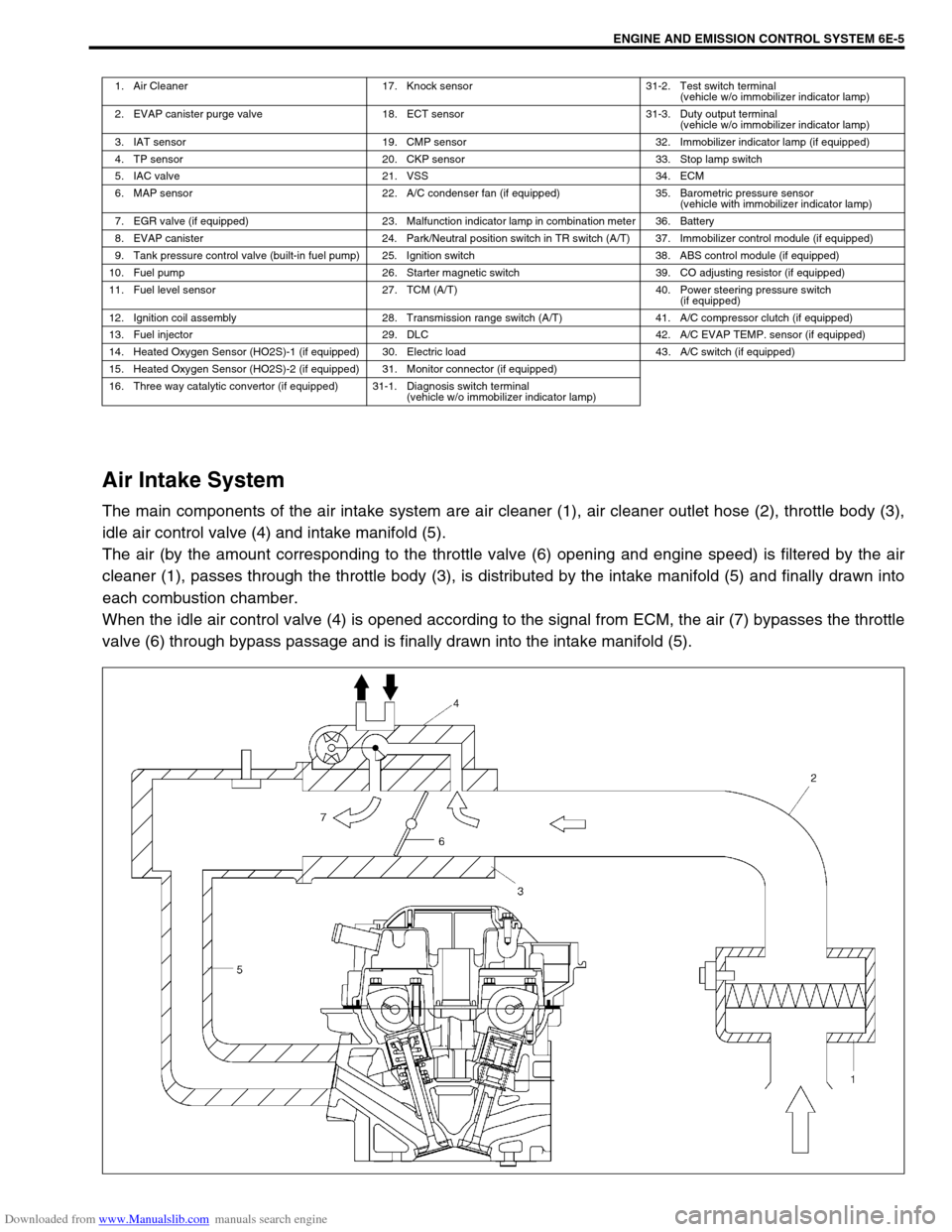

Air Intake System

The main components of the air intake system are air cleaner (1), air cleaner outlet hose (2), throttle body (3),

idle air control valve (4) and intake manifold (5).

