fluid level SUZUKI SWIFT 2005 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 853 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-1

Transmission / Transaxle

Clutch

General Description

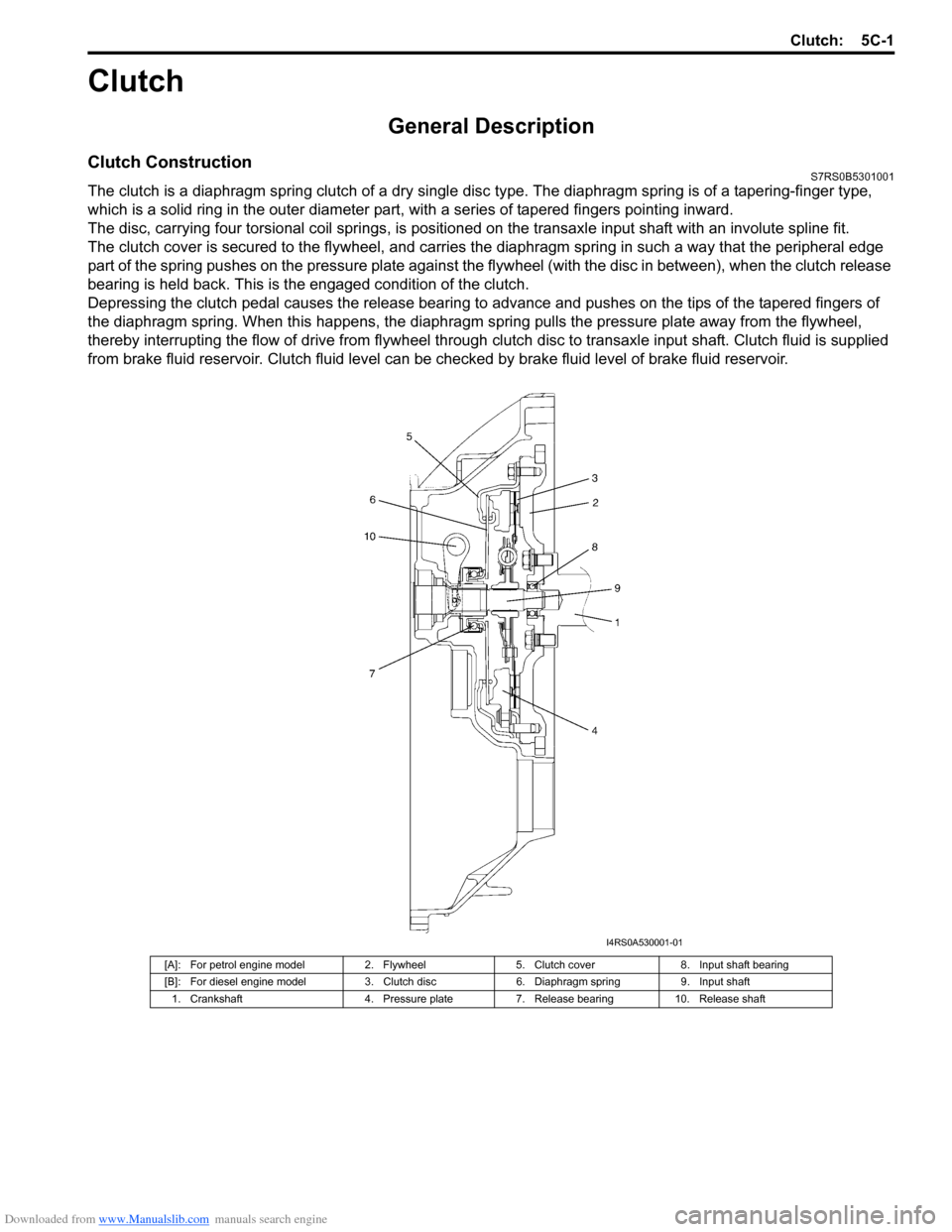

Clutch ConstructionS7RS0B5301001

The clutch is a diaphragm spring clutch of a dry single disc type. The diaphragm spring is of a tapering-finger type,

which is a solid ring in the outer diameter part, with a series of tapered fingers pointing inward.

The disc, carrying four torsional coil springs, is positione d on the transaxle input shaft with an involute spline fit.

The clutch cover is secured to the flywheel, and carries the diaphragm spring in such a way that the peripheral edge

part of the spring pushes on the pressure plate against the flywheel (with the disc in between), when the clutch release

bearing is held back. This is the engaged condition of the clutch.

Depressing the clutch pedal c auses the release bearing to advance and pushes on the tips of the tapered fingers of

the diaphragm spring. When this happens, the diaphragm sp ring pulls the pressure plate away from the flywheel,

thereby interrupting the flow of drive from flywheel through clutch disc to transaxle input shaft. Clutch fluid is supplied

from brake fluid reservoir. Clutch fluid level can be checked by brake fluid level of brake fluid reservoir.

