valve SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 555 of 698

6A1-54 ENGINE MECHANICAL (M13 ENGINE)

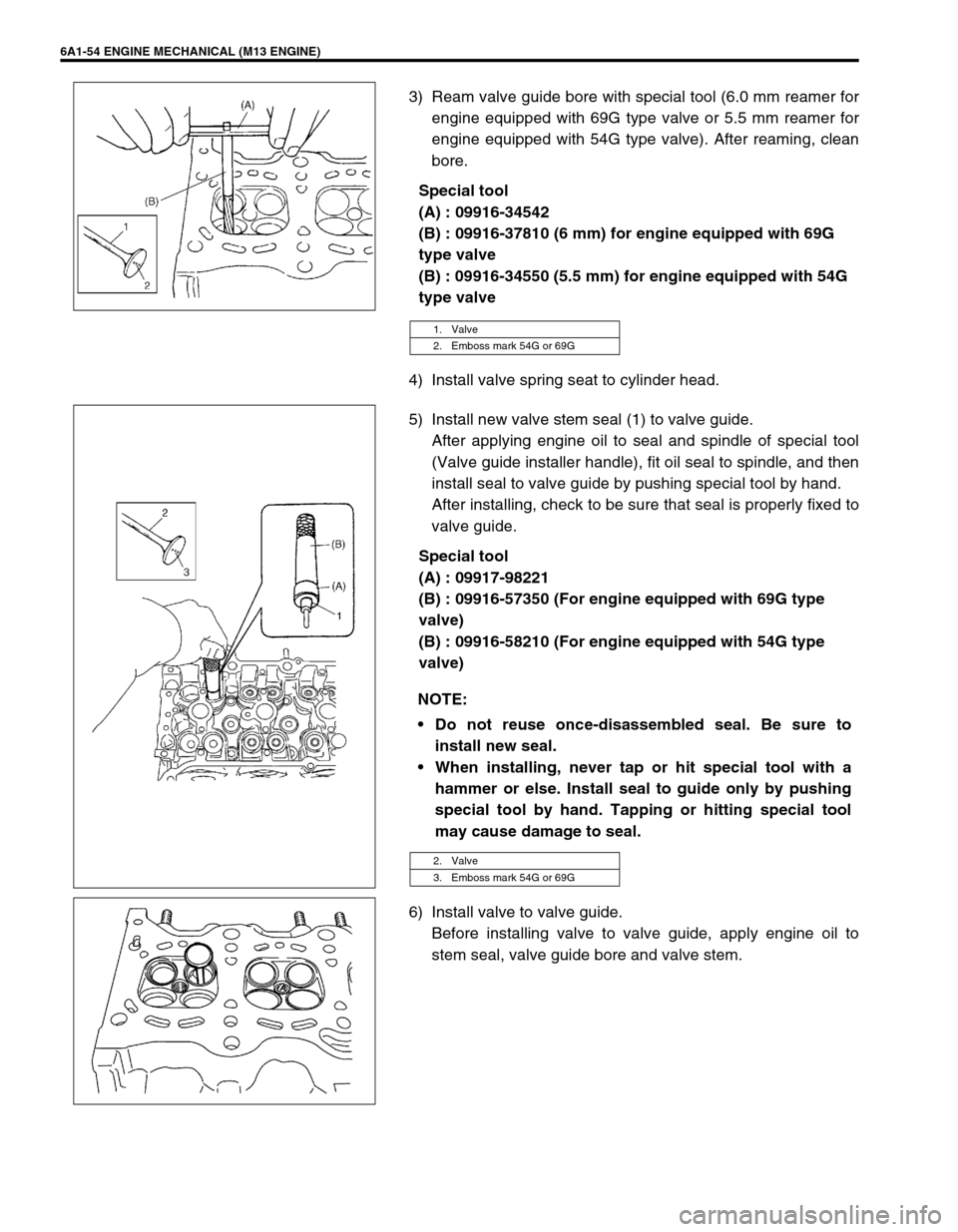

3) Ream valve guide bore with special tool (6.0 mm reamer for

engine equipped with 69G type valve or 5.5 mm reamer for

engine equipped with 54G type valve). After reaming, clean

bore.

Special tool

(A) : 09916-34542

(B) : 09916-37810 (6 mm) for engine equipped with 69G

type valve

(B) : 09916-34550 (5.5 mm) for engine equipped with 54G

type valve

4) Install valve spring seat to cylinder head.

5) Install new valve stem seal (1) to valve guide.

After applying engine oil to seal and spindle of special tool

(Valve guide installer handle), fit oil seal to spindle, and then

install seal to valve guide by pushing special tool by hand.

After installing, check to be sure that seal is properly fixed to

valve guide.

Special tool

(A) : 09917-98221

(B) : 09916-57350 (For engine equipped with 69G type

valve)

(B) : 09916-58210 (For engine equipped with 54G type

valve)

6) Install valve to valve guide.

Before installing valve to valve guide, apply engine oil to

stem seal, valve guide bore and valve stem.

1. Valve

2. Emboss mark 54G or 69G

NOTE:

Do not reuse once-disassembled seal. Be sure to

install new seal.

When installing, never tap or hit special tool with a

hammer or else. Install seal to guide only by pushing

special tool by hand. Tapping or hitting special tool

may cause damage to seal.