The air (by the amount corresponding to the throttle valve (6) opening and engine speed) is filtered by the air

cleaner (1), passes through the throttle body (3), is distributed by the intake manifold (5) and finally drawn into

each combustion chamber.

When the idle air control valve (4) is opened according to the signal from ECM, the air (7) bypasses the throttle

valve (6) through bypass passage and is finally drawn into the intake manifold (5).

1. Air Cleaner 17. Knock sensor 31-2. Test switch terminal

(vehicle w/o immobilizer indicator lamp)

2. EVAP canister purge valve 18. ECT sensor 31-3. Duty output terminal

(vehicle w/o immobilizer indicator lamp)

3. IAT sensor 19. CMP sensor 32. Immobilizer indicator lamp (if equipped)

4. TP sensor 20. CKP sensor 33. Stop lamp switch

5. IAC valve 21. VSS 34. ECM

6. MAP sensor 22. A/C condenser fan (if equipped) 35. Barometric pressure sensor

(vehicle with immobilizer indicator lamp)

7. EGR valve (if equipped) 23. Malfunction indicator lamp in combination meter 36. Battery

8. EVAP canister 24. Park/Neutral position switch in TR switch (A/T) 37. Immobilizer control module (if equipped)

9. Tank pressure control valve (built-in fuel pump) 25. Ignition switch 38. ABS control module (if equipped)

10. Fuel pump 26. Starter magnetic switch 39. CO adjusting resistor (if equipped)

11. Fuel level sensor 27. TCM (A/T) 40. Power steering pressure switch

(if equipped)

12. Ignition coil assembly 28. Transmission range switch (A/T) 41. A/C compressor clutch (if equipped)

13. Fuel injector 29. DLC 42. A/C EVAP TEMP. sensor (if equipped)

14. Heated Oxygen Sensor (HO2S)-1 (if equipped) 30. Electric load 43. A/C switch (if equipped)

15. Heated Oxygen Sensor (HO2S)-2 (if equipped) 31. Monitor connector (if equipped)

16. Three way catalytic convertor (if equipped) 31-1. Diagnosis switch terminal

(vehicle w/o immobilizer indicator lamp)

Page 611 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-6 ENGINE AND EMISSION CONTROL SYSTEM

