Map sensor SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 27 of 687

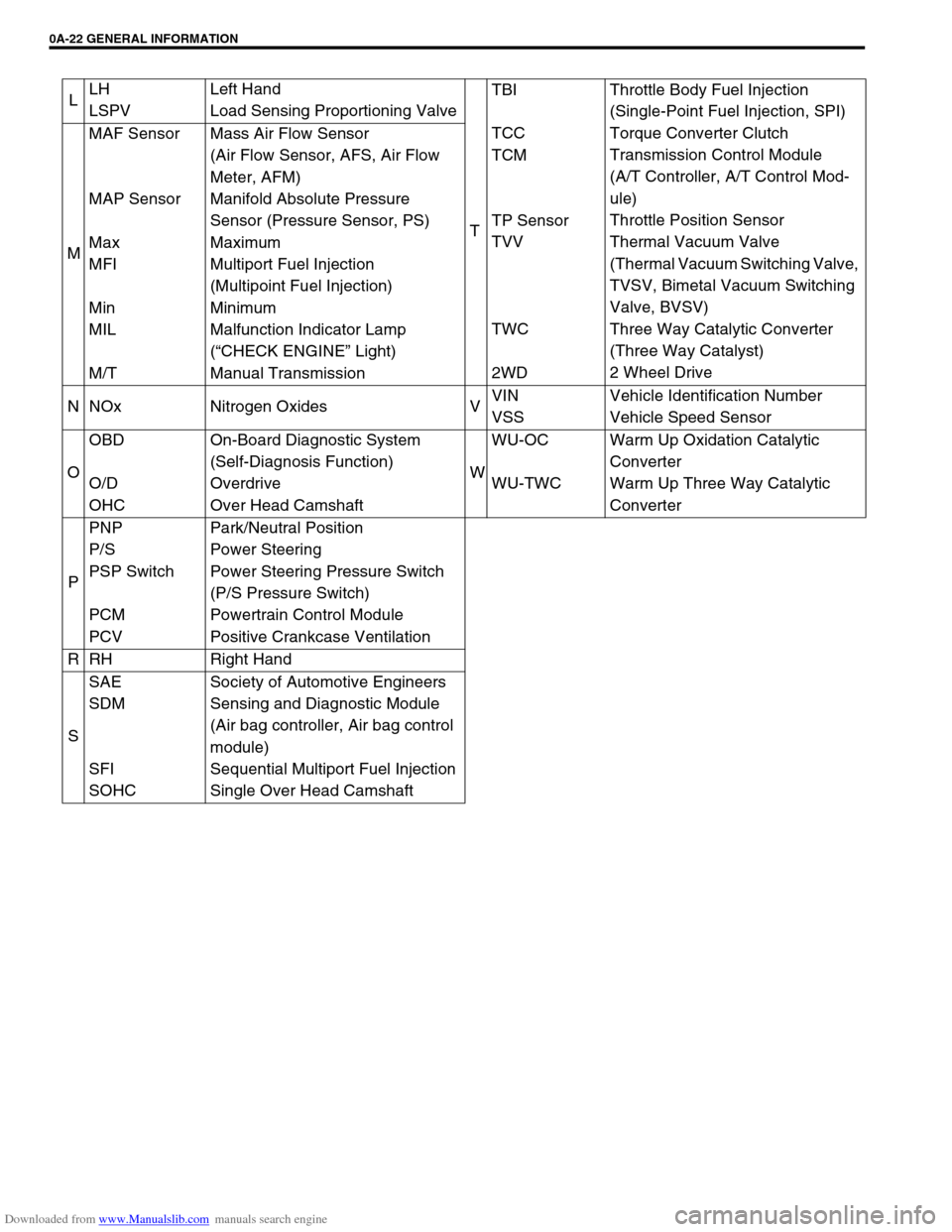

Downloaded from www.Manualslib.com manuals search engine 0A-22 GENERAL INFORMATION

LLH

LSPVLeft Hand

Load Sensing Proportioning Valve

TTBI

TCC

TCM

TP Sensor

TVV

TWC

2WDThrottle Body Fuel Injection

(Single-Point Fuel Injection, SPI)

Torque Converter Clutch

Transmission Control Module

(A/T Controller, A/T Control Mod-

ule)

Throttle Position Sensor

Thermal Vacuum Valve

(Thermal Vacuum Switching Valve,

TVSV, Bimetal Vacuum Switching

Valve, BVSV)

Three Way Catalytic Converter

(Three Way Catalyst)

2 Wheel Drive MMAF Sensor

MAP Sensor

Max

MFI

Min

MIL

M/TMass Air Flow Sensor

(Air Flow Sensor, AFS, Air Flow

Meter, AFM)

Manifold Absolute Pressure

Sensor (Pressure Sensor, PS)

Maximum

Multiport Fuel Injection

(Multipoint Fuel Injection)

Minimum

Malfunction Indicator Lamp

(“CHECK ENGINE” Light)

Manual Transmission

N NOx Nitrogen Oxides VVIN

VSSVehicle Identification Number

Vehicle Speed Sensor

OOBD

O/D

OHCOn-Board Diagnostic System

(Self-Diagnosis Function)

Overdrive

Over Head CamshaftWWU-OC

WU-TWCWarm Up Oxidation Catalytic

Converter

Warm Up Three Way Catalytic

Converter

PPNP

P/S

PSP Switch

PCM

PCVPark/Neutral Position

Power Steering

Power Steering Pressure Switch

(P/S Pressure Switch)

Powertrain Control Module

Positive Crankcase Ventilation

R RH Right Hand

SSAE

SDM

SFI

SOHCSociety of Automotive Engineers

Sensing and Diagnostic Module

(Air bag controller, Air bag control

module)