[A]: For petrol engine model2. Flywheel5. Clutch cover 8. Input shaft bearing

[B]: For diesel engine model 3. Clutch disc6. Diaphragm spring 9. Input shaft

1. Crankshaft 4. Pressure plate7. Release bearing 10. Release shaft

I4RS0A530001-01

Page 855 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-3

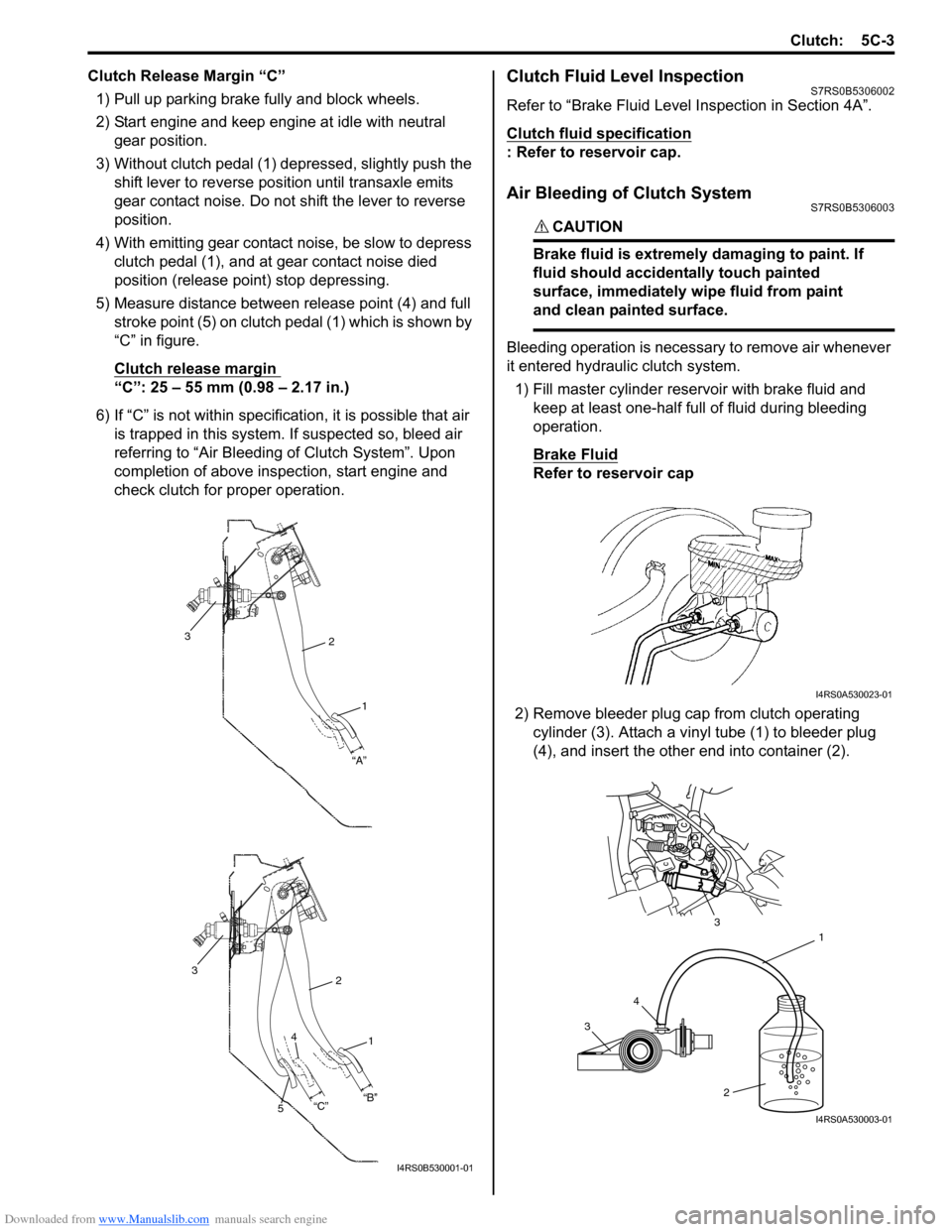

Clutch Release Margin “C”1) Pull up parking brake fully and block wheels.

2) Start engine and keep engine at idle with neutral gear position.

3) Without clutch pedal (1) dep ressed, slightly push the

shift lever to re verse position until transaxle emits

gear contact noise. Do not shift the lever to reverse

position.

4) With emitting gear contact noise, be slow to depress clutch pedal (1), and at gear contact noise died

position (release point) stop depressing.

5) Measure distance between release point (4) and full stroke point (5) on clutch pedal (1) which is shown by

“C” in figure.

Clutch release margin

“C”: 25 – 55 mm (0.98 – 2.17 in.)

6) If “C” is not within specificat ion, it is possible that air

is trapped in this system. If suspected so, bleed air

referring to “Air Bleeding of Clutch System”. Upon

completion of above inspection, start engine and

check clutch for proper operation.

Clutch Fluid Level InspectionS7RS0B5306002

Refer to “Brake Fluid Level Inspection in Section 4A”.

Clutch fluid specification

: Refer to reservoir cap.

Air Bleeding of Clutch SystemS7RS0B5306003

CAUTION!

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

Bleeding operation is necessary to remove air whenever

it entered hydraulic clutch system.

1) Fill master cylinder reservoir with brake fluid and keep at least one-half full of fluid during bleeding

operation.

Brake Fluid

Refer to reservoir cap

2) Remove bleeder plug cap from clutch operating cylinder (3). Attach a vinyl tube (1) to bleeder plug

(4), and insert the other end into container (2).

2

1

“A”

3

2

1

3

“B”

“C”

4

5

I4RS0B530001-01

I4RS0A530023-01

3 4 1

2

3

I4RS0A530003-01

Page 856 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-4 Clutch:

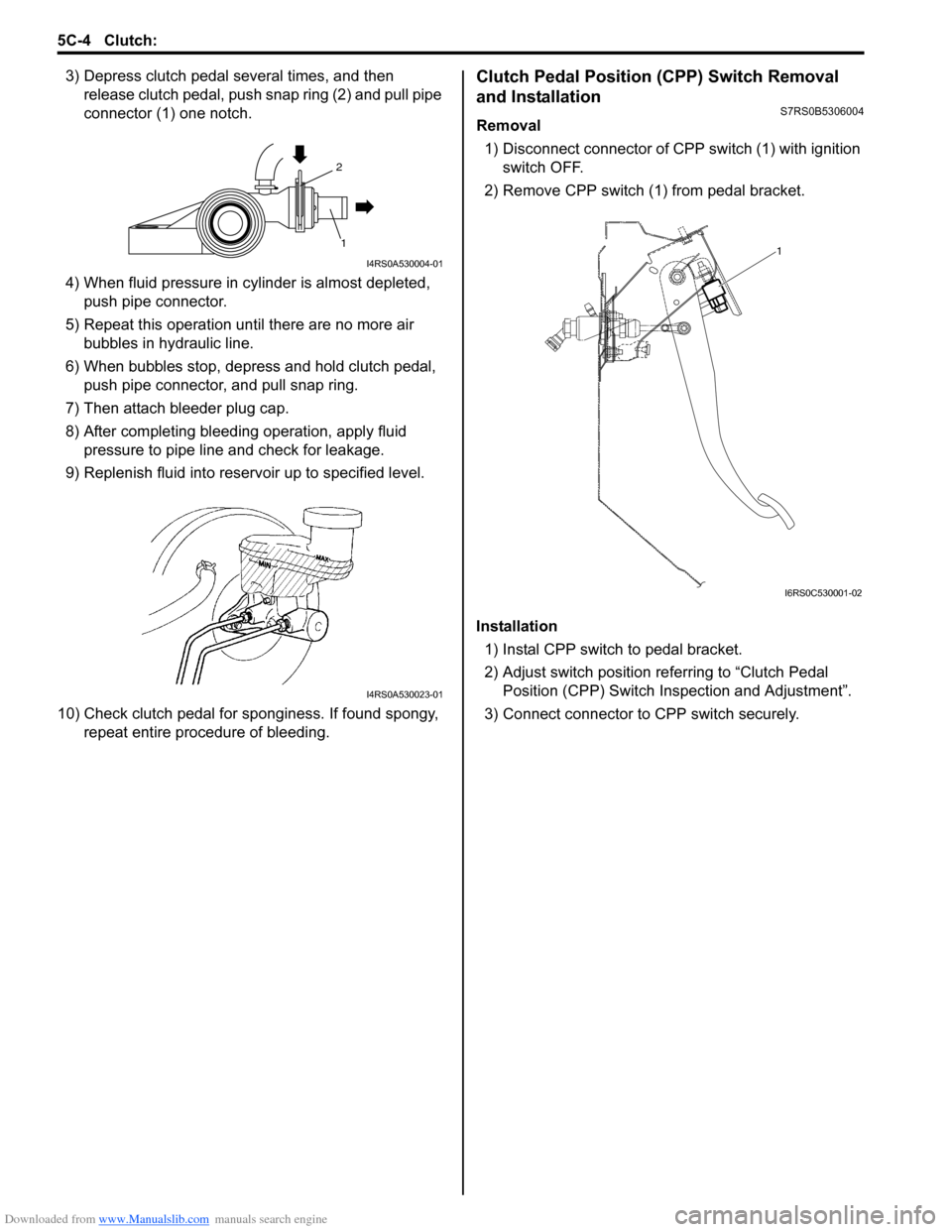

3) Depress clutch pedal several times, and then release clutch pedal, push snap ring (2) and pull pipe

connector (1) one notch.

