3B1-10 SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 142 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-1

6F1

6F2

6G

6H

6K

7A

7A1

3B1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3B1

ELECTRICAL POWER STEERING (P/S) SYSTEM

CONTENTS

GENERAL DESCRIPTION .............................3B1-2

SYSTEM COMPONENTS ........................... 3B1-2

WIRING DIAGRAM ..................................... 3B1-3

DIAGNOSIS ....................................................3B1-4

ON-BOARD DIAGNOSTIC SYSTEM .......... 3B1-4

PRECAUTIONS IN DIAGNOSING

TROUBLES ................................................. 3B1-4

SYSTEM CHECK FLOW TABLE ................ 3B1-5

MALFUNCTION INDICATOR LAMP

(“EPS” WARNING LAMP) CHECK.............. 3B1-7

DTC CHECK ............................................... 3B1-8

DTC CLEARANCE ...................................... 3B1-9

SERIAL DATA LINK CIRCUIT CHECK ..... 3B1-10

DTC TABLE .............................................. 3B1-11

TABLE A - MALFUNCTION INDICATOR

LAMP DOES NOT COME ON AT

IGNITION SWITCH ON BUT LEAVING

ENGINE OFF ............................................ 3B1-13

TABLE B - MALFUNCTION INDICATOR

LAMP FLASHES AT IGNITION SWITCH

ON ............................................................. 3B1-15

TABLE C - MALFUNCTION INDICATOR

LAMP DOES NOT FLASH, JUST

REMAINS ON OR JUST REMAINS OFF

EVEN WITH DIAGNOSIS SWITCH

TERMINAL GROUNDED .......................... 3B1-15

DTC C1111 (DTC No.11) TORQUE

SENSOR MAIN CIRCUIT FAILURE ......... 3B1-16

DTC C1113 (DTC No.13) TORQUE

SENSOR MAIN AND SUB CIRCUIT

FAILURE ................................................... 3B1-16DTC C1115 (DTC No.15) TORQUE

SENSOR SUB CIRCUIT FAILURE........... 3B1-16

DTC C1114 (DTC No.14) TORQUE

SENSOR 5V POWER SUPPLY CIRCUIT

FAILURE ................................................... 3B1-17

DTC C1116 (DTC No.16) TORQUE

SENSOR 8V POWER SUPPLY CIRCUIT

FAILURE ................................................... 3B1-18

DTC C1121/C1123/C1124

(DTC No.21/23/24) VSS CIRCUIT

FAILURE ................................................... 3B1-19

DTC C1122 (DTC No.22) ENGINE

SPEED SIGNAL CIRCUIT FAILURE ........ 3B1-20

DTC C1141/C1142/C1143/C1144/C1145

(DTC No.41/42/43/44/45) MOTOR

CIRCUIT FAILURE ................................... 3B1-21

DTC C1151 (DTC No.51) CLUTCH

CIRCUIT FAILURE ................................... 3B1-22

DTC C1153(DTC No.53) P/S CONTROL

MODULE POWER SUPPLY CIRCUIT

FAILURE ................................................... 3B1-24

DTC C1152/C1154/C1155

(DTC No.52/54/55) P/S CONTROL

MODULE FAILURE .................................. 3B1-24

TROUBLE DIAGNOSIS (FOR TROUBLE

NOT INDICATED BY ON BOARD

DIAGNOSTIC SYSTEM)........................... 3B1-25

INSPECTION OF P/S CONTROL

MODULE AND ITS CIRCUITS ................. 3B1-26

STEERING WHEEL PLAY

INSPECTION ............................................ 3B1-28 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 151 of 698