Sequential Multiport Fuel Injection

Single Over Head Camshaft

Page 359 of 687

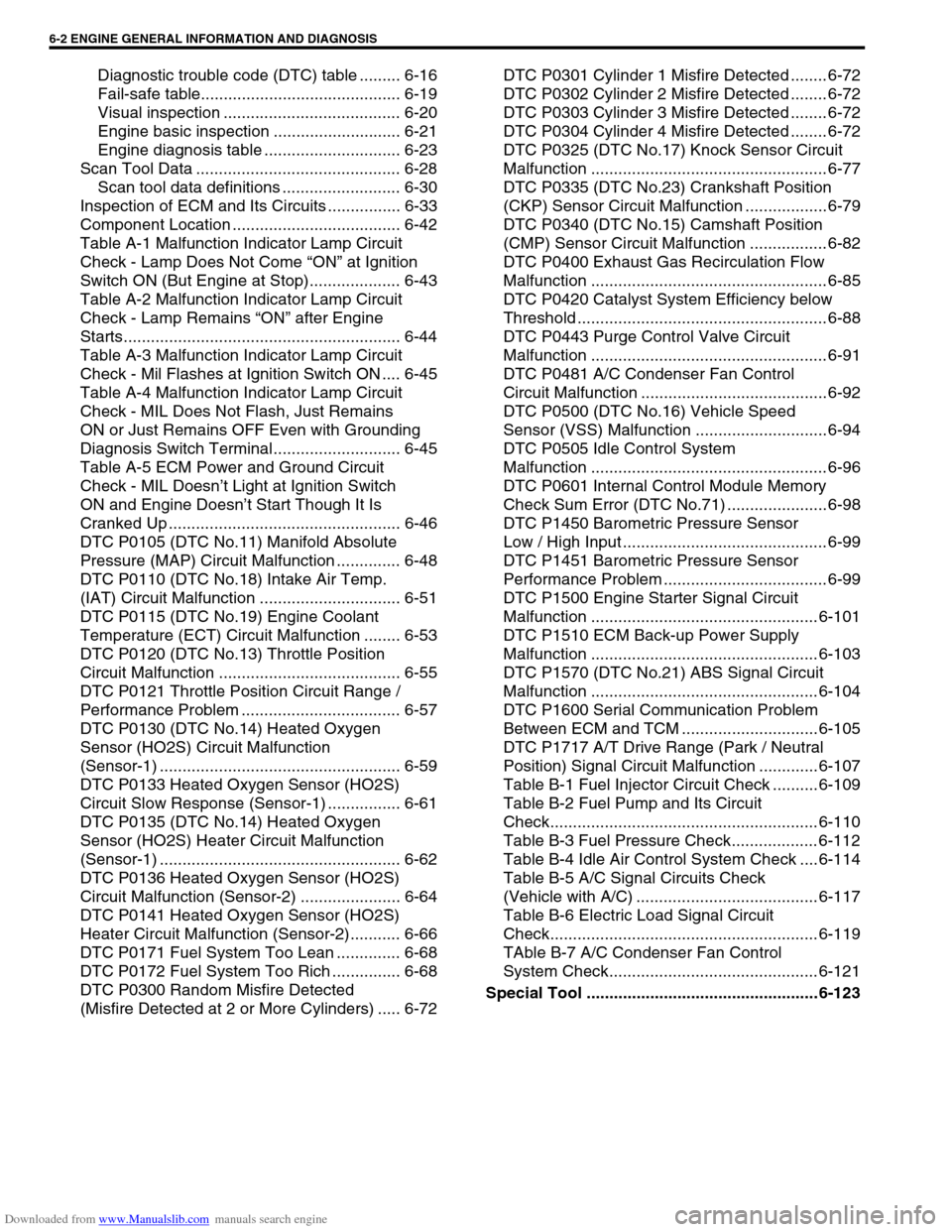

Downloaded from www.Manualslib.com manuals search engine 6-2 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Diagnostic trouble code (DTC) table ......... 6-16

Fail-safe table............................................ 6-19

Visual inspection ....................................... 6-20

Engine basic inspection ............................ 6-21

Engine diagnosis table .............................. 6-23

Scan Tool Data ............................................. 6-28

Scan tool data definitions .......................... 6-30

Inspection of ECM and Its Circuits ................ 6-33

Component Location ..................................... 6-42

Table A-1 Malfunction Indicator Lamp Circuit

Check - Lamp Does Not Come “ON” at Ignition

Switch ON (But Engine at Stop).................... 6-43

Table A-2 Malfunction Indicator Lamp Circuit

Check - Lamp Remains “ON” after Engine

Starts............................................................. 6-44

Table A-3 Malfunction Indicator Lamp Circuit

Check - Mil Flashes at Ignition Switch ON .... 6-45

Table A-4 Malfunction Indicator Lamp Circuit

Check - MIL Does Not Flash, Just Remains

ON or Just Remains OFF Even with Grounding

Diagnosis Switch Terminal............................ 6-45

Table A-5 ECM Power and Ground Circuit

Check - MIL Doesn’t Light at Ignition Switch

ON and Engine Doesn’t Start Though It Is

Cranked Up ................................................... 6-46

DTC P0105 (DTC No.11) Manifold Absolute

Pressure (MAP) Circuit Malfunction .............. 6-48

DTC P0110 (DTC No.18) Intake Air Temp.

(IAT) Circuit Malfunction ............................... 6-51

DTC P0115 (DTC No.19) Engine Coolant

Temperature (ECT) Circuit Malfunction ........ 6-53

DTC P0120 (DTC No.13) Throttle Position

Circuit Malfunction ........................................ 6-55

DTC P0121 Throttle Position Circuit Range /

Performance Problem ................................... 6-57

DTC P0130 (DTC No.14) Heated Oxygen

Sensor (HO2S) Circuit Malfunction

(Sensor-1) ..................................................... 6-59

DTC P0133 Heated Oxygen Sensor (HO2S)

Circuit Slow Response (Sensor-1) ................ 6-61

DTC P0135 (DTC No.14) Heated Oxygen

Sensor (HO2S) Heater Circuit Malfunction

(Sensor-1) ..................................................... 6-62

DTC P0136 Heated Oxygen Sensor (HO2S)

Circuit Malfunction (Sensor-2) ...................... 6-64

DTC P0141 Heated Oxygen Sensor (HO2S)

Heater Circuit Malfunction (Sensor-2)........... 6-66

DTC P0171 Fuel System Too Lean .............. 6-68

DTC P0172 Fuel System Too Rich ............... 6-68

DTC P0300 Random Misfire Detected

(Misfire Detected at 2 or More Cylinders) ..... 6-72DTC P0301 Cylinder 1 Misfire Detected ........ 6-72

