Signal SUZUKI JIMNY 2005 3.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 612 of 687

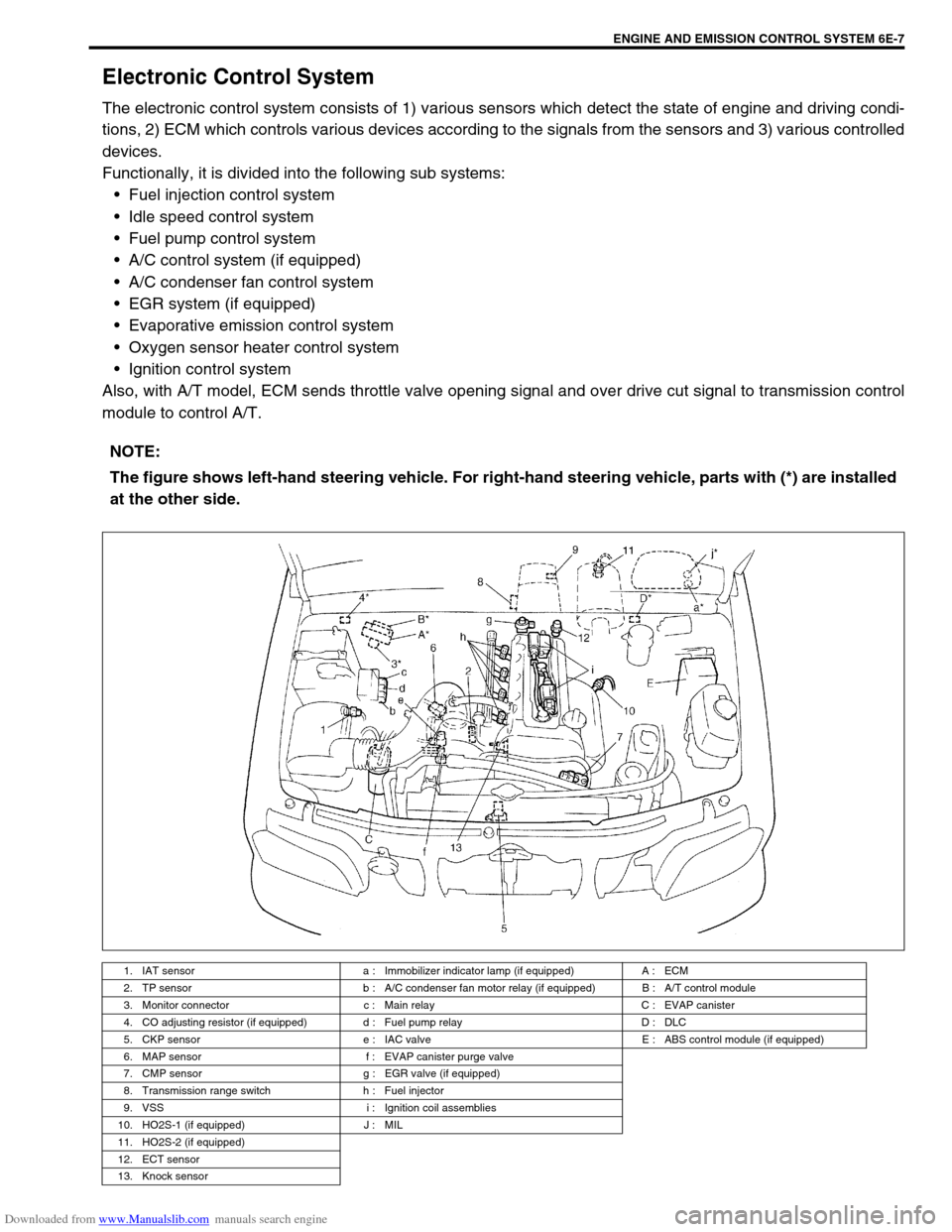

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-7

Electronic Control System

The electronic control system consists of 1) various sensors which detect the state of engine and driving condi-

tions, 2) ECM which controls various devices according to the signals from the sensors and 3) various controlled

devices.

Functionally, it is divided into the following sub systems:

Fuel injection control system

Idle speed control system

Fuel pump control system

A/C control system (if equipped)

A/C condenser fan control system

EGR system (if equipped)

Evaporative emission control system

Oxygen sensor heater control system

Ignition control system

Also, with A/T model, ECM sends throttle valve opening signal and over drive cut signal to transmission control

module to control A/T.

NOTE:

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the other side.

1. IAT sensor a : Immobilizer indicator lamp (if equipped) A : ECM

2. TP sensor b : A/C condenser fan motor relay (if equipped) B : A/T control module

3. Monitor connector c : Main relay C : EVAP canister

4. CO adjusting resistor (if equipped) d : Fuel pump relay D : DLC

5. CKP sensor e : IAC valve E : ABS control module (if equipped)

6. MAP sensor f : EVAP canister purge valve

7. CMP sensor g : EGR valve (if equipped)

8. Transmission range switch h : Fuel injector

9. VSS i : Ignition coil assemblies

10. HO2S-1 (if equipped) J : MIL

11. HO2S-2 (if equipped)

12. ECT sensor

13. Knock sensor

Page 613 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-8 ENGINE AND EMISSION CONTROL SYSTEM

