engine coolant SUZUKI SWIFT 2000 1.G RG413 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 600 of 698

ENGINE COOLING 6B-11

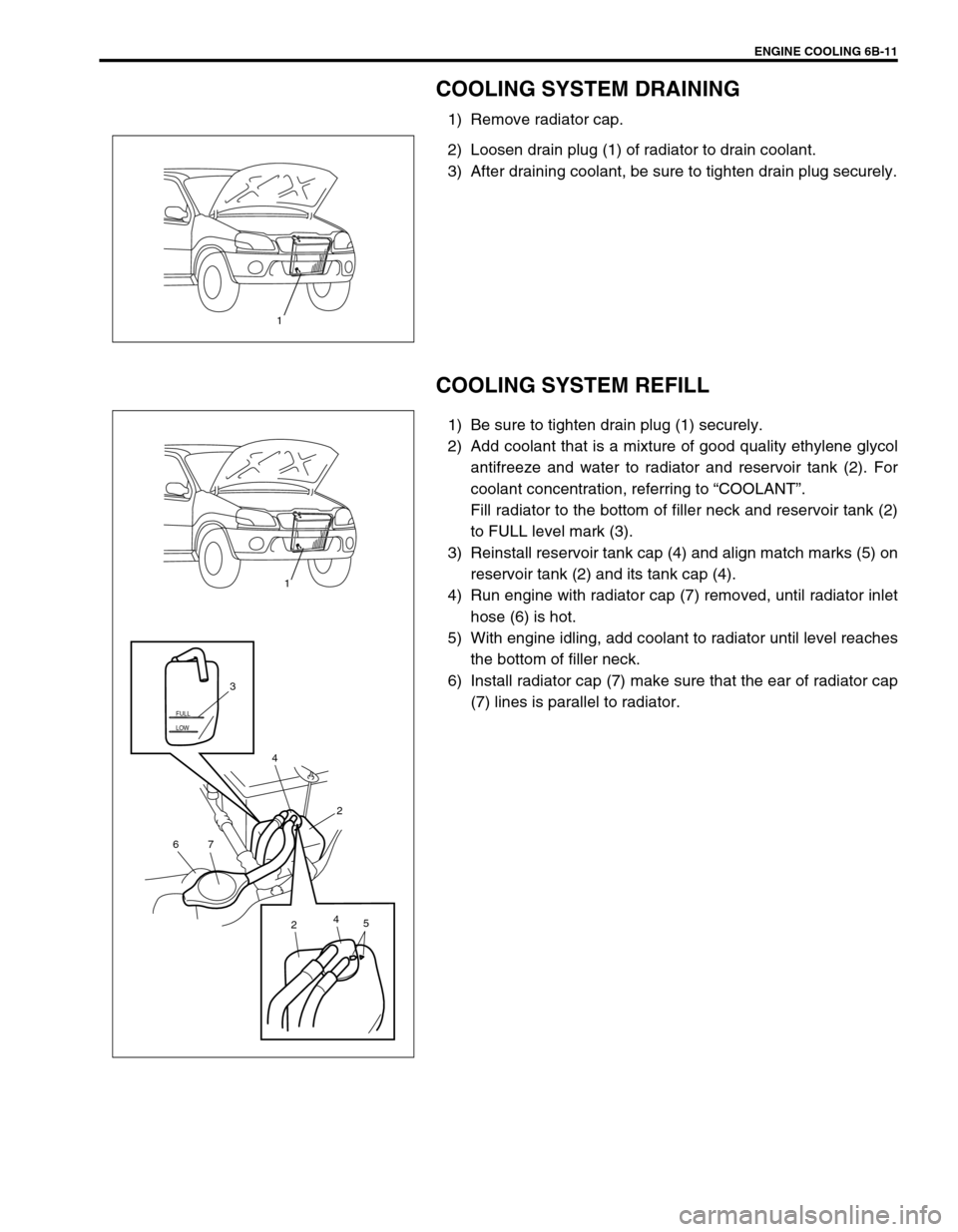

COOLING SYSTEM DRAINING

1) Remove radiator cap.

2) Loosen drain plug (1) of radiator to drain coolant.

3) After draining coolant, be sure to tighten drain plug securely.

