auto lock SUZUKI SWIFT 2005 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 784 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-140 Automatic Transmission/Transaxle:

Valve Body Assembly Disassembly and

Reassembly

S7RS0B5106053

CAUTION!

When replacing pressure control solenoid

valve and/or TCC pressure control solenoid

valve, it is strictly required to replace it

together with valve body assembly as a set.

Replacing pressure control solenoid valve

and/or TCC pressure control solenoid valve

independently may cause excessive shift

shock.

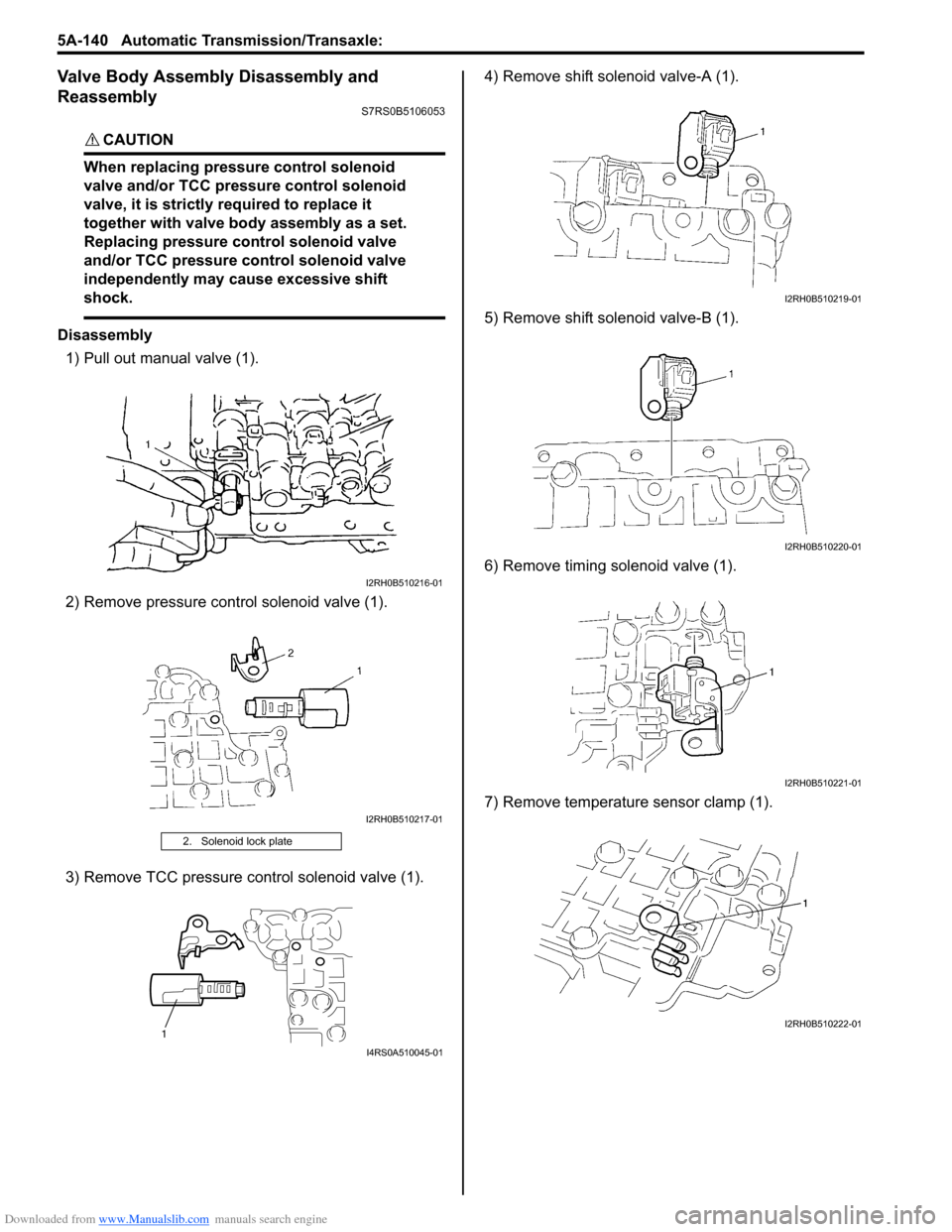

Disassembly1) Pull out manual valve (1).

2) Remove pressure cont rol solenoid valve (1).

3) Remove TCC pressure control solenoid valve (1). 4) Remove shift solenoid valve-A (1).

5) Remove shift solenoid valve-B (1).

6) Remove timing solenoid valve (1).

7) Remove temperature sensor clamp (1).

2. Solenoid lock plate

I2RH0B510216-01

I2RH0B510217-01

1

I4RS0A510045-01

I2RH0B510219-01

I2RH0B510220-01

I2RH0B510221-01

I2RH0B510222-01

Page 794 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-150 Automatic Transmission/Transaxle:

Automatic Transaxle Unit AssemblyS7RS0B5106060

CAUTION!

• Automatic transaxle consists of highly precise parts. As even flaw in small part

may cause oil leakage or decrease in

function, check each part carefully before

installation.

• Clean all parts with compressed air. Never use wiping cloths or rags.

• Before assembling new clutch or brake discs, soak them in automatic transaxle

fluid for at least 2 hours.

• Be sure to use new gaskets and O-rings.

• Lubricate O-rings with automatic transaxle

fluid.

• Apply automatic transaxle fluid on sliding or rotating surfaces of the parts before

assembly.

• Use Suzuki Super Grease “C” to retain parts in place.

• Be sure to install thrust bearings and races in correct direction and position.

• Make sure that snap ring ends are not aligned with one of cut outs and are

installed in groove correctly.

• Do not use adhesive cements on gaskets and similar parts.

• Be sure to torque each bolt and nut to specification.

