SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 561 of 698

6A1-60 ENGINE MECHANICAL (M13 ENGINE)

Piston clearance:

Measure cylinder bore diameter and piston diameter to find

their difference which is piston clearance. Piston clearance

should be within specification as given below. If it is out of

specification, rebore cylinder and use oversize piston.

Piston clearance

: 0.032 – 0.061 mm (0.0013 – 0.0024 in.)

: 0.016 – 0.045 mm (0.0006 – 0.0018 in.) with coating

Ring groove clearance:

Before checking, piston grooves must be clean, dry and free

of carbon deposits.

Fit new piston ring (1) into piston groove, and measure clear-

ance between ring and ring land by using thickness gauge

(2). If clearance is out of limit, replace piston.

Ring groove clearance

Top ring

Standard : 0.03 – 0.07 mm (0.0012 – 0.0028 in.)

Limit : 0.12 mm (0.0047 in.)

2nd ring

Standard : 0.02 – 0.06 mm (0.0008 – 0.0024 in.)

Limit : 0.10 mm (0.0039 in.)

Oil ring

Standard : 0.03 – 0.17 mm (0.0012 – 0.0067 in.)

Piston Pin

Check piston pin, connecting rod small end bore and piston

bore for wear or damage, paying particular attention to con-

dition of small end bore bush. If pin, connecting rod small

end bore or piston bore is badly worn or damaged, replace

pin, connecting rod and/or piston. NOTE:

Cylinder bore diameters used here are measured in

thrust direction at two positions.

“a” : 19.5 mm (0.77 in.)

Page 562 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-61

Piston pin clearance :

Check piston pin clearance in small end and piston. Replace

connecting rod and/or piston if its small end is badly worn or

damaged or if measured clearance exceeds limit.

Piston pin clearance in connecting rod small end

: 0.003 – 0.014 mm (0.0001 – 0.0006 in.)

Piston pin clearance in piston

: 0.006 – 0.017 mm (0.00026 – 0.00067 in.)

Small-end bore

: 20.003 – 20.011 mm (0.7875 – 0.7878 in.)

Piston pin dia.

: 19.997 – 20.000 mm (0.7873 – 0.7874 in.)

Piston bore

: 20.006 – 20.014 mm (0.7870 – 0.7874 in.)

Piston Rings

To measure end gap, insert piston ring (1) into cylinder bore and

then measure the gap by using thickness gauge (2).

If measured gap is out of specification, replace ring.

Piston ring end gap

Connecting Rod

Big-end side clearance:

Check big-end of connecting rod for side clearance, with rod

fitted and connected to its crank pin in the normal manner. If

measured clearance is found to exceed its limit, replace con-

necting rod.

Big-end side clearance

Standard : 0.25 - 0.40 mm (0.0098 - 0.0157 in.)

Limit : 0.35 mm (0.0138 in.)

NOTE:

Decarbonize and clean top of cylinder bore before insert-

ing piston ring.

Item Standard Limit

Top ring0.20 – 0.35 mm

(0.0079 – 0.0138 in.)0.7 mm

(0.0276 in.)

2nd ring0.30 – 0.45 mm

(0.0118 – 0.0177 in.)1.0 mm

(0.0039 in.)

Oil ring0.20 – 0.70 mm

(0.0079 – 0.0276 in.)1.5 mm

(0.059 in.)

“a” : 120 mm (4.72 in.)

Page 563 of 698

6A1-62 ENGINE MECHANICAL (M13 ENGINE)

Connecting rod alignment :

Mount connecting rod on aligner to check it for bow and

twist. If limit is exceeded, replace it.

Connecting rod alignment

Limit on bow : 0.05 mm (0.0020 in.)

Limit on twist : 0.10 mm (0.0039 in.)

Connecting rod bolt deformation (Plastic deformation tight-

ening bolt)

Measure connecting rod (1) bolt (2) for diameter “A” on 32

mm (1.25 in.) from bolt mounting surface and diameter “B”

on 40 mm (1.57 in.) from bolt mounting surface by using a

micrometer (3).

Bolt diameter difference should be specification as given

below. If it is out of specification, replace connecting rod.

Connecting rod bolt diameter difference

limit (“A” – “B”) : 0.1 mm (0.004 in.)