4) When fluid pressure in cylinder is almost depleted, push pipe connector.

5) Repeat this operation until there are no more air bubbles in hydraulic line.

6) When bubbles stop, depress and hold clutch pedal, push pipe connector, and pull snap ring.

7) Then attach bleeder plug cap.

8) After completing bleeding operation, apply fluid pressure to pipe line and check for leakage.

9) Replenish fluid into reserv oir up to specified level.

10) Check clutch pedal for sponginess. If found spongy, repeat entire procedure of bleeding.Clutch Pedal Position (CPP) Switch Removal

and Installation

S7RS0B5306004

Removal

1) Disconnect connector of C PP switch (1) with ignition

switch OFF.

2) Remove CPP switch (1 ) from pedal bracket.

Installation 1) Instal CPP switch to pedal bracket.

2) Adjust switch position re ferring to “Clutch Pedal

Position (CPP) Switch Inspection and Adjustment”.

3) Connect connector to CPP switch securely.

2

1

I4RS0A530004-01

I4RS0A530023-01

1

I6RS0C530001-02

Page 858 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-6 Clutch:

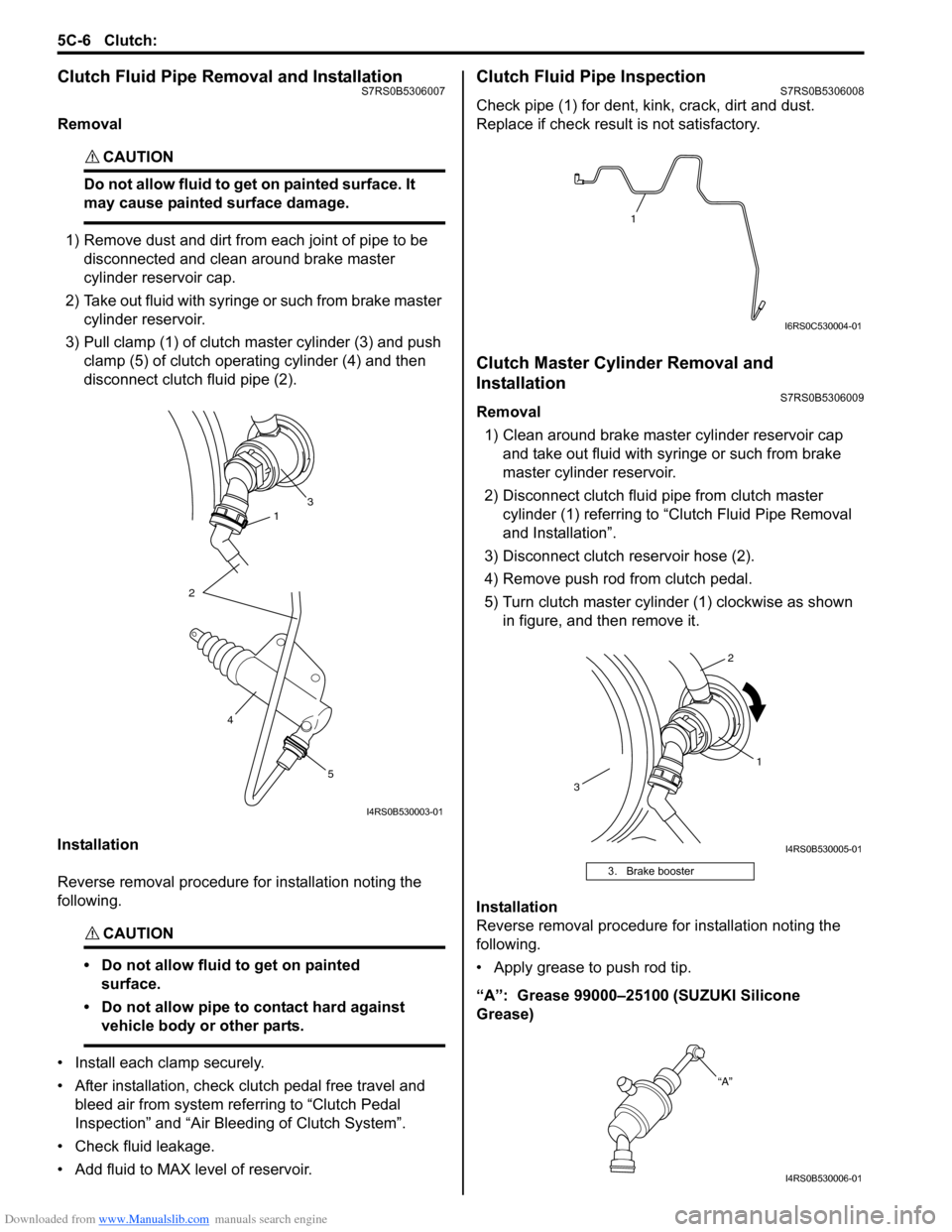

Clutch Fluid Pipe Removal and InstallationS7RS0B5306007

Removal

CAUTION!

Do not allow fluid to get on painted surface. It

may cause painted surface damage.

1) Remove dust and dirt from each joint of pipe to be disconnected and clean around brake master

cylinder reservoir cap.

2) Take out fluid with syringe or such from brake master cylinder reservoir.

3) Pull clamp (1) of clutch master cylinder (3) and push clamp (5) of clutch operating cylinder (4) and then

disconnect clutch fluid pipe (2).

Installation

Reverse removal procedure for installation noting the

following.

CAUTION!

• Do not allow fluid to get on painted surface.

• Do not allow pipe to contact hard against vehicle body or other parts.

• Install each clamp securely.

• After installation, check clutch pedal free travel and bleed air from system referring to “Clutch Pedal

Inspection” and “Air Blee ding of Clutch System”.

• Check fluid leakage.

• Add fluid to MAX level of reservoir.