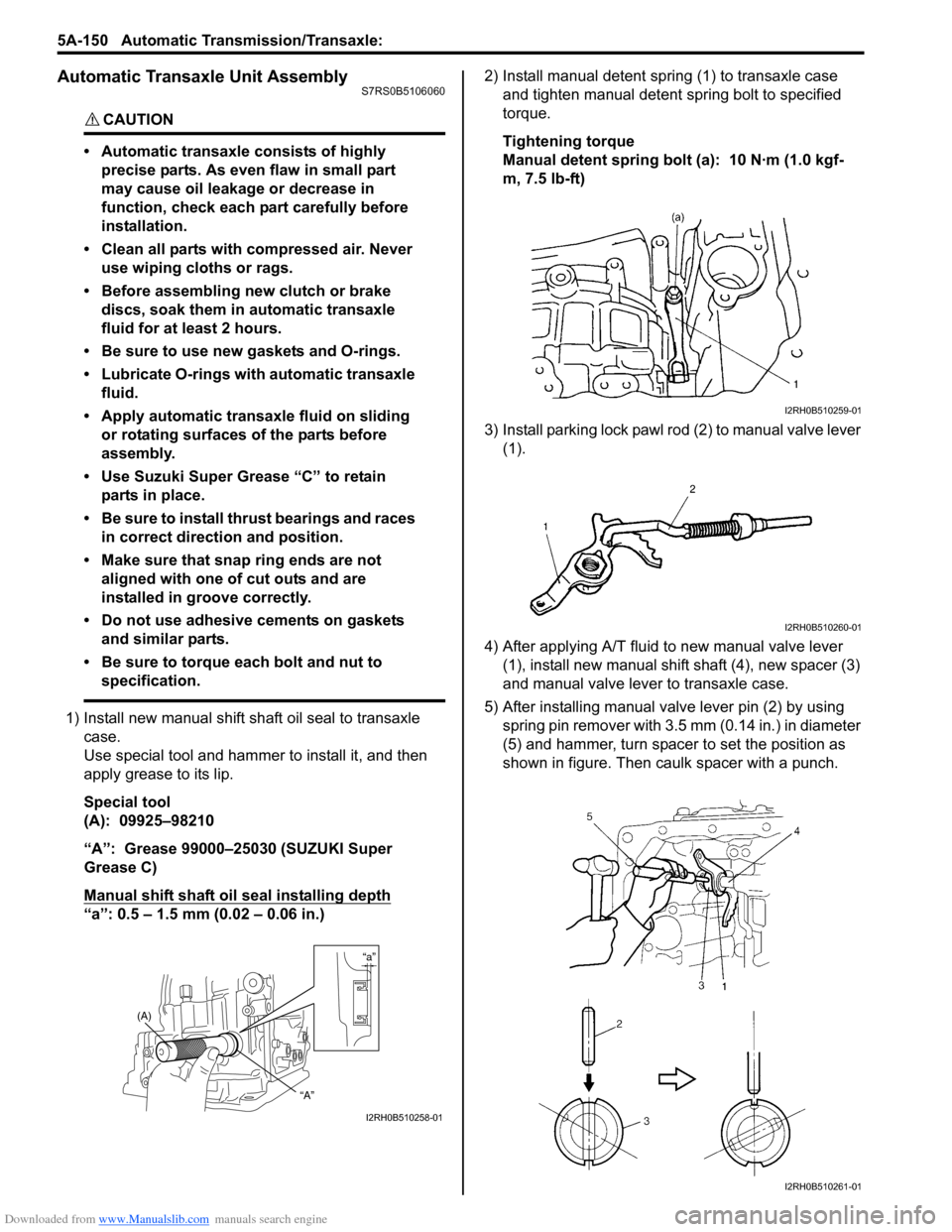

1) Install new manual shift sh aft oil seal to transaxle

case.

Use special tool and hammer to install it, and then

apply grease to its lip.

Special tool

(A): 09925–98210

“A”: Grease 99000–25030 (SUZUKI Super

Grease C)

Manual shift shaft oil seal installing depth

“a”: 0.5 – 1.5 mm (0.02 – 0.06 in.) 2) Install manual detent spring (1) to transaxle case

and tighten manual detent spring bolt to specified

torque.

Tightening torque

Manual detent spring bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

3) Install parking lock pawl ro d (2) to manual valve lever

(1).

4) After applying A/T fluid to new manual valve lever (1), install new manual shift shaft (4), new spacer (3)

and manual valve lever to transaxle case.

5) After installing manual valve lever pin (2) by using spring pin remover with 3.5 mm (0.14 in.) in diameter

(5) and hammer, turn spacer to set the position as

shown in figure. Then caulk spacer with a punch.

“a”

(A)

“A”

