Air SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 262 of 698

FRONT DRIVE SHAFT 4A-9

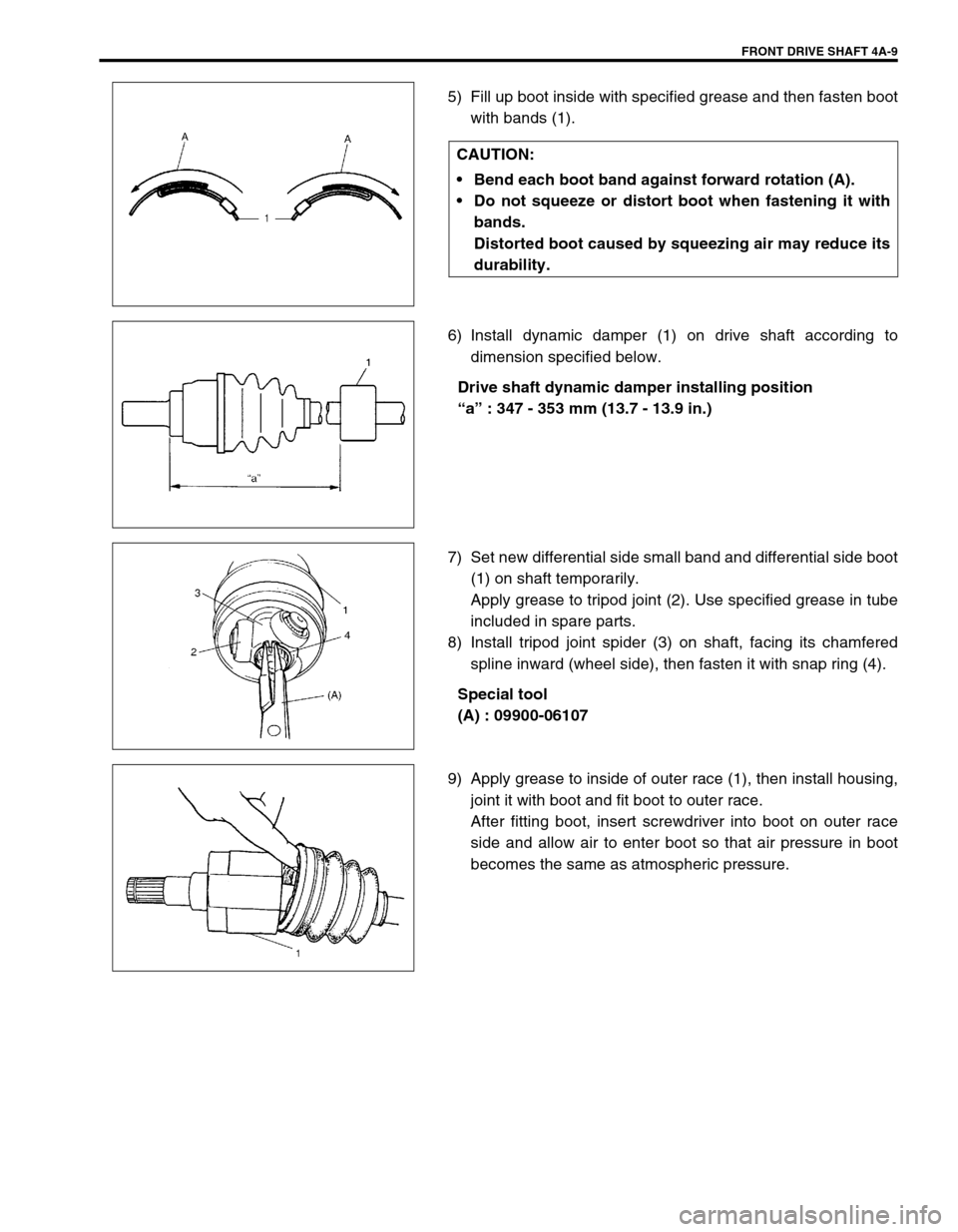

5) Fill up boot inside with specified grease and then fasten boot

with bands (1).

6) Install dynamic damper (1) on drive shaft according to

dimension specified below.

Drive shaft dynamic damper installing position

βaβ : 347 - 353 mm (13.7 - 13.9 in.)

7) Set new differential side small band and differential side boot

(1) on shaft temporarily.

Apply grease to tripod joint (2). Use specified grease in tube

included in spare parts.

8) Install tripod joint spider (3) on shaft, facing its chamfered

spline inward (wheel side), then fasten it with snap ring (4).

Special tool

(A) : 09900-06107

9) Apply grease to inside of outer race (1), then install housing,

joint it with boot and fit boot to outer race.

After fitting boot, insert screwdriver into boot on outer race

side and allow air to enter boot so that air pressure in boot

becomes the same as atmospheric pressure. CAUTION:

Bend each boot band against forward rotation (A).

Do not squeeze or distort boot when fastening it with

bands.

Distorted boot caused by squeezing air may reduce its

durability.

