valve SUZUKI SWIFT 2000 1.G RG413 Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 537 of 698

6A1-36 ENGINE MECHANICAL (M13 ENGINE)

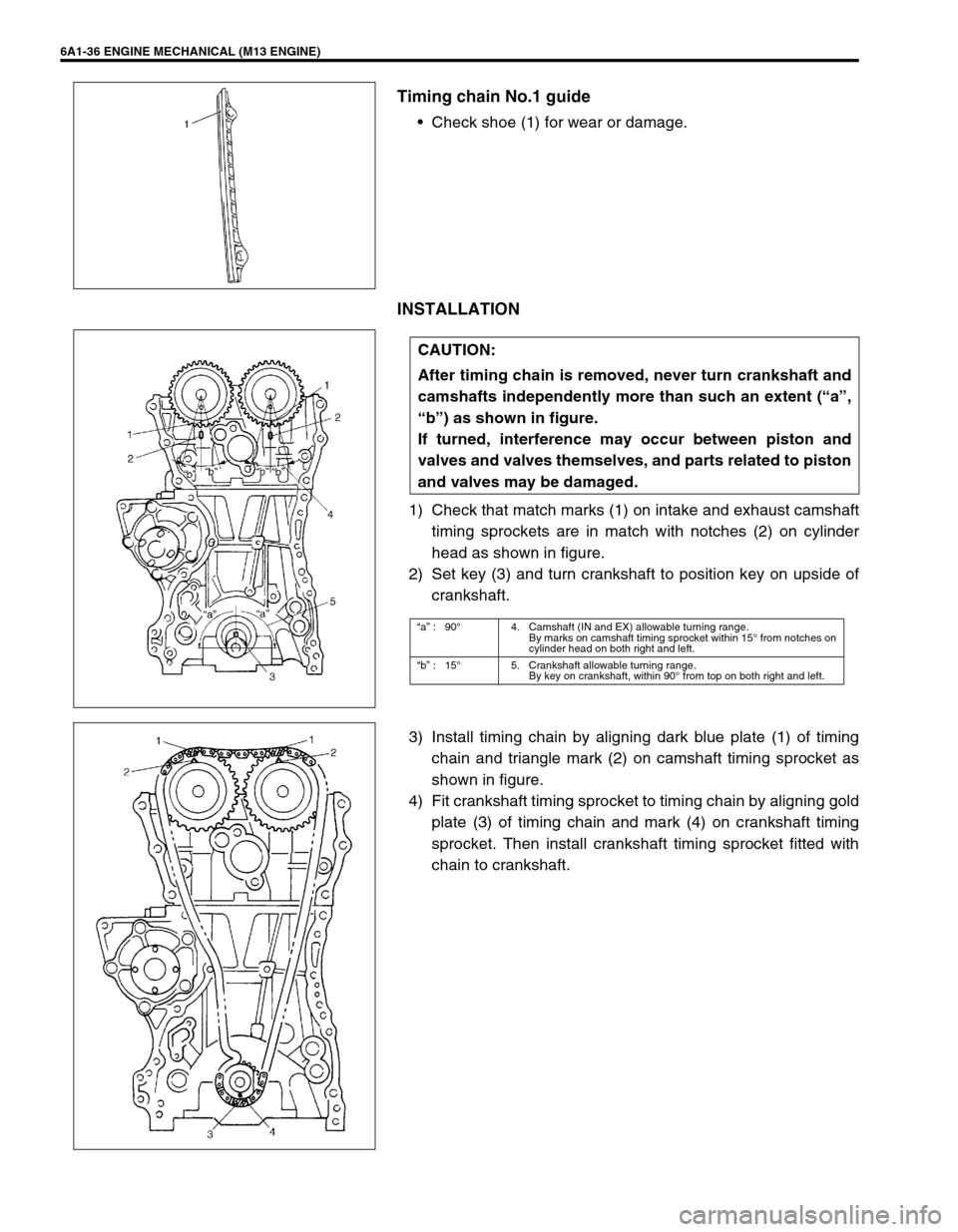

Timing chain No.1 guide

Check shoe (1) for wear or damage.

INSTALLATION

1) Check that match marks (1) on intake and exhaust camshaft

timing sprockets are in match with notches (2) on cylinder

head as shown in figure.

2) Set key (3) and turn crankshaft to position key on upside of

crankshaft.

3) Install timing chain by aligning dark blue plate (1) of timing

chain and triangle mark (2) on camshaft timing sprocket as

shown in figure.

4) Fit crankshaft timing sprocket to timing chain by aligning gold

plate (3) of timing chain and mark (4) on crankshaft timing

sprocket. Then install crankshaft timing sprocket fitted with

chain to crankshaft.

CAUTION:

After timing chain is removed, never turn crankshaft and

camshafts independently more than such an extent (“a”,

“b”) as shown in figure.

If turned, interference may occur between piston and

valves and valves themselves, and parts related to piston

and valves may be damaged.

“a” :90°4. Camshaft (IN and EX) allowable turning range.

By marks on camshaft timing sprocket within 15° from notches on

cylinder head on both right and left.

“b” :15°5. Crankshaft allowable turning range.

By key on crankshaft, within 90° from top on both right and left.