2. Valve

3. Emboss mark 54G or 69G

Page 556 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-55

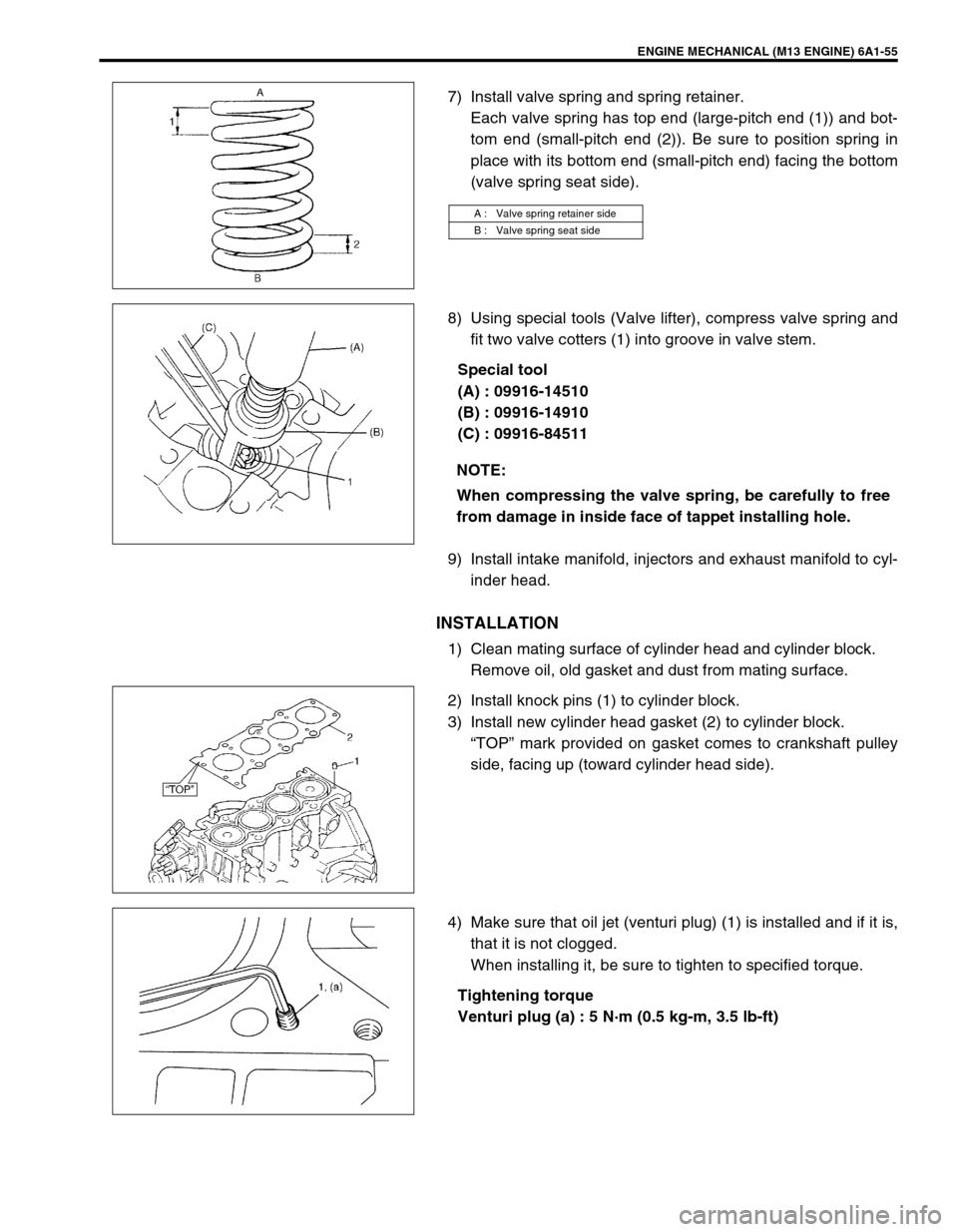

7) Install valve spring and spring retainer.

Each valve spring has top end (large-pitch end (1)) and bot-

tom end (small-pitch end (2)). Be sure to position spring in

place with its bottom end (small-pitch end) facing the bottom

(valve spring seat side).

8) Using special tools (Valve lifter), compress valve spring and

fit two valve cotters (1) into groove in valve stem.

Special tool

(A) : 09916-14510

(B) : 09916-14910

(C) : 09916-84511

9) Install intake manifold, injectors and exhaust manifold to cyl-

inder head.

INSTALLATION

1) Clean mating surface of cylinder head and cylinder block.

Remove oil, old gasket and dust from mating surface.

2) Install knock pins (1) to cylinder block.

3) Install new cylinder head gasket (2) to cylinder block.

“TOP” mark provided on gasket comes to crankshaft pulley

side, facing up (toward cylinder head side).

4) Make sure that oil jet (venturi plug) (1) is installed and if it is,

that it is not clogged.

When installing it, be sure to tighten to specified torque.

Tightening torque

Venturi plug (a) : 5 N·m (0.5 kg-m, 3.5 lb-ft)

A : Valve spring retainer side

B : Valve spring seat side

NOTE:

When compressing the valve spring, be carefully to free

from damage in inside face of tappet installing hole.

