Air SUZUKI SWIFT 2000 1.G Transmission Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 57 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-15

1. CUSTOMER COMPLAINT ANALYSIS

Record details of the problem (failure, complaint) and how it occurred as described by the customer. For this

purpose, use of such a questionnaire form as shown below will facilitate collecting information to the point

required for proper analysis and diagnosis.

CUSTOMER QUESTIONNAIRE (EXAMPLE)

NOTE:

The above form is a standard sample. It should be modified according to conditions

characteristic of each market.

Page 59 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-17

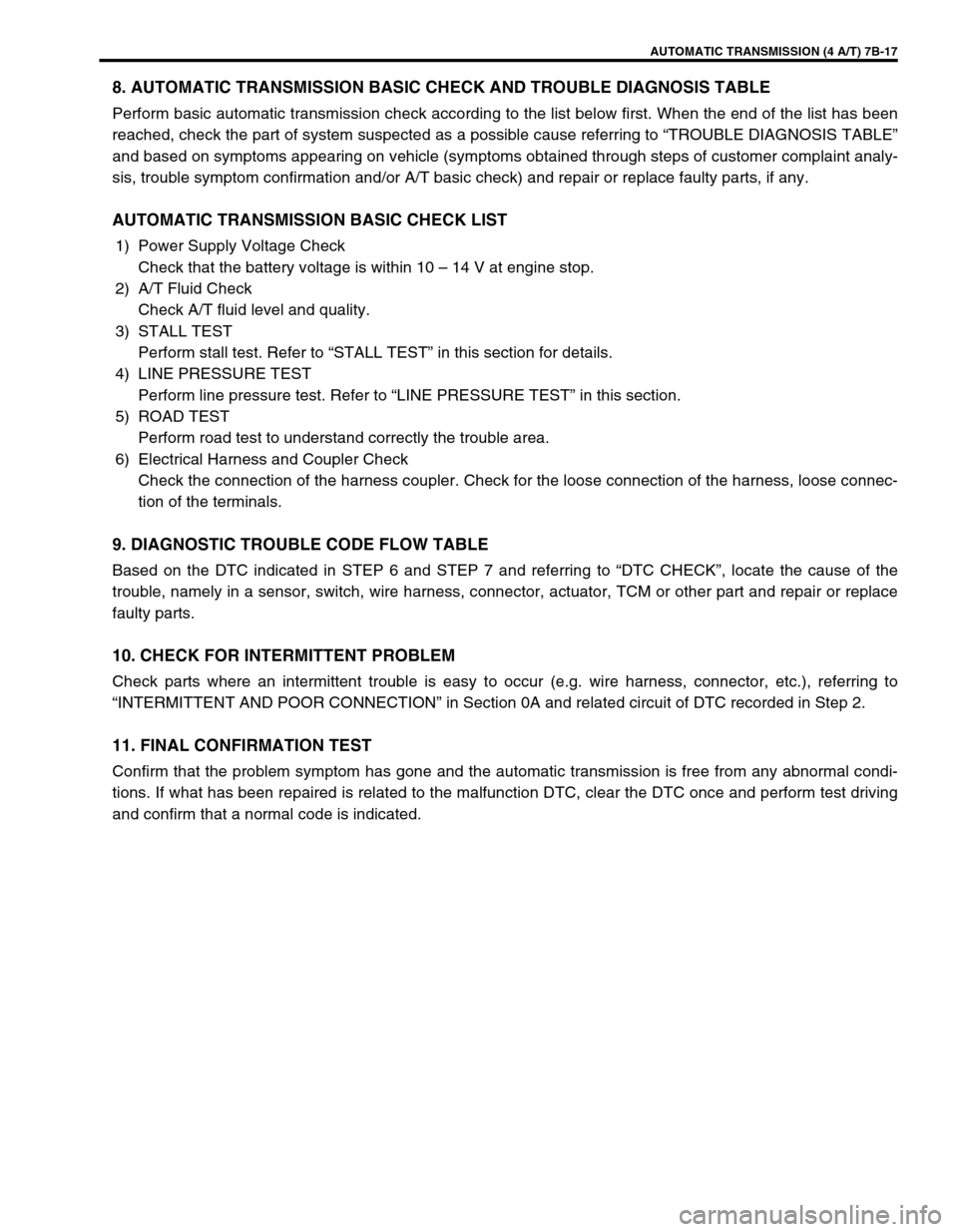

8. AUTOMATIC TRANSMISSION BASIC CHECK AND TROUBLE DIAGNOSIS TABLE

Perform basic automatic transmission check according to the list below first. When the end of the list has been

reached, check the part of system suspected as a possible cause referring to “TROUBLE DIAGNOSIS TABLE”

and based on symptoms appearing on vehicle (symptoms obtained through steps of customer complaint analy-

sis, trouble symptom confirmation and/or A/T basic check) and repair or replace faulty parts, if any.

AUTOMATIC TRANSMISSION BASIC CHECK LIST

1) Power Supply Voltage Check

Check that the battery voltage is within 10 – 14 V at engine stop.

2) A/T Fluid Check

Check A/T fluid level and quality.

3) STALL TEST

Perform stall test. Refer to “STALL TEST” in this section for details.

4) LINE PRESSURE TEST

Perform line pressure test. Refer to “LINE PRESSURE TEST” in this section.

5) ROAD TEST

Perform road test to understand correctly the trouble area.

6) Electrical Harness and Coupler Check

Check the connection of the harness coupler. Check for the loose connection of the harness, loose connec-

tion of the terminals.

9. DIAGNOSTIC TROUBLE CODE FLOW TABLE

Based on the DTC indicated in STEP 6 and STEP 7 and referring to “DTC CHECK”, locate the cause of the

trouble, namely in a sensor, switch, wire harness, connector, actuator, TCM or other part and repair or replace

faulty parts.

10. CHECK FOR INTERMITTENT PROBLEM

Check parts where an intermittent trouble is easy to occur (e.g. wire harness, connector, etc.), referring to

“INTERMITTENT AND POOR CONNECTION” in Section 0A and related circuit of DTC recorded in Step 2.

11. FINAL CONFIRMATION TEST

Confirm that the problem symptom has gone and the automatic transmission is free from any abnormal condi-

tions. If what has been repaired is related to the malfunction DTC, clear the DTC once and perform test driving

and confirm that a normal code is indicated.