Page 263 of 698

4A-10 FRONT DRIVE SHAFT

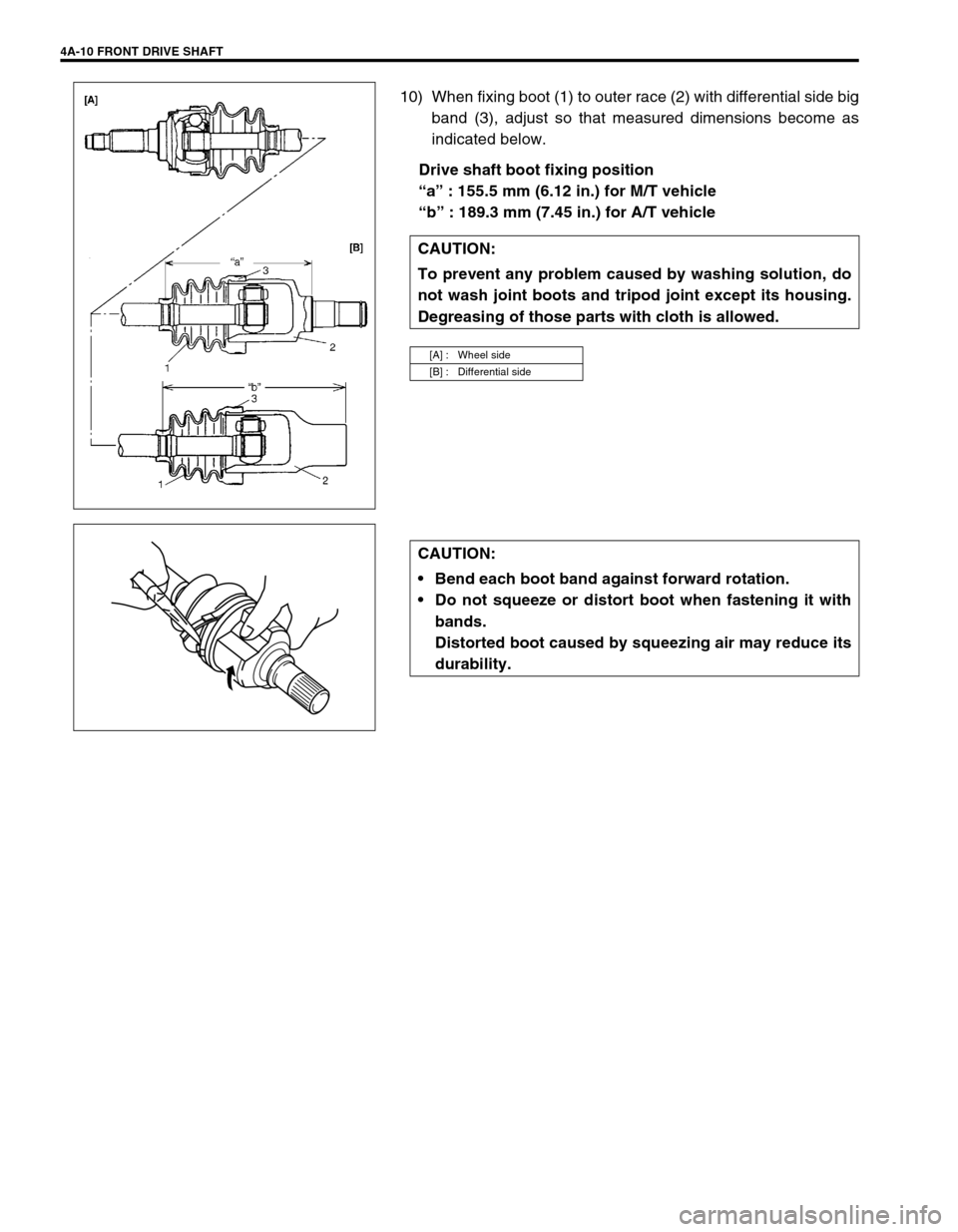

10) When fixing boot (1) to outer race (2) with differential side big

band (3), adjust so that measured dimensions become as

indicated below.

Drive shaft boot fixing position

βaβ : 155.5 mm (6.12 in.) for M/T vehicle

βbβ : 189.3 mm (7.45 in.) for A/T vehicle

CAUTION:

To prevent any problem caused by washing solution, do

not wash joint boots and tripod joint except its housing.

Degreasing of those parts with cloth is allowed.

[A] : Wheel side

[B] : Differential side

CAUTION:

Bend each boot band against forward rotation.

Do not squeeze or distort boot when fastening it with

bands.

Distorted boot caused by squeezing air may reduce its

durability.

Page 264 of 698

FRONT DRIVE SHAFT 4A-11

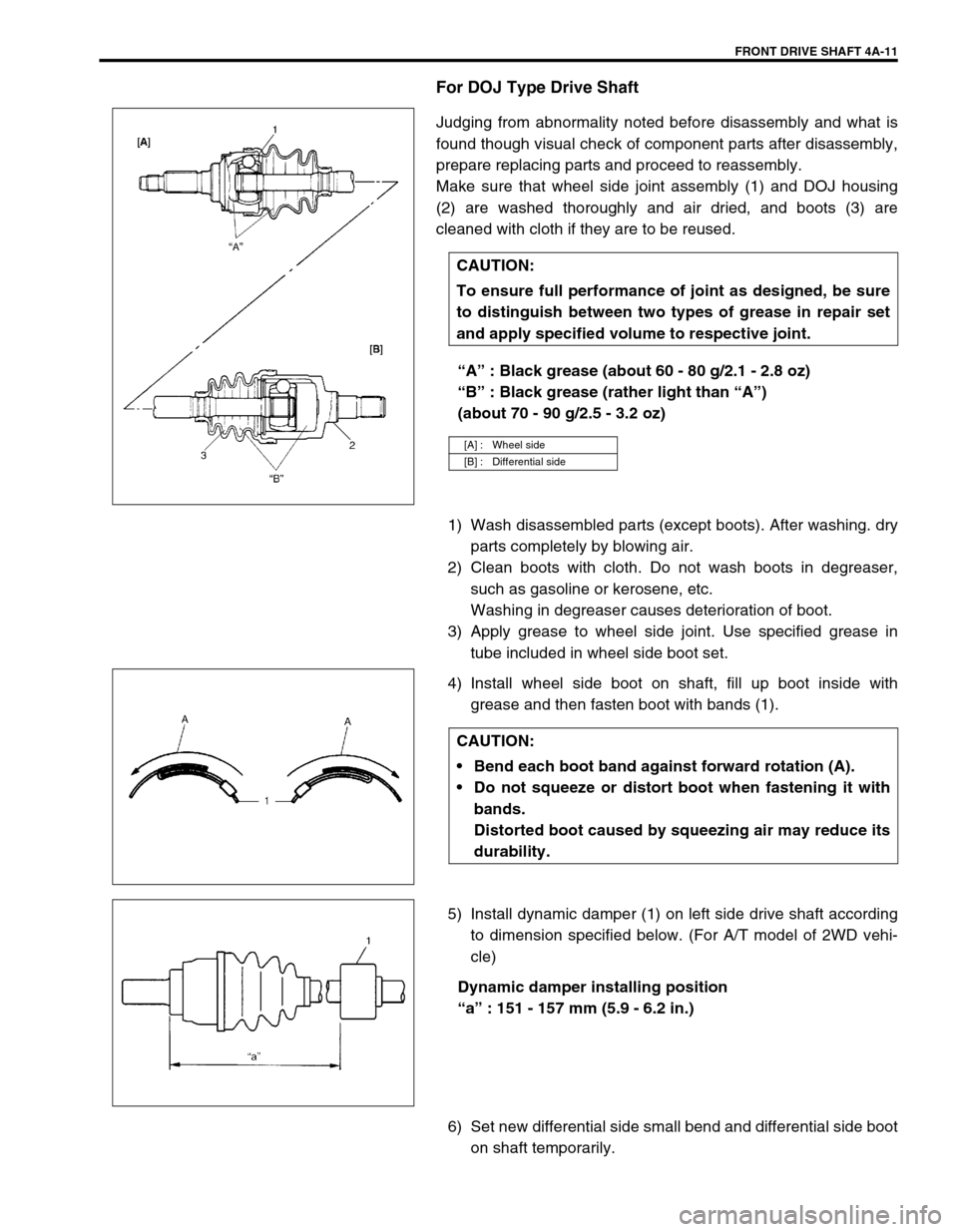

For DOJ Type Drive Shaft

Judging from abnormality noted before disassembly and what is

found though visual check of component parts after disassembly,

prepare replacing parts and proceed to reassembly.

Make sure that wheel side joint assembly (1) and DOJ housing

(2) are washed thoroughly and air dried, and boots (3) are

cleaned with cloth if they are to be reused.