Page 558 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-57

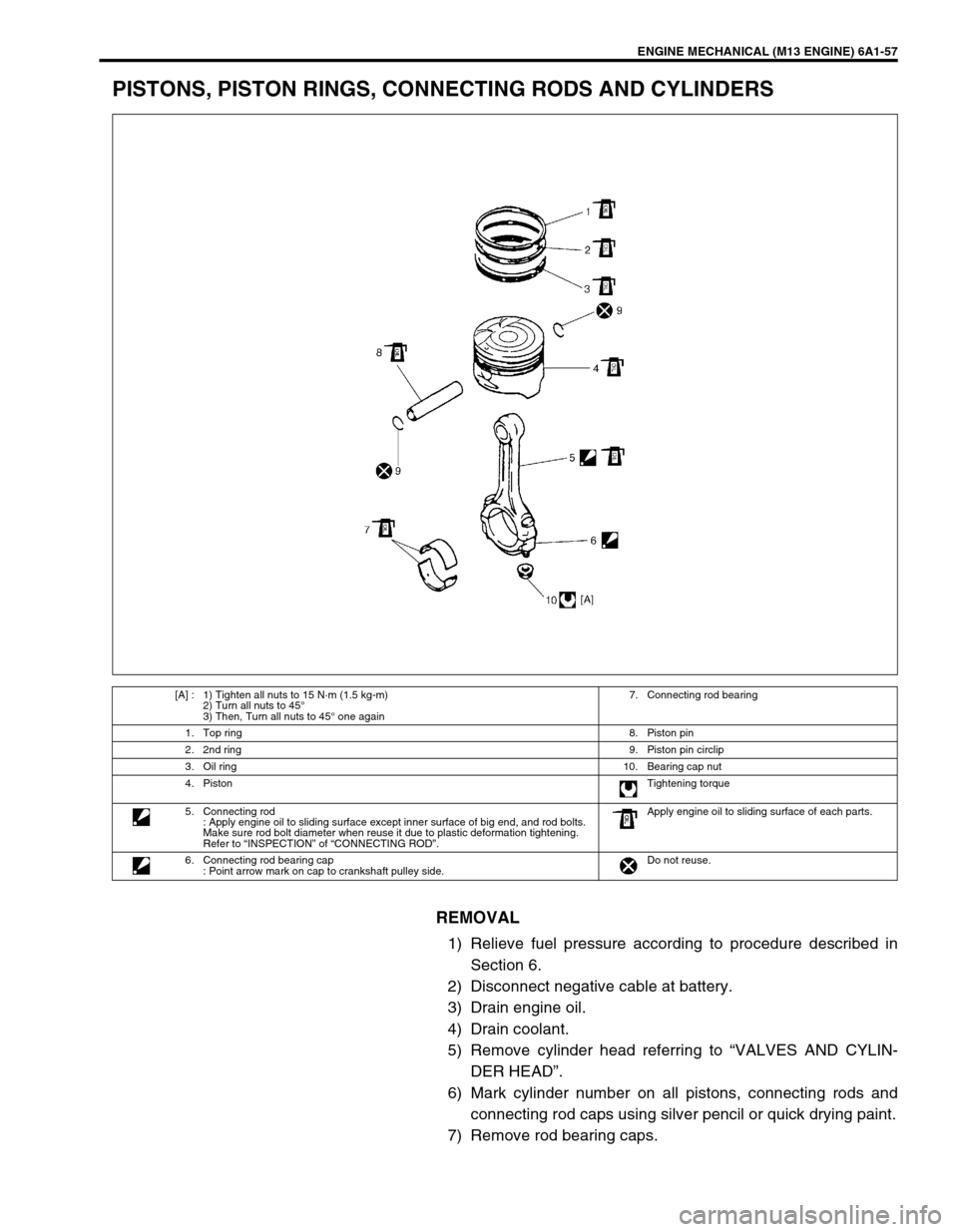

PISTONS, PISTON RINGS, CONNECTING RODS AND CYLINDERS

REMOVAL

1) Relieve fuel pressure according to procedure described in

Section 6.

2) Disconnect negative cable at battery.

3) Drain engine oil.

4) Drain coolant.

5) Remove cylinder head referring to “VALVES AND CYLIN-

DER HEAD”.

6) Mark cylinder number on all pistons, connecting rods and

connecting rod caps using silver pencil or quick drying paint.

7) Remove rod bearing caps.

[A] : 1) Tighten all nuts to 15 N·m (1.5 kg-m)

2) Turn all nuts to 45°

3) Then, Turn all nuts to 45° one again7. Connecting rod bearing

1. Top ring8. Piston pin

2. 2nd ring9. Piston pin circlip

3. Oil ring10. Bearing cap nut

4. PistonTightening torque

5. Connecting rod

: Apply engine oil to sliding surface except inner surface of big end, and rod bolts.

Make sure rod bolt diameter when reuse it due to plastic deformation tightening.

Refer to “INSPECTION” of “CONNECTING ROD”.Apply engine oil to sliding surface of each parts.

6. Connecting rod bearing cap

: Point arrow mark on cap to crankshaft pulley side.Do not reuse.