Page 60 of 447

7B-18 AUTOMATIC TRANSMISSION (4 A/T)

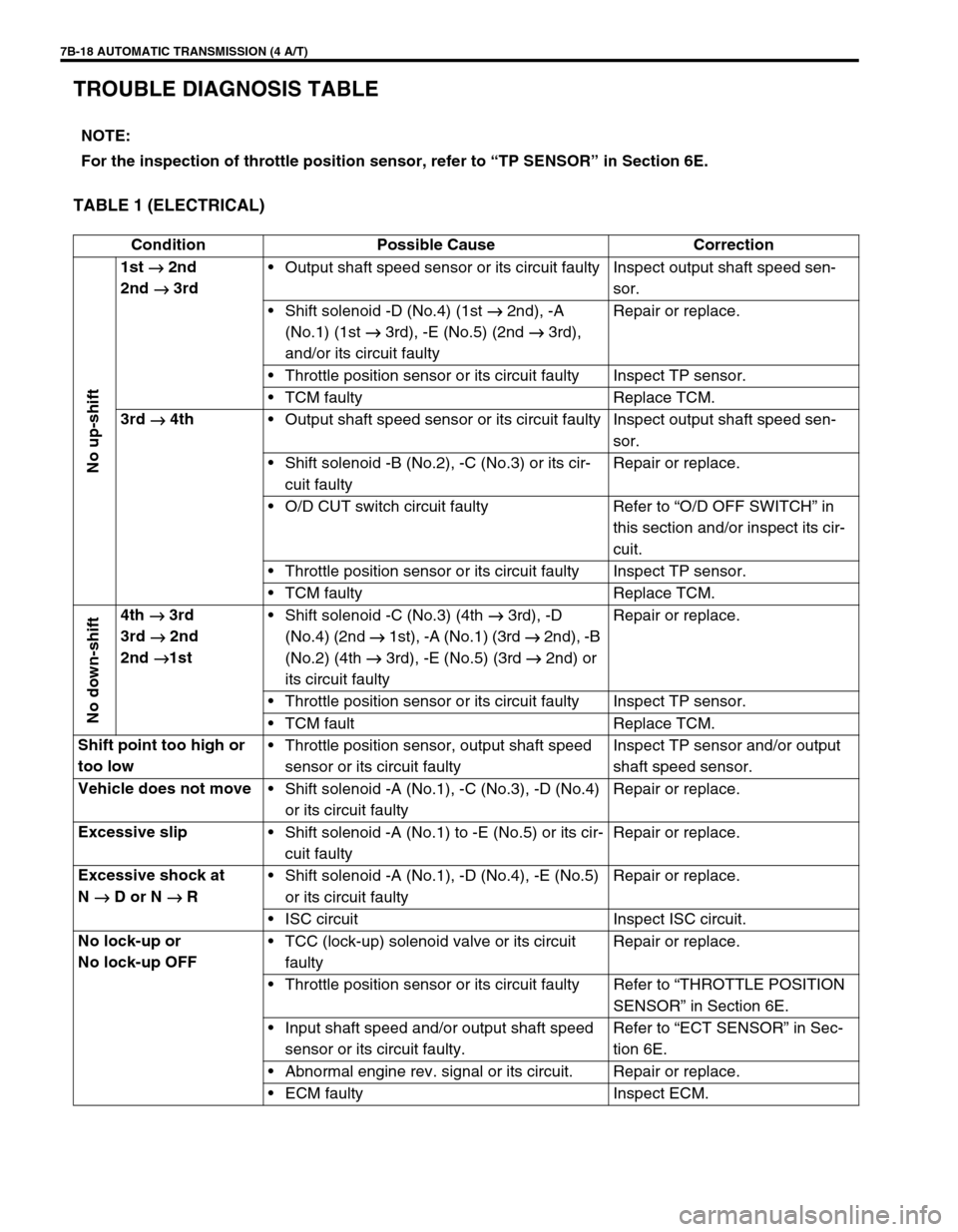

TROUBLE DIAGNOSIS TABLE

TABLE 1 (ELECTRICAL)

NOTE:

For the inspection of throttle position sensor, refer to “TP SENSOR” in Section 6E.

Condition Possible Cause Correction

No up-shift

1st

→

→→ → 2nd

2nd

→

→→ → 3rdOutput shaft speed sensor or its circuit faulty Inspect output shaft speed sen-

sor.

Shift solenoid -D (No.4) (1st →

→→ →

2nd), -A

(No.1) (1st →

→→ →

3rd), -E (No.5) (2nd →

→→ →

3rd),

and/or its circuit faultyRepair or replace.

Throttle position sensor or its circuit faulty Inspect TP sensor.

TCM faulty Replace TCM.

3rd

→

→→ → 4th

Output shaft speed sensor or its circuit faulty Inspect output shaft speed sen-

sor.

Shift solenoid -B (No.2), -C (No.3) or its cir-

cuit faultyRepair or replace.

O/D CUT switch circuit faulty Refer to “O/D OFF SWITCH” in

this section and/or inspect its cir-

cuit.

Throttle position sensor or its circuit faulty Inspect TP sensor.

TCM faulty Replace TCM.

No down-shift

4th

→

→→ → 3rd

3rd

→

→→ → 2nd

2nd

→

→→ →1stShift solenoid -C (No.3) (4th →

→→ →

3rd), -D

(No.4) (2nd →

→→ →

1st), -A (No.1) (3rd →

→→ →

2nd), -B

(No.2) (4th →

→→ →

3rd), -E (No.5) (3rd →

→→ →

2nd) or

its circuit faultyRepair or replace.

Throttle position sensor or its circuit faulty Inspect TP sensor.

TCM fault Replace TCM.

Shift point too high or

too lowThrottle position sensor, output shaft speed

sensor or its circuit faultyInspect TP sensor and/or output

shaft speed sensor.

Vehicle does not move

Shift solenoid -A (No.1), -C (No.3), -D (No.4)

or its circuit faultyRepair or replace.

Excessive slip

Shift solenoid -A (No.1) to -E (No.5) or its cir-

cuit faultyRepair or replace.

Excessive shock at

N

→

→→ → D or N

→

→→ → RShift solenoid -A (No.1), -D (No.4), -E (No.5)

or its circuit faultyRepair or replace.