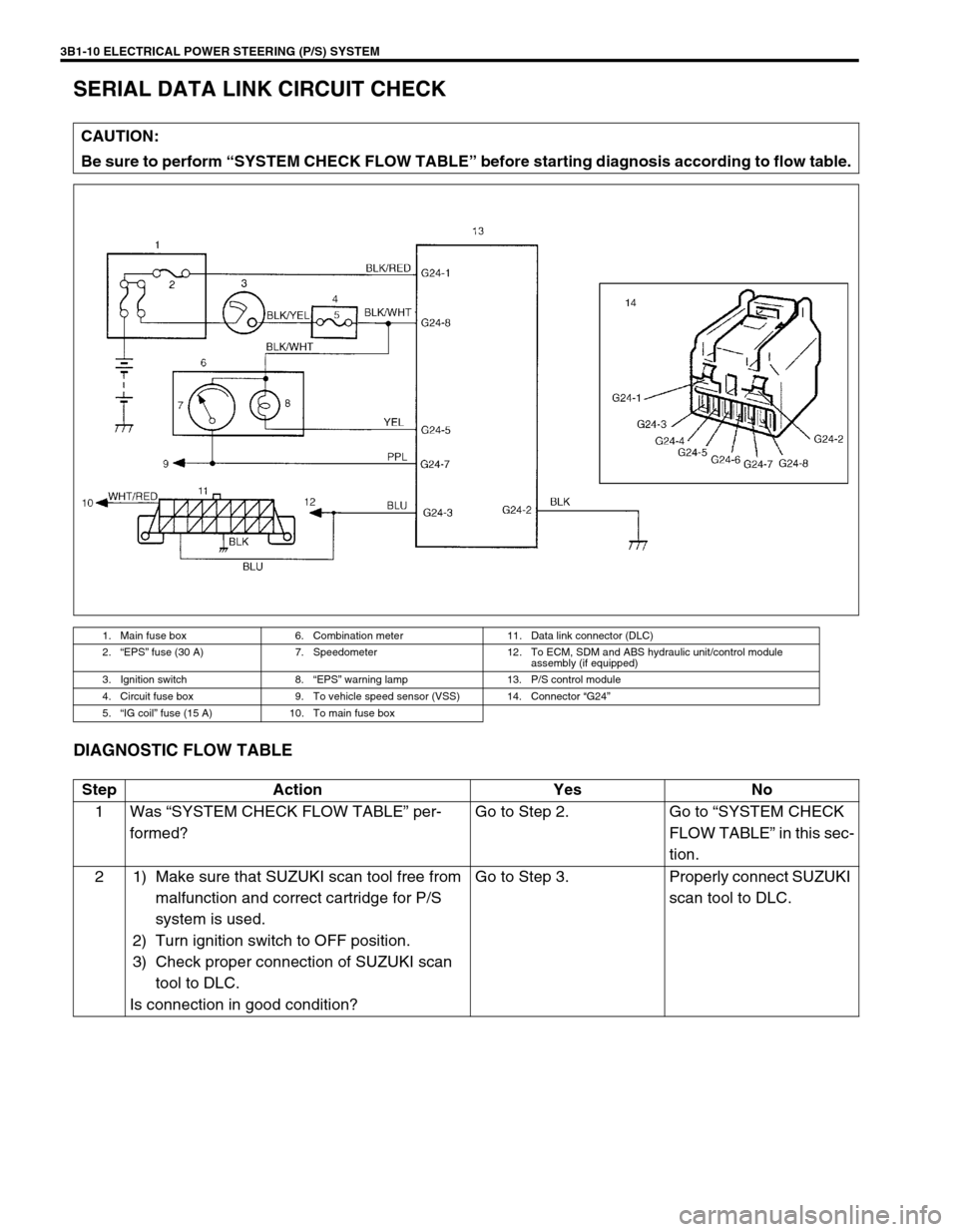

3B1-10 ELECTRICAL POWER STEERING (P/S) SYSTEM

SERIAL DATA LINK CIRCUIT CHECK

DIAGNOSTIC FLOW TABLE

CAUTION:

Be sure to perform “SYSTEM CHECK FLOW TABLE” before starting diagnosis according to flow table.

1. Main fuse box 6. Combination meter 11. Data link connector (DLC)

2.“EPS” fuse (30 A) 7. Speedometer 12. To ECM, SDM and ABS hydraulic unit/control module

assembly (if equipped)

3. Ignition switch 8.“EPS” warning lamp 13. P/S control module

4. Circuit fuse box 9. To vehicle speed sensor (VSS) 14. Connector “G24”

5.“IG coil” fuse (15 A) 10. To main fuse box

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to Step 2. Go to “SYSTEM CHECK

FLOW TABLE” in this sec-

tion.

2 1) Make sure that SUZUKI scan tool free from

malfunction and correct cartridge for P/S

system is used.

2) Turn ignition switch to OFF position.

3) Check proper connection of SUZUKI scan

tool to DLC.

Is connection in good condition?Go to Step 3. Properly connect SUZUKI

scan tool to DLC.