Connecting rod bolt measurement distance

“a” : 32 mm (1.25 in.)

“b” : 40 mm (1.57 in.)

Crank Pin and Connecting Rod Bearings

Inspect crank pin for uneven wear or damage. Measure

crank pin for out-of-round or taper with a micrometer. If crank

pin is damaged or out-of round or taper is out of limit, replace

crankshaft or regrind crank pin to undersize and use under-

size bearing.

Crank pin diameter

Crank pin taper and out-of-round

Limit : 0.01 mm (0.0004 in.)

Out-of-round : A – B

Taper : a – b

Connecting rod

bearing sizeCrank pin diameter

Standard41.982 – 42.000 mm

(1.6528 – 1.6535 in.)

Undersize

0.25 mm (0.0098 in.)41.732 – 41.750 mm

(1.6430 – 1.6437 in.)

Page 564 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-63

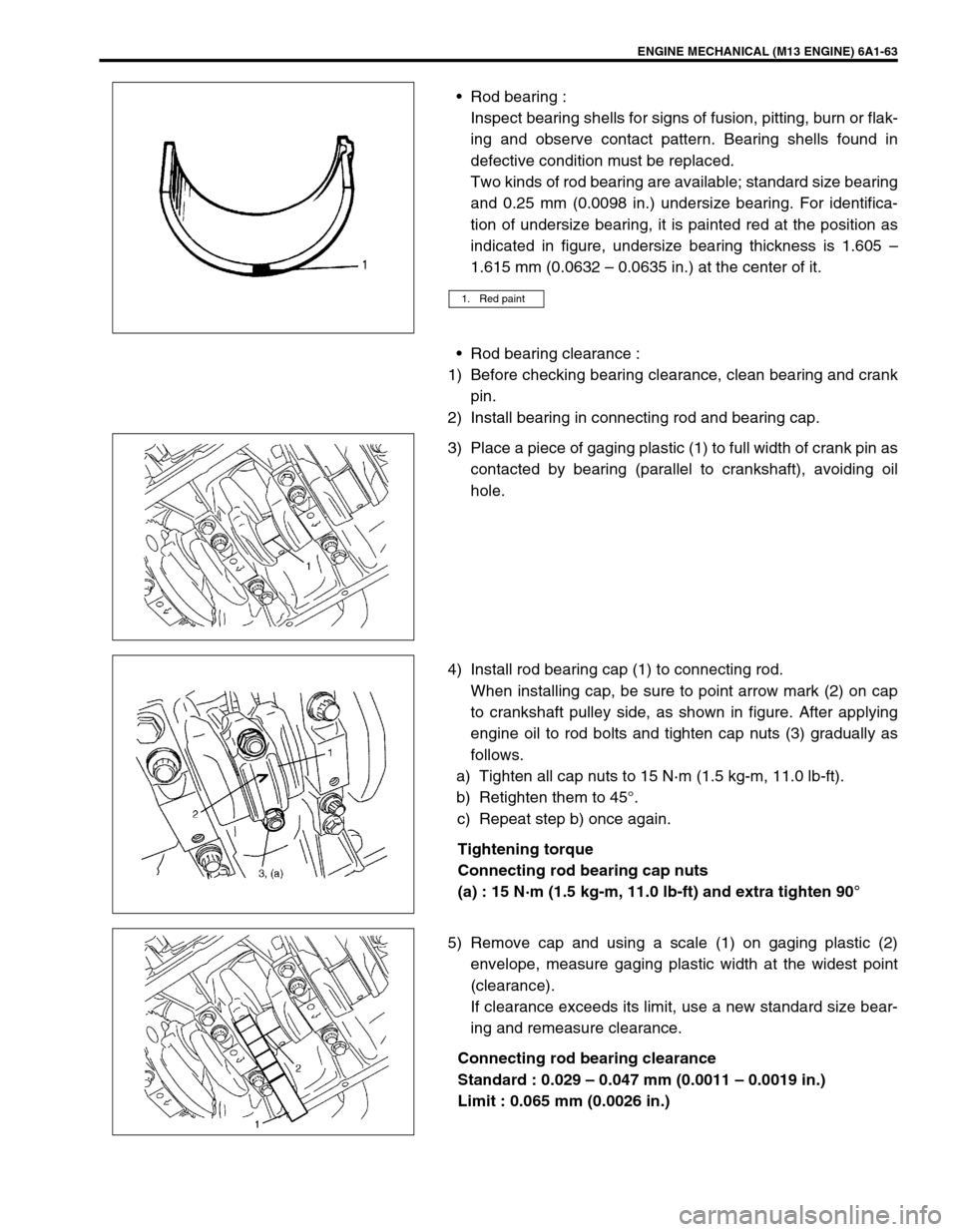

Rod bearing :

