Air SUZUKI SWIFT 2000 1.G Transmission Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 169 of 447

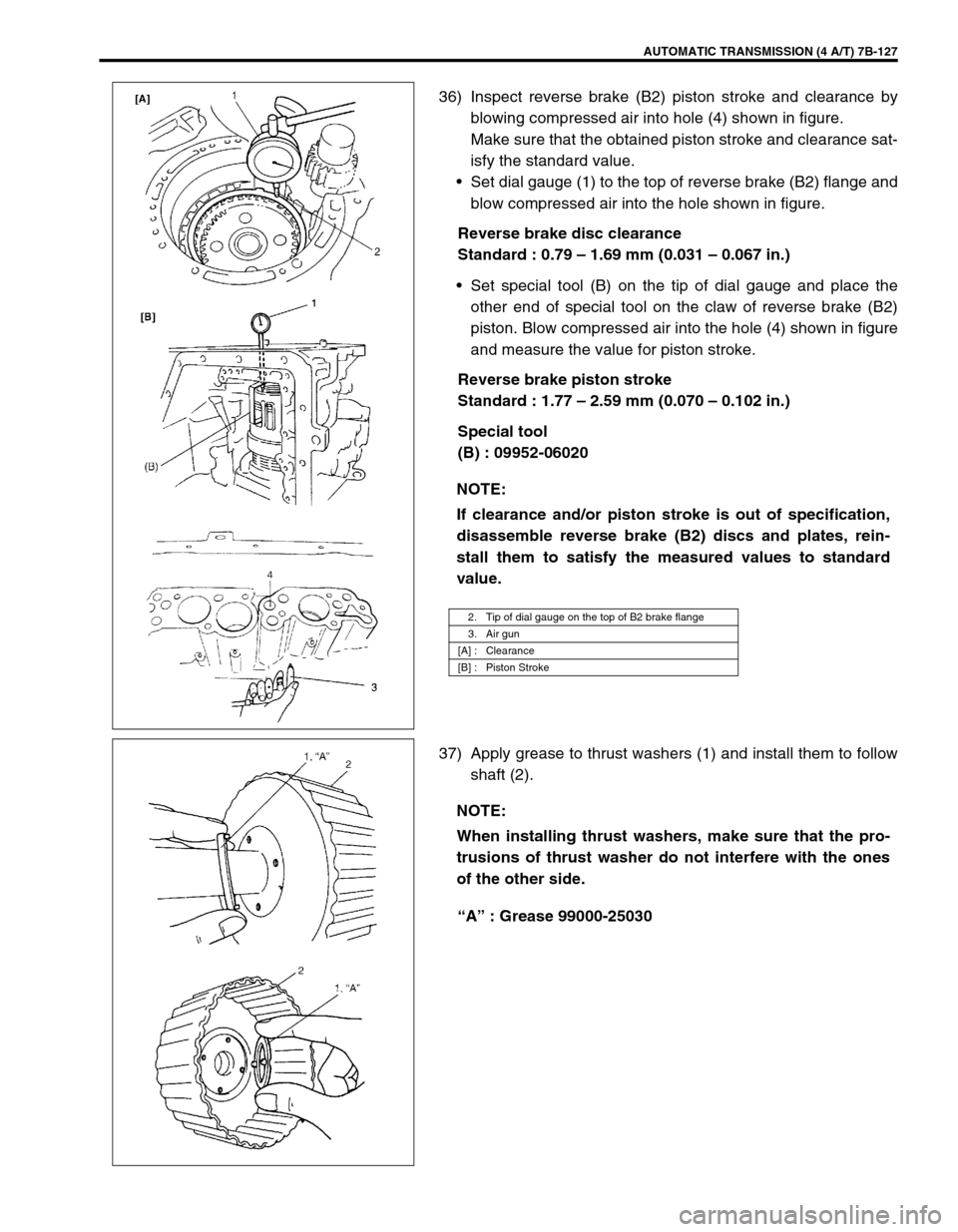

AUTOMATIC TRANSMISSION (4 A/T) 7B-127

36) Inspect reverse brake (B2) piston stroke and clearance by

blowing compressed air into hole (4) shown in figure.

Make sure that the obtained piston stroke and clearance sat-

isfy the standard value.

Set dial gauge (1) to the top of reverse brake (B2) flange and

blow compressed air into the hole shown in figure.

Reverse brake disc clearance

Standard : 0.79 – 1.69 mm (0.031 – 0.067 in.)

Set special tool (B) on the tip of dial gauge and place the

other end of special tool on the claw of reverse brake (B2)

piston. Blow compressed air into the hole (4) shown in figure

and measure the value for piston stroke.

Reverse brake piston stroke

Standard : 1.77 – 2.59 mm (0.070 – 0.102 in.)

Special tool

(B) : 09952-06020

37) Apply grease to thrust washers (1) and install them to follow

shaft (2).

