R p m SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 271 of 1496

Downloaded from www.Manualslib.com manuals search engine Aux. Emission Control Devices: 1B-4

EVAP Canister InspectionS7RS0B1206006

WARNING!

DO NOT SUCK nozzles on EVAP canister.

Fuel vapor inside EVAP canister is harmful.

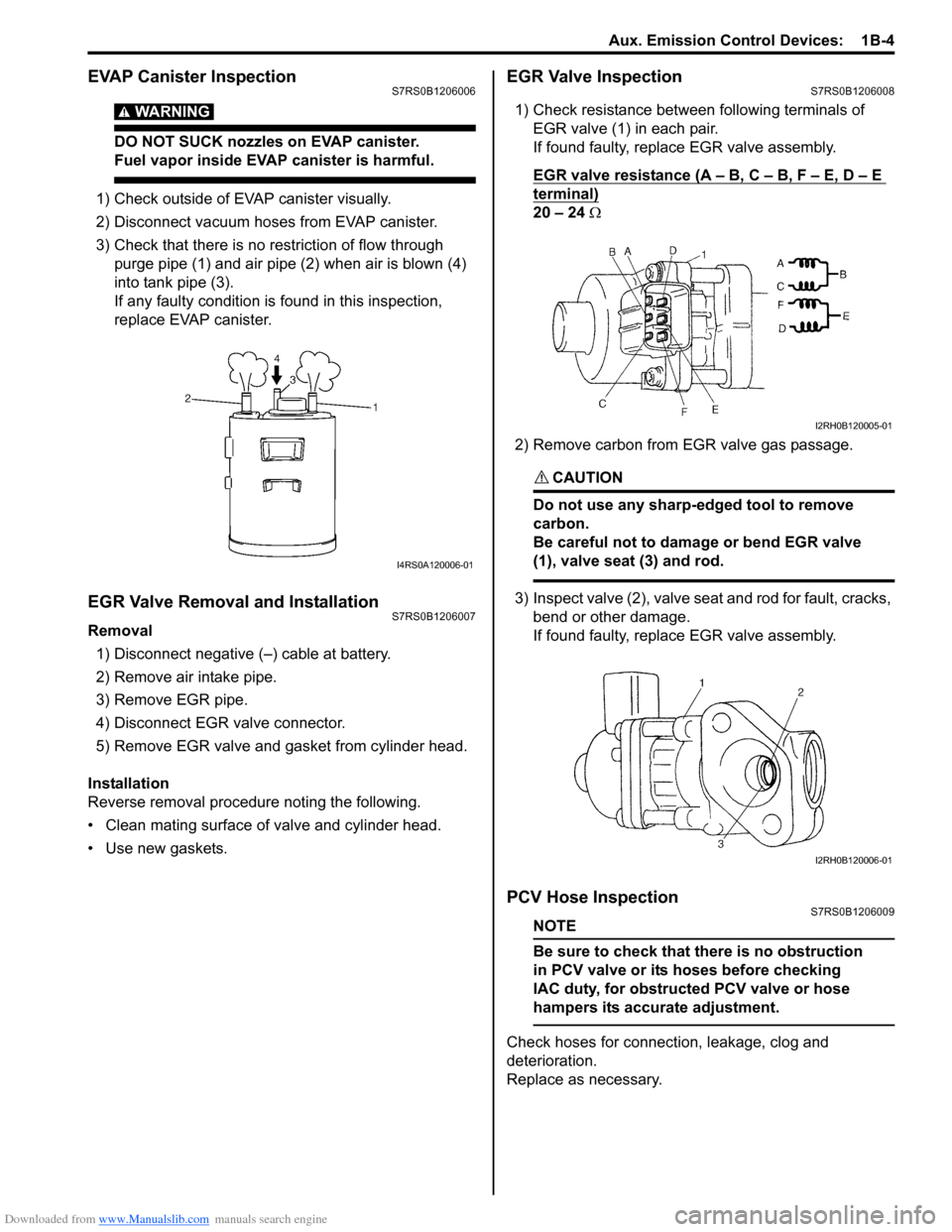

1) Check outside of EVAP canister visually.

2) Disconnect vacuum hoses from EVAP canister.

3) Check that there is no restriction of flow through purge pipe (1) and air pipe (2) when air is blown (4)

into tank pipe (3).

If any faulty condition is found in this inspection,

replace EVAP canister.

EGR Valve Removal and InstallationS7RS0B1206007

Removal

1) Disconnect negative (–) cable at battery.

2) Remove air intake pipe.

3) Remove EGR pipe.

4) Disconnect EGR valve connector.

5) Remove EGR valve and gasket from cylinder head.

Installation

Reverse removal procedure noting the following.

• Clean mating surface of valve and cylinder head.

• Use new gaskets.