βAβ : Black grease (about 60 - 80 g/2.1 - 2.8 oz)

βBβ : Black grease (rather light than βAβ)

(about 70 - 90 g/2.5 - 3.2 oz)

1) Wash disassembled parts (except boots). After washing. dry

parts completely by blowing air.

2) Clean boots with cloth. Do not wash boots in degreaser,

such as gasoline or kerosene, etc.

Washing in degreaser causes deterioration of boot.

3) Apply grease to wheel side joint. Use specified grease in

tube included in wheel side boot set.

4) Install wheel side boot on shaft, fill up boot inside with

grease and then fasten boot with bands (1).

5) Install dynamic damper (1) on left side drive shaft according

to dimension specified below. (For A/T model of 2WD vehi-

cle)

Dynamic damper installing position

βaβ : 151 - 157 mm (5.9 - 6.2 in.)

6) Set new differential side small bend and differential side boot

on shaft temporarily. CAUTION:

To ensure full performance of joint as designed, be sure

to distinguish between two types of grease in repair set

and apply specified volume to respective joint.

[A] : Wheel side

[B] : Differential side

CAUTION:

Bend each boot band against forward rotation (A).

Do not squeeze or distort boot when fastening it with

bands.

Distorted boot caused by squeezing air may reduce its

durability.

Page 265 of 698

4A-12 FRONT DRIVE SHAFT

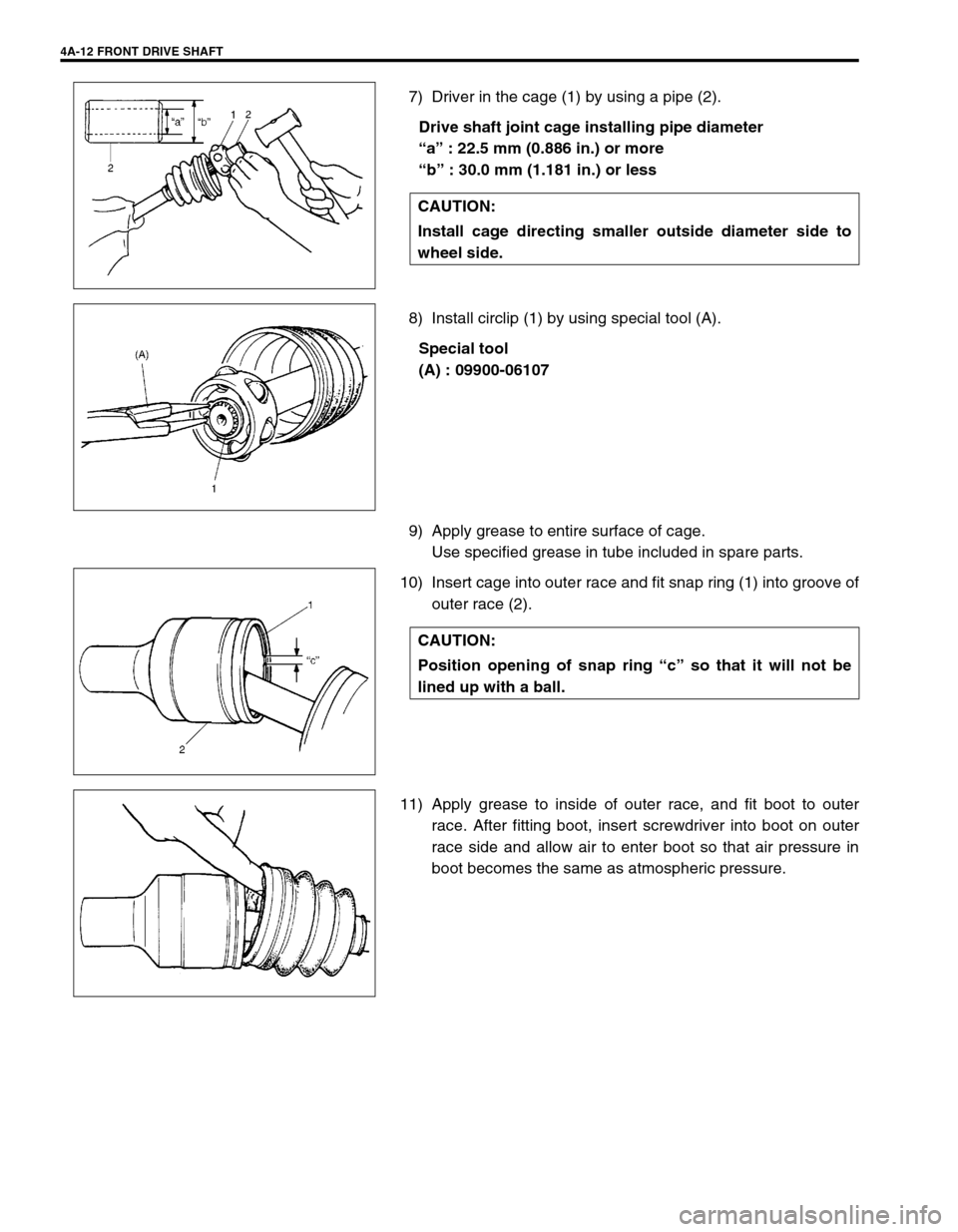

7) Driver in the cage (1) by using a pipe (2).

Drive shaft joint cage installing pipe diameter

βaβ : 22.5 mm (0.886 in.) or more

βbβ : 30.0 mm (1.181 in.) or less

8) Install circlip (1) by using special tool (A).

Special tool

(A) : 09900-06107

9) Apply grease to entire surface of cage.

Use specified grease in tube included in spare parts.

10) Insert cage into outer race and fit snap ring (1) into groove of

outer race (2).

11) Apply grease to inside of outer race, and fit boot to outer

race. After fitting boot, insert screwdriver into boot on outer

race side and allow air to enter boot so that air pressure in

boot becomes the same as atmospheric pressure. CAUTION:

Install cage directing smaller outside diameter side to

wheel side.

CAUTION:

Position opening of snap ring βcβ so that it will not be

lined up with a ball.