Inspect bearing shells for signs of fusion, pitting, burn or flak-

ing and observe contact pattern. Bearing shells found in

defective condition must be replaced.

Two kinds of rod bearing are available; standard size bearing

and 0.25 mm (0.0098 in.) undersize bearing. For identifica-

tion of undersize bearing, it is painted red at the position as

indicated in figure, undersize bearing thickness is 1.605 –

1.615 mm (0.0632 – 0.0635 in.) at the center of it.

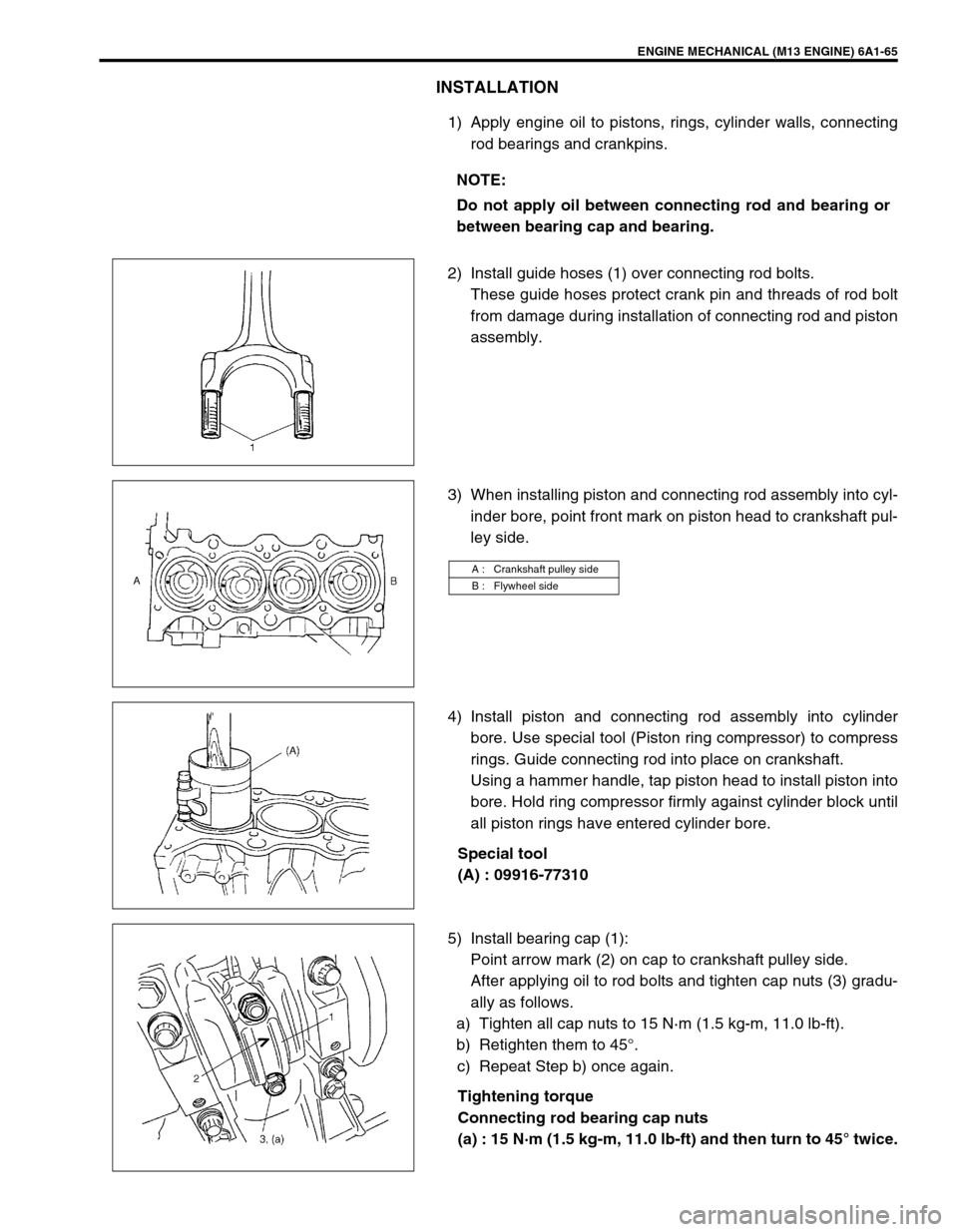

Rod bearing clearance :

1) Before checking bearing clearance, clean bearing and crank

pin.

2) Install bearing in connecting rod and bearing cap.

3) Place a piece of gaging plastic (1) to full width of crank pin as

contacted by bearing (parallel to crankshaft), avoiding oil

hole.

