R p m SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 261 of 1496

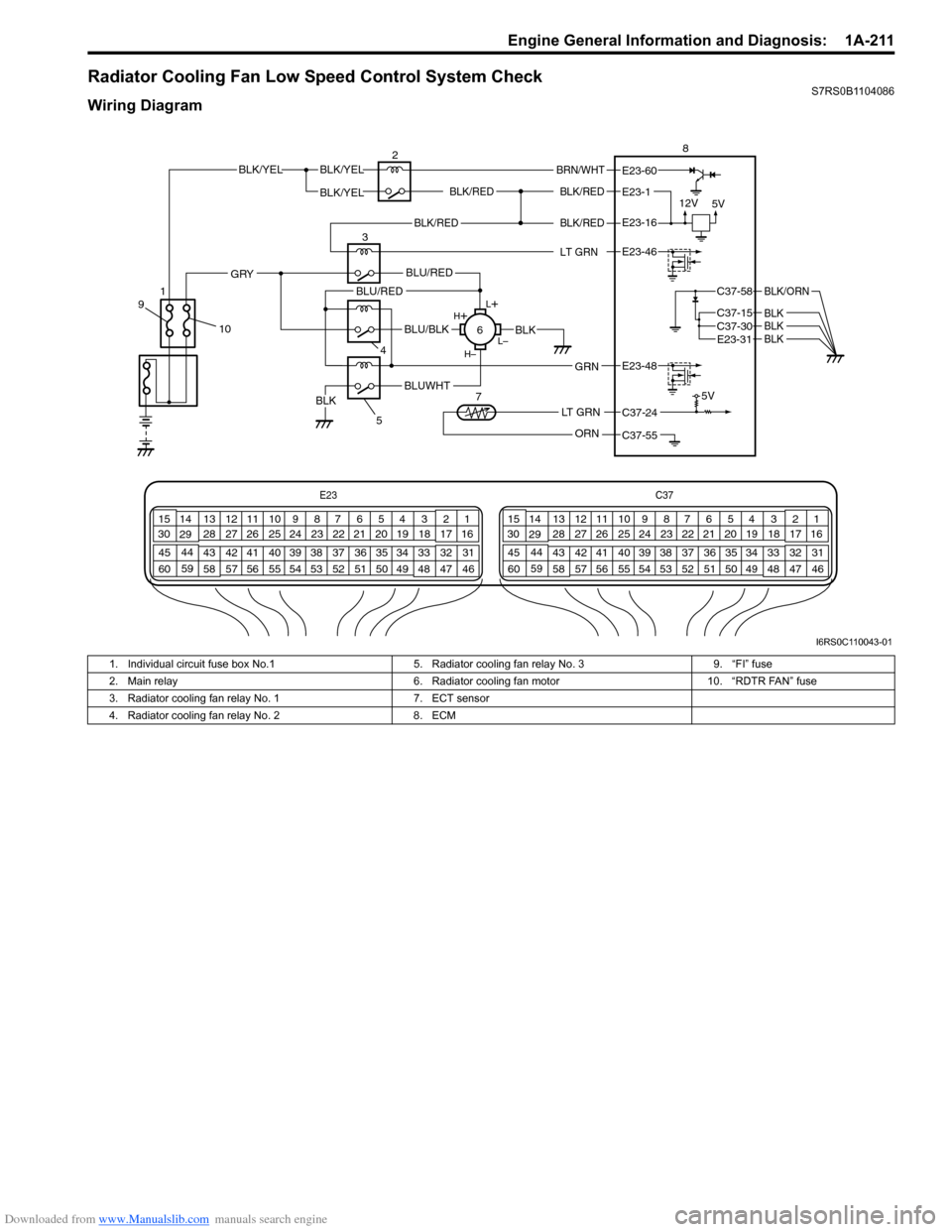

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-211

Radiator Cooling Fan Low Speed Control System CheckS7RS0B1104086

Wiring Diagram

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V

5V5V

2

8

E23-1

E23-60

C37-58

C37-15 C37-30

BLK/ORN

BLKBLKE23-31 BLK

BLK/RED

LT GRN

BLK/REDE23-16

E23-46

L+

L–

H–

H

+

BLU/RED

BLK

BLUWHTBLK

BLU/BLK

BLU/RED

4

GRN

GRY

E23-48

LT GRN

ORN

C37-24

C37-55

35

6

7

10

9

1

I6RS0C110043-01

1. Individual circuit fuse box No.1

5. Radiator cooling fan relay No. 3 9. “FI” fuse

2. Main relay 6. Radiator cooling fan motor10. “RDTR FAN” fuse

3. Radiator cooling fan relay No. 1 7. ECT sensor

4. Radiator cooling fan relay No. 2 8. ECM

Page 262 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-212 Engine General Information and Diagnosis:

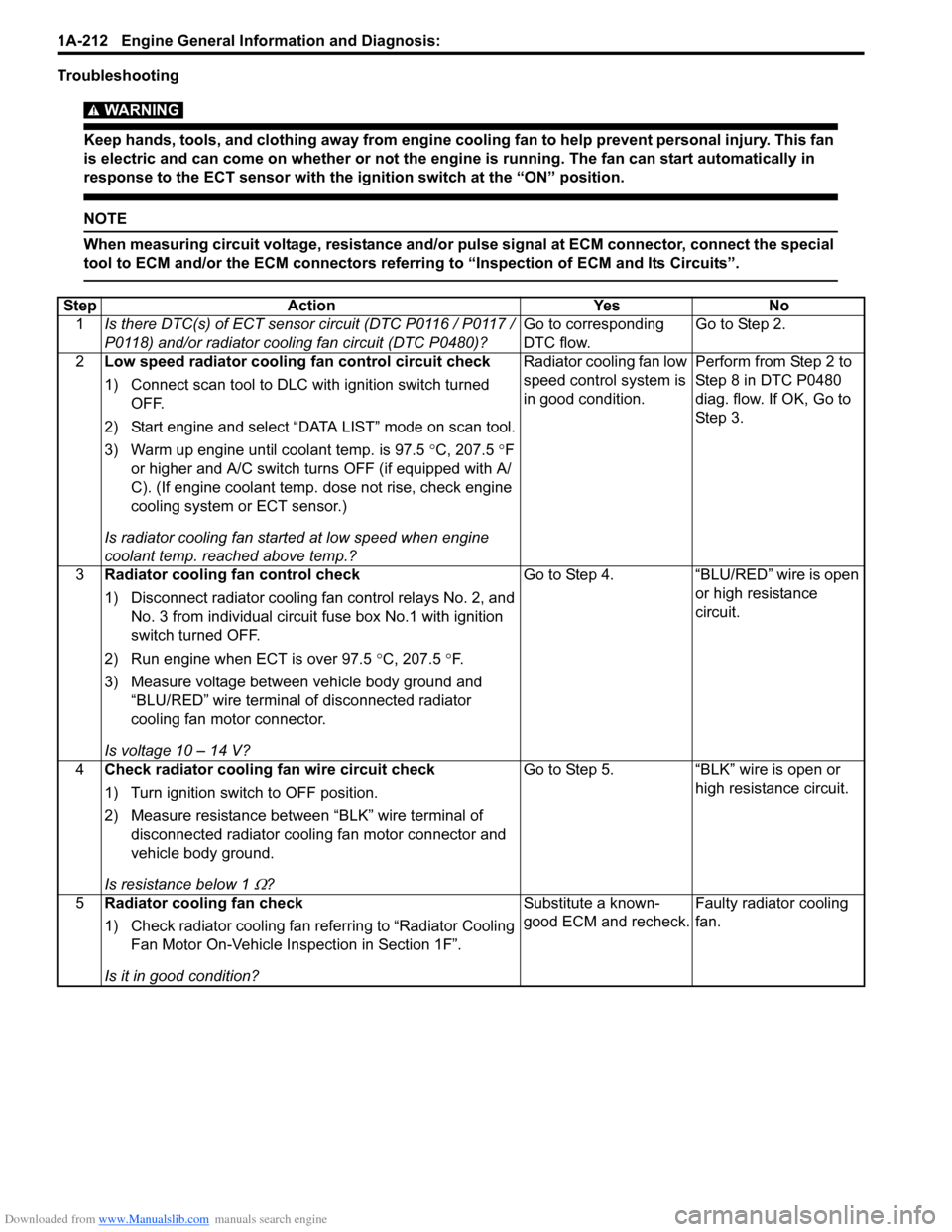

Troubleshooting

WARNING!