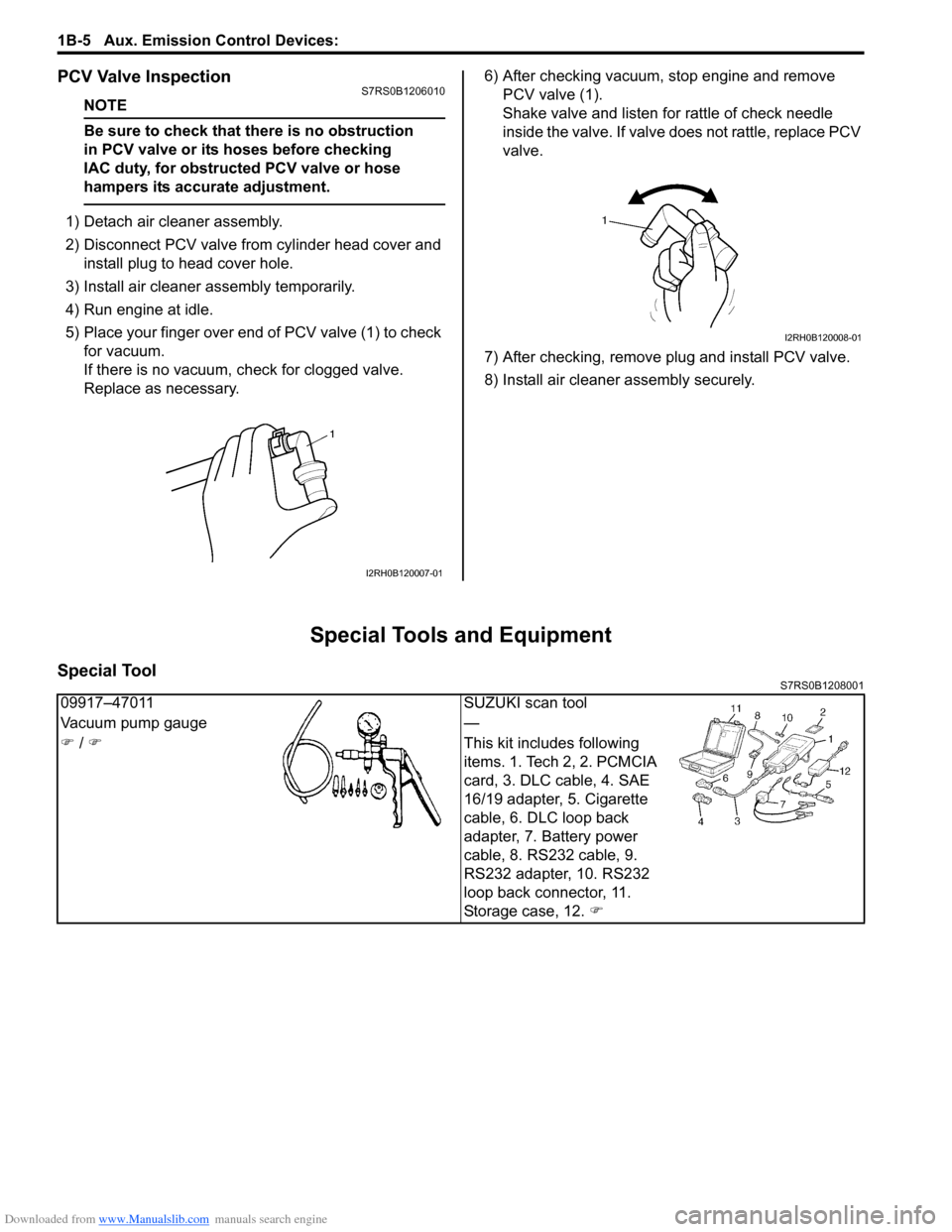

EGR Valve InspectionS7RS0B1206008

1) Check resistance between following terminals of EGR valve (1) in each pair.

If found faulty, replace EGR valve assembly.

EGR valve resistance (A – B, C – B, F – E, D – E

terminal)

20 – 24 Ω

2) Remove carbon from EGR valve gas passage.

CAUTION!

Do not use any sharp-edged tool to remove

carbon.

Be careful not to damage or bend EGR valve

(1), valve seat (3) and rod.

3) Inspect valve (2), valve seat and rod for fault, cracks, bend or other damage.

If found faulty, replace EGR valve assembly.

PCV Hose InspectionS7RS0B1206009

NOTE

Be sure to check that there is no obstruction

in PCV valve or its hoses before checking

IAC duty, for obstructed PCV valve or hose

hampers its accurate adjustment.

Check hoses for connection, leakage, clog and

deterioration.

Replace as necessary.

I4RS0A120006-01

I2RH0B120005-01

I2RH0B120006-01

Page 272 of 1496

Downloaded from www.Manualslib.com manuals search engine 1B-5 Aux. Emission Control Devices:

PCV Valve InspectionS7RS0B1206010

NOTE

Be sure to check that there is no obstruction

in PCV valve or its hoses before checking

IAC duty, for obstructed PCV valve or hose

hampers its accurate adjustment.

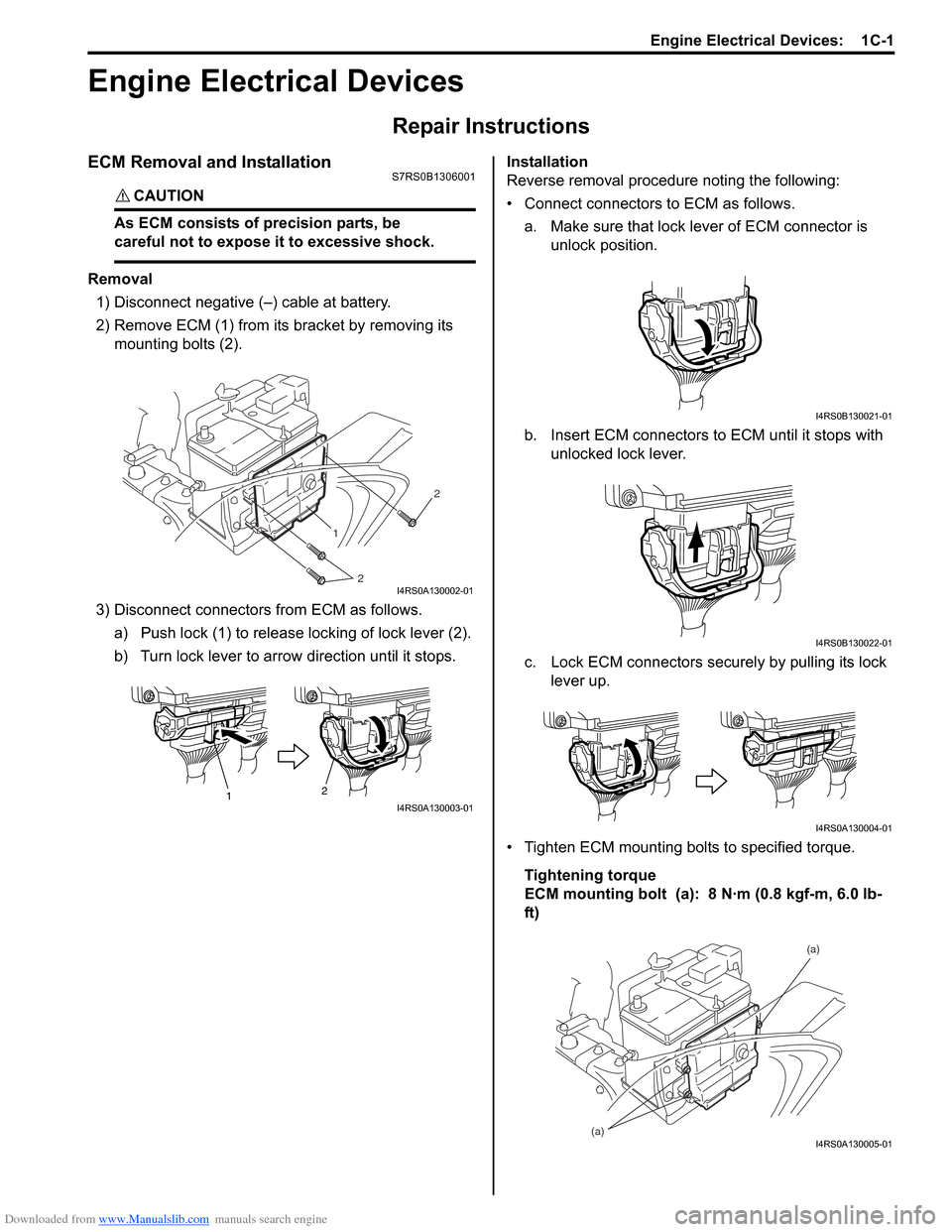

1) Detach air cleaner assembly.

2) Disconnect PCV valve from cylinder head cover and install plug to head cover hole.

3) Install air cleaner assembly temporarily.

4) Run engine at idle.

5) Place your finger over end of PCV valve (1) to check for vacuum.

If there is no vacuum, ch eck for clogged valve.

Replace as necessary. 6) After checking vacuum, stop engine and remove

PCV valve (1).

Shake valve and listen for rattle of check needle

inside the valve. If valve does not rattle, replace PCV

valve.

7) After checking, remove plug and install PCV valve.

8) Install air cleaner assembly securely.

Special Tools and Equipment

Special ToolS7RS0B1208001

I2RH0B120007-01

I2RH0B120008-01

09917–47011 SUZUKI scan tool

Vacuum pump gauge —

�) / �) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �)

Page 273 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-1

Engine

Engine Electrical Devices

Repair Instructions

ECM Removal and InstallationS7RS0B1306001

CAUTION!