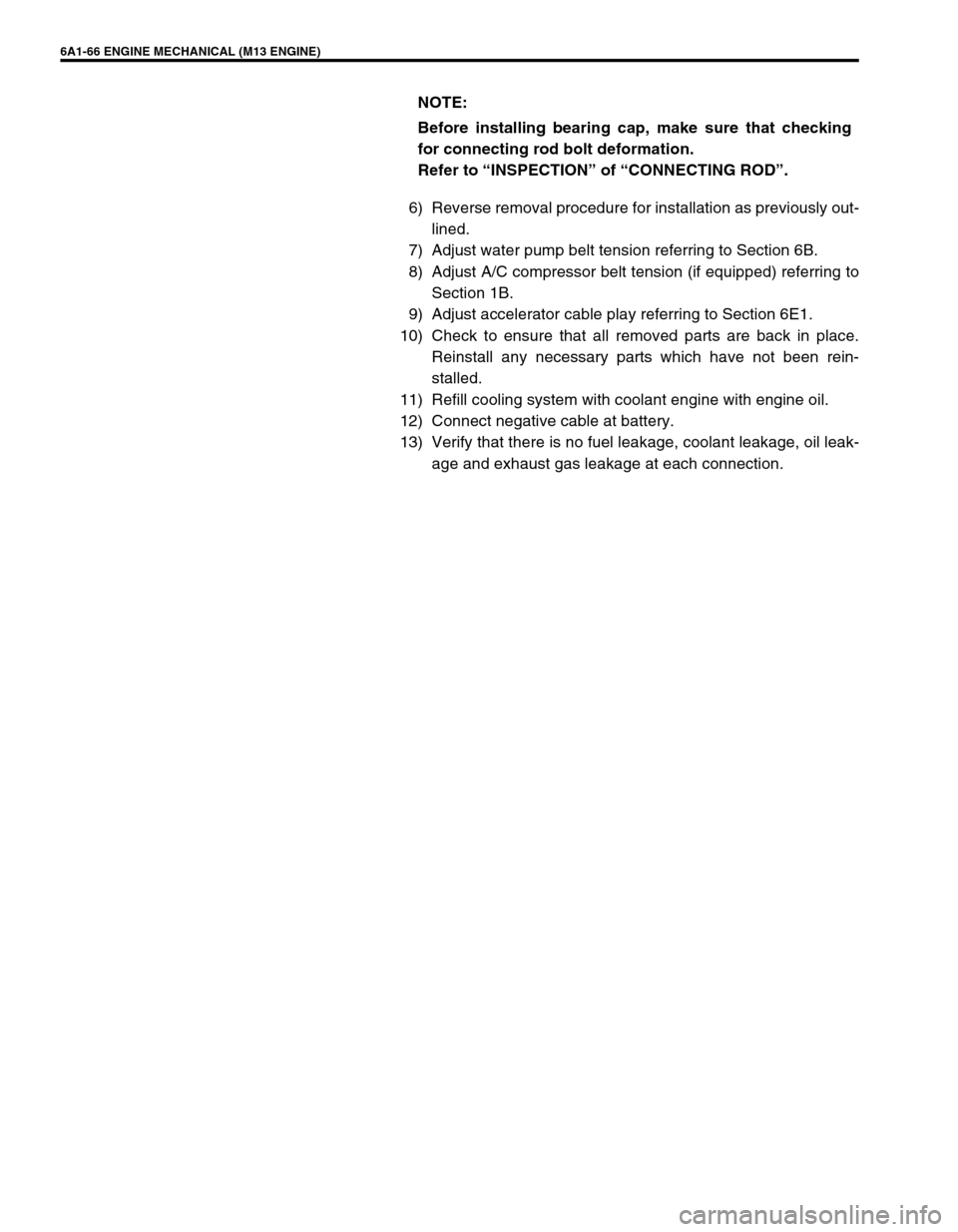

4) Install rod bearing cap (1) to connecting rod.

When installing cap, be sure to point arrow mark (2) on cap

to crankshaft pulley side, as shown in figure. After applying

engine oil to rod bolts and tighten cap nuts (3) gradually as

follows.

a) Tighten all cap nuts to 15 N·m (1.5 kg-m, 11.0 lb-ft).

b) Retighten them to 45°.

c) Repeat step b) once again.