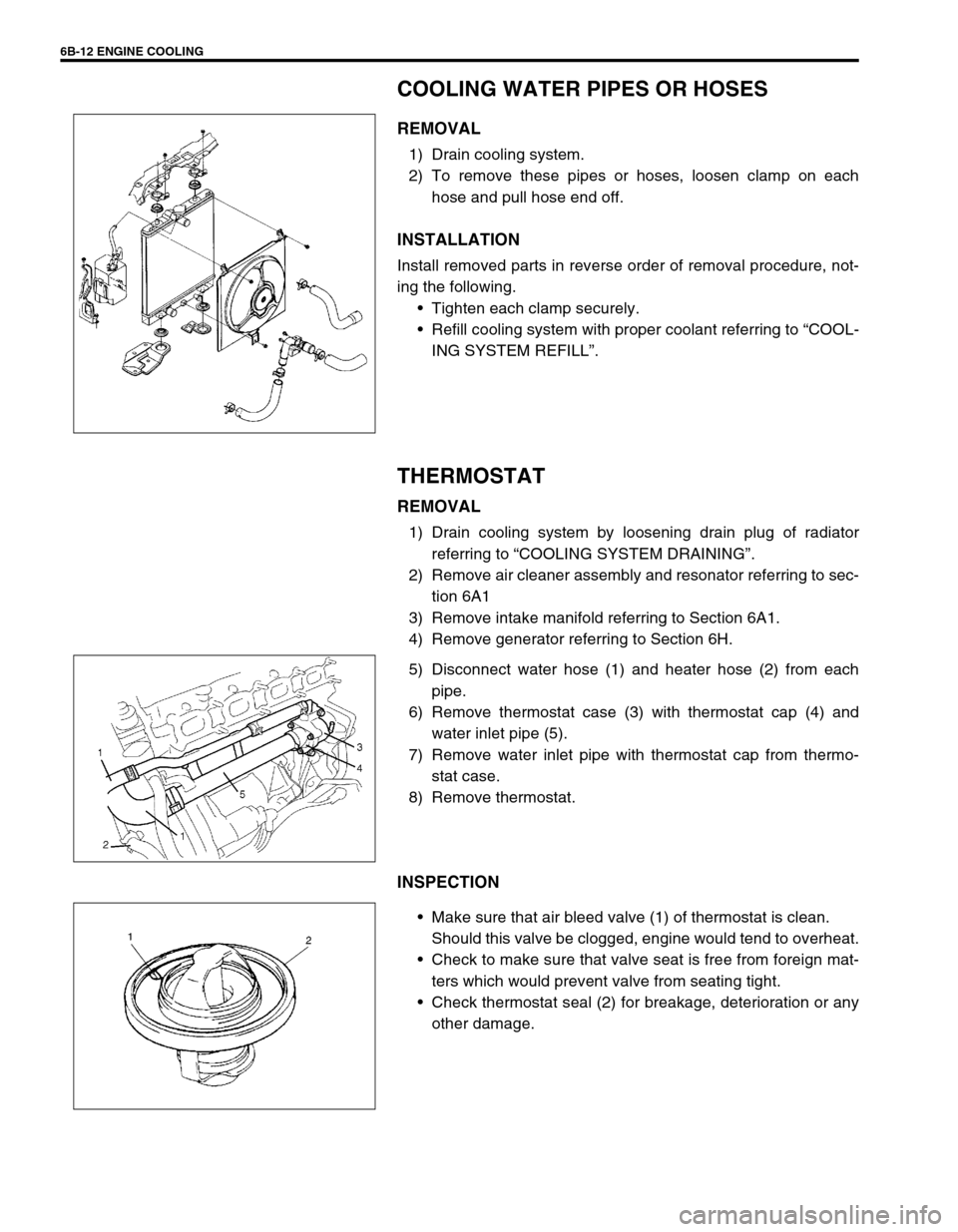

COOLING SYSTEM REFILL

1) Be sure to tighten drain plug (1) securely.

2) Add coolant that is a mixture of good quality ethylene glycol

antifreeze and water to radiator and reservoir tank (2). For

coolant concentration, referring to “COOLANT”.

Fill radiator to the bottom of filler neck and reservoir tank (2)

to FULL level mark (3).