DTC P0302 Cylinder 2 Misfire Detected ........ 6-72

DTC P0303 Cylinder 3 Misfire Detected ........ 6-72

DTC P0304 Cylinder 4 Misfire Detected ........ 6-72

DTC P0325 (DTC No.17) Knock Sensor Circuit

Malfunction .................................................... 6-77

DTC P0335 (DTC No.23) Crankshaft Position

(CKP) Sensor Circuit Malfunction .................. 6-79

DTC P0340 (DTC No.15) Camshaft Position

(CMP) Sensor Circuit Malfunction ................. 6-82

DTC P0400 Exhaust Gas Recirculation Flow

Malfunction .................................................... 6-85

DTC P0420 Catalyst System Efficiency below

Threshold ....................................................... 6-88

DTC P0443 Purge Control Valve Circuit

Malfunction .................................................... 6-91

DTC P0481 A/C Condenser Fan Control

Circuit Malfunction ......................................... 6-92

DTC P0500 (DTC No.16) Vehicle Speed

Sensor (VSS) Malfunction ............................. 6-94

DTC P0505 Idle Control System

Malfunction .................................................... 6-96

DTC P0601 Internal Control Module Memory

Check Sum Error (DTC No.71) ...................... 6-98

DTC P1450 Barometric Pressure Sensor

Low / High Input ............................................. 6-99

DTC P1451 Barometric Pressure Sensor

Performance Problem .................................... 6-99

DTC P1500 Engine Starter Signal Circuit

Malfunction .................................................. 6-101

DTC P1510 ECM Back-up Power Supply

Malfunction .................................................. 6-103

DTC P1570 (DTC No.21) ABS Signal Circuit

Malfunction .................................................. 6-104

DTC P1600 Serial Communication Problem

Between ECM and TCM .............................. 6-105

DTC P1717 A/T Drive Range (Park / Neutral

Position) Signal Circuit Malfunction ............. 6-107

Table B-1 Fuel Injector Circuit Check ..........6-109

Table B-2 Fuel Pump and Its Circuit

Check........................................................... 6-110

Table B-3 Fuel Pressure Check................... 6-112

Table B-4 Idle Air Control System Check ....6-114

Table B-5 A/C Signal Circuits Check

(Vehicle with A/C) ........................................ 6-117

Table B-6 Electric Load Signal Circuit

Check........................................................... 6-119

TAble B-7 A/C Condenser Fan Control

System Check.............................................. 6-121

Special Tool ................................................... 6-123

Page 366 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-9

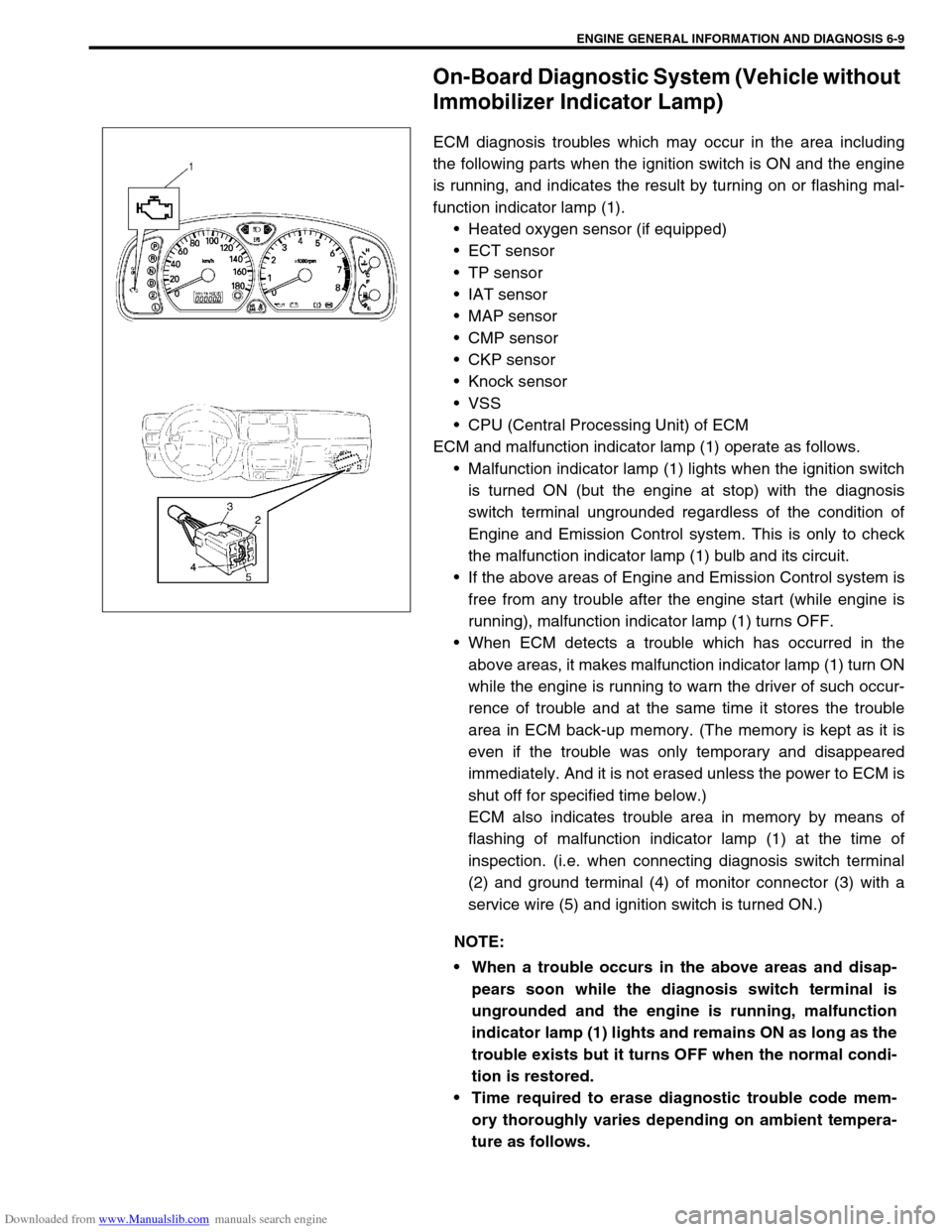

On-Board Diagnostic System (Vehicle without

Immobilizer Indicator Lamp)

ECM diagnosis troubles which may occur in the area including

the following parts when the ignition switch is ON and the engine

is running, and indicates the result by turning on or flashing mal-

function indicator lamp (1).

Heated oxygen sensor (if equipped)

ECT sensor

TP sensor

IAT sensor

MAP sensor

CMP sensor

CKP sensor

Knock sensor

VSS

CPU (Central Processing Unit) of ECM

ECM and malfunction indicator lamp (1) operate as follows.

Malfunction indicator lamp (1) lights when the ignition switch

is turned ON (but the engine at stop) with the diagnosis

switch terminal ungrounded regardless of the condition of

Engine and Emission Control system. This is only to check

the malfunction indicator lamp (1) bulb and its circuit.

If the above areas of Engine and Emission Control system is

free from any trouble after the engine start (while engine is

running), malfunction indicator lamp (1) turns OFF.

When ECM detects a trouble which has occurred in the

above areas, it makes malfunction indicator lamp (1) turn ON

while the engine is running to warn the driver of such occur-

rence of trouble and at the same time it stores the trouble

area in ECM back-up memory. (The memory is kept as it is

even if the trouble was only temporary and disappeared

immediately. And it is not erased unless the power to ECM is

shut off for specified time below.)

ECM also indicates trouble area in memory by means of

flashing of malfunction indicator lamp (1) at the time of

inspection. (i.e. when connecting diagnosis switch terminal

(2) and ground terminal (4) of monitor connector (3) with a

service wire (5) and ignition switch is turned ON.)

