R p m SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 231 of 1496

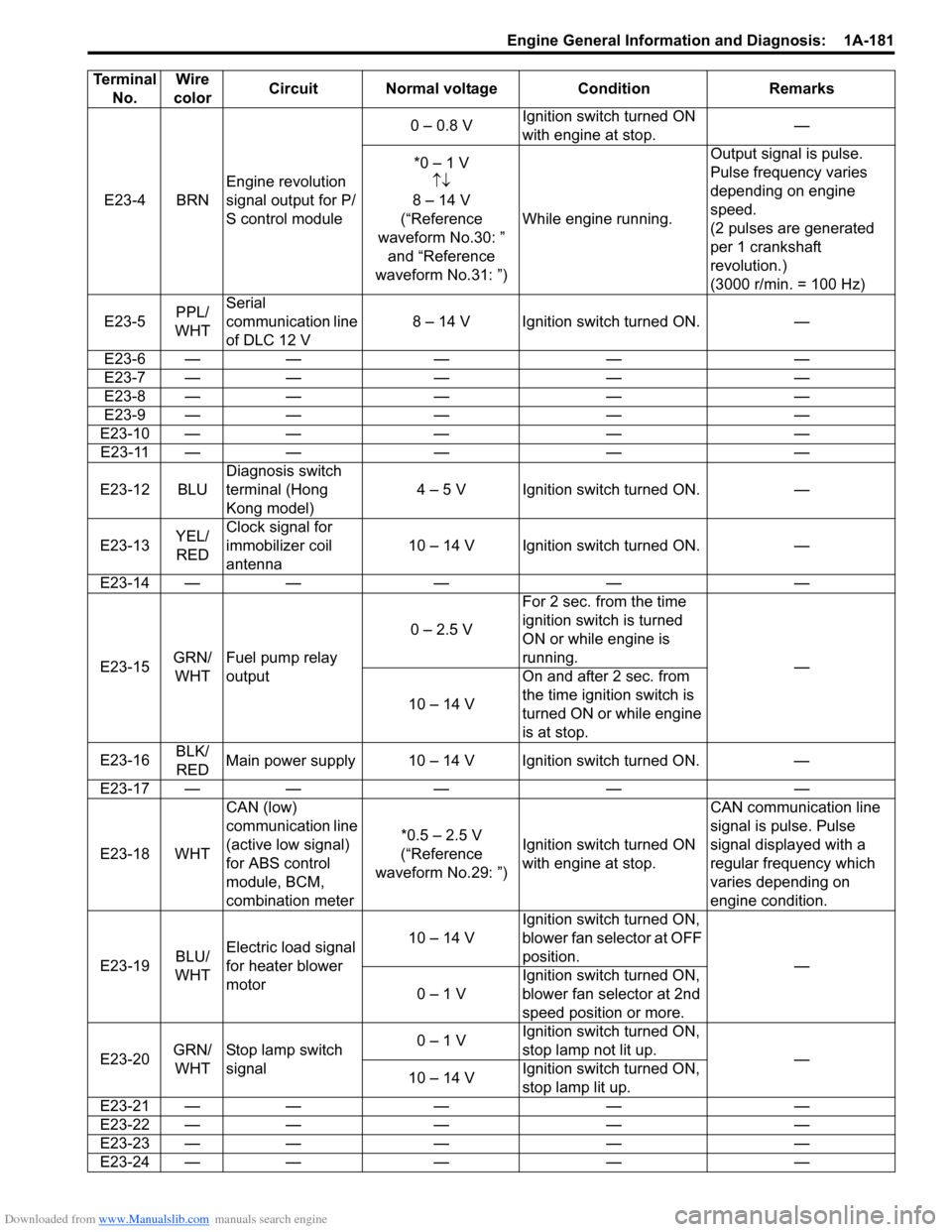

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-181

E23-4 BRNEngine revolution

signal output for P/

S control module 0 – 0.8 V

Ignition switch turned ON

with engine at stop. —

*0 – 1 V ↑↓

8 – 14 V

(“Reference

waveform No.30: ” and “Reference

waveform No.31: ”) While engine running. Output signal is pulse.

Pulse frequency varies

depending on engine

speed.

(2 pulses are generated

per 1 crankshaft

revolution.)

(3000 r/min. = 100 Hz)

E23-5 PPL/

WHT Serial

communication line

of DLC 12 V

8 – 14 V Ignition switch turned ON. —

E23-6 — — — — —

E23-7 — — — — —

E23-8 — — — — —

E23-9 — — — — —

E23-10 — — — — — E23-11 — — — — —

E23-12 BLU Diagnosis switch

terminal (Hong

Kong model) 4 – 5 V Ignition switch turned ON. —

E23-13 YEL/

RED Clock signal for

immobilizer coil

antenna

10 – 14 V Ignition switch turned ON. —

E23-14 — — — — —

E23-15 GRN/

WHT Fuel pump relay

output 0 – 2.5 V

For 2 sec. from the time

ignition switch is turned

ON or while engine is

running.

—

10 – 14 V On and after 2 sec. from

the time ignition switch is

turned ON or while engine

is at stop.

E23-16 BLK/

RED Main power supply 10 – 14 V Ignition switch turned ON. —

E23-17 — — — — —

E23-18 WHT CAN (low)

communication line

(active low signal)

for ABS control

module, BCM,

combination meter *0.5 – 2.5 V

(“Reference

waveform No.29: ”) Ignition switch turned ON

with engine at stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency which

varies depending on

engine condition.

E23-19 BLU/

WHT Electric load signal

for heater blower

motor 10 – 14 V

Ignition switch turned ON,

blower fan selector at OFF

position.

—

0 – 1 V Ignition switch turned ON,

blower fan selector at 2nd

speed position or more.

E23-20 GRN/

WHT Stop lamp switch

signal 0 – 1 V

Ignition switch turned ON,

stop lamp not lit up.

—

10 – 14 V Ignition switch turned ON,

stop lamp lit up.