I2RH0B510258-01

I2RH0B510259-01

I2RH0B510260-01

I2RH0B510261-01

Page 795 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-151

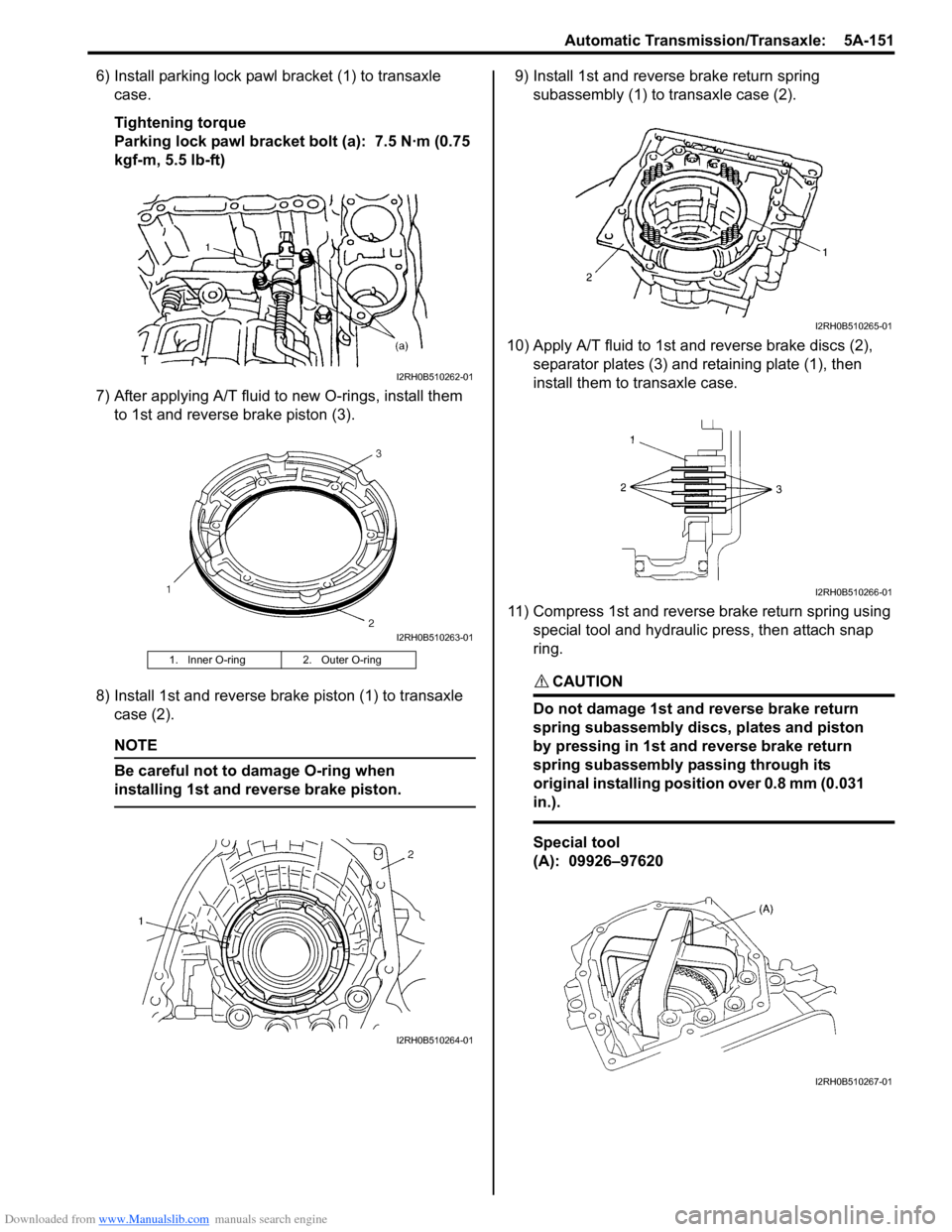

6) Install parking lock pawl bracket (1) to transaxle

case.

Tightening torque

Parking lock pawl bracket bolt (a): 7.5 N·m (0.75

kgf-m, 5.5 lb-ft)

7) After applying A/T fluid to new O-rings, install them to 1st and reverse brake piston (3).

8) Install 1st and reverse brake piston (1) to transaxle case (2).

NOTE

Be careful not to damage O-ring when

installing 1st and reverse brake piston.

9) Install 1st and reverse brake return spring subassembly (1) to transaxle case (2).

10) Apply A/T fluid to 1st and reverse brake discs (2), separator plates (3) and retaining plate (1), then

install them to transaxle case.

11) Compress 1st and reverse brake return spring using special tool and hydraulic press, then attach snap

ring.

CAUTION!

Do not damage 1st and reverse brake return

spring subassembly discs, plates and piston

by pressing in 1st and reverse brake return

spring subassembly passing through its

original installing position over 0.8 mm (0.031

in.).

Special tool

(A): 09926–97620

1. Inner O-ring 2. Outer O-ring

I2RH0B510262-01

I2RH0B510263-01

I2RH0B510264-01

I2RH0B510265-01

I2RH0B510266-01

I2RH0B510267-01

Page 796 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-152 Automatic Transmission/Transaxle:

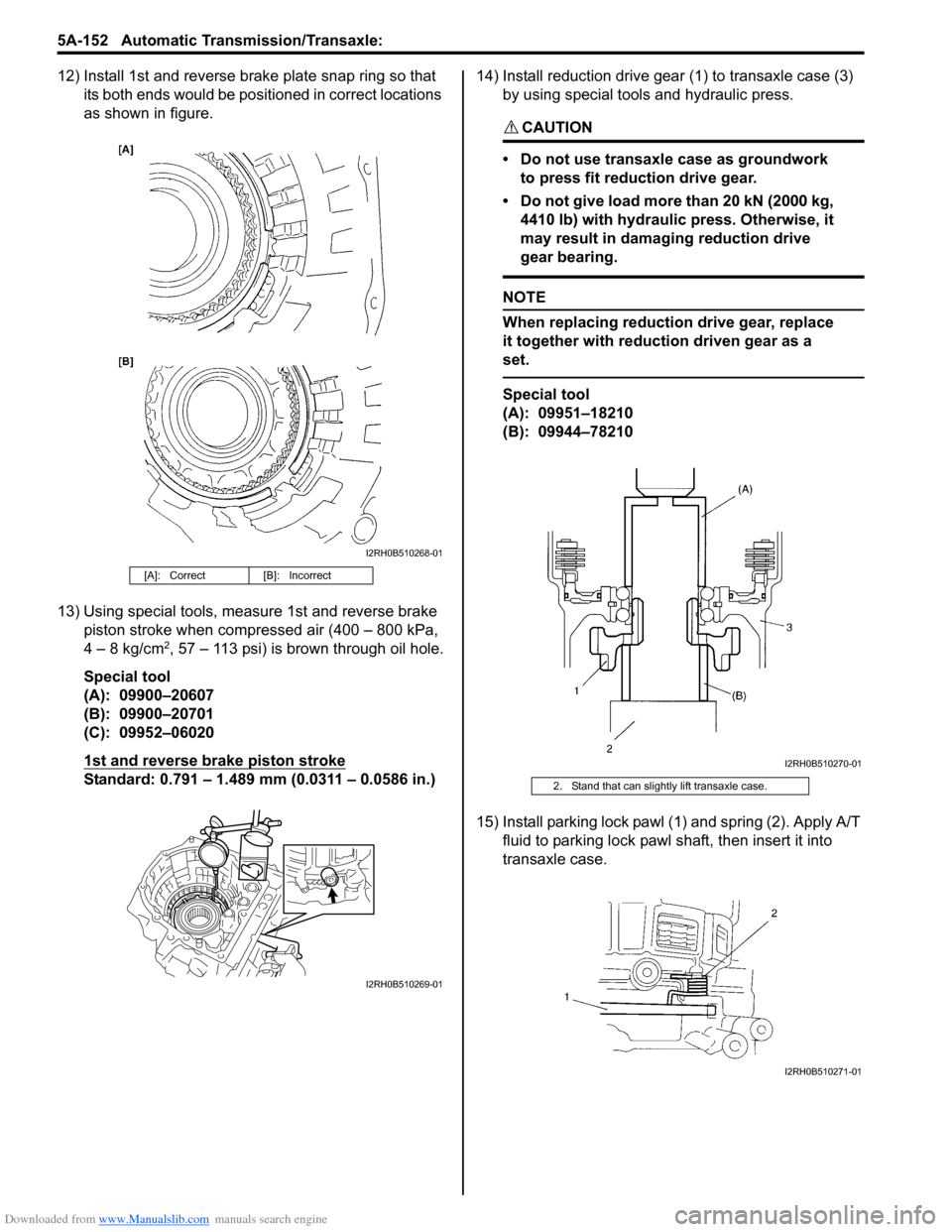

12) Install 1st and reverse brake plate snap ring so that its both ends would be positioned in correct locations

as shown in figure.

13) Using special tools, meas ure 1st and reverse brake

piston stroke when compressed air (400 – 800 kPa,

4 – 8 kg/cm

2, 57 – 113 psi) is brown through oil hole.