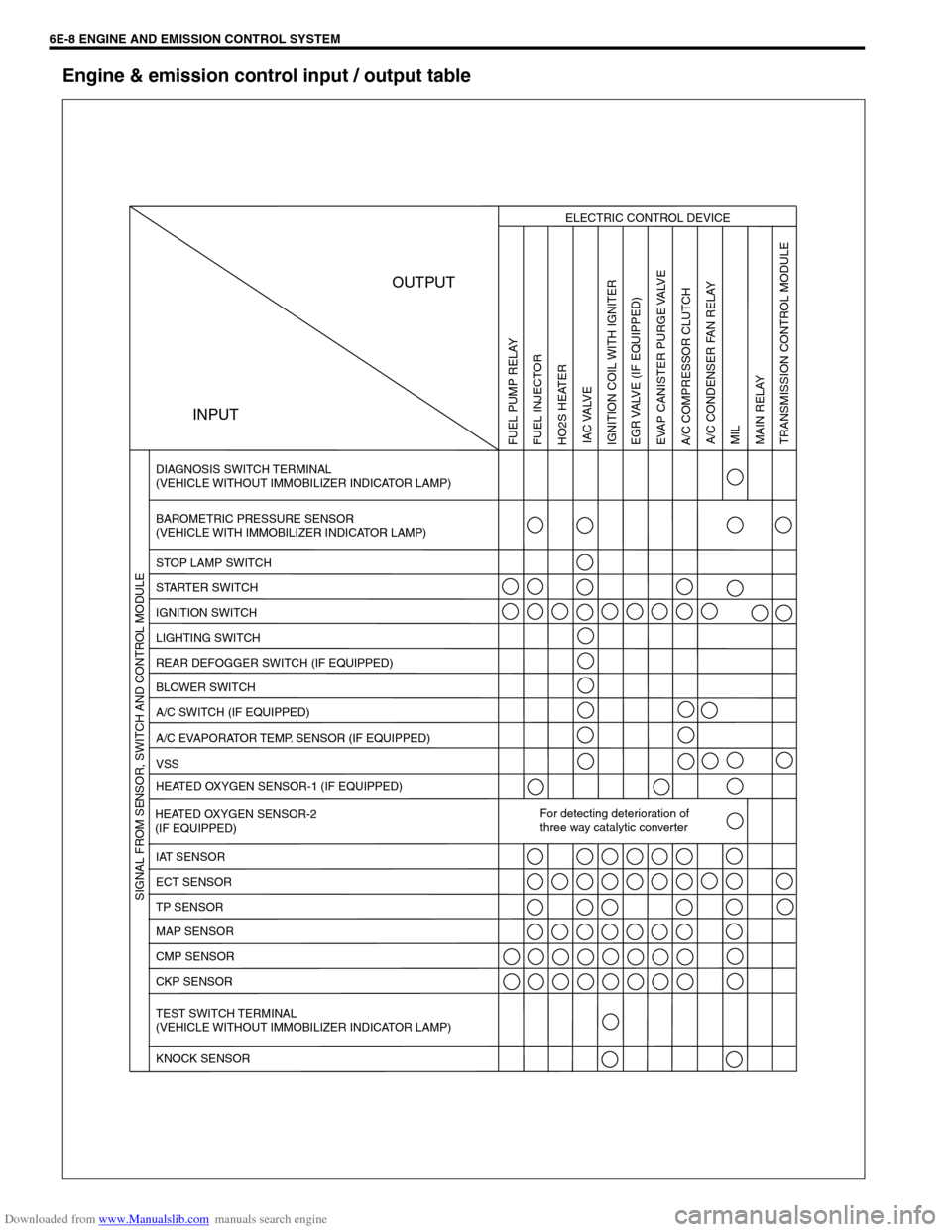

Engine & emission control input / output table

INPUTOUTPUT

ELECTRIC CONTROL DEVICE

DIAGNOSIS SWITCH TERMINAL

(VEHICLE WITHOUT IMMOBILIZER INDICATOR LAMP)

BAROMETRIC PRESSURE SENSOR

(VEHICLE WITH IMMOBILIZER INDICATOR LAMP)

STOP LAMP SWITCH

STARTER SWITCH

IGNITION SWITCH

LIGHTING SWITCH

REAR DEFOGGER SWITCH (IF EQUIPPED)

BLOWER SWITCH

A/C SWITCH (IF EQUIPPED)

A/C EVAPORATOR TEMP. SENSOR (IF EQUIPPED)

VSS

HEATED OXYGEN SENSOR-1 (IF EQUIPPED)

HEATED OXYGEN SENSOR-2

(IF EQUIPPED)For detecting deterioration of

three way catalytic converter

IAT SENSOR

ECT SENSOR

TP SENSOR

MAP SENSOR

CMP SENSOR

CKP SENSOR

TEST SWITCH TERMINAL

(VEHICLE WITHOUT IMMOBILIZER INDICATOR LAMP)

KNOCK SENSOR

FUEL PUMP RELAY

FUEL INJECTOR

HO2S HEATER

IAC VALVE

IGNITION COIL WITH IGNITER

EGR VALVE (IF EQUIPPED)

EVAP CANISTER PURGE VALVE

A/C COMPRESSOR CLUTCH

MIL

MAIN RELAY

TRANSMISSION CONTROL MODULE SIGNAL FROM SENSOR, SWITCH AND CONTROL MODULEA/C CONDENSER FAN RELAY

Page 618 of 687

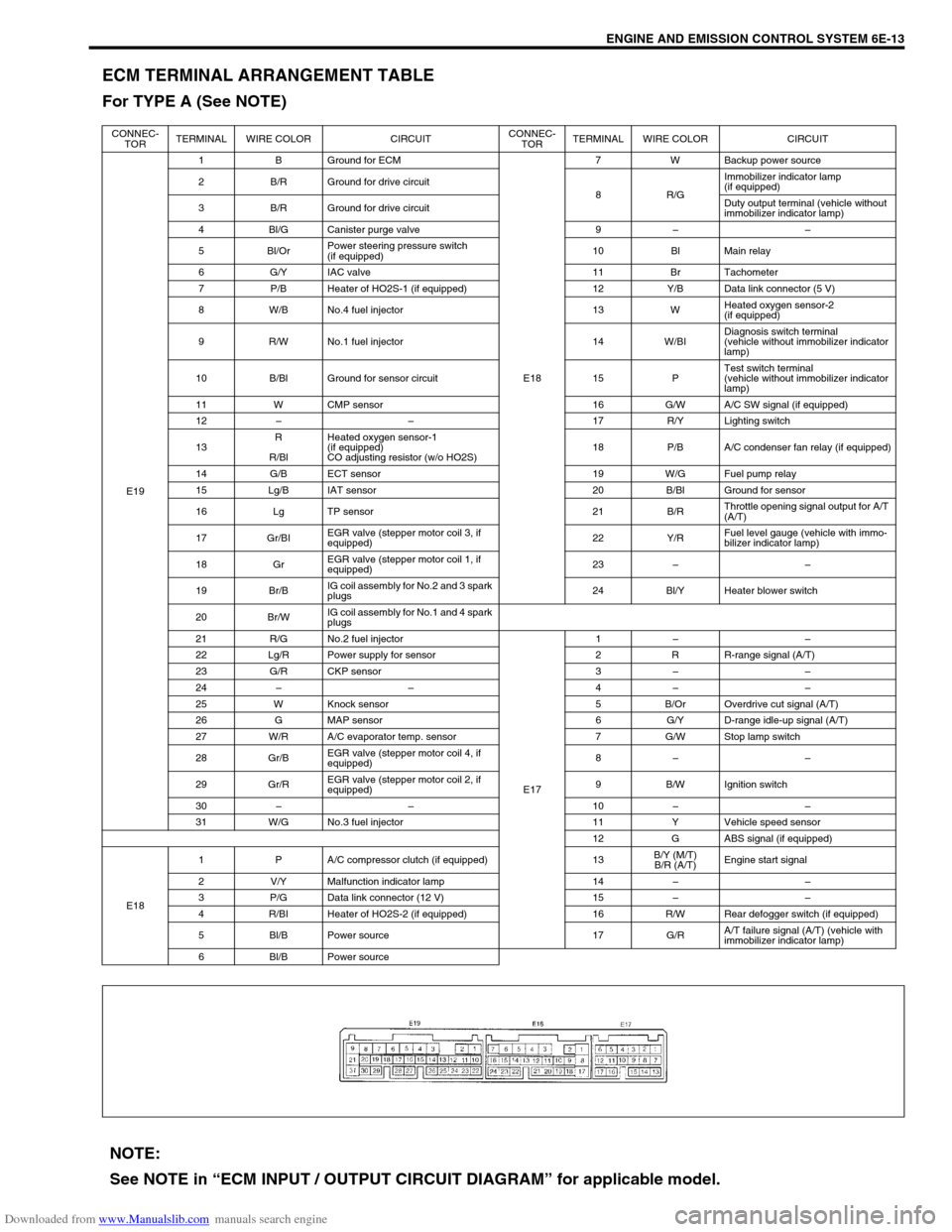

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-13

ECM TERMINAL ARRANGEMENT TABLE

For TYPE A (See NOTE)