NOTE:

When a trouble occurs in the above areas and disap-

pears soon while the diagnosis switch terminal is

ungrounded and the engine is running, malfunction

indicator lamp (1) lights and remains ON as long as the

trouble exists but it turns OFF when the normal condi-

tion is restored.

Time required to erase diagnostic trouble code mem-

ory thoroughly varies depending on ambient tempera-

ture as follows.

Page 367 of 687

Downloaded from www.Manualslib.com manuals search engine 6-10 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Precaution in Diagnosing Trouble

Don’t disconnect couplers from ECM, battery cable at battery, ECM ground wire harness from engine or

main fuse before confirming diagnostic information (DTC, freeze frame data, etc.) stored in ECM memory.

Such disconnection will erase memorized information in ECM memory.

Diagnostic information stored in ECM memory can be cleared as well as checked by using SUZUKI scan

tool or generic scan tool. Before using scan tool, read its Operator’s (Instruction) Manual carefully to have

good understanding as to what functions are available and how to use it.

Priorities for diagnosing troubles (Vehicle with Immobilizer indicator lamp).

If multiple diagnostic trouble codes (DTCs) are stored, proceed to the flow table of the DTC which has

detected earliest in the order and follow the instruction in that table.

If no instructions are given, troubleshoot diagnostic trouble codes according to the following priorities.

–Diagnostic trouble codes (DTCs) other than DTC P0171/P0172 (Fuel system too lean / too rich), DTC

P0300/P0301/P0302/P0303/P0304 (Misfire detected) and DTC P0400 (EGR flow malfunction)

–DTC P0171/P0172 (Fuel system too lean / too rich) and DTC P0400 (EGR flow malfunction)

–DTC P0300/P0301/P0302/P0303/P0304 (Misfire detected)

Be sure to read “Precautions for Electrical Circuit Service” in Section 0A before inspection and observe what

is written there.

ECM Replacement

When substituting a known-good ECM, check for following conditions. Neglecting this check may cause

damage to a known-good ECM.

–Resistance value of all relays, actuators is as specified respectively.

–MAP sensor and TP sensor are in good condition and none of power circuits of these sensors is shorted

to ground.AMBIENT TEMPERATURE TIME TO CUT POWER TO

ECM

Over 0 °C (32 °F) 60 sec. or longer

Under 0 °C (32 °F)Not specifiable.

Select a place with higher than

0 °C (32 °F) temperature.

Page 373 of 687

Downloaded from www.Manualslib.com manuals search engine 6-16 ENGINE GENERAL INFORMATION AND DIAGNOSIS

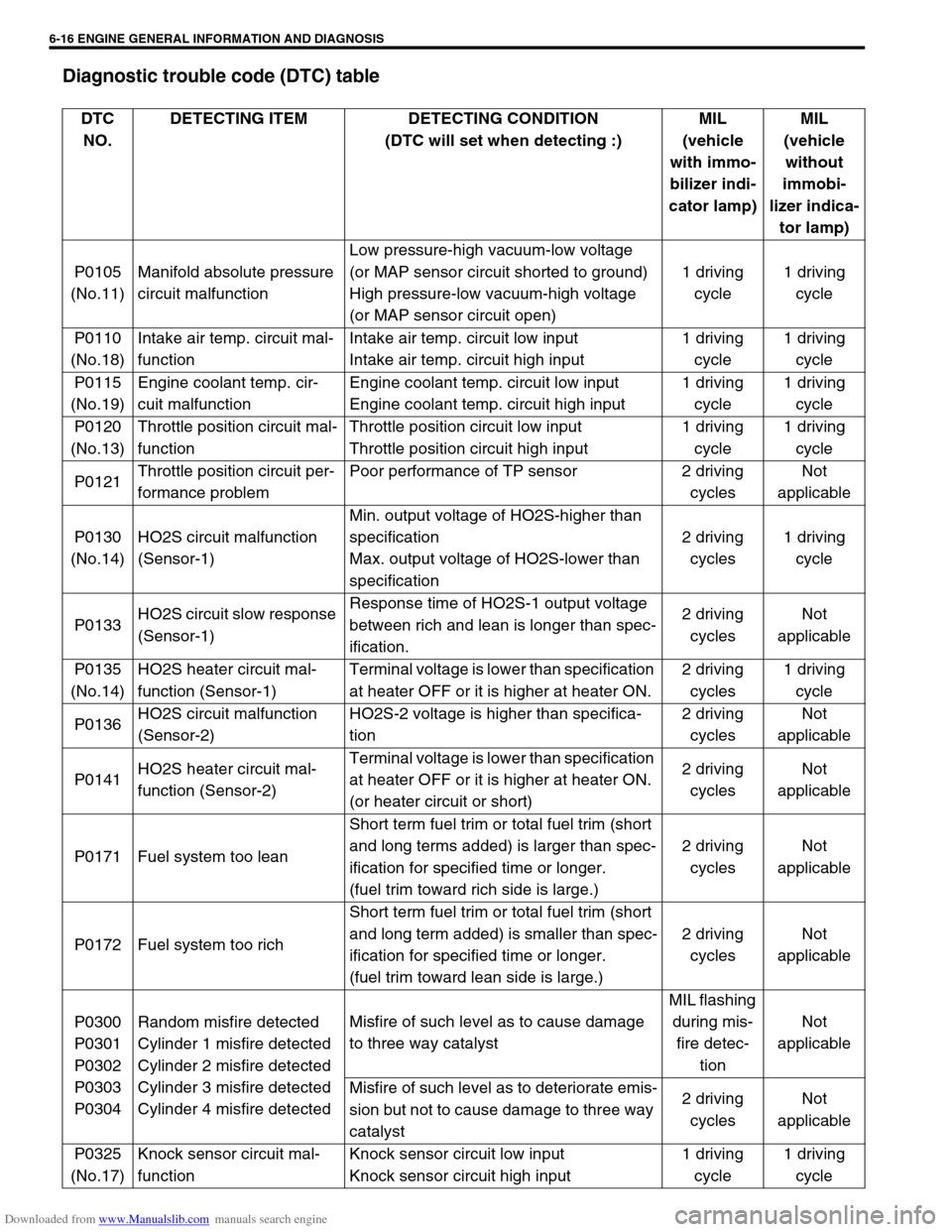

Diagnostic trouble code (DTC) table

DTC

NO.DETECTING ITEM DETECTING CONDITION

(DTC will set when detecting :)MIL

(vehicle

with immo-

bilizer indi-

cator lamp)MIL

(vehicle

without

immobi-

lizer indica-

tor lamp)

P0105

(No.11)Manifold absolute pressure

circuit malfunctionLow pressure-high vacuum-low voltage

(or MAP sensor circuit shorted to ground)