ISC circuit Inspect ISC circuit.

No lock-up or

No lock-up OFFTCC (lock-up) solenoid valve or its circuit

faultyRepair or replace.

Throttle position sensor or its circuit faulty Refer to “THROTTLE POSITION

SENSOR” in Section 6E.

Input shaft speed and/or output shaft speed

sensor or its circuit faulty.Refer to “ECT SENSOR” in Sec-

tion 6E.

Abnormal engine rev. signal or its circuit. Repair or replace.

ECM faulty Inspect ECM.

Page 61 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-19

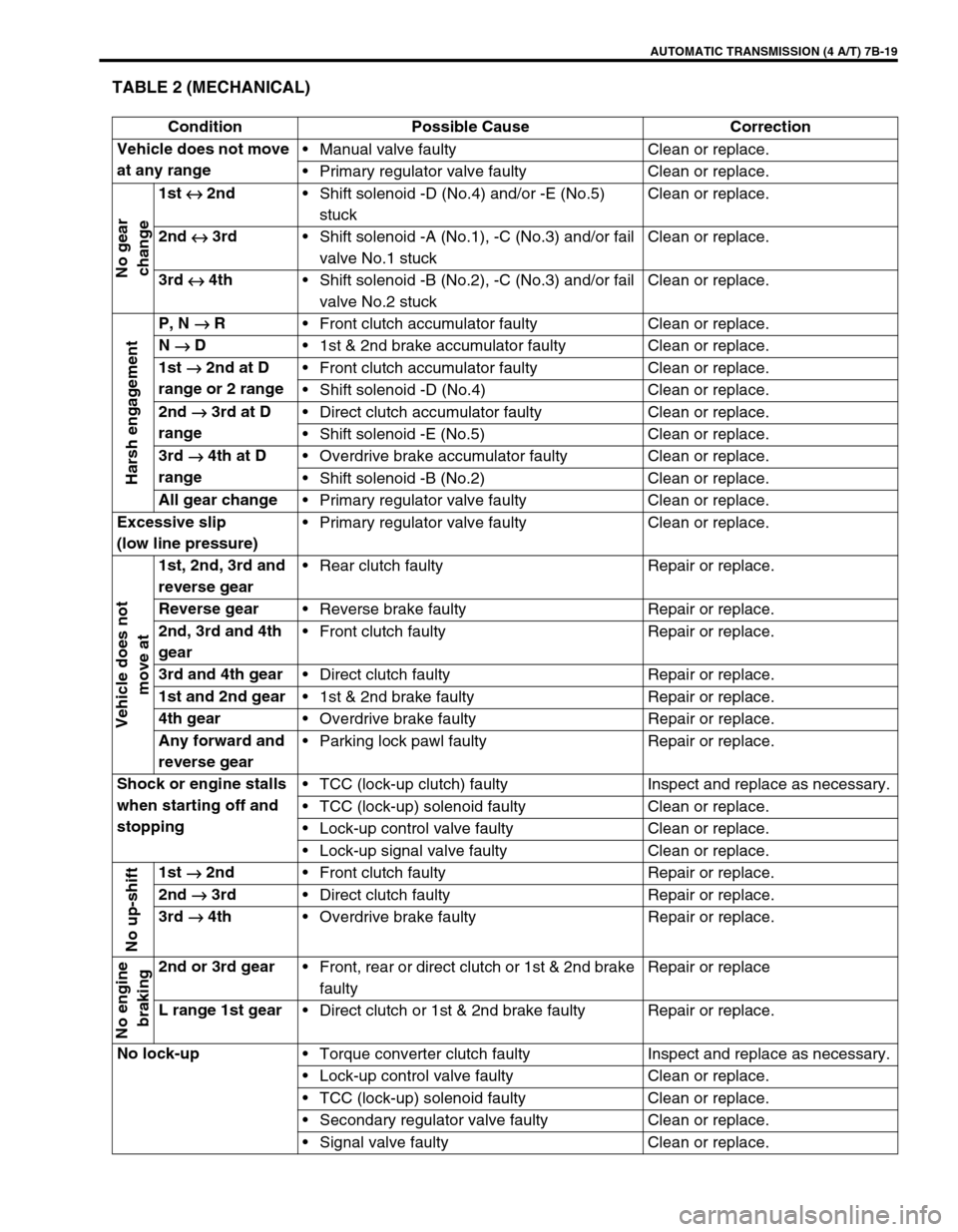

TABLE 2 (MECHANICAL)

Condition Possible Cause Correction

Vehicle does not move

at any rangeManual valve faulty Clean or replace.

Primary regulator valve faulty Clean or replace.

No gear

change

1st

↔

↔↔ ↔ 2nd

Shift solenoid -D (No.4) and/or -E (No.5)

stuck Clean or replace.

2nd

↔

↔↔ ↔ 3rd

Shift solenoid -A (No.1), -C (No.3) and/or fail

valve No.1 stuckClean or replace.

3rd

↔

↔↔ ↔ 4th

Shift solenoid -B (No.2), -C (No.3) and/or fail

valve No.2 stuckClean or replace.

Harsh engagement

P, N

→

→→ → R

Front clutch accumulator faulty Clean or replace.

N

→

→→ → D

1st & 2nd brake accumulator faulty Clean or replace.

1st

→

→→ → 2nd at D

range or 2 rangeFront clutch accumulator faulty Clean or replace.

Shift solenoid -D (No.4) Clean or replace.

2nd

→

→→ → 3rd at D

rangeDirect clutch accumulator faulty Clean or replace.

Shift solenoid -E (No.5) Clean or replace.

3rd

→

→→ → 4th at D

rangeOverdrive brake accumulator faulty Clean or replace.

Shift solenoid -B (No.2) Clean or replace.

All gear change

Primary regulator valve faulty Clean or replace.

Excessive slip

(low line pressure)Primary regulator valve faulty Clean or replace.

Vehicle does not

move at

1st, 2nd, 3rd and

reverse gearRear clutch faulty Repair or replace.

Reverse gear

Reverse brake faulty Repair or replace.

2nd, 3rd and 4th

gearFront clutch faulty Repair or replace.

3rd and 4th gear

Direct clutch faulty Repair or replace.