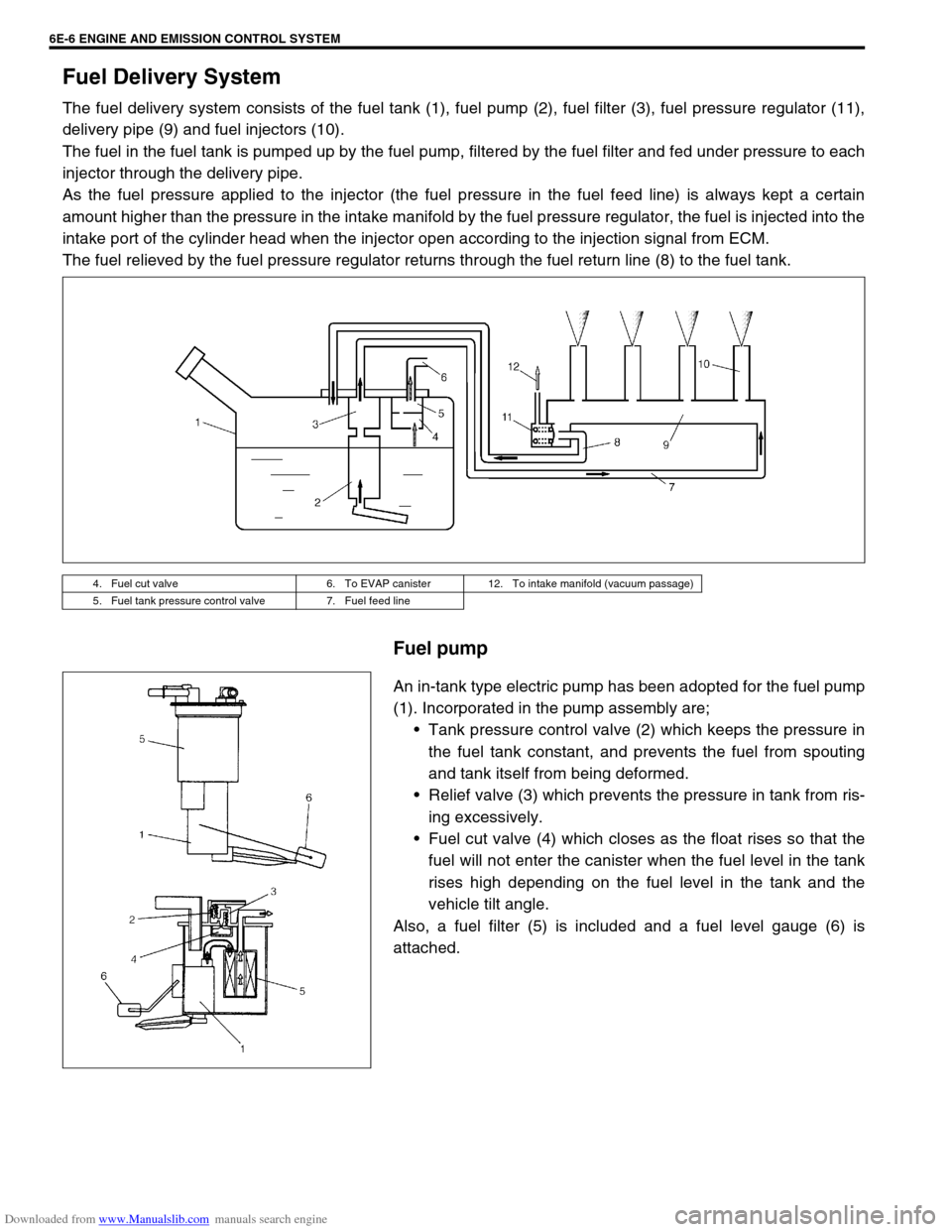

Fuel Delivery System

The fuel delivery system consists of the fuel tank (1), fuel pump (2), fuel filter (3), fuel pressure regulator (11),

delivery pipe (9) and fuel injectors (10).

The fuel in the fuel tank is pumped up by the fuel pump, filtered by the fuel filter and fed under pressure to each

injector through the delivery pipe.

As the fuel pressure applied to the injector (the fuel pressure in the fuel feed line) is always kept a certain

amount higher than the pressure in the intake manifold by the fuel pressure regulator, the fuel is injected into the

intake port of the cylinder head when the injector open according to the injection signal from ECM.

The fuel relieved by the fuel pressure regulator returns through the fuel return line (8) to the fuel tank.

Fuel pump

An in-tank type electric pump has been adopted for the fuel pump

(1). Incorporated in the pump assembly are;

Tank pressure control valve (2) which keeps the pressure in

the fuel tank constant, and prevents the fuel from spouting

and tank itself from being deformed.

Relief valve (3) which prevents the pressure in tank from ris-

ing excessively.

Fuel cut valve (4) which closes as the float rises so that the

fuel will not enter the canister when the fuel level in the tank

rises high depending on the fuel level in the tank and the

vehicle tilt angle.

Also, a fuel filter (5) is included and a fuel level gauge (6) is

attached.