High pressure-low vacuum-high voltage

(or MAP sensor circuit open)1 driving

cycle1 driving

cycle

P0110

(No.18)Intake air temp. circuit mal-

functionIntake air temp. circuit low input

Intake air temp. circuit high input1 driving

cycle1 driving

cycle

P0115

(No.19)Engine coolant temp. cir-

cuit malfunctionEngine coolant temp. circuit low input

Engine coolant temp. circuit high input1 driving

cycle1 driving

cycle

P0120

(No.13)Throttle position circuit mal-

functionThrottle position circuit low input

Throttle position circuit high input1 driving

cycle1 driving

cycle

P0121Throttle position circuit per-

formance problemPoor performance of TP sensor 2 driving

cyclesNot

applicable

P0130

(No.14)HO2S circuit malfunction

(Sensor-1)Min. output voltage of HO2S-higher than

specification

Max. output voltage of HO2S-lower than

specification2 driving

cycles1 driving

cycle

P0133HO2S circuit slow response

(Sensor-1)Response time of HO2S-1 output voltage

between rich and lean is longer than spec-

ification.2 driving

cyclesNot

applicable

P0135

(No.14)HO2S heater circuit mal-

function (Sensor-1)Terminal voltage is lower than specification

at heater OFF or it is higher at heater ON.2 driving

cycles1 driving

cycle

P0136HO2S circuit malfunction

(Sensor-2)HO2S-2 voltage is higher than specifica-

tion2 driving

cyclesNot

applicable

P0141HO2S heater circuit mal-

function (Sensor-2)Terminal voltage is lower than specification

at heater OFF or it is higher at heater ON.

(or heater circuit or short)2 driving

cyclesNot

applicable

P0171 Fuel system too leanShort term fuel trim or total fuel trim (short

and long terms added) is larger than spec-

ification for specified time or longer.

(fuel trim toward rich side is large.)2 driving

cyclesNot

applicable

P0172 Fuel system too richShort term fuel trim or total fuel trim (short

and long term added) is smaller than spec-

ification for specified time or longer.

(fuel trim toward lean side is large.)2 driving

cyclesNot

applicable

P0300

P0301

P0302

P0303

P0304Random misfire detected

Cylinder 1 misfire detected

Cylinder 2 misfire detected

Cylinder 3 misfire detected

Cylinder 4 misfire detectedMisfire of such level as to cause damage

to three way catalystMIL flashing

during mis-

fire detec-

tionNot

applicable

Misfire of such level as to deteriorate emis-

sion but not to cause damage to three way

catalyst2 driving

cyclesNot

applicable

P0325

(No.17)Knock sensor circuit mal-

functionKnock sensor circuit low input

Knock sensor circuit high input1 driving

cycle1 driving

cycle

Page 374 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-17

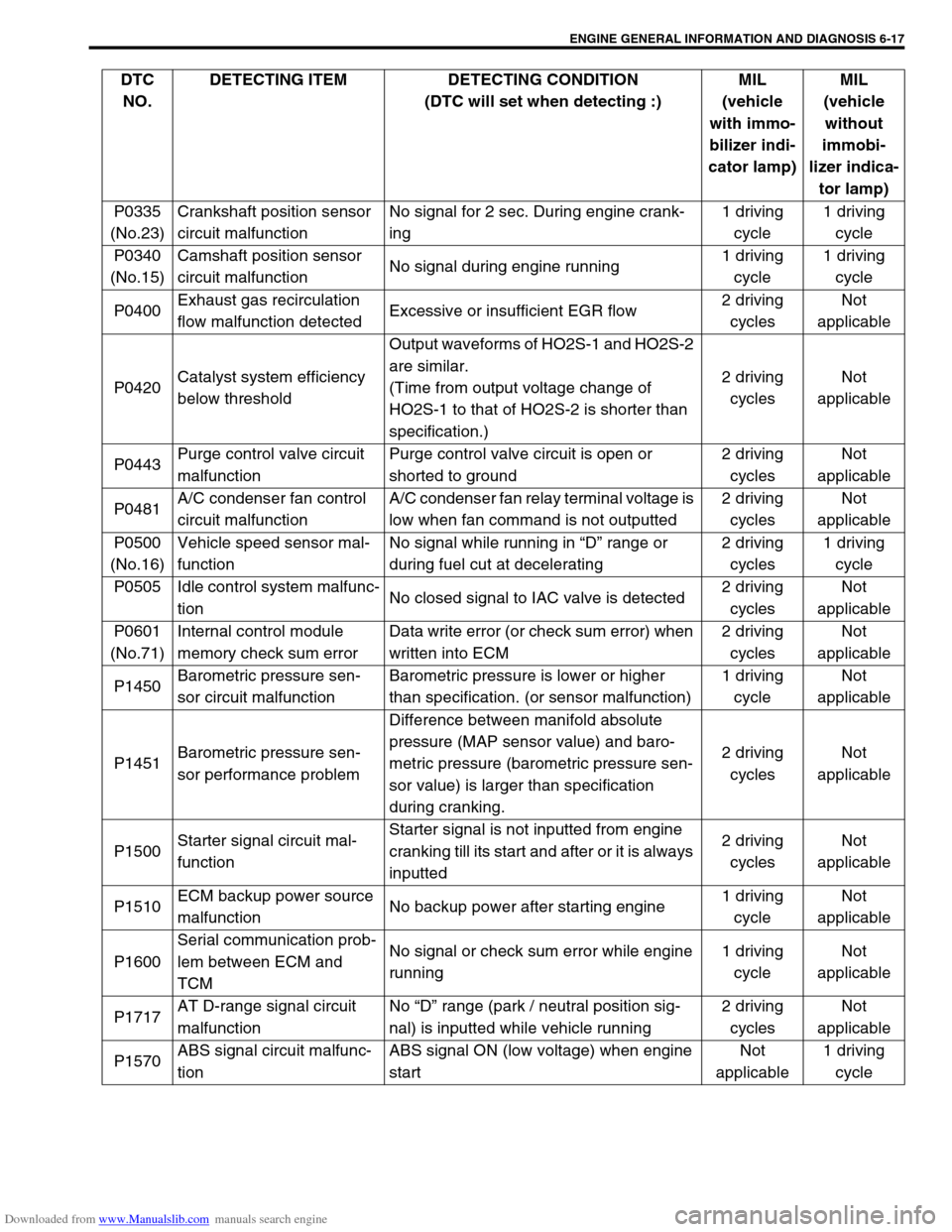

P0335

(No.23)Crankshaft position sensor

circuit malfunctionNo signal for 2 sec. During engine crank-

ing1 driving

cycle1 driving

cycle

P0340

(No.15)Camshaft position sensor

circuit malfunctionNo signal during engine running1 driving

cycle1 driving

cycle

P0400Exhaust gas recirculation

flow malfunction detectedExcessive or insufficient EGR flow2 driving

cyclesNot

applicable

P0420Catalyst system efficiency

below thresholdOutput waveforms of HO2S-1 and HO2S-2

are similar.

