R p m SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 241 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-191

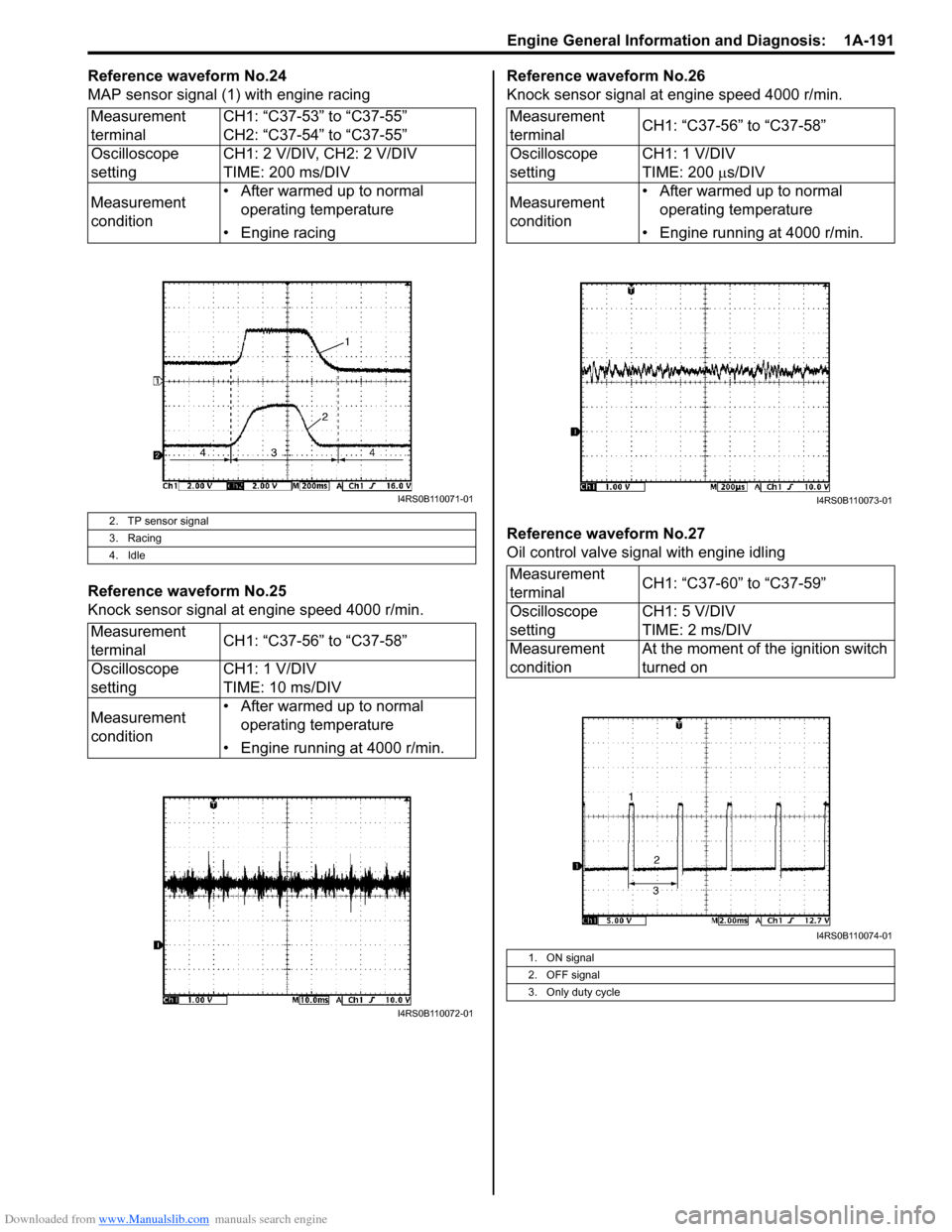

Reference waveform No.24

MAP sensor signal (1) with engine racing

Reference waveform No.25

Knock sensor signal at engine speed 4000 r/min.Reference waveform No.26

Knock sensor signal at engine speed 4000 r/min.

