heating SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 3 of 698

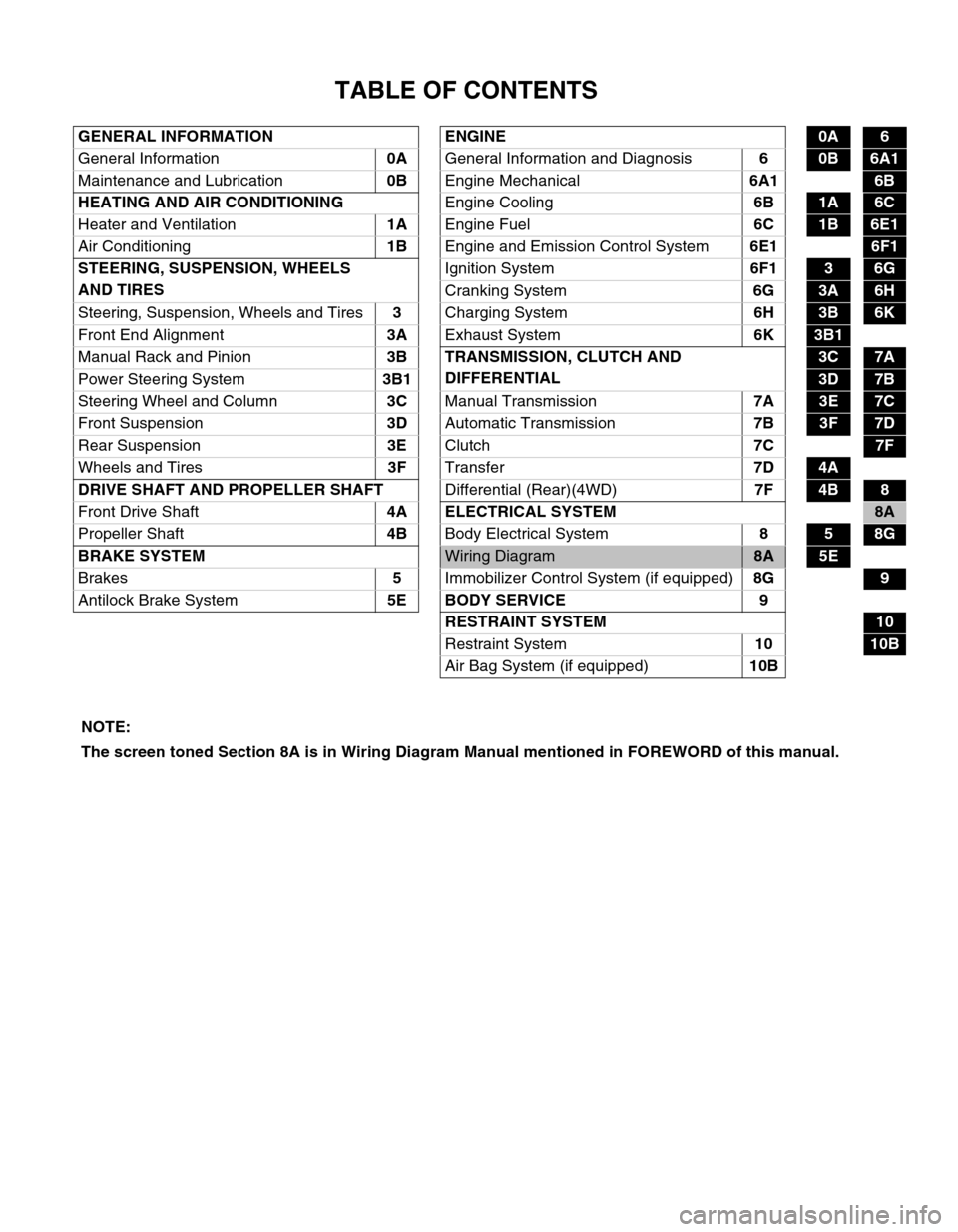

TABLE OF CONTENTS

GENERAL INFORMATION ENGINE0A6

General Information0A

General Information and Diagnosis6

0B6A1

Maintenance and Lubrication0B

Engine Mechanical6A1

6B

HEATING AND AIR CONDITIONING

Engine Cooling6B

1A6C

Heater and Ventilation1A

Engine Fuel6C

1B6E1

Air Conditioning1B

Engine and Emission Control System6E1

6F1

STEERING, SUSPENSION, WHEELS

AND TIRESIgnition System6F1

36G

Cranking System6G

3A6H

Steering, Suspension, Wheels and Tires3

Charging System6H

3B6K

Front End Alignment3A

Exhaust System6K

3B1 6B

Manual Rack and Pinion3B TRANSMISSION, CLUTCH AND

DIFFERENTIAL

3C7A

Power Steering System3B1

3D7B

Steering Wheel and Column3C

Manual Transmission7A

3E7C

Front Suspension3D

Automatic Transmission7B

3F7D

Rear Suspension3E

Clutch7C

7F

Wheels and Tires3F

Transfer7D

4A

DRIVE SHAFT AND PROPELLER SHAFT

Differential (Rear)(4WD)7F

4B8

Front Drive Shaft 4A ELECTRICAL SYSTEM

8A

Propeller Shaft4B

Body Electrical System8

58G

BRAKE SYSTEM

Wiring Diagram8A5E

Brakes5

Immobilizer Control System (if equipped)8G

9

Antilock Brake System5E BODY SERVICE 9

RESTRAINT SYSTEM

10

Restraint System10

10B

Air Bag System (if equipped)10B

NOTE:

The screen toned Section 8A is in Wiring Diagram Manual mentioned in FOREWORD of this manual.