(Time from output voltage change of

HO2S-1 to that of HO2S-2 is shorter than

specification.)2 driving

cyclesNot

applicable

P0443Purge control valve circuit

malfunctionPurge control valve circuit is open or

shorted to ground2 driving

cyclesNot

applicable

P0481A/C condenser fan control

circuit malfunctionA/C condenser fan relay terminal voltage is

low when fan command is not outputted2 driving

cyclesNot

applicable

P0500

(No.16)Vehicle speed sensor mal-

functionNo signal while running in “D” range or

during fuel cut at decelerating2 driving

cycles1 driving

cycle

P0505 Idle control system malfunc-

tionNo closed signal to IAC valve is detected2 driving

cyclesNot

applicable

P0601

(No.71)Internal control module

memory check sum errorData write error (or check sum error) when

written into ECM2 driving

cyclesNot

applicable

P1450 Barometric pressure sen-

sor circuit malfunctionBarometric pressure is lower or higher

than specification. (or sensor malfunction)1 driving

cycleNot

applicable

P1451Barometric pressure sen-

sor performance problemDifference between manifold absolute

pressure (MAP sensor value) and baro-

metric pressure (barometric pressure sen-

sor value) is larger than specification

during cranking.2 driving

cyclesNot

applicable

P1500Starter signal circuit mal-

functionStarter signal is not inputted from engine

cranking till its start and after or it is always

inputted2 driving

cyclesNot

applicable

P1510ECM backup power source

malfunctionNo backup power after starting engine1 driving

cycleNot

applicable

P1600Serial communication prob-

lem between ECM and

TCMNo signal or check sum error while engine

running1 driving

cycleNot

applicable

P1717AT D-range signal circuit

malfunctionNo “D” range (park / neutral position sig-

nal) is inputted while vehicle running2 driving

cyclesNot

applicable

P1570ABS signal circuit malfunc-

tionABS signal ON (low voltage) when engine

startNot

applicable1 driving

cycle DTC

NO.DETECTING ITEM DETECTING CONDITION

(DTC will set when detecting :)MIL

(vehicle

with immo-

bilizer indi-

cator lamp)MIL

(vehicle

without

immobi-

lizer indica-

tor lamp)

Page 380 of 687

![SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

Engine diagnosis tab SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

Engine diagnosis tab](/img/20/7588/w960_7588-379.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

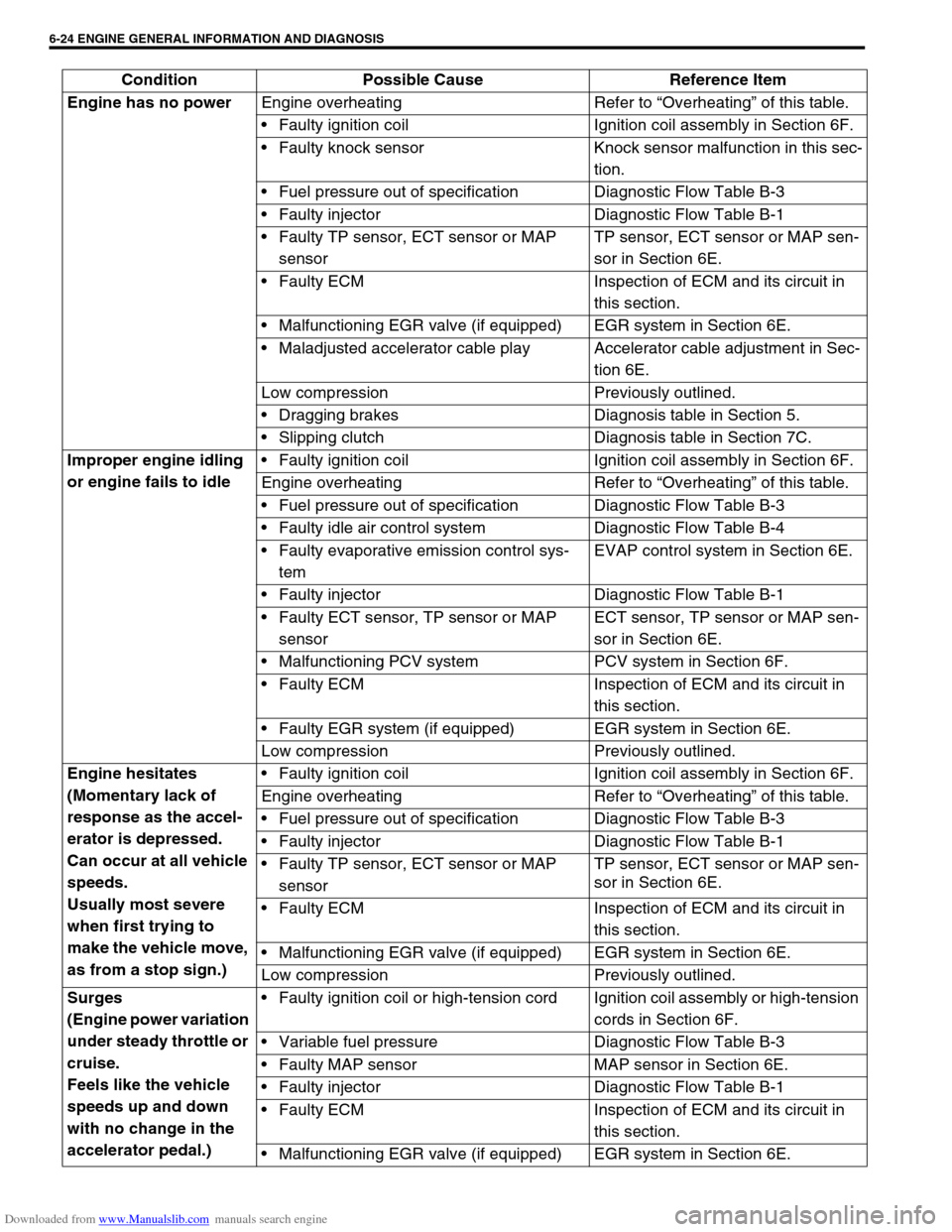

Engine diagnosis table

Perform troubleshooting referring to following table when ECM has no DTC and no abnormality found in visual

inspection and engine basic inspection previously.

Condition Possible Cause Reference Item

Hard Starting

(Engine cranks OK)Faulty ignition coil Ignition coil assembly in Section 6F.

Faulty CMP sensing rotor or CKP sensing

rotorCMP sensing rotor or CKP sensing

rotor inspection in Section 6E.

Faulty idle air control system Diagnostic Flow Table B-4

Faulty ECT sensor, TP sensor, CKP sen-

sor, CMP sensor or MAP sensorECT sensor, TP sensor, CKP sensor,

CMP sensor or MAP sensor in Sec-

tion 6E.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty fuel injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning PCV system PCV system in Section 6E.