Page 266 of 698

FRONT DRIVE SHAFT 4A-13

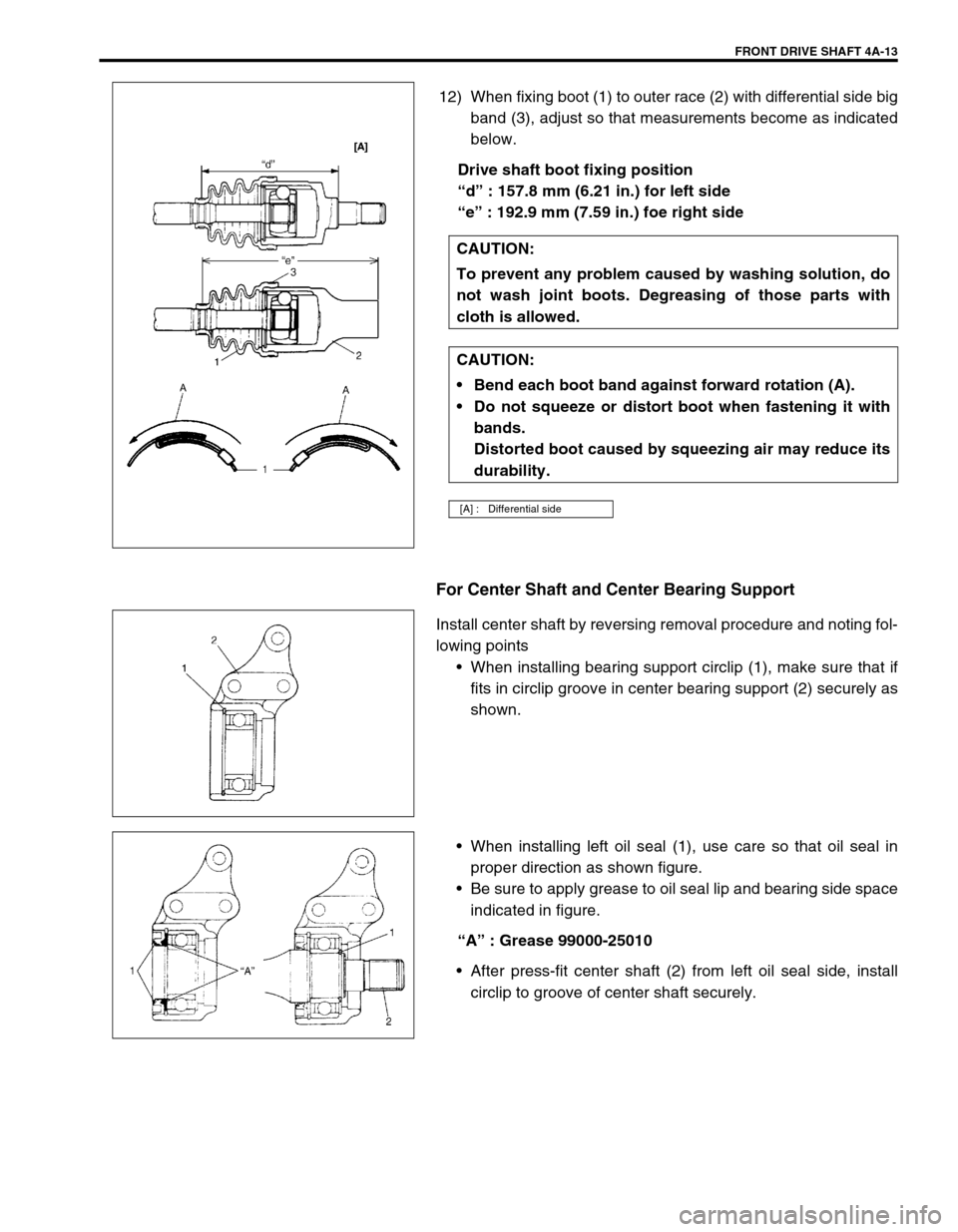

12) When fixing boot (1) to outer race (2) with differential side big

band (3), adjust so that measurements become as indicated

below.

Drive shaft boot fixing position

βdβ : 157.8 mm (6.21 in.) for left side

βeβ : 192.9 mm (7.59 in.) foe right side

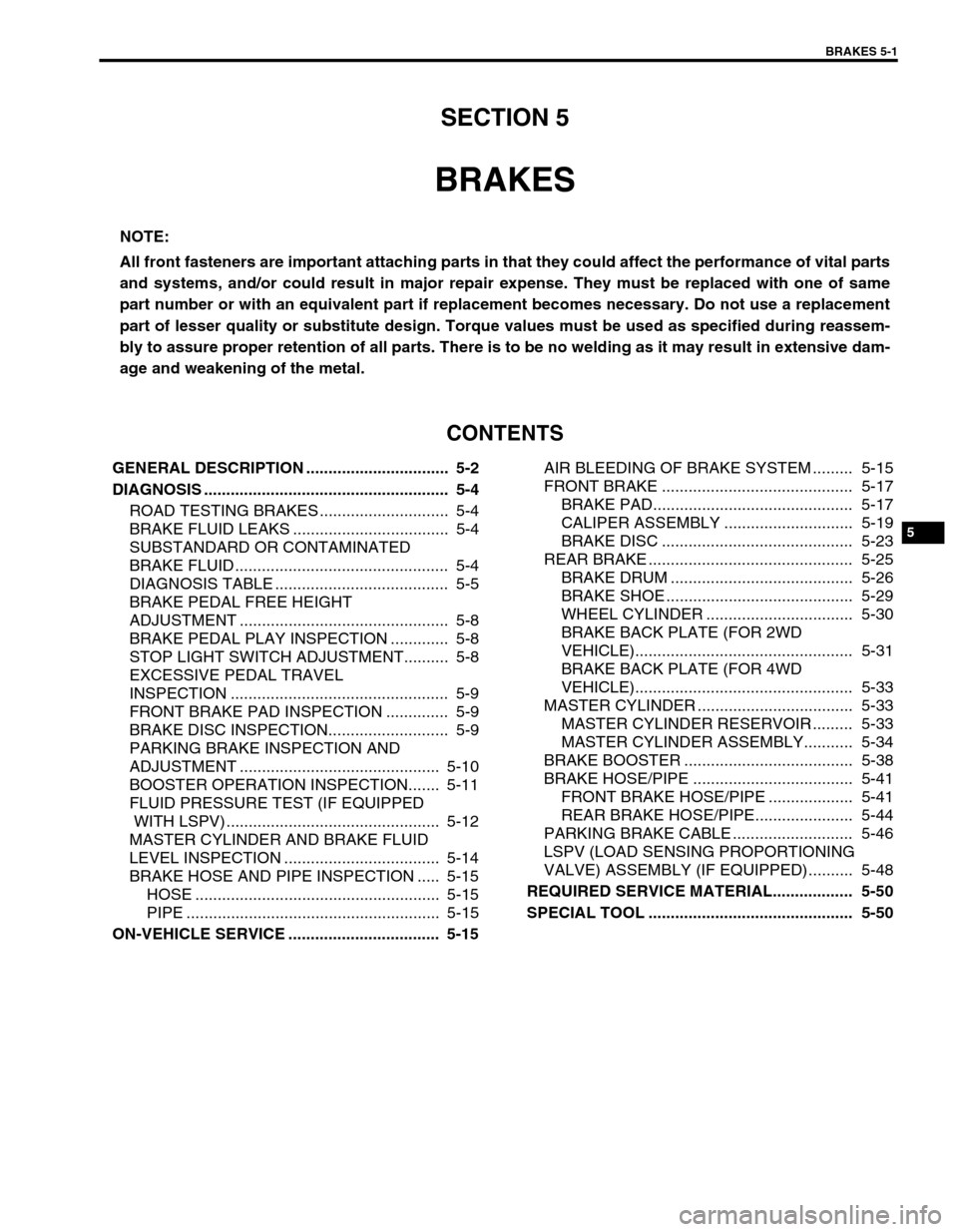

For Center Shaft and Center Bearing Support

Install center shaft by reversing removal procedure and noting fol-

lowing points

When installing bearing support circlip (1), make sure that if

fits in circlip groove in center bearing support (2) securely as

shown.