Page 39 of 698

0B-10 MAINTENANCE AND LUBRICATION

EXHAUST SYSTEM

INSPECTION

When carrying out periodic maintenance, or the vehicle is raised

for other service, check exhaust system as follows:

Check rubber mountings for damage, deterioration, and out

of position.

Check exhaust system for leakage, loose connections, dents

and damages.

If bolts or nuts are loose, tighten them to specification.

Check nearby body areas for damaged, missing, or misposi-

tioned parts, open seams, holes, loose connections or other

defects which could permit exhaust fumes to seep into the

vehicle.

Make sure that exhaust system components have enough

clearance from the underbody to avoid overheating and pos-

sible damage to the floor carpet.

Any defects should be fixed at once.

IGNITION SYSTEM

SPARK PLUGS

REPLACEMENT

Replace spark plugs with new ones referring to “SPARK PLUG”

in Section 6F1.

FUEL SYSTEM

AIR CLEANER FILTER

INSPECTION

1) Remove air cleaner case clamps.

2) Take air cleaner filter out of case.

3) Check that filter is not excessively dirty, damaged or oily,

clean filter with compressed air from air outlet side of filter. WARNING:

To avoid danger of being burned, do not touch exhaust

system when it is still hot. Any service on exhaust sys-

tem should be performed when it is cool.

Page 250 of 698

WHEELS AND TIRES 3F-5

MAINTENANCE AND MINOR ADJUSTMENTS

WHEEL MAINTENANCE

Wheel repairs that use welding, heating, or peening are not approved. All damaged wheels should be replaced.

WHEEL ATTACHING STUDS

If a broken stud is found, see Section 3E (rear) or Section 3D (front) for Note and Replacement procedure.

MATCHED TIRES AND WHEELS

Tires and wheels are match mounted at the assembly plant.

This means that the radially stiffest part of the tire, or “high spot”,

is matched to the smallest radius or “low spot” of the wheel.

This is done to provide the smoothest possible ride.

The “high spot” of the tire is originally marked by paint dot (1) on

the outboard sidewall. This paint dot will eventually wash off the

tire.

The “ow spot” of the wheel is originally marked by paint dot (2) on

the wheel rim-flange. Properly assembled, the wheel rims’ paint

dot should be aligned with the tires’ paint dot as shown in left fig-

ure.

Whenever a tire is dismounted from its wheel, it should be

remounted so that the tire and wheel are matched. If the tire’s

paint dot cannot be located, a line should be scribed on the tire

and wheel before dismounting to assure that it is remounted in

the same position.

TIRE MAINTENANCE

TIRE PLACARD

The “Tire Placard” is located on the left door (right door for right-hand side steering vehicle) lock pillar and

should be referred to tire information.

The placard lists the maximum load, tire size and cold tire pressure where applicable.

NOTE:

Whether rim size and/or maximum load are listed or not depends on regulations of each country.