4. Fuel cut valve 6. To EVAP canister 12. To intake manifold (vacuum passage)

5. Fuel tank pressure control valve 7. Fuel feed line

Page 612 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-7

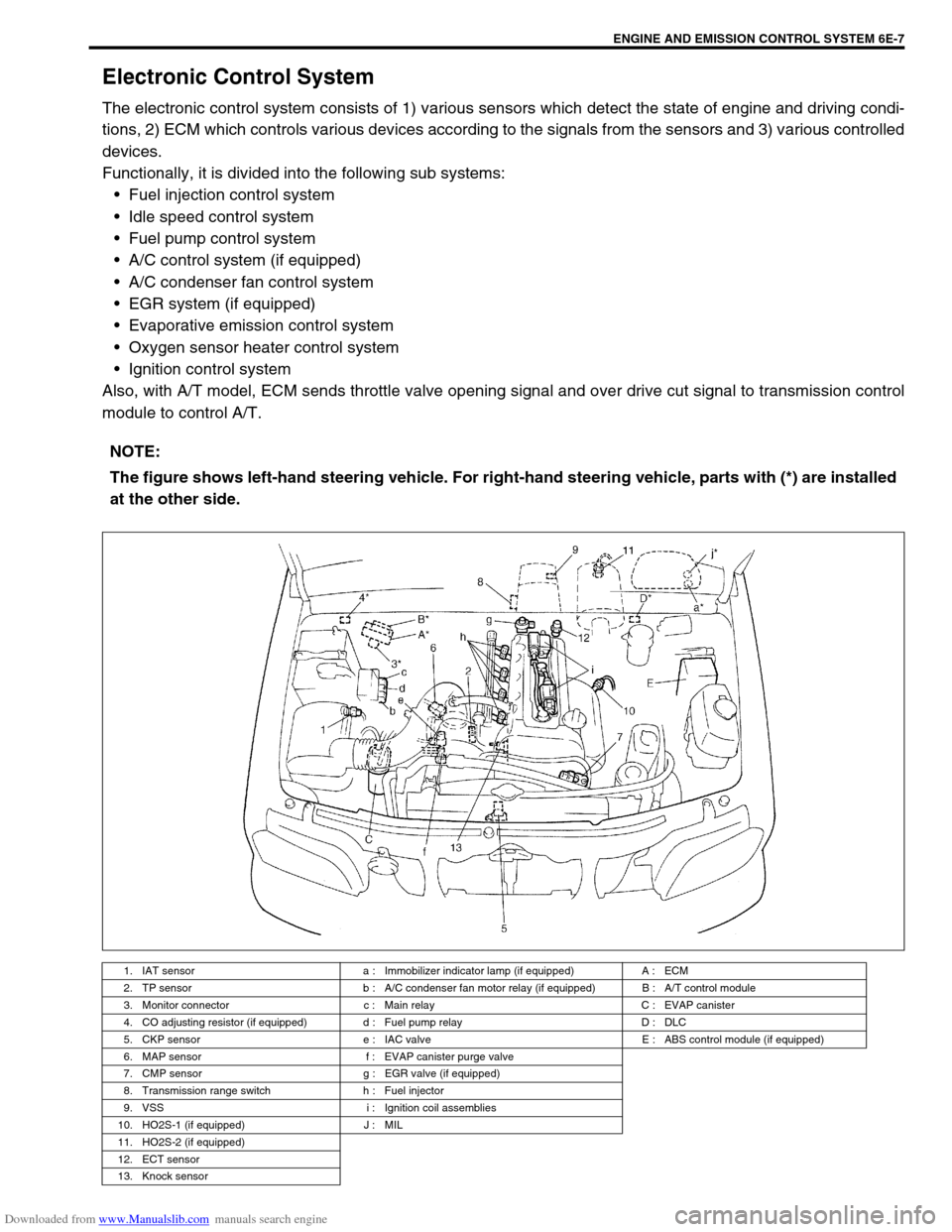

Electronic Control System

The electronic control system consists of 1) various sensors which detect the state of engine and driving condi-

tions, 2) ECM which controls various devices according to the signals from the sensors and 3) various controlled

devices.

Functionally, it is divided into the following sub systems:

Fuel injection control system

Idle speed control system

Fuel pump control system

A/C control system (if equipped)

A/C condenser fan control system

EGR system (if equipped)

Evaporative emission control system

Oxygen sensor heater control system

Ignition control system

Also, with A/T model, ECM sends throttle valve opening signal and over drive cut signal to transmission control

module to control A/T.

NOTE:

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the other side.