CONNEC-

TORTERMINAL WIRE COLOR CIRCUITCONNEC-

TORTERMINAL WIRE COLOR CIRCUIT

E191 B Ground for ECM

E187 W Backup power source

2 B/R Ground for drive circuit

8R/GImmobilizer indicator lamp

(if equipped)

3 B/R Ground for drive circuitDuty output terminal (vehicle without

immobilizer indicator lamp)

4 Bl/G Canister purge valve 9––

5 Bl/OrPower steering pressure switch

(if equipped)10 Bl Main relay

6 G/Y IAC valve 11 Br Tachometer

7 P/B Heater of HO2S-1 (if equipped) 12 Y/B Data link connector (5 V)

8 W/B No.4 fuel injector 13 WHeated oxygen sensor-2

(if equipped)

9 R/W No.1 fuel injector 14 W/BIDiagnosis switch terminal

(vehicle without immobilizer indicator

lamp)

10 B/Bl Ground for sensor circuit 15 PTest switch terminal

(vehicle without immobilizer indicator

lamp)

11 W CMP sensor 16 G/W A/C SW signal (if equipped)

12––17 R/Y Lighting switch

13R

R/BlHeated oxygen sensor-1

(if equipped)

CO adjusting resistor (w/o HO2S)18 P/B A/C condenser fan relay (if equipped)

14 G/B ECT sensor 19 W/G Fuel pump relay

15 Lg/B IAT sensor 20 B/Bl Ground for sensor

16 Lg TP sensor 21 B/RThrottle opening signal output for A/T

(A/T)

17 Gr/BIEGR valve (stepper motor coil 3, if

equipped)22 Y/RFuel level gauge (vehicle with immo-

bilizer indicator lamp)

18 GrEGR valve (stepper motor coil 1, if

equipped)23––

19 Br/BIG coil assembly for No.2 and 3 spark

plugs24 Bl/Y Heater blower switch

20 Br/WIG coil assembly for No.1 and 4 spark

plugs

21 R/G No.2 fuel injector

E171––

22 Lg/R Power supply for sensor 2 R R-range signal (A/T)

23 G/R CKP sensor 3––

24––4––

25 W Knock sensor 5 B/Or Overdrive cut signal (A/T)

26 G MAP sensor 6 G/Y D-range idle-up signal (A/T)

27 W/R A/C evaporator temp. sensor 7 G/W Stop lamp switch

28 Gr/BEGR valve (stepper motor coil 4, if

equipped)8––

29 Gr/REGR valve (stepper motor coil 2, if

equipped)9 B/W Ignition switch

30––10––

31 W/G No.3 fuel injector 11 Y Vehicle speed sensor

12 G ABS signal (if equipped)

E181 P A/C compressor clutch (if equipped) 13B/Y (M/T)

B/R (A/T)Engine start signal

2 V/Y Malfunction indicator lamp 14––

3 P/G Data link connector (12 V) 15––

4 R/BI Heater of HO2S-2 (if equipped) 16 R/W Rear defogger switch (if equipped)

5 Bl/B Power source 17 G/RA/T failure signal (A/T) (vehicle with

immobilizer indicator lamp)

6 Bl/B Power source

NOTE:

See NOTE in “ECM INPUT / OUTPUT CIRCUIT DIAGRAM” for applicable model.