Page 390 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-21

P0340

(No.15)CMP SENSOR ECM changes injection control sys-

tem from sequential injection to simul-

taneous one.Hard starting

P0400 EGR VALVE–Hard starting/rough or incorrect

idle/ excessive fuel consumption/

hesitation/ poor acceleration/

surge/ detonation or spark knock/

engine stall

P0420 CATALYST––

P0443 PURGE CONTROL

VALVE–Rough or incorrect idle/ surge/

hard starting/ engine stall

P0480 RADIATOR FAN

CONTROL SYSTEM–Engine overheating

P0500

(No.16)VEHICLE SPEED

SENSORECM stops idle air control. Rough or incorrect idle

P0505 IDLE CONTROL

SYSTEM–Engine stall/ rough or incorrect idle

P0601

(No.71)ECM INTERNAL–Hard starting/ rough or incorrect

idle/ excessive fuel consumption/

detonation or spark knock/ hesita-

tion poor acceleration/

P1450

(No.29)BAROMETRIC

PRESSURE SEN-

SORECM controls actuators assuming

that barometric pressure is

100 kPa (760 mmHg).Hard starting/ rough or incorrect

idle DTC NO. TROUBLE AREA FAIL-SAFE OPERATION SYMPTOM

Page 396 of 698

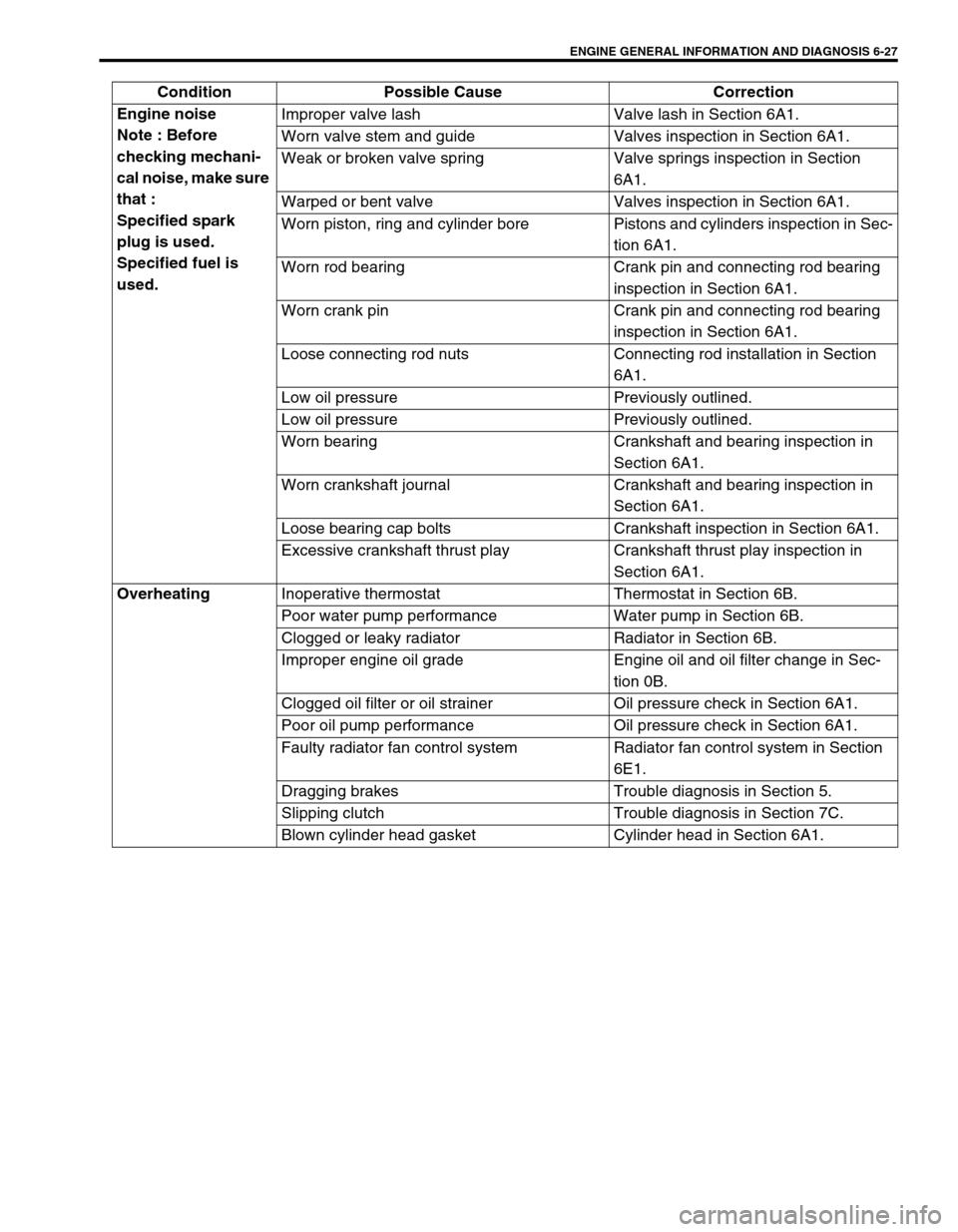

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-27

Engine noise

Note : Before

checking mechani-

cal noise, make sure

that :

Specified spark

plug is used.

Specified fuel is

used.Improper valve lash Valve lash in Section 6A1.

Worn valve stem and guide Valves inspection in Section 6A1.

Weak or broken valve spring Valve springs inspection in Section

6A1.

Warped or bent valve Valves inspection in Section 6A1.

Worn piston, ring and cylinder bore Pistons and cylinders inspection in Sec-

tion 6A1.

Worn rod bearing Crank pin and connecting rod bearing

inspection in Section 6A1.

Worn crank pin Crank pin and connecting rod bearing

inspection in Section 6A1.

Loose connecting rod nuts Connecting rod installation in Section

6A1.

Low oil pressure Previously outlined.

Low oil pressure Previously outlined.

Worn bearing Crankshaft and bearing inspection in

Section 6A1.

Worn crankshaft journal Crankshaft and bearing inspection in

Section 6A1.

Loose bearing cap bolts Crankshaft inspection in Section 6A1.

Excessive crankshaft thrust play Crankshaft thrust play inspection in

Section 6A1.

Overheating

Inoperative thermostat Thermostat in Section 6B.

Poor water pump performance Water pump in Section 6B.

Clogged or leaky radiator Radiator in Section 6B.

Improper engine oil grade Engine oil and oil filter change in Sec-

tion 0B.

Clogged oil filter or oil strainer Oil pressure check in Section 6A1.

Poor oil pump performance Oil pressure check in Section 6A1.

Faulty radiator fan control system Radiator fan control system in Section

6E1.

Dragging brakes Trouble diagnosis in Section 5.

Slipping clutch Trouble diagnosis in Section 7C.

Blown cylinder head gasket Cylinder head in Section 6A1. Condition Possible Cause Correction