“A” : Grease 99000-25030 NOTE:

If clearance and/or piston stroke is out of specification,

disassemble reverse brake (B2) discs and plates, rein-

stall them to satisfy the measured values to standard

value.

2. Tip of dial gauge on the top of B2 brake flange

3. Air gun

[A] : Clearance

[B] : Piston Stroke

NOTE:

When installing thrust washers, make sure that the pro-

trusions of thrust washer do not interfere with the ones

of the other side.

Page 179 of 447

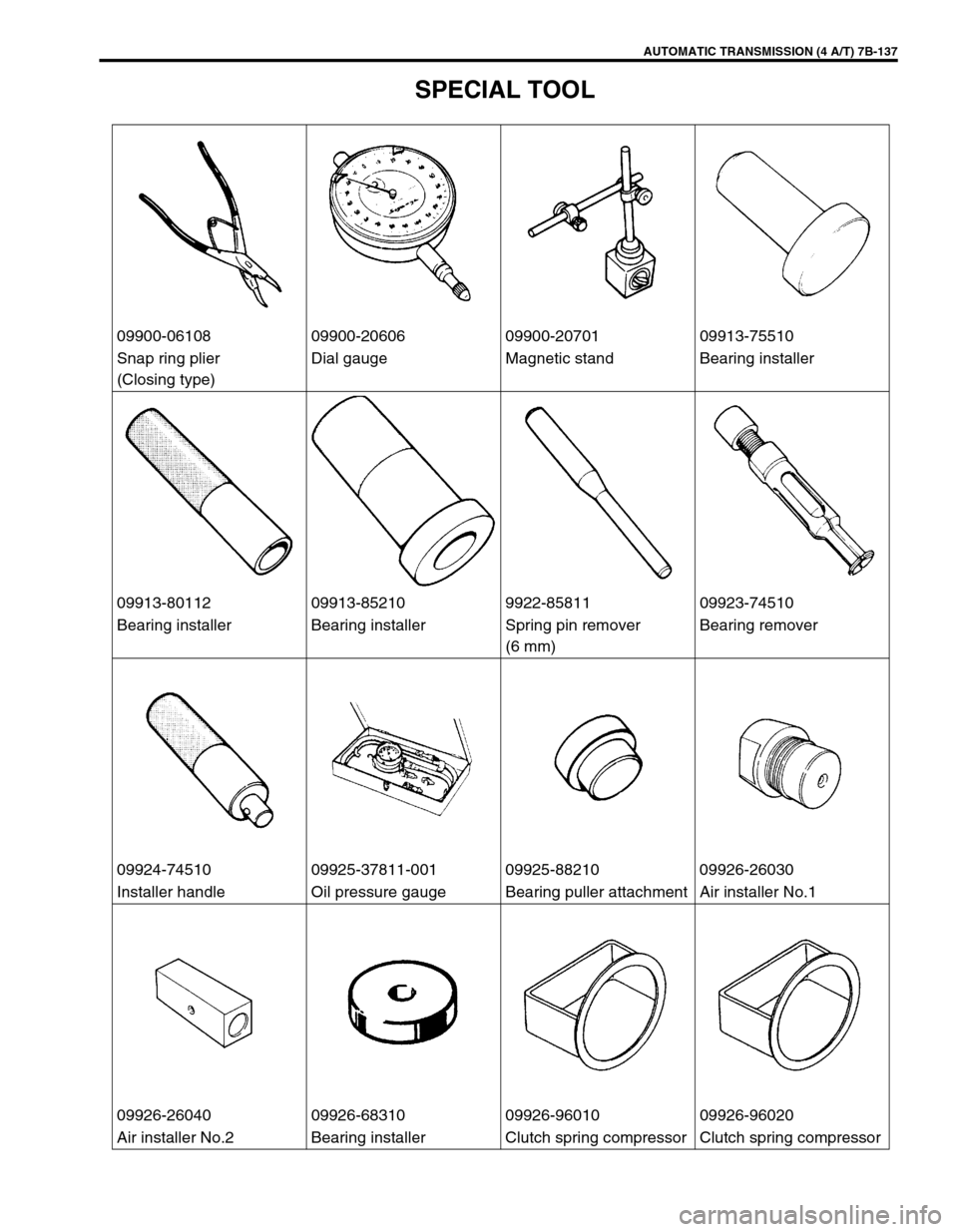

AUTOMATIC TRANSMISSION (4 A/T) 7B-137

SPECIAL TOOL

09900-06108 09900-20606 09900-20701 09913-75510

Snap ring plier

(Closing type)Dial gauge Magnetic stand Bearing installer

09913-80112 09913-85210 9922-85811 09923-74510

Bearing installer Bearing installer Spring pin remover

(6 mm)Bearing remover

09924-74510 09925-37811-001 09925-88210 09926-26030

Installer handle Oil pressure gauge Bearing puller attachment Air installer No.1

09926-26040 09926-68310 09926-96010 09926-96020

Air installer No.2 Bearing installer Clutch spring compressor Clutch spring compressor

