ect SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 627 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-22 ENGINE AND EMISSION CONTROL SYSTEM

Fuel Delivery System

Fuel pressure inspection

1) Relieve fuel pressure in fuel feed line referring to “Fuel Pres-

sure Relief Procedure” in Section 6.

2) Disconnect fuel feed hose from fuel delivery pipe.

3) Connect special tools and hose between fuel delivery pipe

(1) and fuel feed hose (2) as shown in figure, and clamp

hoses securely to ensure no leaks occur during checking.

Special tool

(A) : 09912-58442

(B) : 09912-58432

(C) : 09912-58490

4) Check that battery voltage is above 11 V.

5) Turn ignition switch ON to operate fuel pump and after 2 sec-

onds turn it OFF. Repeat this 3 or 4 times and then check

fuel pressure.

Fuel pressure specification WARNING:

Be sure to perform work in a well-ventilated area and

away from any open flames, or there is a risk of a fire

breaking out.

CAUTION:

A small amount of fuel may be released when fuel hose is

disconnected. Place container under the joint with a

shop cloth so that released fuel is caught in container or

absorbed in cloth. Place that cloth in an approved con-

tainer.

3. Fuel return pipe

CONDITION FUEL PRESSURE

With fuel pump operating and

engine stopped270 – 310 kPa

2.7 – 3.1 kg/cm

2,

38.4 – 44.0 psi

At specified idle speed 210 – 260 kPa

2.1 – 2.6 kg/cm

2,

29.8 – 37.0 psi

With 1 min. after engine (fuel

pump) stop (Pressure

reduces as time passes)over 200 kPa

2.0 kg/cm

2, 28.4 psi

Page 628 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-23

6) Start engine and warm it up to normal operating tempera-

ture.

7) Measure fuel pressure at idling.

If measured pressure doesn’t satisfy specification, refer to

“Diagnostic Flow Table B-3” in Section 6 and check each

possibly defective part. Replace if found defective.

8) After checking fuel pressure, remove fuel pressure gauge.

9) Remove special tools from fuel delivery pipe.

10) Connect fuel feed hose to fuel delivery pipe and clamp it

securely.

11) With engine “OFF” and ignition switch “ON”, check for fuel

leaks.

Fuel pump

ON-VEHICLE INSPECTION

1) Remove filler cap and turn ON ignition switch (2). Then fuel

pump operating sound should be heard from fuel filler (1) for

about 2 seconds and stop. Be sure to reinstall fuel filler cap

after checking.

If above check result is not satisfactory, advance to “Diag-

nostic Flow Table B-2” in Section 6.

2) Turn OFF ignition switch and leave over 10 minutes as it is.CAUTION:

As fuel feed line is still under high fuel pressure, make

sure to release fuel pressure according to following pro-

cedures.

Place fuel container under joint.

Cover joint with rag and loosen joint nut slowly to

release fuel pressure gradually.

CAUTION:

When fuel filler cap is removed in any procedure, work

must be done in a well-ventilated area, keep away from

any open flames and without smoking.

NOTE:

The fuel pressure regulator is the one body with the fuel

pump assembly so individual inspection of it is impossi-

ble.

Page 629 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-24 ENGINE AND EMISSION CONTROL SYSTEM