E23-21 — — — — —

E23-22 — — — — —

E23-23 — — — — —

E23-24 — — — — —

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

Page 232 of 1496

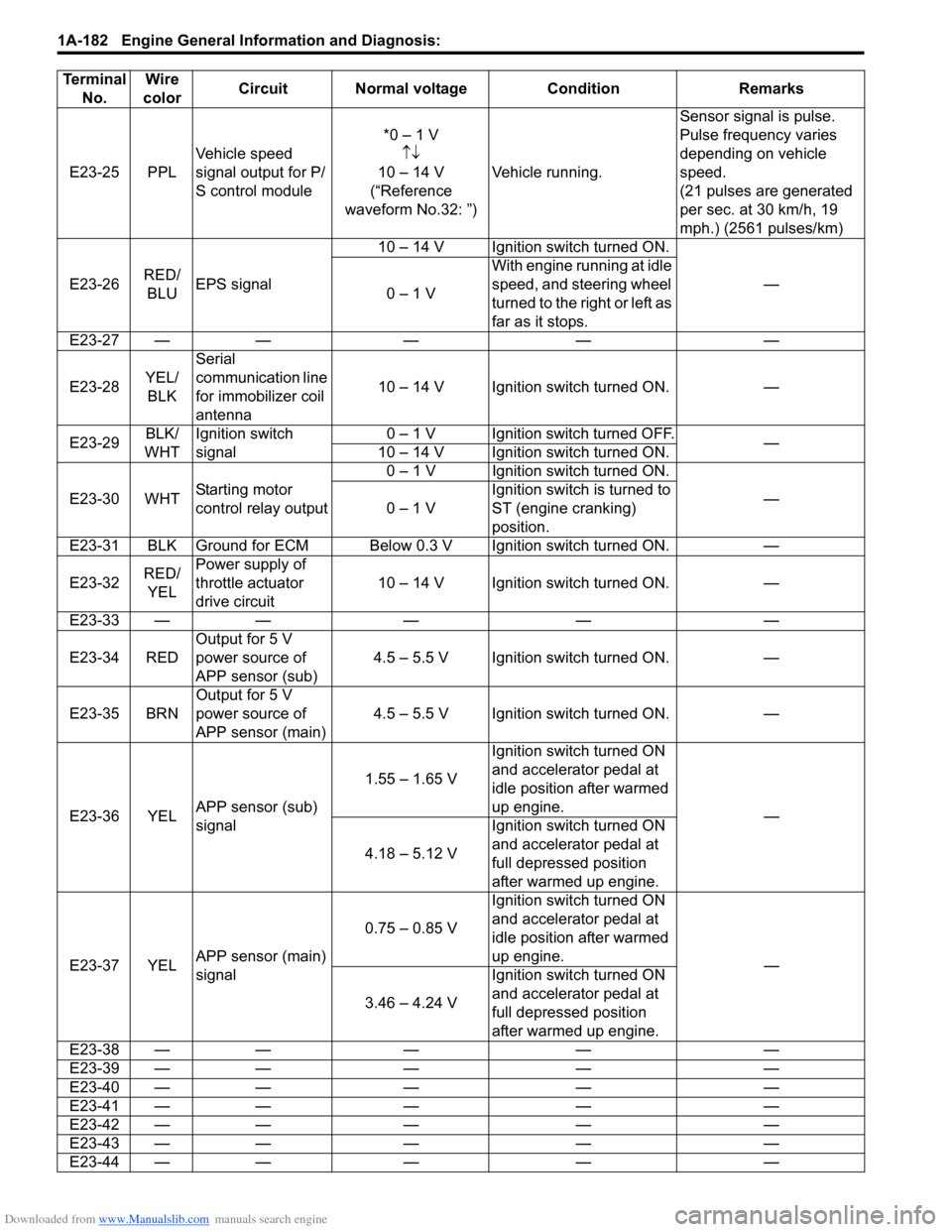

Downloaded from www.Manualslib.com manuals search engine 1A-182 Engine General Information and Diagnosis:

E23-25 PPLVehicle speed

signal output for P/

S control module *0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.32: ”) Vehicle running. Sensor signal is pulse.

Pulse frequency varies

depending on vehicle

speed.

(21 pulses are generated

per sec. at 30 km/h, 19

mph.) (2561 pulses/km)

E23-26 RED/

BLU EPS signal 10 – 14 V Ignition switch turned ON.

—

0 – 1 V With engine running at idle

speed, and steering wheel

turned to the right or left as

far as it stops.

E23-27 — — — — —

E23-28 YEL/

BLK Serial

communication line

for immobilizer coil

antenna

10 – 14 V Ignition switch turned ON. —

E23-29 BLK/

WHT Ignition switch

signal 0 – 1 V Ignition switch turned OFF.

—

10 – 14 V Ignition switch turned ON.

E23-30 WHT Starting motor

control relay output 0 – 1 V Ignition switch turned ON.

—

0 – 1 V Ignition switch is turned to

ST (engine cranking)

position.

E23-31 BLK Ground for ECM Below 0.3 V Ignition switch turned ON. —

E23-32 RED/

YEL Power supply of

throttle actuator

drive circuit

10 – 14 V Ignition switch turned ON. —

E23-33 — — — — —

E23-34 RED Output for 5 V

power source of

APP sensor (sub) 4.5 – 5.5 V Ignition switch turned ON. —

E23-35 BRN Output for 5 V

power source of

APP sensor (main) 4.5 – 5.5 V Ignition switch turned ON. —

E23-36 YEL APP sensor (sub)

signal 1.55 – 1.65 V

Ignition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

—

4.18 – 5.12 V Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

E23-37 YEL APP sensor (main)