Page 180 of 447

7B-138 AUTOMATIC TRANSMISSION (4 A/T)

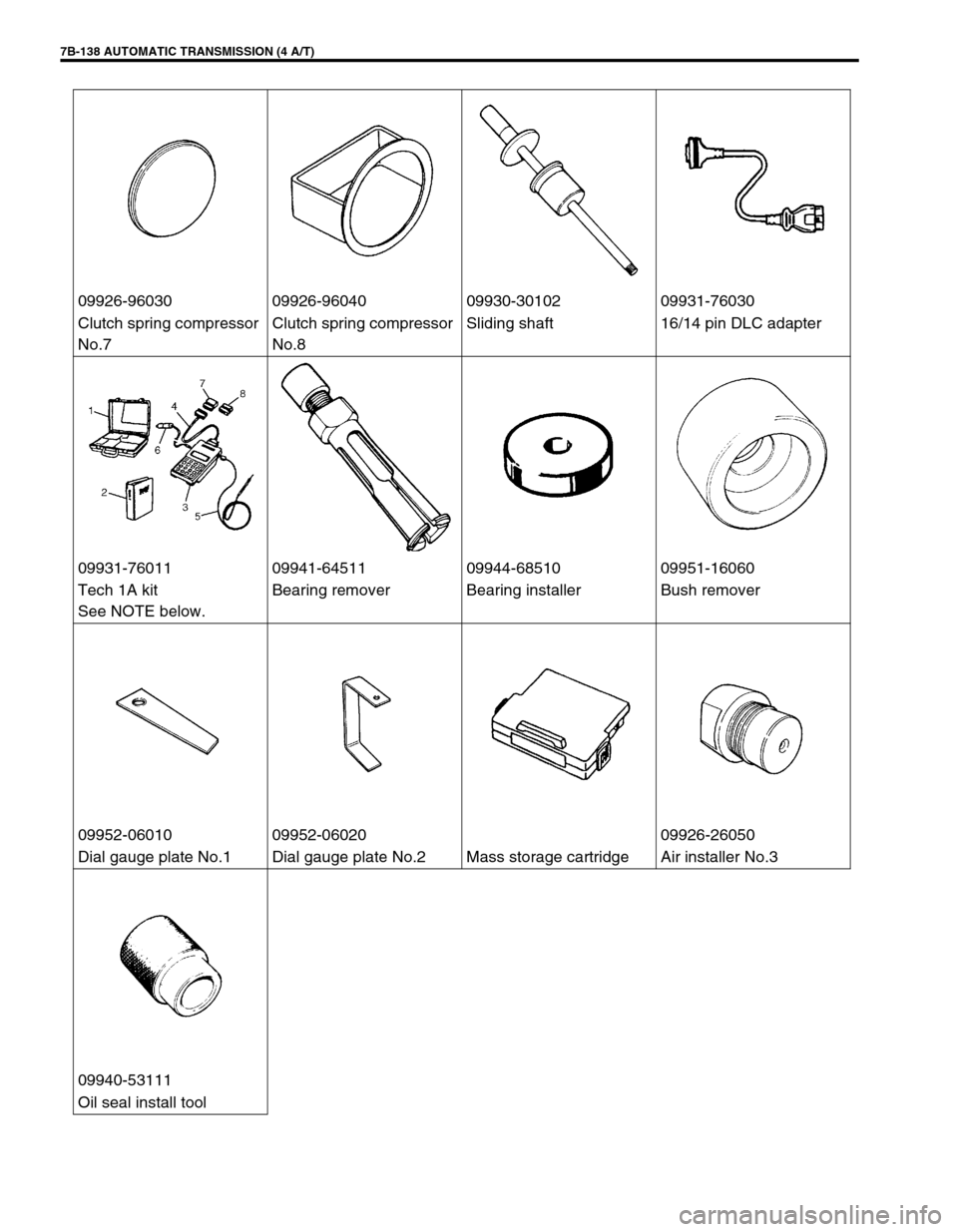

09926-96030 09926-96040 09930-30102 09931-76030

Clutch spring compressor

No.7Clutch spring compressor

No.8Sliding shaft 16/14 pin DLC adapter

09931-76011 09941-64511 09944-68510 09951-16060

Tech 1A kit

See NOTE below.Bearing remover Bearing installer Bush remover

09952-06010 09952-06020 09926-26050

Dial gauge plate No.1 Dial gauge plate No.2 Mass storage cartridge Air installer No.3