Special tool

(A): 09900–20607

(B): 09900–20701

(C): 09952–06020

1st and reverse brake piston stroke

Standard: 0.791 – 1.489 mm (0.0311 – 0.0586 in.) 14) Install reduction drive gear (1) to transaxle case (3)

by using special tools and hydraulic press.

CAUTION!

• Do not use transaxle case as groundwork to press fit reduction drive gear.

• Do not give load more than 20 kN (2000 kg, 4410 lb) with hydraulic press. Otherwise, it

may result in damaging reduction drive

gear bearing.

NOTE

When replacing reduction drive gear, replace

it together with reduction driven gear as a

set.

Special tool

(A): 09951–18210

(B): 09944–78210

15) Install parking lock pawl (1) and spring (2). Apply A/T fluid to parking lock pawl sh aft, then insert it into

transaxle case.

[A]: Correct [B]: Incorrect

I2RH0B510268-01

I2RH0B510269-01

2. Stand that can slightly lift transaxle case.

I2RH0B510270-01

I2RH0B510271-01

Page 798 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-154 Automatic Transmission/Transaxle:

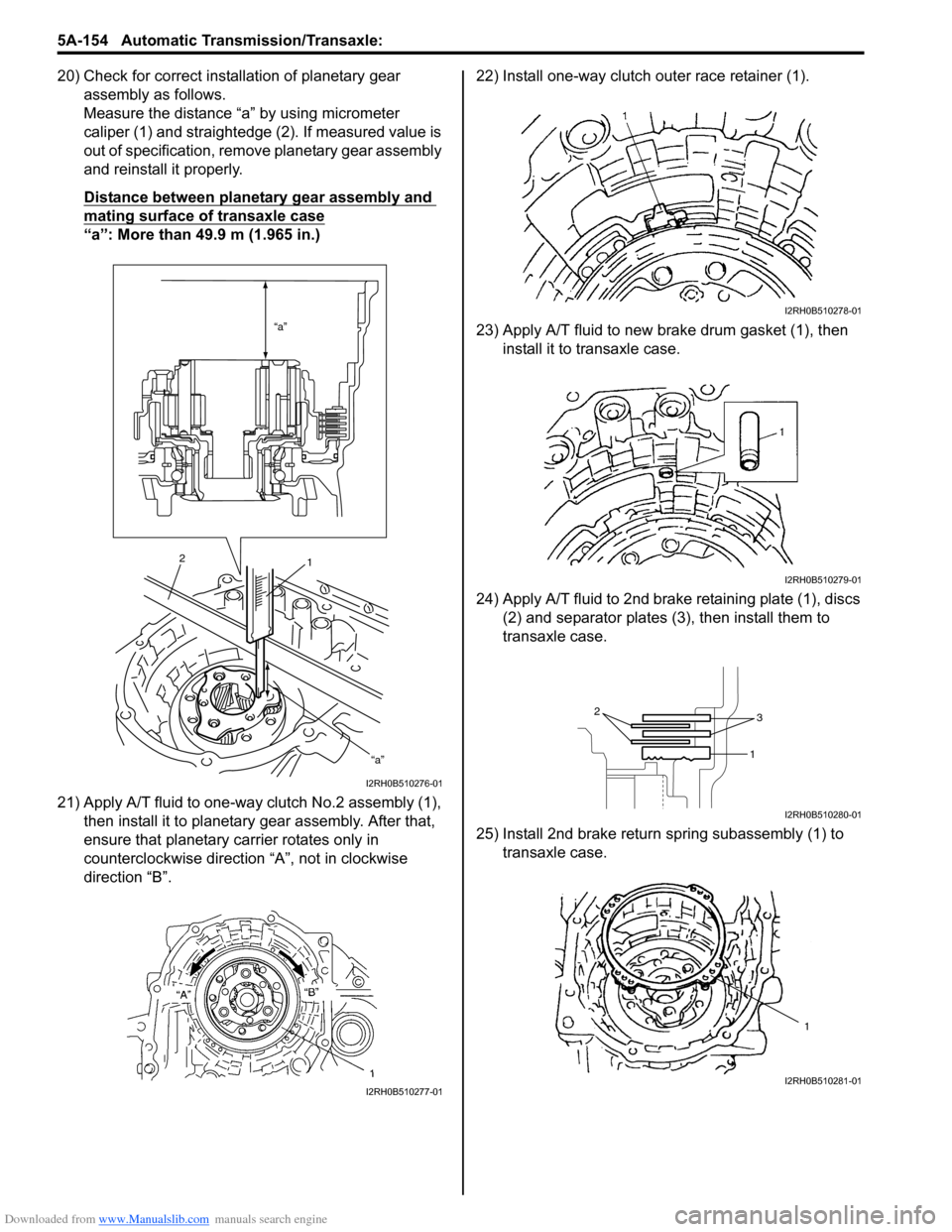

20) Check for correct installation of planetary gear assembly as follows.

Measure the distance “a” by using micrometer

caliper (1) and straightedge (2). If measured value is

out of specification, remove planetary gear assembly

and reinstall it properly.

Distance between planetary gear assembly and

mating surface of transaxle case

“a”: More than 49.9 m (1.965 in.)

21) Apply A/T fluid to one-way clutch No.2 assembly (1), then install it to planetar y gear assembly. After that,

ensure that planetary carrier rotates only in

counterclockwise direction “A”, not in clockwise

direction “B”. 22) Install one-way clutch outer race retainer (1).

23) Apply A/T fluid to new brake drum gasket (1), then

install it to transaxle case.

24) Apply A/T fluid to 2nd brak e retaining plate (1), discs

(2) and separator plates (3), then install them to

transaxle case.

25) Install 2nd brake return spring subassembly (1) to transaxle case.

“a”

“a”