signal 0.75 – 0.85 V

Ignition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

—

3.46 – 4.24 V Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

E23-38 — — — — —

E23-39 — — — — —

E23-40 — — — — —

E23-41 — — — — —

E23-42 — — — — —

E23-43 — — — — —

E23-44 — — — — —

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

Page 233 of 1496

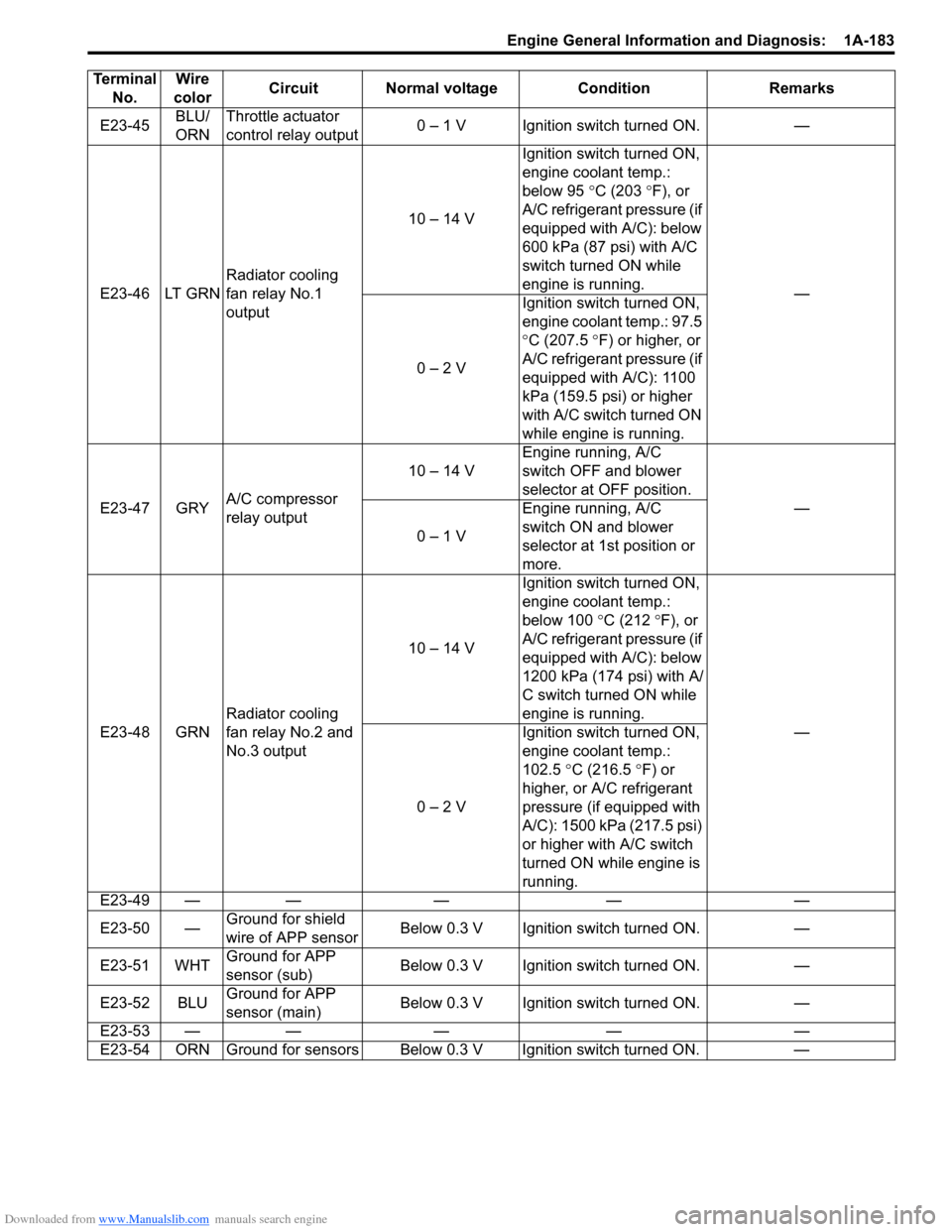

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-183

E23-45BLU/

ORNThrottle actuator

control relay output

0 – 1 V Ignition switch turned ON. —

E23-46 LT GRN Radiator cooling

fan relay No.1

output 10 – 14 V

Ignition switch turned ON,

engine coolant temp.:

below 95

°C (203 ° F), or

A/C refrigerant pressure (if

equipped with A/C): below

600 kPa (87 psi) with A/C

switch turned ON while

engine is running. —

0 – 2 V Ignition switch turned ON,

engine coolant temp.: 97.5

°

C (207.5 ° F) or higher, or

A/C refrigerant pressure (if

equipped with A/C): 1100

kPa (159.5 psi) or higher

with A/C switch turned ON

while engine is running.

E23-47 GRY A/C compressor

relay output 10 – 14 V

Engine running, A/C

switch OFF and blower

selector at OFF position.

—

0 – 1 V Engine running, A/C

switch ON and blower

selector at 1st position or

more.

E23-48 GRN Radiator cooling

fan relay No.2 and

No.3 output 10 – 14 V

Ignition switch turned ON,

engine coolant temp.:

below 100

°C (212 °F), or

A/C refrigerant pressure (if

equipped with A/C): below

1200 kPa (174 psi) with A/

C switch turned ON while

engine is running. —

0 – 2 V Ignition switch turned ON,

engine coolant temp.:

102.5

°C (216.5 °F) or

higher, or A/C refrigerant

pressure (if equipped with

A/C): 1500 kPa (217.5 psi)

or higher with A/C switch

turned ON while engine is

running.

E23-49 — — — — —

E23-50 — Ground for shield

wire of APP sensor Below 0.3 V Ignition switch turned ON. —

E23-51 WHT Ground for APP

sensor (sub) Below 0.3 V Ignition switch turned ON. —

E23-52 BLU Ground for APP

sensor (main) Below 0.3 V Ignition switch turned ON. —

E23-53 — — — — —

E23-54 ORN Ground for sensors Below 0.3 V Ignition switch turned ON. —

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

Page 234 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-184 Engine General Information and Diagnosis:

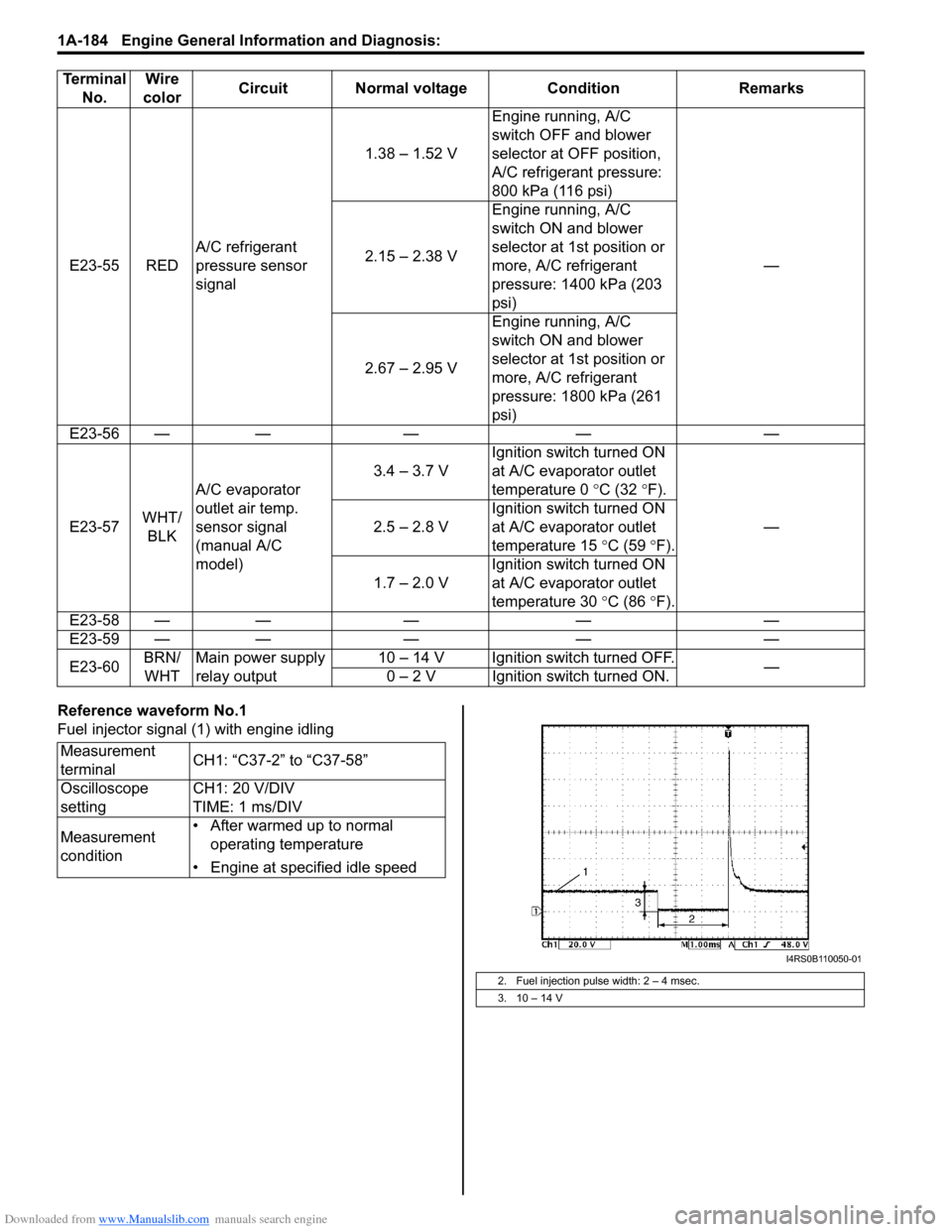

Reference waveform No.1

Fuel injector signal (1) with engine idling

E23-55 RED

A/C refrigerant

pressure sensor

signal 1.38 – 1.52 V

Engine running, A/C

switch OFF and blower

selector at OFF position,

A/C refrigerant pressure:

800 kPa (116 psi)

—

2.15 – 2.38 V Engine running, A/C

switch ON and blower

selector at 1st position or

more, A/C refrigerant

pressure: 1400 kPa (203

psi)

2.67 – 2.95 V Engine running, A/C

switch ON and blower

selector at 1st position or

more, A/C refrigerant

pressure: 1800 kPa (261

psi)

E23-56 — — — — —

E23-57 WHT/

BLK A/C evaporator

outlet air temp.

sensor signal

(manual A/C

model) 3.4 – 3.7 V

Ignition switch turned ON

at A/C evaporator outlet

temperature 0

°C (32 °F).

—

2.5 – 2.8 V Ignition switch turned ON

at A/C evaporator outlet

temperature 15

°C (59 °F).

1.7 – 2.0 V Ignition switch turned ON

at A/C evaporator outlet

temperature 30

°C (86 °F).

E23-58 — — — — —

E23-59 — — — — —

E23-60 BRN/

WHT Main power supply

relay output 10 – 14 V Ignition switch turned OFF.

—

0 – 2 V Ignition switch turned ON.

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

Measurement

terminal CH1: “C37-2” to “C37-58”