09940-53111

Oil seal install tool

Page 183 of 447

CLUTCH 7C-1

6F1

6F2

6G

6H

6K

7A1

7B1

7C1

7D

7E

7C

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 7C

CLUTCH

CONTENTS

GENERAL DESCRIPTION .............................. 7C-2

DIAGNOSIS ..................................................... 7C-3

ON-VEHICLE SERVICE .................................. 7C-4

CLUTCH CABLE .......................................... 7C-4

CLUTCH PEDAL AND CLUTCH PEDAL

BRACKET .................................................... 7C-6

CLUTCH PEDAL HEIGHT ....................... 7C-7

CLUTCH PEDAL FREE TRAVEL ............ 7C-7UNIT REPAIR OVERHAUL ............................. 7C-8

CLUTCH COVER, CLUTCH DISC AND

FLYWHEEL.................................................. 7C-8

CLUTCH RELEASE SYSTEM ................... 7C-11

TIGHTENING TORQUE SPECIFICATION.... 7C-14

REQUIRED SERVICE MATERIAL................ 7C-14

SPECIAL TOOL ............................................ 7C-14

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 185 of 447

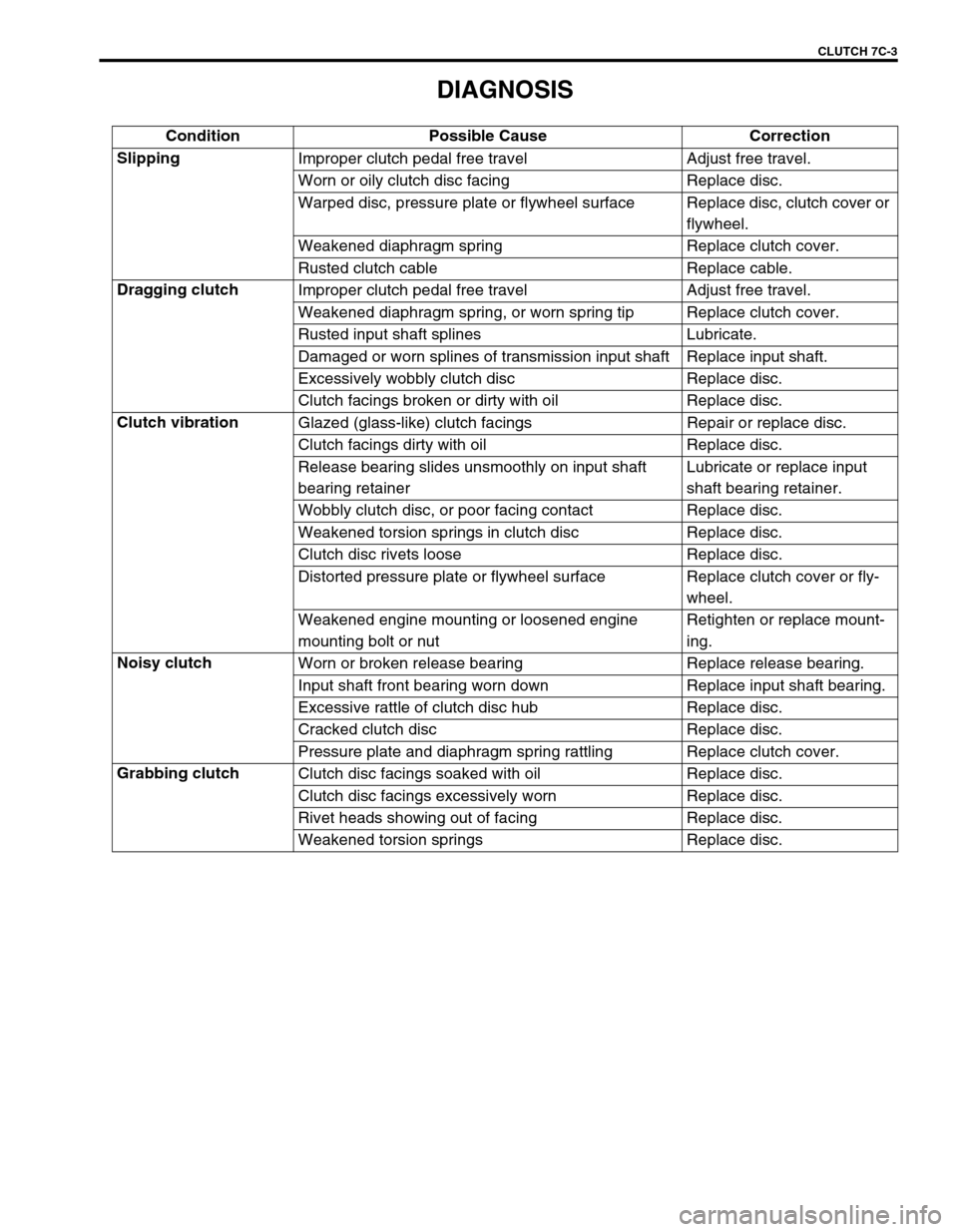

CLUTCH 7C-3

DIAGNOSIS

Condition Possible Cause Correction

Slipping

Improper clutch pedal free travel Adjust free travel.