Page 619 of 687

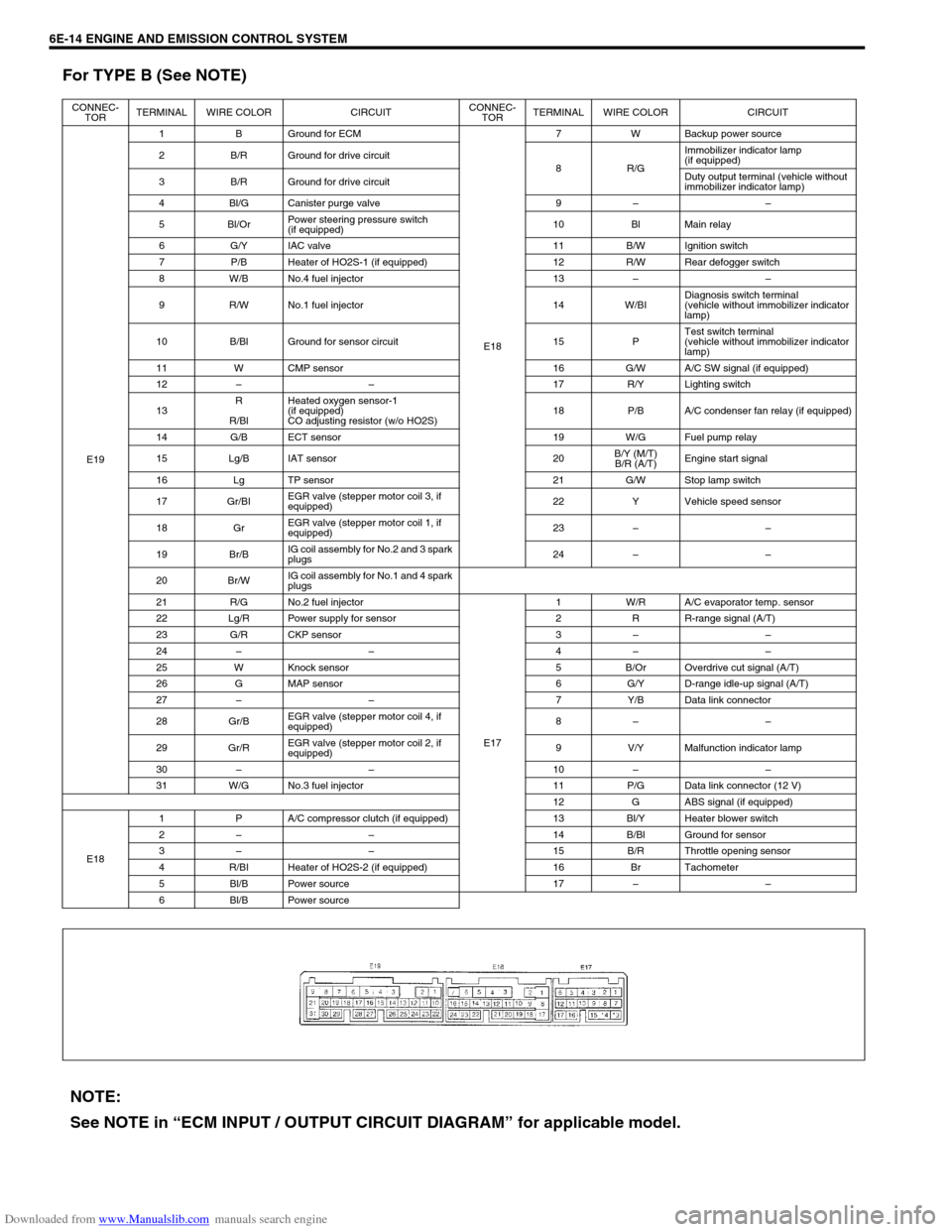

Downloaded from www.Manualslib.com manuals search engine 6E-14 ENGINE AND EMISSION CONTROL SYSTEM

For TYPE B (See NOTE)

CONNEC-

TORTERMINAL WIRE COLOR CIRCUITCONNEC-

TORTERMINAL WIRE COLOR CIRCUIT

E191 B Ground for ECM

E187 W Backup power source

2 B/R Ground for drive circuit

8R/GImmobilizer indicator lamp

(if equipped)

3 B/R Ground for drive circuitDuty output terminal (vehicle without

immobilizer indicator lamp)

4 Bl/G Canister purge valve 9––

5 Bl/OrPower steering pressure switch

(if equipped)10 Bl Main relay

6 G/Y IAC valve 11 B/W Ignition switch

7 P/B Heater of HO2S-1 (if equipped) 12 R/W Rear defogger switch

8 W/B No.4 fuel injector 13––

9 R/W No.1 fuel injector 14 W/BIDiagnosis switch terminal

(vehicle without immobilizer indicator

lamp)

10 B/Bl Ground for sensor circuit 15 PTest switch terminal

(vehicle without immobilizer indicator

lamp)

11 W CMP sensor 16 G/W A/C SW signal (if equipped)

12––17 R/Y Lighting switch

13R

R/BlHeated oxygen sensor-1

(if equipped)

CO adjusting resistor (w/o HO2S)18 P/B A/C condenser fan relay (if equipped)

14 G/B ECT sensor 19 W/G Fuel pump relay

15 Lg/B IAT sensor 20B/Y (M/T)

B/R (A/T)Engine start signal

16 Lg TP sensor 21 G/W Stop lamp switch

17 Gr/BIEGR valve (stepper motor coil 3, if

equipped)22 Y Vehicle speed sensor

18 GrEGR valve (stepper motor coil 1, if

equipped)23––

19 Br/BIG coil assembly for No.2 and 3 spark

plugs24––

20 Br/WIG coil assembly for No.1 and 4 spark

plugs

21 R/G No.2 fuel injector

E171 W/R A/C evaporator temp. sensor

22 Lg/R Power supply for sensor 2 R R-range signal (A/T)

23 G/R CKP sensor 3––

24––4––

25 W Knock sensor 5 B/Or Overdrive cut signal (A/T)

26 G MAP sensor 6 G/Y D-range idle-up signal (A/T)

27––7 Y/B Data link connector

28 Gr/BEGR valve (stepper motor coil 4, if

equipped)8––

29 Gr/REGR valve (stepper motor coil 2, if

equipped)9 V/Y Malfunction indicator lamp

30––10––

31 W/G No.3 fuel injector 11 P/G Data link connector (12 V)

12 G ABS signal (if equipped)

E181 P A/C compressor clutch (if equipped) 13 Bl/Y Heater blower switch

2––14 B/Bl Ground for sensor

3––15 B/R Throttle opening sensor

4 R/BI Heater of HO2S-2 (if equipped) 16 Br Tachometer

5 Bl/B Power source 17––

6 Bl/B Power source

NOTE:

See NOTE in “ECM INPUT / OUTPUT CIRCUIT DIAGRAM” for applicable model.

Page 621 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-16 ENGINE AND EMISSION CONTROL SYSTEM

1) Connect SUZUKI scan tool to DLC with ignition switch OFF,

if it is available.

2) Warm up engine to normal operating temperature.

3) Check engine idle speed and “IAC duty” as follows:

a) When using SUZUKI scan tool:

i) Select “Data List” mode on scan tool to check “IAC duty”.

(A) : SUZUKI scan tool

b) When using duty meter (3) (Vehicle without immobilizer

indicator lamp):

i) Set tachometer.

ii) Using service wire (2), ground “Diag. switch terminal” in

monitor connector (1) and connect duty meter between

“Duty output terminal (4)” and “Ground terminal (5)” of

monitor connector (1).

4) If duty and/or idle speed is out of specifications, inspect idle

air control system referring to “Diagnostic Flow Table B-4 Idle

Air Control System Check” in Section 6.

Engine idle speed and IAC duty

5) Remove service wire from monitor connector.

6) Check that specified engine idle speed is obtained with A/C

ON if vehicle is equipped with A/C.

If not, check A/C ON signal circuit and idle air control sys-

tem. NOTE:

IAC duty can be checked using monitor connector only

for vehicle not equipped with immobilizer indicator lamp.

[A] : When using SUZUKI scan tool

[B] : When using duty meter (Vehicle without immobilizer indicator lamp)

A/C OFF A/C ON

M/T vehicle700 ± 50 r/min (rpm)

5 – 25 %900 ± 50 r/min

(rpm)

A/T vehicle

at P/N range750 ± 50 r/min (rpm)

5 – 25 %900 ± 50 r/min

(rpm)

NOTE:

Above duty values are ON duty (low voltage rate) meter

indications.