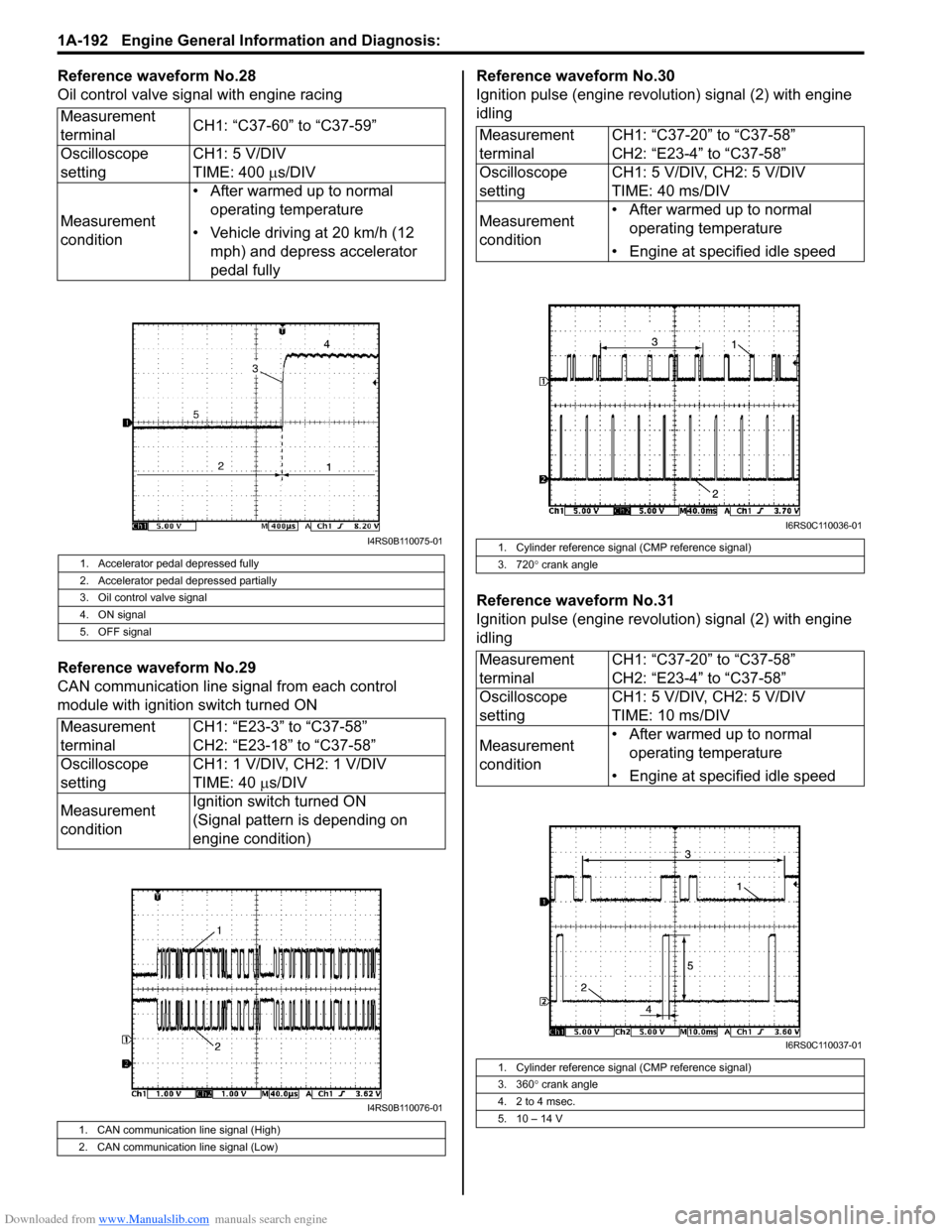

Reference waveform No.27

Oil control valve signal with engine idling

Measurement

terminal

CH1: “C37-53” to “C37-55”

CH2: “C37-54” to “C37-55”

Oscilloscope

setting CH1: 2 V/DIV, CH2: 2 V/DIV

TIME: 200 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine racing

2. TP sensor signal

3. Racing

4. Idle

Measurement

terminal CH1: “C37-56” to “C37-58”

Oscilloscope

setting CH1: 1 V/DIV

TIME: 10 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine running at 4000 r/min.

I4RS0B110071-01

I4RS0B110072-01

Measurement

terminal CH1: “C37-56” to “C37-58”

Oscilloscope

setting CH1: 1 V/DIV

TIME: 200

µs/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine running at 4000 r/min.

Measurement

terminal CH1: “C37-60” to “C37-59”

Oscilloscope

setting CH1: 5 V/DIV

TIME: 2 ms/DIV

Measurement

condition At the moment of the ignition switch

turned on

1. ON signal

2. OFF signal

3. Only duty cycle

I4RS0B110073-01

I4RS0B110074-01

Page 242 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-192 Engine General Information and Diagnosis:

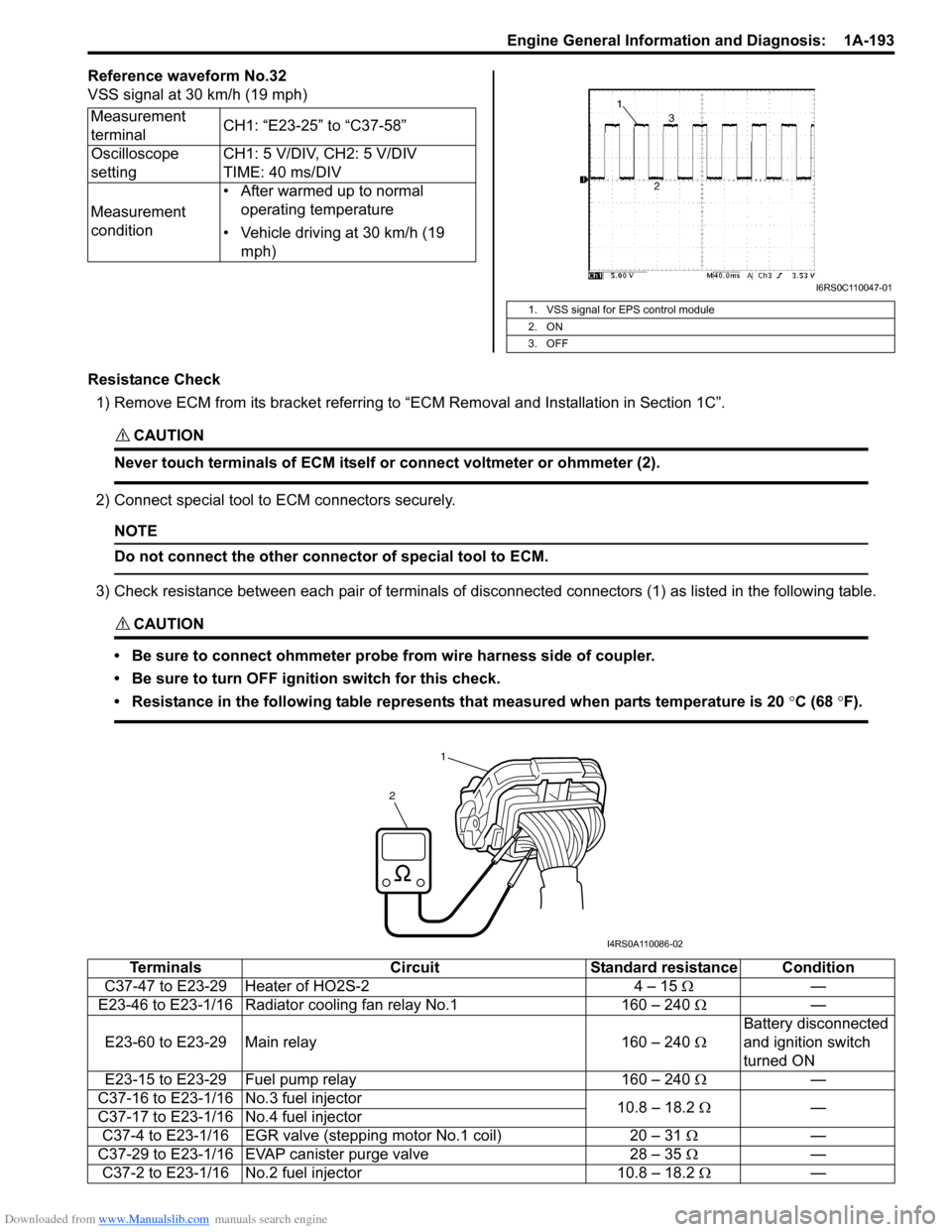

Reference waveform No.28

Oil control valve signal with engine racing

Reference waveform No.29

CAN communication line signal from each control

module with ignition switch turned ONReference waveform No.30

Ignition pulse (engine revolution) signal (2) with engine

idling

Reference waveform No.31

Ignition pulse (engine revolution) signal (2) with engine

idling

Measurement

terminal

CH1: “C37-60” to “C37-59”

Oscilloscope

setting CH1: 5 V/DIV

TIME: 400

µs/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Vehicle driving at 20 km/h (12 mph) and depress accelerator

pedal fully

1. Accelerator pedal depressed fully

2. Accelerator pedal depressed partially

3. Oil control valve signal

4. ON signal

5. OFF signal

Measurement

terminal CH1: “E23-3” to “C37-58”

CH2: “E23-18” to “C37-58”

Oscilloscope

setting CH1: 1 V/DIV, CH2: 1 V/DIV

TIME: 40

µs/DIV

Measurement

condition Ignition switch turned ON

(Signal pattern is depending on

engine condition)

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

I4RS0B110075-01

I4RS0B110076-01

Measurement

terminal

CH1: “C37-20” to “C37-58”

CH2: “E23-4” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 720 ° crank angle

Measurement

terminal CH1: “C37-20” to “C37-58”

CH2: “E23-4” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 10 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 360 ° crank angle

4. 2 to 4 msec.