Worn or oily clutch disc facing Replace disc.

Warped disc, pressure plate or flywheel surface Replace disc, clutch cover or

flywheel.

Weakened diaphragm spring Replace clutch cover.

Rusted clutch cable Replace cable.

Dragging clutch

Improper clutch pedal free travel Adjust free travel.

Weakened diaphragm spring, or worn spring tip Replace clutch cover.

Rusted input shaft splines Lubricate.

Damaged or worn splines of transmission input shaft Replace input shaft.

Excessively wobbly clutch disc Replace disc.

Clutch facings broken or dirty with oil Replace disc.

Clutch vibration

Glazed (glass-like) clutch facings Repair or replace disc.

Clutch facings dirty with oil Replace disc.

Release bearing slides unsmoothly on input shaft

bearing retainerLubricate or replace input

shaft bearing retainer.

Wobbly clutch disc, or poor facing contact Replace disc.

Weakened torsion springs in clutch disc Replace disc.

Clutch disc rivets loose Replace disc.

Distorted pressure plate or flywheel surface Replace clutch cover or fly-

wheel.

Weakened engine mounting or loosened engine

mounting bolt or nutRetighten or replace mount-

ing.

Noisy clutch

Worn or broken release bearing Replace release bearing.

Input shaft front bearing worn down Replace input shaft bearing.

Excessive rattle of clutch disc hub Replace disc.

Cracked clutch disc Replace disc.

Pressure plate and diaphragm spring rattling Replace clutch cover.

Grabbing clutch

Clutch disc facings soaked with oil Replace disc.

Clutch disc facings excessively worn Replace disc.

Rivet heads showing out of facing Replace disc.

Weakened torsion springs Replace disc.