Page 544 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-43

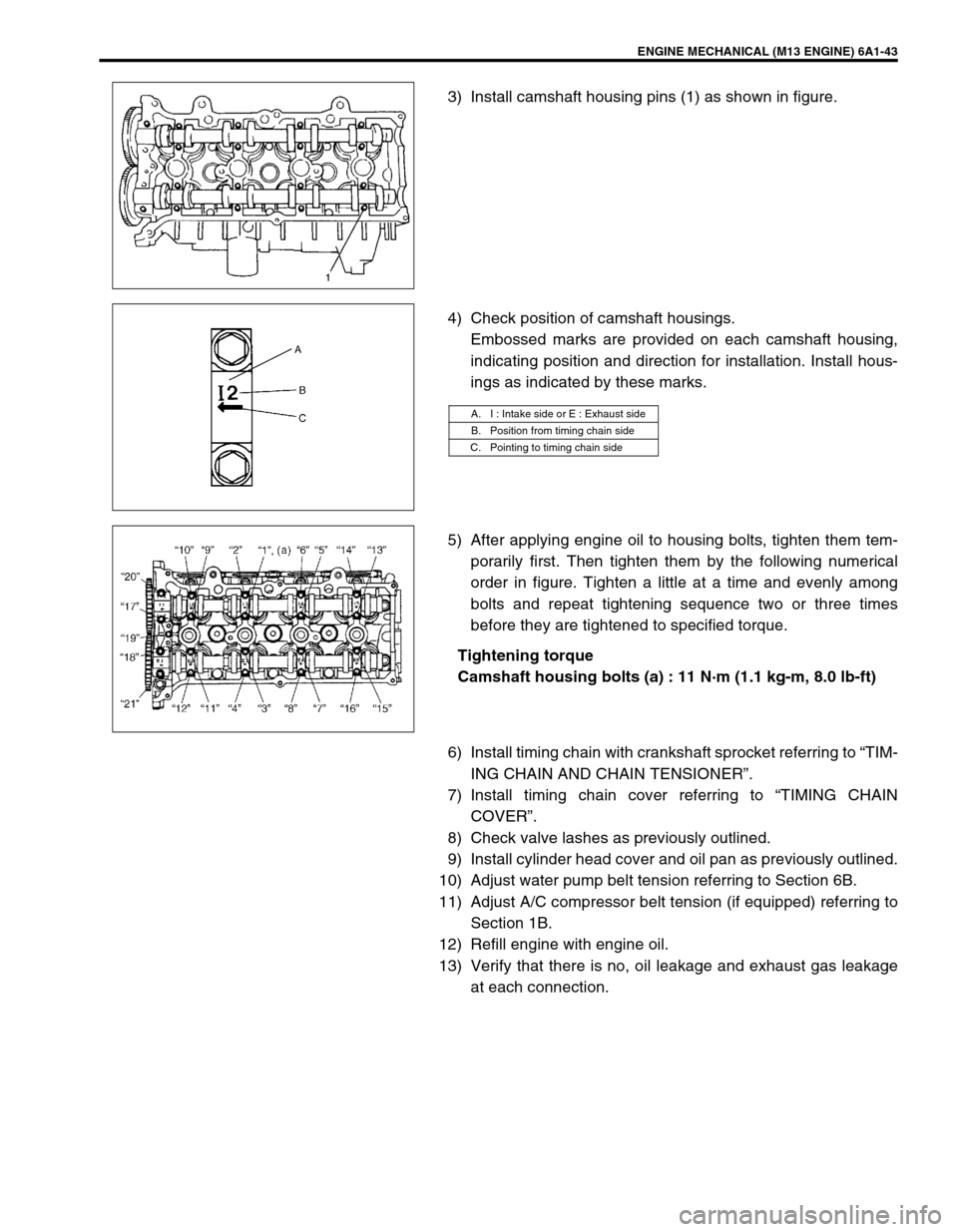

3) Install camshaft housing pins (1) as shown in figure.

4) Check position of camshaft housings.

Embossed marks are provided on each camshaft housing,

indicating position and direction for installation. Install hous-

ings as indicated by these marks.

5) After applying engine oil to housing bolts, tighten them tem-

porarily first. Then tighten them by the following numerical

order in figure. Tighten a little at a time and evenly among

bolts and repeat tightening sequence two or three times

before they are tightened to specified torque.

Tightening torque

Camshaft housing bolts (a) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

6) Install timing chain with crankshaft sprocket referring to “TIM-

ING CHAIN AND CHAIN TENSIONER”.

7) Install timing chain cover referring to “TIMING CHAIN

COVER”.

8) Check valve lashes as previously outlined.

9) Install cylinder head cover and oil pan as previously outlined.

10) Adjust water pump belt tension referring to Section 6B.

11) Adjust A/C compressor belt tension (if equipped) referring to

Section 1B.

12) Refill engine with engine oil.

13) Verify that there is no, oil leakage and exhaust gas leakage

at each connection.

A. I : Intake side or E : Exhaust side

B. Position from timing chain side

C. Pointing to timing chain side

Page 545 of 698

6A1-44 ENGINE MECHANICAL (M13 ENGINE)

VALVES AND CYLINDER HEAD

REMOVAL

1) Relieve fuel pressure according to procedure described in

Section 6.

2) Disconnect negative cable at battery.

3) Drain engine oil.

[A]✱1) Tighten all bolts at 40 N·m (4.0 kg-m)

2) Turn all bolts at 60°

3) Then, Turn all bolt at 60° once again6. Intake valve 12. Knock pin

1. Valve cotters 7. Exhaust valve

Tightening torque

2. Valve spring retainer 8. Valve guide

Do not reuse.

3. Valve spring 9. Cylinder head bolt

: Never reuse it due to plastic deformation

tightening bolt.Apply engine oil to sliding surface of

each part.

4. Valve stem seal 10. Cylinder head

5. Valve spring seat 11. Cylinder head gasket

: “TOP” mark provided on gasket comes to

crankshaft pulley side, facing up.

