automatic transmission SUZUKI SWIFT 2000 1.G Transmission Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 73 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-31

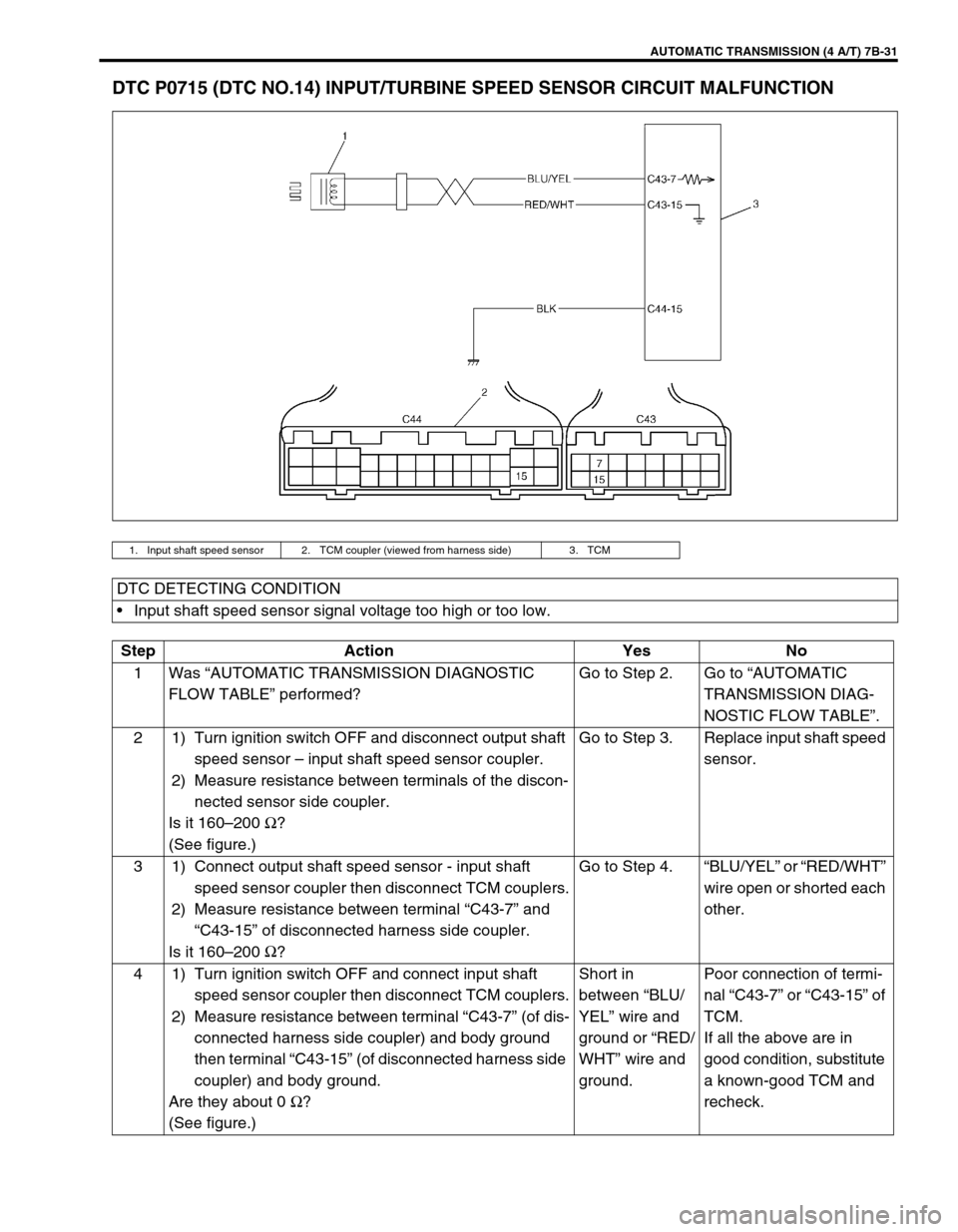

DTC P0715 (DTC NO.14) INPUT/TURBINE SPEED SENSOR CIRCUIT MALFUNCTION

1. Input shaft speed sensor 2. TCM coupler (viewed from harness side) 3. TCM

DTC DETECTING CONDITION

Input shaft speed sensor signal voltage too high or too low.