1st and 2nd gear

1st & 2nd brake faulty Repair or replace.

4th gear

Overdrive brake faulty Repair or replace.

Any forward and

reverse gearParking lock pawl faulty Repair or replace.

Shock or engine stalls

when starting off and

stoppingTCC (lock-up clutch) faulty Inspect and replace as necessary.

TCC (lock-up) solenoid faulty Clean or replace.

Lock-up control valve faulty Clean or replace.

Lock-up signal valve faulty Clean or replace.

No up-shift

1st

→

→→ → 2nd

Front clutch faulty Repair or replace.

2nd

→

→→ → 3rd

Direct clutch faulty Repair or replace.

3rd

→

→→ → 4th

Overdrive brake faulty Repair or replace.

No engine

braking

2nd or 3rd gear

Front, rear or direct clutch or 1st & 2nd brake

faultyRepair or replace

L range 1st gear

Direct clutch or 1st & 2nd brake faulty Repair or replace.

No lock-up

Torque converter clutch faulty Inspect and replace as necessary.

Lock-up control valve faulty Clean or replace.

TCC (lock-up) solenoid faulty Clean or replace.

Secondary regulator valve faulty Clean or replace.

Signal valve faulty Clean or replace.

Page 79 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-37

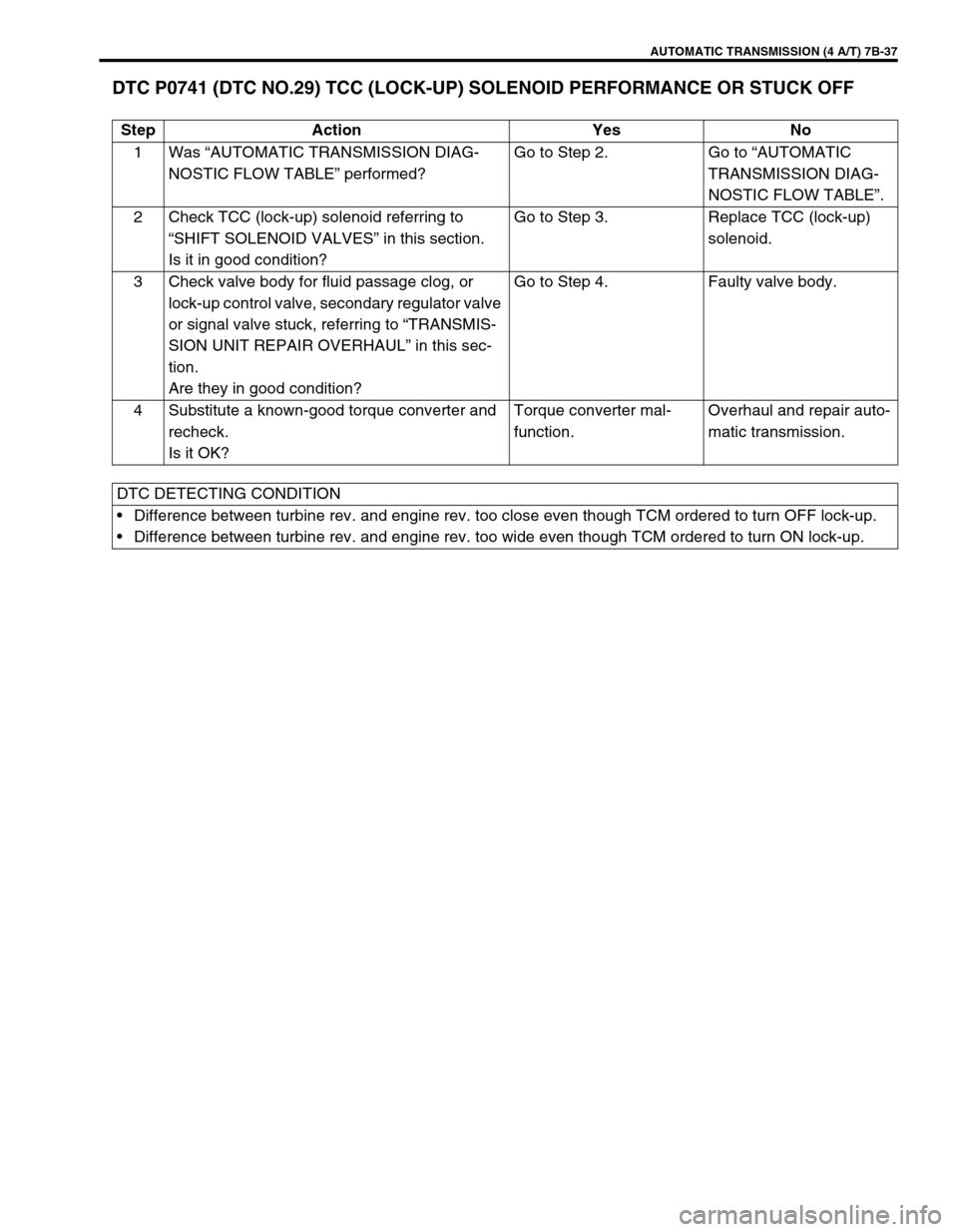

DTC P0741 (DTC NO.29) TCC (LOCK-UP) SOLENOID PERFORMANCE OR STUCK OFF

Step Action Yes No

1Was “AUTOMATIC TRANSMISSION DIAG-

NOSTIC FLOW TABLE” performed?Go to Step 2. Go to “AUTOMATIC

TRANSMISSION DIAG-

NOSTIC FLOW TABLE”.

2 Check TCC (lock-up) solenoid referring to

“SHIFT SOLENOID VALVES” in this section.

Is it in good condition?Go to Step 3. Replace TCC (lock-up)

solenoid.

3 Check valve body for fluid passage clog, or

lock-up control valve, secondary regulator valve

or signal valve stuck, referring to “TRANSMIS-

SION UNIT REPAIR OVERHAUL” in this sec-

tion.

Are they in good condition?Go to Step 4. Faulty valve body.

4 Substitute a known-good torque converter and

recheck.

Is it OK?Torque converter mal-

function.Overhaul and repair auto-

matic transmission.

DTC DETECTING CONDITION

Difference between turbine rev. and engine rev. too close even though TCM ordered to turn OFF lock-up.

Difference between turbine rev. and engine rev. too wide even though TCM ordered to turn ON lock-up.