Page 190 of 447

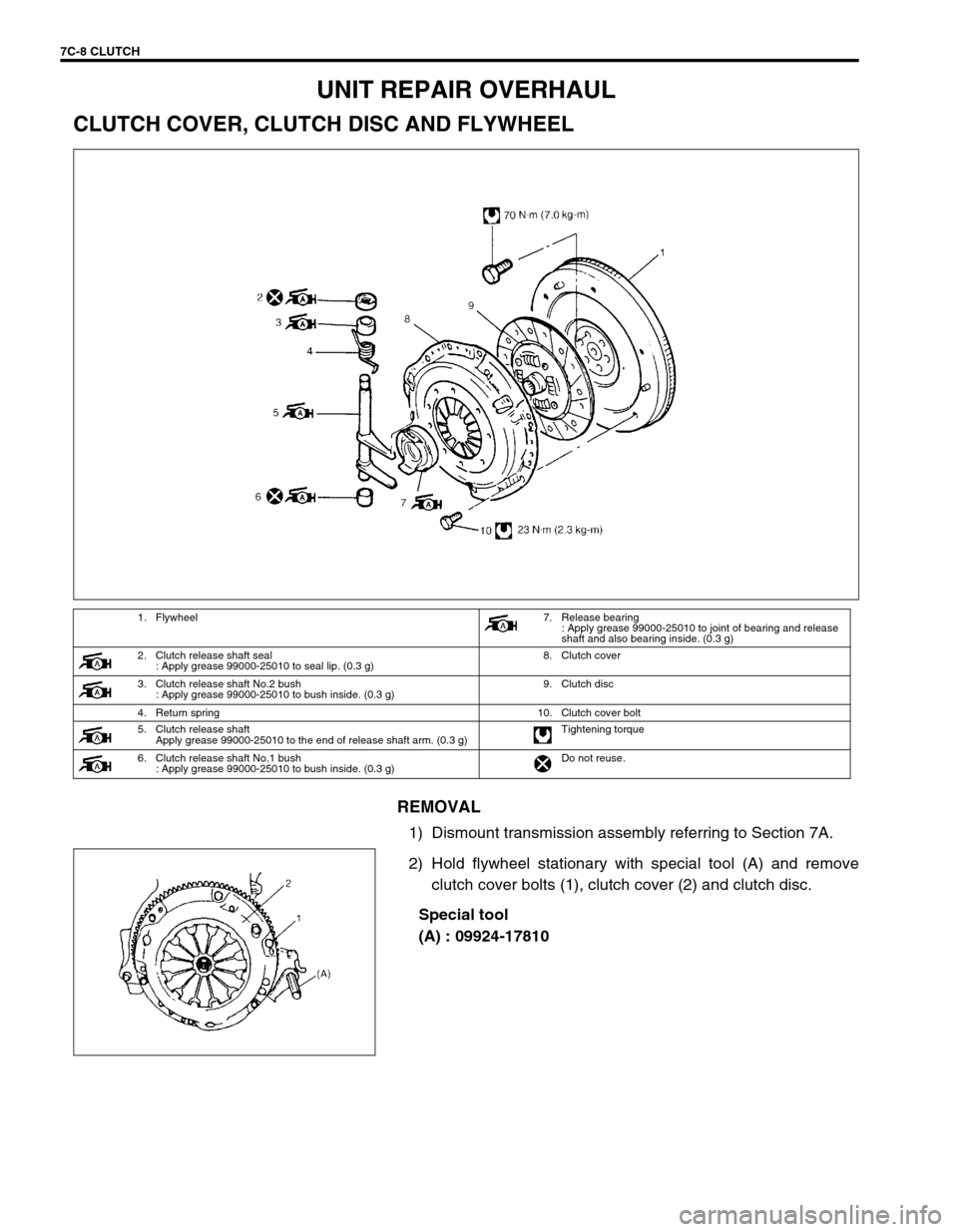

7C-8 CLUTCH

UNIT REPAIR OVERHAUL

CLUTCH COVER, CLUTCH DISC AND FLYWHEEL

REMOVAL

1) Dismount transmission assembly referring to Section 7A.

2) Hold flywheel stationary with special tool (A) and remove

clutch cover bolts (1), clutch cover (2) and clutch disc.

Special tool

(A) : 09924-17810

1. Flywheel7. Release bearing

: Apply grease 99000-25010 to joint of bearing and release

shaft and also bearing inside. (0.3 g)

2. Clutch release shaft seal

: Apply grease 99000-25010 to seal lip. (0.3 g)8. Clutch cover

3. Clutch release shaft No.2 bush

: Apply grease 99000-25010 to bush inside. (0.3 g)9. Clutch disc

4. Return spring 10. Clutch cover bolt

5. Clutch release shaft

Apply grease 99000-25010 to the end of release shaft arm. (0.3 g)Tightening torque

6. Clutch release shaft No.1 bush

: Apply grease 99000-25010 to bush inside. (0.3 g)Do not reuse.

Page 191 of 447

CLUTCH 7C-9

3) Pull out input shaft bearing (1) by using special tool (B), and

wrench.

Special tool

(B) : 09921-26020

09930-30104

INSPECTION

Input Shaft Bearing

Check bearing (1) for smooth rotation and replace it if abnormality

is found.

Clutch Disc

Measure depth of rivet head depression, i.e. distance between

rivet head and facing surface. If depression is found to have

reached service limit at any of holes, replace disc assembly.

Rivet head depth

Standard : 1.65 – 2.25 mm (0.06 – 0.09 in.)

Service limit : 0.5 mm (0.02 in.)

Clutch Cover

1) Check diaphragm spring (1) for abnormal wear or damage.

2) Inspect pressure plate (2) for wear or heat spots.

3) If abnormality is found, replace it as assembly. Do not disas-

semble it into diaphragm and pressure plate.

Flywheel

Check surface contacting clutch disc for abnormal wear or heat

spots. Replace or repair as required.