Tightening torque

Connecting rod bearing cap nuts

(a) : 15 N·m (1.5 kg-m, 11.0 lb-ft) and extra tighten 90°

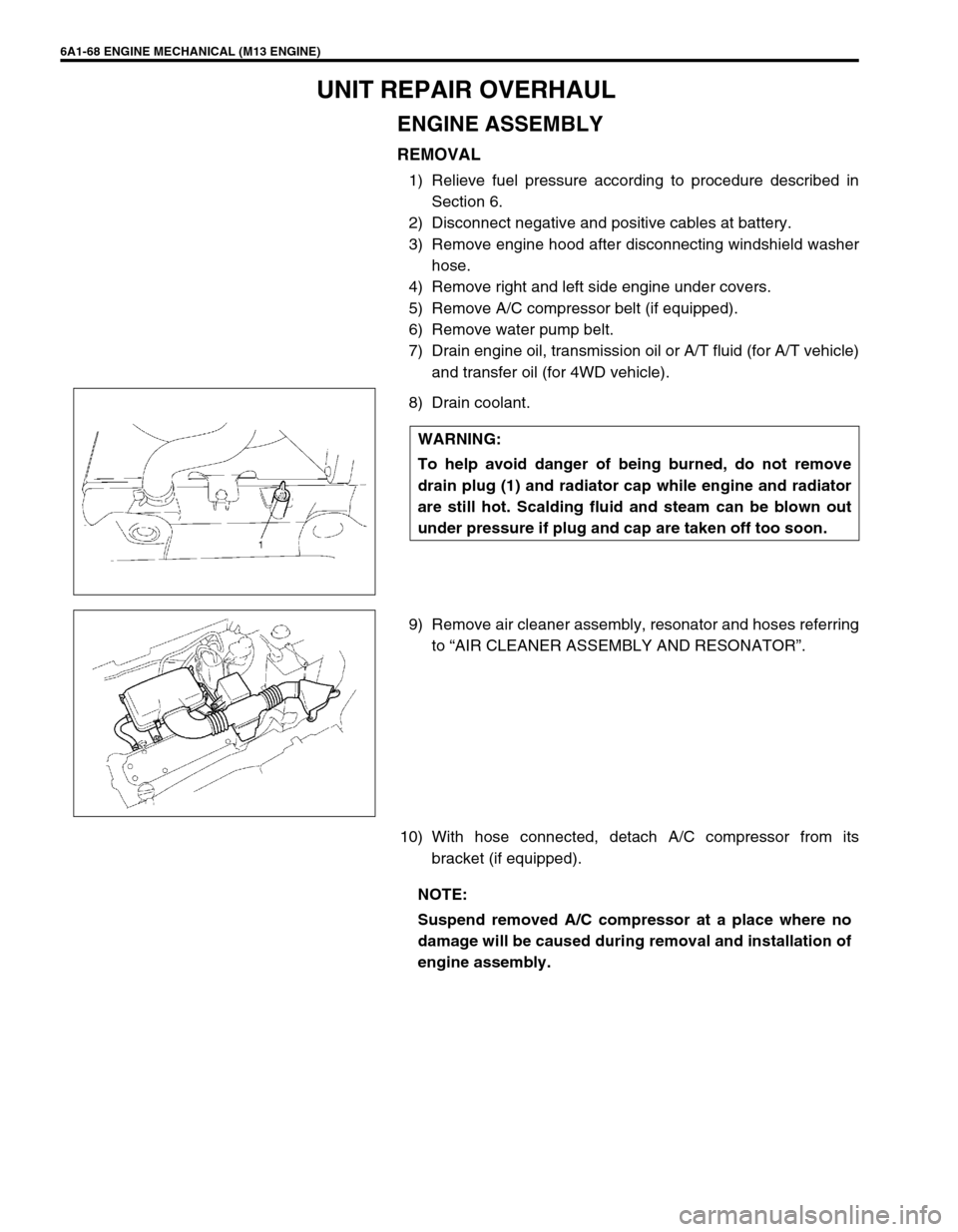

5) Remove cap and using a scale (1) on gaging plastic (2)

envelope, measure gaging plastic width at the widest point

(clearance).

If clearance exceeds its limit, use a new standard size bear-

ing and remeasure clearance.

Connecting rod bearing clearance

Standard : 0.029 – 0.047 mm (0.0011 – 0.0019 in.)

Limit : 0.065 mm (0.0026 in.)

1. Red paint

Page 565 of 698

6A1-64 ENGINE MECHANICAL (M13 ENGINE)

6) If clearance can not be brought to within its limit even by

using a new standard size bearing, regrind crankpin to

undersize and use 0.25 mm undersize bearing.

ASSEMBLY

1) Install piston pin to piston (1) and connecting rod (2) :

a) After applying engine oil to piston pin and piston pin holes

in piston and connecting rod.

b) Fit connecting rod as shown in figure.

c) Insert piston pin to piston and connecting rod.

d) Install piston pin circlips (3).

2) Install piston rings to piston :

a) As indicated in figure, 1st and 2nd rings have “T” mark

respectively. When installing these piston rings to piston,

direct marked side of each ring toward top of piston.

b) 1st ring (1) differs from 2nd ring (2) in thickness, shape and

color of surface contacting cylinder wall.

Distinguish 1st ring from 2nd ring by referring to figure.

c) When installing oil ring (3) install spacer first and then two

rails.

3) After installing three rings (1st, 2nd and oil rings), distribute

their end gaps as shown in figure. NOTE:

After checking the rod bearing clearance, make sure that

checking for Connecting rod bolt deformation.

Refer to “INSPECTION” of “CONNECTING ROD”.