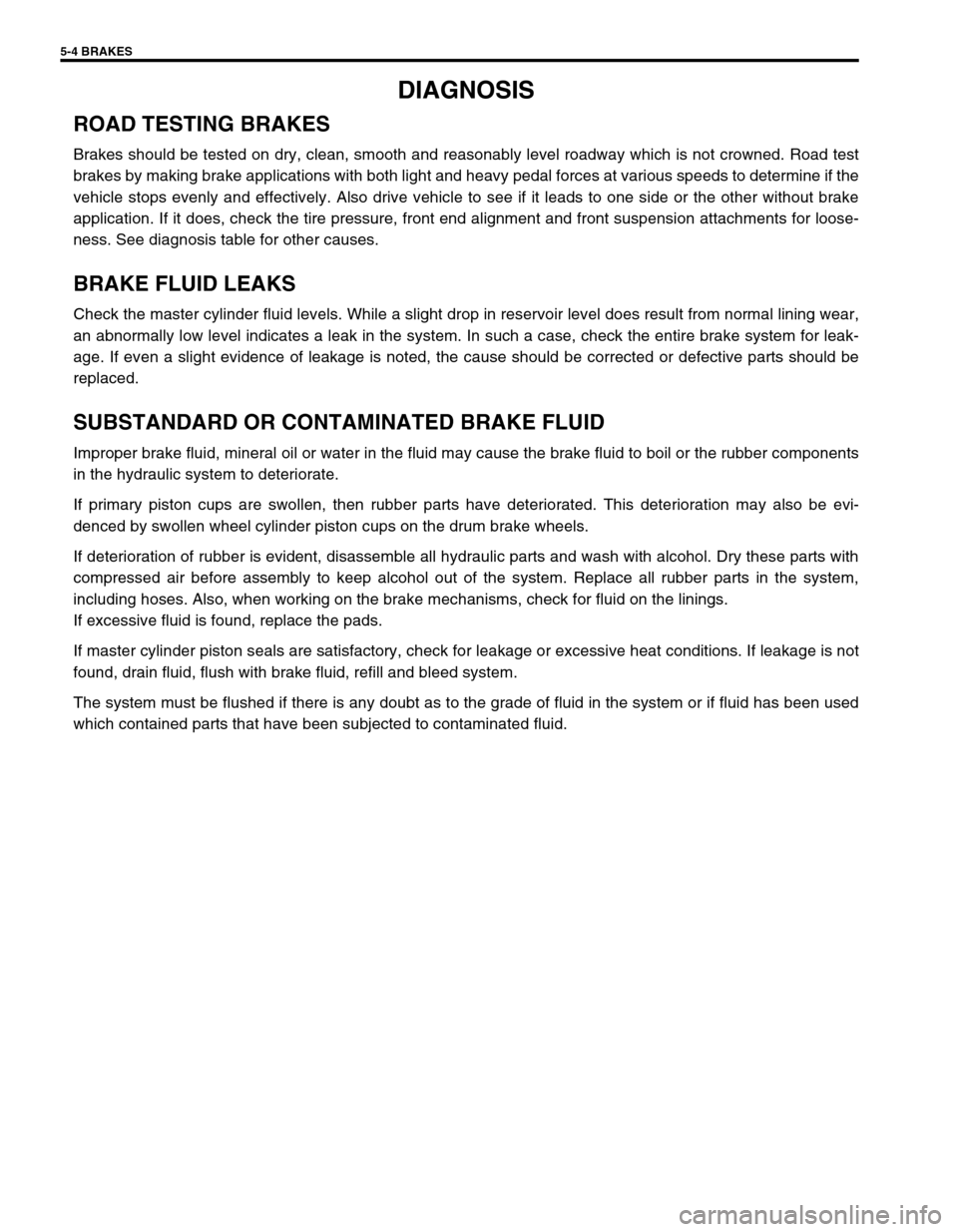

When installing left oil seal (1), use care so that oil seal in

proper direction as shown figure.

Be sure to apply grease to oil seal lip and bearing side space

indicated in figure.

βAβ : Grease 99000-25010

After press-fit center shaft (2) from left oil seal side, install

circlip to groove of center shaft securely. CAUTION:

To prevent any problem caused by washing solution, do

not wash joint boots. Degreasing of those parts with

cloth is allowed.

CAUTION:

Bend each boot band against forward rotation (A).

Do not squeeze or distort boot when fastening it with

bands.

Distorted boot caused by squeezing air may reduce its

durability.