3) Reinstall reservoir tank cap (4) and align match marks (5) on

reservoir tank (2) and its tank cap (4).

4) Run engine with radiator cap (7) removed, until radiator inlet

hose (6) is hot.

5) With engine idling, add coolant to radiator until level reaches

the bottom of filler neck.

6) Install radiator cap (7) make sure that the ear of radiator cap

(7) lines is parallel to radiator.

1

LOW FULL

5 2

7 6

2 3

4

4

1

Page 601 of 698

6B-12 ENGINE COOLING

COOLING WATER PIPES OR HOSES

REMOVAL

1) Drain cooling system.

2) To remove these pipes or hoses, loosen clamp on each

hose and pull hose end off.

INSTALLATION

Install removed parts in reverse order of removal procedure, not-

ing the following.

Tighten each clamp securely.

Refill cooling system with proper coolant referring to “COOL-

ING SYSTEM REFILL”.

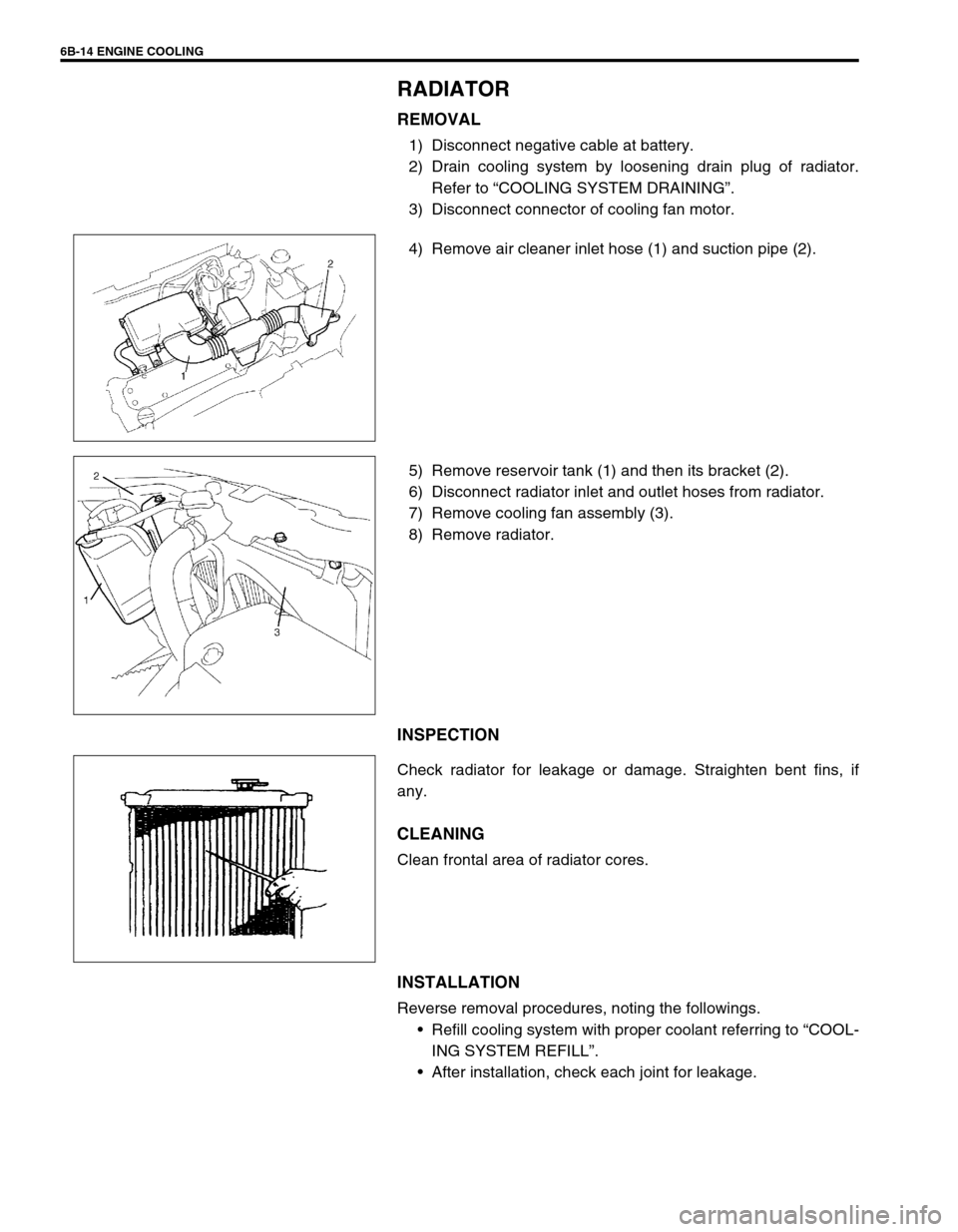

THERMOSTAT

REMOVAL

1) Drain cooling system by loosening drain plug of radiator

referring to “COOLING SYSTEM DRAINING”.

2) Remove air cleaner assembly and resonator referring to sec-

tion 6A1

3) Remove intake manifold referring to Section 6A1.

4) Remove generator referring to Section 6H.

5) Disconnect water hose (1) and heater hose (2) from each

pipe.

6) Remove thermostat case (3) with thermostat cap (4) and

water inlet pipe (5).

7) Remove water inlet pipe with thermostat cap from thermo-

stat case.

8) Remove thermostat.

INSPECTION

Make sure that air bleed valve (1) of thermostat is clean.