Oscilloscope

setting CH1: 20 V/DIV

TIME: 1 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

2. Fuel injection pulse width: 2 – 4 msec.

3. 10 – 14 V

I4RS0B110050-01

Page 235 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-185

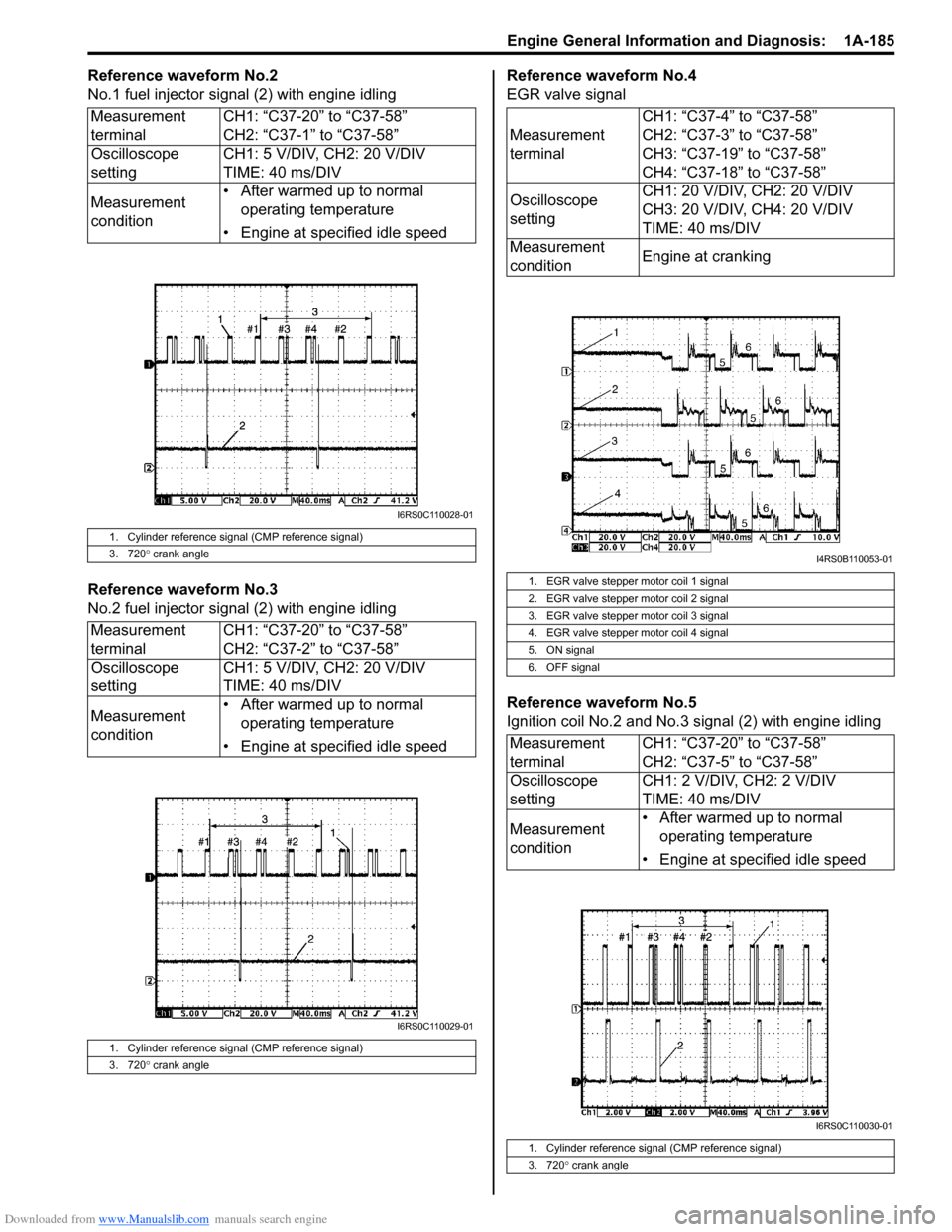

Reference waveform No.2

No.1 fuel injector signal (2) with engine idling

Reference waveform No.3

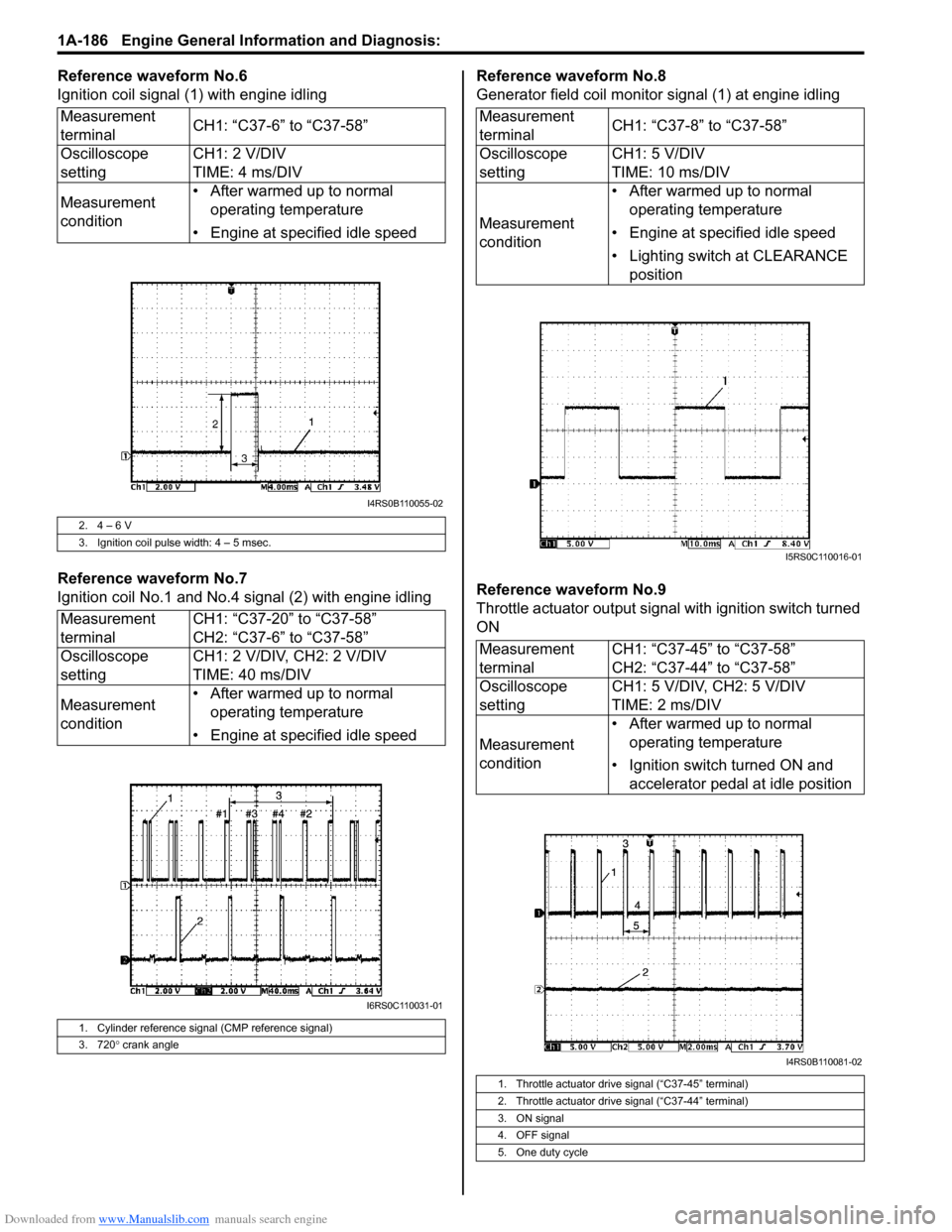

No.2 fuel injector sig nal (2) with engine idling Reference waveform No.4

EGR valve signal

Reference waveform No.5

Ignition coil No.2 and No.3 signal (2) with engine idling

Measurement

terminal

CH1: “C37-20” to “C37-58”

CH2: “C37-1” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 20 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 720 ° crank angle

Measurement

terminal CH1: “C37-20” to “C37-58”

CH2: “C37-2” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 20 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 720 ° crank angle

I6RS0C110028-01

I6RS0C110029-01

Measurement

terminal CH1: “C37-4” to “C37-58”

CH2: “C37-3” to “C37-58”

CH3: “C37-19” to “C37-58”

CH4: “C37-18” to “C37-58”

Oscilloscope

setting CH1: 20 V/DIV, CH2: 20 V/DIV

CH3: 20 V/DIV, CH4: 20 V/DIV

TIME: 40 ms/DIV

Measurement

condition Engine at cranking

1. EGR valve stepper motor coil 1 signal

2. EGR valve stepper motor coil 2 signal

3. EGR valve stepper motor coil 3 signal

4. EGR valve stepper motor coil 4 signal

5. ON signal

6. OFF signal

Measurement

terminalCH1: “C37-20” to “C37-58”

CH2: “C37-5” to “C37-58”

Oscilloscope

setting CH1: 2 V/DIV, CH2: 2 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 720 ° crank angle

I4RS0B110053-01

I6RS0C110030-01

Page 236 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-186 Engine General Information and Diagnosis:

Reference waveform No.6

Ignition coil signal (1) with engine idling

Reference waveform No.7

Ignition coil No.1 and No.4 signal (2) with engine idlingReference waveform No.8

Generator field coil monitor signal (1) at engine idling

Reference waveform No.9

Throttle actuator output signal with ignition switch turned

ON

Measurement

terminal

CH1: “C37-6” to “C37-58”

Oscilloscope

setting CH1: 2 V/DIV

TIME: 4 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

2. 4 – 6 V

3. Ignition coil pulse width: 4 – 5 msec.

Measurement

terminal CH1: “C37-20” to “C37-58”

CH2: “C37-6” to “C37-58”

Oscilloscope

setting CH1: 2 V/DIV, CH2: 2 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 720 ° crank angle

I4RS0B110055-02

I6RS0C110031-01

Measurement

terminal CH1: “C37-8” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV

TIME: 10 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

• Lighting switch at CLEARANCE position

Measurement

terminal CH1: “C37-45” to “C37-58”

CH2: “C37-44” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 2 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Ignition switch turned ON and accelerator pedal at idle position