Page 397 of 698

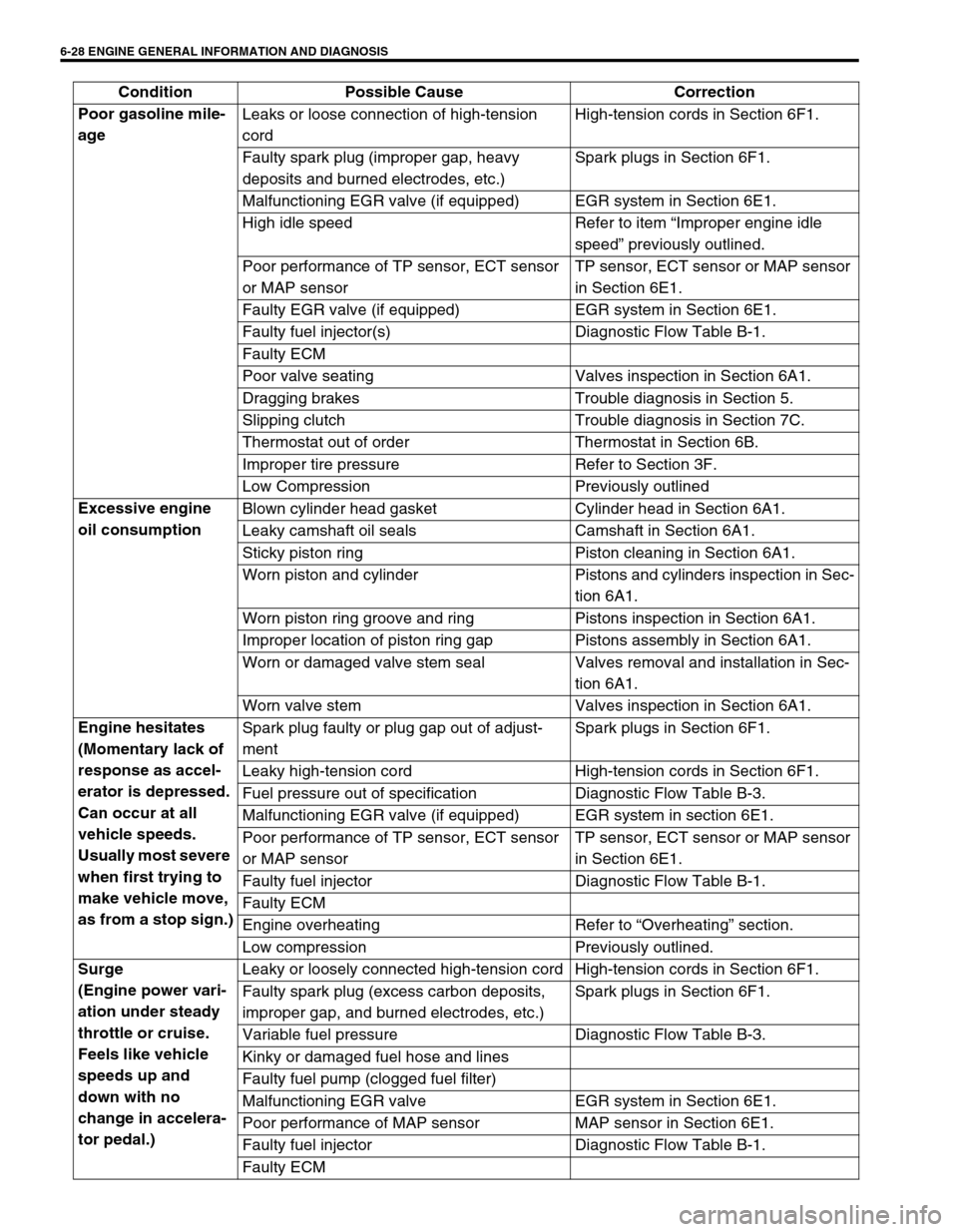

6-28 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Poor gasoline mile-

age Leaks or loose connection of high-tension

cordHigh-tension cords in Section 6F1.

Faulty spark plug (improper gap, heavy

deposits and burned electrodes, etc.)Spark plugs in Section 6F1.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E1.

High idle speed Refer to item “Improper engine idle

speed” previously outlined.

Poor performance of TP sensor, ECT sensor

or MAP sensorTP sensor, ECT sensor or MAP sensor

in Section 6E1.

Faulty EGR valve (if equipped) EGR system in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Faulty ECM

Poor valve seating Valves inspection in Section 6A1.

Dragging brakes Trouble diagnosis in Section 5.

Slipping clutch Trouble diagnosis in Section 7C.

Thermostat out of order Thermostat in Section 6B.

Improper tire pressure Refer to Section 3F.

Low Compression Previously outlined

Excessive engine

oil consumption Blown cylinder head gasket Cylinder head in Section 6A1.

Leaky camshaft oil seals Camshaft in Section 6A1.

Sticky piston ring Piston cleaning in Section 6A1.

Worn piston and cylinder Pistons and cylinders inspection in Sec-

tion 6A1.

Worn piston ring groove and ring Pistons inspection in Section 6A1.

Improper location of piston ring gap Pistons assembly in Section 6A1.

Worn or damaged valve stem seal Valves removal and installation in Sec-

tion 6A1.

Worn valve stem Valves inspection in Section 6A1.

Engine hesitates

(Momentary lack of

response as accel-

erator is depressed.

Can occur at all

vehicle speeds.

Usually most severe

when first trying to

make vehicle move,

as from a stop sign.)Spark plug faulty or plug gap out of adjust-

mentSpark plugs in Section 6F1.

Leaky high-tension cord High-tension cords in Section 6F1.

Fuel pressure out of specification Diagnostic Flow Table B-3.

Malfunctioning EGR valve (if equipped) EGR system in section 6E1.

Poor performance of TP sensor, ECT sensor

or MAP sensorTP sensor, ECT sensor or MAP sensor

in Section 6E1.

Faulty fuel injector Diagnostic Flow Table B-1.

Faulty ECM

Engine overheating Refer to “Overheating” section.

Low compression Previously outlined.

Surge

(Engine power vari-

ation under steady

throttle or cruise.

Feels like vehicle

speeds up and

down with no

change in accelera-

tor pedal.)Leaky or loosely connected high-tension cord High-tension cords in Section 6F1.

Faulty spark plug (excess carbon deposits,

improper gap, and burned electrodes, etc.)Spark plugs in Section 6F1.

Variable fuel pressure Diagnostic Flow Table B-3.

Kinky or damaged fuel hose and lines

Faulty fuel pump (clogged fuel filter)

Malfunctioning EGR valve EGR system in Section 6E1.

Poor performance of MAP sensor MAP sensor in Section 6E1.

Faulty fuel injector Diagnostic Flow Table B-1.