Page 199 of 447

TRANSFER 7D-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7E

7F

7D

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 7D

TRANSFER

CONTENTS

GENERAL DESCRIPTION ...............................7D-2

DIAGNOSIS ......................................................7D-2

ON-VEHICLE SERVICE ...................................7D-3

UNIT REPAIR OVERHAUL ..............................7D-4

UNIT DISMOUNTING ...................................7D-5

UNIT DISASSEMBLY ...................................7D-6

TRANSFER ASSEMBLY...........................7D-6

REDUCTION DRIVEN GEAR ...................7D-7

INTERMEDIATE SHAFT ...........................7D-8

TRANSFER OUTPUT RETAINER ............7D-9

COMPONENT INSPECTION ......................7D-10

UNIT ASSEMBLY .......................................7D-10REDUCTION DRIVEN GEAR ................. 7D-10

BEVEL GEAR SHIM ............................... 7D-11

TRANSFER OUTPUT RETAINER .......... 7D-12

RIGHT CASE .......................................... 7D-16

LEFT CASE............................................. 7D-17

TRANSFER ASSEMBLY ........................ 7D-17

BEVEL GEAR BACK LASH .................... 7D-18

UNIT INSTALLATION ................................. 7D-20

TIGHTENING TORQUE SPECIFICATION..... 7D-22

REQUIRED SERVICE MATERIAL................. 7D-22

SPECIAL TOOL ............................................. 7D-22

Page 201 of 447

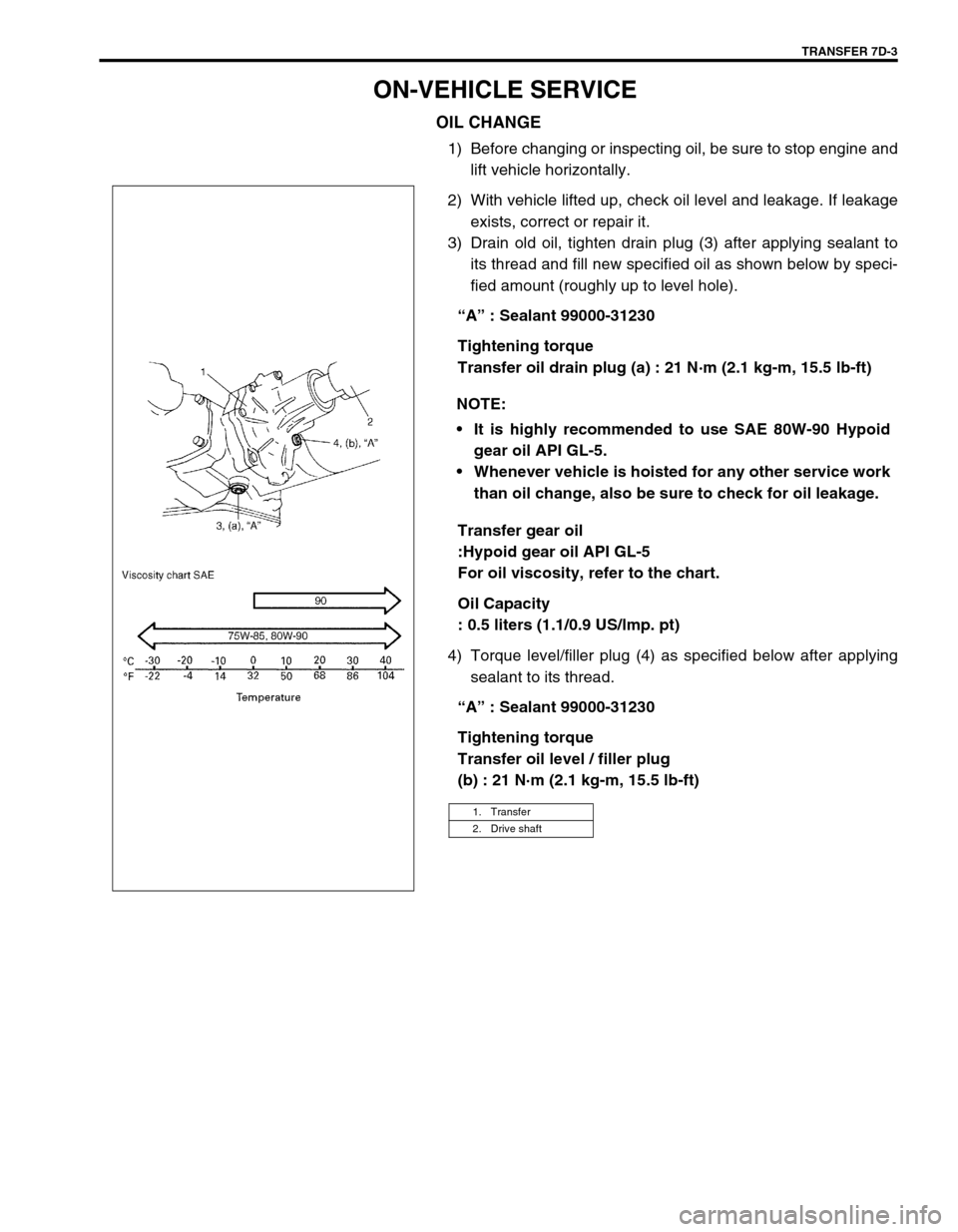

TRANSFER 7D-3

ON-VEHICLE SERVICE

OIL CHANGE

1) Before changing or inspecting oil, be sure to stop engine and

lift vehicle horizontally.

2) With vehicle lifted up, check oil level and leakage. If leakage

exists, correct or repair it.

3) Drain old oil, tighten drain plug (3) after applying sealant to

its thread and fill new specified oil as shown below by speci-

fied amount (roughly up to level hole).

“A” : Sealant 99000-31230

Tightening torque

Transfer oil drain plug (a) : 21 N·m (2.1 kg-m, 15.5 lb-ft)

Transfer gear oil

:Hypoid gear oil API GL-5

For oil viscosity, refer to the chart.

Oil Capacity

: 0.5 liters (1.1/0.9 US/lmp. pt)

4) Torque level/filler plug (4) as specified below after applying

sealant to its thread.

“A” : Sealant 99000-31230

Tightening torque

Transfer oil level / filler plug

(b) : 21 N·m (2.1 kg-m, 15.5 lb-ft) NOTE:

It is highly recommended to use SAE 80W-90 Hypoid

gear oil API GL-5.

Whenever vehicle is hoisted for any other service work

than oil change, also be sure to check for oil leakage.