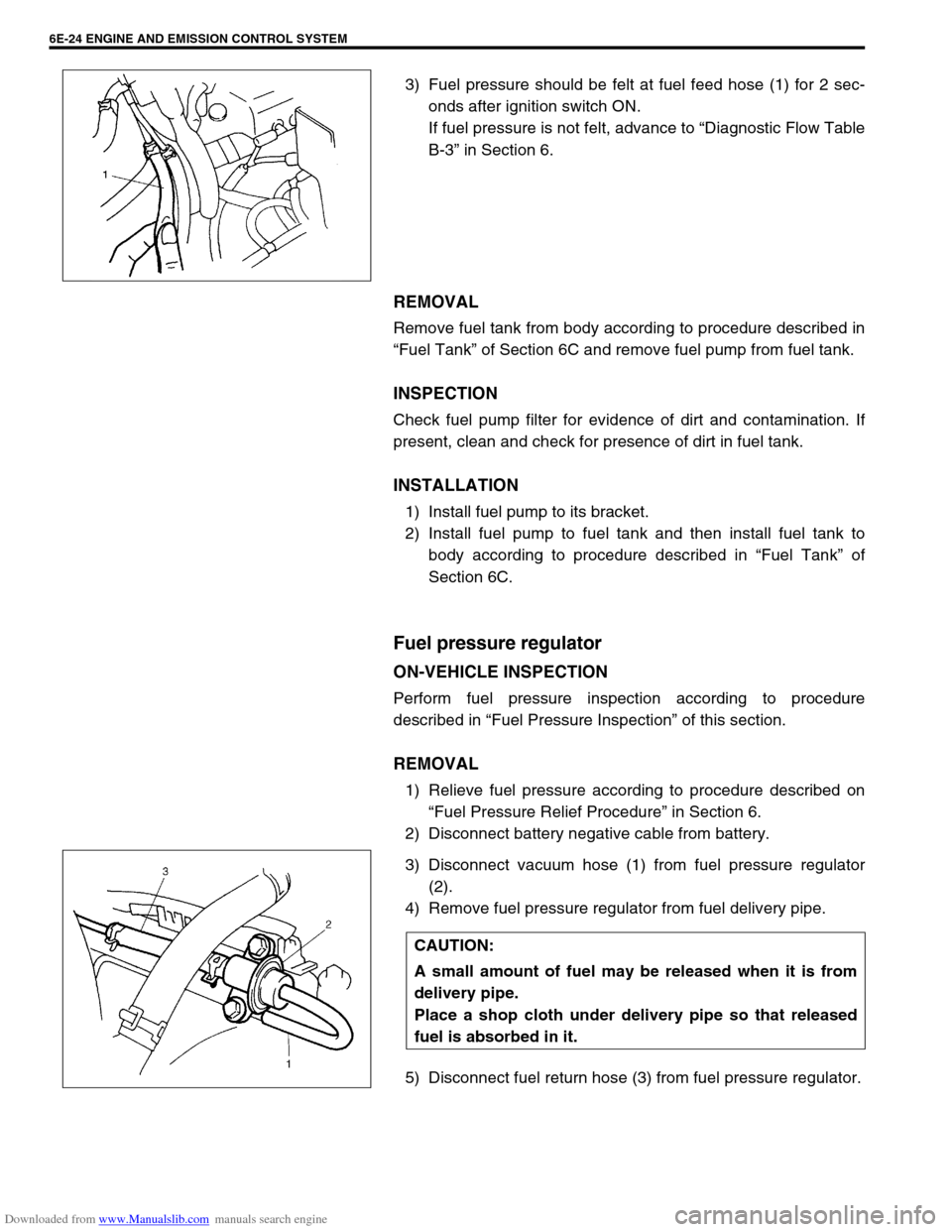

3) Fuel pressure should be felt at fuel feed hose (1) for 2 sec-

onds after ignition switch ON.

If fuel pressure is not felt, advance to “Diagnostic Flow Table

B-3” in Section 6.

REMOVAL

Remove fuel tank from body according to procedure described in

“Fuel Tank” of Section 6C and remove fuel pump from fuel tank.

INSPECTION

Check fuel pump filter for evidence of dirt and contamination. If

present, clean and check for presence of dirt in fuel tank.

INSTALLATION

1) Install fuel pump to its bracket.

2) Install fuel pump to fuel tank and then install fuel tank to

body according to procedure described in “Fuel Tank” of

Section 6C.

Fuel pressure regulator

ON-VEHICLE INSPECTION

Perform fuel pressure inspection according to procedure

described in “Fuel Pressure Inspection” of this section.

REMOVAL

1) Relieve fuel pressure according to procedure described on

“Fuel Pressure Relief Procedure” in Section 6.

2) Disconnect battery negative cable from battery.

3) Disconnect vacuum hose (1) from fuel pressure regulator

(2).

4) Remove fuel pressure regulator from fuel delivery pipe.

5) Disconnect fuel return hose (3) from fuel pressure regulator.

CAUTION:

A small amount of fuel may be released when it is from

delivery pipe.

Place a shop cloth under delivery pipe so that released

fuel is absorbed in it.