5. 10 – 14 V

I6RS0C110036-01

I6RS0C110037-01

Page 243 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-193

Reference waveform No.32

VSS signal at 30 km/h (19 mph)

Resistance Check1) Remove ECM from its bracket referring to “ECM Removal and Installation in Section 1C”.

CAUTION!

Never touch terminals of ECM itself or connect voltmeter or ohmmeter (2).

2) Connect special tool to ECM connectors securely.

NOTE

Do not connect the other connector of special tool to ECM.

3) Check resistance between each pair of terminals of disconnected connectors (1) as listed in the following table.

CAUTION!

• Be sure to connect ohmmeter probe from wire harness side of coupler.

• Be sure to turn OFF ignition switch for this check.

• Resistance in the following table represents that measured when parts temperature is 20 °C (68 °F).

Measurement

terminal CH1: “E23-25” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Vehicle driving at 30 km/h (19 mph)

1. VSS signal for EPS control module

2. ON

3. OFF

I6RS0C110047-01

1

2

I4RS0A110086-02

Terminals CircuitStandard resistance Condition

C37-47 to E23-29 Heater of HO2S-2 4 – 15 Ω—

E23-46 to E23-1/16 Radiator cooling fan relay No.1 160 – 240 Ω —

E23-60 to E23-29 Main relay 160 – 240 ΩBattery disconnected

and ignition switch

turned ON

E23-15 to E23-29 Fuel pump relay 160 – 240 Ω —

C37-16 to E23-1/16 No.3 fuel injector 10.8 – 18.2 Ω —

C37-17 to E23-1/16 No.4 fuel injector

C37-4 to E23-1/16 EGR valve (st epping motor No.1 coil) 20 – 31 Ω —

C37-29 to E23-1/16 EVAP canister purge valve 28 – 35 Ω —

C37-2 to E23-1/16 No.2 fuel injector 10.8 – 18.2 Ω—

Page 244 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-194 Engine General Information and Diagnosis:

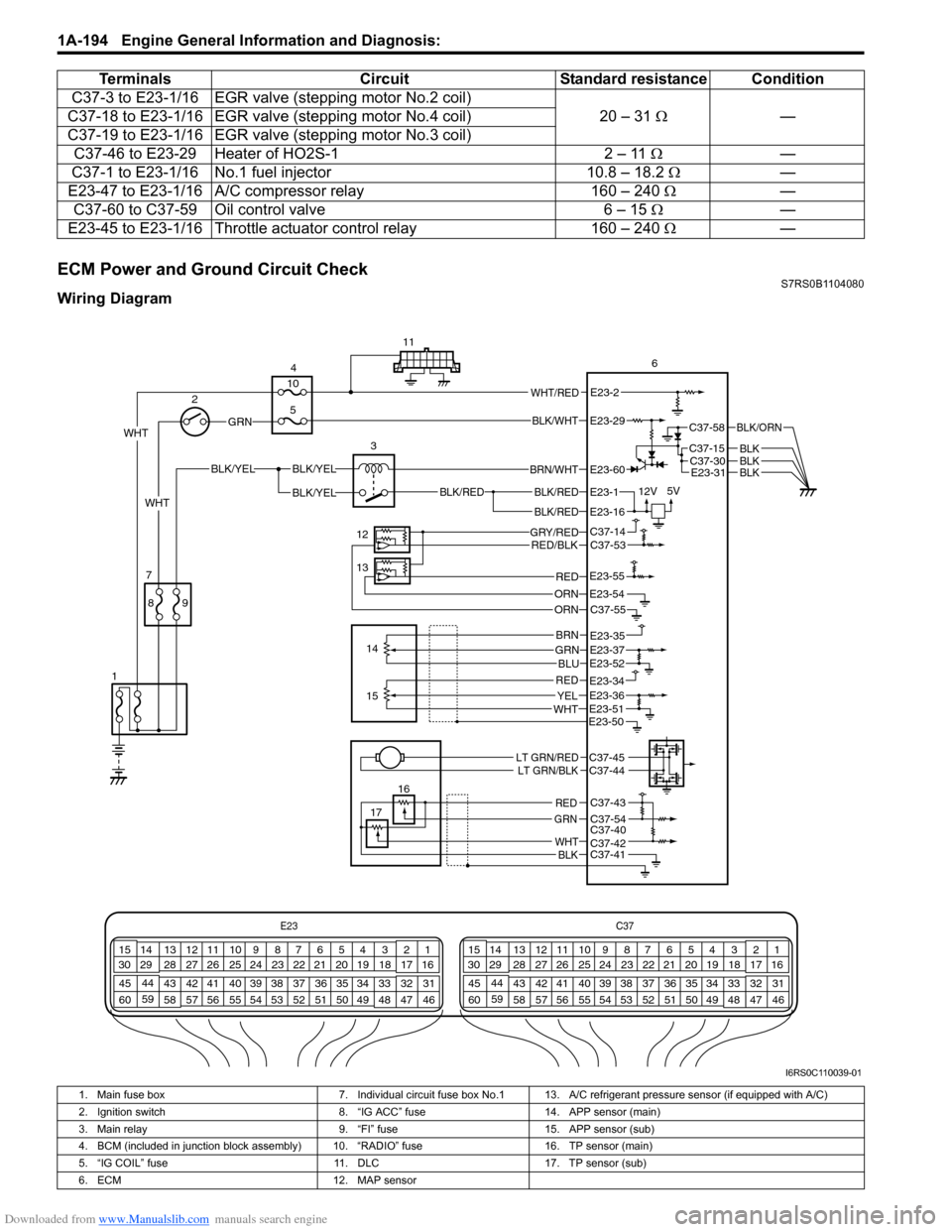

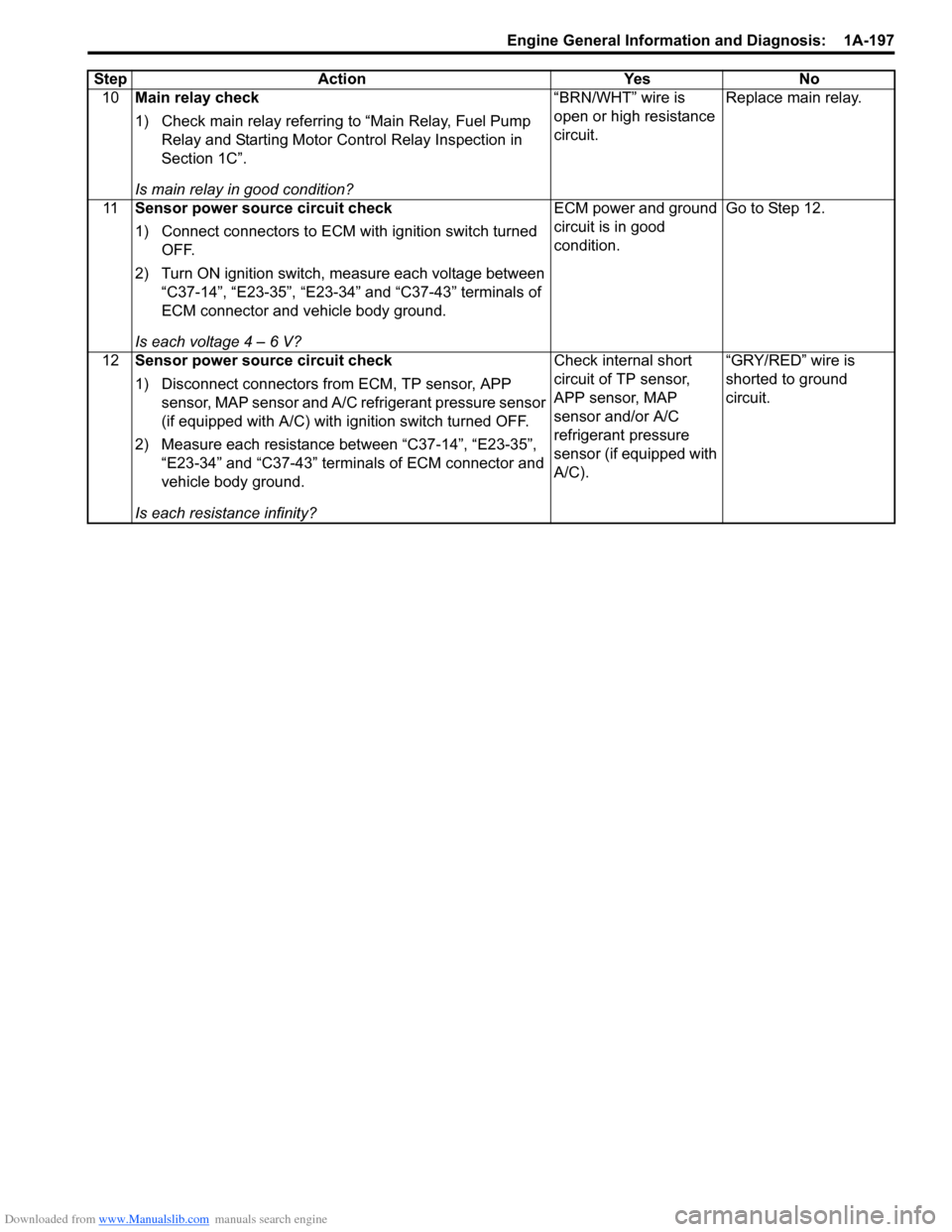

ECM Power and Ground Circuit CheckS7RS0B1104080

Wiring DiagramC37-3 to E23-1/16 EGR valve

(stepping motor No.2 coil)

20 – 31 Ω —

C37-18 to E23-1/16 EGR valv e (stepping motor No.4 coil)

C37-19 to E23-1/16 EGR valv e (stepping motor No.3 coil)

C37-46 to E23-29 Heater of HO2S-1 2 – 11 Ω—

C37-1 to E23-1/16 No.1 fuel injector 10.8 – 18.2 Ω —

E23-47 to E23-1/16 A/C compressor relay 160 – 240 Ω —

C37-60 to C37-59 Oil control valve 6 – 15 Ω —

E23-45 to E23-1/16 Throttle actuator control relay 160 – 240 Ω —

Terminals

CircuitStandard resistance Condition

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/RED

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

GRN

BRN/WHT

12V

5VE23-1

E23-60

E23-16

WHT 2

4

11

6

3

12

13 14

7

1

16

17

89

15

10

5

WHT/REDE23-2

C37-58

C37-15C37-30

BLK/ORN

BLKBLKE23-31BLK

WHT

GRY/REDRED/BLK

ORN

C37-14C37-53

C37-55E23-54

REDE23-55

GRNBRN

BLU

REDYELWHT

E23-35E23-37E23-52

E23-51

E23-34E23-36

E23-50

LT GRN/REDLT GRN/BLKC37-45C37-44

C37-43

C37-54C37-40C37-42C37-41

RED

GRN

WHTBLK

ORN

BLK/WHTE23-29

I6RS0C110039-01

1. Main fuse box 7. Individual circuit fuse box No.1 13. A/C refrigerant pressure sensor (if equipped with A/C)

2. Ignition switch 8. “IG ACC” fuse14. APP sensor (main)

3. Main relay 9. “FI” fuse15. APP sensor (sub)

4. BCM (included in junction block assembly) 10. “RADIO” fuse 16. TP sensor (main)

5. “IG COIL” fuse 11. DLC17. TP sensor (sub)

6. ECM 12. MAP sensor

Page 245 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-195

Circuit Description

When the ignition switch is turned ON, the main relay turns ON (the contact point closes) and the main power is

supplied to ECM.

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Circuit fuse check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection to ECM connector at “E23- 2”, “E23-29”, “E23-60”, “E23-1”, “E23-16”, “E23-31”,

“C37-58”, “C37-15” and “C37-30” terminals.

3) If OK, check “RADIO” fuse and “IG COIL” fuse for blowing.

Are “RADIO” fuse and “IG COIL” fuse in good condition? Go to Step 2.

Replace fuse (s) and

check for short in

circuits connected to

fuse(s).

2 Power supply circuit check

1) Measure voltage between “E23-2” terminal of ECM

connector and body ground.

Is voltage 10 – 14 V? Go to Step 3.

“WHT/RED” or “WHT”

wire is open circuit.

3 Ignition signal check

1) Turn ignition switch to ON position.