1. Transfer

2. Drive shaft

Page 202 of 447

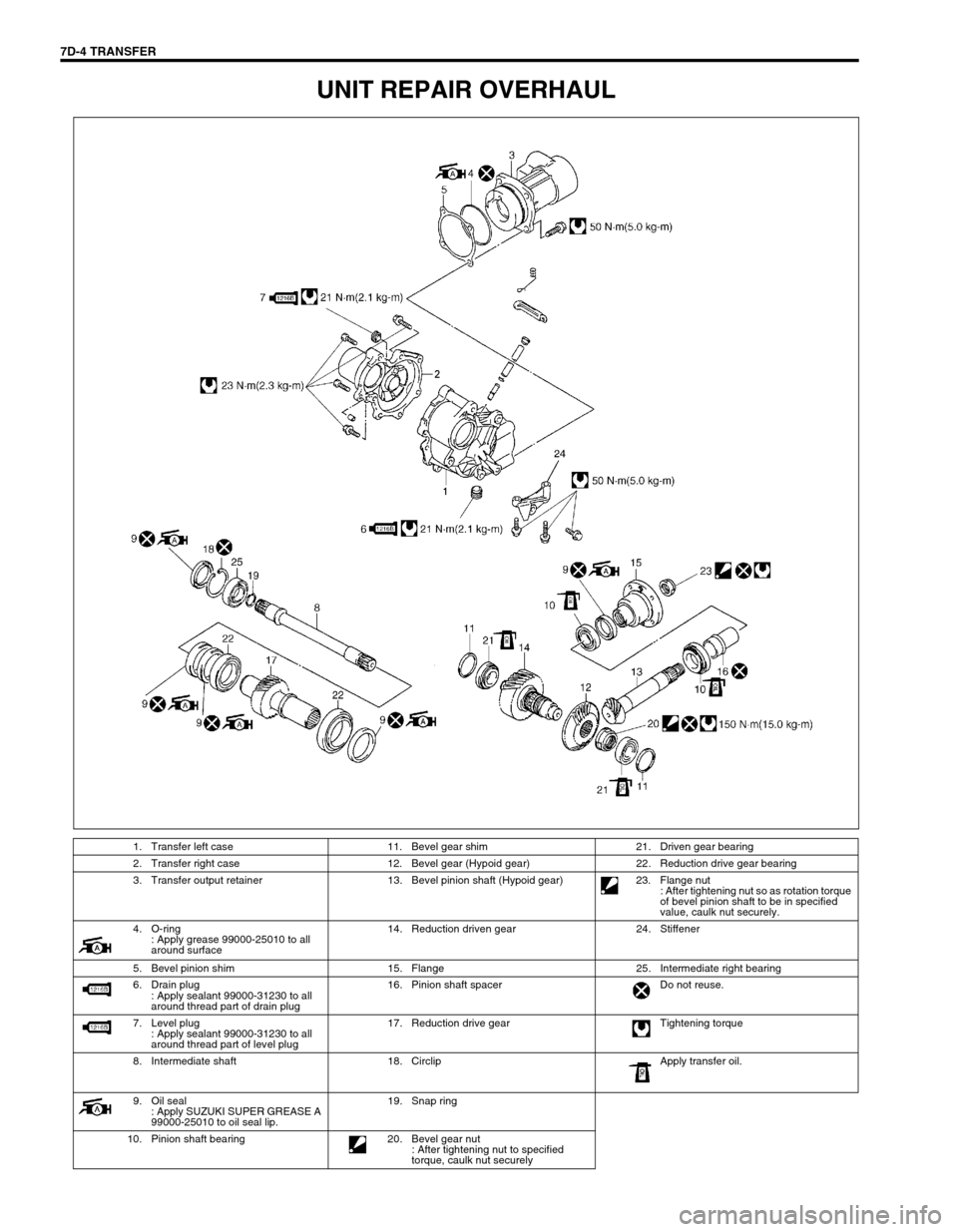

7D-4 TRANSFER

UNIT REPAIR OVERHAUL

1. Transfer left case 11. Bevel gear shim 21. Driven gear bearing

2. Transfer right case 12. Bevel gear (Hypoid gear) 22. Reduction drive gear bearing

3. Transfer output retainer 13. Bevel pinion shaft (Hypoid gear) 23. Flange nut

: After tightening nut so as rotation torque

of bevel pinion shaft to be in specified

value, caulk nut securely.

4. O-ring

: Apply grease 99000-25010 to all

around surface14. Reduction driven gear 24. Stiffener

5. Bevel pinion shim 15. Flange 25. Intermediate right bearing

6. Drain plug

: Apply sealant 99000-31230 to all

around thread part of drain plug16. Pinion shaft spacer Do not reuse.

7. Level plug

: Apply sealant 99000-31230 to all

around thread part of level plug17. Reduction drive gear Tightening torque

8. Intermediate shaft 18. Circlip Apply transfer oil.

9. Oil seal

: Apply SUZUKI SUPER GREASE A

99000-25010 to oil seal lip.19. Snap ring

10. Pinion shaft bearing 20. Bevel gear nut

: After tightening nut to specified

torque, caulk nut securely