Should this valve be clogged, engine would tend to overheat.

Check to make sure that valve seat is free from foreign mat-

ters which would prevent valve from seating tight.

Check thermostat seal (2) for breakage, deterioration or any

other damage.

Page 602 of 698

ENGINE COOLING 6B-13

Check thermostatic movement of wax pellet as follows :

a) Immerse thermostat (1) in water, and heat water gradually.

b) Check that valve starts to open at specific temperature.

Temperature at which valve begins to open

: 80 – 84°C (176 – 183°F)

Temperature at which valve become fully open

: 95 – 97°C (203°F)

Valve lift

: More than 8 mm at 95°C (203°F)

If valve starts to open at a temperature substantially below or

above specific temperature, thermostat unit should be replaced

with a new one. Such a unit, if reused, will bring about overcool-

ing or overheating tendency.

INSTALLATION

Reverse removal procedure for installation noting the following

points.

When positioning thermostat (1) on thermostat case (2), be

sure to position it so that air bleed valve (3) comes at posi-

tion as shown in figure.

Use new O-rings when installing.

Adjust water pump belt tension referring to WATER PUMP/

GENERATOR DRIVE BELT TENSION INSPECTION AND

ADJUSTMENT in this section.

Adjust A/C compressor belt tension (if equipped) referring to

Section 1B.

Refill cooling system with proper coolant referring to “COOL-

ING SYSTEM REFILL”.

Verify that there is no coolant leakage at each connection.