Page 570 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-69

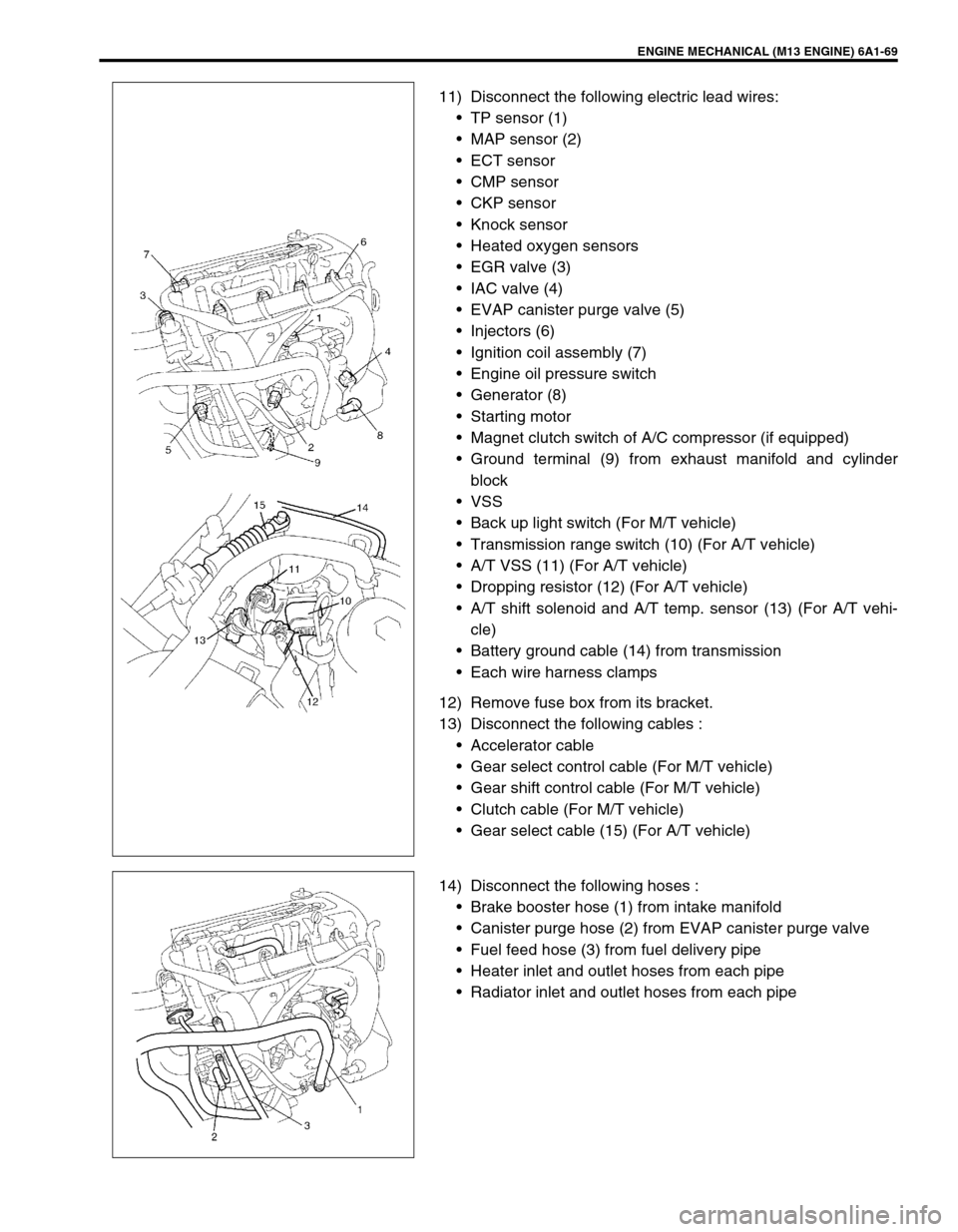

11) Disconnect the following electric lead wires:

TP sensor (1)

MAP sensor (2)

ECT sensor

CMP sensor

CKP sensor

Knock sensor

Heated oxygen sensors

EGR valve (3)

IAC valve (4)

EVAP canister purge valve (5)

Injectors (6)

Ignition coil assembly (7)

Engine oil pressure switch

Generator (8)

Starting motor

Magnet clutch switch of A/C compressor (if equipped)

Ground terminal (9) from exhaust manifold and cylinder

block

VSS

Back up light switch (For M/T vehicle)

Transmission range switch (10) (For A/T vehicle)

A/T VSS (11) (For A/T vehicle)

Dropping resistor (12) (For A/T vehicle)

A/T shift solenoid and A/T temp. sensor (13) (For A/T vehi-

cle)

Battery ground cable (14) from transmission

Each wire harness clamps

12) Remove fuse box from its bracket.

13) Disconnect the following cables :

Accelerator cable

Gear select control cable (For M/T vehicle)

Gear shift control cable (For M/T vehicle)

Clutch cable (For M/T vehicle)

Gear select cable (15) (For A/T vehicle)

14) Disconnect the following hoses :