[A] : Differential side

Page 274 of 698

BRAKES 5-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

5

9

10

10A

10B

SECTION 5

BRAKES

CONTENTS

GENERAL DESCRIPTION ................................ 5-2

DIAGNOSIS ....................................................... 5-4

ROAD TESTING BRAKES ............................. 5-4

BRAKE FLUID LEAKS ................................... 5-4

SUBSTANDARD OR CONTAMINATED

BRAKE FLUID ................................................ 5-4

DIAGNOSIS TABLE ....................................... 5-5

BRAKE PEDAL FREE HEIGHT

ADJUSTMENT ............................................... 5-8

BRAKE PEDAL PLAY INSPECTION ............. 5-8

STOP LIGHT SWITCH ADJUSTMENT.......... 5-8

EXCESSIVE PEDAL TRAVEL

INSPECTION ................................................. 5-9

FRONT BRAKE PAD INSPECTION .............. 5-9

BRAKE DISC INSPECTION........................... 5-9

PARKING BRAKE INSPECTION AND

ADJUSTMENT ............................................. 5-10

BOOSTER OPERATION INSPECTION....... 5-11

FLUID PRESSURE TEST (IF EQUIPPED

WITH LSPV) ................................................ 5-12

MASTER CYLINDER AND BRAKE FLUID

LEVEL INSPECTION ................................... 5-14

BRAKE HOSE AND PIPE INSPECTION ..... 5-15

HOSE ....................................................... 5-15

PIPE ......................................................... 5-15

ON-VEHICLE SERVICE .................................. 5-15AIR BLEEDING OF BRAKE SYSTEM ......... 5-15

FRONT BRAKE ........................................... 5-17

BRAKE PAD............................................. 5-17

CALIPER ASSEMBLY ............................. 5-19

BRAKE DISC ........................................... 5-23

REAR BRAKE .............................................. 5-25

BRAKE DRUM ......................................... 5-26

BRAKE SHOE .......................................... 5-29

WHEEL CYLINDER ................................. 5-30

BRAKE BACK PLATE (FOR 2WD

VEHICLE)................................................. 5-31

BRAKE BACK PLATE (FOR 4WD

VEHICLE)................................................. 5-33

MASTER CYLINDER ................................... 5-33

MASTER CYLINDER RESERVOIR ......... 5-33

MASTER CYLINDER ASSEMBLY........... 5-34

BRAKE BOOSTER ...................................... 5-38

BRAKE HOSE/PIPE .................................... 5-41

FRONT BRAKE HOSE/PIPE ................... 5-41

REAR BRAKE HOSE/PIPE...................... 5-44

PARKING BRAKE CABLE ........................... 5-46

LSPV (LOAD SENSING PROPORTIONING

VALVE) ASSEMBLY (IF EQUIPPED).......... 5-48

REQUIRED SERVICE MATERIAL.................. 5-50

SPECIAL TOOL .............................................. 5-50

NOTE:

All front fasteners are important attaching parts in that they could affect the performance of vital parts

and systems, and/or could result in major repair expense. They must be replaced with one of same

part number or with an equivalent part if replacement becomes necessary. Do not use a replacement

part of lesser quality or substitute design. Torque values must be used as specified during reassem-

bly to assure proper retention of all parts. There is to be no welding as it may result in extensive dam-

age and weakening of the metal.

Page 277 of 698

5-4 BRAKES

DIAGNOSIS

ROAD TESTING BRAKES

Brakes should be tested on dry, clean, smooth and reasonably level roadway which is not crowned. Road test

brakes by making brake applications with both light and heavy pedal forces at various speeds to determine if the

vehicle stops evenly and effectively. Also drive vehicle to see if it leads to one side or the other without brake

application. If it does, check the tire pressure, front end alignment and front suspension attachments for loose-

ness. See diagnosis table for other causes.

BRAKE FLUID LEAKS

Check the master cylinder fluid levels. While a slight drop in reservoir level does result from normal lining wear,

an abnormally low level indicates a leak in the system. In such a case, check the entire brake system for leak-

age. If even a slight evidence of leakage is noted, the cause should be corrected or defective parts should be

replaced.

SUBSTANDARD OR CONTAMINATED BRAKE FLUID

Improper brake fluid, mineral oil or water in the fluid may cause the brake fluid to boil or the rubber components

in the hydraulic system to deteriorate.

If primary piston cups are swollen, then rubber parts have deteriorated. This deterioration may also be evi-

denced by swollen wheel cylinder piston cups on the drum brake wheels.

If deterioration of rubber is evident, disassemble all hydraulic parts and wash with alcohol. Dry these parts with

compressed air before assembly to keep alcohol out of the system. Replace all rubber parts in the system,

including hoses. Also, when working on the brake mechanisms, check for fluid on the linings.

If excessive fluid is found, replace the pads.

If master cylinder piston seals are satisfactory, check for leakage or excessive heat conditions. If leakage is not

found, drain fluid, flush with brake fluid, refill and bleed system.

The system must be flushed if there is any doubt as to the grade of fluid in the system or if fluid has been used

which contained parts that have been subjected to contaminated fluid.