2. Thermometer

3. Heater

Page 603 of 698

6B-14 ENGINE COOLING

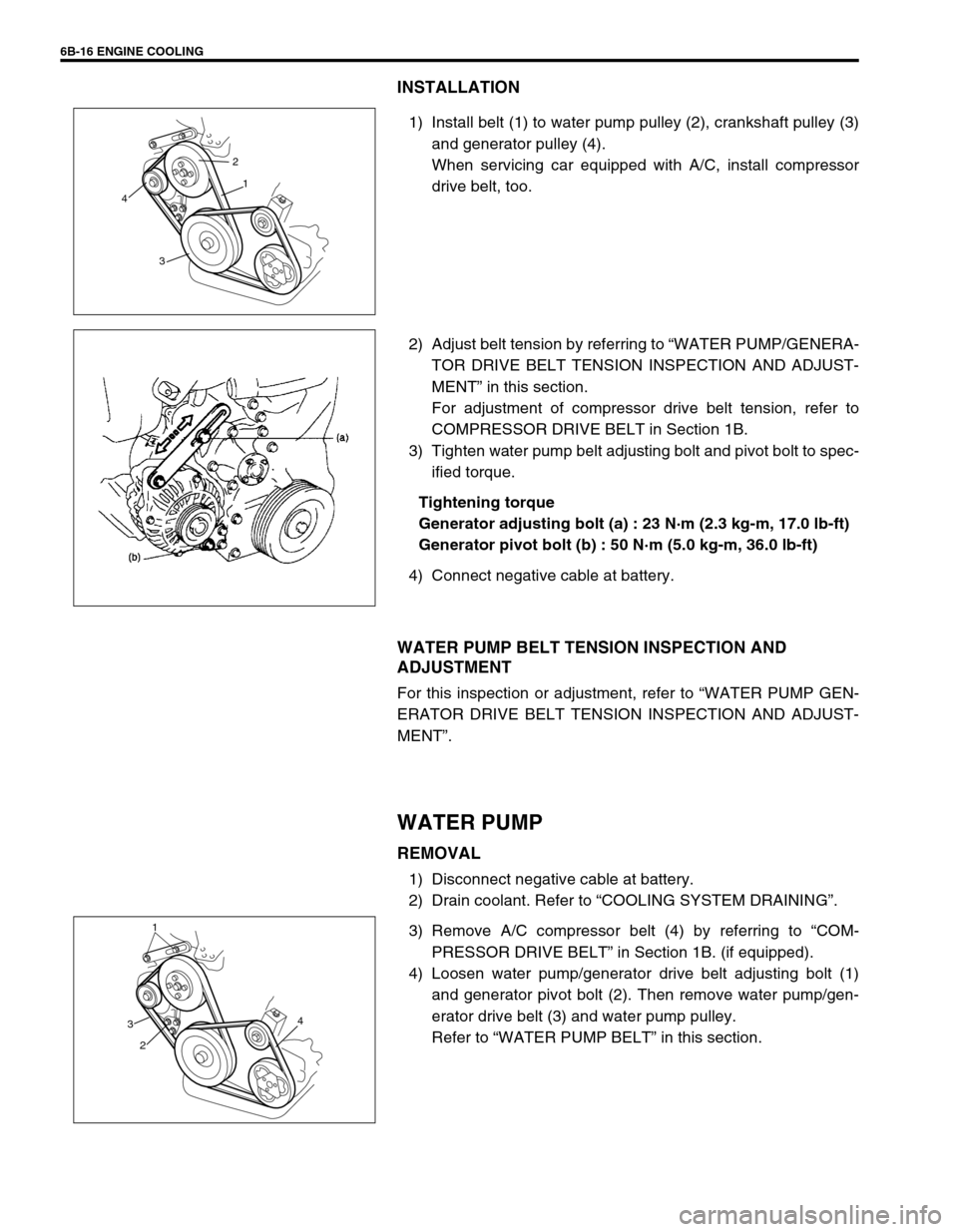

RADIATOR

REMOVAL

1) Disconnect negative cable at battery.

2) Drain cooling system by loosening drain plug of radiator.

Refer to “COOLING SYSTEM DRAINING”.

3) Disconnect connector of cooling fan motor.

4) Remove air cleaner inlet hose (1) and suction pipe (2).

5) Remove reservoir tank (1) and then its bracket (2).

6) Disconnect radiator inlet and outlet hoses from radiator.

7) Remove cooling fan assembly (3).

8) Remove radiator.

INSPECTION

Check radiator for leakage or damage. Straighten bent fins, if

any.

CLEANING

Clean frontal area of radiator cores.

INSTALLATION

Reverse removal procedures, noting the followings.

Refill cooling system with proper coolant referring to “COOL-

ING SYSTEM REFILL”.

After installation, check each joint for leakage.

Page 605 of 698

6B-16 ENGINE COOLING

INSTALLATION

1) Install belt (1) to water pump pulley (2), crankshaft pulley (3)

and generator pulley (4).

When servicing car equipped with A/C, install compressor

drive belt, too.

2) Adjust belt tension by referring to “WATER PUMP/GENERA-

TOR DRIVE BELT TENSION INSPECTION AND ADJUST-

MENT” in this section.

For adjustment of compressor drive belt tension, refer to

COMPRESSOR DRIVE BELT in Section 1B.

3) Tighten water pump belt adjusting bolt and pivot bolt to spec-

ified torque.

Tightening torque

Generator adjusting bolt (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

Generator pivot bolt (b) : 50 N·m (5.0 kg-m, 36.0 lb-ft)

4) Connect negative cable at battery.

WATER PUMP BELT TENSION INSPECTION AND

ADJUSTMENT

For this inspection or adjustment, refer to “WATER PUMP GEN-

ERATOR DRIVE BELT TENSION INSPECTION AND ADJUST-

MENT”.