Brake booster hose (1) from intake manifold

Canister purge hose (2) from EVAP canister purge valve

Fuel feed hose (3) from fuel delivery pipe

Heater inlet and outlet hoses from each pipe

Radiator inlet and outlet hoses from each pipe

Page 588 of 698

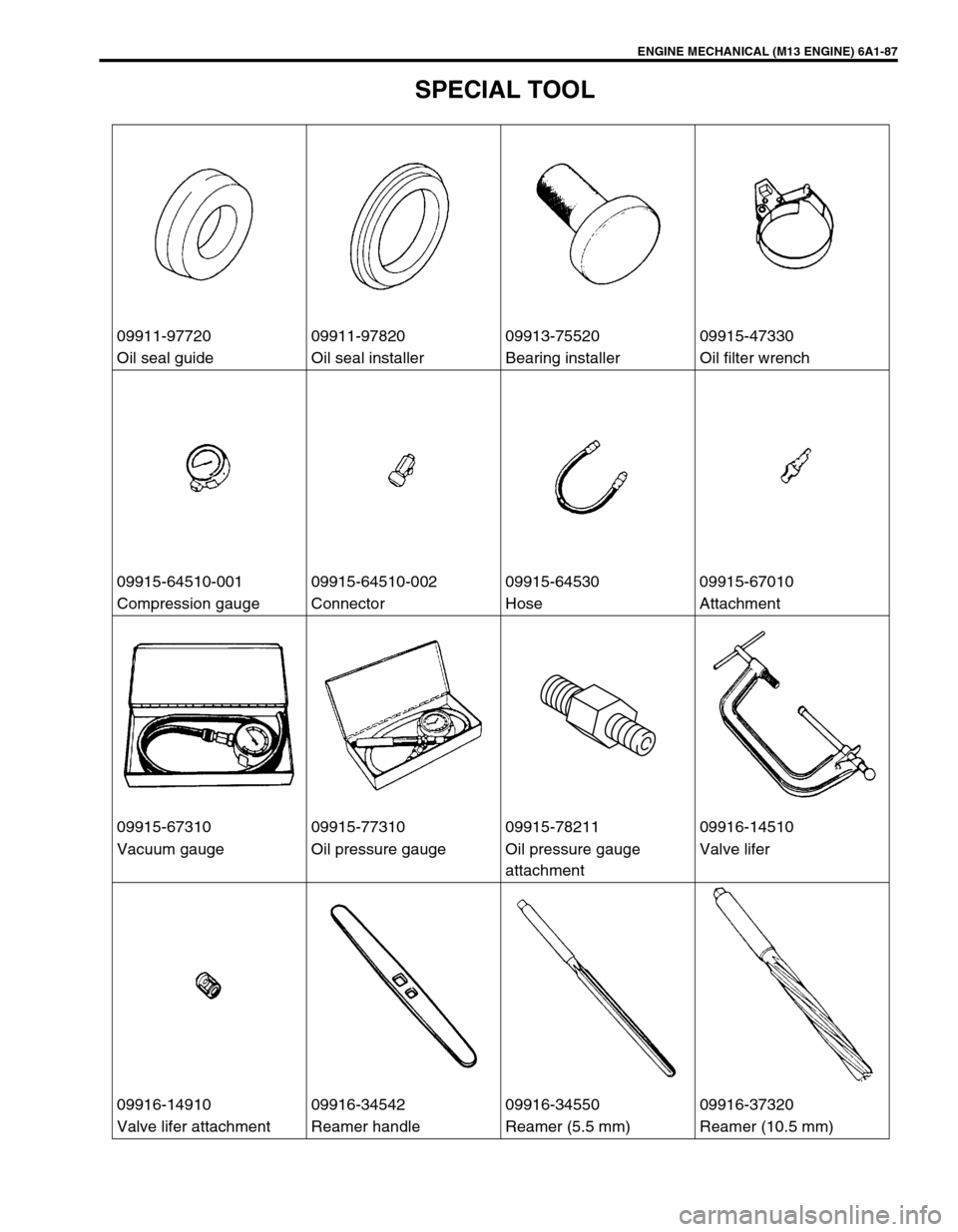

ENGINE MECHANICAL (M13 ENGINE) 6A1-87

SPECIAL TOOL

09911-97720 09911-97820 09913-75520 09915-47330

Oil seal guide Oil seal installer Bearing installer Oil filter wrench

09915-64510-001 09915-64510-002 09915-64530 09915-67010

Compression gauge Connector Hose Attachment

09915-67310 09915-77310 09915-78211 09916-14510

Vacuum gauge Oil pressure gauge Oil pressure gauge

attachmentValve lifer

09916-14910 09916-34542 09916-34550 09916-37320

Valve lifer attachment Reamer handle Reamer (5.5 mm) Reamer (10.5 mm)