Page 546 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-45

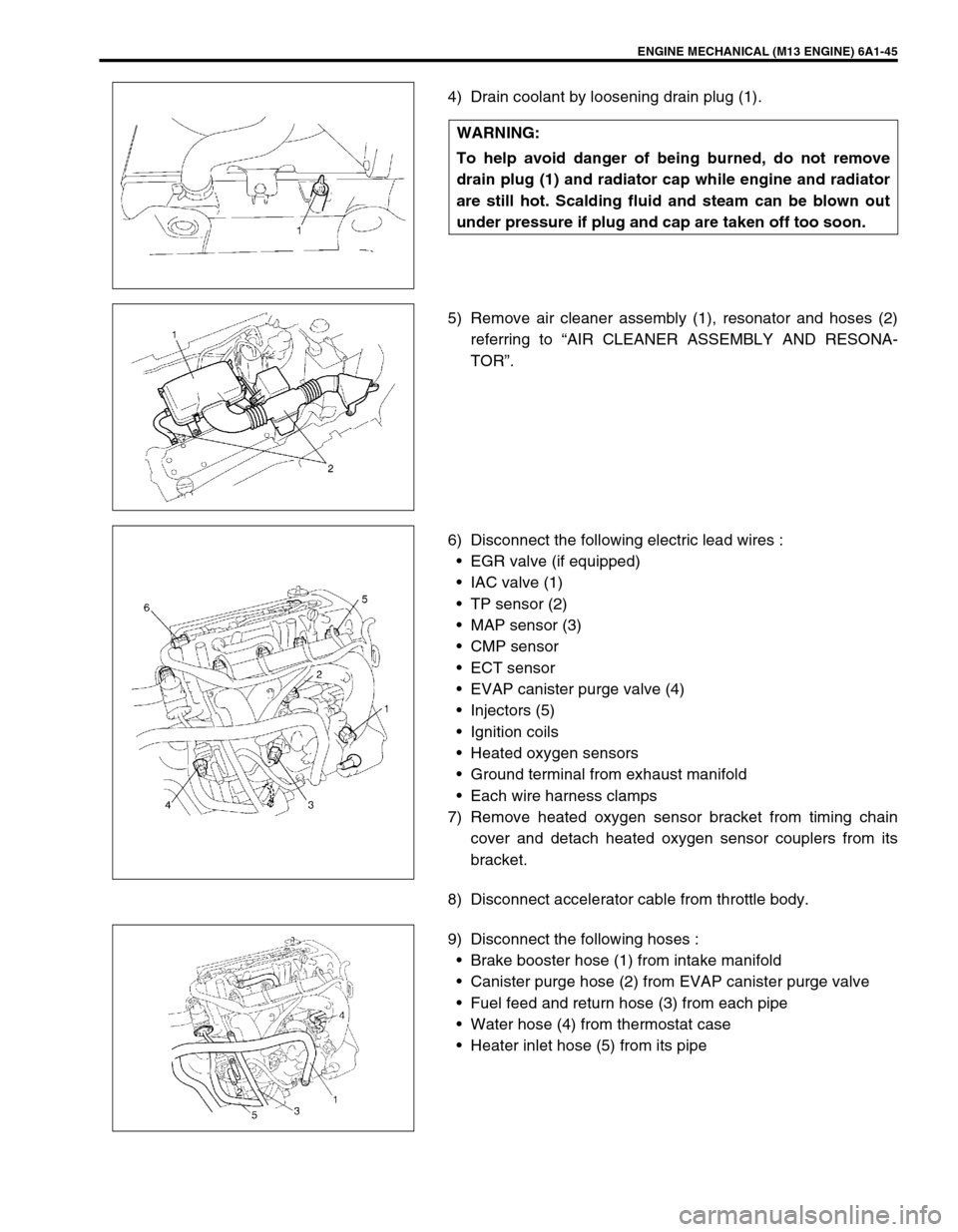

4) Drain coolant by loosening drain plug (1).

5) Remove air cleaner assembly (1), resonator and hoses (2)

referring to “AIR CLEANER ASSEMBLY AND RESONA-

TOR”.

6) Disconnect the following electric lead wires :

EGR valve (if equipped)

IAC valve (1)

TP sensor (2)

MAP sensor (3)

CMP sensor

ECT sensor

EVAP canister purge valve (4)

Injectors (5)

Ignition coils

Heated oxygen sensors

Ground terminal from exhaust manifold

Each wire harness clamps

7) Remove heated oxygen sensor bracket from timing chain

cover and detach heated oxygen sensor couplers from its

bracket.

8) Disconnect accelerator cable from throttle body.

9) Disconnect the following hoses :

Brake booster hose (1) from intake manifold

Canister purge hose (2) from EVAP canister purge valve

Fuel feed and return hose (3) from each pipe

Water hose (4) from thermostat case

Heater inlet hose (5) from its pipe WARNING:

To help avoid danger of being burned, do not remove

drain plug (1) and radiator cap while engine and radiator

are still hot. Scalding fluid and steam can be blown out

under pressure if plug and cap are taken off too soon.