WATER PUMP

REMOVAL

1) Disconnect negative cable at battery.

2) Drain coolant. Refer to “COOLING SYSTEM DRAINING”.

3) Remove A/C compressor belt (4) by referring to “COM-

PRESSOR DRIVE BELT” in Section 1B. (if equipped).

4) Loosen water pump/generator drive belt adjusting bolt (1)

and generator pivot bolt (2). Then remove water pump/gen-

erator drive belt (3) and water pump pulley.

Refer to “WATER PUMP BELT” in this section.

2

1

3

4

1

2

43

Page 606 of 698

ENGINE COOLING 6B-17

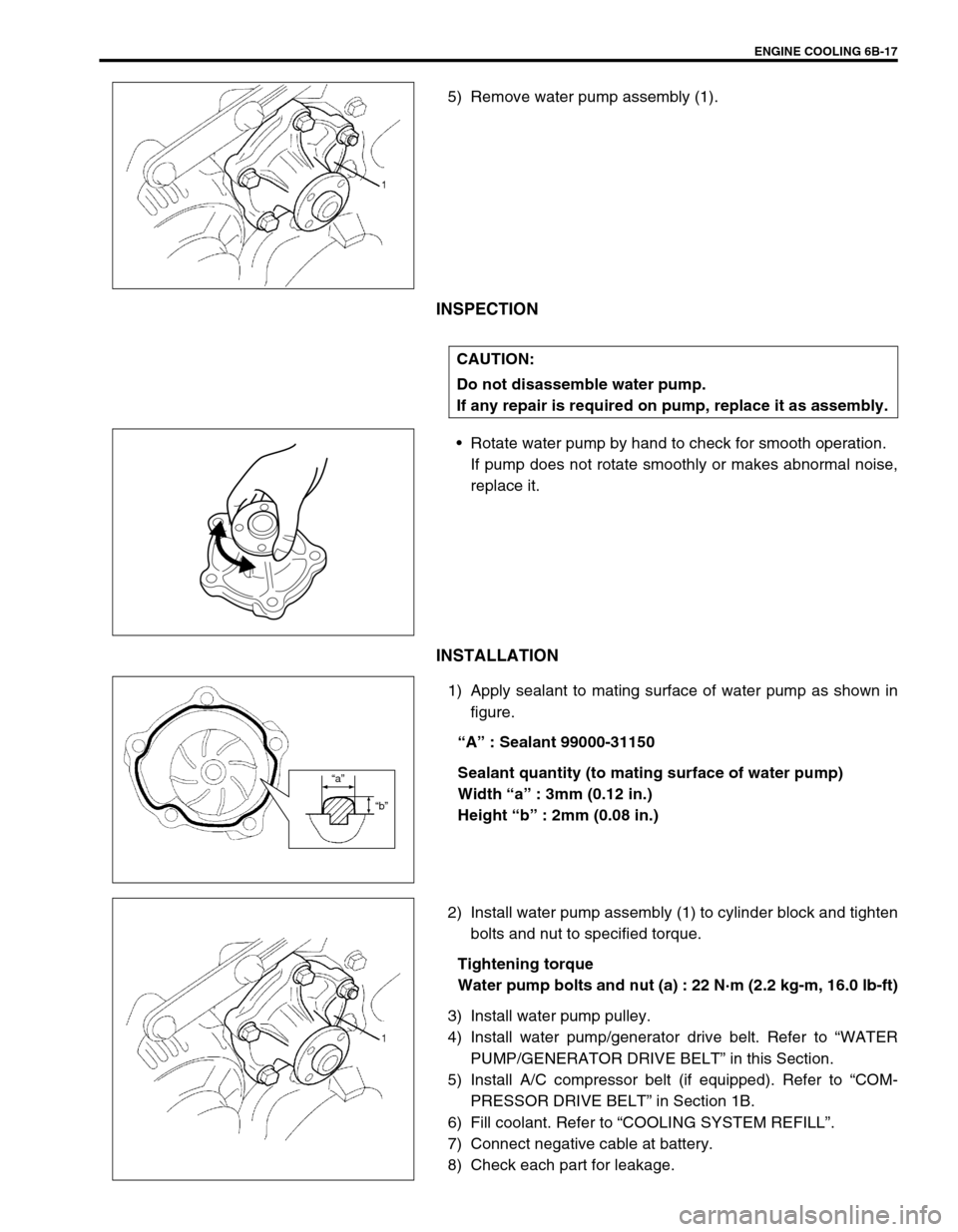

5) Remove water pump assembly (1).