NOTE:

Circlip should be installed with its cut part facing as

shown in figure. Install so that circlip end gap comes

within such range as indicated by arrow.

1. 1st ring

2. 2nd ring

3. Oil ring

1. Arrow mark

2. 1st ring end gap

3. 2nd ring end gap and oil ring spacer gap

4. Oil ring upper rail gap

5. Oil ring lower rail gap

Page 566 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-65

INSTALLATION

1) Apply engine oil to pistons, rings, cylinder walls, connecting

rod bearings and crankpins.

2) Install guide hoses (1) over connecting rod bolts.

These guide hoses protect crank pin and threads of rod bolt

from damage during installation of connecting rod and piston

assembly.

3) When installing piston and connecting rod assembly into cyl-

inder bore, point front mark on piston head to crankshaft pul-

ley side.

4) Install piston and connecting rod assembly into cylinder

bore. Use special tool (Piston ring compressor) to compress

rings. Guide connecting rod into place on crankshaft.

Using a hammer handle, tap piston head to install piston into

bore. Hold ring compressor firmly against cylinder block until

all piston rings have entered cylinder bore.

Special tool

(A) : 09916-77310

5) Install bearing cap (1):

Point arrow mark (2) on cap to crankshaft pulley side.

After applying oil to rod bolts and tighten cap nuts (3) gradu-

ally as follows.

a) Tighten all cap nuts to 15 N·m (1.5 kg-m, 11.0 lb-ft).

b) Retighten them to 45°.

c) Repeat Step b) once again.

Tightening torque

Connecting rod bearing cap nuts

(a) : 15 N·m (1.5 kg-m, 11.0 lb-ft) and then turn to 45° twice. NOTE:

Do not apply oil between connecting rod and bearing or

between bearing cap and bearing.