As ECM consists of precision parts, be

careful not to expose it to excessive shock.

Removal1) Disconnect negative (–) cable at battery.

2) Remove ECM (1) from its bracket by removing its

mounting bolts (2).

3) Disconnect connectors from ECM as follows. a) Push lock (1) to release locking of lock lever (2).

b) Turn lock lever to arrow direction until it stops. Installation

Reverse removal procedure noting the following:

• Connect connectors to ECM as follows.

a. Make sure that lock lever of ECM connector is unlock position.

b. Insert ECM connectors to ECM until it stops with unlocked lock lever.

c. Lock ECM connectors securely by pulling its lock lever up.

• Tighten ECM mounting bolts to specified torque. Tightening torque

ECM mounting bolt (a): 8 N·m (0.8 kgf-m, 6.0 lb-

ft)

1

2 2

I4RS0A130002-01

1

2I4RS0A130003-01

I4RS0B130021-01

I4RS0B130022-01

I4RS0A130004-01

(a) (a)I4RS0A130005-01

Page 274 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-2 Engine Electrical Devices:

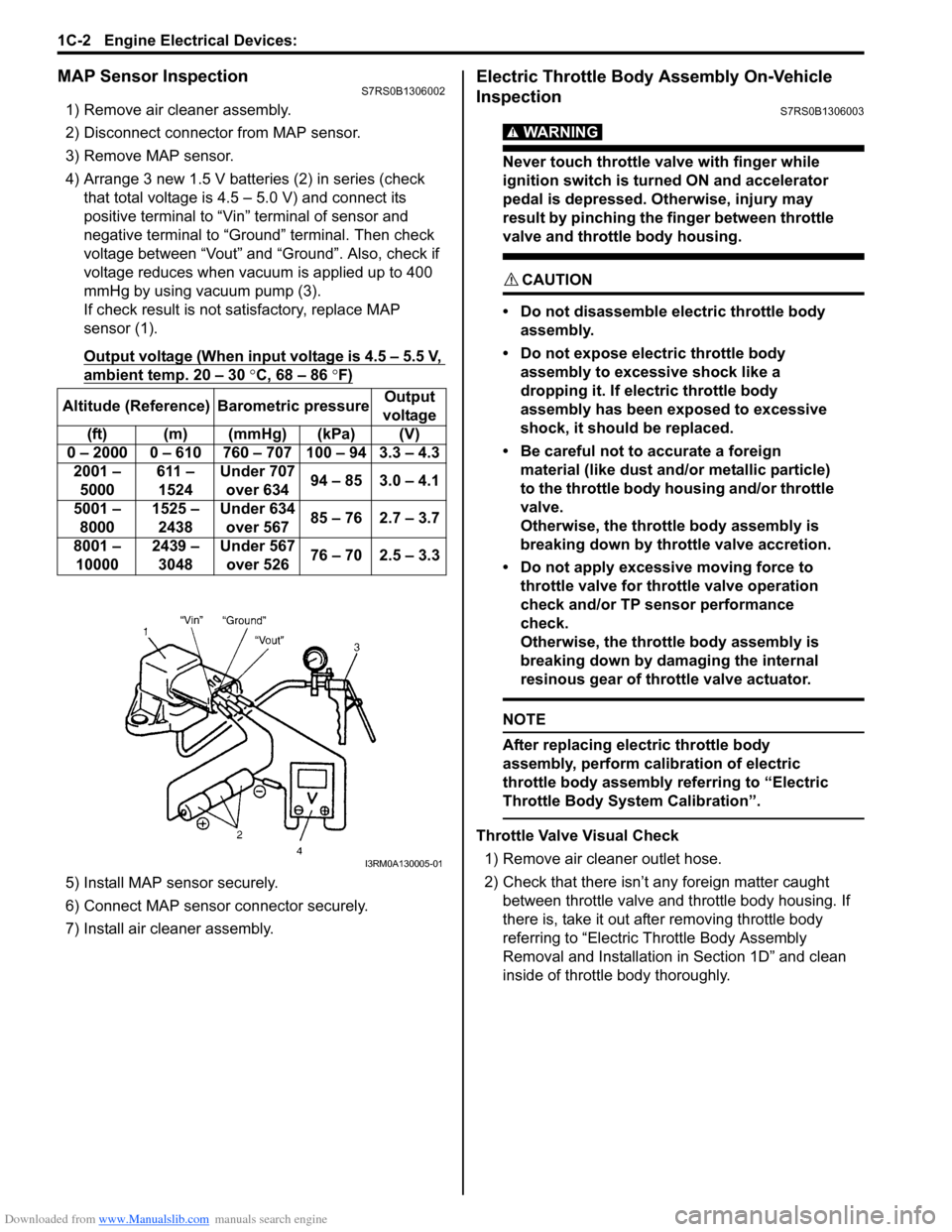

MAP Sensor InspectionS7RS0B1306002

1) Remove air cleaner assembly.

2) Disconnect connector from MAP sensor.

3) Remove MAP sensor.

4) Arrange 3 new 1.5 V batteries (2) in series (check that total voltage is 4.5 – 5.0 V) and connect its

positive terminal to “Vin ” terminal of sensor and

negative terminal to “Ground” terminal. Then check

voltage between “Vout” and “Ground”. Also, check if

voltage reduces when vacuum is applied up to 400

mmHg by using vacuum pump (3).

If check result is not satisfactory, replace MAP

sensor (1).

Output voltage (When input voltage is 4.5 – 5.5 V,

ambient temp. 20 – 30 °C, 68 – 86 °F)

5) Install MAP sensor securely.

6) Connect MAP sensor connector securely.

7) Install air cleaner assembly.

Electric Throttle Body Assembly On-Vehicle

Inspection

S7RS0B1306003

WARNING!

Never touch throttle valve with finger while

ignition switch is turned ON and accelerator

pedal is depressed. Otherwise, injury may

result by pinching the finger between throttle

valve and throttle body housing.

CAUTION!

• Do not disassemble electric throttle body assembly.

• Do not expose electric throttle body assembly to excessive shock like a

dropping it. If electric throttle body

assembly has been exposed to excessive

shock, it should be replaced.

• Be careful not to accurate a foreign material (like dust and/ or metallic particle)

to the throttle body housing and/or throttle

valve.

Otherwise, the throttle body assembly is

breaking down by throttle valve accretion.

• Do not apply excessive moving force to throttle valve for thro ttle valve operation

check and/or TP sensor performance

check.

Otherwise, the throttle body assembly is

breaking down by damaging the internal

resinous gear of throttle valve actuator.

NOTE

After replacing electric throttle body

assembly, perform calibration of electric

throttle body assembly referring to “Electric

Throttle Body System Calibration”.

Throttle Valve Visual Check

1) Remove air cleaner outlet hose.

2) Check that there isn’t any foreign matter caught between throttle valve and throttle body housing. If

there is, take it out after removing throttle body

referring to “Electric Th rottle Body Assembly

Removal and Installation in Section 1D” and clean

inside of throttle body thoroughly.