Page 548 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-47

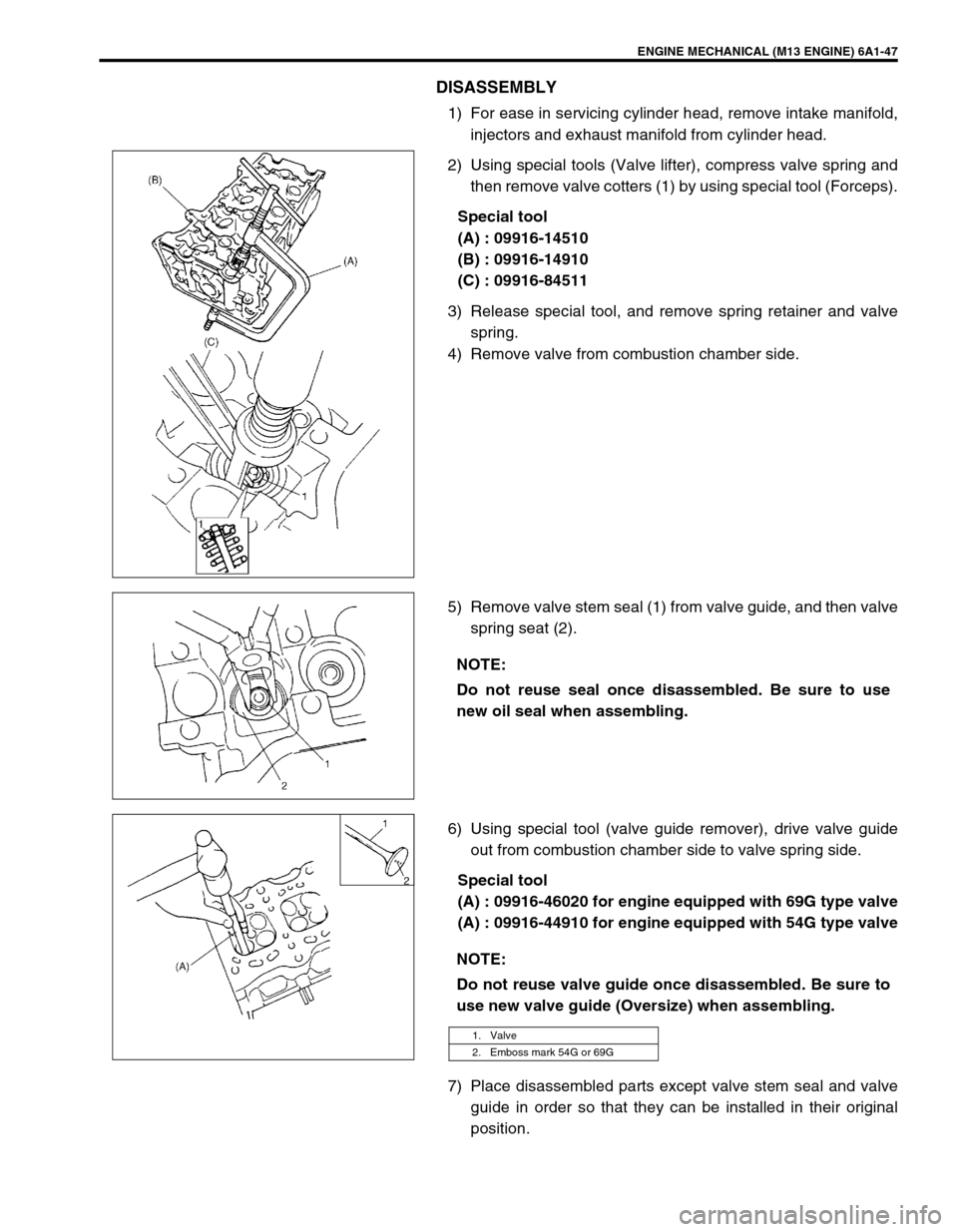

DISASSEMBLY

1) For ease in servicing cylinder head, remove intake manifold,

injectors and exhaust manifold from cylinder head.

2) Using special tools (Valve lifter), compress valve spring and

then remove valve cotters (1) by using special tool (Forceps).

Special tool

(A) : 09916-14510

(B) : 09916-14910

(C) : 09916-84511

3) Release special tool, and remove spring retainer and valve

spring.

4) Remove valve from combustion chamber side.

5) Remove valve stem seal (1) from valve guide, and then valve

spring seat (2).

6) Using special tool (valve guide remover), drive valve guide

out from combustion chamber side to valve spring side.

Special tool

(A) : 09916-46020 for engine equipped with 69G type valve

(A) : 09916-44910 for engine equipped with 54G type valve

7) Place disassembled parts except valve stem seal and valve

guide in order so that they can be installed in their original

position.

NOTE:

Do not reuse seal once disassembled. Be sure to use

new oil seal when assembling.

NOTE:

Do not reuse valve guide once disassembled. Be sure to

use new valve guide (Oversize) when assembling.

1. Valve

2. Emboss mark 54G or 69G

Page 549 of 698

6A1-48 ENGINE MECHANICAL (M13 ENGINE)

INSPECTION

Valve Guides

Using a micrometer and bore gauge, take diameter readings on

valve stems and guides to check stem-to-guide clearance. Be

sure to take reading at more than one place along the length of

each stem and guide.

If clearance exceeds limit, replace valve and valve guide.

Valve stem-to-guide clearance

Valve stem diameter [A]

Valve guide bore [B] standard

In and Ex : 6.000 – 6.012 mm (0.2362 – 0.2367 in.) for 69G

type valve

In and Ex : 5.485 – 5.510 mm (0.2159 – 0.2169 in.) for 54G

type valve

If bore gauge is not available, check end deflection of valve stem

with a dial gauge instead.

Move stem end in directions (1) and (2) to measure end deflec-

tion.

If deflection exceeds its limit, replace valve stem and valve guide.

Valve stem end deflection limit

In : 0.14 mm (0.005 in.)

Ex : 0.18 mm (0.007 in.)Valve type Standard Limit

69GIn0.020 – 0.047 mm

(0.0008 – 0.0019 in.)0.07 mm

(0.0028 in.)

Ex0.045 – 0.072 mm

(0.0018 – 0.0028 in.)0.09 mm

(0.0035 in.)