A : Crankshaft pulley side

B : Flywheel side

Page 567 of 698

6A1-66 ENGINE MECHANICAL (M13 ENGINE)

6) Reverse removal procedure for installation as previously out-

lined.

7) Adjust water pump belt tension referring to Section 6B.

8) Adjust A/C compressor belt tension (if equipped) referring to

Section 1B.

9) Adjust accelerator cable play referring to Section 6E1.

10) Check to ensure that all removed parts are back in place.

Reinstall any necessary parts which have not been rein-

stalled.

11) Refill cooling system with coolant engine with engine oil.

12) Connect negative cable at battery.

13) Verify that there is no fuel leakage, coolant leakage, oil leak-

age and exhaust gas leakage at each connection. NOTE:

Before installing bearing cap, make sure that checking

for connecting rod bolt deformation.

Refer to “INSPECTION” of “CONNECTING ROD”.

Page 568 of 698

![SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual ENGINE MECHANICAL (M13 ENGINE) 6A1-67

ENGINE MOUNTINGS

[A] : 4WD MODEL 3. Engine left mounting 6. Engine rear mounting No.1 bracket

1. Engine right mounting 4. Engine left mounting bracket 7. Engine r SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual ENGINE MECHANICAL (M13 ENGINE) 6A1-67

ENGINE MOUNTINGS

[A] : 4WD MODEL 3. Engine left mounting 6. Engine rear mounting No.1 bracket

1. Engine right mounting 4. Engine left mounting bracket 7. Engine r](/img/20/7606/w960_7606-567.png)

ENGINE MECHANICAL (M13 ENGINE) 6A1-67

ENGINE MOUNTINGS

[A] : 4WD MODEL 3. Engine left mounting 6. Engine rear mounting No.1 bracket

1. Engine right mounting 4. Engine left mounting bracket 7. Engine rear mounting No.2 bracket

2. Engine right body side bracket 5. Engine rear mounting Tightening torque

Page 569 of 698

6A1-68 ENGINE MECHANICAL (M13 ENGINE)

UNIT REPAIR OVERHAUL

ENGINE ASSEMBLY

REMOVAL

1) Relieve fuel pressure according to procedure described in

Section 6.

2) Disconnect negative and positive cables at battery.

3) Remove engine hood after disconnecting windshield washer

hose.

4) Remove right and left side engine under covers.

5) Remove A/C compressor belt (if equipped).

6) Remove water pump belt.

7) Drain engine oil, transmission oil or A/T fluid (for A/T vehicle)

and transfer oil (for 4WD vehicle).

8) Drain coolant.

9) Remove air cleaner assembly, resonator and hoses referring

to “AIR CLEANER ASSEMBLY AND RESONATOR”.

10) With hose connected, detach A/C compressor from its

bracket (if equipped). WARNING:

To help avoid danger of being burned, do not remove

drain plug (1) and radiator cap while engine and radiator

are still hot. Scalding fluid and steam can be blown out

under pressure if plug and cap are taken off too soon.

NOTE:

Suspend removed A/C compressor at a place where no

damage will be caused during removal and installation of

engine assembly.