Step Action Yes No

1Was “AUTOMATIC TRANSMISSION DIAGNOSTIC

FLOW TABLE” performed?Go to Step 2. Go to “AUTOMATIC

TRANSMISSION DIAG-

NOSTIC FLOW TABLE”.

2 1) Turn ignition switch OFF and disconnect output shaft

speed sensor – input shaft speed sensor coupler.

2) Measure resistance between terminals of the discon-

nected sensor side coupler.

Is it 160–200 Ω

?

(See figure.)Go to Step 3. Replace input shaft speed

sensor.

3 1) Connect output shaft speed sensor - input shaft

speed sensor coupler then disconnect TCM couplers.

2) Measure resistance between terminal “C43-7” and

“C43-15” of disconnected harness side coupler.

Is it 160–200 Ω

?Go to Step 4.“BLU/YEL” or “RED/WHT”

wire open or shorted each

other.

4 1) Turn ignition switch OFF and connect input shaft

speed sensor coupler then disconnect TCM couplers.

2) Measure resistance between terminal “C43-7” (of dis-

connected harness side coupler) and body ground

then terminal “C43-15” (of disconnected harness side

coupler) and body ground.

Are they about 0 Ω

?

(See figure.)Short in

between “BLU/

YEL” wire and

ground or “RED/

WHT” wire and

ground.Poor connection of termi-

nal “C43-7” or “C43-15” of

TCM.

If all the above are in

good condition, substitute

a known-good TCM and

recheck.

Page 74 of 447

7B-32 AUTOMATIC TRANSMISSION (4 A/T)