Altitude (Reference) Barometric pressure

Output

voltage

(ft) (m) (mmHg) (kPa) (V)

0 – 2000 0 – 610 760 – 707 100 – 94 3.3 – 4.3 2001 – 5000 611 –

1524 Under 707

over 634 94 – 85 3.0 – 4.1

5001 – 8000 1525 –

2438 Under 634

over 567 85 – 76 2.7 – 3.7

8001 – 10000 2439 –

3048 Under 567

over 526 76 – 70 2.5 – 3.3

I3RM0A130005-01

Page 275 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-3

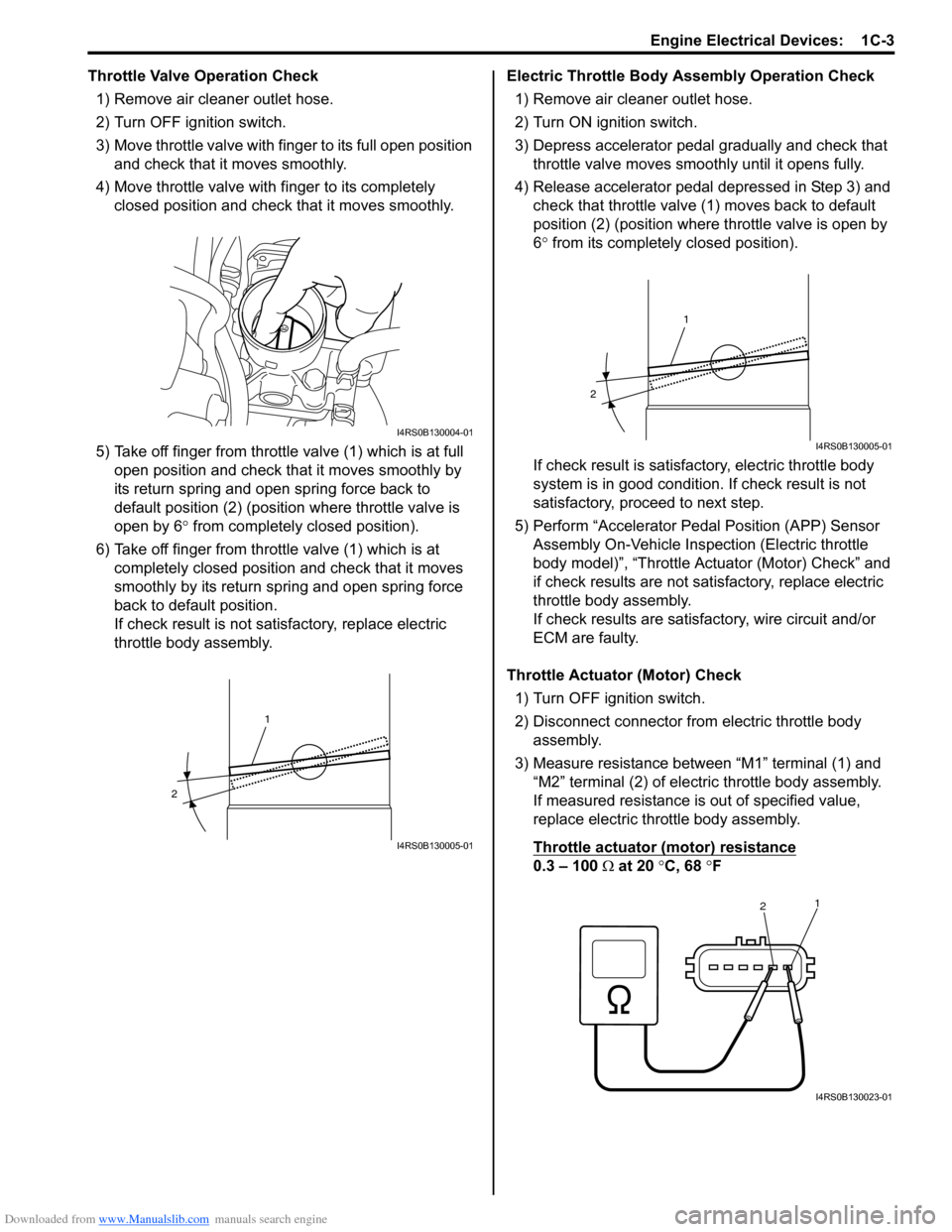

Throttle Valve Operation Check1) Remove air cleaner outlet hose.

2) Turn OFF ignition switch.

3) Move throttle valve with finger to its full open position and check that it moves smoothly.

4) Move throttle valve with fi nger to its completely

closed position and check that it moves smoothly.

5) Take off finger from throttle valve (1) which is at full open position and check that it moves smoothly by

its return spring and open spring force back to

default position (2) (positio n where throttle valve is

open by 6 ° from completely closed position).

6) Take off finger from throttle valve (1) which is at completely closed position and check that it moves

smoothly by its return spring and open spring force

back to default position.

If check result is not satisfactory, replace electric

throttle body assembly. Electric Throttle Body

Assembly Operation Check

1) Remove air cleaner outlet hose.

2) Turn ON ignition switch.

3) Depress accelerator pedal gradually and check that throttle valve moves smoo thly until it opens fully.

4) Release accelerator pedal depressed in Step 3) and check that throttle valve (1) moves back to default

position (2) (position where throttle valve is open by

6° from its completely closed position).

If check result is satisfactory, electric throttle body

system is in good condition. If check result is not

satisfactory, proceed to next step.

5) Perform “Accelerator Pe dal Position (APP) Sensor

Assembly On-Vehicle Inspection (Electric throttle

body model)”, “Throttle Actuator (Motor) Check” and

if check results are not satisfactory, replace electric

throttle body assembly.

If check results are satisfactory, wire circuit and/or

ECM are faulty.

Throttle Actuator (Motor) Check 1) Turn OFF ignition switch.

2) Disconnect connector from electric throttle body assembly.

3) Measure resistance between “M1” terminal (1) and “M2” terminal (2) of electric throttle body assembly.

If measured resistance is out of specified value,

replace electric throttle body assembly.

Throttle actuator (motor) resistance

0.3 – 100 Ω at 20 °C, 68 °F

I4RS0B130004-01

1

2

I4RS0B130005-01

1

2

I4RS0B130005-01

2 1

I4RS0B130023-01

Page 276 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-4 Engine Electrical Devices:

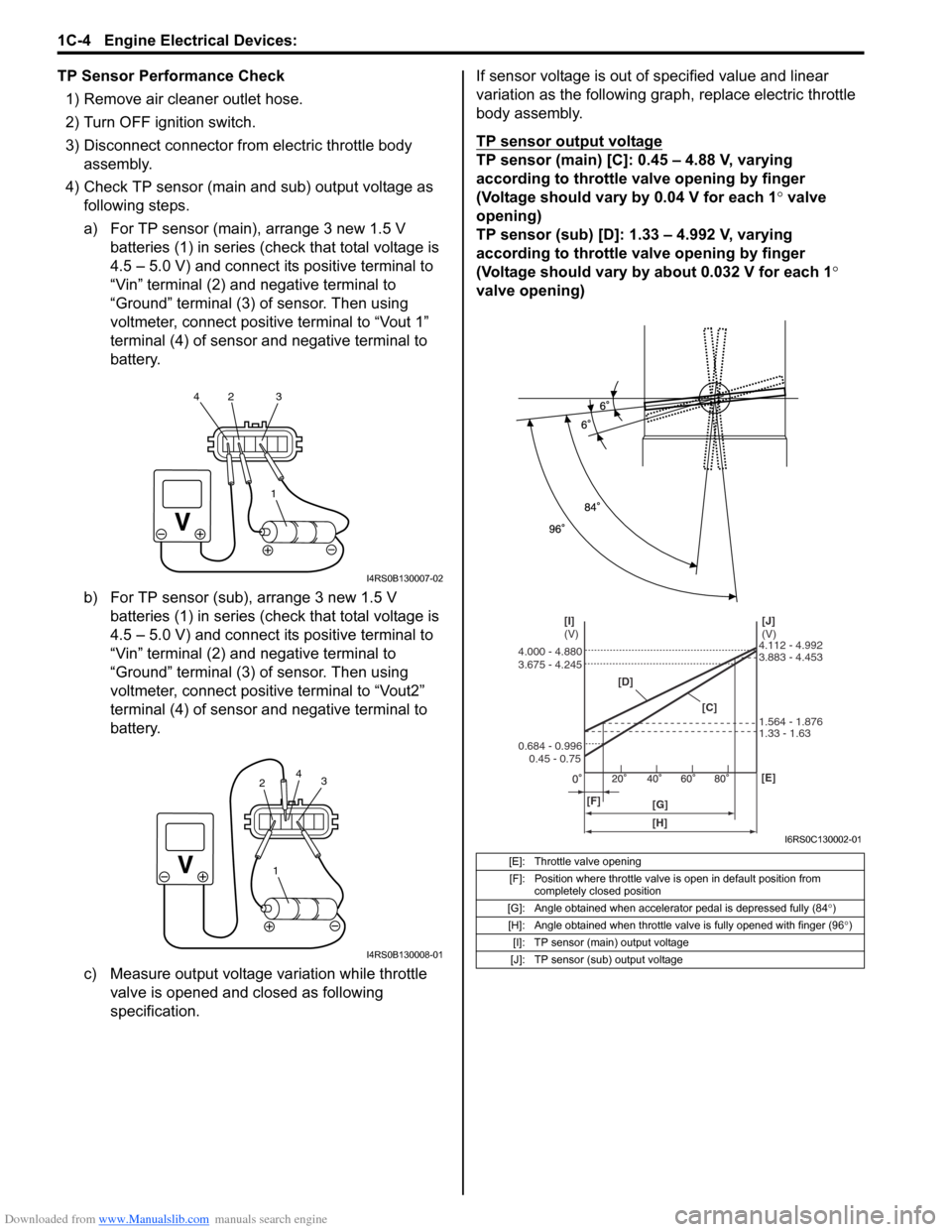

TP Sensor Performance Check1) Remove air cleaner outlet hose.

2) Turn OFF ignition switch.

3) Disconnect connector from electric throttle body assembly.

4) Check TP sensor (main and sub) output voltage as following steps.

a) For TP sensor (main), arrange 3 new 1.5 V batteries (1) in series (c heck that total voltage is

4.5 – 5.0 V) and connect its positive terminal to

“Vin” terminal (2) and negative terminal to

“Ground” terminal (3) of sensor. Then using

voltmeter, connect positive terminal to “Vout 1”

terminal (4) of sensor and negative terminal to

battery.

b) For TP sensor (sub), arrange 3 new 1.5 V batteries (1) in series (c heck that total voltage is

4.5 – 5.0 V) and connect its positive terminal to

“Vin” terminal (2) and negative terminal to

“Ground” terminal (3) of sensor. Then using

voltmeter, connect positive terminal to “Vout2”

terminal (4) of sensor and negative terminal to

battery.

c) Measure output voltage variation while throttle valve is opened and closed as following

specification. If sensor voltage is out of specified value and linear

variation as the following gra

ph, replace electric throttle

body assembly.

TP sensor output voltage

TP sensor (main) [C]: 0.45 – 4.88 V, varying

according to throttle valve opening by finger

(Voltage should vary by 0.04 V for each 1° valve

opening)

TP sensor (sub) [D]: 1.33 – 4.992 V, varying

according to throttle valve opening by finger

(Voltage should vary by about 0.032 V for each 1 °

valve opening)

1

42 3

I4RS0B130007-02

1

3

2 4

I4RS0B130008-01

[E]: Throttle valve opening

[F]: Position where throttle valve is open in default position from completely closed position

[G]: Angle obtained when accelerator pedal is depressed fully (84 °)

[H]: Angle obtained when throttle valve is fully opened with finger (96 °)

[I]: TP sensor (main) output voltage

[J]: TP sensor (sub) output voltage

[D]

[C][J]

(V)

[I]

(V)

[F] [G] [E]

0.45 - 0.75

0.684 - 0.996 3.675 - 4.245 4.000 - 4.880

1.33 - 1.63 1.564 - 1.876 3.883 - 4.453 4.112 - 4.992

[H]

I6RS0C130002-01

Page 277 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-5

Electric Throttle Body System CalibrationS7RS0B1306004

NOTE

If working the service described under the

“Precautions of Electric Throttle Body

System Calibration in Section 1A” perform

following steps for electric throttle body

system calibration.

1) If electric throttle body assembly and/or APP sensor

assembly are replaced, perform following steps.

a) Disconnect negative cable at battery for 20 seconds or more for the purpose of clearing

calibration data of closed throttle position from

memory in ECM.

b) Connect negative cable to battery.

2) Keep ignition switch at ON position for 5 seconds or more without running engine.