2 1

I2RH0B510276-01

I2RH0B510277-01

I2RH0B510278-01

I2RH0B510279-01

2

3

1

I2RH0B510280-01

1

I2RH0B510281-01

Page 801 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-157

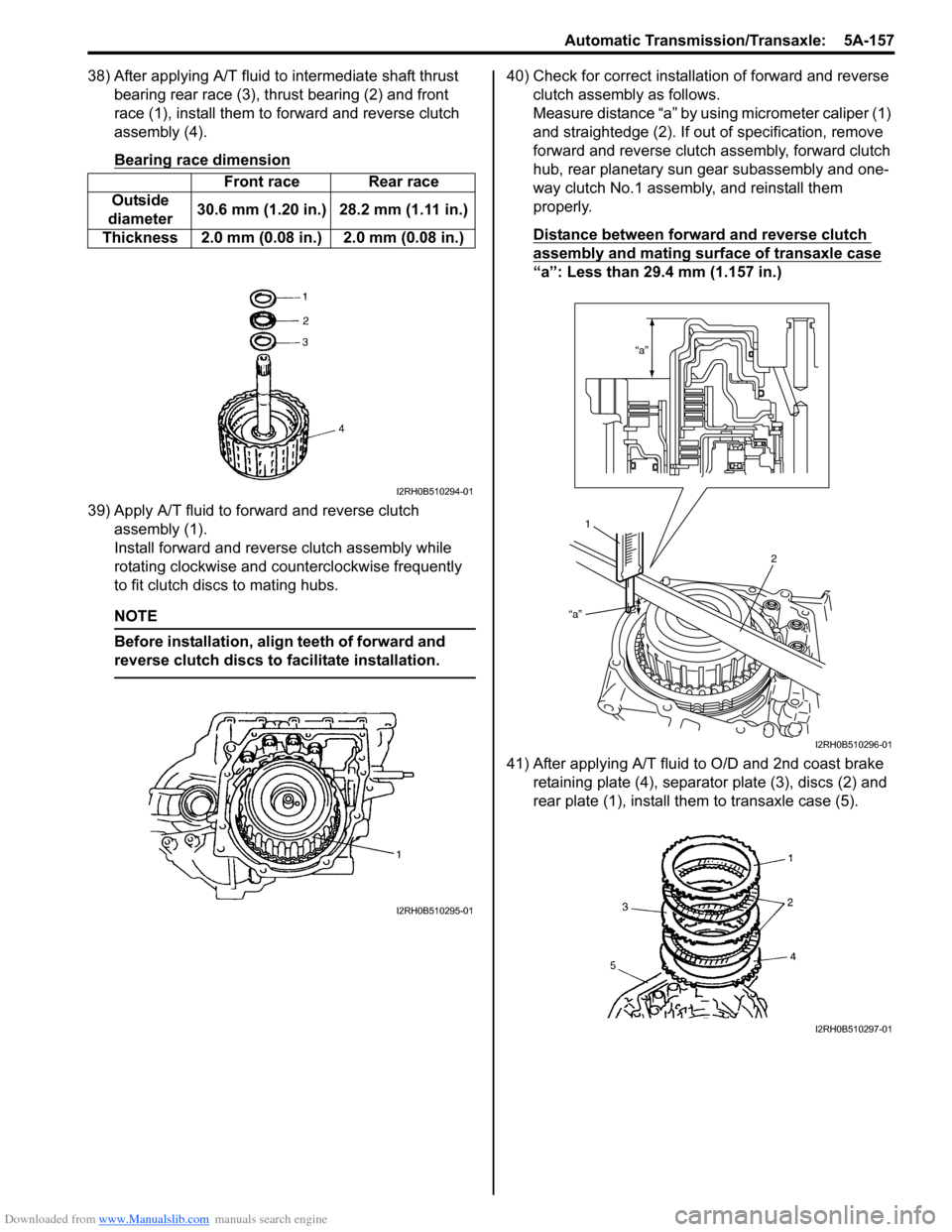

38) After applying A/T fluid to intermediate shaft thrust bearing rear race (3), thrust bearing (2) and front

race (1), install them to forward and reverse clutch

assembly (4).

Bearing race dimension

39) Apply A/T fluid to forward and reverse clutch assembly (1).

Install forward and revers e clutch assembly while

rotating clockwise and co unterclockwise frequently

to fit clutch discs to mating hubs.

NOTE

Before installation, align teeth of forward and

reverse clutch discs to facilitate installation.

40) Check for correct installation of forward and reverse clutch assembly as follows.

Measure distance “a” by using micrometer caliper (1)

and straightedge (2). If out of specification, remove

forward and reverse clutch assembly, forward clutch

hub, rear planetary sun gear subassembly and one-

way clutch No.1 assemb ly, and reinstall them

properly.

Distance between forward and reverse clutch

assembly and mating surface of transaxle case

“a”: Less than 29.4 mm (1.157 in.)

41) After applying A/T fluid to O/D and 2nd coast brake retaining plate (4), separator plate (3), discs (2) and

rear plate (1), install th em to transaxle case (5).

Front race Rear race

Outside

diameter 30.6 mm (1.20 in.) 28.2 mm (1.11 in.)

Thickness 2.0 mm (0.08 in.) 2.0 mm (0.08 in.)

I2RH0B510294-01

I2RH0B510295-01

“a”

“a”

1 2

I2RH0B510296-01

I2RH0B510297-01

Page 804 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-160 Automatic Transmission/Transaxle:

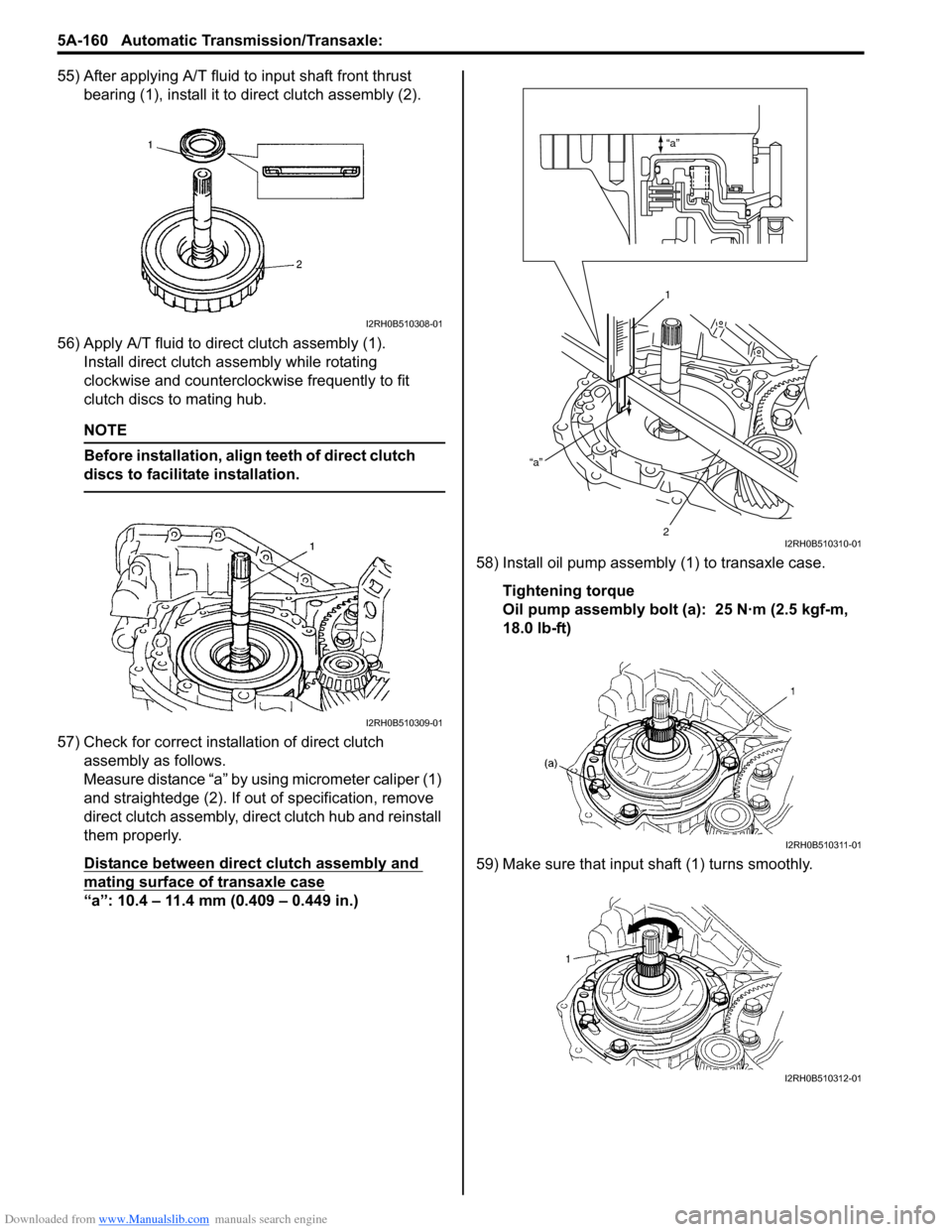

55) After applying A/T fluid to input shaft front thrust bearing (1), install it to direct clutch assembly (2).

56) Apply A/T fluid to direct clutch assembly (1). Install direct clutch a ssembly while rotating

clockwise and counterclockwise frequently to fit

clutch discs to mating hub.

NOTE

Before installation, align teeth of direct clutch

discs to facilitate installation.

57) Check for correct installation of direct clutch assembly as follows.

Measure distance “a” by using micrometer caliper (1)

and straightedge (2). If out of specification, remove

direct clutch assembly, direct clutch hub and reinstall

them properly.

Distance between direct clutch assembly and

mating surface of transaxle case

“a”: 10.4 – 11.4 mm (0.409 – 0.449 in.) 58) Install oil pump assembly

(1) to transaxle case.

Tightening torque

Oil pump assembly bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

59) Make sure that input shaft (1) turns smoothly.

I2RH0B510308-01

I2RH0B510309-01

“a”

“a”

1

2

I2RH0B510310-01

I2RH0B510311-01

I2RH0B510312-01

Page 809 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-165

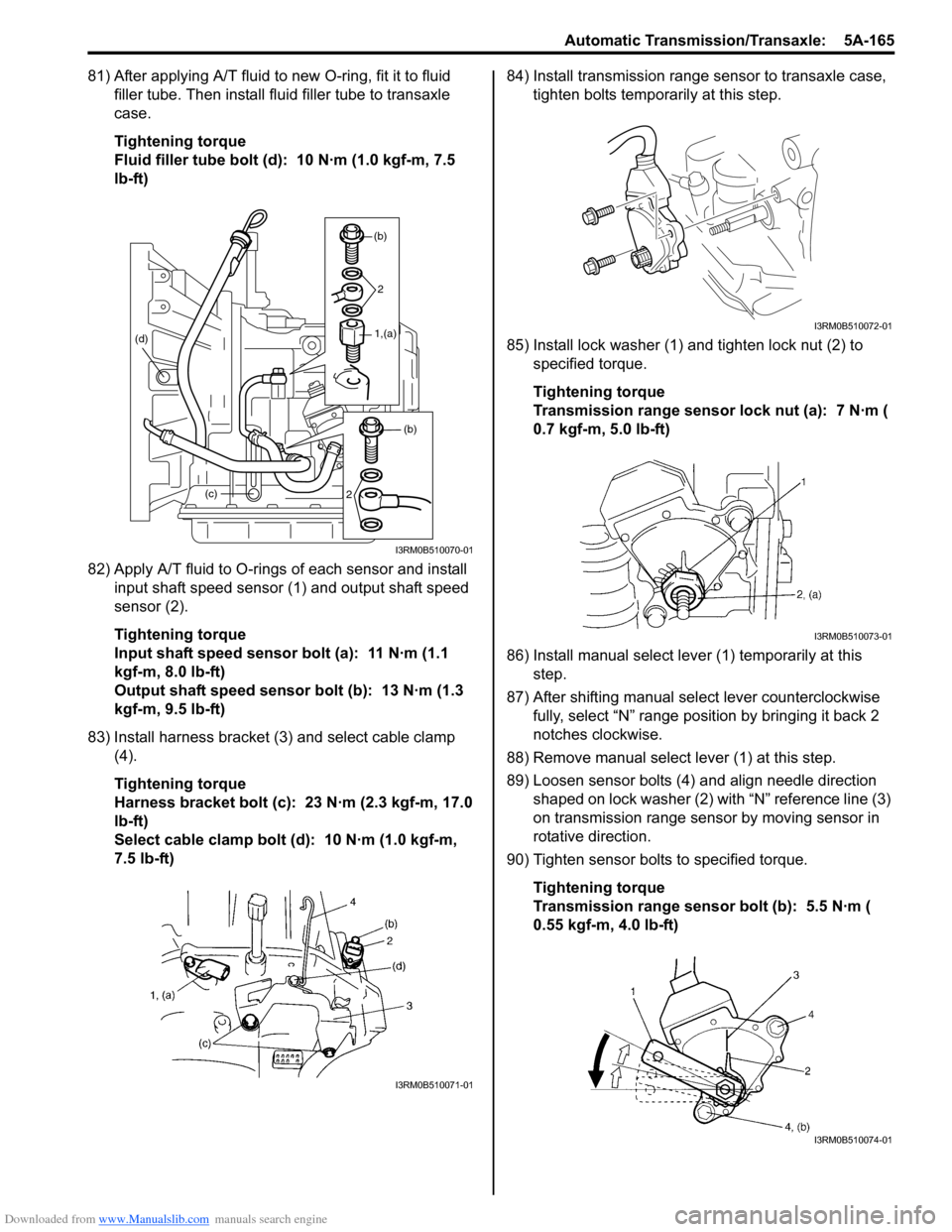

81) After applying A/T fluid to new O-ring, fit it to fluid filler tube. Then install fl uid filler tube to transaxle

case.