Page 278 of 698

BRAKES 5-5

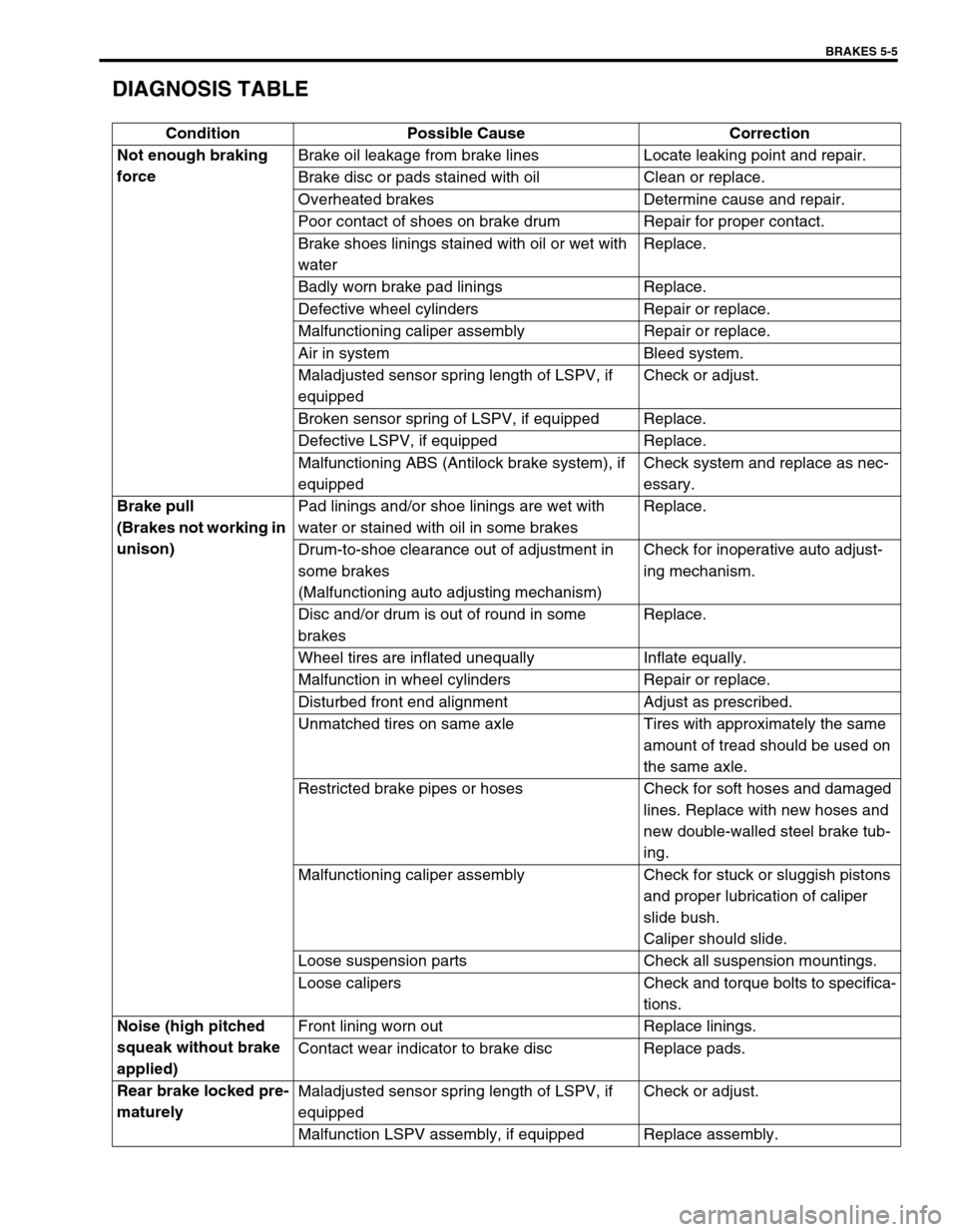

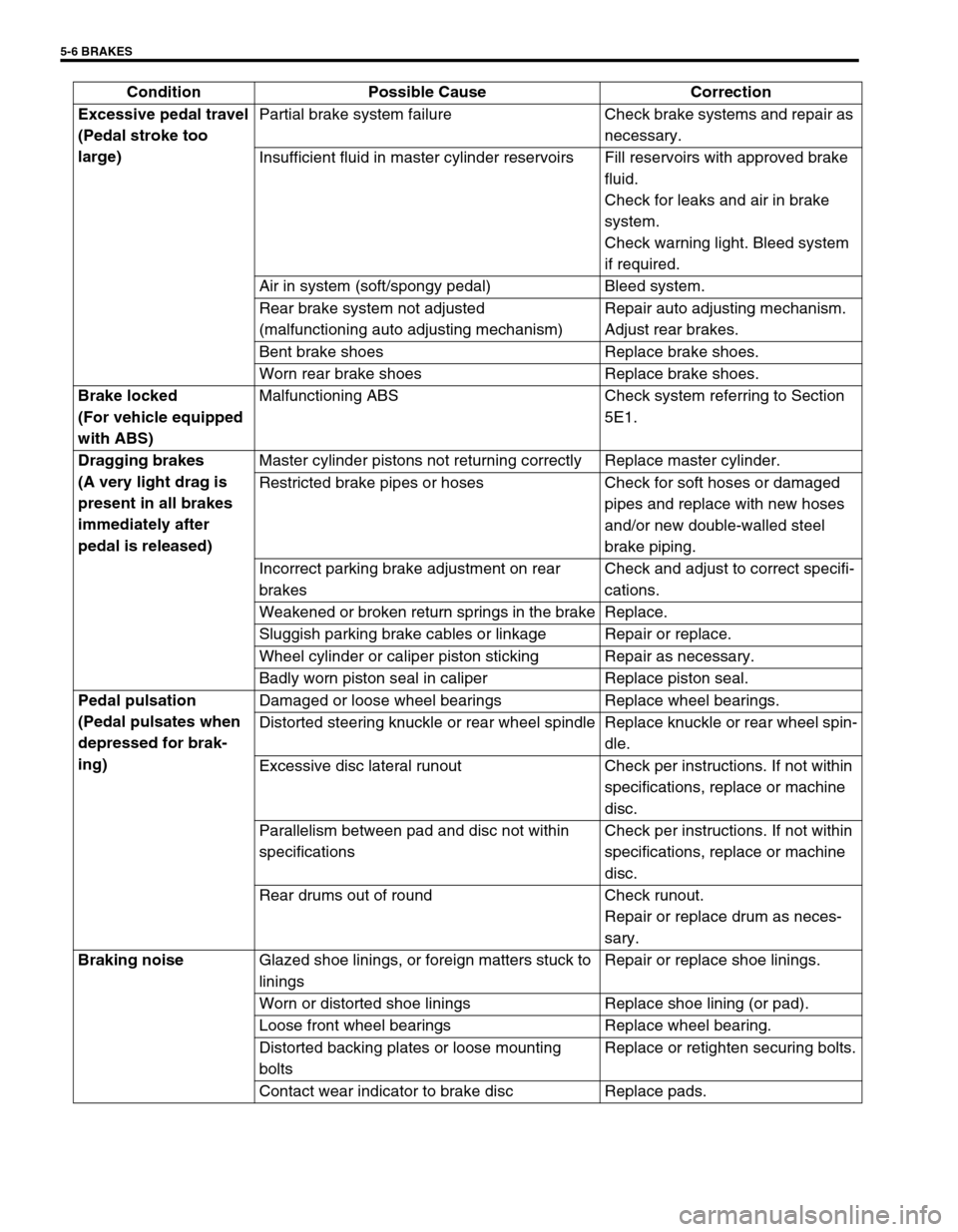

DIAGNOSIS TABLE

Condition Possible Cause Correction

Not enough braking

forceBrake oil leakage from brake lines Locate leaking point and repair.

Brake disc or pads stained with oil Clean or replace.

Overheated brakes Determine cause and repair.

Poor contact of shoes on brake drum Repair for proper contact.

Brake shoes linings stained with oil or wet with

waterReplace.

Badly worn brake pad linings Replace.

Defective wheel cylinders Repair or replace.

Malfunctioning caliper assembly Repair or replace.

Air in system Bleed system.

Maladjusted sensor spring length of LSPV, if

equippedCheck or adjust.

Broken sensor spring of LSPV, if equipped Replace.

Defective LSPV, if equipped Replace.

Malfunctioning ABS (Antilock brake system), if

equippedCheck system and replace as nec-

essary.

Brake pull

(Brakes not working in

unison)Pad linings and/or shoe linings are wet with

water or stained with oil in some brakesReplace.

Drum-to-shoe clearance out of adjustment in

some brakes

(Malfunctioning auto adjusting mechanism)Check for inoperative auto adjust-

ing mechanism.

Disc and/or drum is out of round in some

brakesReplace.

Wheel tires are inflated unequally Inflate equally.

Malfunction in wheel cylinders Repair or replace.

Disturbed front end alignment Adjust as prescribed.

Unmatched tires on same axle Tires with approximately the same

amount of tread should be used on

the same axle.

Restricted brake pipes or hoses Check for soft hoses and damaged

lines. Replace with new hoses and

new double-walled steel brake tub-

ing.

Malfunctioning caliper assembly Check for stuck or sluggish pistons

and proper lubrication of caliper

slide bush.

Caliper should slide.

Loose suspension parts Check all suspension mountings.

Loose calipers Check and torque bolts to specifica-

tions.

Noise (high pitched

squeak without brake

applied)Front lining worn out Replace linings.

Contact wear indicator to brake disc Replace pads.

Rear brake locked pre-

maturelyMaladjusted sensor spring length of LSPV, if

equippedCheck or adjust.

Malfunction LSPV assembly, if equipped Replace assembly.

Page 279 of 698

5-6 BRAKES

Excessive pedal travel

(Pedal stroke too

large)Partial brake system failure Check brake systems and repair as

necessary.

Insufficient fluid in master cylinder reservoirs Fill reservoirs with approved brake

fluid.

Check for leaks and air in brake

system.

Check warning light. Bleed system

if required.

Air in system (soft/spongy pedal) Bleed system.

Rear brake system not adjusted

(malfunctioning auto adjusting mechanism)Repair auto adjusting mechanism.

Adjust rear brakes.

Bent brake shoes Replace brake shoes.

Worn rear brake shoes Replace brake shoes.