Page 630 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-25

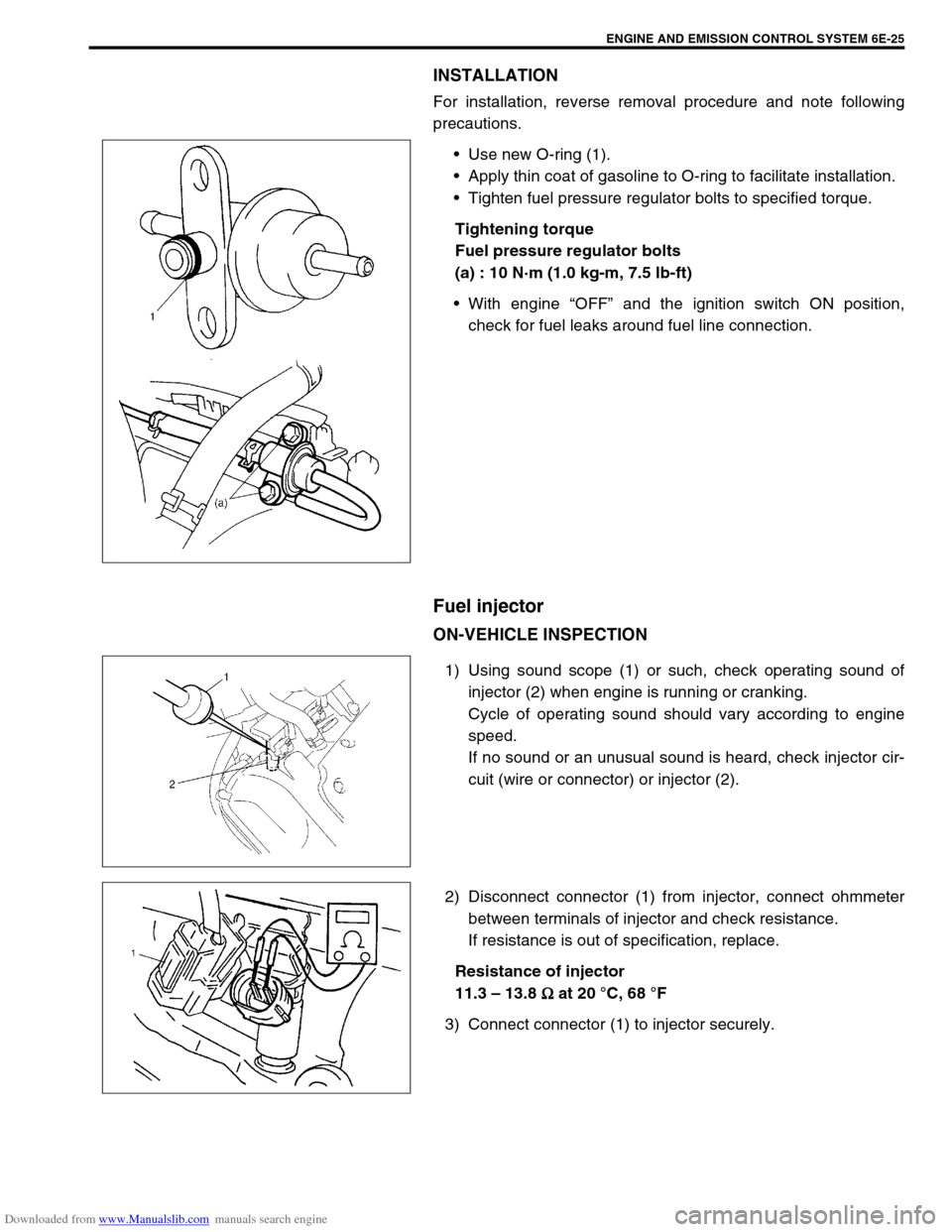

INSTALLATION

For installation, reverse removal procedure and note following

precautions.

Use new O-ring (1).

Apply thin coat of gasoline to O-ring to facilitate installation.

Tighten fuel pressure regulator bolts to specified torque.

Tightening torque

Fuel pressure regulator bolts

(a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

With engine “OFF” and the ignition switch ON position,

check for fuel leaks around fuel line connection.

Fuel injector

ON-VEHICLE INSPECTION

1) Using sound scope (1) or such, check operating sound of

injector (2) when engine is running or cranking.

Cycle of operating sound should vary according to engine

speed.

If no sound or an unusual sound is heard, check injector cir-

cuit (wire or connector) or injector (2).

2) Disconnect connector (1) from injector, connect ohmmeter

between terminals of injector and check resistance.

If resistance is out of specification, replace.

Resistance of injector

11.3 – 13.8

Ω

ΩΩ Ω at 20 °C, 68 °F

3) Connect connector (1) to injector securely.

Page 631 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-26 ENGINE AND EMISSION CONTROL SYSTEM