1. IAT sensor a : Immobilizer indicator lamp (if equipped) A : ECM

2. TP sensor b : A/C condenser fan motor relay (if equipped) B : A/T control module

3. Monitor connector c : Main relay C : EVAP canister

4. CO adjusting resistor (if equipped) d : Fuel pump relay D : DLC

5. CKP sensor e : IAC valve E : ABS control module (if equipped)

6. MAP sensor f : EVAP canister purge valve

7. CMP sensor g : EGR valve (if equipped)

8. Transmission range switch h : Fuel injector

9. VSS i : Ignition coil assemblies

10. HO2S-1 (if equipped) J : MIL

11. HO2S-2 (if equipped)

12. ECT sensor

13. Knock sensor

Page 613 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-8 ENGINE AND EMISSION CONTROL SYSTEM

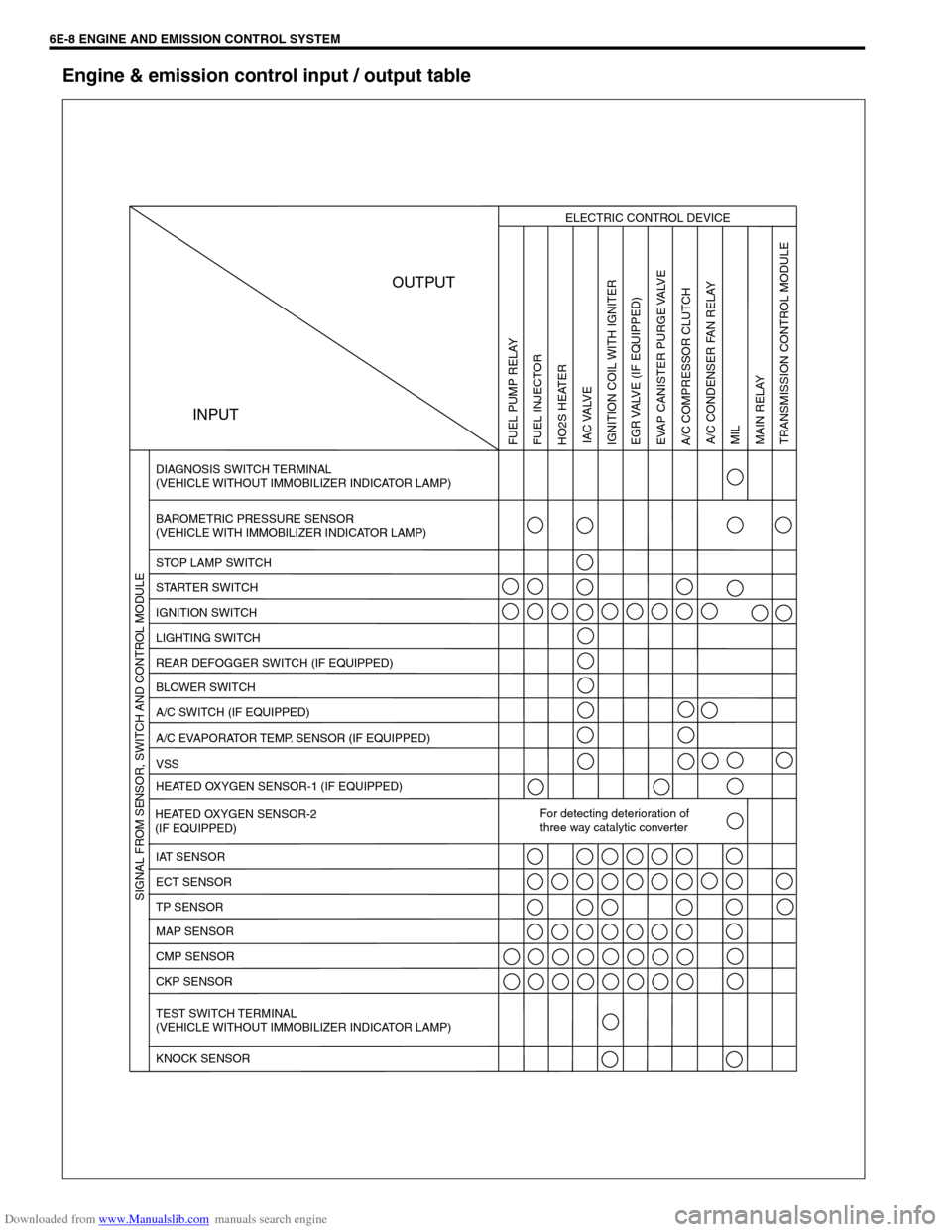

Engine & emission control input / output table

INPUTOUTPUT

ELECTRIC CONTROL DEVICE

DIAGNOSIS SWITCH TERMINAL

(VEHICLE WITHOUT IMMOBILIZER INDICATOR LAMP)