Clutch Fluid Pipe InspectionS7RS0B5306008

Check pipe (1) for dent, kink, crack, dirt and dust.

Replace if check result is not satisfactory.

Clutch Master Cylinder Removal and

Installation

S7RS0B5306009

Removal 1) Clean around brake master cylinder reservoir cap and take out fluid with syringe or such from brake

master cylinder reservoir.

2) Disconnect clutch fluid pipe from clutch master cylinder (1) referring to “C lutch Fluid Pipe Removal

and Installation”.

3) Disconnect clutch reservoir hose (2).

4) Remove push rod from clutch pedal.

5) Turn clutch master cylinder (1) clockwise as shown in figure, and then remove it.

Installation

Reverse removal procedure for installation noting the

following.

• Apply grease to push rod tip.

“A”: Grease 99000–25100 (SUZUKI Silicone

Grease)

31

2

5

4

I4RS0B530003-01

3. Brake booster

1

I6RS0C530004-01

1

2

3

I4RS0B530005-01

“A”

I4RS0B530006-01

Page 997 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-49

Step 7. Final confirmation test

Confirm if the problem symptom is troubleshoot and the A/C system is free from any abnormal conditions. If there

existed DTC, clear the DTC. Then , check if the DTC is still detected and if there is any other DTC.

Visual InspectionS7RS0B7224009

Check visually the following parts and systems.

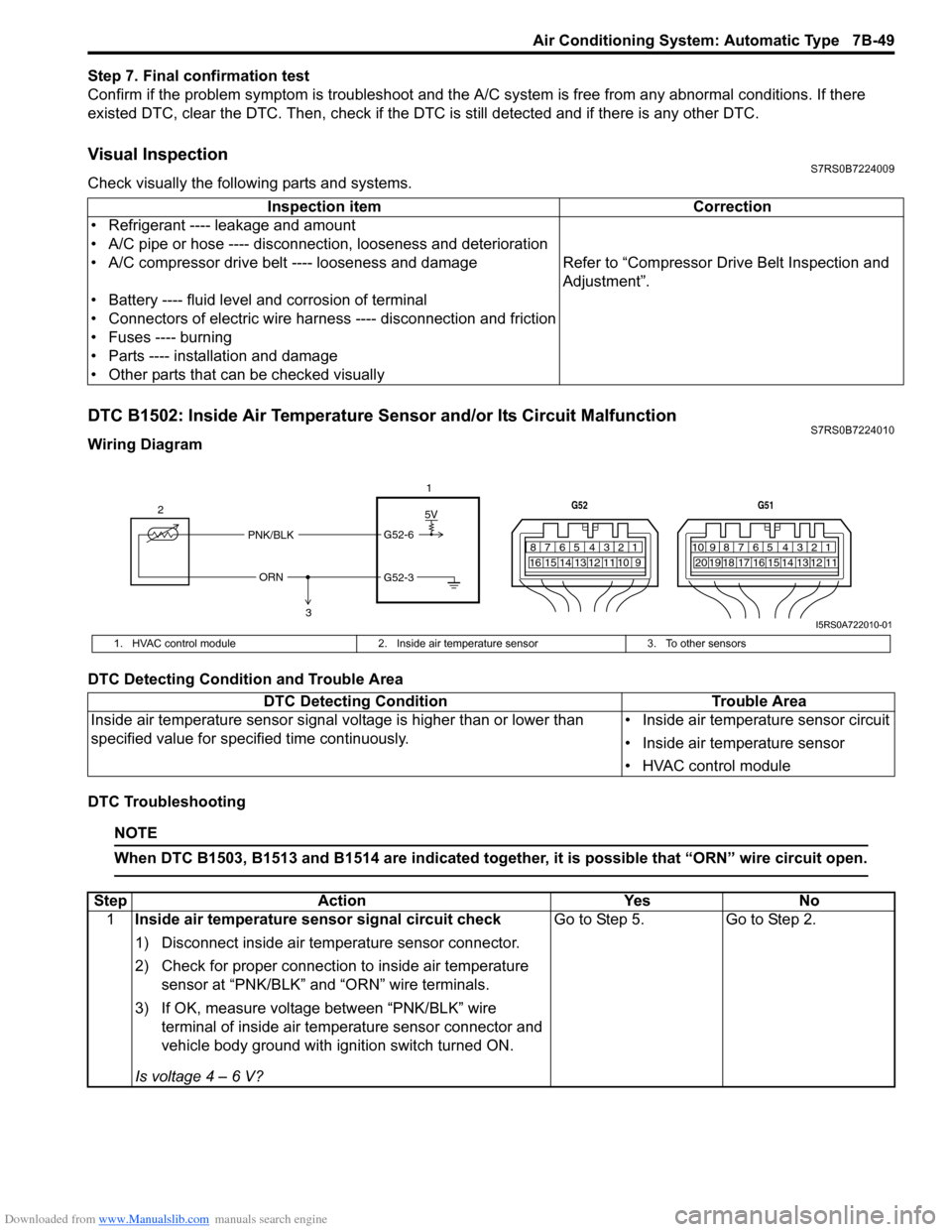

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit MalfunctionS7RS0B7224010

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

When DTC B1503, B1513 and B1514 are indicated together, it is possible that “ORN” wire circuit open.

Inspection item Correction

• Refrigerant ---- leakage and amount

• A/C pipe or hose ---- disconnection, looseness and deterioration

• A/C compressor drive belt ---- looseness and damage Refer to “Compressor Drive Belt Inspection and

Adjustment”.

• Battery ---- fluid level and corrosion of terminal

• Connectors of electric wire harn ess ---- disconnection and friction

• Fuses ---- burning

• Parts ---- installation and damage

• Other parts that can be checked visually

5V

PNK/BLK

ORN G52-6

G52-3

2

1

3

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

I5RS0A722010-01

1. HVAC control module

2. Inside air temperature sensor 3. To other sensors

DTC Detecting Condition Trouble Area

Inside air temperature sensor signal voltage is higher than or lower than

specified value for specified time continuously. • Inside air temperature sensor circuit

• Inside air temperature sensor

• HVAC control module

Step

Action YesNo

1 Inside air temperature sensor signal circuit check

1) Disconnect inside air temperature sensor connector.

2) Check for proper connection to inside air temperature

sensor at “PNK/BLK” and “ORN” wire terminals.

3) If OK, measure voltage between “PNK/BLK” wire terminal of inside air temp erature sensor connector and

vehicle body ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 2.