Tightening torque

Fluid filler tube bolt (d): 10 N·m (1.0 kgf-m, 7.5

lb-ft)

82) Apply A/T fluid to O-rings of each sensor and install input shaft speed sensor (1) and output shaft speed

sensor (2).

Tightening torque

Input shaft speed sensor bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

Output shaft speed sensor bolt (b): 13 N·m (1.3

kgf-m, 9.5 lb-ft)

83) Install harness bracket (3) and select cable clamp (4).

Tightening torque

Harness bracket bolt (c): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

Select cable clamp bolt (d): 10 N·m (1.0 kgf-m,

7.5 lb-ft) 84) Install transmission range sensor to transaxle case,

tighten bolts temporarily at this step.

85) Install lock washer (1) and tighten lock nut (2) to specified torque.

Tightening torque

Transmission range sensor lock nut (a): 7 N·m (

0.7 kgf-m, 5.0 lb-ft)

86) Install manual select leve r (1) temporarily at this

step.

87) After shifting manual se lect lever counterclockwise

fully, select “N” range position by bringing it back 2

notches clockwise.

88) Remove manual select lever (1) at this step.

89) Loosen sensor bolts (4) and align needle direction shaped on lock washer (2) with “N” reference line (3)

on transmission range sensor by moving sensor in

rotative direction.

90) Tighten sensor bolts to specified torque.

Tightening torque

Transmission range sensor bolt (b): 5.5 N·m (

0.55 kgf-m, 4.0 lb-ft)

(c)

(d)

(b)

2

1,(a)

(b)

2

I3RM0B510070-01

I3RM0B510071-01

I3RM0B510072-01

I3RM0B510073-01

I3RM0B510074-01

Page 810 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-166 Automatic Transmission/Transaxle:

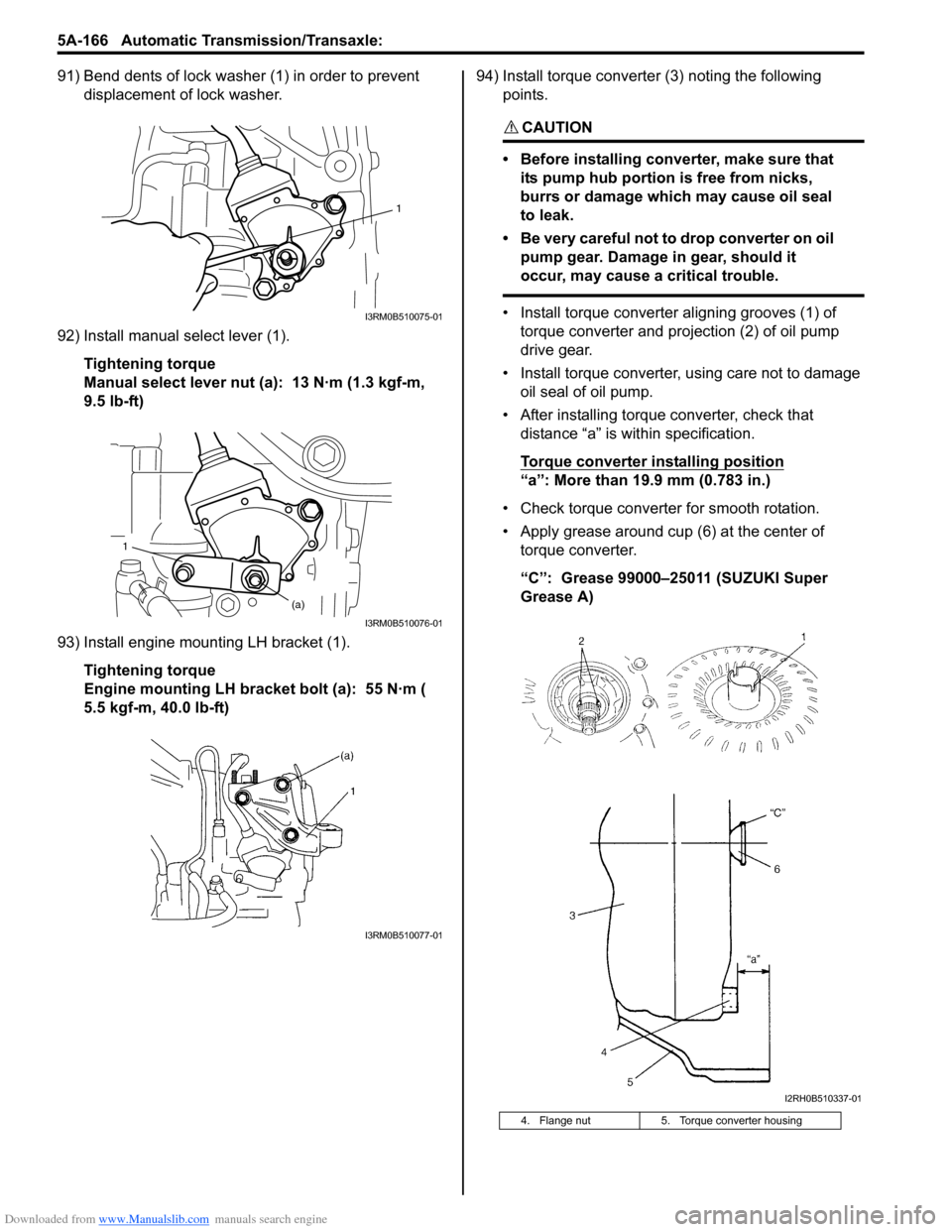

91) Bend dents of lock washer (1) in order to prevent displacement of lock washer.

92) Install manual select lever (1). Tightening torque

Manual select lever nut (a): 13 N·m (1.3 kgf-m,

9.5 lb-ft)

93) Install engine mounting LH bracket (1). Tightening torque

Engine mounting LH bracket bolt (a): 55 N·m (

5.5 kgf-m, 40.0 lb-ft) 94) Install torque converter (3) noting the following

points.

CAUTION!

• Before installing converter, make sure that its pump hub portion is free from nicks,

burrs or damage which may cause oil seal

to leak.

• Be very careful not to drop converter on oil pump gear. Damage in gear, should it

occur, may cause a critical trouble.

• Install torque converter aligning grooves (1) of torque converter and projection (2) of oil pump

drive gear.

• Install torque converter, using care not to damage oil seal of oil pump.

• After installing torque converter, check that distance “a” is within specification.

Torque converter installing position

“a”: More than 19.9 mm (0.783 in.)

• Check torque converter for smooth rotation.

• Apply grease around cup (6) at the center of torque converter.