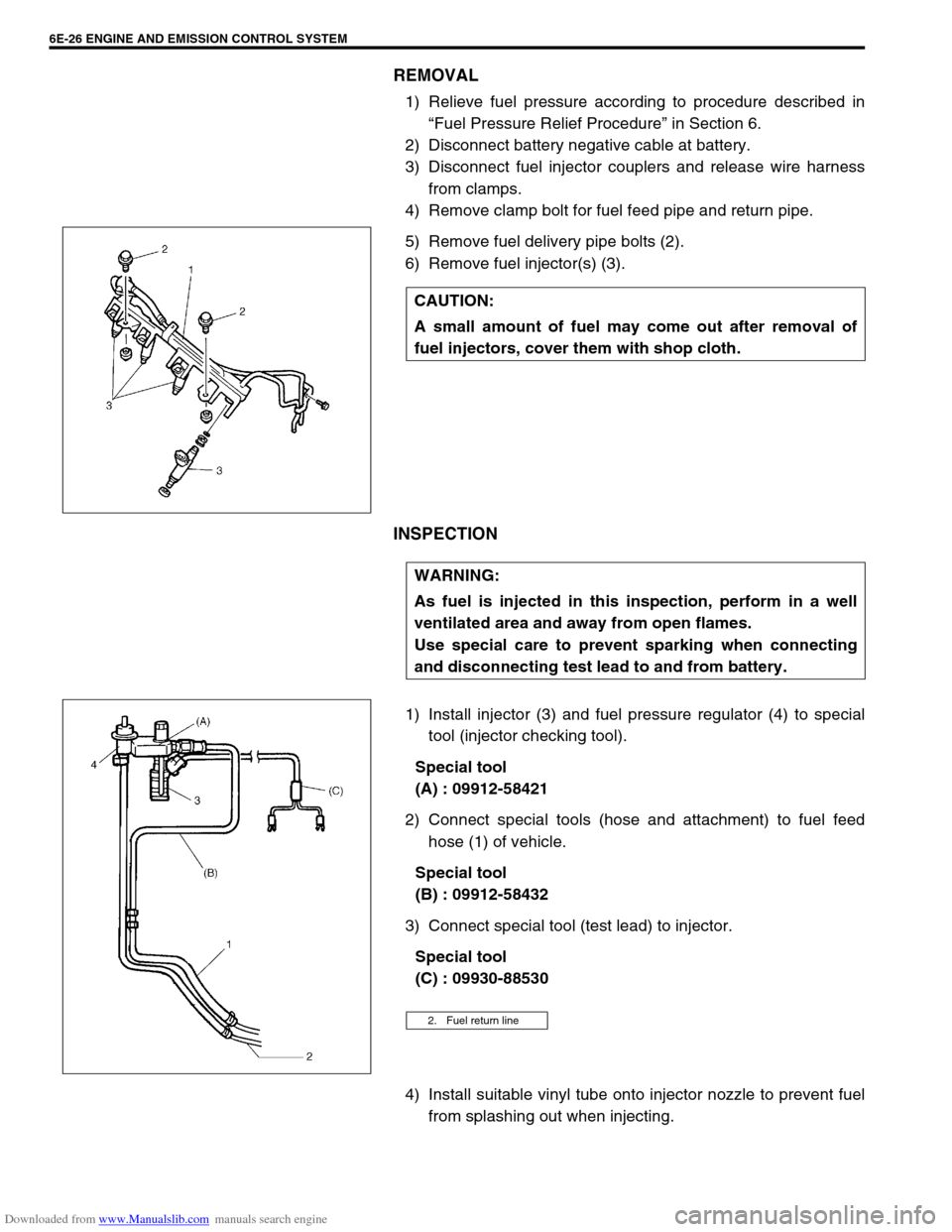

REMOVAL

1) Relieve fuel pressure according to procedure described in

“Fuel Pressure Relief Procedure” in Section 6.

2) Disconnect battery negative cable at battery.

3) Disconnect fuel injector couplers and release wire harness

from clamps.

4) Remove clamp bolt for fuel feed pipe and return pipe.

5) Remove fuel delivery pipe bolts (2).

6) Remove fuel injector(s) (3).

INSPECTION

1) Install injector (3) and fuel pressure regulator (4) to special

tool (injector checking tool).

Special tool

(A) : 09912-58421

2) Connect special tools (hose and attachment) to fuel feed

hose (1) of vehicle.

Special tool

(B) : 09912-58432

3) Connect special tool (test lead) to injector.

Special tool

(C) : 09930-88530

4) Install suitable vinyl tube onto injector nozzle to prevent fuel

from splashing out when injecting. CAUTION:

A small amount of fuel may come out after removal of

fuel injectors, cover them with shop cloth.

WARNING:

As fuel is injected in this inspection, perform in a well

ventilated area and away from open flames.

Use special care to prevent sparking when connecting

and disconnecting test lead to and from battery.