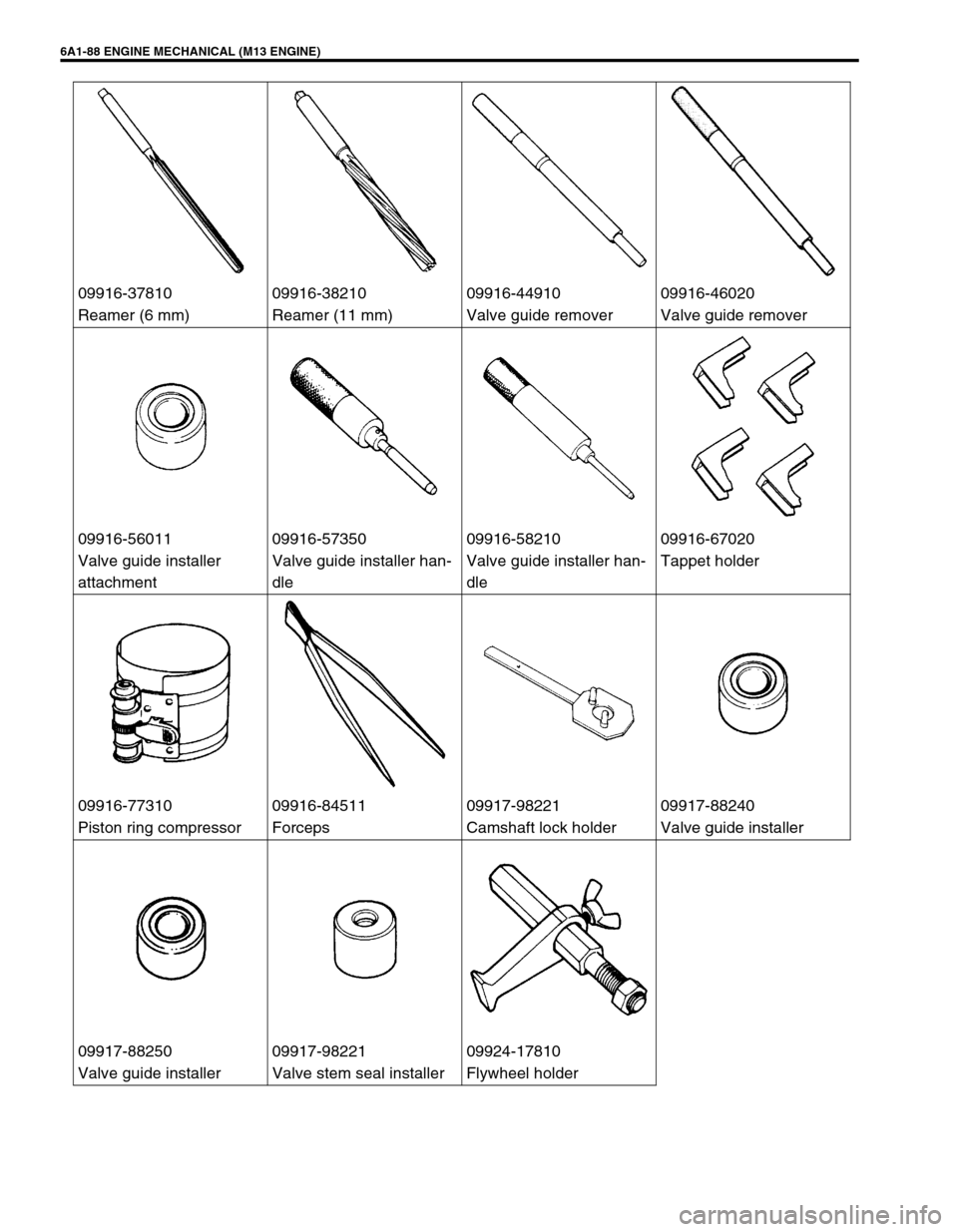

Page 589 of 698

6A1-88 ENGINE MECHANICAL (M13 ENGINE)