Page 639 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-34 ENGINE AND EMISSION CONTROL SYSTEM

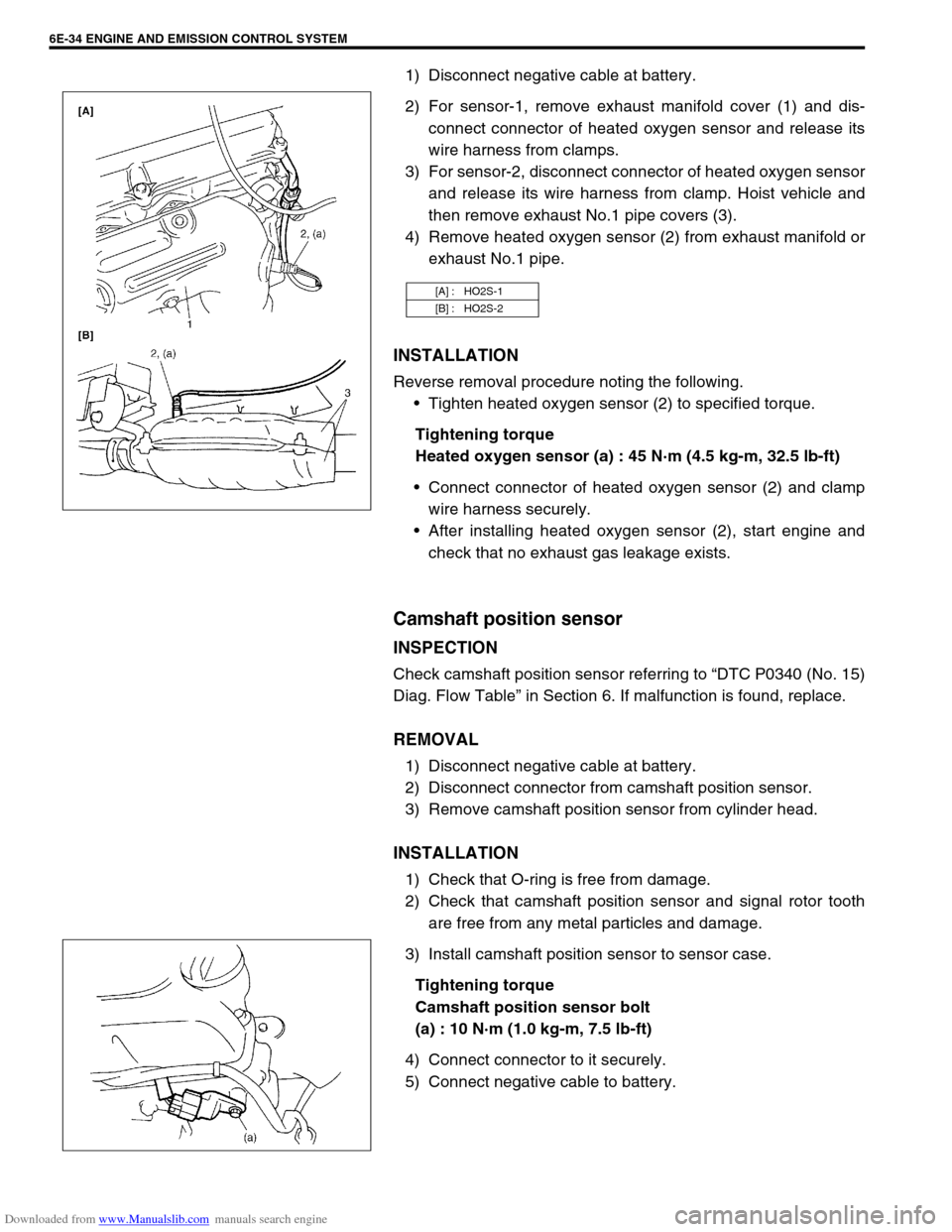

1) Disconnect negative cable at battery.

2) For sensor-1, remove exhaust manifold cover (1) and dis-

connect connector of heated oxygen sensor and release its

wire harness from clamps.

3) For sensor-2, disconnect connector of heated oxygen sensor

and release its wire harness from clamp. Hoist vehicle and

then remove exhaust No.1 pipe covers (3).

4) Remove heated oxygen sensor (2) from exhaust manifold or

exhaust No.1 pipe.

INSTALLATION

Reverse removal procedure noting the following.

Tighten heated oxygen sensor (2) to specified torque.

Tightening torque

Heated oxygen sensor (a) : 45 N·m (4.5 kg-m, 32.5 lb-ft)

Connect connector of heated oxygen sensor (2) and clamp

wire harness securely.

After installing heated oxygen sensor (2), start engine and

check that no exhaust gas leakage exists.

Camshaft position sensor

INSPECTION

Check camshaft position sensor referring to “DTC P0340 (No. 15)

Diag. Flow Table” in Section 6. If malfunction is found, replace.

REMOVAL

1) Disconnect negative cable at battery.

2) Disconnect connector from camshaft position sensor.

3) Remove camshaft position sensor from cylinder head.

INSTALLATION

1) Check that O-ring is free from damage.

2) Check that camshaft position sensor and signal rotor tooth

are free from any metal particles and damage.

3) Install camshaft position sensor to sensor case.

Tightening torque

Camshaft position sensor bolt

(a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

4) Connect connector to it securely.

5) Connect negative cable to battery.

[A] : HO2S-1

[B] : HO2S-2

Page 643 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-38 ENGINE AND EMISSION CONTROL SYSTEM