Faulty ECM Condition Possible Cause Correction

Page 398 of 698

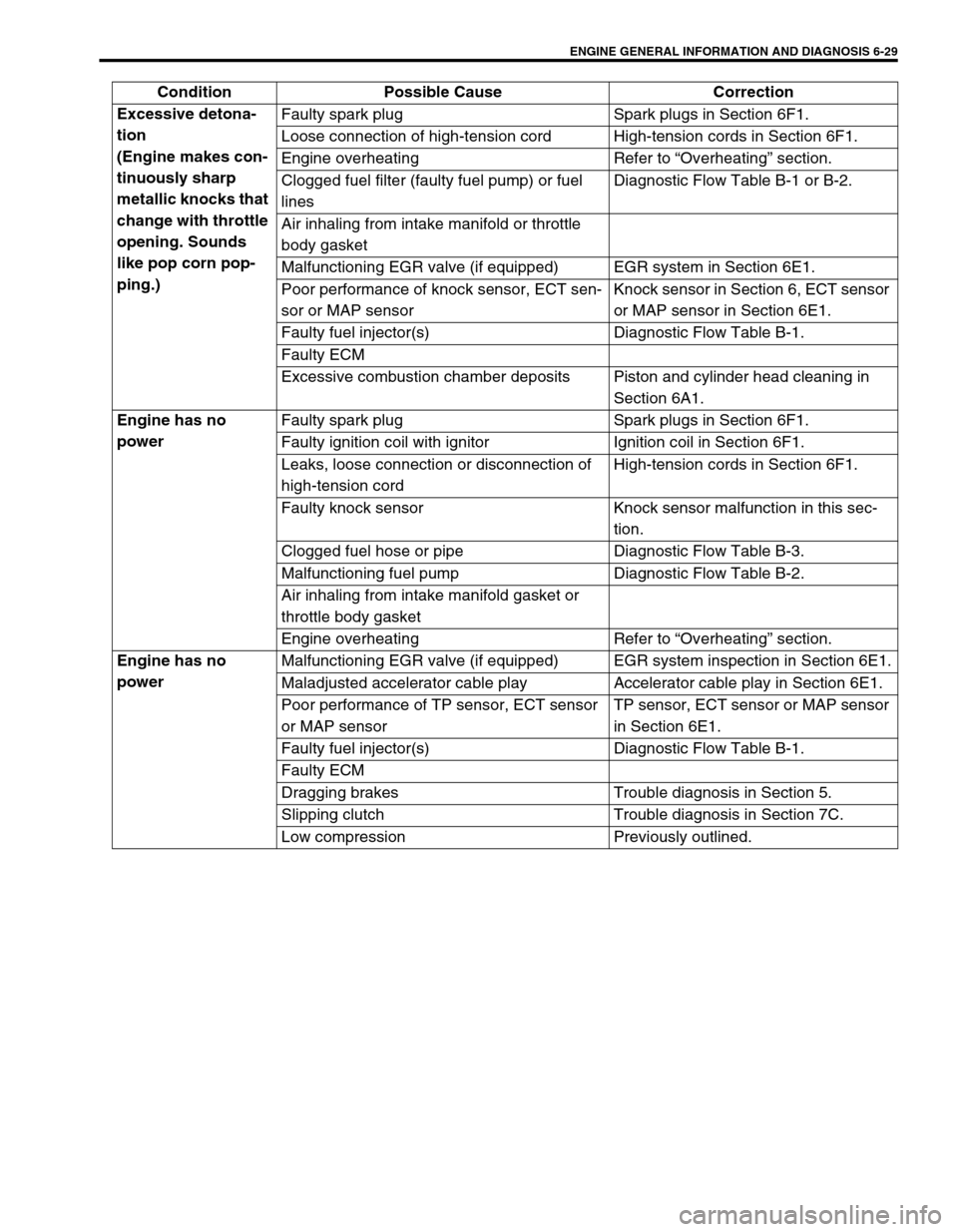

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-29

Excessive detona-

tion

(Engine makes con-

tinuously sharp

metallic knocks that

change with throttle

opening. Sounds

like pop corn pop-

ping.)Faulty spark plug Spark plugs in Section 6F1.

Loose connection of high-tension cord High-tension cords in Section 6F1.

Engine overheating Refer to “Overheating” section.

Clogged fuel filter (faulty fuel pump) or fuel

linesDiagnostic Flow Table B-1 or B-2.

Air inhaling from intake manifold or throttle

body gasket

Malfunctioning EGR valve (if equipped) EGR system in Section 6E1.

Poor performance of knock sensor, ECT sen-

sor or MAP sensorKnock sensor in Section 6, ECT sensor

or MAP sensor in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Faulty ECM

Excessive combustion chamber deposits Piston and cylinder head cleaning in

Section 6A1.

Engine has no

powerFaulty spark plug Spark plugs in Section 6F1.

Faulty ignition coil with ignitor Ignition coil in Section 6F1.

Leaks, loose connection or disconnection of

high-tension cordHigh-tension cords in Section 6F1.

Faulty knock sensor Knock sensor malfunction in this sec-

tion.

Clogged fuel hose or pipe Diagnostic Flow Table B-3.

Malfunctioning fuel pump Diagnostic Flow Table B-2.

Air inhaling from intake manifold gasket or

throttle body gasket

Engine overheating Refer to “Overheating” section.

Engine has no

powerMalfunctioning EGR valve (if equipped) EGR system inspection in Section 6E1.

Maladjusted accelerator cable play Accelerator cable play in Section 6E1.

Poor performance of TP sensor, ECT sensor

or MAP sensorTP sensor, ECT sensor or MAP sensor

in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Faulty ECM

Dragging brakes Trouble diagnosis in Section 5.

Slipping clutch Trouble diagnosis in Section 7C.