09916-37810 09916-38210 09916-44910 09916-46020

Reamer (6 mm) Reamer (11 mm) Valve guide remover Valve guide remover

09916-56011 09916-57350 09916-58210 09916-67020

Valve guide installer

attachmentValve guide installer han-

dleValve guide installer han-

dleTappet holder

09916-77310 09916-84511 09917-98221 09917-88240

Piston ring compressor Forceps Camshaft lock holder Valve guide installer

09917-88250 09917-98221 09924-17810

Valve guide installer Valve stem seal installer Flywheel holder

Page 601 of 698

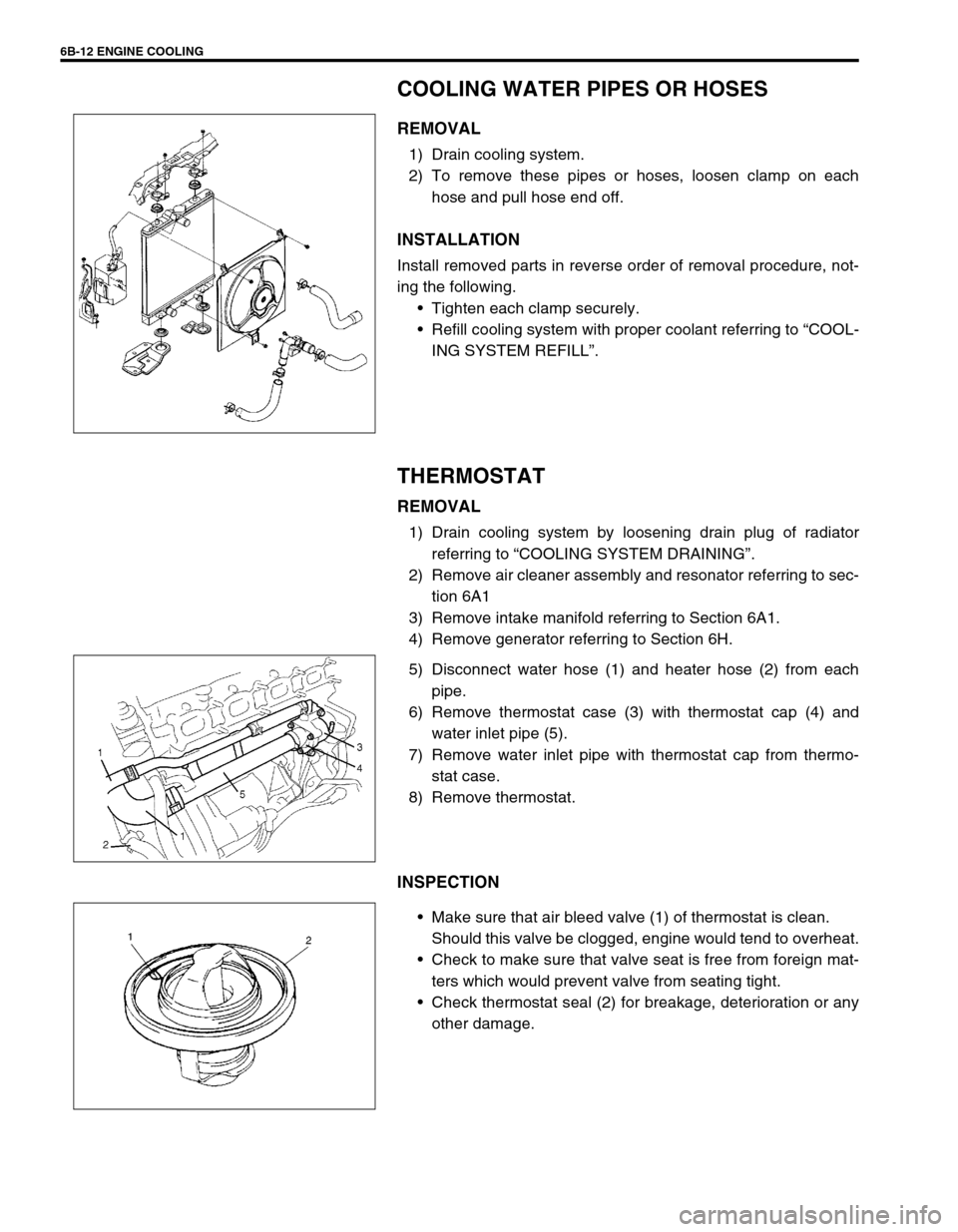

6B-12 ENGINE COOLING

COOLING WATER PIPES OR HOSES

REMOVAL

1) Drain cooling system.

2) To remove these pipes or hoses, loosen clamp on each

hose and pull hose end off.

INSTALLATION

Install removed parts in reverse order of removal procedure, not-

ing the following.

Tighten each clamp securely.

Refill cooling system with proper coolant referring to “COOL-

ING SYSTEM REFILL”.

THERMOSTAT

REMOVAL

1) Drain cooling system by loosening drain plug of radiator

referring to “COOLING SYSTEM DRAINING”.

2) Remove air cleaner assembly and resonator referring to sec-

tion 6A1

3) Remove intake manifold referring to Section 6A1.

4) Remove generator referring to Section 6H.

5) Disconnect water hose (1) and heater hose (2) from each

pipe.

6) Remove thermostat case (3) with thermostat cap (4) and

water inlet pipe (5).

7) Remove water inlet pipe with thermostat cap from thermo-

stat case.

8) Remove thermostat.

INSPECTION

Make sure that air bleed valve (1) of thermostat is clean.

Should this valve be clogged, engine would tend to overheat.

Check to make sure that valve seat is free from foreign mat-

ters which would prevent valve from seating tight.

Check thermostat seal (2) for breakage, deterioration or any

other damage.

Page 602 of 698

ENGINE COOLING 6B-13

Check thermostatic movement of wax pellet as follows :

a) Immerse thermostat (1) in water, and heat water gradually.

b) Check that valve starts to open at specific temperature.

Temperature at which valve begins to open

: 80 – 84°C (176 – 183°F)

Temperature at which valve become fully open

: 95 – 97°C (203°F)

Valve lift

: More than 8 mm at 95°C (203°F)

If valve starts to open at a temperature substantially below or

above specific temperature, thermostat unit should be replaced

with a new one. Such a unit, if reused, will bring about overcool-

ing or overheating tendency.

INSTALLATION

Reverse removal procedure for installation noting the following

points.

When positioning thermostat (1) on thermostat case (2), be

sure to position it so that air bleed valve (3) comes at posi-

tion as shown in figure.

Use new O-rings when installing.

Adjust water pump belt tension referring to WATER PUMP/

GENERATOR DRIVE BELT TENSION INSPECTION AND

ADJUSTMENT in this section.

Adjust A/C compressor belt tension (if equipped) referring to

Section 1B.

Refill cooling system with proper coolant referring to “COOL-

ING SYSTEM REFILL”.

Verify that there is no coolant leakage at each connection.