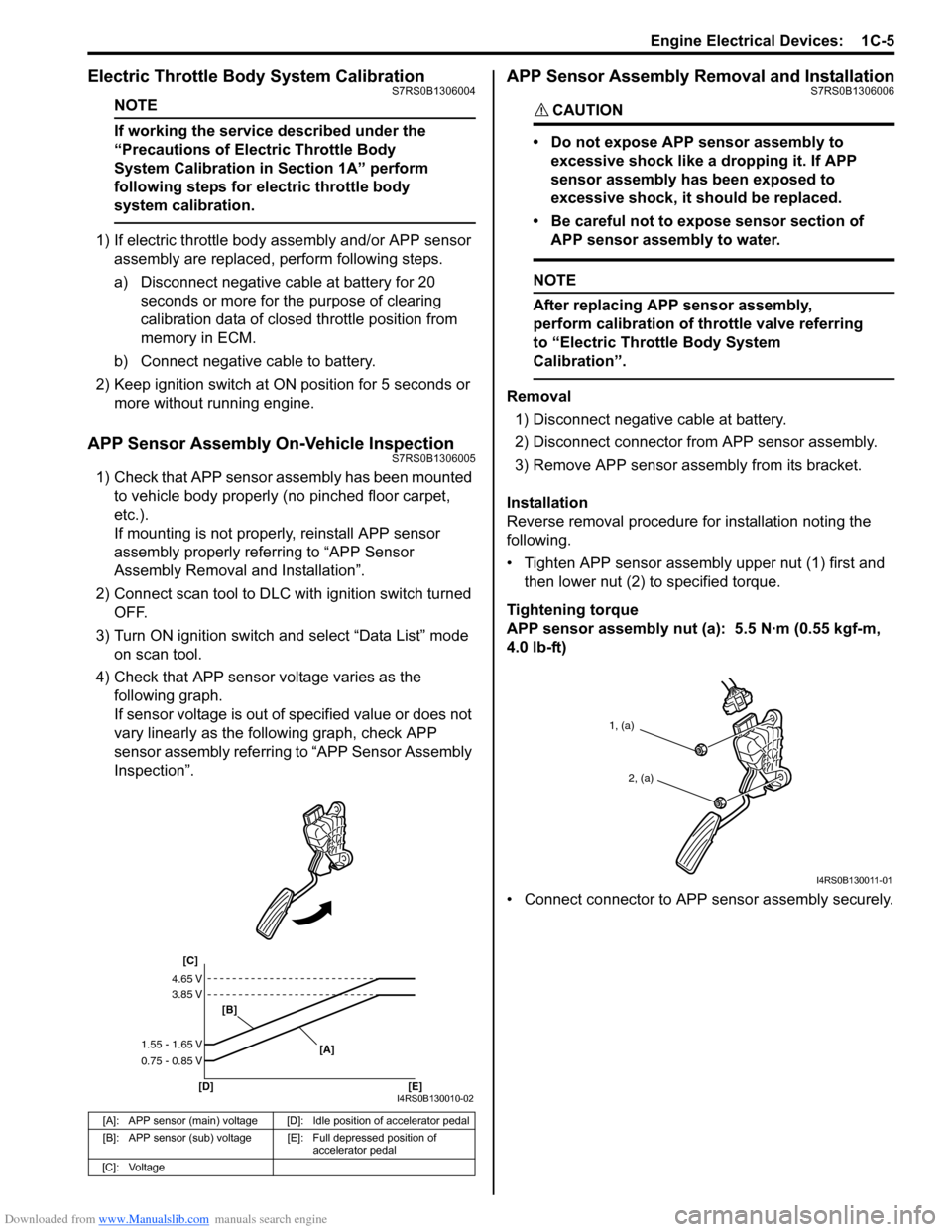

APP Sensor Assembly On-Vehicle InspectionS7RS0B1306005

1) Check that APP sensor a ssembly has been mounted

to vehicle body properly (no pinched floor carpet,

etc.).

If mounting is not pro perly, reinstall APP sensor

assembly properly refe rring to “APP Sensor

Assembly Removal and Installation”.

2) Connect scan tool to DLC with ignition switch turned OFF.

3) Turn ON ignition switch and select “Data List” mode on scan tool.

4) Check that APP sensor voltage varies as the following graph.

If sensor voltage is out of specified value or does not

vary linearly as the fo llowing graph, check APP

sensor assembly referring to “APP Sensor Assembly

Inspection”.

APP Sensor Assembly Removal and InstallationS7RS0B1306006

CAUTION!

• Do not expose APP sensor assembly to

excessive shock like a dropping it. If APP

sensor assembly has been exposed to

excessive shock, it should be replaced.

• Be careful not to expose sensor section of APP sensor assembly to water.

NOTE

After replacing APP sensor assembly,

perform calibration of th rottle valve referring

to “Electric Throttle Body System

Calibration”.

Removal

1) Disconnect negative cable at battery.

2) Disconnect connector from APP sensor assembly.

3) Remove APP sensor asse mbly from its bracket.

Installation

Reverse removal procedure for installation noting the

following.

• Tighten APP sensor assembly upper nut (1) first and then lower nut (2) to specified torque.

Tightening torque

APP sensor assembly nut (a): 5.5 N·m (0.55 kgf-m,

4.0 lb-ft)

• Connect connector to APP sensor assembly securely.

[A]: APP sensor (main) voltage [D]: Idle position of accelerator pedal

[B]: APP sensor (sub) voltage [E]: Full depressed position of

accelerator pedal

[C]: Voltage

[C]

[B]

[D] [E] [A]

4.65 V

3.85 V

1.55 - 1.65 V

0.75 - 0.85 V

I4RS0B130010-02

1, (a)

2, (a)

I4RS0B130011-01

Page 278 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-6 Engine Electrical Devices:

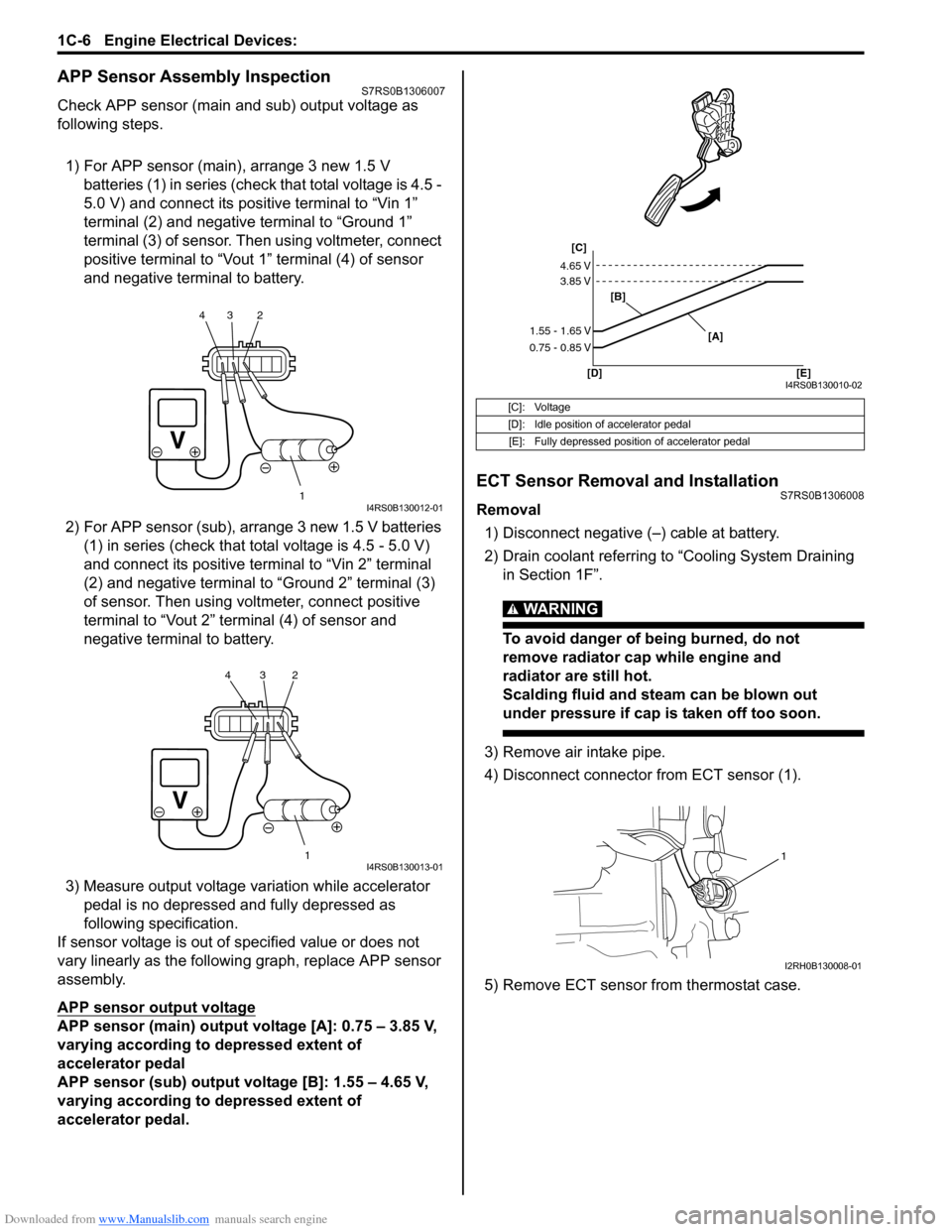

APP Sensor Assembly InspectionS7RS0B1306007

Check APP sensor (main and sub) output voltage as

following steps.