1. Throttle actuator drive signal (“C37-45” terminal)

2. Throttle actuator drive signal (“C37-44” terminal)

3. ON signal

4. OFF signal

5. One duty cycle

I5RS0C110016-01

I4RS0B110081-02

Page 237 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-187

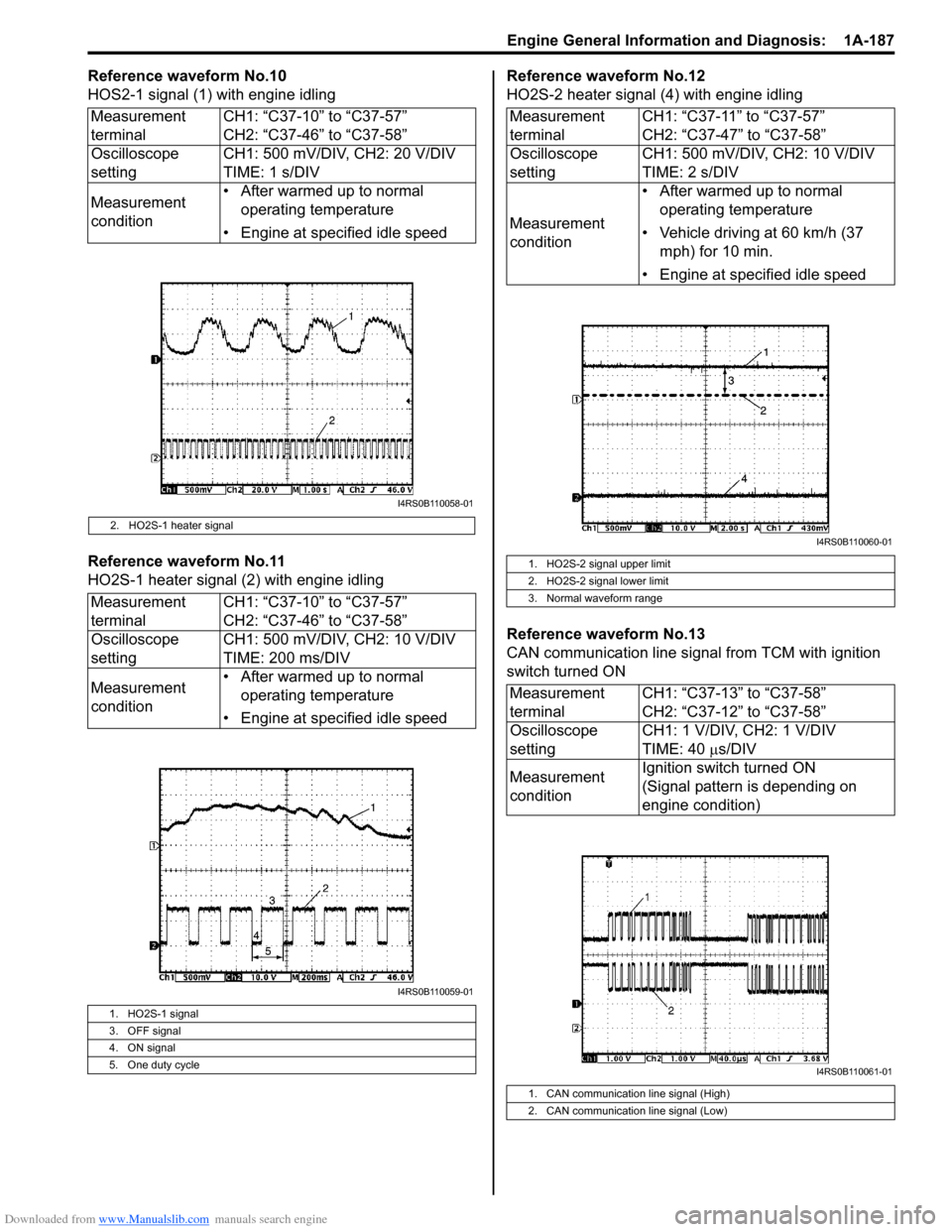

Reference waveform No.10

HOS2-1 signal (1) with engine idling

Reference waveform No.11

HO2S-1 heater signal (2) with engine idlingReference waveform No.12

HO2S-2 heater signal (4) with engine idling

Reference waveform No.13

CAN communication line signal from TCM with ignition

switch turned ON

Measurement

terminal

CH1: “C37-10” to “C37-57”

CH2: “C37-46” to “C37-58”

Oscilloscope

setting CH1: 500 mV/DIV, CH2: 20 V/DIV

TIME: 1 s/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

2. HO2S-1 heater signal

Measurement

terminal CH1: “C37-10” to “C37-57”

CH2: “C37-46” to “C37-58”

Oscilloscope

setting CH1: 500 mV/DIV, CH2: 10 V/DIV

TIME: 200 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. HO2S-1 signal

3. OFF signal

4. ON signal

5. One duty cycle

I4RS0B110058-01

I4RS0B110059-01

Measurement

terminal CH1: “C37-11” to “C37-57”

CH2: “C37-47” to “C37-58”

Oscilloscope

setting CH1: 500 mV/DIV, CH2: 10 V/DIV

TIME: 2 s/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Vehicle driving at 60 km/h (37 mph) for 10 min.

• Engine at specified idle speed

1. HO2S-2 signal upper limit

2. HO2S-2 signal lower limit

3. Normal waveform range

Measurement

terminal CH1: “C37-13” to “C37-58”

CH2: “C37-12” to “C37-58”

Oscilloscope

setting CH1: 1 V/DIV, CH2: 1 V/DIV

TIME: 40

µs/DIV

Measurement

condition Ignition switch turned ON

(Signal pattern is depending on

engine condition)

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

I4RS0B110060-01

I4RS0B110061-01

Page 238 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-188 Engine General Information and Diagnosis:

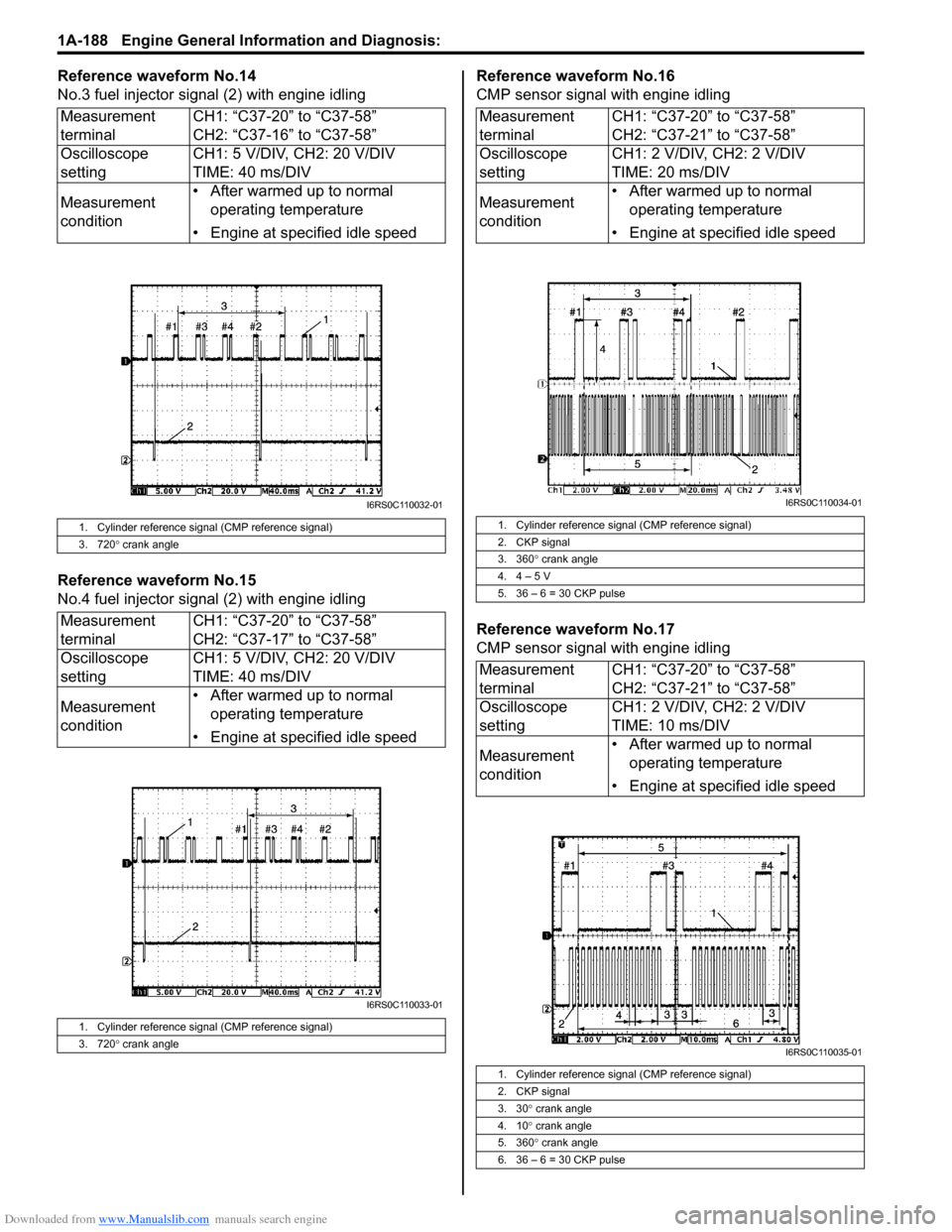

Reference waveform No.14

No.3 fuel injector signal (2) with engine idling

Reference waveform No.15

No.4 fuel injector sig nal (2) with engine idling Reference waveform No.16

CMP sensor signal with engine idling

Reference waveform No.17

CMP sensor signal with engine idling

Measurement

terminal

CH1: “C37-20” to “C37-58”

CH2: “C37-16” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 20 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 720 ° crank angle

Measurement

terminal CH1: “C37-20” to “C37-58”

CH2: “C37-17” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 20 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 720 ° crank angle

I6RS0C110032-01

I6RS0C110033-01

Measurement

terminal CH1: “C37-20” to “C37-58”

CH2: “C37-21” to “C37-58”

Oscilloscope

setting CH1: 2 V/DIV, CH2: 2 V/DIV

TIME: 20 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

2. CKP signal

3. 360 ° crank angle

4. 4 – 5 V

5. 36 – 6 = 30 CKP pulse

Measurement

terminal CH1: “C37-20” to “C37-58”

CH2: “C37-21” to “C37-58”