INSPECTION

Rotate water pump by hand to check for smooth operation.

If pump does not rotate smoothly or makes abnormal noise,

replace it.

INSTALLATION

1) Apply sealant to mating surface of water pump as shown in

figure.

“A” : Sealant 99000-31150

Sealant quantity (to mating surface of water pump)

Width “a” : 3mm (0.12 in.)

Height “b” : 2mm (0.08 in.)

2) Install water pump assembly (1) to cylinder block and tighten

bolts and nut to specified torque.

Tightening torque

Water pump bolts and nut (a) : 22 N·m (2.2 kg-m, 16.0 lb-ft)

3) Install water pump pulley.

4) Install water pump/generator drive belt. Refer to “WATER

PUMP/GENERATOR DRIVE BELT” in this Section.

5) Install A/C compressor belt (if equipped). Refer to “COM-

PRESSOR DRIVE BELT” in Section 1B.

6) Fill coolant. Refer to “COOLING SYSTEM REFILL”.

7) Connect negative cable at battery.

8) Check each part for leakage.

CAUTION:

Do not disassemble water pump.

If any repair is required on pump, replace it as assembly.

“a”

“b”

Page 607 of 698

6B-18 ENGINE COOLING

ECT SENSOR

Refer to “ECT SENSOR” in Section 6E1.

REQUIRED SERVICE MATERIAL

TIGHTENING TORQUE SPECIFICATION

MaterialRecommended SUZUKI product

(Part Number)Use

Ethylene glycol base

coolant (Anti-freeze/

Anti-corrosion coolant)—Additive to engine cooling system for improving

cooling efficiency and for protection against

rusting.