Low compression Previously outlined. Condition Possible Cause Correction

Page 399 of 698

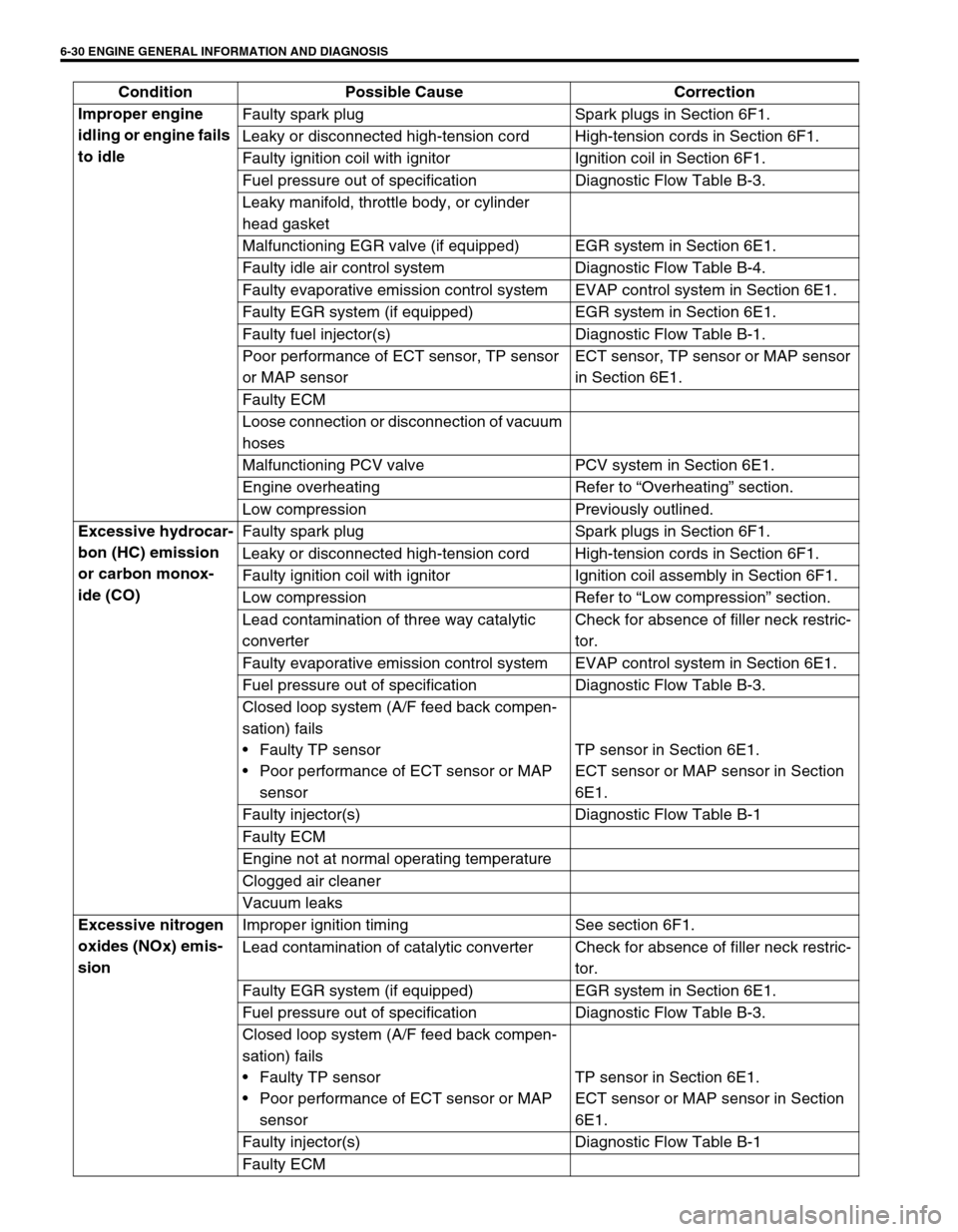

6-30 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Improper engine

idling or engine fails

to idleFaulty spark plug Spark plugs in Section 6F1.

Leaky or disconnected high-tension cord High-tension cords in Section 6F1.

Faulty ignition coil with ignitor Ignition coil in Section 6F1.

Fuel pressure out of specification Diagnostic Flow Table B-3.

Leaky manifold, throttle body, or cylinder

head gasket

Malfunctioning EGR valve (if equipped) EGR system in Section 6E1.

Faulty idle air control system Diagnostic Flow Table B-4.

Faulty evaporative emission control system EVAP control system in Section 6E1.

Faulty EGR system (if equipped) EGR system in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Poor performance of ECT sensor, TP sensor

or MAP sensorECT sensor, TP sensor or MAP sensor

in Section 6E1.

Faulty ECM

Loose connection or disconnection of vacuum

hoses

Malfunctioning PCV valve PCV system in Section 6E1.

Engine overheating Refer to “Overheating” section.

Low compression Previously outlined.

Excessive hydrocar-

bon (HC) emission

or carbon monox-

ide (CO)Faulty spark plug Spark plugs in Section 6F1.

Leaky or disconnected high-tension cord High-tension cords in Section 6F1.

Faulty ignition coil with ignitor Ignition coil assembly in Section 6F1.

Low compression Refer to “Low compression” section.

Lead contamination of three way catalytic

converterCheck for absence of filler neck restric-

tor.

Faulty evaporative emission control system EVAP control system in Section 6E1.

Fuel pressure out of specification Diagnostic Flow Table B-3.

Closed loop system (A/F feed back compen-

sation) fails

Faulty TP sensor

Poor performance of ECT sensor or MAP

sensorTP sensor in Section 6E1.

ECT sensor or MAP sensor in Section

6E1.