Page 570 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-69

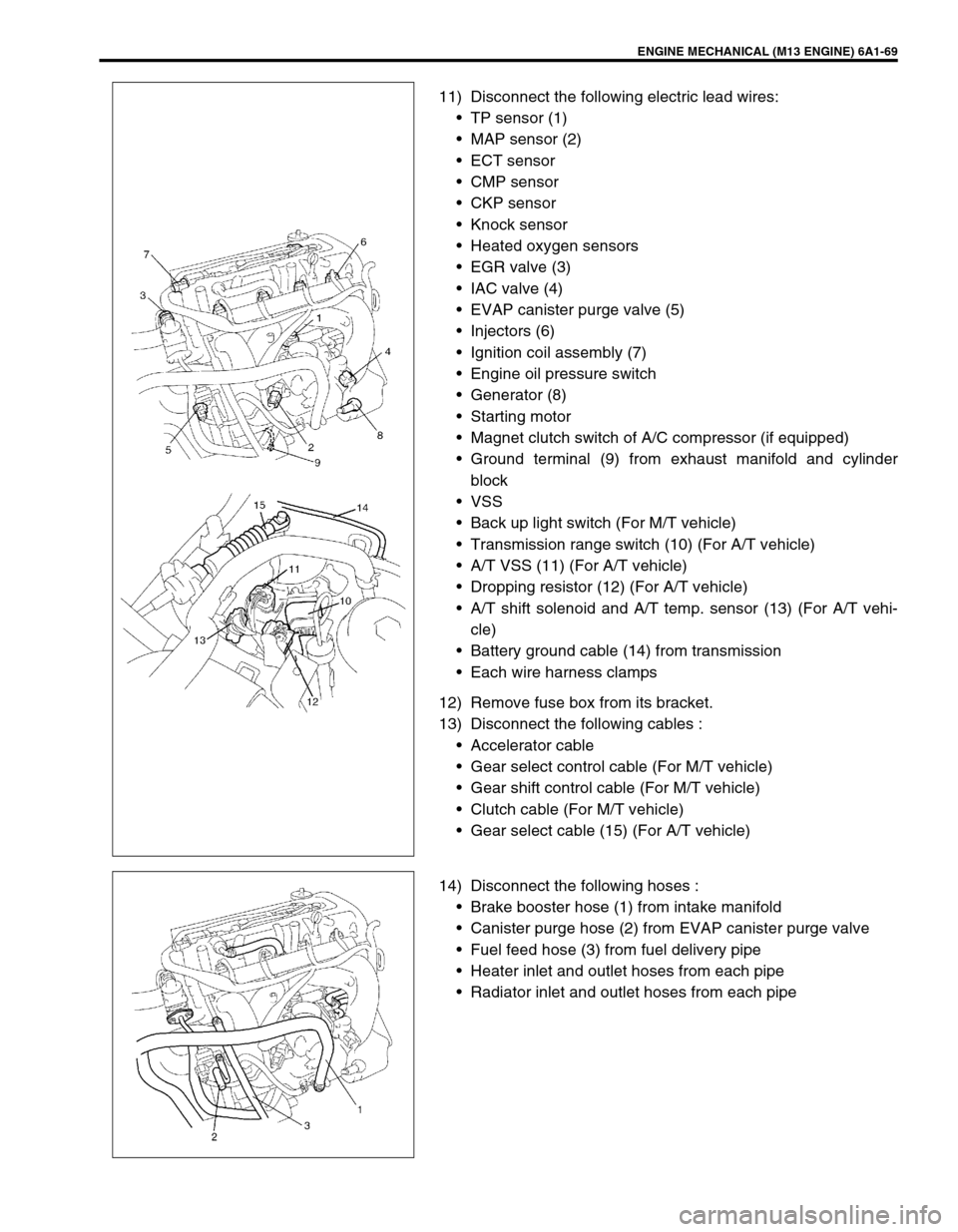

11) Disconnect the following electric lead wires:

TP sensor (1)

MAP sensor (2)

ECT sensor

CMP sensor

CKP sensor

Knock sensor

Heated oxygen sensors

EGR valve (3)

IAC valve (4)

EVAP canister purge valve (5)

Injectors (6)

Ignition coil assembly (7)

Engine oil pressure switch

Generator (8)

Starting motor

Magnet clutch switch of A/C compressor (if equipped)

Ground terminal (9) from exhaust manifold and cylinder

block

VSS

Back up light switch (For M/T vehicle)

Transmission range switch (10) (For A/T vehicle)

A/T VSS (11) (For A/T vehicle)

Dropping resistor (12) (For A/T vehicle)

A/T shift solenoid and A/T temp. sensor (13) (For A/T vehi-

cle)

Battery ground cable (14) from transmission

Each wire harness clamps

12) Remove fuse box from its bracket.

13) Disconnect the following cables :

Accelerator cable

Gear select control cable (For M/T vehicle)

Gear shift control cable (For M/T vehicle)

Clutch cable (For M/T vehicle)

Gear select cable (15) (For A/T vehicle)

14) Disconnect the following hoses :

Brake booster hose (1) from intake manifold

Canister purge hose (2) from EVAP canister purge valve

Fuel feed hose (3) from fuel delivery pipe

Heater inlet and outlet hoses from each pipe

Radiator inlet and outlet hoses from each pipe