Low compression Compression check in Section 6A1.

Improper valve lash Valve lash in Section 6A1.

Improper valve timing Timing chain and chain tensioner in

Section 6A1.

Compression leak from valve seat Valves and cylinder head in Section

6A1.

Sticky valve stem Valves and cylinder head in Section

6A1.

Weak or damaged valve springs Valves and cylinder head in Section

6A1.

Compression leak at cylinder head gasket Valves and cylinder head in Section

6A1.

Sticking or damaged piston ring Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Worn piston, ring or cylinder Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Page 381 of 687

Downloaded from www.Manualslib.com manuals search engine 6-24 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Engine has no power

Engine overheating Refer to “Overheating” of this table.

Faulty ignition coil Ignition coil assembly in Section 6F.

Faulty knock sensor Knock sensor malfunction in this sec-

tion.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty injector Diagnostic Flow Table B-1

Faulty TP sensor, ECT sensor or MAP

sensorTP sensor, ECT sensor or MAP sen-

sor in Section 6E.

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

Maladjusted accelerator cable play Accelerator cable adjustment in Sec-

tion 6E.

Low compression Previously outlined.

Dragging brakes Diagnosis table in Section 5.

Slipping clutch Diagnosis table in Section 7C.

Improper engine idling

or engine fails to idleFaulty ignition coil Ignition coil assembly in Section 6F.

Engine overheating Refer to “Overheating” of this table.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty idle air control system Diagnostic Flow Table B-4

Faulty evaporative emission control sys-

temEVAP control system in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECT sensor, TP sensor or MAP

sensorECT sensor, TP sensor or MAP sen-

sor in Section 6E.

Malfunctioning PCV system PCV system in Section 6F.

Faulty ECM Inspection of ECM and its circuit in

this section.

Faulty EGR system (if equipped) EGR system in Section 6E.

Low compression Previously outlined.

Engine hesitates

(Momentary lack of

response as the accel-

erator is depressed.

Can occur at all vehicle

speeds.

Usually most severe

when first trying to

make the vehicle move,

as from a stop sign.)Faulty ignition coil Ignition coil assembly in Section 6F.

Engine overheating Refer to “Overheating” of this table.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty injector Diagnostic Flow Table B-1

Faulty TP sensor, ECT sensor or MAP

sensorTP sensor, ECT sensor or MAP sen-

sor in Section 6E.

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

Low compression Previously outlined.

Surges

(Engine power variation

under steady throttle or

cruise.

Feels like the vehicle

speeds up and down

with no change in the

accelerator pedal.)Faulty ignition coil or high-tension cord Ignition coil assembly or high-tension

cords in Section 6F.

Variable fuel pressure Diagnostic Flow Table B-3

Faulty MAP sensor MAP sensor in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E. Condition Possible Cause Reference Item

Page 382 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-25

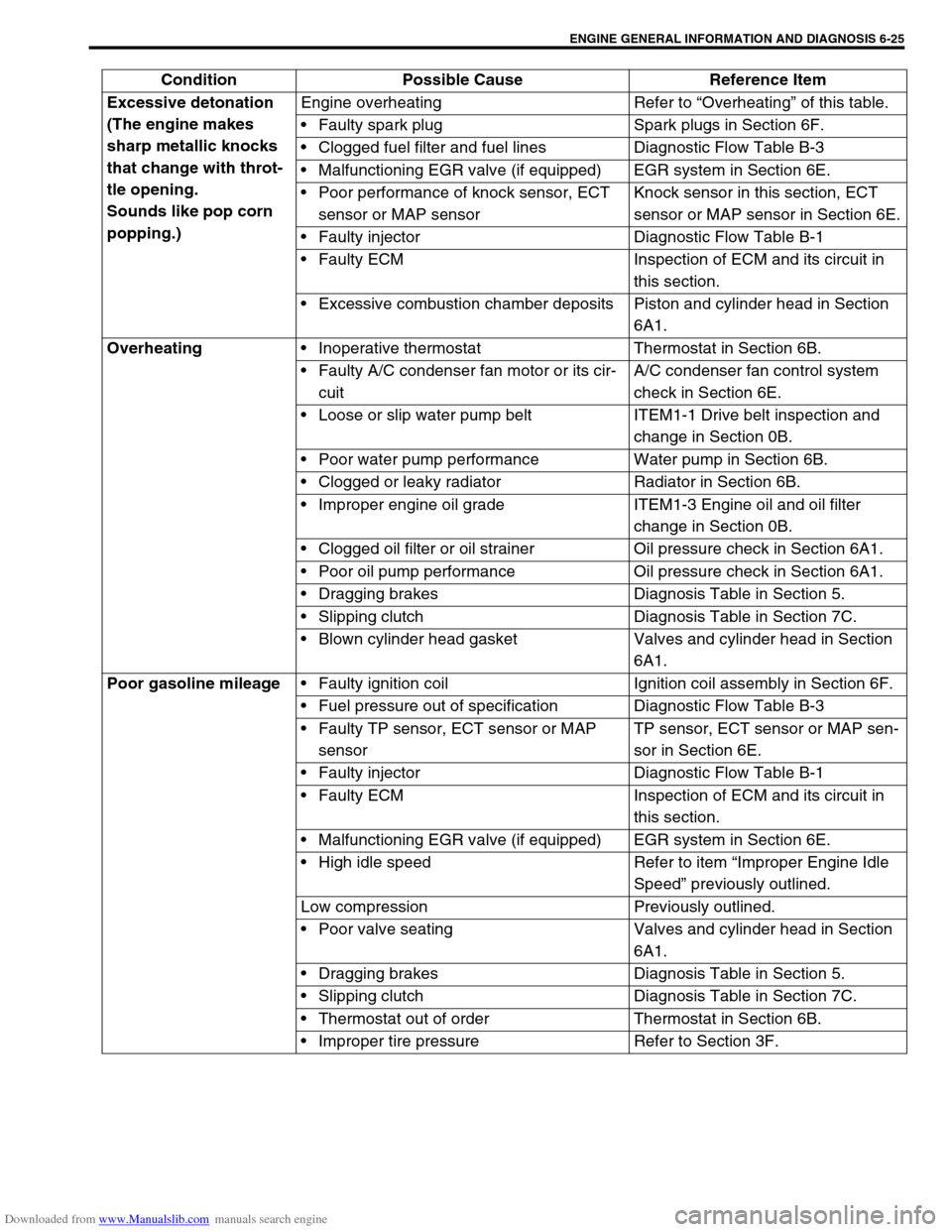

Excessive detonation

(The engine makes

sharp metallic knocks

that change with throt-

tle opening.

Sounds like pop corn

popping.)Engine overheating Refer to “Overheating” of this table.