54GIn0.020 – 0.030 mm

(0.0008 – 0.0012 in.)0.05 mm

(0.0017 in.)

Ex0.045 – 0.055 mm

(0.0018 – 0.0022 in.)0.07 mm

(0.0028 in.)

Valve type Standard

69GIn5.965 – 5.980 mm

(0.2348 – 0.2354 in.)

Ex5.940 – 5.955 mm

(0.2339 – 0.2344 in.)

54GIn5.465 – 5.480 mm

(0.2152 – 0.2157 in.)

Ex5.440 – 5.455 mm

(0.2142 – 0.2148 in.)

1. Emboss mark 54G or 69G

Page 550 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-49

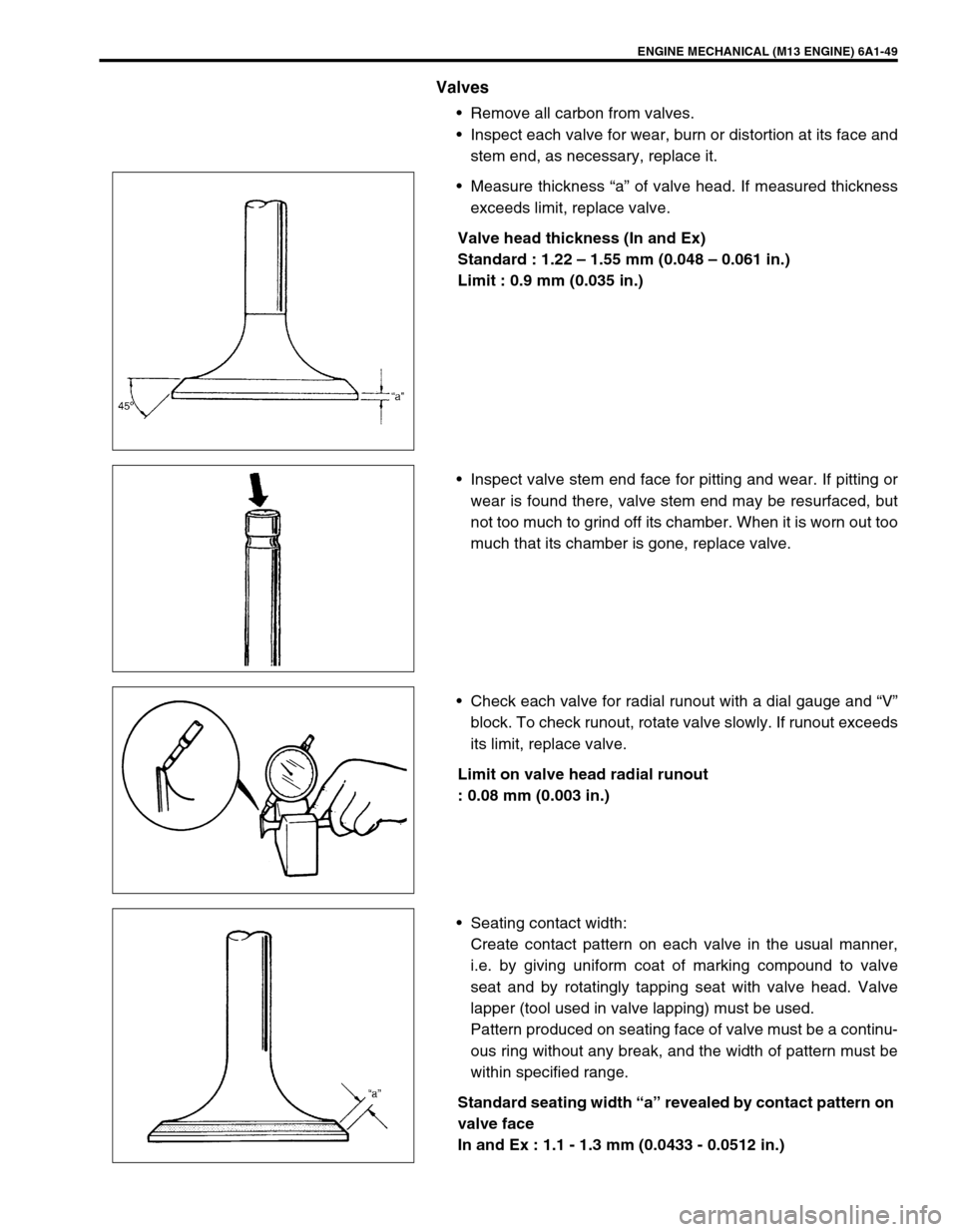

Valves

Remove all carbon from valves.

Inspect each valve for wear, burn or distortion at its face and

stem end, as necessary, replace it.

Measure thickness “a” of valve head. If measured thickness

exceeds limit, replace valve.

Valve head thickness (In and Ex)

Standard : 1.22 – 1.55 mm (0.048 – 0.061 in.)

Limit : 0.9 mm (0.035 in.)

Inspect valve stem end face for pitting and wear. If pitting or

wear is found there, valve stem end may be resurfaced, but

not too much to grind off its chamber. When it is worn out too

much that its chamber is gone, replace valve.

Check each valve for radial runout with a dial gauge and “V”

block. To check runout, rotate valve slowly. If runout exceeds

its limit, replace valve.

Limit on valve head radial runout

: 0.08 mm (0.003 in.)

Seating contact width:

Create contact pattern on each valve in the usual manner,

i.e. by giving uniform coat of marking compound to valve

seat and by rotatingly tapping seat with valve head. Valve

lapper (tool used in valve lapping) must be used.