Keep hands, tools, and clothing away from engine cooling fan to help prevent personal injury. This fan

is electric and can come on whether or not the engi ne is running. The fan can start automatically in

response to the ECT sensor with the ig nition switch at the “ON” position.

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Is there DTC(s) of ECT sensor circuit (DTC P0116 / P0117 /

P0118) and/or radiator cooling fan circuit (DTC P0480)? Go to corresponding

DTC flow.Go to Step 2.

2 Low speed radiator cooling fan control circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Warm up engine until coolant temp. is 97.5 °C, 207.5 °F

or higher and A/C switch turns OFF (if equipped with A/

C). (If engine coolant temp. dose not rise, check engine

cooling system or ECT sensor.)

Is radiator cooling fan started at low speed when engine

coolant temp. reached above temp.? Radiator cooling fan low

speed control system is

in good condition.

Perform from Step 2 to

Step 8 in DTC P0480

diag. flow. If OK, Go to

Ste p 3.

3 Radiator cooling fan control check

1) Disconnect radiator cooling fan control relays No. 2, and

No. 3 from individual circuit fuse box No.1 with ignition

switch turned OFF.

2) Run engine when ECT is over 97.5 °C, 207.5 °F.

3) Measure voltage between vehicle body ground and “BLU/RED” wire terminal of disconnected radiator

cooling fan motor connector.

Is voltage 10 – 14 V? Go to Step 4.

“BLU/RED” wire is open

or high resistance

circuit.

4 Check radiator cooling fan wire circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “BLK” wire terminal of

disconnected radiator coolin g fan motor connector and

vehicle body ground.

Is resistance below 1

Ω? Go to Step 5. “BLK” wire is open or

high resistance circuit.

5 Radiator cooling fan check

1) Check radiator cooling fan referring to “Radiator Cooling

Fan Motor On-Vehicle Inspection in Section 1F”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Faulty radiator cooling

fan.