BAROMETRIC PRESSURE SENSOR

(VEHICLE WITH IMMOBILIZER INDICATOR LAMP)

STOP LAMP SWITCH

STARTER SWITCH

IGNITION SWITCH

LIGHTING SWITCH

REAR DEFOGGER SWITCH (IF EQUIPPED)

BLOWER SWITCH

A/C SWITCH (IF EQUIPPED)

A/C EVAPORATOR TEMP. SENSOR (IF EQUIPPED)

VSS

HEATED OXYGEN SENSOR-1 (IF EQUIPPED)

HEATED OXYGEN SENSOR-2

(IF EQUIPPED)For detecting deterioration of

three way catalytic converter

IAT SENSOR

ECT SENSOR

TP SENSOR

MAP SENSOR

CMP SENSOR

CKP SENSOR

TEST SWITCH TERMINAL

(VEHICLE WITHOUT IMMOBILIZER INDICATOR LAMP)

KNOCK SENSOR

FUEL PUMP RELAY

FUEL INJECTOR

HO2S HEATER

IAC VALVE

IGNITION COIL WITH IGNITER

EGR VALVE (IF EQUIPPED)

EVAP CANISTER PURGE VALVE

A/C COMPRESSOR CLUTCH

MIL

MAIN RELAY

TRANSMISSION CONTROL MODULE SIGNAL FROM SENSOR, SWITCH AND CONTROL MODULEA/C CONDENSER FAN RELAY

Page 615 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-10 ENGINE AND EMISSION CONTROL SYSTEM