Figure for Step 2

Figure for Step 4

1. Output shaft speed sensor - Input shaft speed sensor coupler

2. Input shaft speed sensor terminal

Page 75 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-33

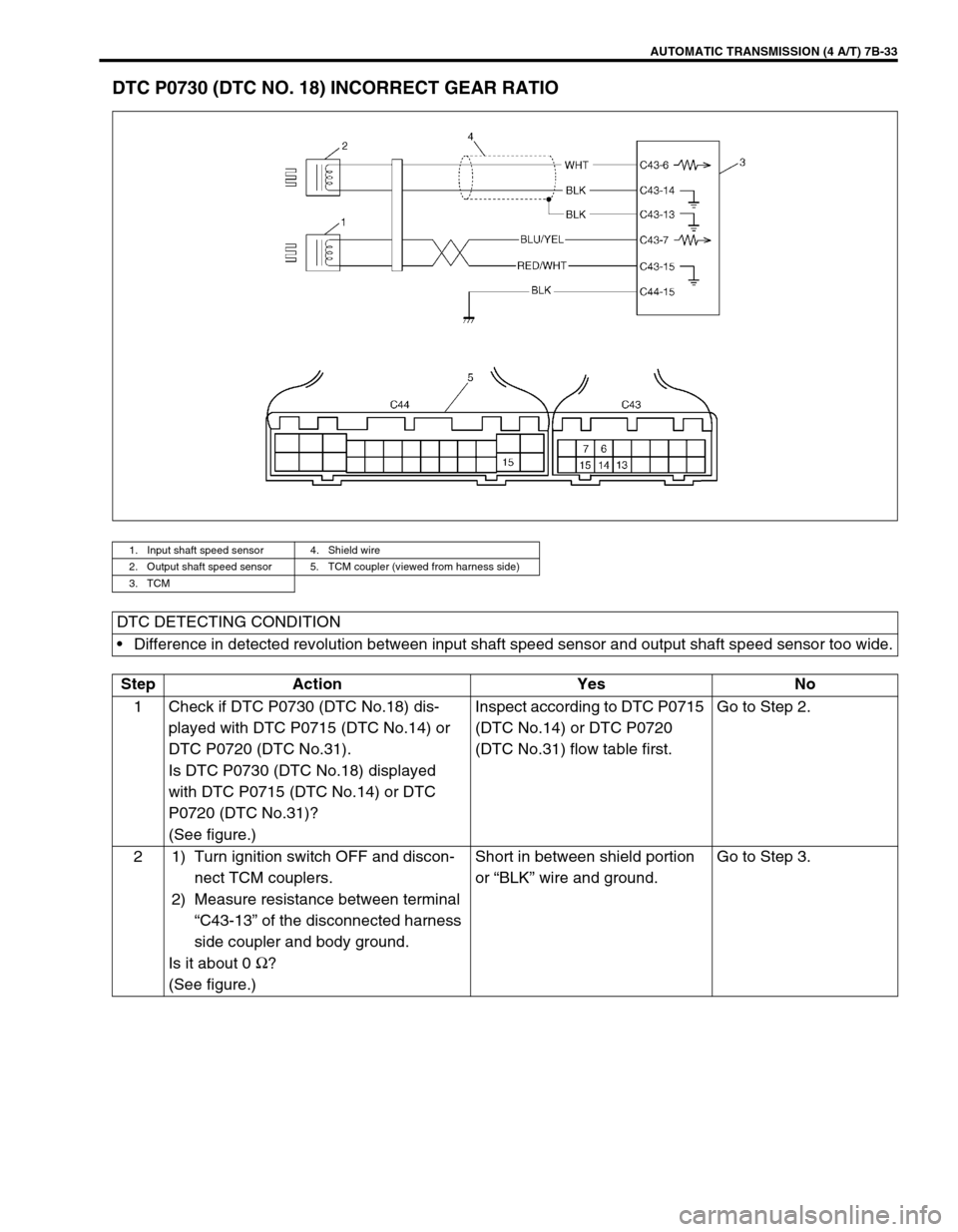

DTC P0730 (DTC NO. 18) INCORRECT GEAR RATIO

1. Input shaft speed sensor 4. Shield wire

2. Output shaft speed sensor 5. TCM coupler (viewed from harness side)

3. TCM

DTC DETECTING CONDITION

Difference in detected revolution between input shaft speed sensor and output shaft speed sensor too wide.

Step Action Yes No

1 Check if DTC P0730 (DTC No.18) dis-

played with DTC P0715 (DTC No.14) or

DTC P0720 (DTC No.31).

Is DTC P0730 (DTC No.18) displayed

with DTC P0715 (DTC No.14) or DTC

P0720 (DTC No.31)?

(See figure.)Inspect according to DTC P0715

(DTC No.14) or DTC P0720

(DTC No.31) flow table first.Go to Step 2.

2 1) Turn ignition switch OFF and discon-

nect TCM couplers.

2) Measure resistance between terminal

“C43-13” of the disconnected harness

side coupler and body ground.

Is it about 0 Ω

?

(See figure.)Short in between shield portion

or “BLK” wire and ground.Go to Step 3.

Page 76 of 447

7B-34 AUTOMATIC TRANSMISSION (4 A/T)