Faulty injector(s) Diagnostic Flow Table B-1

Faulty ECM

Engine not at normal operating temperature

Clogged air cleaner

Vacuum leaks

Excessive nitrogen

oxides (NOx) emis-

sionImproper ignition timing See section 6F1.

Lead contamination of catalytic converter Check for absence of filler neck restric-

tor.

Faulty EGR system (if equipped) EGR system in Section 6E1.

Fuel pressure out of specification Diagnostic Flow Table B-3.

Closed loop system (A/F feed back compen-

sation) fails

Faulty TP sensor

Poor performance of ECT sensor or MAP

sensorTP sensor in Section 6E1.

ECT sensor or MAP sensor in Section

6E1.

Faulty injector(s) Diagnostic Flow Table B-1

Faulty ECM Condition Possible Cause Correction

Page 426 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-57

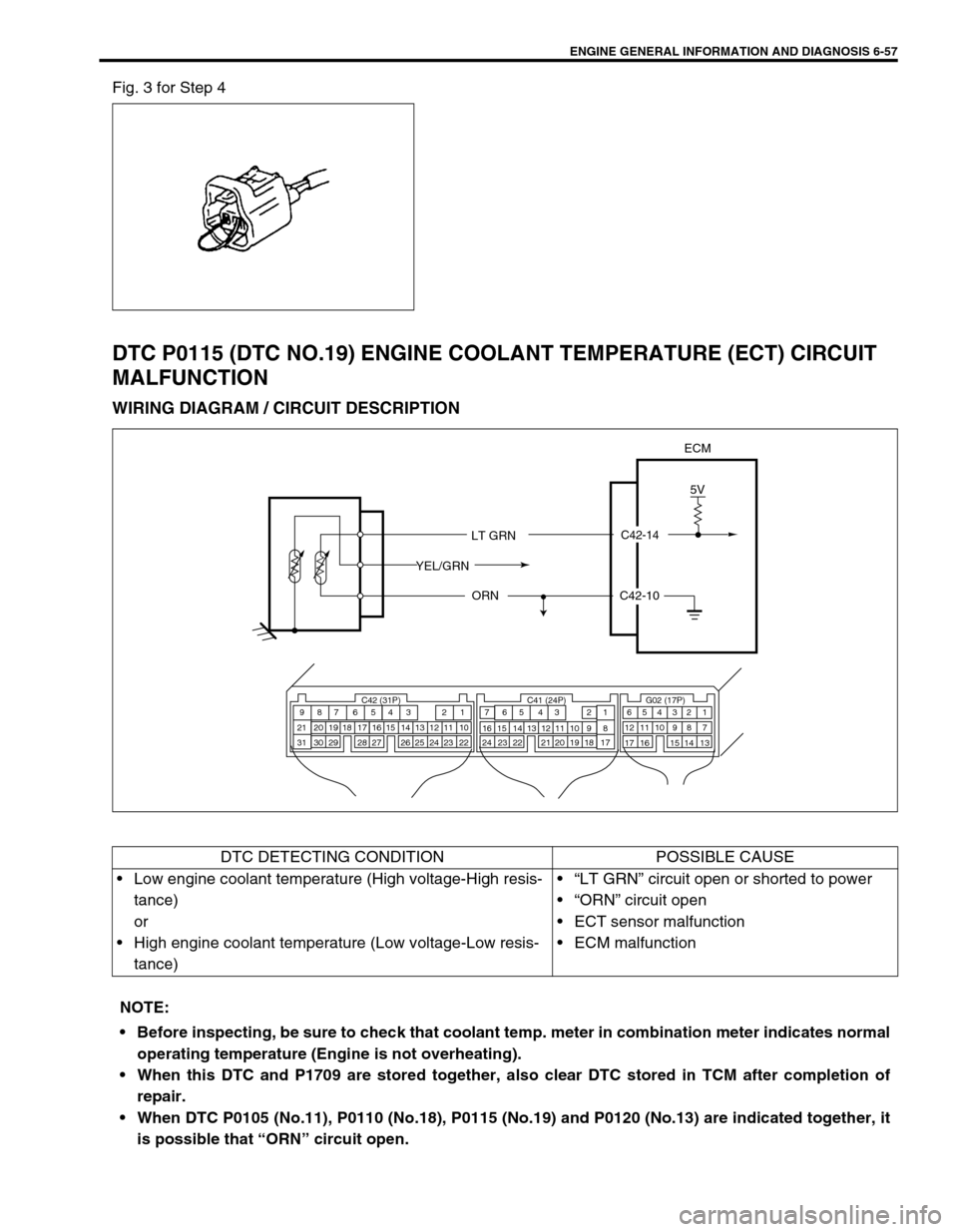

Fig. 3 for Step 4

DTC P0115 (DTC NO.19) ENGINE COOLANT TEMPERATURE (ECT) CIRCUIT

MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

C42-14

5V

ECM

LT GRN

ORN

YEL/GRN

C42-10

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

DTC DETECTING CONDITION POSSIBLE CAUSE

Low engine coolant temperature (High voltage-High resis-

tance)

or

High engine coolant temperature (Low voltage-Low resis-

tance)“LT GRN” circuit open or shorted to power

“ORN” circuit open

ECT sensor malfunction

ECM malfunction

NOTE:

Before inspecting, be sure to check that coolant temp. meter in combination meter indicates normal

operating temperature (Engine is not overheating).

When this DTC and P1709 are stored together, also clear DTC stored in TCM after completion of

repair.

When DTC P0105 (No.11), P0110 (No.18), P0115 (No.19) and P0120 (No.13) are indicated together, it

is possible that “ORN” circuit open.