2) Measure voltage between “E23-29” terminal of ECM

connector and body ground.

Is voltage 10 – 14 V? Go to Step 4.

“BLK/WHT” or “GRN”

wire is open circuit.

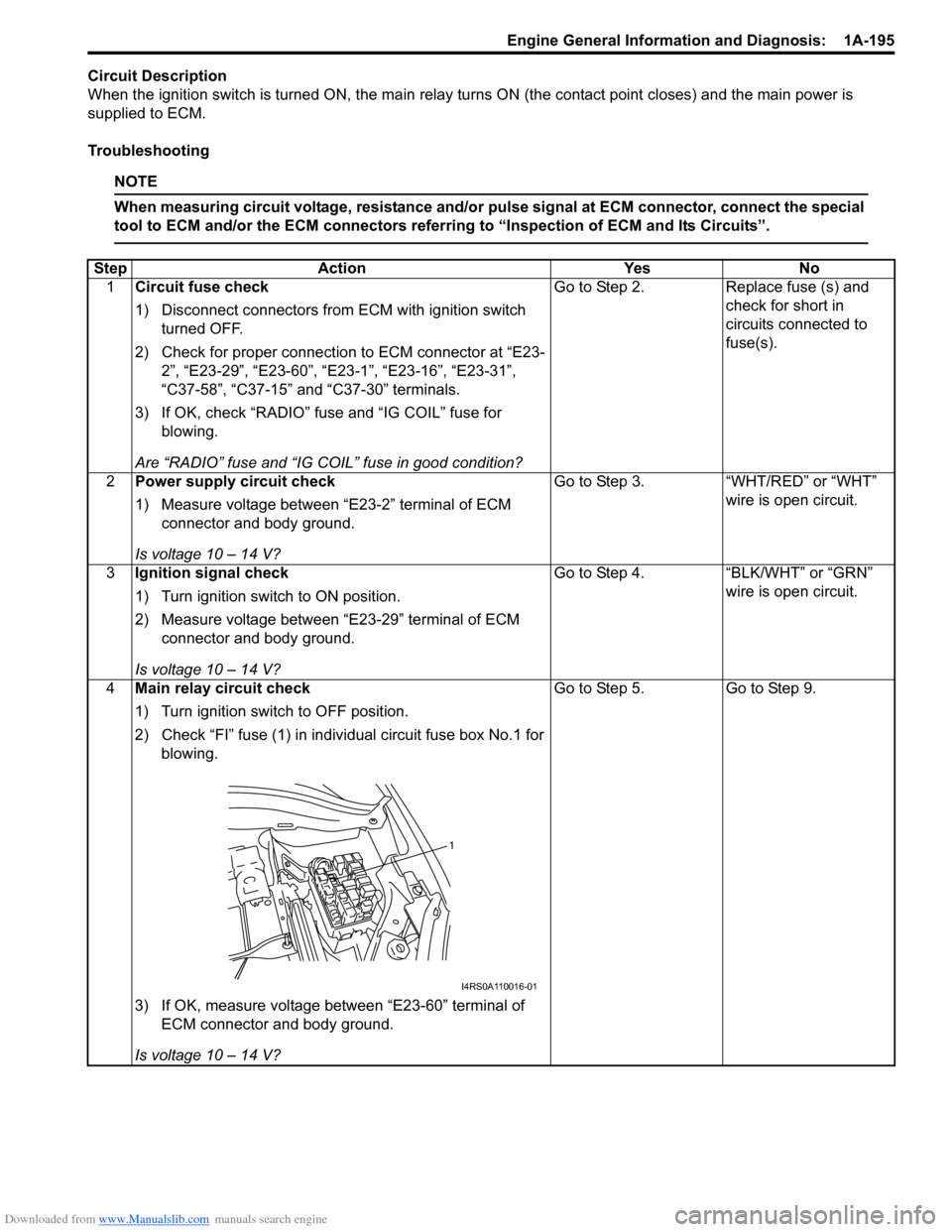

4 Main relay circuit check

1) Turn ignition switch to OFF position.

2) Check “FI” fuse (1) in indivi dual circuit fuse box No.1 for

blowing.

3) If OK, measure voltage between “E23-60” terminal of ECM connector and body ground.

Is voltage 10 – 14 V? Go to Step 5.

Go to Step 9.

1

I4RS0A110016-01

Page 246 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-196 Engine General Information and Diagnosis:

5Main relay circuit check

1) Connect connectors to ECM with ignition switch turned

OFF.

2) Turn ignition switch to ON position.

3) Measure voltage between “E23-60” terminal of ECM connector and body ground.

Is voltage 0 – 1 V? Go to Step 7. Go to Step 6.

6 ECM ground circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from ECM.

3) Measure resistance between each “E23-31”, “C37-58”,

“C37-15” and “C37-30” terminals of ECM connector and

body ground.

Is resistance 1

Ω or less? Substitute a known-

good ECM and recheck.

“BLK/ORN” or “BLK”

wire is open or high

resistance circuit.

7 Main relay circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Using service wire, ground “E23-60” terminal of ECM connector and measure voltage between each “E23-1”

and “E23-16” terminals of ECM connector and body

ground.

Is voltage 10 – 14 V? Go to Step 11. Go to Step 8.