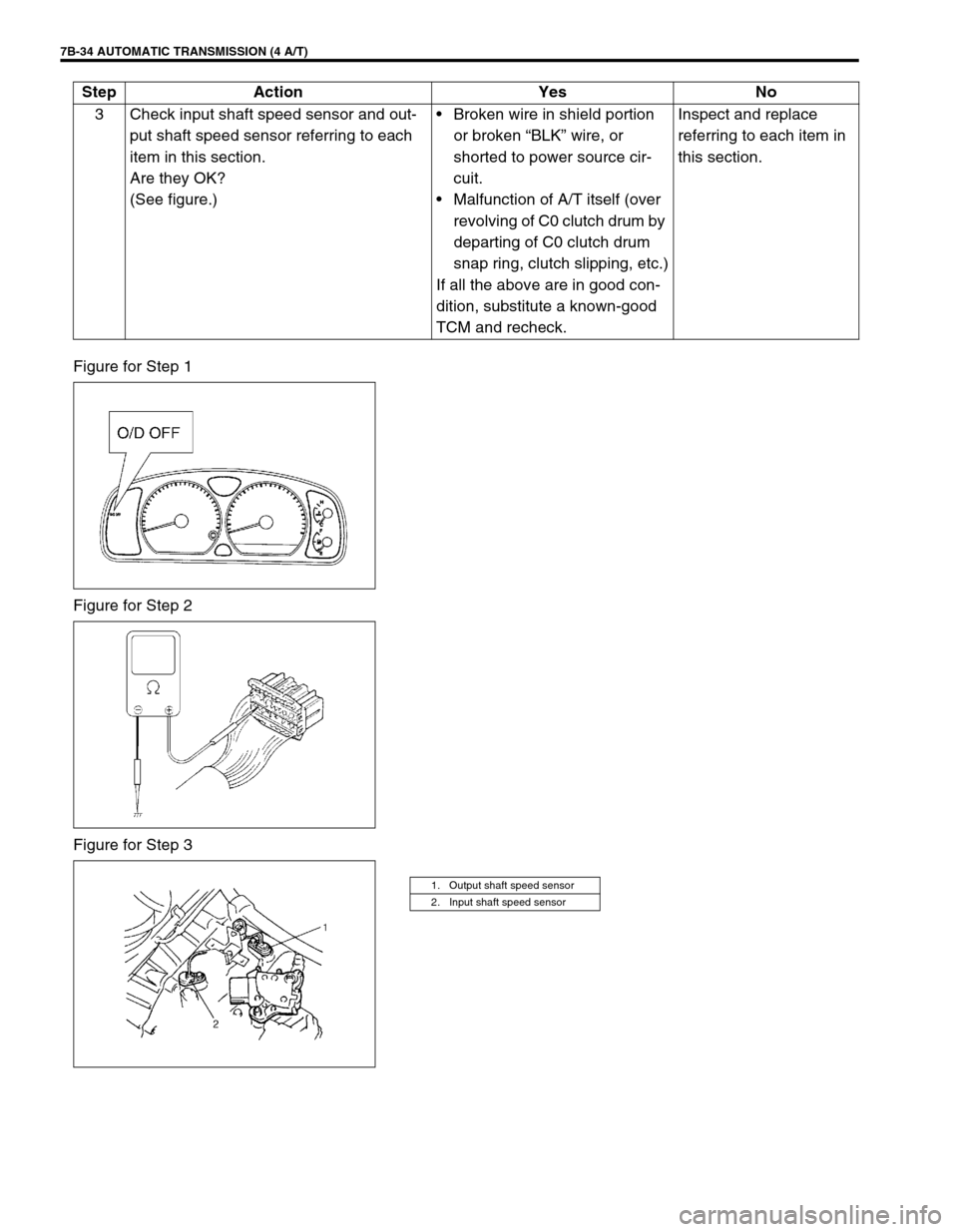

Figure for Step 1

Figure for Step 2

Figure for Step 33 Check input shaft speed sensor and out-

put shaft speed sensor referring to each

item in this section.

Are they OK?

(See figure.)Broken wire in shield portion

or broken “BLK” wire, or

shorted to power source cir-

cuit.

Malfunction of A/T itself (over

revolving of C0 clutch drum by

departing of C0 clutch drum

snap ring, clutch slipping, etc.)