“C”: Grease 99000–25011 (SUZUKI Super

Grease A)

1

I3RM0B510075-01

1

(a)

I3RM0B510076-01

I3RM0B510077-01

4. Flange nut 5. Torque converter housing

I2RH0B510337-01

Page 811 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-167

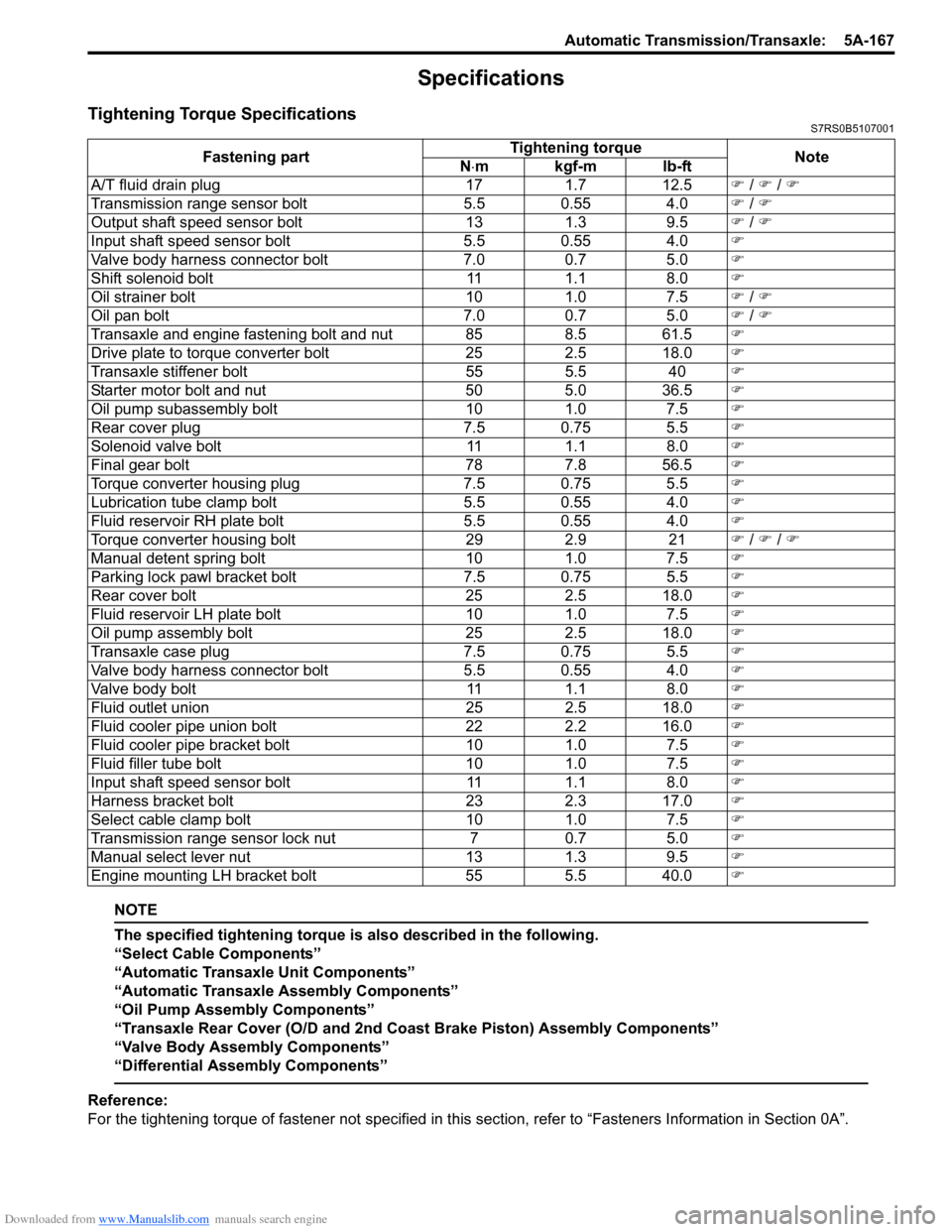

Specifications

Tightening Torque SpecificationsS7RS0B5107001

NOTE

The specified tightening torque is also described in the following.

“Select Cable Components”

“Automatic Transaxle Unit Components”

“Automatic Transaxle Assembly Components”

“Oil Pump Assembly Components”

“Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Components”

“Valve Body Assembly Components”

“Differential Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

A/T fluid drain plug 171.7 12.5 �) / �) / �)

Transmission range sensor bolt 5.5 0.55 4.0�) / �)

Output shaft speed sensor bolt 131.3 9.5 �) / �)

Input shaft speed sensor bolt 5.5 0.55 4.0�)

Valve body harness connector bolt 7.00.7 5.0 �)

Shift solenoid bolt 111.1 8.0 �)

Oil strainer bolt 101.0 7.5 �) / �)

Oil pan bolt 7.00.7 5.0 �) / �)

Transaxle and engine fastening bolt and nut 85 8.5 61.5�)

Drive plate to torque converter bolt 252.5 18.0 �)

Transaxle stiffener bolt 555.5 40�)

Starter motor bolt and nut 505.0 36.5 �)

Oil pump subassembly bolt 101.0 7.5 �)

Rear cover plug 7.5 0.75 5.5�)

Solenoid valve bolt 111.1 8.0 �)

Final gear bolt 787.8 56.5 �)

Torque converter housing plug 7.5 0.75 5.5�)

Lubrication tube clamp bolt 5.5 0.55 4.0�)

Fluid reservoir RH plate bolt 5.5 0.55 4.0�)

Torque converter housing bolt 292.9 21�) / �) / �)

Manual detent spring bolt 101.0 7.5 �)

Parking lock pawl bracket bolt 7.5 0.75 5.5�)

Rear cover bolt 252.5 18.0 �)

Fluid reservoir LH plate bolt 101.0 7.5 �)

Oil pump assembly bolt 252.5 18.0 �)

Transaxle case plug 7.5 0.75 5.5�)

Valve body harness connector bolt 5.5 0.55 4.0�)

Valve body bolt 111.1 8.0 �)

Fluid outlet union 252.5 18.0 �)

Fluid cooler pipe union bolt 222.2 16.0 �)

Fluid cooler pipe bracket bolt 101.0 7.5 �)

Fluid filler tube bolt 101.0 7.5 �)

Input shaft speed sensor bolt 111.1 8.0 �)

Harness bracket bolt 232.3 17.0 �)

Select cable clamp bolt 101.0 7.5 �)

Transmission range sensor lock nut 70.7 5.0 �)

Manual select lever nut 131.3 9.5 �)

Engine mounting LH bracket bolt 555.5 40.0

�)