Faulty spark plug Spark plugs in Section 6F.

Clogged fuel filter and fuel lines Diagnostic Flow Table B-3

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

Poor performance of knock sensor, ECT

sensor or MAP sensorKnock sensor in this section, ECT

sensor or MAP sensor in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Excessive combustion chamber deposits Piston and cylinder head in Section

6A1.

Overheating

Inoperative thermostat Thermostat in Section 6B.

Faulty A/C condenser fan motor or its cir-

cuitA/C condenser fan control system

check in Section 6E.

Loose or slip water pump belt ITEM1-1 Drive belt inspection and

change in Section 0B.

Poor water pump performance Water pump in Section 6B.

Clogged or leaky radiator Radiator in Section 6B.

Improper engine oil grade ITEM1-3 Engine oil and oil filter

change in Section 0B.

Clogged oil filter or oil strainer Oil pressure check in Section 6A1.

Poor oil pump performance Oil pressure check in Section 6A1.

Dragging brakes Diagnosis Table in Section 5.

Slipping clutch Diagnosis Table in Section 7C.

Blown cylinder head gasket Valves and cylinder head in Section

6A1.

Poor gasoline mileage

Faulty ignition coil Ignition coil assembly in Section 6F.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty TP sensor, ECT sensor or MAP

sensorTP sensor, ECT sensor or MAP sen-

sor in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

High idle speed Refer to item “Improper Engine Idle

Speed” previously outlined.

Low compression Previously outlined.

Poor valve seating Valves and cylinder head in Section

6A1.

Dragging brakes Diagnosis Table in Section 5.

Slipping clutch Diagnosis Table in Section 7C.

Thermostat out of order Thermostat in Section 6B.

Improper tire pressure Refer to Section 3F. Condition Possible Cause Reference Item

Page 384 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-27

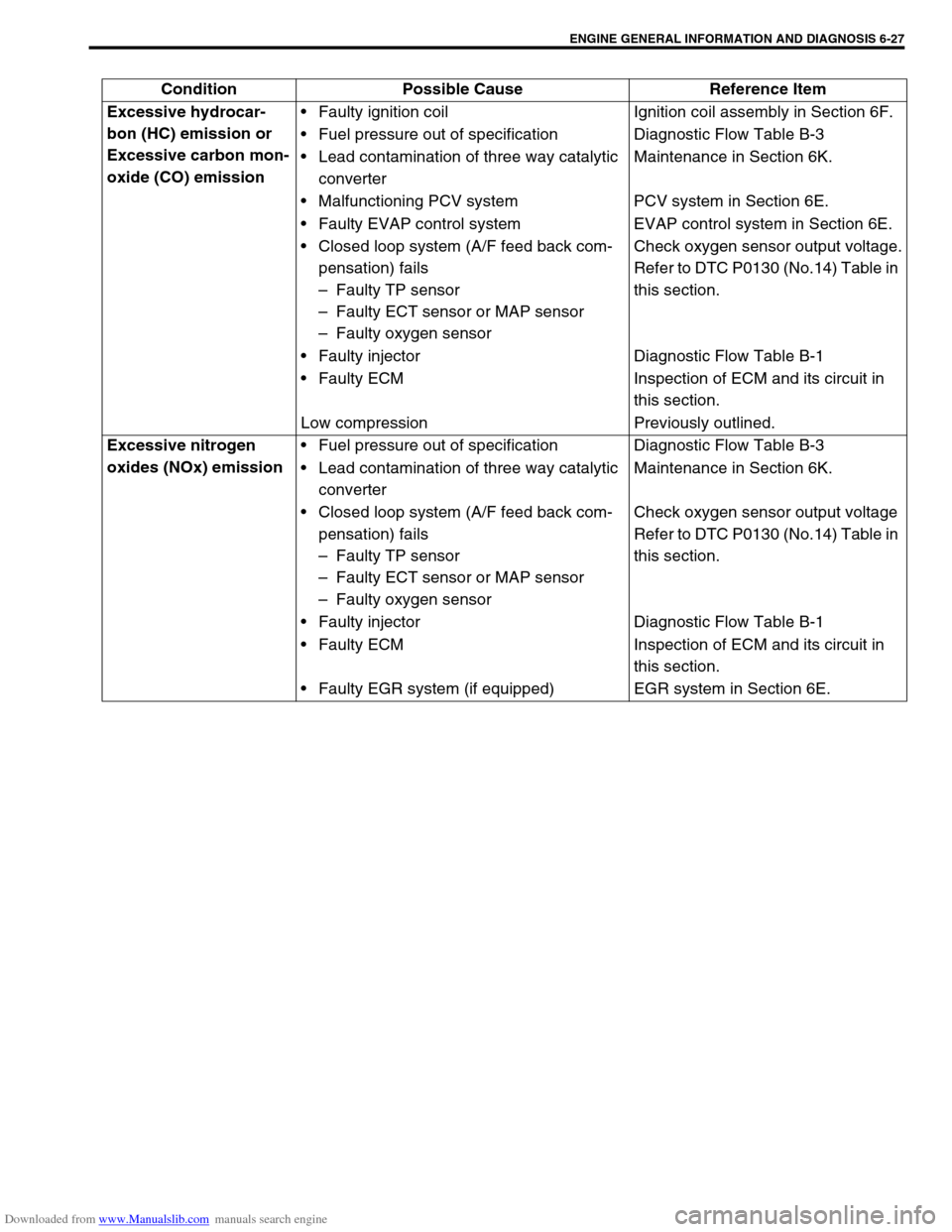

Condition Possible Cause Reference Item

Excessive hydrocar-

bon (HC) emission or

Excessive carbon mon-

oxide (CO) emissionFaulty ignition coil Ignition coil assembly in Section 6F.

Fuel pressure out of specification Diagnostic Flow Table B-3

Lead contamination of three way catalytic

converterMaintenance in Section 6K.

Malfunctioning PCV system PCV system in Section 6E.

Faulty EVAP control system EVAP control system in Section 6E.

Closed loop system (A/F feed back com-

pensation) fails

–Faulty TP sensor

–Faulty ECT sensor or MAP sensor

–Faulty oxygen sensorCheck oxygen sensor output voltage.

Refer to DTC P0130 (No.14) Table in

this section.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Low compression Previously outlined.

Excessive nitrogen

oxides (NOx) emissionFuel pressure out of specification Diagnostic Flow Table B-3

Lead contamination of three way catalytic

converterMaintenance in Section 6K.

Closed loop system (A/F feed back com-

pensation) fails

–Faulty TP sensor

–Faulty ECT sensor or MAP sensor

–Faulty oxygen sensorCheck oxygen sensor output voltage

Refer to DTC P0130 (No.14) Table in

this section.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Faulty EGR system (if equipped) EGR system in Section 6E.