If all the above are in good con-

dition, substitute a known-good

TCM and recheck.Inspect and replace

referring to each item in

this section. Step Action Yes No

1. Output shaft speed sensor

2. Input shaft speed sensor

Page 77 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-35

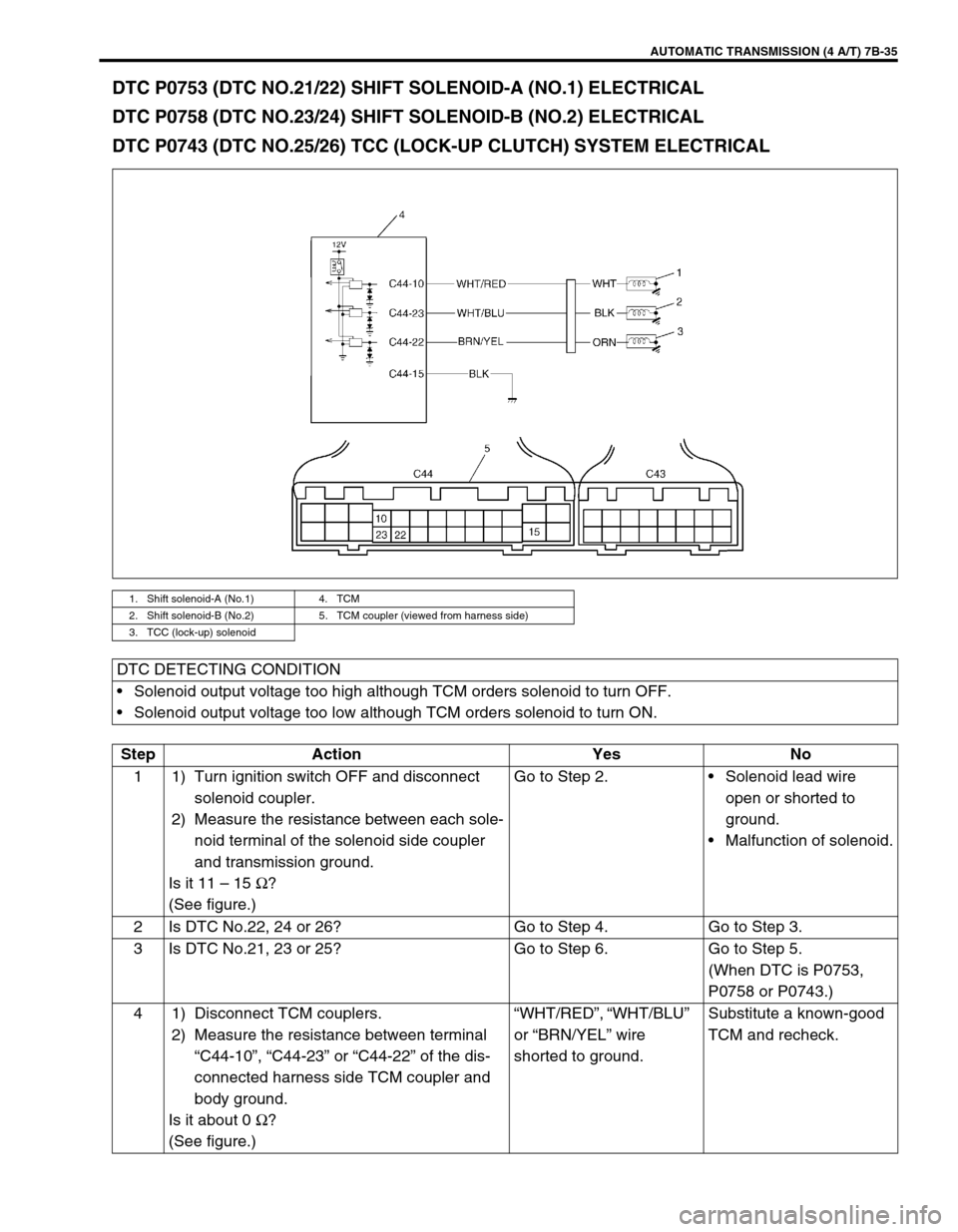

DTC P0753 (DTC NO.21/22) SHIFT SOLENOID-A (NO.1) ELECTRICAL

DTC P0758 (DTC NO.23/24) SHIFT SOLENOID-B (NO.2) ELECTRICAL

DTC P0743 (DTC NO.25/26) TCC (LOCK-UP CLUTCH) SYSTEM ELECTRICAL

1. Shift solenoid-A (No.1) 4. TCM

2. Shift solenoid-B (No.2) 5. TCM coupler (viewed from harness side)

3. TCC (lock-up) solenoid

DTC DETECTING CONDITION

Solenoid output voltage too high although TCM orders solenoid to turn OFF.