SealantSUZUKI BOND NO. 1207C

(99000-31150)To apply to mating surface of water pump

Fastening partTightening torque

Nm kg-m lb-ft

Generator adjusting bolt 23 2.3 17

Generator pivot bolt 50 5 36

Water pump bolt and Nuts 22 2.2 16

Page 622 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-1

6F1

6F2

6G

6H

6E1

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 6E1

ENGINE AND EMISSION CONTROL SYSTEM

CONTENTS

GENERAL DESCRIPTION ............................ 6E1-2

AIR INTAKE SYSTEM ............................... 6E1-5

FUEL DELIVERY SYSTEM ....................... 6E1-6

FUEL PUMP ........................................... 6E1-6

ELECTRONIC CONTROL SYSTEM .......... 6E1-7

ENGINE & EMISSION CONTROL

INPUT/OUTPUT TABLE ........................ 6E1-8

ECM INPUT/OUTPUT CIRCUIT

DIAGRAM............................................... 6E1-9

ECM TERMINAL ARRANGEMENT

TABLE .................................................. 6E1-13

ON-VEHICLE SERVICE .............................. 6E1-15

ACCELERATOR CABLE

ADJUSTMENT ..................................... 6E1-15

IDLE SPEED/IDLE AIR CONTROL

(IAC) DUTY INSPECTION ................... 6E1-15

IDLE MIXTURE INSPECTION /

ADJUSTMENT (VEHICLE WITHOUT

HEATED OXYGEN SENSOR) ............. 6E1-17

AIR INTAKE SYSTEM ............................. 6E1-18

THROTTLE BODY ............................... 6E1-18IDLE AIR CONTROL VALVE (IAC

VALVE) ................................................ 6E1-20

FUEL DELIVERY SYSTEM ..................... 6E1-21

FUEL PRESSURE INSPECTION ........ 6E1-21

FUEL PUMP WITH PRESSURE

REGULATOR ....................................... 6E1-22

FUEL INJECTOR ................................. 6E1-23

ELECTRONIC CONTROL SYSTEM ....... 6E1-27

ENGINE CONTROL MODULE

(ECM) ................................................... 6E1-27

MANIFOLD ABSOLUTE PRESSURE

SENSOR (MAP SENSOR)................... 6E1-27

THROTTLE POSITION SENSOR (TP

SENSOR) ............................................. 6E1-28

INTAKE AIR TEMPERATURE

SENSOR (IAT SENSOR) ..................... 6E1-29

ENGINE COOLANT TEMPERATURE

SENSOR (ECT SENSOR) ................... 6E1-30

HEATED OXYGEN SENSOR (HO2S-1

AND HO2S-2) ...................................... 6E1-31

CAMSHAFT POSITION SENSOR ....... 6E1-32 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Whether the following system (parts) are used in the particular vehicle or not depends on vehicle

specifications. Be sure to bear this in mind when performing service work.

EGR valve

Heated oxygen sensor(s) or CO adjusting resistor

Three way catalytic converter

Immobilizer indicator lamp

Knock sensor

Page 623 of 698

6E1-2 ENGINE AND EMISSION CONTROL SYSTEM

CRANKSHAFT POSITION SENSOR .. 6E1-32

VEHICLE SPEED SENSOR (VSS) ...... 6E1-33

FUEL LEVEL SENSOR (GAUGE) ....... 6E1-33

KNOCK SENSOR (IF EQUIPPED) ...... 6E1-33

MAIN RELAY, FUEL PUMP RELAY

AND RADIATOR FAN RELAY NO.1.... 6E1-33

FUEL CUT OPERATION ..................... 6E1-34

RADIATOR FAN CONTROL

SYSTEM .............................................. 6E1-34

RADIATOR FAN RELAY NO. 2 AND

NO.3 ..................................................... 6E1-34OUTPUT SIGNALS OF THROTTLE

VALVE OPENING AND ENGINE

COOLANT TEMP. (VEHICLE WITH

A/T ONLY) ........................................... 6E1-36

EMISSION CONTROL SYSTEM ............. 6E1-36

EGR SYSTEM ..................................... 6E1-36

EVAPORATIVE EMISSION CONTROL

SYSTEM .............................................. 6E1-37

PCV SYSTEM ...................................... 6E1-39

SPECIAL TOOL .......................................... 6E1-40

TIGHTENING TORQUE SPECIFICATION . 6E1-41

GENERAL DESCRIPTION

The engine and emission control system is divided into 4 major sub-systems : air intake system, fuel delivery

system, electronic control system and emission control system.

Air intake system includes air cleaner, throttle body, IAC valve and intake manifold.

Fuel delivery system includes fuel pump, delivery pipe, fuel pressure regulator, etc. Electronic control system

includes ECM, various sensors and controlled devices.

Emission control system includes EGR, EVAP and PCV system.

Page 628 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-7

ELECTRONIC CONTROL SYSTEM

The electronic control system consists of 1) various sensors which detect the state of engine and driving condi-

tions, 2) ECM which controls various devices according to the signals from the sensors and 3) various controlled

devices.

Functionally, it is divided into nine sub systems :

Fuel injection control system

Idle speed control system

Fuel pump control system

A/C control system (if equipped)

Radiator fan control system

EGR system (if equipped)

Evaporative emission control system

Oxygen sensor heater control system (if equipped)

Ignition control system

Also, with A/T model, ECM sends throttle valve opening signal and coolant temp. signal to transmission control

module to control A/T.

INFORMATION SENSORS CONTROL DEVICES OTHERS

1. MAP sensor a : Fuel injector A : ECM

2. TP sensor b : EVAP canister purge valve B : Main relay

3. IAT sensor c : Fuel pump relay C : EVAP canister

4. ECT sensor d : EGR valve (step motor) (if equipped) D : Monitor connector

5. Heated oxygen sensor-1 (if equipped) e : Malfunction indicator lamp E : Data link connector

5-1. Heated oxygen sensor-2 (if equipped) f : Ignition coil assembly F : A/C EVAP thermistor (if equipped)

6. VSS g : Radiator fan control relay G : TCM (A/T)

7. Transmission range switch (A/T) h : IAC valve

8. Battery i : Immobilizer indicator lamp

9. CMP sensor

10. CKP sensor

11. Fuel level sensor (gauge) (in fuel tank)

12. Stop lamp switch

13. Knock sensor (if equipped)