1) For APP sensor (main) , arrange 3 new 1.5 V

batteries (1) in series (check that total voltage is 4.5 -

5.0 V) and connect its positive terminal to “Vin 1”

terminal (2) and negative terminal to “Ground 1”

terminal (3) of sensor. Then using voltmeter, connect

positive terminal to “Vout 1” terminal (4) of sensor

and negative terminal to battery.

2) For APP sensor (s ub), arrange 3 new 1.5 V batteries

(1) in series (check that total voltage is 4.5 - 5.0 V)

and connect its positive terminal to “Vin 2” terminal

(2) and negative terminal to “Ground 2” terminal (3)

of sensor. Then using volt meter, connect positive

terminal to “Vout 2” terminal (4) of sensor and

negative termin al to battery.

3) Measure output voltage variation while accelerator pedal is no depressed and fully depressed as

following specification.

If sensor voltage is out of specified value or does not

vary linearly as the followin g graph, replace APP sensor

assembly.

APP sensor output voltage

APP sensor (main) output voltage [A]: 0.75 – 3.85 V,

varying according to depressed extent of

accelerator pedal

APP sensor (sub) output voltage [B]: 1.55 – 4.65 V,

varying according to depressed extent of

accelerator pedal.

ECT Sensor Removal and InstallationS7RS0B1306008

Removal

1) Disconnect negative (–) cable at battery.

2) Drain coolant referring to “Cooling System Draining in Section 1F”.

WARNING!

To avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot.

Scalding fluid and steam can be blown out

under pressure if cap is taken off too soon.

3) Remove air intake pipe.

4) Disconnect connector from ECT sensor (1).

5) Remove ECT sensor from thermostat case.

1

234I4RS0B130012-01

1

234I4RS0B130013-01

[C]: Voltage

[D]: Idle position of accelerator pedal

[E]: Fully depressed position of accelerator pedal

[C]

[B]

[D] [E] [A]

4.65 V

3.85 V

1.55 - 1.65 V

0.75 - 0.85 V

I4RS0B130010-02

1

I2RH0B130008-01

Page 279 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-7

Installation

Reverse removal procedure noting the following.

• Clean mating surfaces of ECT sensor and thermostat case.

• Check O-ring for damage and replace, if necessary.

• Tighten ECT sensor (1) to specified torque.

Tightening torque

ECT sensor (a): 15 N·m (1.5 kgf-m, 11.0 lb-ft)

• Connect connector to ECT sensor securely.

• Refill coolant referring to “Cooling System Flush and

Refill in Section 1F”.

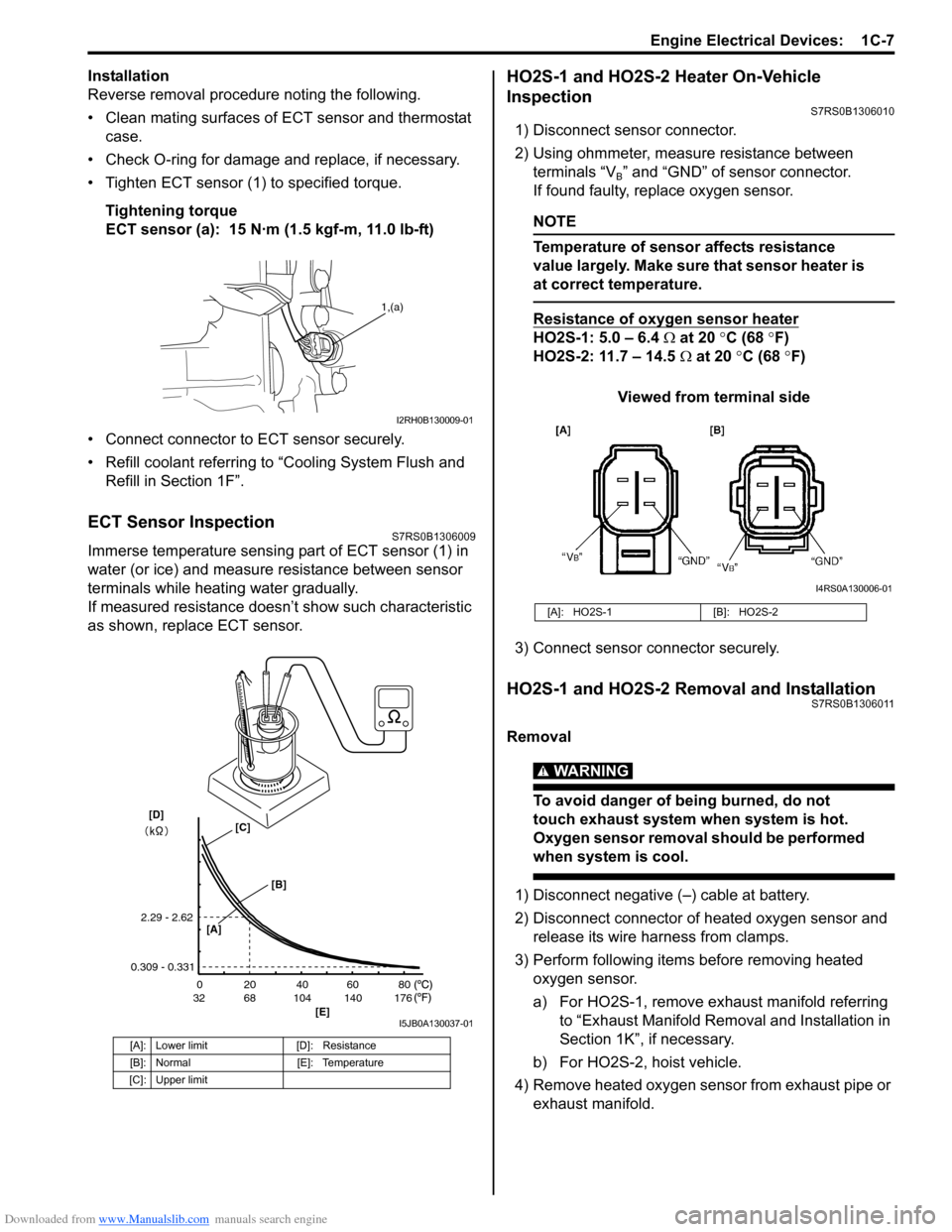

ECT Sensor InspectionS7RS0B1306009

Immerse temperature sensing part of ECT sensor (1) in

water (or ice) and measure resistance between sensor

terminals while heating water gradually.

If measured resistance doesn’t show such characteristic

as shown, replace ECT sensor.

HO2S-1 and HO2S-2 Heater On-Vehicle

Inspection

S7RS0B1306010

1) Disconnect sensor connector.

2) Using ohmmeter, measure resistance between terminals “V

B” and “GND” of sensor connector.