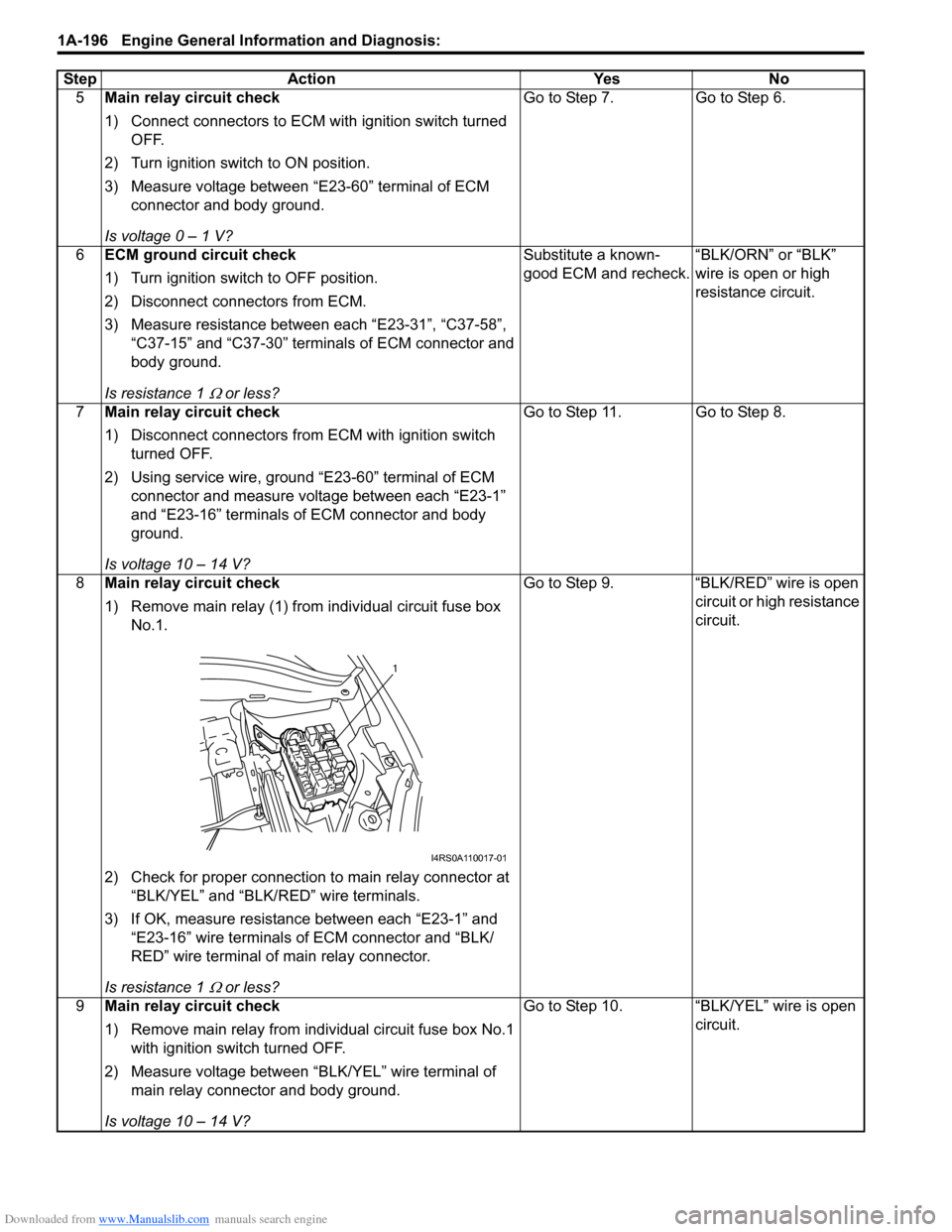

8 Main relay circuit check

1) Remove main relay (1) from individual circuit fuse box

No.1.

2) Check for proper connection to main relay connector at “BLK/YEL” and “BLK/RED” wire terminals.

3) If OK, measure resistance between each “E23-1” and “E23-16” wire terminals of ECM connector and “BLK/

RED” wire terminal of main relay connector.

Is resistance 1

Ω or less? Go to Step 9. “BLK/RED” wire is open

circuit or high resistance

circuit.

9 Main relay circuit check

1) Remove main relay from individual circuit fuse box No.1

with ignition swit ch turned OFF.

2) Measure voltage between “BLK/YEL” wire terminal of main relay connector and body ground.

Is voltage 10 – 14 V? Go to Step 10. “BLK/YEL” wire is open

circuit.

Step Action Yes No

1

I4RS0A110017-01

Page 247 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-197

10Main relay check

1) Check main relay referring to “Main Relay, Fuel Pump

Relay and Starting Motor Control Relay Inspection in

Section 1C”.

Is main relay in good condition? “BRN/WHT” wire is

open or high resistance

circuit.

Replace main relay.

11 Sensor power source circuit check

1) Connect connectors to ECM with ignition switch turned

OFF.

2) Turn ON ignition switch, measure each voltage between “C37-14”, “E23-35”, “E23-34” and “C37-43” terminals of

ECM connector and vehicle body ground.

Is each voltage 4 – 6 V? ECM power and ground

circuit is in good

condition.

Go to Step 12.

12 Sensor power source circuit check

1) Disconnect connectors from ECM, TP sensor, APP

sensor, MAP sensor and A/C refrigerant pressure sensor

(if equipped with A/C) with i gnition switch turned OFF.

2) Measure each resistance between “C37-14”, “E23-35”, “E23-34” and “C37-43” terminals of ECM connector and

vehicle body ground.

Is each resistance infinity? Check internal short

circuit of TP sensor,

APP sensor, MAP

sensor and/or A/C

refrigerant pressure

sensor (if equipped with

A/C).

“GRY/RED” wire is

shorted to ground

circuit.

Step Action Yes No

Page 248 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-198 Engine General Information and Diagnosis:

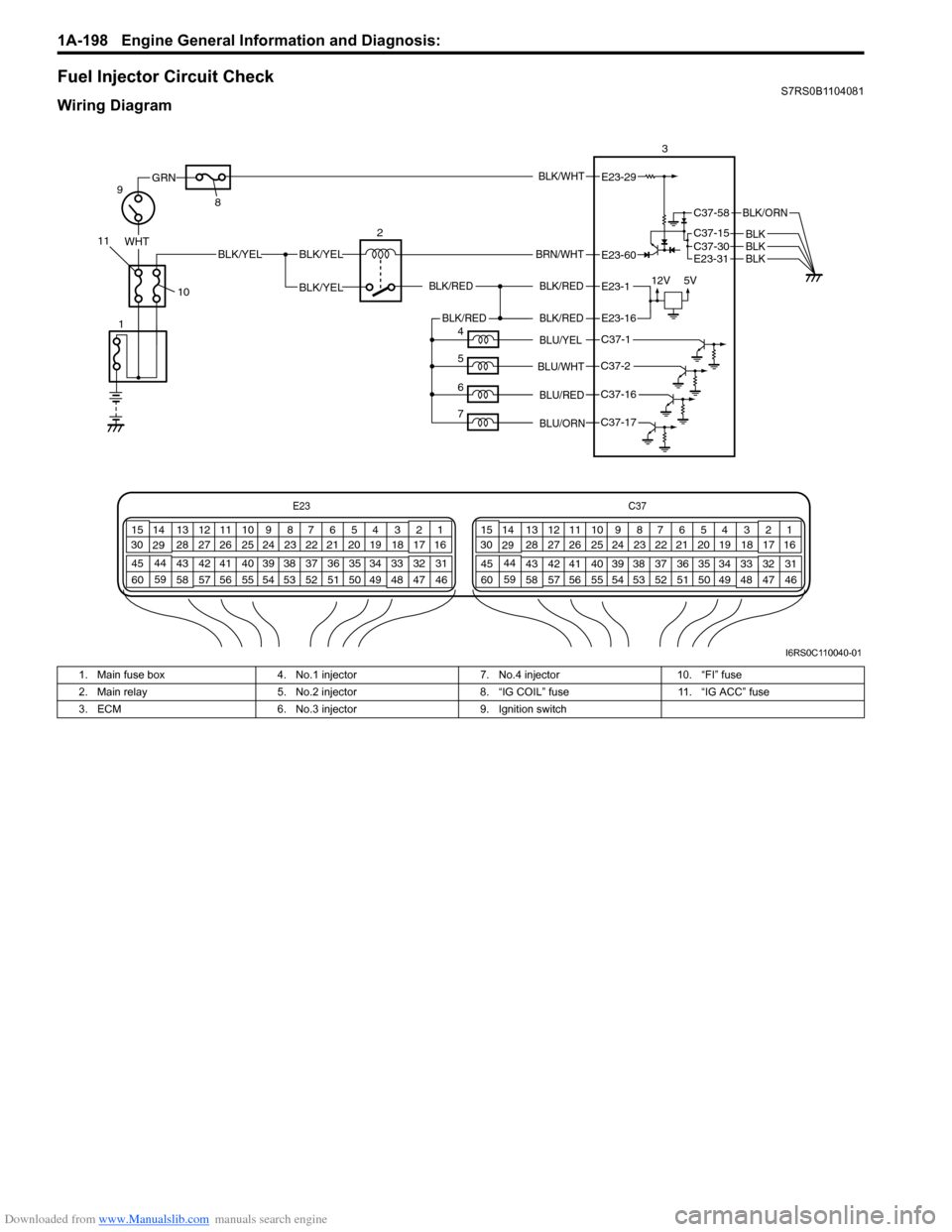

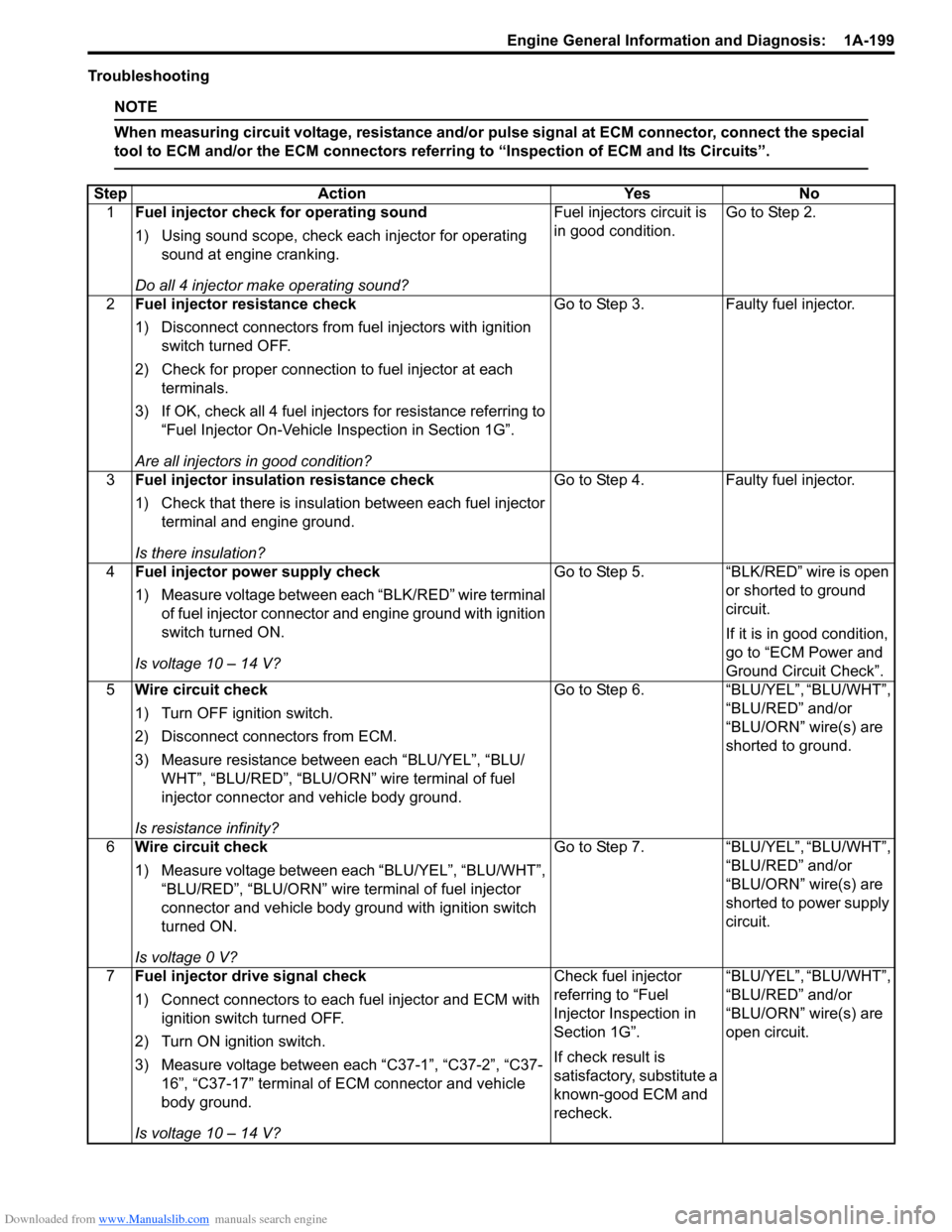

Fuel Injector Circuit CheckS7RS0B1104081

Wiring Diagram

BLK/WHTBLK/RED

BLK/RED

WHTBLK/YELBLK/YEL

BLK/YEL

GRN

BRN/WHT

12V 5V

9

2

8 3E23-29

E23-1

E23-60

10

11

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

C37-1

C37-2

C37-16

C37-17

BLK/REDBLK/RED

BLU/YEL

BLU/RED

BLU/ORN

BLU/WHT

E23-16

4

5

6

71

C37-58

C37-15 C37-30 E23-31

BLK/ORN

BLKBLKBLK

I6RS0C110040-01

1. Main fuse box 4. No.1 injector 7. No.4 injector10. “FI” fuse

2. Main relay 5. No.2 injector 8. “IG COIL” fuse 11. “IG ACC” fuse

3. ECM 6. No.3 injector 9. Ignition switch

Page 249 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-199

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Fuel injector check for operating sound

1) Using sound scope, check each injector for operating

sound at engine cranking.

Do all 4 injector ma ke operating sound? Fuel injectors circuit is

in good condition.

Go to Step 2.

2 Fuel injector resistance check

1) Disconnect connectors from fuel injectors with ignition

switch turned OFF.