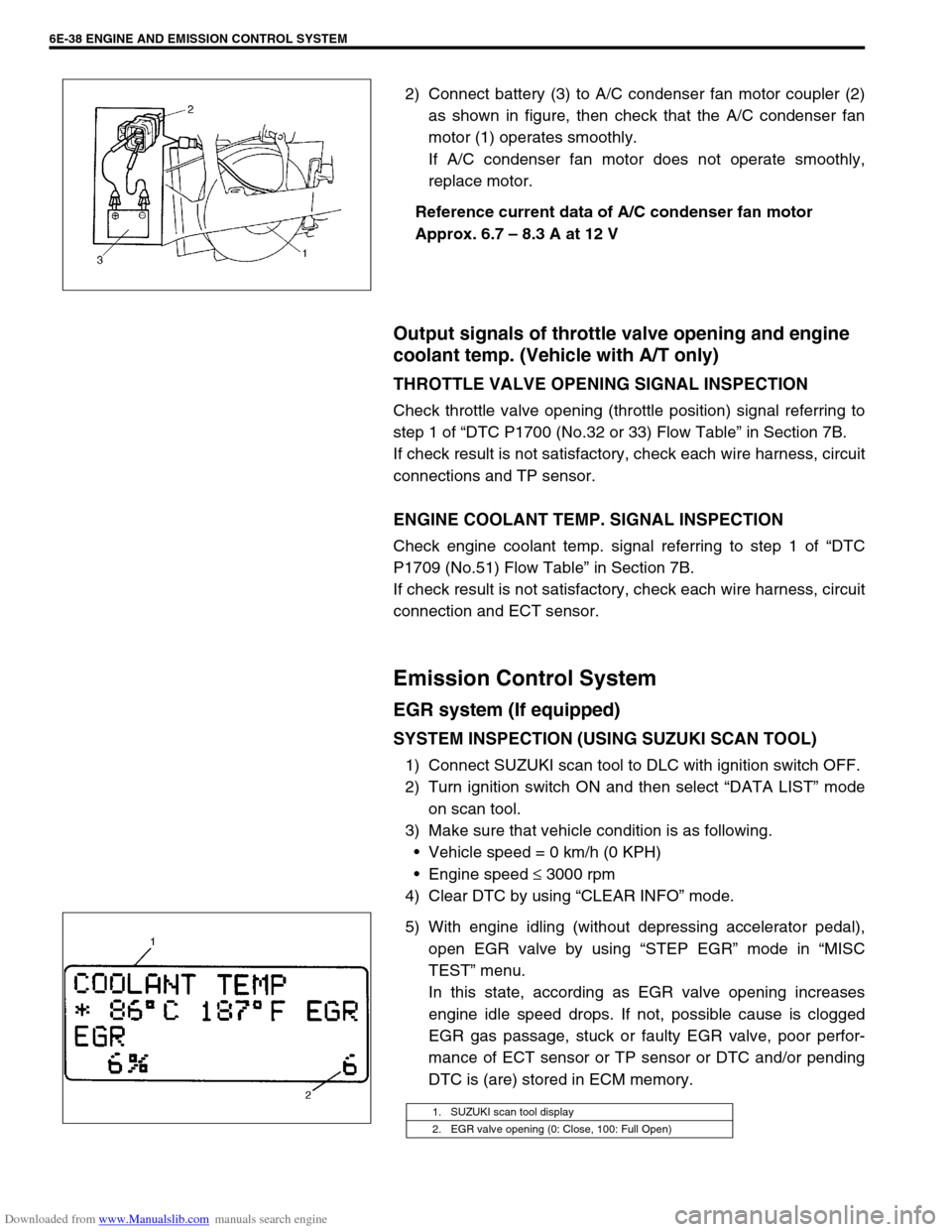

2) Connect battery (3) to A/C condenser fan motor coupler (2)

as shown in figure, then check that the A/C condenser fan

motor (1) operates smoothly.

If A/C condenser fan motor does not operate smoothly,

replace motor.

Reference current data of A/C condenser fan motor

Approx. 6.7 – 8.3 A at 12 V

Output signals of throttle valve opening and engine

coolant temp. (Vehicle with A/T only)

THROTTLE VALVE OPENING SIGNAL INSPECTION

Check throttle valve opening (throttle position) signal referring to

step 1 of “DTC P1700 (No.32 or 33) Flow Table” in Section 7B.

If check result is not satisfactory, check each wire harness, circuit

connections and TP sensor.

ENGINE COOLANT TEMP. SIGNAL INSPECTION

Check engine coolant temp. signal referring to step 1 of “DTC

P1709 (No.51) Flow Table” in Section 7B.

If check result is not satisfactory, check each wire harness, circuit

connection and ECT sensor.

Emission Control System

EGR system (If equipped)

SYSTEM INSPECTION (USING SUZUKI SCAN TOOL)

1) Connect SUZUKI scan tool to DLC with ignition switch OFF.

2) Turn ignition switch ON and then select “DATA LIST” mode

on scan tool.

3) Make sure that vehicle condition is as following.

Vehicle speed = 0 km/h (0 KPH)

Engine speed ≤ 3000 rpm

4) Clear DTC by using “CLEAR INFO” mode.

5) With engine idling (without depressing accelerator pedal),

open EGR valve by using “STEP EGR” mode in “MISC

TEST” menu.

In this state, according as EGR valve opening increases

engine idle speed drops. If not, possible cause is clogged

EGR gas passage, stuck or faulty EGR valve, poor perfor-

mance of ECT sensor or TP sensor or DTC and/or pending

DTC is (are) stored in ECM memory.

1. SUZUKI scan tool display

2. EGR valve opening (0: Close, 100: Full Open)

Page 651 of 687

Downloaded from www.Manualslib.com manuals search engine 6F-2 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

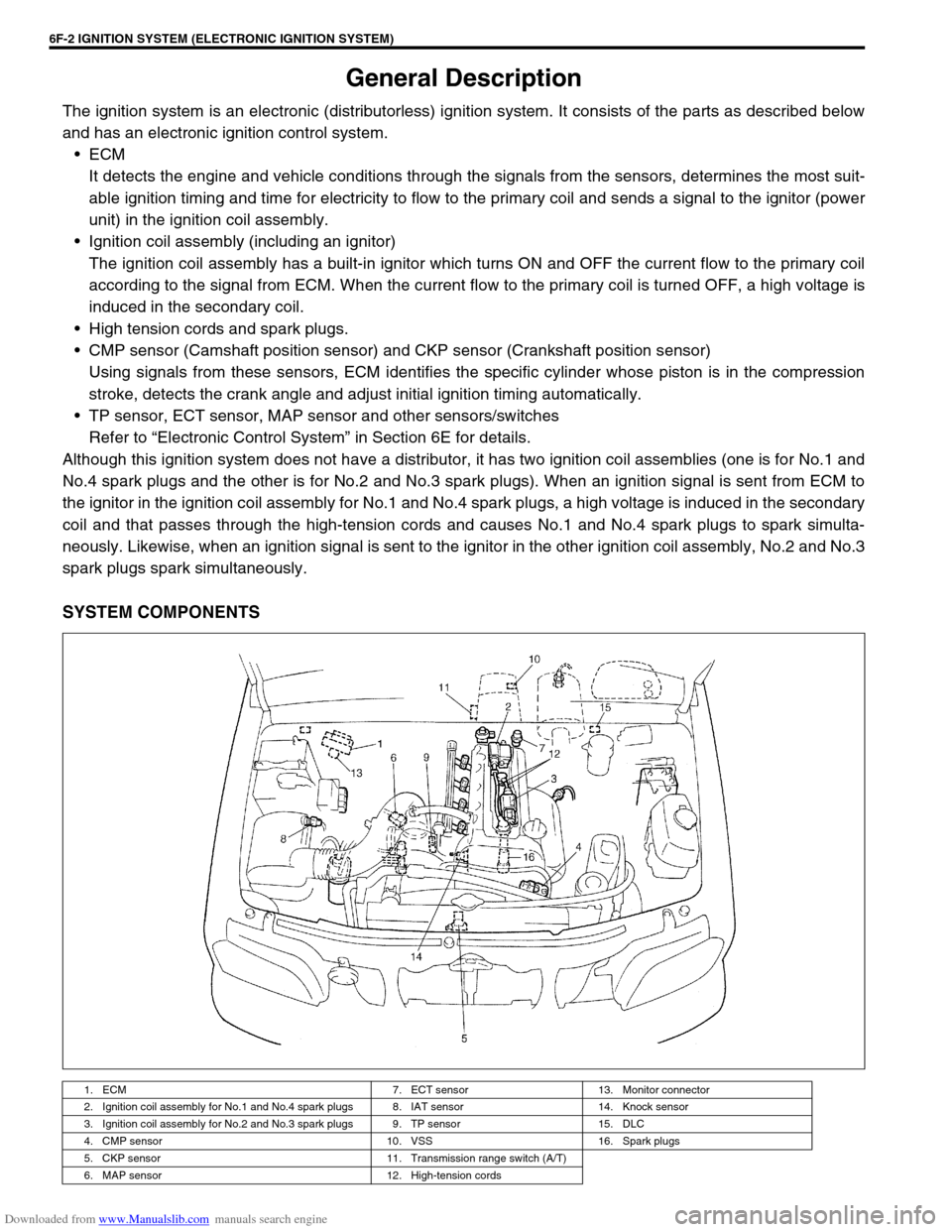

General Description

The ignition system is an electronic (distributorless) ignition system. It consists of the parts as described below

and has an electronic ignition control system.