Page 263 of 1496

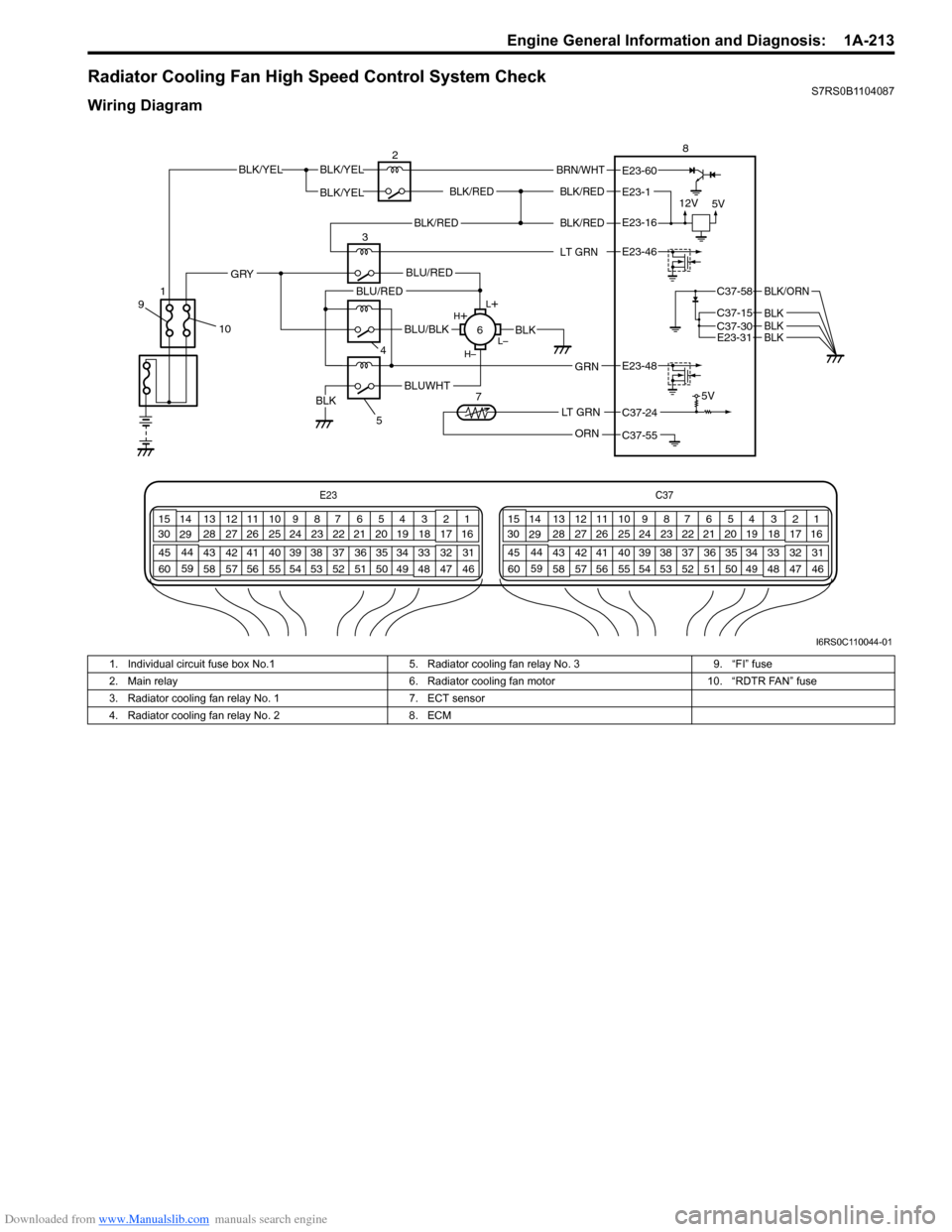

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-213

Radiator Cooling Fan High Speed Control System CheckS7RS0B1104087

Wiring Diagram

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V

5V5V

2

8

E23-1

E23-60

C37-58

C37-15 C37-30

BLK/ORN

BLKBLKE23-31 BLK

BLK/RED

LT GRN

BLK/REDE23-16

E23-46

L+

L–

H–

H

+

BLU/RED

BLK

BLUWHTBLK

BLU/BLK

BLU/RED

4

GRN

GRY

E23-48

LT GRN

ORN

C37-24

C37-55

35

6

7

10

9

1

I6RS0C110044-01

1. Individual circuit fuse box No.1

5. Radiator cooling fan relay No. 3 9. “FI” fuse

2. Main relay 6. Radiator cooling fan motor10. “RDTR FAN” fuse

3. Radiator cooling fan relay No. 1 7. ECT sensor

4. Radiator cooling fan relay No. 2 8. ECM

Page 264 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-214 Engine General Information and Diagnosis:

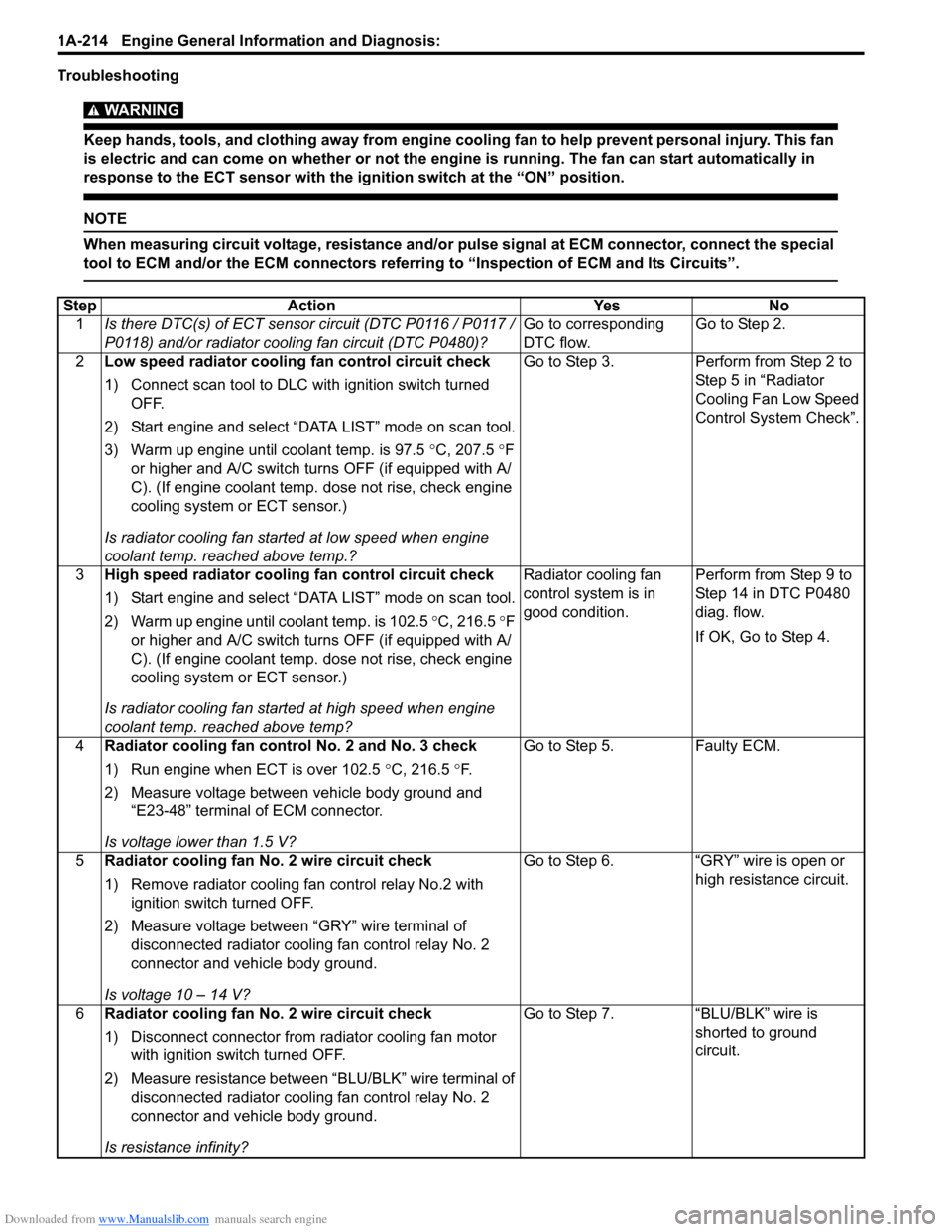

Troubleshooting

WARNING!

Keep hands, tools, and clothing away from engine cooling fan to help prevent personal injury. This fan

is electric and can come on whether or not the engi ne is running. The fan can start automatically in

response to the ECT sensor with the ig nition switch at the “ON” position.

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Is there DTC(s) of ECT sensor circuit (DTC P0116 / P0117 /

P0118) and/or radiator cooling fan circuit (DTC P0480)? Go to corresponding

DTC flow.Go to Step 2.

2 Low speed radiator cooling fan control circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Warm up engine until coolant temp. is 97.5 °C, 207.5 °F

or higher and A/C switch turns OFF (if equipped with A/

C). (If engine coolant temp. dose not rise, check engine

cooling system or ECT sensor.)

Is radiator cooling fan started at low speed when engine

coolant temp. reached above temp.? Go to Step 3.

Perform from Step 2 to

Step 5 in “Radiator

Cooling Fan Low Speed

Control System Check”.

3 High speed radiator cooling fan control circuit check

1) Start engine and select “DATA LIST” mode on scan tool.

2) Warm up engine until coolant temp. is 102.5 °C, 216.5 °F

or higher and A/C switch turns OFF (if equipped with A/

C). (If engine coolant temp. dose not rise, check engine

cooling system or ECT sensor.)

Is radiator cooling fan started at high speed when engine

coolant temp. reached above temp? Radiator cooling fan

control system is in

good condition.

Perform from Step 9 to

Step 14 in DTC P0480

diag. flow.

If OK, Go to Step 4.

4 Radiator cooling fan control No. 2 and No. 3 check

1) Run engine when ECT is over 102.5 °C, 216.5 °F.

2) Measure voltage between vehicle body ground and “E23-48” terminal of ECM connector.

Is voltage lower than 1.5 V? Go to Step 5.

Faulty ECM.

5 Radiator cooling fan No. 2 wire circuit check

1) Remove radiator cooling fan control relay No.2 with

ignition switch turned OFF.

2) Measure voltage between “GRY” wire terminal of disconnected radiator cooling fan control relay No. 2

connector and vehicle body ground.

Is voltage 10 – 14 V? Go to Step 6.

“GRY” wire is open or

high resistance circuit.