Page 83 of 447

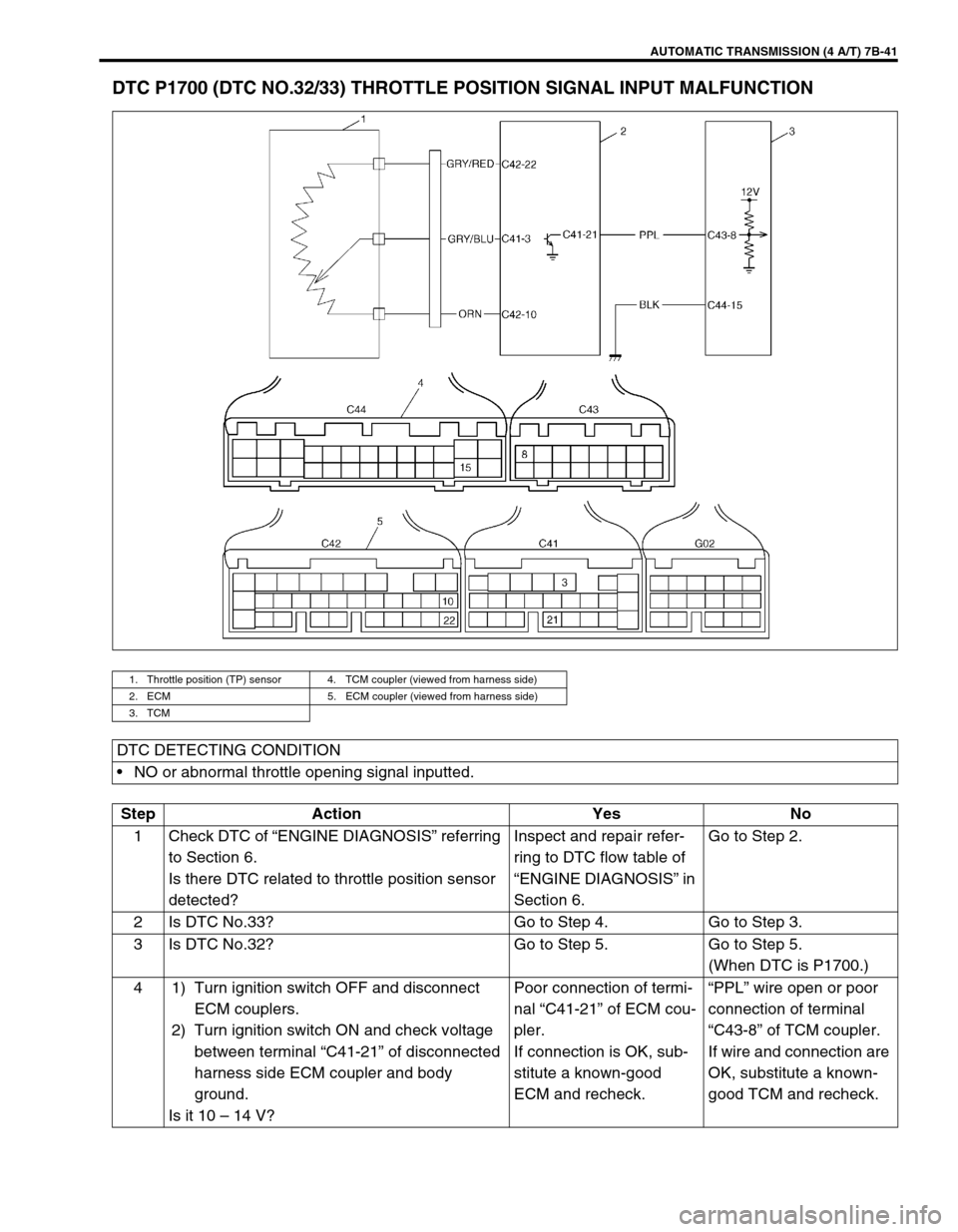

AUTOMATIC TRANSMISSION (4 A/T) 7B-41

DTC P1700 (DTC NO.32/33) THROTTLE POSITION SIGNAL INPUT MALFUNCTION

1. Throttle position (TP) sensor 4. TCM coupler (viewed from harness side)

2. ECM 5. ECM coupler (viewed from harness side)

3. TCM

DTC DETECTING CONDITION

NO or abnormal throttle opening signal inputted.

Step Action Yes No

1 Check DTC of “ENGINE DIAGNOSIS” referring

to Section 6.

Is there DTC related to throttle position sensor

detected?Inspect and repair refer-

ring to DTC flow table of

“ENGINE DIAGNOSIS” in

Section 6.Go to Step 2.

2 Is DTC No.33? Go to Step 4. Go to Step 3.

3 Is DTC No.32? Go to Step 5. Go to Step 5.

(When DTC is P1700.)

4 1) Turn ignition switch OFF and disconnect

ECM couplers.

2) Turn ignition switch ON and check voltage

between terminal “C41-21” of disconnected

harness side ECM coupler and body

ground.

Is it 10 – 14 V?Poor connection of termi-

nal “C41-21” of ECM cou-

pler.

If connection is OK, sub-

stitute a known-good

ECM and recheck.“PPL” wire open or poor

connection of terminal

“C43-8” of TCM coupler.

If wire and connection are

OK, substitute a known-

good TCM and recheck.