Pattern produced on seating face of valve must be a continu-

ous ring without any break, and the width of pattern must be

within specified range.

Standard seating width “a” revealed by contact pattern on

valve face

In and Ex : 1.1 - 1.3 mm (0.0433 - 0.0512 in.)

Page 551 of 698

6A1-50 ENGINE MECHANICAL (M13 ENGINE)

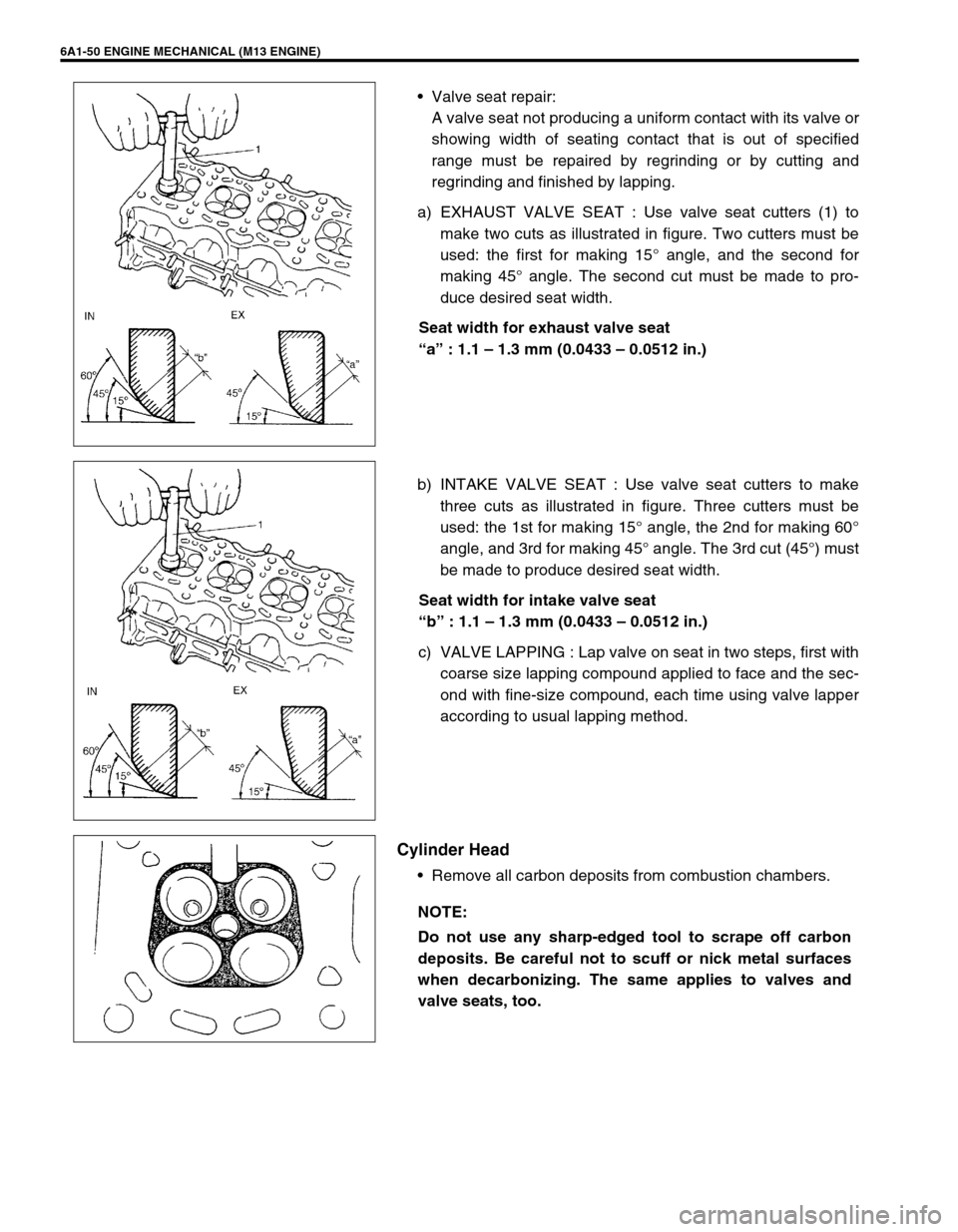

Valve seat repair:

A valve seat not producing a uniform contact with its valve or

showing width of seating contact that is out of specified

range must be repaired by regrinding or by cutting and

regrinding and finished by lapping.

a) EXHAUST VALVE SEAT : Use valve seat cutters (1) to

make two cuts as illustrated in figure. Two cutters must be

used: the first for making 15° angle, and the second for

making 45° angle. The second cut must be made to pro-

duce desired seat width.

Seat width for exhaust valve seat

“a” : 1.1 – 1.3 mm (0.0433 – 0.0512 in.)

b) INTAKE VALVE SEAT : Use valve seat cutters to make

three cuts as illustrated in figure. Three cutters must be

used: the 1st for making 15° angle, the 2nd for making 60°

angle, and 3rd for making 45° angle. The 3rd cut (45°) must

be made to produce desired seat width.

Seat width for intake valve seat

“b” : 1.1 – 1.3 mm (0.0433 – 0.0512 in.)

c) VALVE LAPPING : Lap valve on seat in two steps, first with

coarse size lapping compound applied to face and the sec-

ond with fine-size compound, each time using valve lapper

according to usual lapping method.

Cylinder Head

Remove all carbon deposits from combustion chambers.

NOTE:

Do not use any sharp-edged tool to scrape off carbon

deposits. Be careful not to scuff or nick metal surfaces

when decarbonizing. The same applies to valves and

valve seats, too.