Solenoid output voltage too low although TCM orders solenoid to turn ON.

Step Action Yes No

1 1) Turn ignition switch OFF and disconnect

solenoid coupler.

2) Measure the resistance between each sole-

noid terminal of the solenoid side coupler

and transmission ground.

Is it 11 – 15 Ω

?

(See figure.)Go to Step 2.Solenoid lead wire

open or shorted to

ground.

Malfunction of solenoid.

2 Is DTC No.22, 24 or 26? Go to Step 4. Go to Step 3.

3 Is DTC No.21, 23 or 25? Go to Step 6. Go to Step 5.

(When DTC is P0753,

P0758 or P0743.)

4 1) Disconnect TCM couplers.

2) Measure the resistance between terminal

“C44-10”, “C44-23” or “C44-22” of the dis-

connected harness side TCM coupler and

body ground.

Is it about 0 Ω

?

(See figure.)“WHT/RED”, “WHT/BLU”

or “BRN/YEL” wire

shorted to ground.Substitute a known-good

TCM and recheck.

Page 78 of 447

7B-36 AUTOMATIC TRANSMISSION (4 A/T)

Figure for Step 1

Figure for Step 4, 5, 6, 75 1) Disconnect TCM couplers.

2) Measure the resistance between terminal

“C44-10”, “C44-23” or “C44-22” of the dis-

connected harness side TCM coupler and

body ground.

Is it about 0 Ω

?

(See figure.)“WHT/RED”, “WHT/BLU”,

or “BRN/YEL” wire

shorted to ground.Go to Step 6.

6 1) Connect solenoid coupler then disconnect

TCM couplers.

2) Measure the resistance between each sole-

noid terminal of the disconnected harness

side TCM coupler and body ground.

Is it 10.5 – 15.5 Ω

?Go to Step 7.“WHT/RED”, “WHT/BLU”

or “BRN/YEL” wire open

or poor connection of shift

solenoid coupler.

7 Turn ignition switch ON then measure voltage

between terminal “C44-10”, “C44-23” or “C44-

22” of the disconnected harness side TCM cou-

pler and body ground.

Is it about 0 V?Poor connection at termi-

nal “C44-10”, “C44-23” or

“C44-22” of TCM.

If all the above are in

good condition, substitute

a known-good TCM and

recheck.“WHT/RED”, “WHT/BLU”

or “BRN/YEL” wire or shift

solenoid lead wire shorted

to power source circuit. Step Action Yes No

Solenoid TCM Terminal NumberLead Wire Color

(between TCM and solenoid coupler)

Shift solenoid -A (No.1) C44-10 WHT/RED

Shift solenoid -B (No.2) C44-23 WHT/BLU

TCC solenoid (Lock-up solenoid) C44-22 BRN/YEL

1. Shift solenoid -A (No.1) terminal

2. Shift solenoid -B (No.2) terminal

3. TCC (Lock-up) solenoid terminal

4. Solenoid coupler

5. Transmission range sensor (Shift switch)

1.“C44-10” terminal

2.“C44-23” terminal

3.“C44-22” terminal

4. TCM couples

Page 79 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-37

DTC P0741 (DTC NO.29) TCC (LOCK-UP) SOLENOID PERFORMANCE OR STUCK OFF

Step Action Yes No

1Was “AUTOMATIC TRANSMISSION DIAG-

NOSTIC FLOW TABLE” performed?Go to Step 2. Go to “AUTOMATIC

TRANSMISSION DIAG-

NOSTIC FLOW TABLE”.