Page 87 of 447

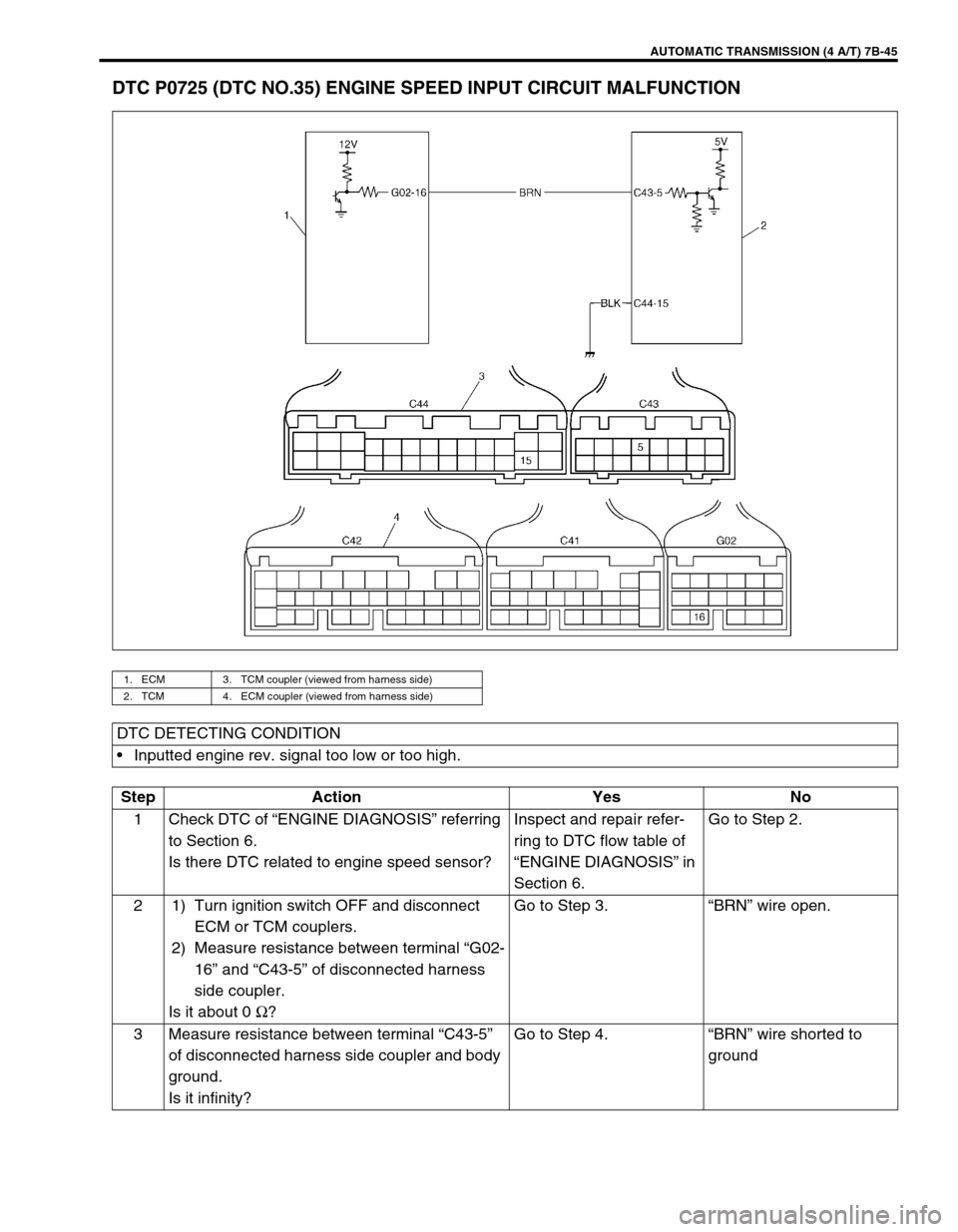

AUTOMATIC TRANSMISSION (4 A/T) 7B-45

DTC P0725 (DTC NO.35) ENGINE SPEED INPUT CIRCUIT MALFUNCTION

1. ECM 3. TCM coupler (viewed from harness side)

2. TCM 4. ECM coupler (viewed from harness side)

DTC DETECTING CONDITION

Inputted engine rev. signal too low or too high.

Step Action Yes No

1 Check DTC of “ENGINE DIAGNOSIS” referring

to Section 6.

Is there DTC related to engine speed sensor?Inspect and repair refer-

ring to DTC flow table of

“ENGINE DIAGNOSIS” in

Section 6.Go to Step 2.

2 1) Turn ignition switch OFF and disconnect

ECM or TCM couplers.

2) Measure resistance between terminal “G02-

16” and “C43-5” of disconnected harness

side coupler.

Is it about 0 Ω

?Go to Step 3.“BRN” wire open.

3 Measure resistance between terminal “C43-5”

of disconnected harness side coupler and body

ground.