Oscilloscope

setting CH1: 2 V/DIV, CH2: 2 V/DIV

TIME: 10 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

2. CKP signal

3. 30 ° crank angle

4. 10 ° crank angle

5. 360 ° crank angle

6. 36 – 6 = 30 CKP pulse

I6RS0C110034-01

I6RS0C110035-01

Page 239 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-189

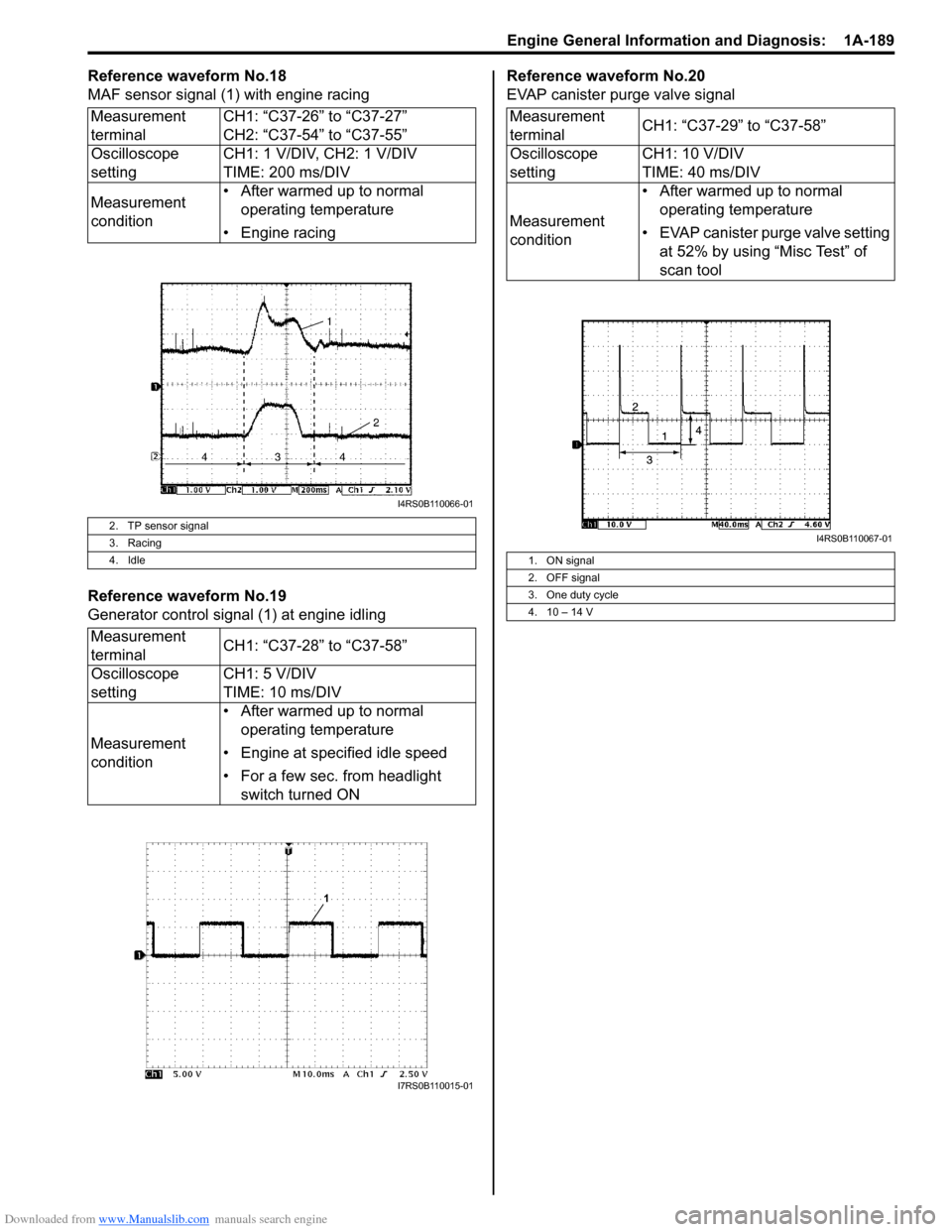

Reference waveform No.18

MAF sensor signal (1) with engine racing

Reference waveform No.19

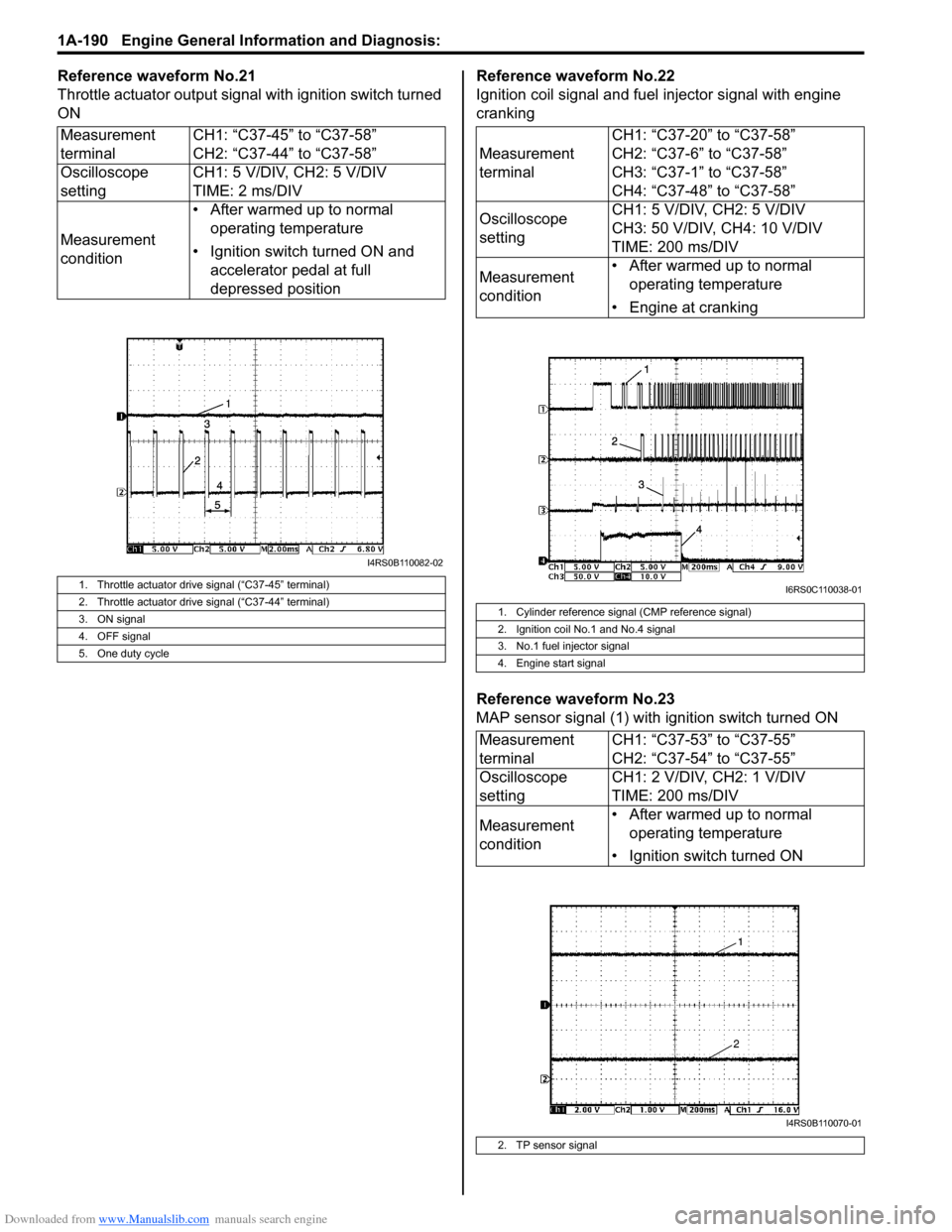

Generator control signal (1) at engine idlingReference waveform No.20

EVAP canister purge valve signal

Measurement

terminal CH1: “C37-26” to “C37-27”

CH2: “C37-54” to “C37-55”

Oscilloscope

setting CH1: 1 V/DIV, CH2: 1 V/DIV

TIME: 200 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine racing

2. TP sensor signal

3. Racing

4. Idle

Measurement

terminal CH1: “C37-28” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV

TIME: 10 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

• For a few sec. from headlight switch turned ON

I4RS0B110066-01

I7RS0B110015-01

Measurement

terminal CH1: “C37-29” to “C37-58”

Oscilloscope

setting CH1: 10 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• EVAP canister purge valve setting at 52% by using “Misc Test” of

scan tool

1. ON signal

2. OFF signal

3. One duty cycle

4. 10 – 14 V

I4RS0B110067-01

Page 240 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-190 Engine General Information and Diagnosis:

Reference waveform No.21

Throttle actuator output signal with ignition switch turned

ONReference waveform No.22

Ignition coil signal and fuel injector signal with engine

cranking

Reference waveform No.23

MAP sensor signal (1) with ignition switch turned ON

Measurement

terminal

CH1: “C37-45” to “C37-58”

CH2: “C37-44” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 2 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Ignition switch turned ON and accelerator pedal at full

depressed position

1. Throttle actuator drive signal (“C37-45” terminal)

2. Throttle actuator drive signal (“C37-44” terminal)

3. ON signal

4. OFF signal

5. One duty cycle

I4RS0B110082-02

Measurement

terminal CH1: “C37-20” to “C37-58”

CH2: “C37-6” to “C37-58”

CH3: “C37-1” to “C37-58”

CH4: “C37-48” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

CH3: 50 V/DIV, CH4: 10 V/DIV

TIME: 200 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at cranking

1. Cylinder reference signal (CMP reference signal)

2. Ignition coil No.1 and No.4 signal

3. No.1 fuel injector signal

4. Engine start signal

Measurement

terminal CH1: “C37-53” to “C37-55”

CH2: “C37-54” to “C37-55”

Oscilloscope

setting CH1: 2 V/DIV, CH2: 1 V/DIV

TIME: 200 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Ignition switch turned ON

2. TP sensor signal

I6RS0C110038-01

I4RS0B110070-01