Page 1168 of 1496

Downloaded from www.Manualslib.com manuals search engine 9-ii Table of Contents

List of Connectors ........................................... 9A-103

C Connector .................................................... 9A-103

D Connector (M16A engine) ........................... 9A-104

E Connector .................................................... 9A-104

G Connector .................................................... 9A-106

J Connector ..................................................... 9A-108

K Connector .................................................... 9A-109

L Connector..................................................... 9A-109

M Connector (SPORT model) ......................... 9A-111

O Connector .................................................... 9A-111

R Connector .................................................... 9A-111

Lighting Systems .................................... 9B-1

Component Location ........... ................................9B-1

Lighting System Component s Location............... 9B-1

Interior Light System Location............................. 9B-2

Diagnostic Information and Procedures ............ 9B-2 Headlight Symptom Diagnosis ............................ 9B-2

Headlight Leveling System Symptom Diagnosis (If Equipped) ..................................... 9B-2

Turn Signal and Hazard Warning Light Symptom Diagnosis .......................................... 9B-3

Clearance, Tail and License Plate Light Symptom Diagnosis .......................................... 9B-3

Back-Up Light Symptom Diagnosis..................... 9B-4

Brake Light Symptom Diagnosis ......................... 9B-4

Front Fog Light Symptom Diagnosis (If Equipped) .......................................................... 9B-4

Interior Light Symptom Diagnosis ....................... 9B-5

Repair Instructions ..............................................9B-5 Headlight Housing Removal and Installation ...... 9B-5

Headlight Bulb Replacemen t............................... 9B-6

Headlight Aiming Adjustment with Screen .......... 9B-6

Headlight Switch (in Lighting Switch) Removal and Installation ................................... 9B-8

Headlight Switch (in Lighting Switch) Inspection .......................................................... 9B-8

Hazard Warning Switch Removal and Installation ......................................................... 9B-8

Hazard Warning Switch Inspection ..................... 9B-9

Brake Light Switch Inspection ............................. 9B-9

Turn Signal Light Switch (in Lighting Switch) Removal and Installation ................................... 9B-9

Turn Signal Light Switch (in Lighting Switch) Inspection .......................................................... 9B-9

Turn Signal and Hazard Warning Relay Removal and Installation ................................... 9B-9

Turn Signal and Hazard Warning Relay Inspection ........................................................ 9B-10

License Light Removal and Installation............. 9B-10

Front Fog Light Removal and Installation (If Equipped) ........................................................ 9B-11

Front Fog Light Bulb Replacement (If Equipped) ........................................................ 9B-11

Front Fog Light Switch Inspection (If Equipped) ........................................................ 9B-11

Front Fog Light Relay Inspection (If Equipped) ........................................................ 9B-11

Front Fog Light Aiming Adjustment with Screen (If Equipped) ....................................... 9B-12 Headlight Leveling Switch Inspection (If

Equipped) ........................................................ 9B-13

Headlight Leveling Actuator Inspection (If Equipped) ........................................................ 9B-13

Instrumentation / Driver Info. / Horn ...... 9C-1

Precautions ...........................................................9C-1 Precautions in Diagnosing Troubles for Combination Meter ............................................9C-1

General Description .............................................9C-1 CAN Communication System Description...........9C-1

Auto Volume Co ntrol System Description (If

Equipped) ..........................................................9C-3

Schematic and Routing Diagram ........................9C-4 Combination Meter Circuit Diagram ....................9C-4

Component Location ............ ...............................9C-6

Audio System Component Location ....................9C-6

Diagnostic Information and Procedures ............9C-6 Speedometer and VSS Symp tom Diagnosis ......9C-6

Tachometer Symptom Diagnosis ........................9C-6

Engine Coolant Temperature (ECT) Meter Symptom Diagnosis ..........................................9C-7

Fuel Meter Symptom Diagnosis ..........................9C-7

Low Fuel Warning Light Symptom Diagnosis .....9C-7

Oil Pressure Warning Light Symptom Diagnosis ..........................................................9C-8

Brake and Parking Brake Warning Light Symptom Diagnosis ..........................................9C-8

Seat Belt Reminder Light Symptom Diagnosis (If Equipped)......................................................9C-8

A/T Shift Position Indicator Symptom Diagnosis (A/T Model).......................................9C-9

Charge Warning Light Sy mptom Diagnosis ........9C-9

Main Beam (High Beam) Indicator Symptom Diagnosis ..........................................................9C-9

Warning Buzzer Circuit Sy mptom Diagnosis ....9C-10

Cigarette Lighter Symptom Diagnosis (If Equipped) ........................................................9C-10

Horn Symptom Diagnosis .................................9C-10

Information Display Symptom Diagnosis (If Equipped) ........................................................9C-11

Clock Symptom Diagnosis (If Equipped)...........9C-12

Audio System Symptom Diagnosis (If Equipped) ........................................................9C-12

Remote Audio Control Switch Symptom Diagnosis (If Equipped) ...................................9C-13

Navigation Symptom Diagnosis (If Equipped)...9C-14

Repair Instructions ............ ................................9C-14

Ignition Switch Removal and Installation...........9C-14

Ignition Switch Inspection..................................9C-14

Combination Meter Removal and Installation ...9C-15

Fuel Level Sensor Removal and Installation .....9C-15

Fuel Level Sensor Inspection ............................9C-15

Oil Pressure Switch Remova l and Installation ..9C-15

Oil Pressure Switch Inspec tion .........................9C-16

Engine Coolant Temperature (ECT) Sensor Inspection ........................................................9C-16