Is it infinity?Go to Step 4.“BRN” wire shorted to

ground

Page 93 of 447

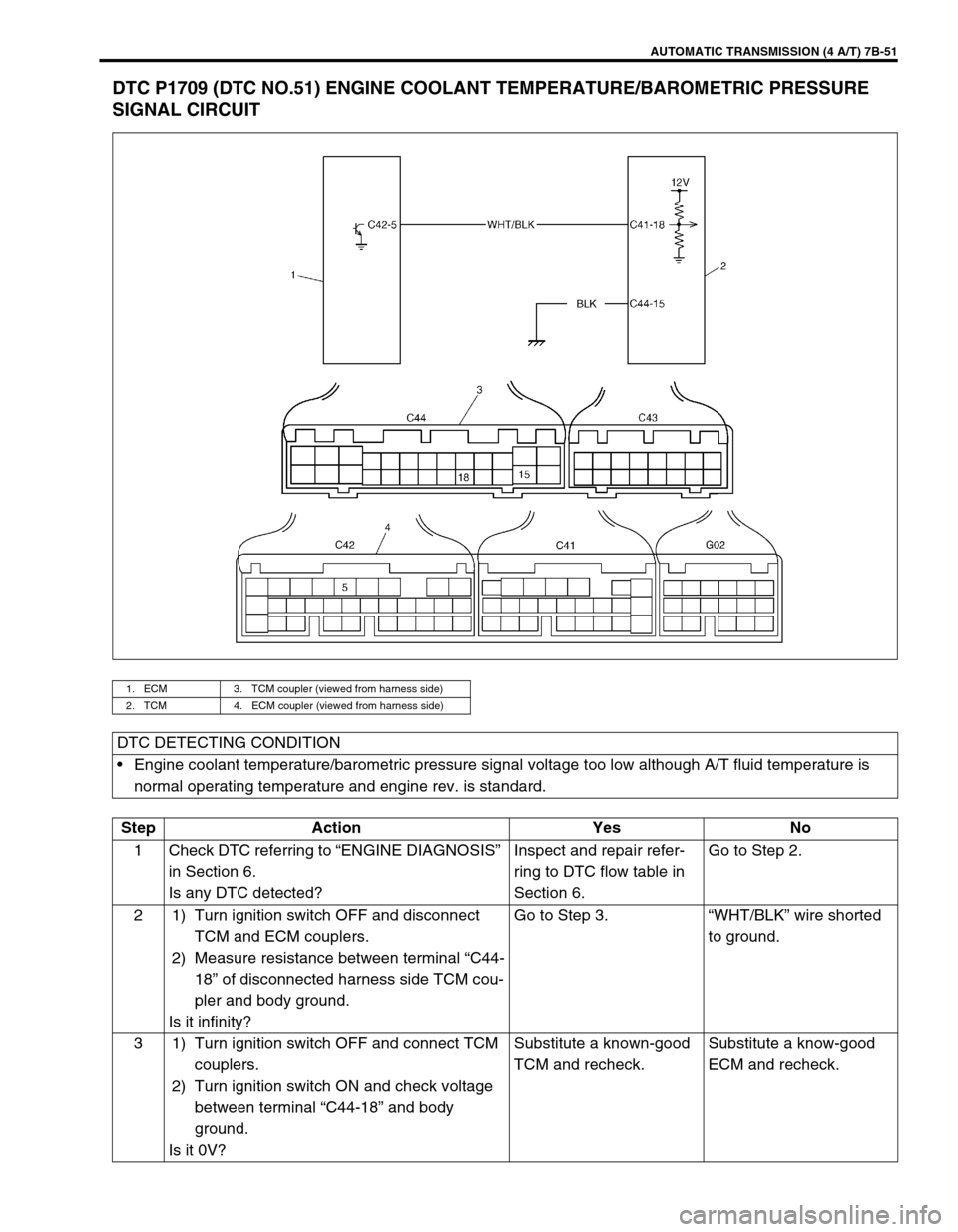

AUTOMATIC TRANSMISSION (4 A/T) 7B-51

DTC P1709 (DTC NO.51) ENGINE COOLANT TEMPERATURE/BAROMETRIC PRESSURE

SIGNAL CIRCUIT

1. ECM 3. TCM coupler (viewed from harness side)

2. TCM 4. ECM coupler (viewed from harness side)

DTC DETECTING CONDITION

Engine coolant temperature/barometric pressure signal voltage too low although A/T fluid temperature is

normal operating temperature and engine rev. is standard.

Step Action Yes No

1 Check DTC referring to “ENGINE DIAGNOSIS”

in Section 6.

Is any DTC detected?Inspect and repair refer-

ring to DTC flow table in

Section 6.Go to Step 2.

2 1) Turn ignition switch OFF and disconnect

TCM and ECM couplers.

2) Measure resistance between terminal “C44-

18” of disconnected harness side TCM cou-

pler and body ground.

Is it infinity?Go to Step 3.“WHT/BLK” wire shorted

to ground.

3 1) Turn ignition switch OFF and connect TCM

couplers.

2) Turn ignition switch ON and check voltage

between terminal “C44-18” and body

ground.

Is it 0V?Substitute a known-good

TCM and recheck.Substitute a know-good

ECM and recheck.

Page 98 of 447

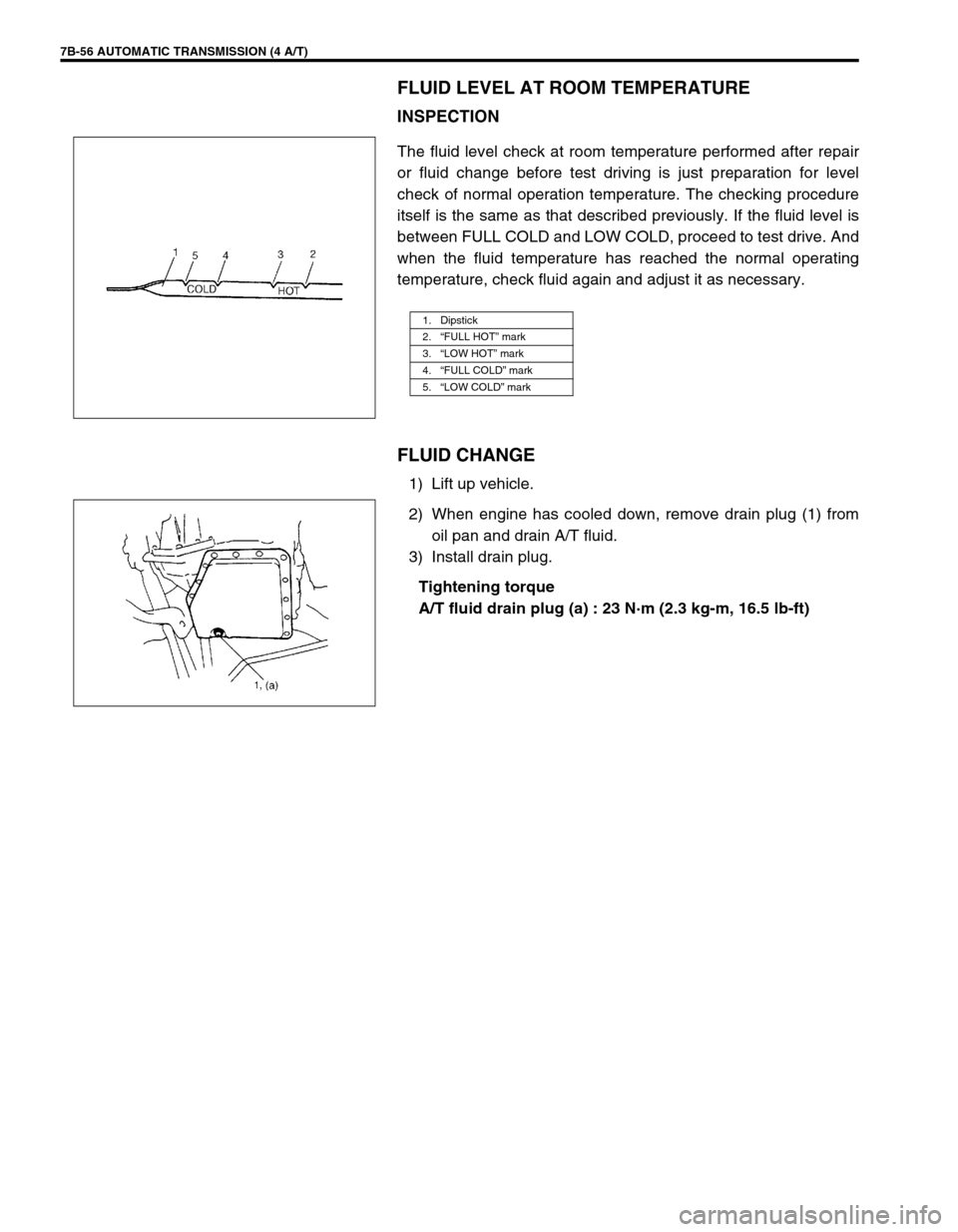

7B-56 AUTOMATIC TRANSMISSION (4 A/T)