If found faulty, replace oxygen sensor.

NOTE

Temperature of sensor affects resistance

value largely. Make sure that sensor heater is

at correct temperature.

Resistance of oxygen sensor heater

HO2S-1: 5.0 – 6.4 Ω at 20 °C (68 °F)

HO2S-2: 11.7 – 14.5 Ω at 20 °C (68 °F)

Viewed from terminal side

3) Connect sensor co nnector securely.

HO2S-1 and HO2S-2 Removal and InstallationS7RS0B1306011

Removal

WARNING!

To avoid danger of being burned, do not

touch exhaust system when system is hot.

Oxygen sensor removal should be performed

when system is cool.

1) Disconnect negative (–) cable at battery.

2) Disconnect connector of heated oxygen sensor and

release its wire harness from clamps.

3) Perform following items before removing heated oxygen sensor.

a) For HO2S-1, remove exhaust manifold referring to “Exhaust Manifold Remo val and Installation in

Section 1K”, if necessary.

b) For HO2S-2, hoist vehicle.

4) Remove heated oxygen sensor from exhaust pipe or exhaust manifold.

[A]: Lower limit [D]: Resistance

[B]: Normal [E]: Temperature

[C]: Upper limit

1,(a)

I2RH0B130009-01

20

0

68

32 104 140 176 40 60 80

[E]

2.29 - 2.62

0.309 - 0.331

[A]

[B]

[C][D]

I5JB0A130037-01

[A]: HO2S-1 [B]: HO2S-2

I4RS0A130006-01

Page 280 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-8 Engine Electrical Devices:

Installation

Reverse removal procedure noting the following.

• Tighten heated oxygen sensor to specified torque.Tightening torque

Heated oxygen sensor (a): 45 N·m (4.5 kgf-m,

32.5 lb-ft)

• Install exhaust manifold referring to “Exhaust Manifold Removal and Installation in Section 1K”, if removed.

• Connect connector of heated oxygen sensor and clamp wire harness securely.

• After installing heated oxygen sensor, start engine and check that no exhaust gas leakage exists.

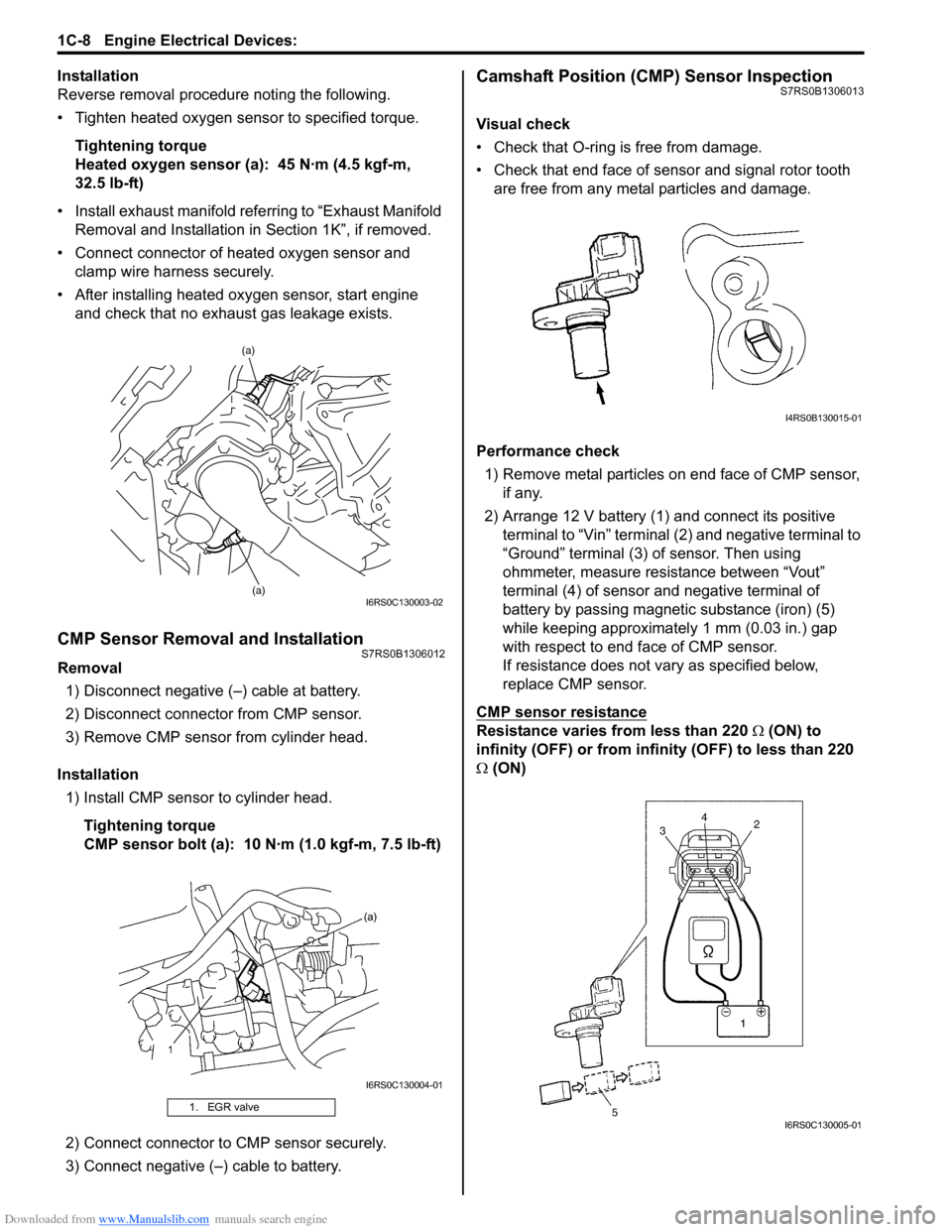

CMP Sensor Removal and InstallationS7RS0B1306012

Removal

1) Disconnect negative (–) cable at battery.

2) Disconnect connector from CMP sensor.

3) Remove CMP sensor from cylinder head.

Installation 1) Install CMP sensor to cylinder head.

Tightening torque

CMP sensor bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

2) Connect connector to CMP sensor securely.

3) Connect negative (–) cable to battery.

Camshaft Position (CMP) Sensor InspectionS7RS0B1306013

Visual check

• Check that O-ring is free from damage.

• Check that end face of sensor and signal rotor tooth are free from any metal particles and damage.

Performance check 1) Remove metal particles on end face of CMP sensor, if any.

2) Arrange 12 V battery (1) and connect its positive terminal to “Vin” terminal (2) and negative terminal to

“Ground” terminal (3) of sensor. Then using

ohmmeter, measure resistance between “Vout”

terminal (4) of sensor and negative terminal of

battery by passing magnetic substance (iron) (5)

while keeping approximately 1 mm (0.03 in.) gap

with respect to end face of CMP sensor.

If resistance does not vary as specified below,

replace CMP sensor.

CMP sensor resistance

Resistance varies from less than 220 Ω (ON) to

infinity (OFF) or from infinity (OFF) to less than 220

Ω (ON)

1. EGR valve

(a)

(a)

I6RS0C130003-02

I6RS0C130004-01

I4RS0B130015-01

I6RS0C130005-01