2. Thermometer

3. Heater

Page 608 of 698

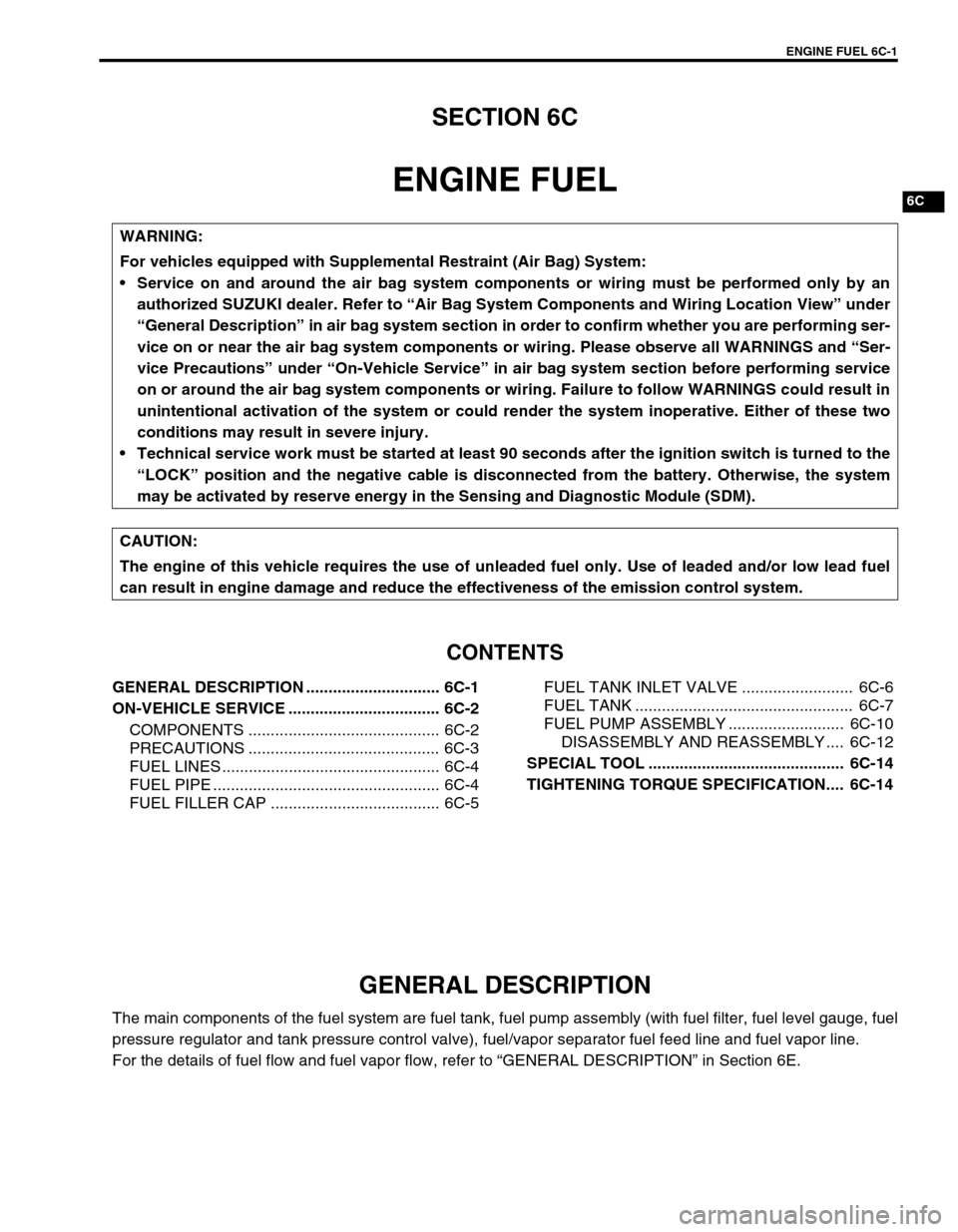

ENGINE FUEL 6C-1

6F1

6F2

6G

6C

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 6C

ENGINE FUEL

CONTENTS

GENERAL DESCRIPTION .............................. 6C-1

ON-VEHICLE SERVICE .................................. 6C-2

COMPONENTS ........................................... 6C-2

PRECAUTIONS ........................................... 6C-3

FUEL LINES ................................................. 6C-4

FUEL PIPE ................................................... 6C-4

FUEL FILLER CAP ...................................... 6C-5FUEL TANK INLET VALVE ......................... 6C-6

FUEL TANK ................................................. 6C-7

FUEL PUMP ASSEMBLY .......................... 6C-10

DISASSEMBLY AND REASSEMBLY .... 6C-12

SPECIAL TOOL ............................................ 6C-14

TIGHTENING TORQUE SPECIFICATION.... 6C-14

GENERAL DESCRIPTION

The main components of the fuel system are fuel tank, fuel pump assembly (with fuel filter, fuel level gauge, fuel

pressure regulator and tank pressure control valve), fuel/vapor separator fuel feed line and fuel vapor line.

For the details of fuel flow and fuel vapor flow, refer to “GENERAL DESCRIPTION” in Section 6E. WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

CAUTION:

The engine of this vehicle requires the use of unleaded fuel only. Use of leaded and/or low lead fuel

can result in engine damage and reduce the effectiveness of the emission control system.

Page 613 of 698

6C-6 ENGINE FUEL

FUEL TANK INLET VALVE

REMOVAL

1) Remove fuel filler cap.

2) Insert hose of a hand operated pump into fuel filler hose (1)

and drain fuel in space “A” in the figure.

3) Hoist vehicle and remove clamp (2) and fuel filler hose (1)

from fuel tank.

4) Remove fuel tank inlet valve (1) using flat-bladed screw-

driver.

INSPECTION

Check fuel tank inlet valve for the followings.

Damage

Smooth opening and closing

If any damage or malfunction is found, replace.WARNING:

Refer to the WARNING at the beginning of ON-VEHICLE

SERVICE in this section.

CAUTION:

Do not force pump hose into fuel tank, or pump hose

may damage fuel tank inlet valve (2).

1

2

CAUTION:

Be careful not to damage fuel tank inlet valve (1) with flat-

bladed screwdriver.