2. Fuel return line

Page 632 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-27

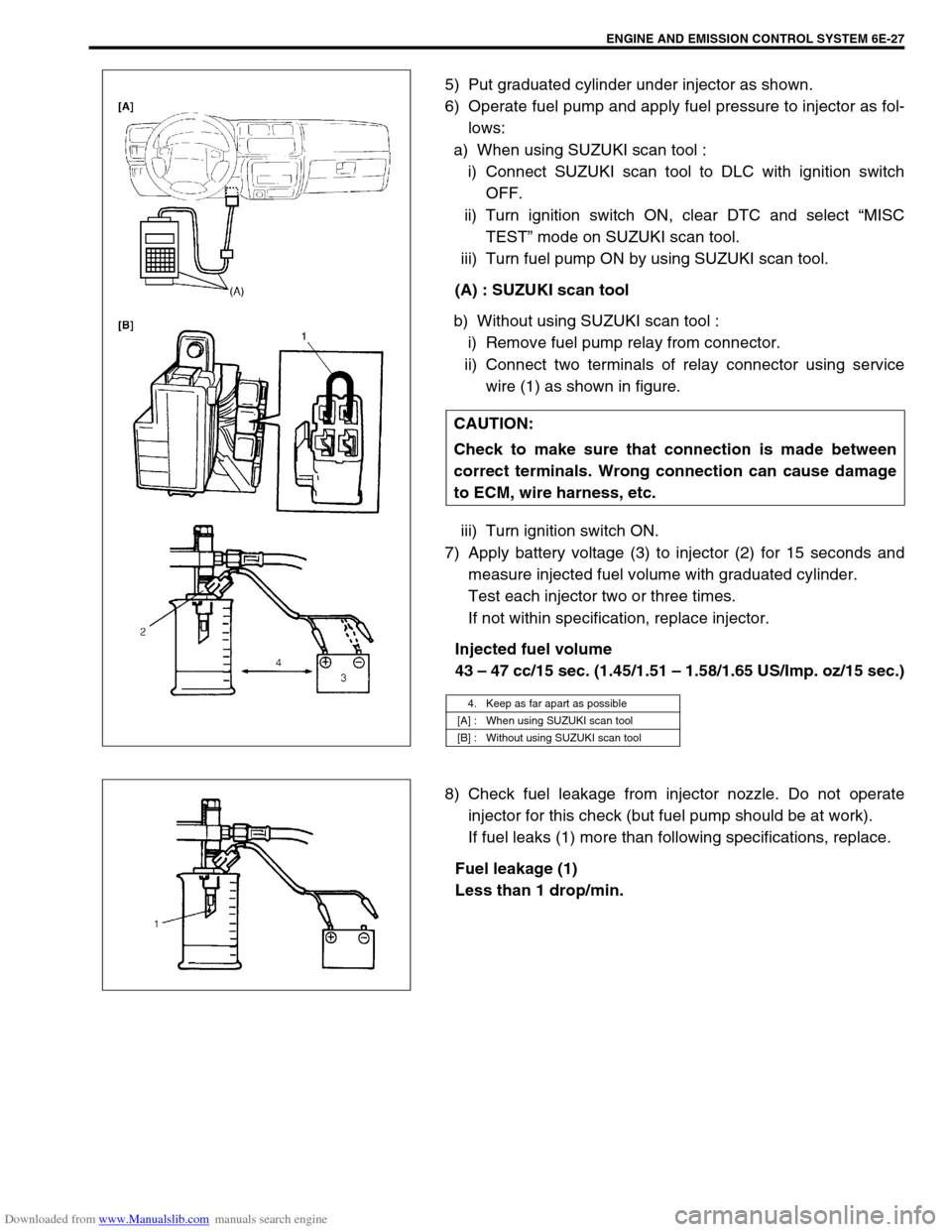

5) Put graduated cylinder under injector as shown.

6) Operate fuel pump and apply fuel pressure to injector as fol-

lows:

a) When using SUZUKI scan tool :

i) Connect SUZUKI scan tool to DLC with ignition switch

OFF.

ii) Turn ignition switch ON, clear DTC and select “MISC

TEST” mode on SUZUKI scan tool.

iii) Turn fuel pump ON by using SUZUKI scan tool.

(A) : SUZUKI scan tool

b) Without using SUZUKI scan tool :

i) Remove fuel pump relay from connector.

ii) Connect two terminals of relay connector using service

wire (1) as shown in figure.

iii) Turn ignition switch ON.

7) Apply battery voltage (3) to injector (2) for 15 seconds and

measure injected fuel volume with graduated cylinder.

Test each injector two or three times.

If not within specification, replace injector.

Injected fuel volume

43 – 47 cc/15 sec. (1.45/1.51 – 1.58/1.65 US/Imp. oz/15 sec.)

8) Check fuel leakage from injector nozzle. Do not operate

injector for this check (but fuel pump should be at work).

If fuel leaks (1) more than following specifications, replace.

Fuel leakage (1)

Less than 1 drop/min. CAUTION:

Check to make sure that connection is made between

correct terminals. Wrong connection can cause damage

to ECM, wire harness, etc.

4. Keep as far apart as possible

[A] : When using SUZUKI scan tool

[B] : Without using SUZUKI scan tool

Page 633 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-28 ENGINE AND EMISSION CONTROL SYSTEM