2) Check for proper connection to fuel injector at each terminals.

3) If OK, check all 4 fuel inject ors for resistance referring to

“Fuel Injector On-Vehicle Inspection in Section 1G”.

Are all injectors in good condition? Go to Step 3.

Faulty fuel injector.

3 Fuel injector insulation resistance check

1) Check that there is insulation between each fuel injector

terminal and engine ground.

Is there insulation? Go to Step 4.

Faulty fuel injector.

4 Fuel injector power supply check

1) Measure voltage between each “BLK/RED” wire terminal

of fuel injector connector and engine ground with ignition

switch turned ON.

Is voltage 10 – 14 V? Go to Step 5.

“BLK/RED” wire is open

or shorted to ground

circuit.

If it is in good condition,

go to “ECM Power and

Ground Circuit Check”.

5 Wire circuit check

1) Turn OFF ignition switch.

2) Disconnect connectors from ECM.

3) Measure resistance between each “BLU/YEL”, “BLU/

WHT”, “BLU/RED”, “BLU/ORN” wire terminal of fuel

injector connector and vehicle body ground.

Is resistance infinity? Go to Step 6.

“BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

shorted to ground.

6 Wire circuit check

1) Measure voltage between each “BLU/YEL”, “BLU/WHT”,

“BLU/RED”, “BLU/ORN” wire terminal of fuel injector

connector and vehicle body ground with ignition switch

turned ON.

Is voltage 0 V? Go to Step 7.

“BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

shorted to power supply

circuit.

7 Fuel injector drive signal check

1) Connect connectors to each fuel injector and ECM with

ignition switch turned OFF.

2) Turn ON ignition switch.

3) Measure voltage between each “C37-1”, “C37-2”, “C37- 16”, “C37-17” terminal of ECM connector and vehicle

body ground.

Is voltage 10 – 14 V? Check fuel injector

referring to “Fuel

Injector Inspection in

Section 1G”.

If check result is

satisfactory, substitute a

known-good ECM and

recheck.

“BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

open circuit.

Page 250 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-200 Engine General Information and Diagnosis:

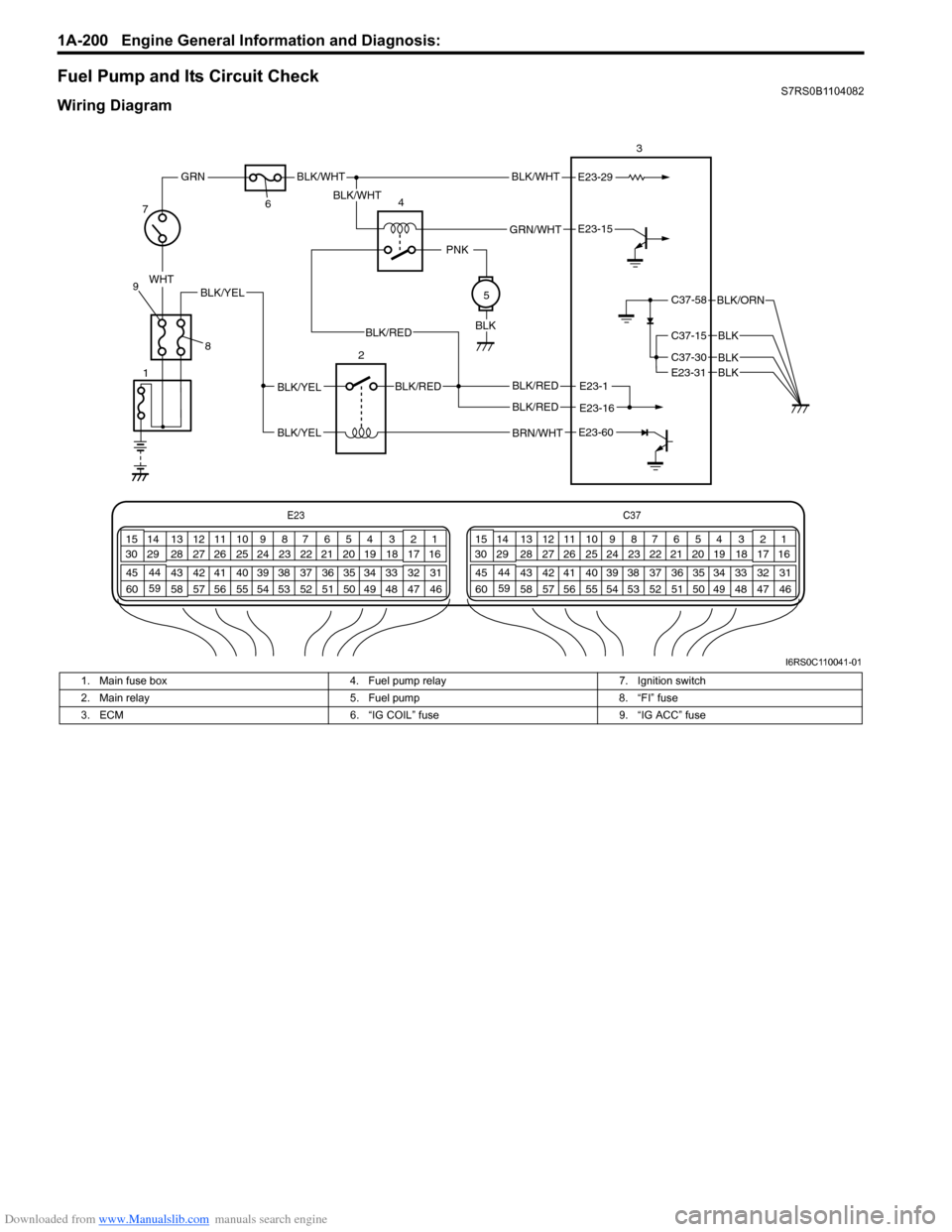

Fuel Pump and Its Circuit CheckS7RS0B1104082

Wiring Diagram

E23-1

E23-60

E23-15

BRN/WHT

BLK/REDBLK/YEL

BLK/YEL

BLK/RED

E23-29BLK/WHT

GRN/WHT

BLK/WHT

BLK/WHT

PNK

BLK

WHT

GRN

C37-58

C37-15

C37-30

BLK/ORN

BLK

BLKE23-31BLK

78

9 6

4 3

2 5

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 48 32 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/YEL

1

E23-16BLK/RED

BLK/RED

I6RS0C110041-01

1. Main fuse box 4. Fuel pump relay 7. Ignition switch

2. Main relay 5. Fuel pump 8. “FI” fuse

3. ECM 6. “IG COIL” fuse 9. “IG ACC” fuse