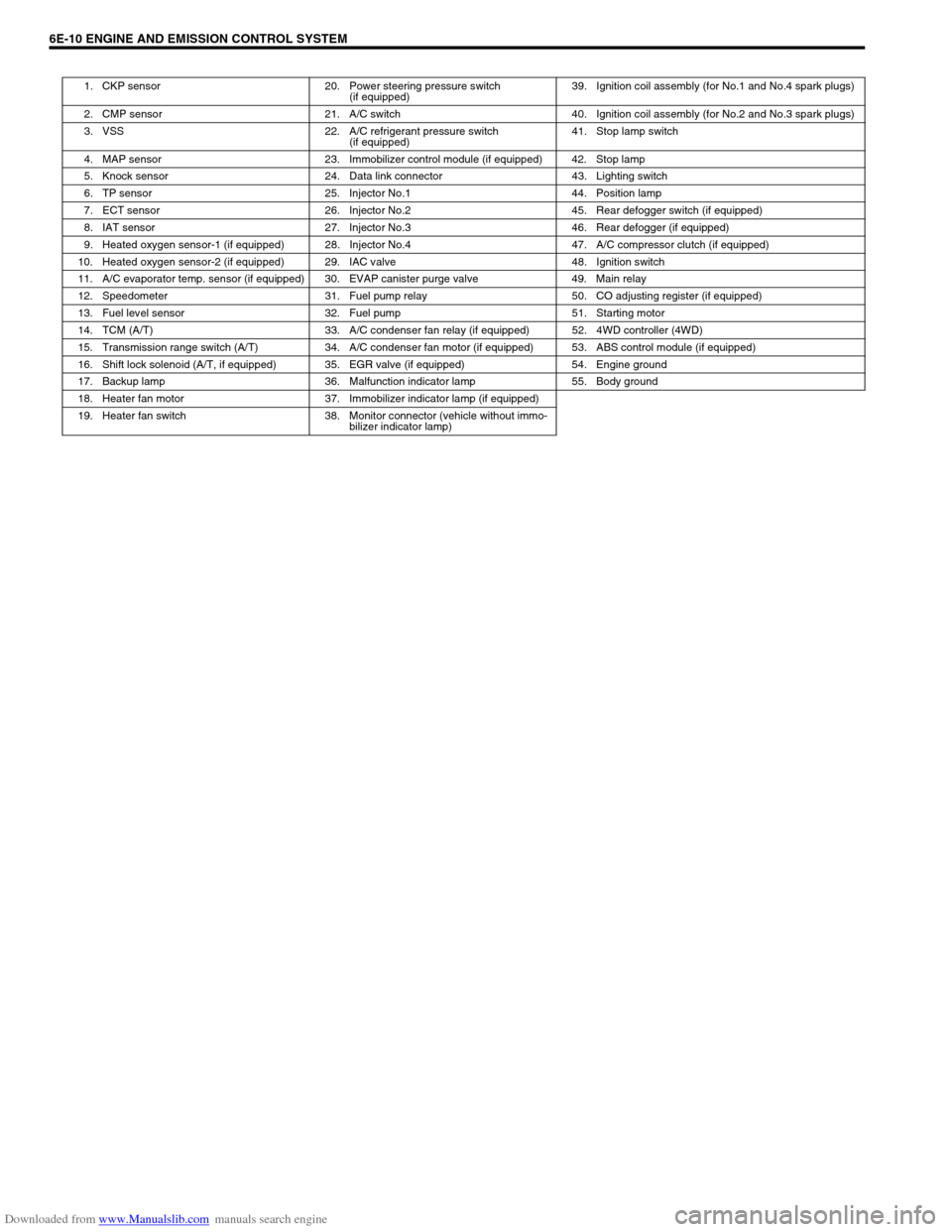

1. CKP sensor 20. Power steering pressure switch

(if equipped)39. Ignition coil assembly (for No.1 and No.4 spark plugs)

2. CMP sensor 21. A/C switch 40. Ignition coil assembly (for No.2 and No.3 spark plugs)

3. VSS 22. A/C refrigerant pressure switch

(if equipped)41. Stop lamp switch

4. MAP sensor 23. Immobilizer control module (if equipped) 42. Stop lamp

5. Knock sensor 24. Data link connector 43. Lighting switch

6. TP sensor 25. Injector No.1 44. Position lamp

7. ECT sensor 26. Injector No.2 45. Rear defogger switch (if equipped)

8. IAT sensor 27. Injector No.3 46. Rear defogger (if equipped)

9. Heated oxygen sensor-1 (if equipped) 28. Injector No.4 47. A/C compressor clutch (if equipped)

10. Heated oxygen sensor-2 (if equipped) 29. IAC valve 48. Ignition switch

11. A/C evaporator temp. sensor (if equipped) 30. EVAP canister purge valve 49. Main relay

12. Speedometer 31. Fuel pump relay 50. CO adjusting register (if equipped)

13. Fuel level sensor 32. Fuel pump 51. Starting motor

14. TCM (A/T) 33. A/C condenser fan relay (if equipped) 52. 4WD controller (4WD)

15. Transmission range switch (A/T) 34. A/C condenser fan motor (if equipped) 53. ABS control module (if equipped)

16. Shift lock solenoid (A/T, if equipped) 35. EGR valve (if equipped) 54. Engine ground

17. Backup lamp 36. Malfunction indicator lamp 55. Body ground

18. Heater fan motor 37. Immobilizer indicator lamp (if equipped)

19. Heater fan switch 38. Monitor connector (vehicle without immo-

bilizer indicator lamp)