Brake locked

(For vehicle equipped

with ABS)Malfunctioning ABS Check system referring to Section

5E1.

Dragging brakes

(A very light drag is

present in all brakes

immediately after

pedal is released)Master cylinder pistons not returning correctly Replace master cylinder.

Restricted brake pipes or hoses Check for soft hoses or damaged

pipes and replace with new hoses

and/or new double-walled steel

brake piping.

Incorrect parking brake adjustment on rear

brakesCheck and adjust to correct specifi-

cations.

Weakened or broken return springs in the brake Replace.

Sluggish parking brake cables or linkage Repair or replace.

Wheel cylinder or caliper piston sticking Repair as necessary.

Badly worn piston seal in caliper Replace piston seal.

Pedal pulsation

(Pedal pulsates when

depressed for brak-

ing)Damaged or loose wheel bearings Replace wheel bearings.

Distorted steering knuckle or rear wheel spindle Replace knuckle or rear wheel spin-

dle.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine

disc.

Parallelism between pad and disc not within

specificationsCheck per instructions. If not within

specifications, replace or machine

disc.

Rear drums out of round Check runout.

Repair or replace drum as neces-

sary.

Braking noise

Glazed shoe linings, or foreign matters stuck to

liningsRepair or replace shoe linings.

Worn or distorted shoe linings Replace shoe lining (or pad).

Loose front wheel bearings Replace wheel bearing.

Distorted backing plates or loose mounting

boltsReplace or retighten securing bolts.

Contact wear indicator to brake disc Replace pads. Condition Possible Cause Correction

Page 280 of 698

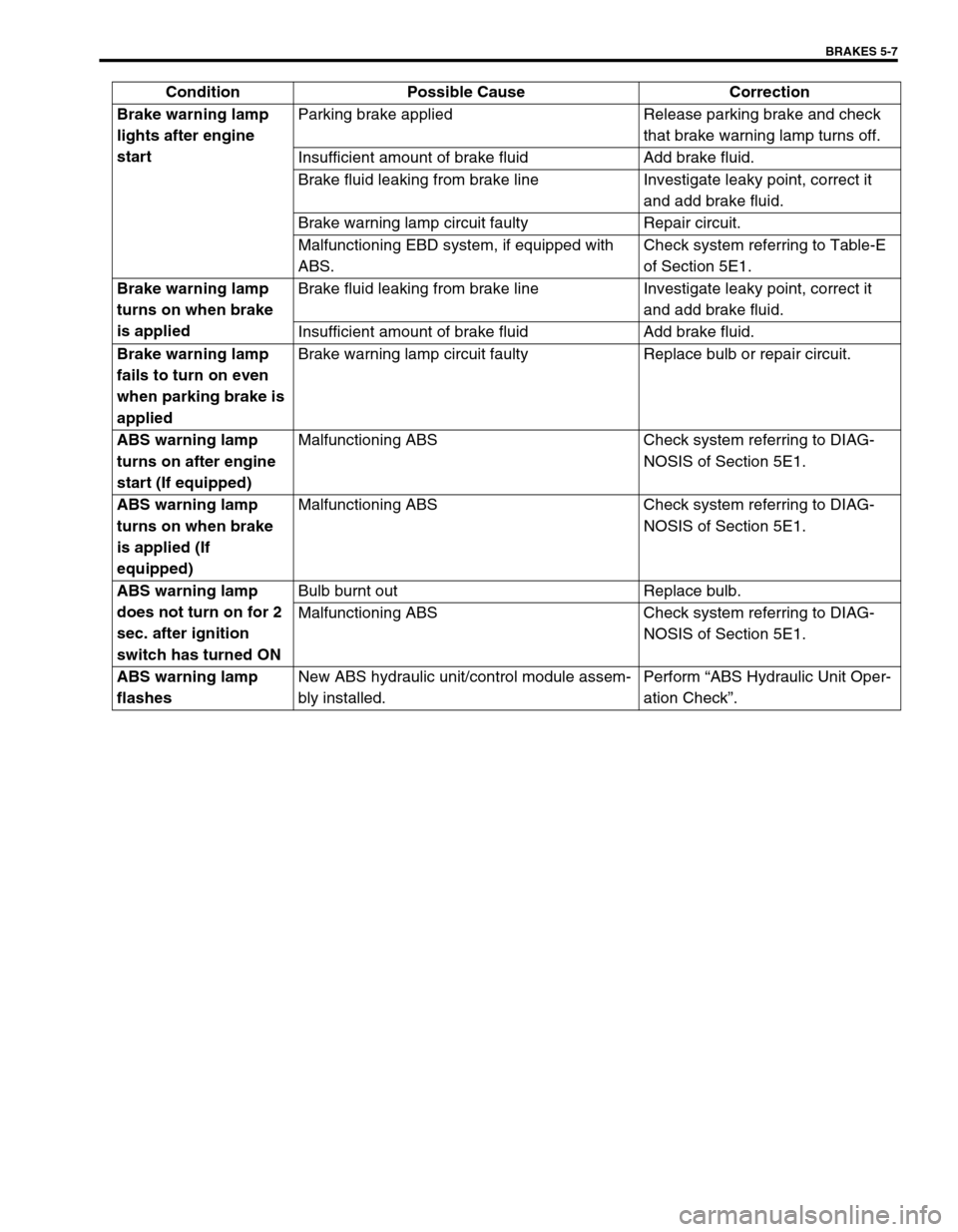

BRAKES 5-7

Brake warning lamp

lights after engine

startParking brake applied Release parking brake and check

that brake warning lamp turns off.

Insufficient amount of brake fluid Add brake fluid.

Brake fluid leaking from brake line Investigate leaky point, correct it

and add brake fluid.

Brake warning lamp circuit faulty Repair circuit.

Malfunctioning EBD system, if equipped with

ABS.Check system referring to Table-E

of Section 5E1.

Brake warning lamp

turns on when brake

is appliedBrake fluid leaking from brake line Investigate leaky point, correct it

and add brake fluid.

Insufficient amount of brake fluid Add brake fluid.

Brake warning lamp

fails to turn on even

when parking brake is

appliedBrake warning lamp circuit faulty Replace bulb or repair circuit.

ABS warning lamp

turns on after engine

start (If equipped)Malfunctioning ABS Check system referring to DIAG-

NOSIS of Section 5E1.

ABS warning lamp

turns on when brake

is applied (If

equipped)Malfunctioning ABS Check system referring to DIAG-

NOSIS of Section 5E1.

ABS warning lamp

does not turn on for 2

sec. after ignition

switch has turned ONBulb burnt out Replace bulb.

Malfunctioning ABS Check system referring to DIAG-

NOSIS of Section 5E1.

ABS warning lamp

flashesNew ABS hydraulic unit/control module assem-

bly installed.Perform βABS Hydraulic Unit Oper-

ation Checkβ. Condition Possible Cause Correction