ECM

It detects the engine and vehicle conditions through the signals from the sensors, determines the most suit-

able ignition timing and time for electricity to flow to the primary coil and sends a signal to the ignitor (power

unit) in the ignition coil assembly.

Ignition coil assembly (including an ignitor)

The ignition coil assembly has a built-in ignitor which turns ON and OFF the current flow to the primary coil

according to the signal from ECM. When the current flow to the primary coil is turned OFF, a high voltage is

induced in the secondary coil.

High tension cords and spark plugs.

CMP sensor (Camshaft position sensor) and CKP sensor (Crankshaft position sensor)

Using signals from these sensors, ECM identifies the specific cylinder whose piston is in the compression

stroke, detects the crank angle and adjust initial ignition timing automatically.

TP sensor, ECT sensor, MAP sensor and other sensors/switches

Refer to “Electronic Control System” in Section 6E for details.

Although this ignition system does not have a distributor, it has two ignition coil assemblies (one is for No.1 and

No.4 spark plugs and the other is for No.2 and No.3 spark plugs). When an ignition signal is sent from ECM to

the ignitor in the ignition coil assembly for No.1 and No.4 spark plugs, a high voltage is induced in the secondary

coil and that passes through the high-tension cords and causes No.1 and No.4 spark plugs to spark simulta-

neously. Likewise, when an ignition signal is sent to the ignitor in the other ignition coil assembly, No.2 and No.3

spark plugs spark simultaneously.

SYSTEM COMPONENTS

1. ECM 7. ECT sensor 13. Monitor connector

2. Ignition coil assembly for No.1 and No.4 spark plugs 8. IAT sensor 14. Knock sensor

3. Ignition coil assembly for No.2 and No.3 spark plugs 9. TP sensor 15. DLC

4. CMP sensor 10. VSS 16. Spark plugs

5. CKP sensor 11. Transmission range switch (A/T)

6. MAP sensor 12. High-tension cords

Page 652 of 687

Downloaded from www.Manualslib.com manuals search engine IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F-3

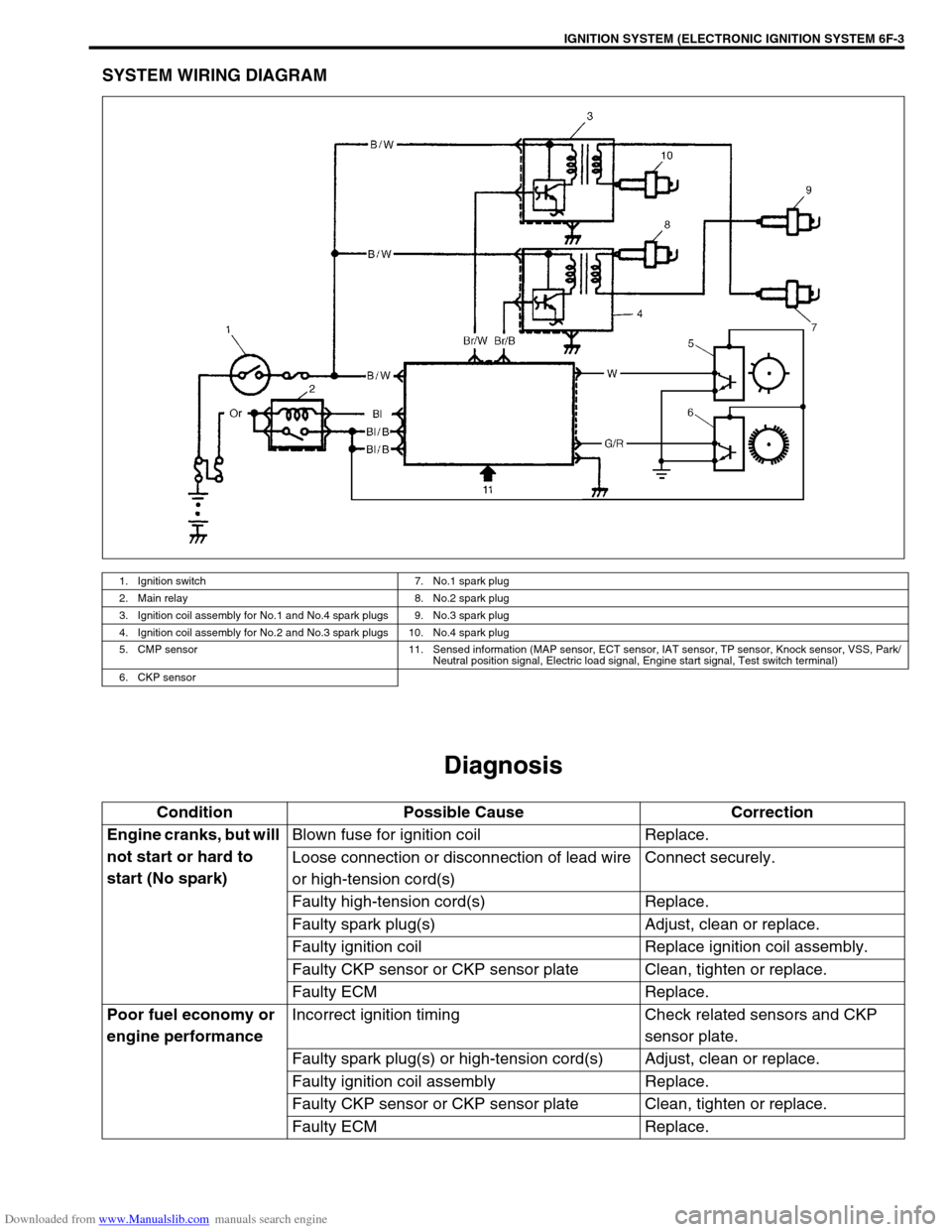

SYSTEM WIRING DIAGRAM

Diagnosis

1. Ignition switch 7. No.1 spark plug

2. Main relay 8. No.2 spark plug

3. Ignition coil assembly for No.1 and No.4 spark plugs 9. No.3 spark plug

4. Ignition coil assembly for No.2 and No.3 spark plugs 10. No.4 spark plug

5. CMP sensor 11. Sensed information (MAP sensor, ECT sensor, IAT sensor, TP sensor, Knock sensor, VSS, Park/

Neutral position signal, Electric load signal, Engine start signal, Test switch terminal)

6. CKP sensor

Condition Possible Cause Correction

Engine cranks, but will

not start or hard to

start (No spark)Blown fuse for ignition coil Replace.