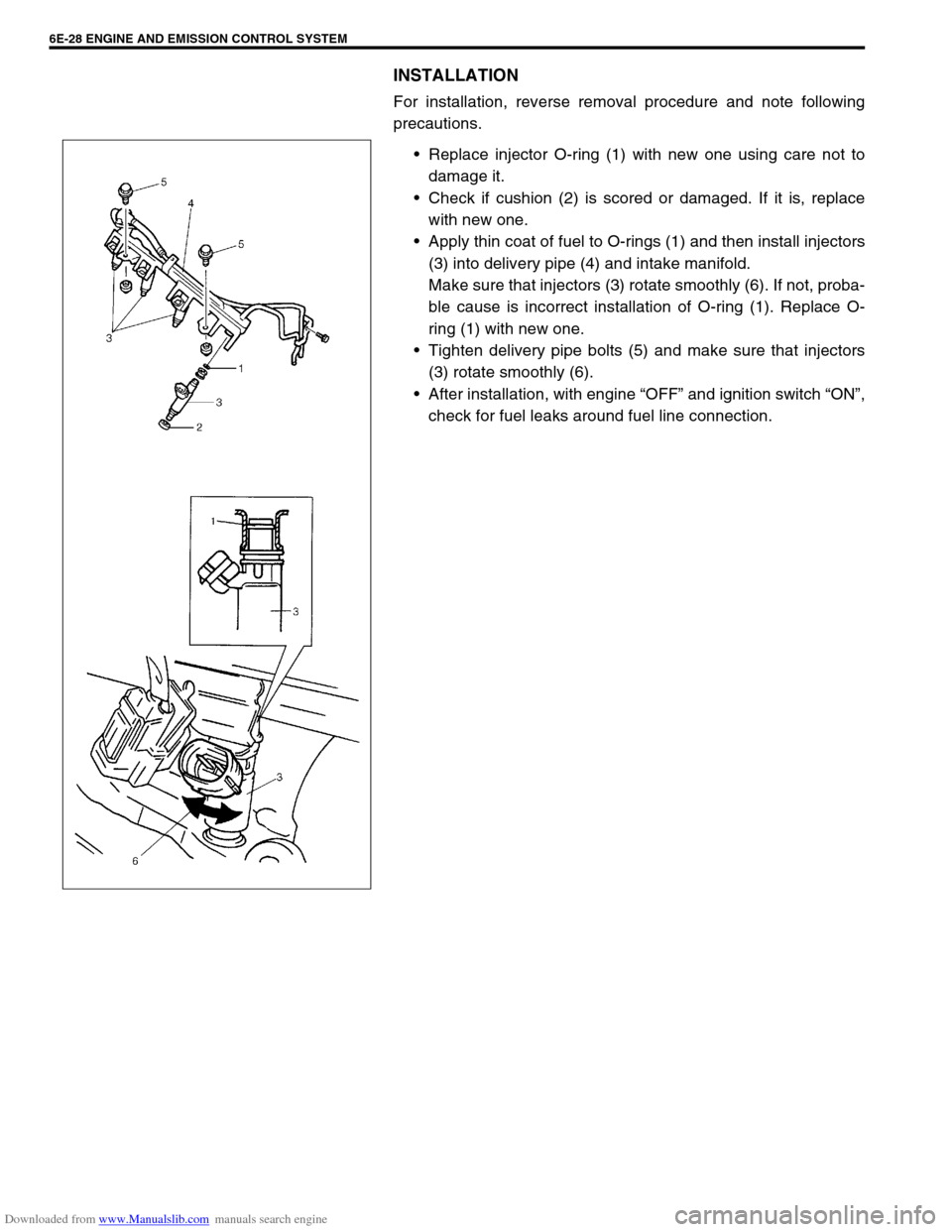

INSTALLATION

For installation, reverse removal procedure and note following

precautions.

Replace injector O-ring (1) with new one using care not to

damage it.

Check if cushion (2) is scored or damaged. If it is, replace

with new one.

Apply thin coat of fuel to O-rings (1) and then install injectors

(3) into delivery pipe (4) and intake manifold.

Make sure that injectors (3) rotate smoothly (6). If not, proba-

ble cause is incorrect installation of O-ring (1). Replace O-

ring (1) with new one.

Tighten delivery pipe bolts (5) and make sure that injectors

(3) rotate smoothly (6).

After installation, with engine “OFF” and ignition switch “ON”,

check for fuel leaks around fuel line connection.

Page 634 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-29

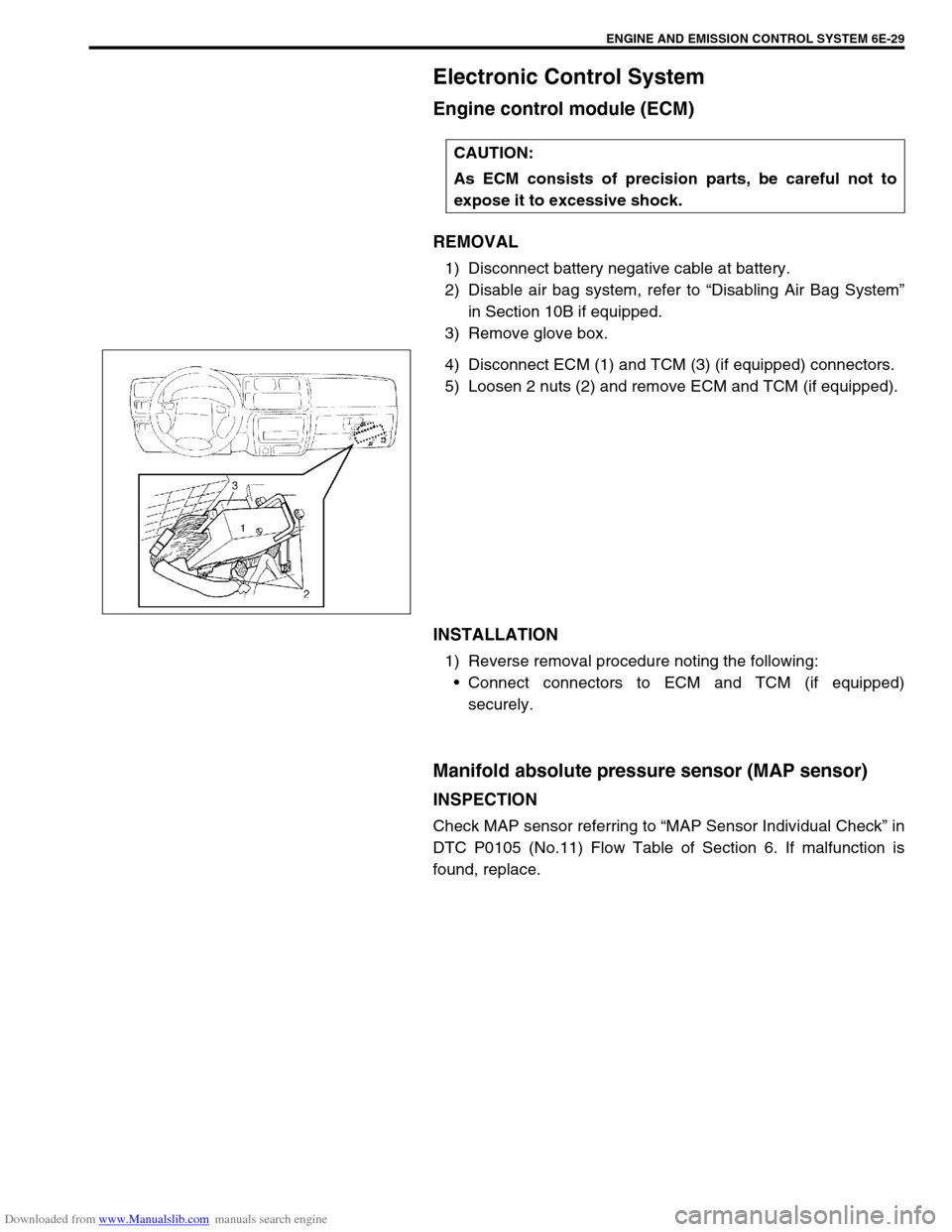

Electronic Control System

Engine control module (ECM)

REMOVAL

1) Disconnect battery negative cable at battery.