Page 553 of 698

6A1-52 ENGINE MECHANICAL (M13 ENGINE)

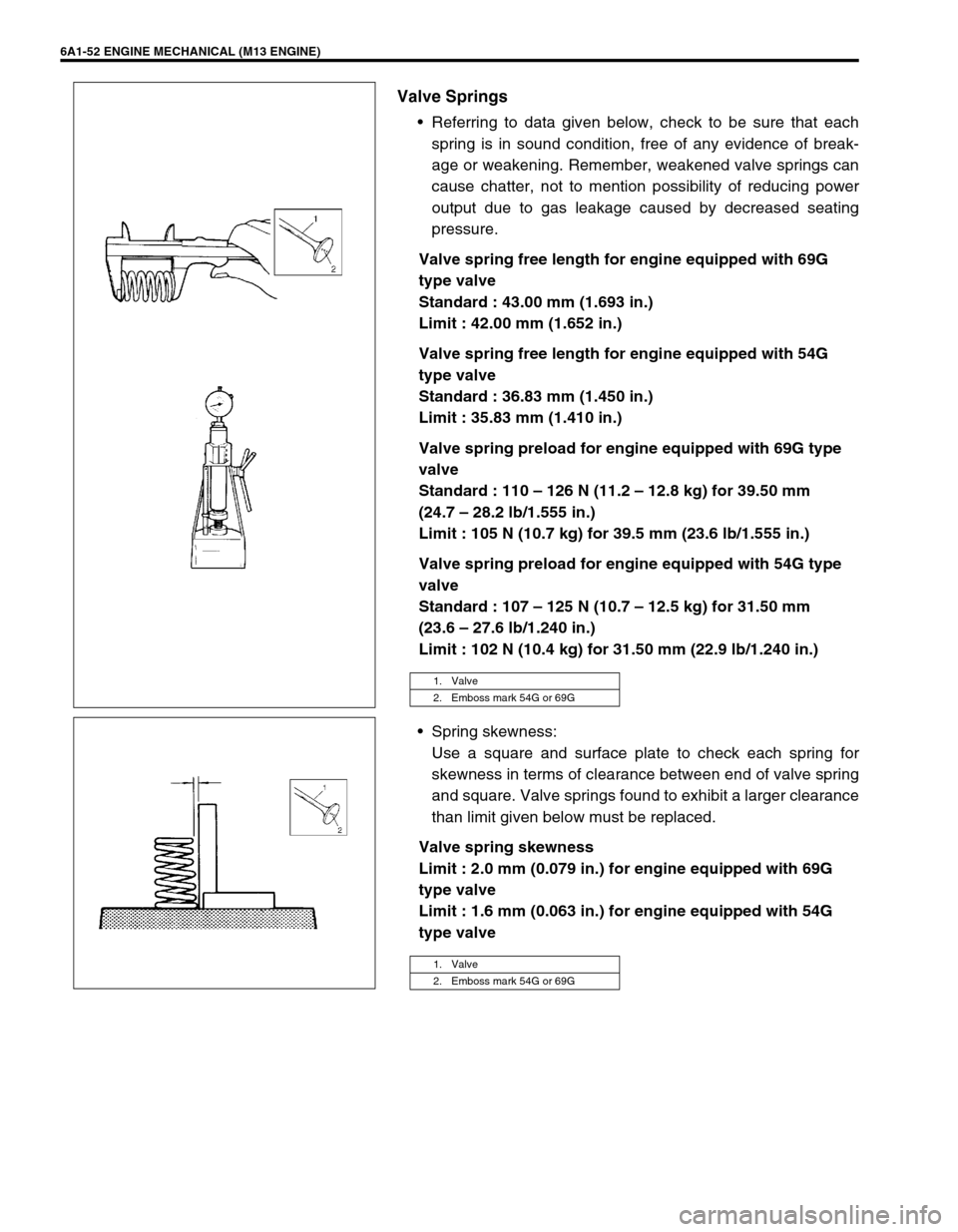

Valve Springs

Referring to data given below, check to be sure that each

spring is in sound condition, free of any evidence of break-

age or weakening. Remember, weakened valve springs can

cause chatter, not to mention possibility of reducing power

output due to gas leakage caused by decreased seating

pressure.

Valve spring free length for engine equipped with 69G

type valve

Standard : 43.00 mm (1.693 in.)

Limit : 42.00 mm (1.652 in.)

Valve spring free length for engine equipped with 54G

type valve

Standard : 36.83 mm (1.450 in.)

Limit : 35.83 mm (1.410 in.)

Valve spring preload for engine equipped with 69G type

valve

Standard : 110 – 126 N (11.2 – 12.8 kg) for 39.50 mm

(24.7 – 28.2 lb/1.555 in.)

Limit : 105 N (10.7 kg) for 39.5 mm (23.6 lb/1.555 in.)

Valve spring preload for engine equipped with 54G type

valve

Standard : 107 – 125 N (10.7 – 12.5 kg) for 31.50 mm

(23.6 – 27.6 lb/1.240 in.)

Limit : 102 N (10.4 kg) for 31.50 mm (22.9 lb/1.240 in.)

Spring skewness:

Use a square and surface plate to check each spring for

skewness in terms of clearance between end of valve spring

and square. Valve springs found to exhibit a larger clearance

than limit given below must be replaced.