Page 451 of 698

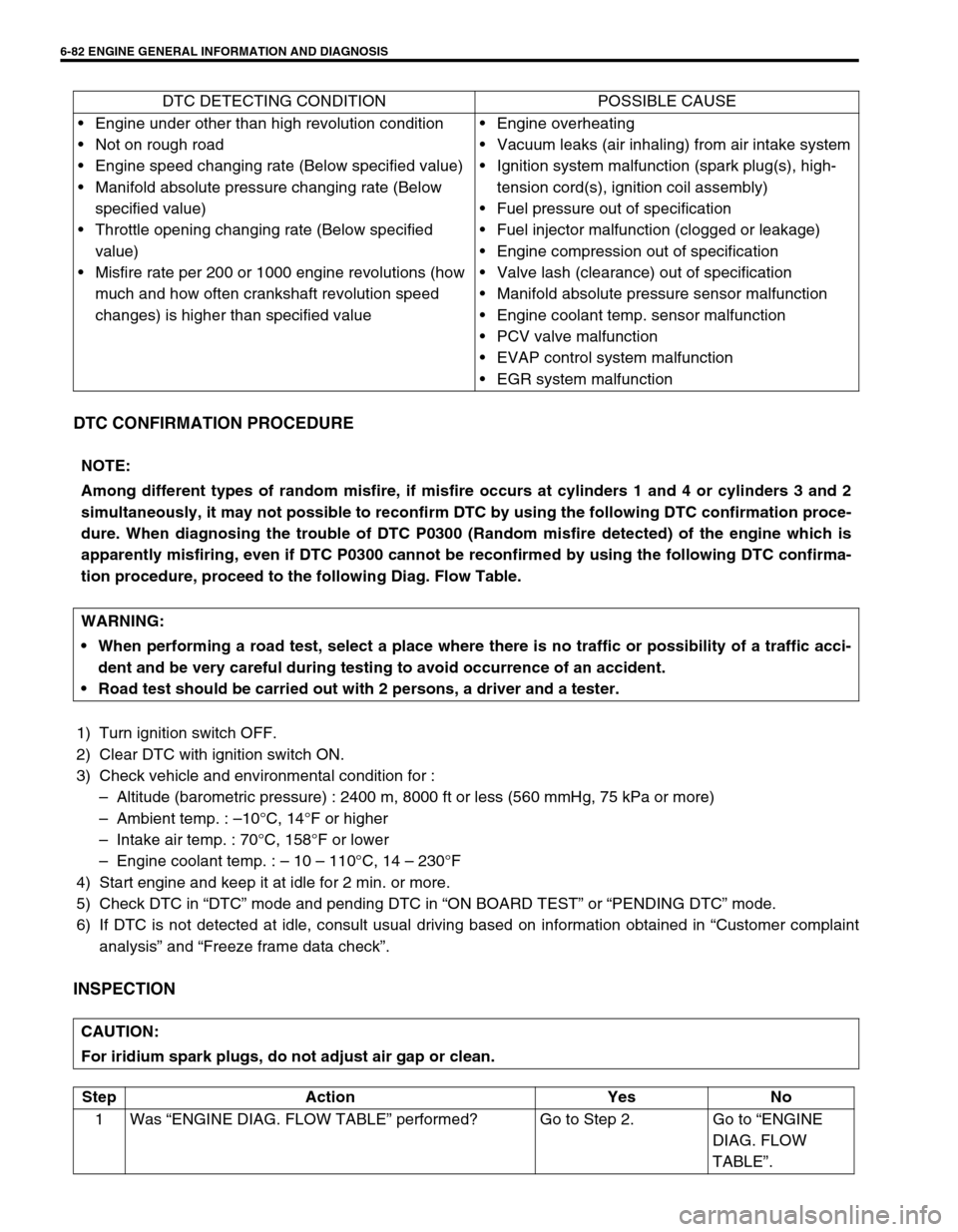

6-82 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10°C, 14°F or higher

–Intake air temp. : 70°C, 158°F or lower

–Engine coolant temp. : – 10 – 110°C, 14 – 230°F

4) Start engine and keep it at idle for 2 min. or more.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

6) If DTC is not detected at idle, consult usual driving based on information obtained in “Customer complaint

analysis” and “Freeze frame data check”.

INSPECTION

DTC DETECTING CONDITION POSSIBLE CAUSE

Engine under other than high revolution condition

Not on rough road

Engine speed changing rate (Below specified value)

Manifold absolute pressure changing rate (Below

specified value)

Throttle opening changing rate (Below specified

value)

Misfire rate per 200 or 1000 engine revolutions (how

much and how often crankshaft revolution speed

changes) is higher than specified valueEngine overheating

Vacuum leaks (air inhaling) from air intake system

Ignition system malfunction (spark plug(s), high-

tension cord(s), ignition coil assembly)

Fuel pressure out of specification

Fuel injector malfunction (clogged or leakage)

Engine compression out of specification

Valve lash (clearance) out of specification

Manifold absolute pressure sensor malfunction

Engine coolant temp. sensor malfunction

PCV valve malfunction

EVAP control system malfunction

EGR system malfunction

NOTE:

Among different types of random misfire, if misfire occurs at cylinders 1 and 4 or cylinders 3 and 2

simultaneously, it may not possible to reconfirm DTC by using the following DTC confirmation proce-

dure. When diagnosing the trouble of DTC P0300 (Random misfire detected) of the engine which is

apparently misfiring, even if DTC P0300 cannot be reconfirmed by using the following DTC confirma-

tion procedure, proceed to the following Diag. Flow Table.

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester.

CAUTION:

For iridium spark plugs, do not adjust air gap or clean.

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” performed? Go to Step 2. Go to “ENGINE

DIAG. FLOW

TABLE”.