2) Disable air bag system, refer to “Disabling Air Bag System”

in Section 10B if equipped.

3) Remove glove box.

4) Disconnect ECM (1) and TCM (3) (if equipped) connectors.

5) Loosen 2 nuts (2) and remove ECM and TCM (if equipped).

INSTALLATION

1) Reverse removal procedure noting the following:

Connect connectors to ECM and TCM (if equipped)

securely.

Manifold absolute pressure sensor (MAP sensor)

INSPECTION

Check MAP sensor referring to “MAP Sensor Individual Check” in

DTC P0105 (No.11) Flow Table of Section 6. If malfunction is

found, replace.CAUTION:

As ECM consists of precision parts, be careful not to

expose it to excessive shock.

Page 635 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-30 ENGINE AND EMISSION CONTROL SYSTEM

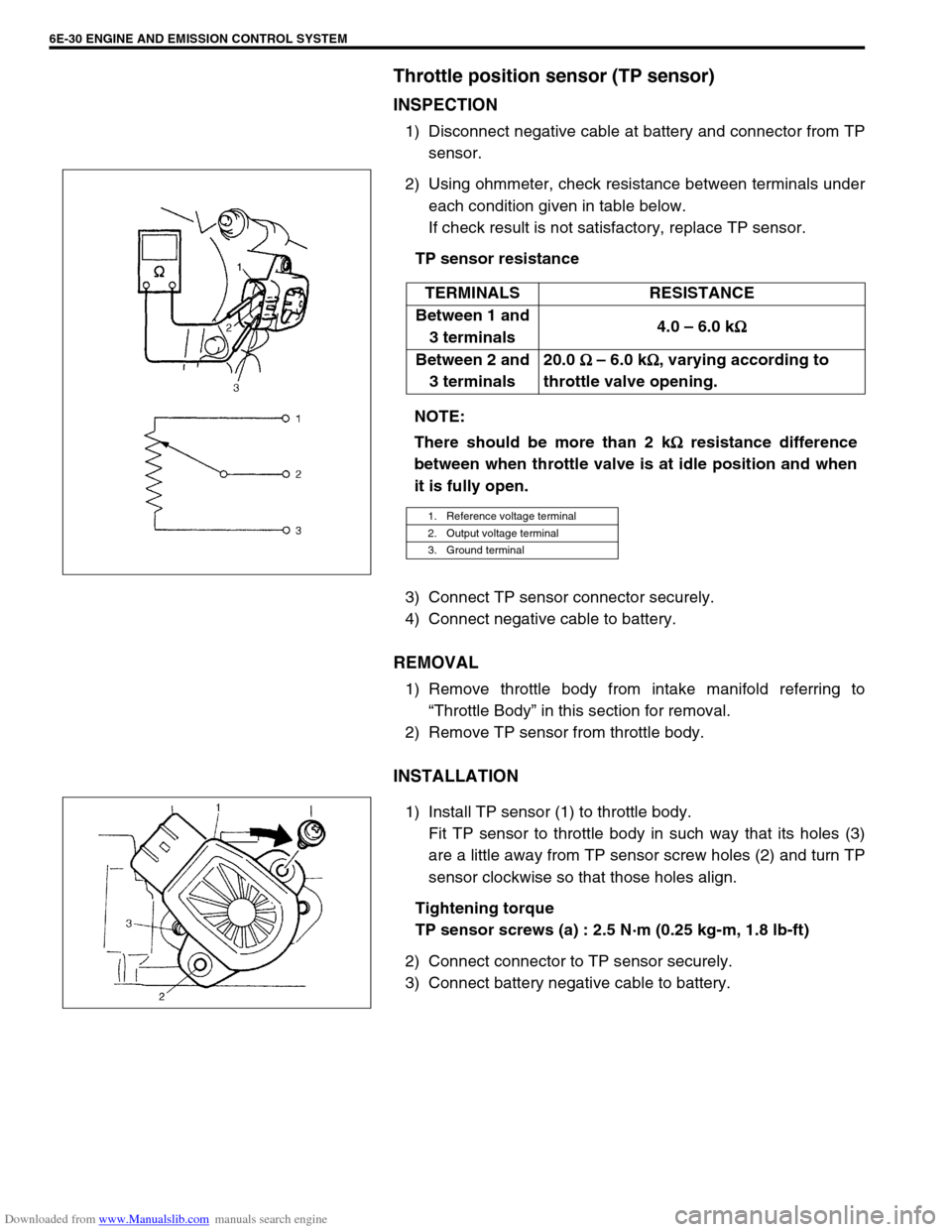

Throttle position sensor (TP sensor)

INSPECTION

1) Disconnect negative cable at battery and connector from TP

sensor.

2) Using ohmmeter, check resistance between terminals under

each condition given in table below.

If check result is not satisfactory, replace TP sensor.

TP sensor resistance

3) Connect TP sensor connector securely.

4) Connect negative cable to battery.

REMOVAL

1) Remove throttle body from intake manifold referring to

“Throttle Body” in this section for removal.

2) Remove TP sensor from throttle body.

INSTALLATION

1) Install TP sensor (1) to throttle body.