Brake Fluid Level Switch Inspection .................9C-16

Parking Brake Switch Inspec tion.......................9C-16

Page 1185 of 1496

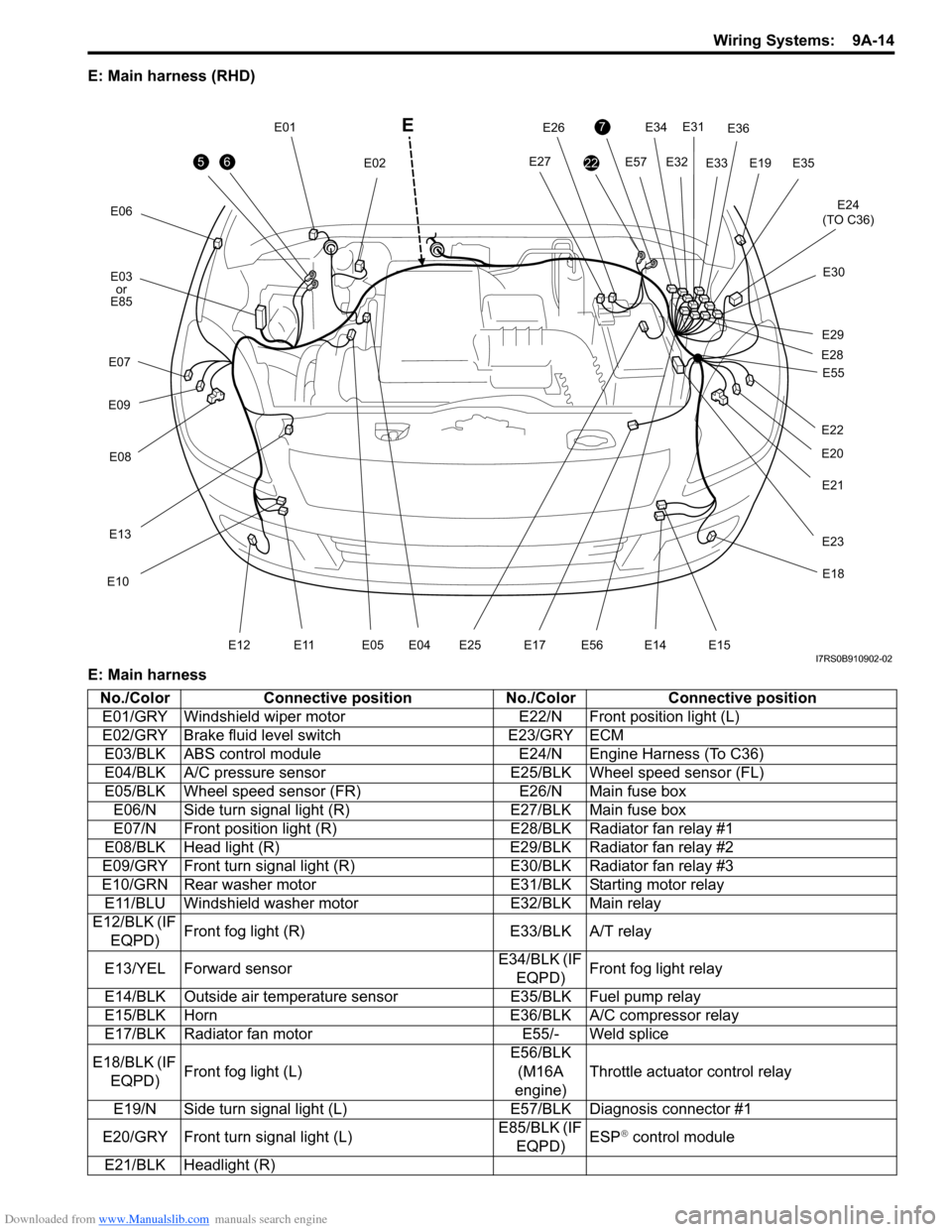

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-14

E: Main harness (RHD)

E: Main harness

56

E06E12

E03or

E85

E07

E09

E08

E13

E10

E11E05 E04

E01 E02

E19

7

22

E34E31

E32

E57

E24

(TO C36)

E33

E36

E35

E30

E29

E28

E20

E21

E22

E27

E26

E23

E25E17E56

E18

E14 E15

E55

E

I7RS0B910902-02

No./Color

Connective position No./ColorConnective position

E01/GRY Windshield wiper motor E22/N Front position light (L)

E02/GRY Brake fluid level switch E23/GRY ECM

E03/BLK ABS control module E24/N Engine Harness (To C36)

E04/BLK A/C pressure sensor E25/BLK Wheel speed sensor (FL)

E05/BLK Wheel speed sensor (FR) E26/N Main fuse box

E06/N Side turn signal light (R) E27/BLK Main fuse box

E07/N Front position light (R) E28/BLK Radiator fan relay #1

E08/BLK Head light (R) E29/BLK Radiator fan relay #2

E09/GRY Front turn signal light (R) E30/BLK Radiator fan relay #3

E10/GRN Rear washer motor E31/BLK Starting motor relay

E11/BLU Windshield washer motor E32/BLK Main relay

E12/BLK (IF EQPD) Front fog light (R)

E33/BLK A/T relay

E13/YEL Forward sensor E34/BLK (IF

EQPD) Front fog light relay

E14/BLK Outside air temperature sensor E35/BLK Fuel pump relay

E15/BLK Horn E36/BLK A/C compressor relay

E17/BLK Radiator fan motor E55/- Weld splice

E18/BLK (IF EQPD) Front fog light (L) E56/BLK

(M16A

engine) Throttle actuator control relay

E19/N Side turn signal light (L) E57/BLK Diagnosis connector #1

E20/GRY Front turn signal light (L) E85/BLK (IF

EQPD) ESP

® control module

E21/BLK Headlight (R)