Loose connection or disconnection of lead wire

or high-tension cord(s)Connect securely.

Faulty high-tension cord(s) Replace.

Faulty spark plug(s) Adjust, clean or replace.

Faulty ignition coil Replace ignition coil assembly.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty ECM Replace.

Poor fuel economy or

engine performanceIncorrect ignition timing Check related sensors and CKP

sensor plate.

Faulty spark plug(s) or high-tension cord(s) Adjust, clean or replace.

Faulty ignition coil assembly Replace.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty ECM Replace.

Page 653 of 687

Downloaded from www.Manualslib.com manuals search engine 6F-4 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

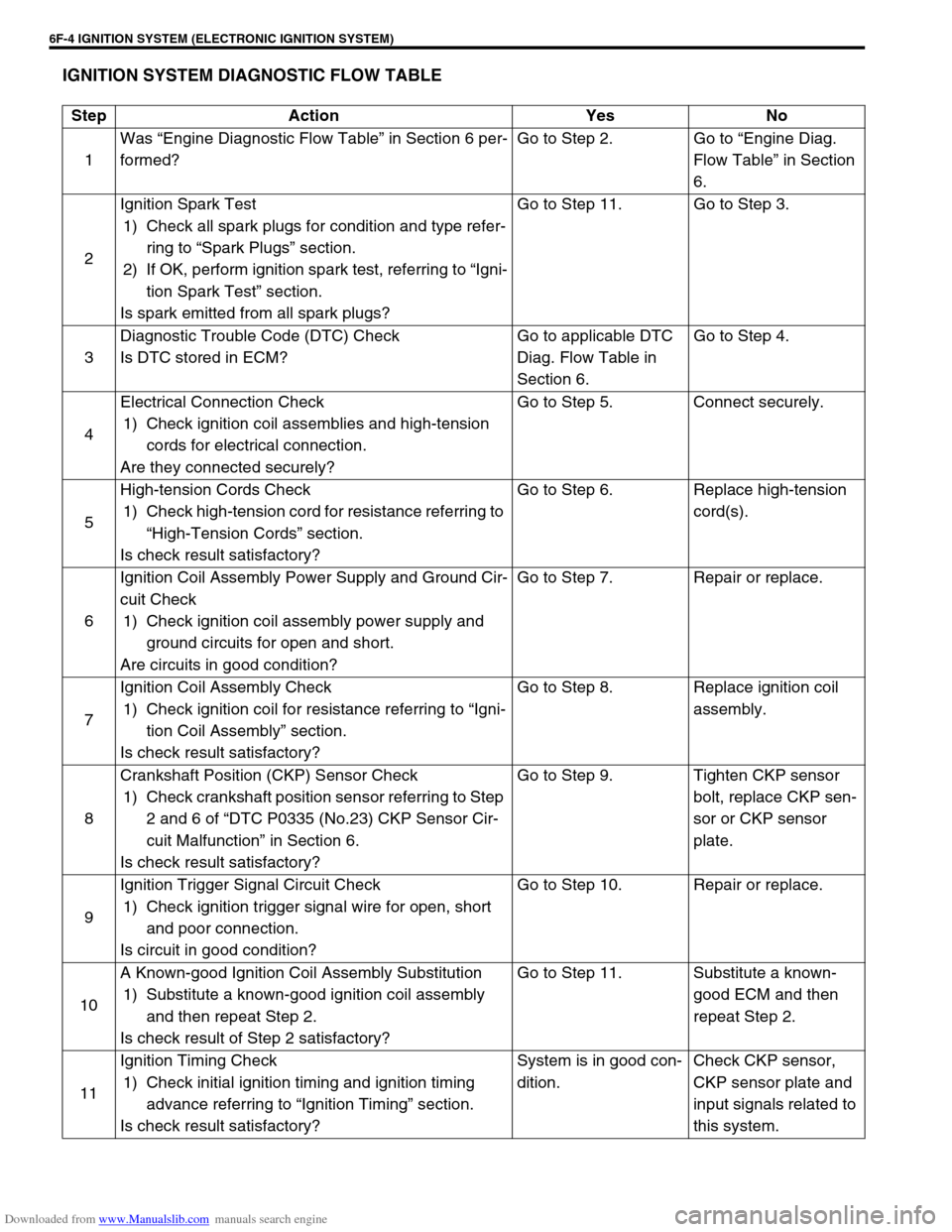

IGNITION SYSTEM DIAGNOSTIC FLOW TABLE

Step Action Yes No

1Was “Engine Diagnostic Flow Table” in Section 6 per-

formed?Go to Step 2. Go to “Engine Diag.

Flow Table” in Section

6.

2Ignition Spark Test

1) Check all spark plugs for condition and type refer-

ring to “Spark Plugs” section.

2) If OK, perform ignition spark test, referring to “Igni-

tion Spark Test” section.

Is spark emitted from all spark plugs?Go to Step 11. Go to Step 3.

3Diagnostic Trouble Code (DTC) Check

Is DTC stored in ECM?Go to applicable DTC

Diag. Flow Table in

Section 6.Go to Step 4.

4Electrical Connection Check

1) Check ignition coil assemblies and high-tension

cords for electrical connection.

Are they connected securely?Go to Step 5. Connect securely.

5High-tension Cords Check

1) Check high-tension cord for resistance referring to

“High-Tension Cords” section.

Is check result satisfactory?Go to Step 6. Replace high-tension

cord(s).

6Ignition Coil Assembly Power Supply and Ground Cir-

cuit Check

1) Check ignition coil assembly power supply and

ground circuits for open and short.

Are circuits in good condition?Go to Step 7. Repair or replace.

7Ignition Coil Assembly Check

1) Check ignition coil for resistance referring to “Igni-

tion Coil Assembly” section.

Is check result satisfactory?Go to Step 8. Replace ignition coil

assembly.

8Crankshaft Position (CKP) Sensor Check

1) Check crankshaft position sensor referring to Step

2 and 6 of “DTC P0335 (No.23) CKP Sensor Cir-

cuit Malfunction” in Section 6.

Is check result satisfactory?Go to Step 9. Tighten CKP sensor

bolt, replace CKP sen-

sor or CKP sensor

plate.

9Ignition Trigger Signal Circuit Check

1) Check ignition trigger signal wire for open, short

and poor connection.

Is circuit in good condition?Go to Step 10. Repair or replace.

10A Known-good Ignition Coil Assembly Substitution

1) Substitute a known-good ignition coil assembly

and then repeat Step 2.

Is check result of Step 2 satisfactory?Go to Step 11. Substitute a known-

good ECM and then

repeat Step 2.

11Ignition Timing Check

1) Check initial ignition timing and ignition timing

advance referring to “Ignition Timing” section.

Is check result satisfactory?System is in good con-

dition.Check CKP sensor,

CKP sensor plate and

input signals related to

this system.