2 Check TCC (lock-up) solenoid referring to

“SHIFT SOLENOID VALVES” in this section.

Is it in good condition?Go to Step 3. Replace TCC (lock-up)

solenoid.

3 Check valve body for fluid passage clog, or

lock-up control valve, secondary regulator valve

or signal valve stuck, referring to “TRANSMIS-

SION UNIT REPAIR OVERHAUL” in this sec-

tion.

Are they in good condition?Go to Step 4. Faulty valve body.

4 Substitute a known-good torque converter and

recheck.

Is it OK?Torque converter mal-

function.Overhaul and repair auto-

matic transmission.

DTC DETECTING CONDITION

Difference between turbine rev. and engine rev. too close even though TCM ordered to turn OFF lock-up.

Difference between turbine rev. and engine rev. too wide even though TCM ordered to turn ON lock-up.

Page 80 of 447

7B-38 AUTOMATIC TRANSMISSION (4 A/T)

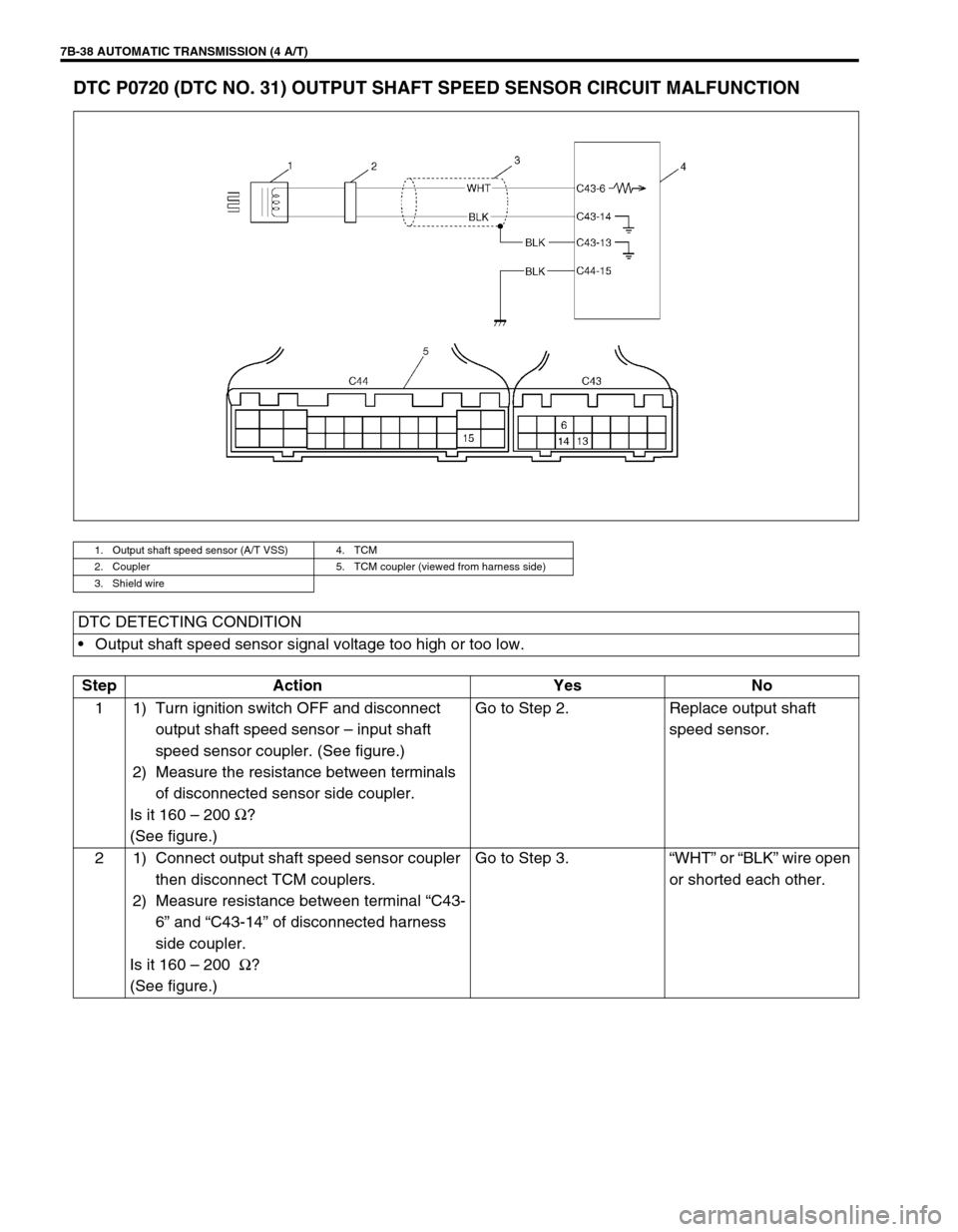

DTC P0720 (DTC NO. 31) OUTPUT SHAFT SPEED SENSOR CIRCUIT MALFUNCTION

1. Output shaft speed sensor (A/T VSS) 4. TCM

2. Coupler 5. TCM coupler (viewed from harness side)

3. Shield wire

DTC DETECTING CONDITION

Output shaft speed sensor signal voltage too high or too low.

Step Action Yes No

1 1) Turn ignition switch OFF and disconnect

output shaft speed sensor – input shaft

speed sensor coupler. (See figure.)

2) Measure the resistance between terminals

of disconnected sensor side coupler.

Is it 160 – 200 Ω

?

(See figure.)Go to Step 2. Replace output shaft

speed sensor.

2 1) Connect output shaft speed sensor coupler

then disconnect TCM couplers.

2) Measure resistance between terminal “C43-

6” and “C43-14” of disconnected harness

side coupler.

Is it 160 – 200 Ω

?