Page 1186 of 1496

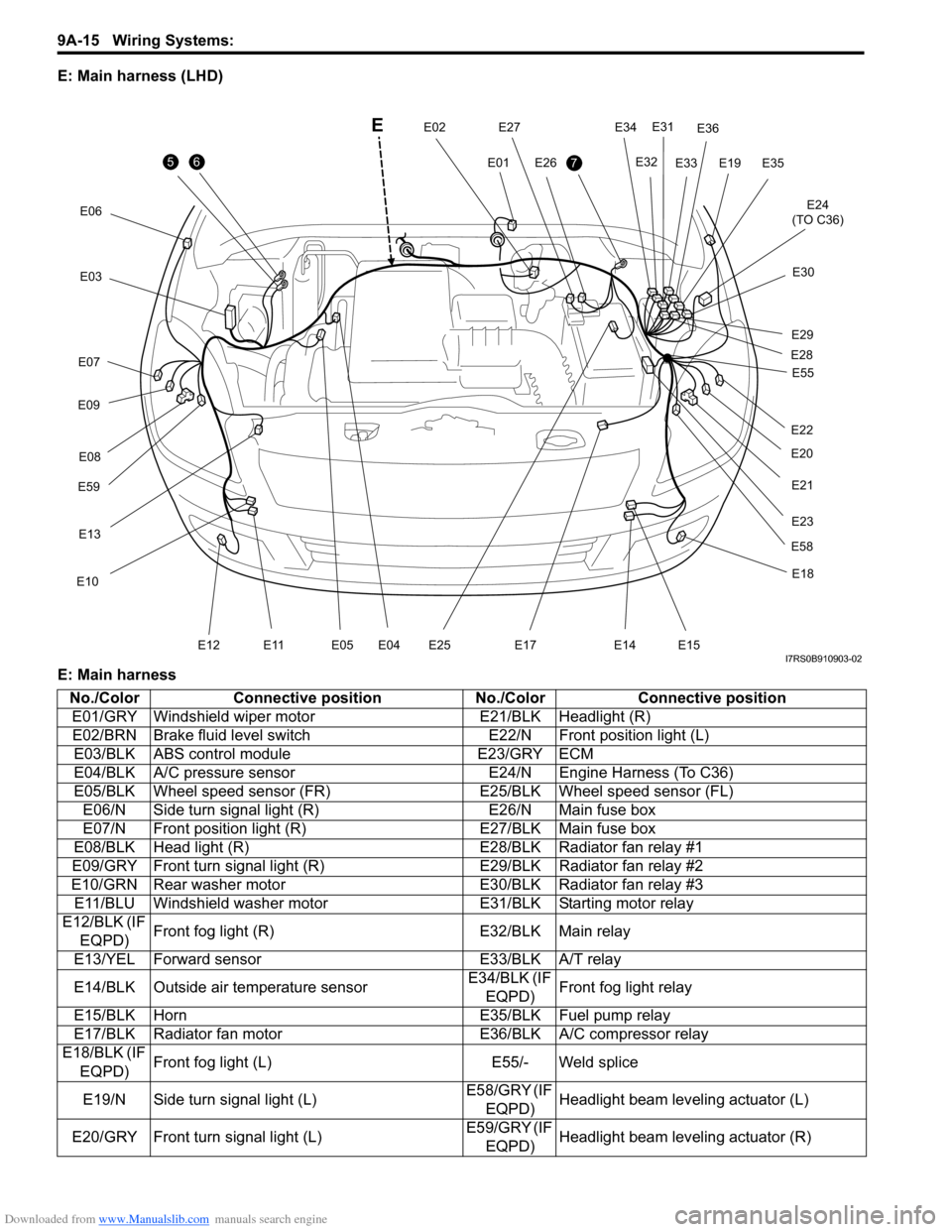

Downloaded from www.Manualslib.com manuals search engine 9A-15 Wiring Systems:

E: Main harness (LHD)

E: Main harness

56

E06E12

E

E03

E07

E09

E59E08

E13

E10

E11E05 E04

E01

E02E197

E34

E31

E32

E24

(TO C36)

E33

E36

E35

E30

E29

E28

E20

E21

E22

E58

E27

E26

E23

E25E17

E18

E14 E15

E55

I7RS0B910903-02

No./Color

Connective position No./ColorConnective position

E01/GRY Windshield wiper motor E21/BLK Headlight (R)

E02/BRN Brake fluid level switch E22/N Front position light (L)

E03/BLK ABS control module E23/GRY ECM

E04/BLK A/C pressure sensor E24/N Engine Harness (To C36)

E05/BLK Wheel speed sensor (FR) E25/BLK Wheel speed sensor (FL)

E06/N Side turn signal light (R) E26/N Main fuse box

E07/N Front position light (R) E27/BLK Main fuse box

E08/BLK Head light (R) E28/BLK Radiator fan relay #1

E09/GRY Front turn signal light (R) E29/BLK Radiator fan relay #2

E10/GRN Rear washer motor E30/BLK Radiator fan relay #3

E11/BLU Windshield washer motor E31/BLK Starting motor relay

E12/BLK (IF EQPD) Front fog light (R)

E32/BLK Main relay

E13/YEL Forward sensor E33/BLK A/T relay

E14/BLK Outside air temperature sensor E34/BLK (IF

EQPD) Front fog light relay

E15/BLK Horn E35/BLK Fuel pump relay

E17/BLK Radiator fan motor E36/BLK A/C compressor relay

E18/BLK (IF

EQPD) Front fog light (L)

E55/- Weld splice

E19/N Side turn signal light (L) E58/GRY (IF

EQPD) Headlight beam leveling actuator (L)

E20/GRY Front turn signal light (L) E59/GRY (IF

EQPD) Headlight beam leveling actuator (R)

Page 1230 of 1496

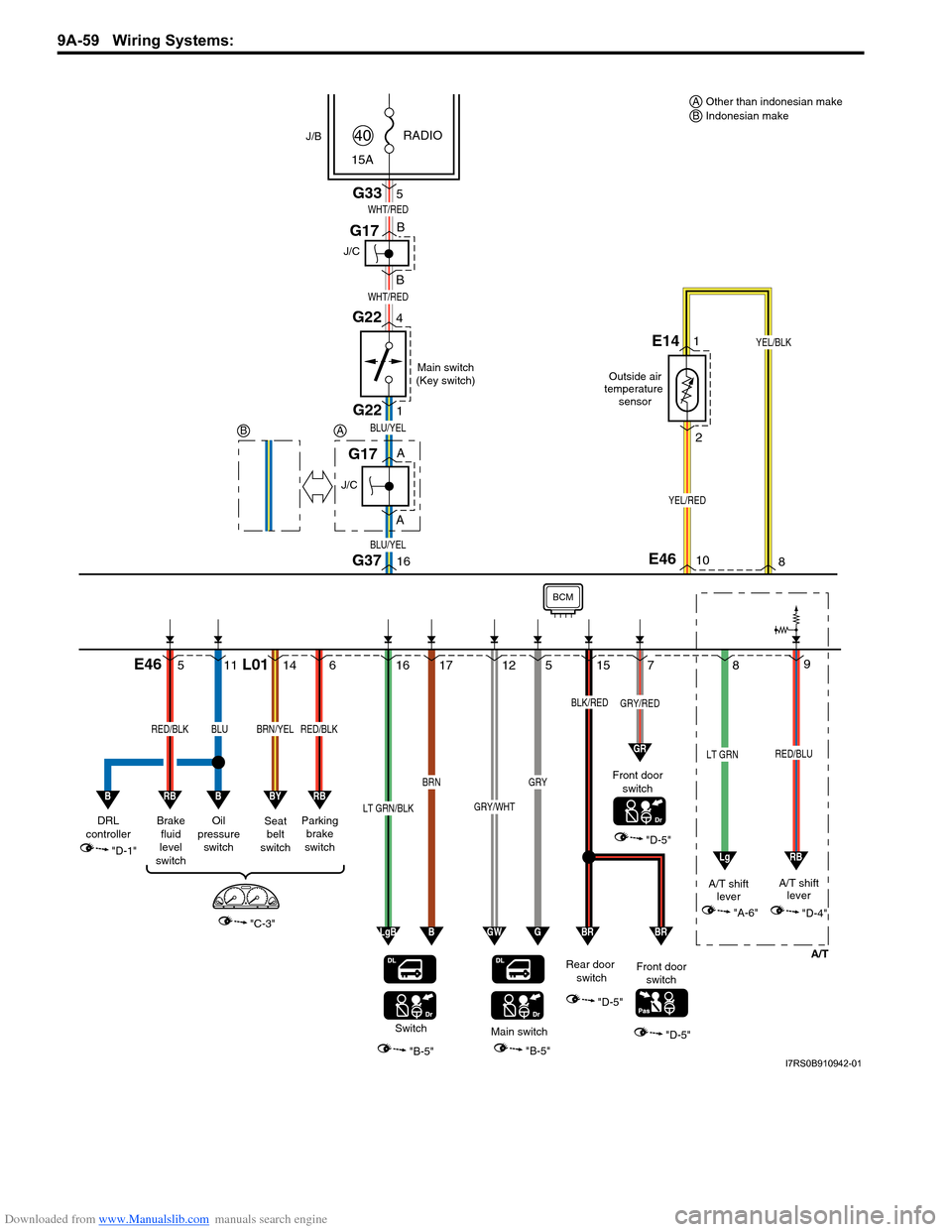

Downloaded from www.Manualslib.com manuals search engine 9A-59 Wiring Systems:

9

15 7

"D-5"

"A-6"

A/T

GRY/RED

RED/BLU

16

A A

B

BG37

BLU/YEL

BLU/YEL

J/C

G17

J/C

G17

G22

G22

1

4

Main switch

(Key switch)

RADIO

G335

15A

40

WHT/RED

WHT/RED

YEL/RED

YEL/BLK1E14

2

Outside air

temperature sensor

"B-5"

Switch

6L0114

1617125

RED/BLKBRN/YEL

LT GRN/BLK

BRN

GRY/WHT

GRY

Parking

brake

switch

Seat

belt

switch

"C-3"

"D-1"

RBBY

8

LT GRN

A/T shift lever A/T shift

lever

115

"D-4"

LgRB

GR

Oil

pressure switchBrakefluid

level

switch

B

DRL

controller

B

E46

10E468

LgBBGWG

Main switch

"B-5"

Front door switch

Front door switch

Rear door switch

"D-5"

"D-5"

BRBR

BLK/RED

J/B

BCM

BLURED/BLK

RB

Other than indonesian make

Indonesian make

A

AB

B

I7RS0B910942-01

Page 1246 of 1496

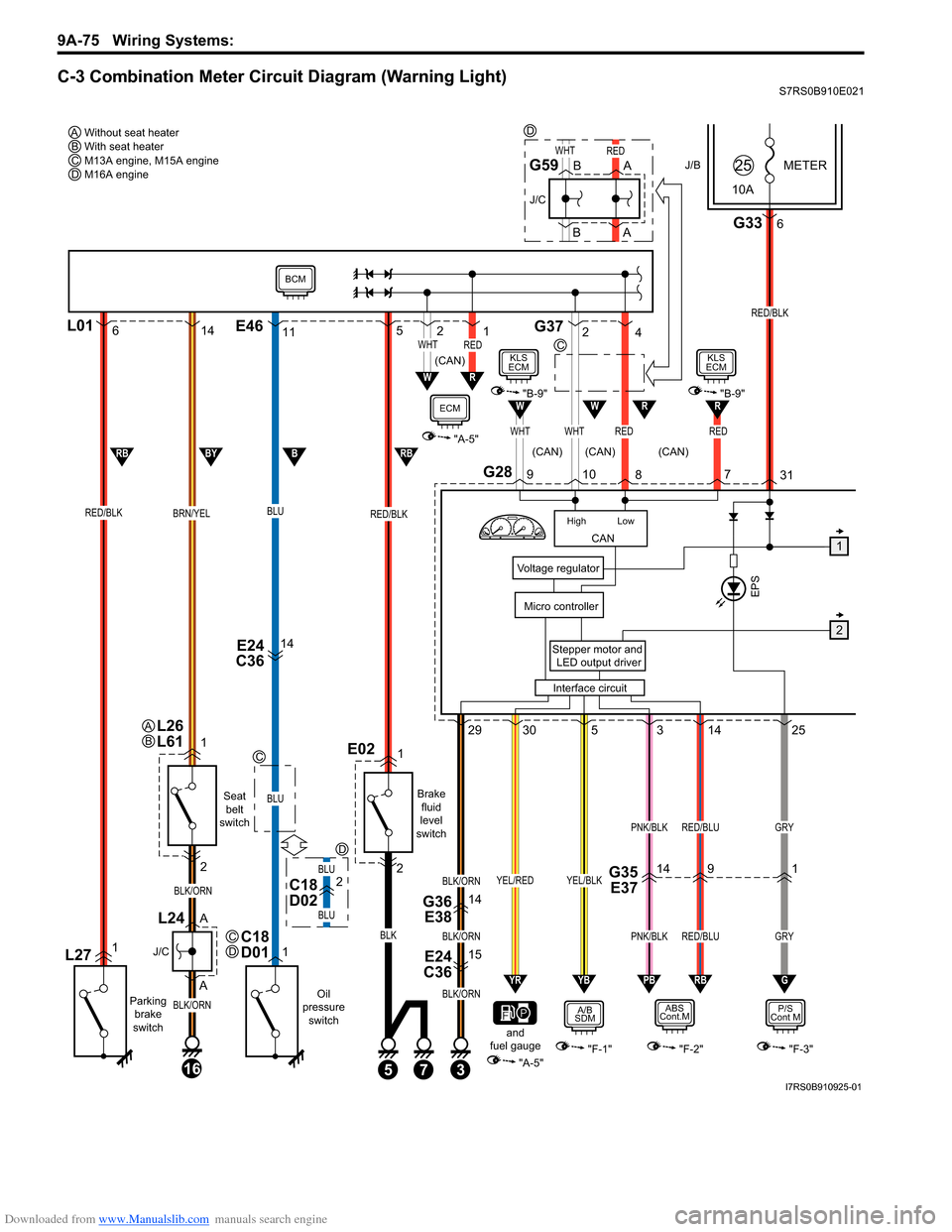

Downloaded from www.Manualslib.com manuals search engine 9A-75 Wiring Systems:

C-3 Combination Meter Circuit Diagram (Warning Light)S7RS0B910E021

J/BMETER

10A25

G2831

3

E24

C3615

G36 E3814

Stepper motor and

LED output driver

Voltage regulator

Interface circuit

Micro controllerEPS

G336

RED/BLK

145293025

PNK/BLKGRY

GRY

RED/BLU

PNK/BLK

BLK/ORN

BLK/ORN

BLK/ORN

RED/BLU

P/S

Cont M

"F-3"

RBPBYBYR

YEL/BLKYEL/RED

A/B

SDM

"F-1""A-5"

ABS

Cont.M

"F-2"

G

CAN

High Low

WHTWHTRED

WHTRED

RED

RW

109 8

6L0114

RED/BLKBRN/YEL

L271

Parking

brake

switch

1

2

A

A

16

BLK/ORN

BLK/ORN

J/C

L24

Seat belt

switch

Oil

pressure switch

E24

C3614

BLU

BLU

1C18

D01

RED/BLK

E021

Brake

fluid

level

switch

and

fuel gauge

2

53

BLK

11 5E46G372

4

RW

W

21WHTRED

"A-5"

1

2

RBBBYRB

7

BCM

ECM"B-9"

KLS

ECM

7

R"B-9"

KLS

ECM

Without seat heater

AWith seat heater

BM13A engine, M15A engine

CM16A engine

D

C

C

C

D

(CAN)

(CAN) (CAN)

(CAN)

L26

L61AB

B

BA

A

J/C

G59

BLU

BLU

D

C18

D022G35 E371419

D

I7RS0B910925-01