Fit TP sensor to throttle body in such way that its holes (3)

are a little away from TP sensor screw holes (2) and turn TP

sensor clockwise so that those holes align.

Tightening torque

TP sensor screws (a) : 2.5 N·m (0.25 kg-m, 1.8 lb-ft)

2) Connect connector to TP sensor securely.

3) Connect battery negative cable to battery.TERMINALS RESISTANCE

Between 1 and

3 terminals4.0 – 6.0 k

Ω

ΩΩ Ω

Between 2 and

3 terminals20.0

Ω

ΩΩ Ω – 6.0 k

Ω

ΩΩ Ω, varying according to

throttle valve opening.

NOTE:

There should be more than 2 k

Ω

ΩΩ Ω resistance difference

between when throttle valve is at idle position and when

it is fully open.

1. Reference voltage terminal

2. Output voltage terminal

3. Ground terminal

Page 636 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-31

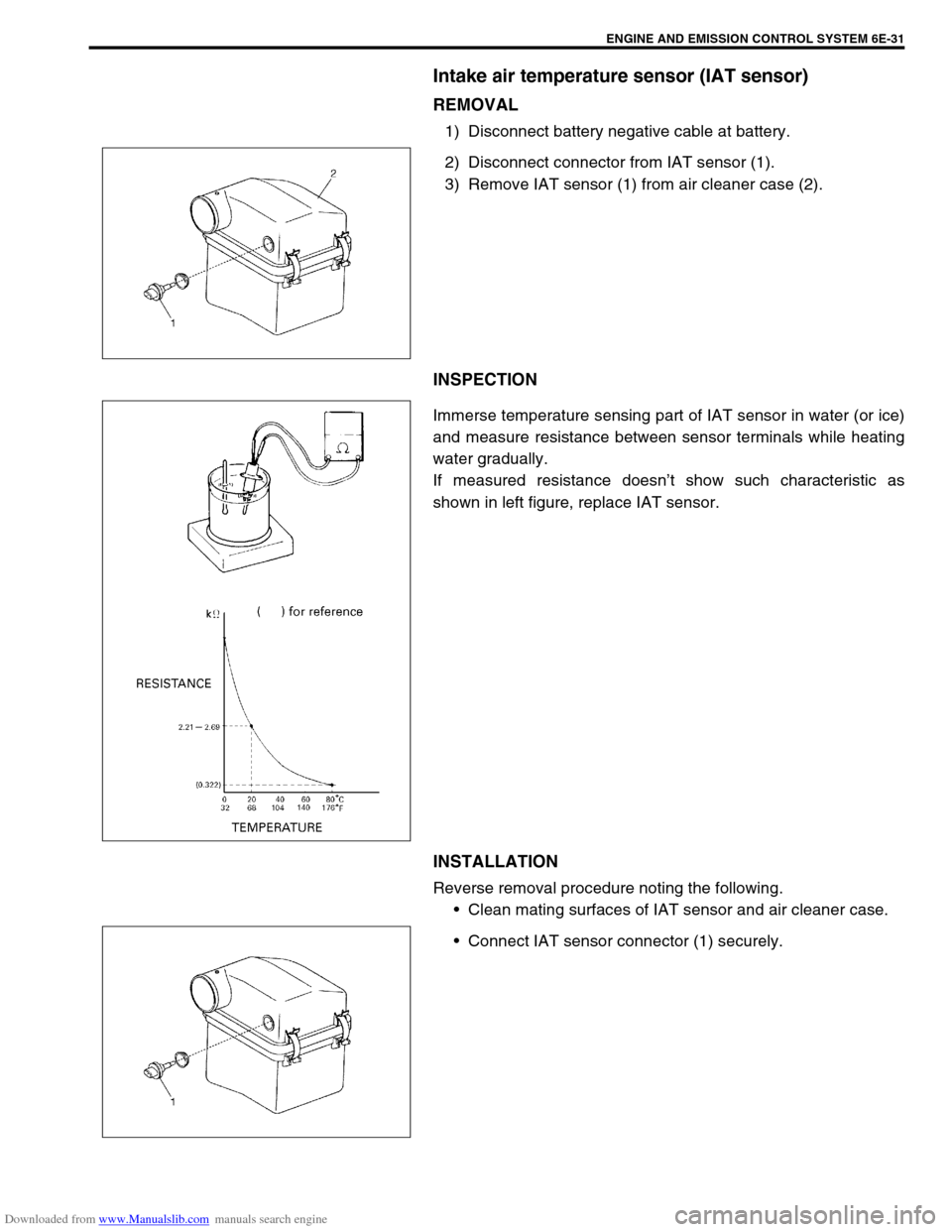

Intake air temperature sensor (IAT sensor)

REMOVAL

1) Disconnect battery negative cable at battery.

2) Disconnect connector from IAT sensor (1).

3) Remove IAT sensor (1) from air cleaner case (2).

INSPECTION

Immerse temperature sensing part of IAT sensor in water (or ice)

and measure resistance between sensor terminals while heating

water gradually.

If measured resistance doesn’t show such characteristic as

shown in left figure, replace IAT sensor.

INSTALLATION

Reverse removal procedure noting the following.

Clean mating surfaces of IAT sensor and air cleaner case.

Connect IAT sensor connector (1) securely.