(See figure.)Go to Step 3.“WHT” or “BLK” wire open

or shorted each other.

Page 81 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-39

Figure for Step 1, 2

Figure for Step 2, 33 1) Turn ignition switch OFF and disconnect

output shaft speed sensor – input shaft

speed sensor coupler. (See figure.)

2) Measure resistance between terminal “3”

(of disconnected sensor side coupler) and

body ground then terminal “4” (of discon-

nected sensor side coupler) and body

ground.

Is it about 0 Ω

?

(See figure.)Replace output shaft

speed sensor.Go to Step 4.

4 1) Turn ignition switch OFF and connect out-

put shaft speed sensor coupler then discon-

nect TCM couplers.

2) Measure resistance between terminal “C43-

6” (of disconnected harness side coupler)

and body ground then terminal “C43-14” (of

disconnected harness side coupler) and

body ground.

Is it about 0 Ω

?

(See figure.)“WHT” or “BLK” wire

shorted to ground.Go to Step 5.

5 Measure resistance between terminal “C43-6”

and “C43-13” (of disconnected harness side

coupler) then terminal “C43-14” and “C43-13”

(of disconnected harness side coupler).

Is it about 0 Ω

?

(See figure.)“WHT” wire or “BLK” wire

shorted to shield portion.Poor connection of termi-

nal “C43-6” or “C43-14” of

the TCM.

If all the above are in

good condition, substitute

a known-good TCM and

recheck. Step Action Yes No

1. Output shaft speed sensor

2. Input shaft speed sensor coupler

1. Terminal “3”

2. Terminal “4”

Page 82 of 447

7B-40 AUTOMATIC TRANSMISSION (4 A/T)

Figure for Step 2, 5

Figure for Step 4

1.“C43-14” terminal

2.“C43-6” terminal

3.“C43-13” terminal

4. TCM coupler

1.“C43-14” terminal

2.“C43-6” terminal

3. TCM coupler