Valve spring skewness

Limit : 2.0 mm (0.079 in.) for engine equipped with 69G

type valve

Limit : 1.6 mm (0.063 in.) for engine equipped with 54G

type valve

1. Valve

2. Emboss mark 54G or 69G

1. Valve

2. Emboss mark 54G or 69G

Page 554 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-53

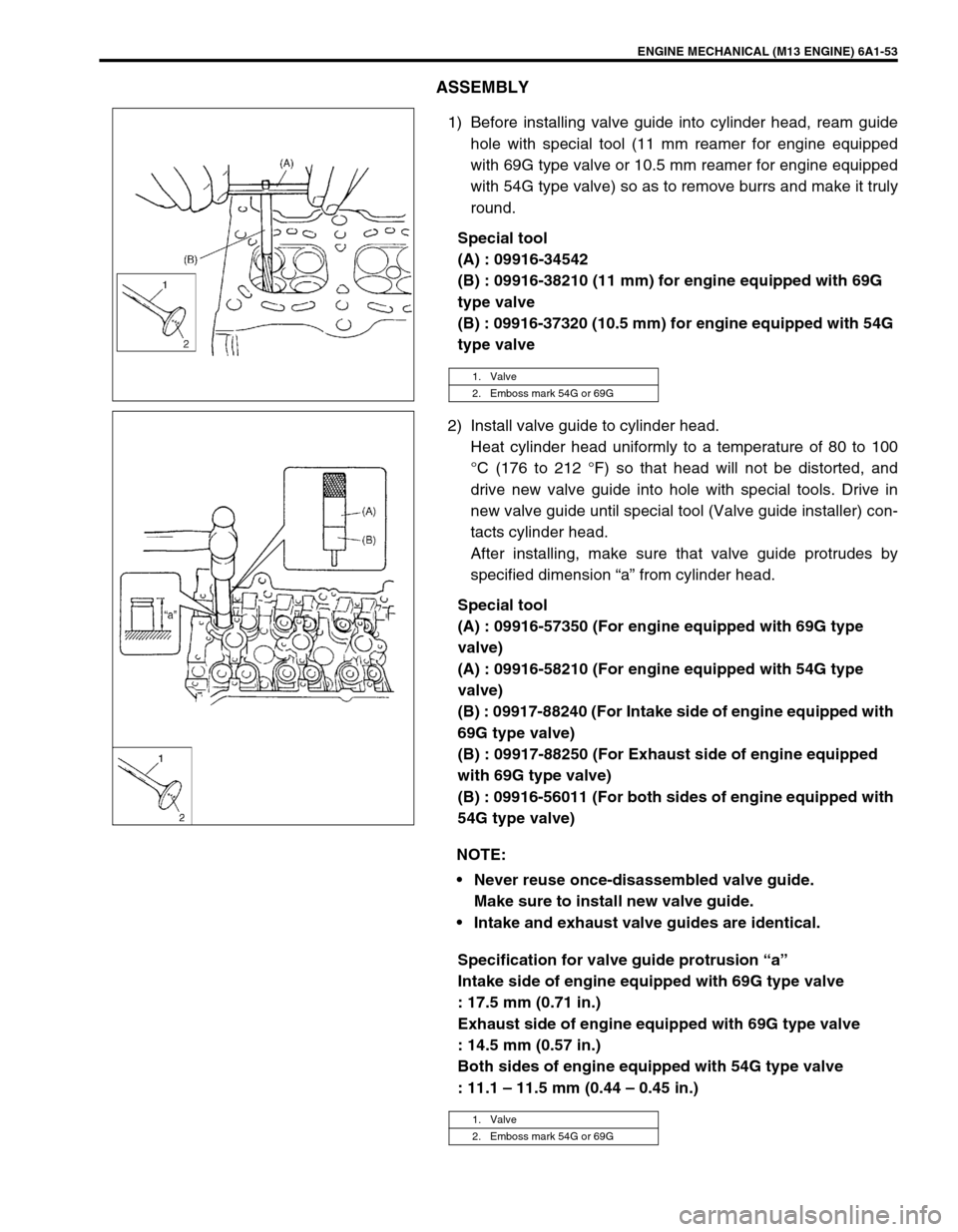

ASSEMBLY

1) Before installing valve guide into cylinder head, ream guide

hole with special tool (11 mm reamer for engine equipped

with 69G type valve or 10.5 mm reamer for engine equipped

with 54G type valve) so as to remove burrs and make it truly

round.

Special tool

(A) : 09916-34542

(B) : 09916-38210 (11 mm) for engine equipped with 69G

type valve

(B) : 09916-37320 (10.5 mm) for engine equipped with 54G

type valve

2) Install valve guide to cylinder head.

Heat cylinder head uniformly to a temperature of 80 to 100

°C (176 to 212 °F) so that head will not be distorted, and

drive new valve guide into hole with special tools. Drive in

new valve guide until special tool (Valve guide installer) con-

tacts cylinder head.

After installing, make sure that valve guide protrudes by

specified dimension “a” from cylinder head.

Special tool

(A) : 09916-57350 (For engine equipped with 69G type

valve)

(A) : 09916-58210 (For engine equipped with 54G type

valve)

(B) : 09917-88240 (For Intake side of engine equipped with

69G type valve)

(B) : 09917-88250 (For Exhaust side of engine equipped

with 69G type valve)

(B) : 09916-56011 (For both sides of engine equipped with

54G type valve)

Specification for valve guide protrusion “a”

Intake side of engine equipped with 69G type valve

: 17.5 mm (0.71 in.)

Exhaust side of engine equipped with 69G type valve

: 14.5 mm (0.57 in.)

Both sides of engine equipped with 54G type valve

: 11.1 – 11.5 mm (0.44 – 0.45 in.)

1. Valve

2. Emboss mark 54G or 69G

NOTE:

Never reuse once-disassembled valve guide.

Make sure to install new valve guide.

Intake and exhaust valve guides are identical.

1. Valve

2. Emboss mark 54G or 69G