FLUID LEVEL AT ROOM TEMPERATURE

INSPECTION

The fluid level check at room temperature performed after repair

or fluid change before test driving is just preparation for level

check of normal operation temperature. The checking procedure

itself is the same as that described previously. If the fluid level is

between FULL COLD and LOW COLD, proceed to test drive. And

when the fluid temperature has reached the normal operating

temperature, check fluid again and adjust it as necessary.

FLUID CHANGE

1) Lift up vehicle.

2) When engine has cooled down, remove drain plug (1) from

oil pan and drain A/T fluid.

3) Install drain plug.

Tightening torque

A/T fluid drain plug (a) : 23 N·m (2.3 kg-m, 16.5 lb-ft)

1. Dipstick

2.“FULL HOT” mark

3.“LOW HOT” mark

4.“FULL COLD” mark

5.“LOW COLD” mark

Page 111 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-69

TRANSMISSION CONTROL MODULE (TCM)

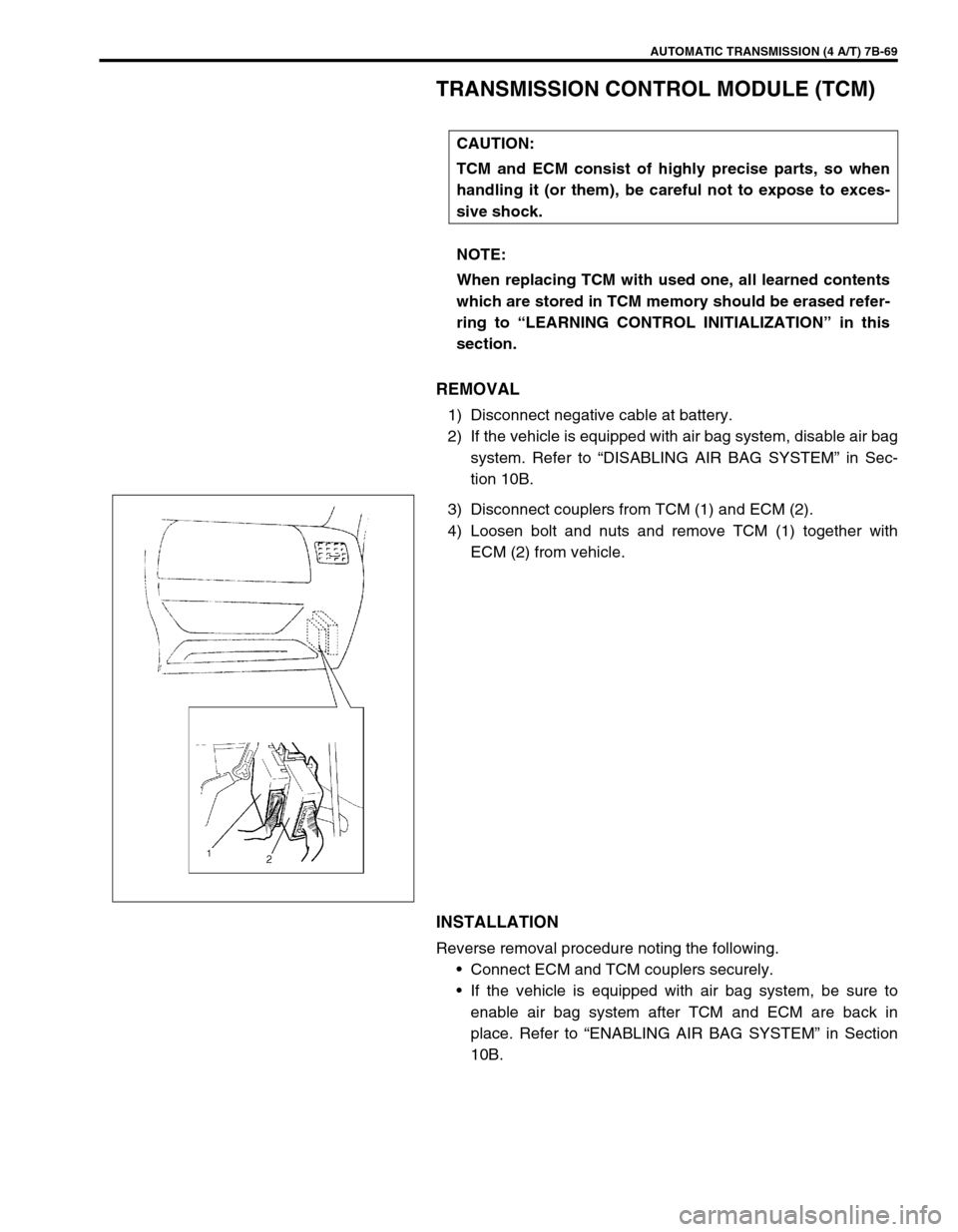

REMOVAL

1) Disconnect negative cable at battery.

2) If the vehicle is equipped with air bag system, disable air bag

system. Refer to “DISABLING AIR BAG SYSTEM” in Sec-

tion 10B.

3) Disconnect couplers from TCM (1) and ECM (2).

4) Loosen bolt and nuts and remove TCM (1) together with

ECM (2) from vehicle.

INSTALLATION

Reverse removal procedure noting the following.

Connect ECM and TCM couplers securely.

If the vehicle is equipped with air bag system, be sure to

enable air bag system after TCM and ECM are back in

place. Refer to “ENABLING AIR BAG SYSTEM” in Section

10B. CAUTION:

TCM and ECM consist of highly precise parts, so when

handling it (or them), be careful not to expose to exces-

sive shock.

NOTE:

When replacing TCM with used one, all learned contents

which are stored in TCM memory should be erased refer-

ring to “LEARNING CONTROL INITIALIZATION” in this

section.