6 Radiator cooling fan No. 2 wire circuit check

1) Disconnect connector from radiator cooling fan motor

with ignition swit ch turned OFF.

2) Measure resistance between “BLU/BLK” wire terminal of disconnected radiator cooling fan control relay No. 2

connector and vehicle body ground.

Is resistance infinity? Go to Step 7.

“BLU/BLK” wire is

shorted to ground

circuit.

Page 265 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-215

7Radiator cooling fan No. 2 wire circuit check

1) Turn ON ignition switch.

2) Measure voltage between “BLU/BLK” wire terminal of

disconnected radiator cooling fan control relay No. 2

connector and vehicle body ground.

Is voltage 0 V? Go to Step 8. “BLU/BLK” wire is

shorted to power supply

circuit.

8 Radiator cooling fan control No. 2 check

1) Connect radiator cooling fan control relay No. 2 to

individual circuit fuse box No.1 with ignition switch

turned OFF.

2) Run engine when ECT is over 102.5 °C, 216.5 °F.

3) Measure voltage between vehicle body ground and “BLU/BLK” wire terminal of disconnected radiator

cooling fan motor connector.

Is voltage 10 – 14 V? Go to Step 10. Go to Step 9.

9 Radiator cooling fan control relay No.2 check

1) Remove radiator cooling fan control relay No.2 with

ignition switch turned OFF.

2) Check radiator cooling fan control relay No.2 referring to “Radiator Cooling Fan Relay Inspection in Section 1F”.

Is it in good condition? “BLU/BLK” wire is open

or high resistance

circuit.

Faulty radiator cooling

fan control relay No.2.

10 Radiator cooling fan No. 3 wire circuit check

1) Remove radiator cooling fan control relay No.3 with

ignition switch turned OFF.

2) Measure resistance between vehicle body ground and “BLK” wire terminal of disconnected radiator cooling fan

control relay No. 3 connector in individual circuit fuse

box No.1.

Is resistance below 1

Ω? Go to Step 11. “BLK” wire is open or

high resistance circuit.

11 Radiator cooling fan control No. 3 check

1) Connect radiator cooling fan control relay No. 3 to

individual circuit fuse box No.1 with ignition switch

turned OFF.

2) Run engine when ECT is over 102.5 °C, 216.5 °F.

3) Measure resistance between vehicle body ground and “BLU/WHT” wire terminal of disconnected radiator

cooling fan motor connector.

Is resistance below 2

Ω? Go to Step 13. Go to Step 12.

12 Radiator cooling fan control relay No. 3 check

1) Remove radiator cooling fan control relay No.3 with

ignition switch turned OFF.

2) Check radiator cooling fan control relay No.3 referring to “Radiator Cooling Fan Relay Inspection in Section 1F”.

Is it in good condition? “BLU/WHT” wire is open

or high resistance

circuit.

Faulty radiator cooling

fan control relay No.3.

13 Radiator cooling fan check

1) Check radiator cooling fan referring to “Radiator Cooling

Fan Motor On-Vehicle Inspection in Section 1F”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Faulty radiator cooling

fan.

Step

Action YesNo

Page 266 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-216 Engine General Information and Diagnosis:

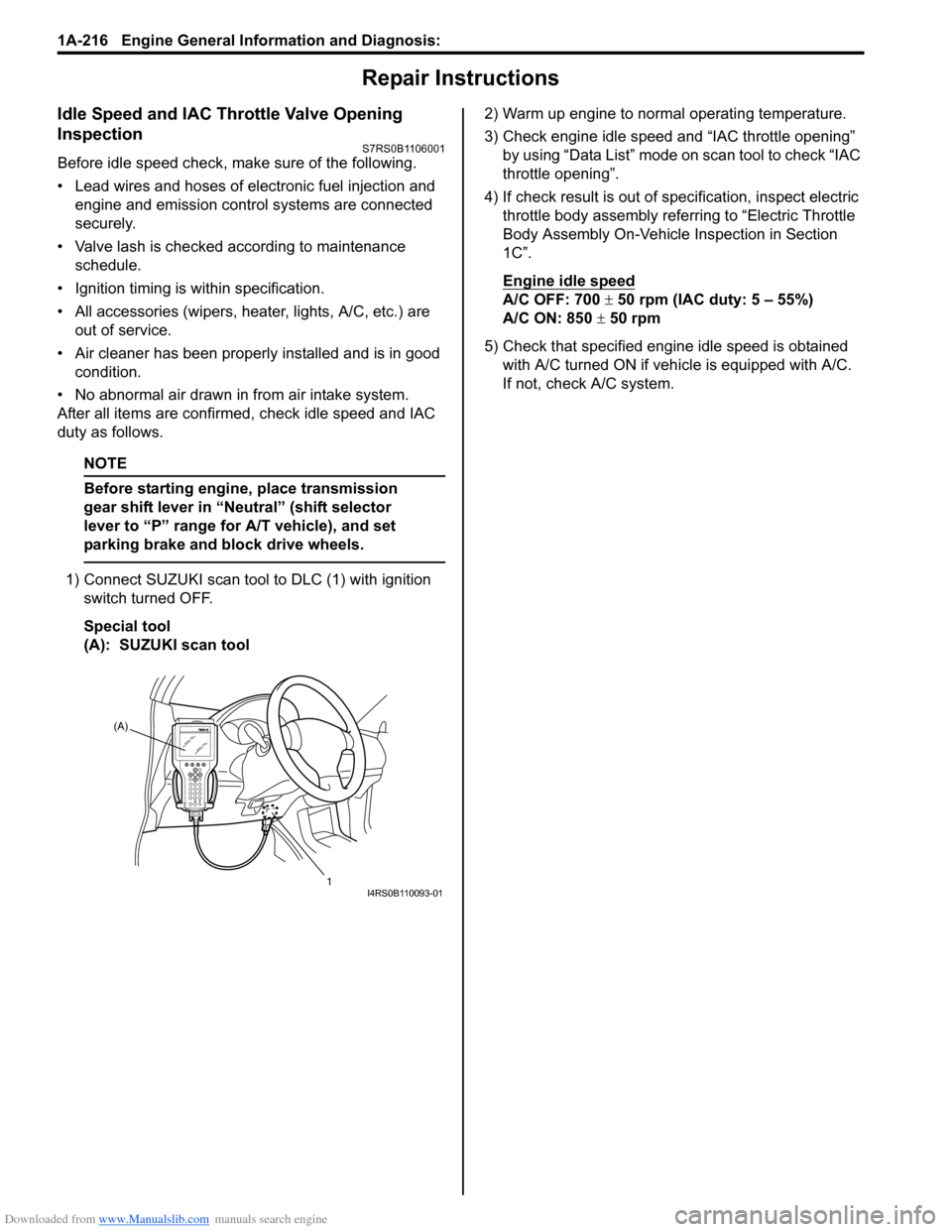

Repair Instructions

Idle Speed and IAC Throttle Valve Opening

Inspection

S7RS0B1106001

Before idle speed check, make sure of the following.

• Lead wires and hoses of electronic fuel injection and engine and emission control systems are connected

securely.

• Valve lash is checked according to maintenance schedule.

• Ignition timing is within specification.

• All accessories (wipers, heater, lights, A/C, etc.) are out of service.

• Air cleaner has been properly installed and is in good condition.

• No abnormal air drawn in from air intake system.

After all items are confirmed, check idle speed and IAC

duty as follows.

NOTE

Before starting engine, place transmission

gear shift lever in “Neutral” (shift selector

lever to “P” range for A/T vehicle), and set

parking brake and block drive wheels.

1) Connect SUZUKI scan tool to DLC (1) with ignition

switch turned OFF.

Special tool

(A): SUZUKI scan tool 2) Warm up engine to normal operating temperature.

3) Check engine idle speed and “IAC throttle opening”

by using “Data List” mode on scan tool to check “IAC

throttle opening”.

4) If check result is out of sp ecification, inspect electric

throttle body assembly referring to “Electric Throttle

Body Assembly On-Vehicle Inspection in Section

1C”.

Engine idle speed

A/C OFF: 700 ± 50 rpm (IAC duty: 5 – 55%)

A/C ON: 850 ± 50 rpm

5) Check that specified engine idle speed is obtained with A/C turned ON if vehi cle is equipped with A/C.

If not, check A/C system.

(A)

1

I4RS0B110093-01

Page 267 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-217

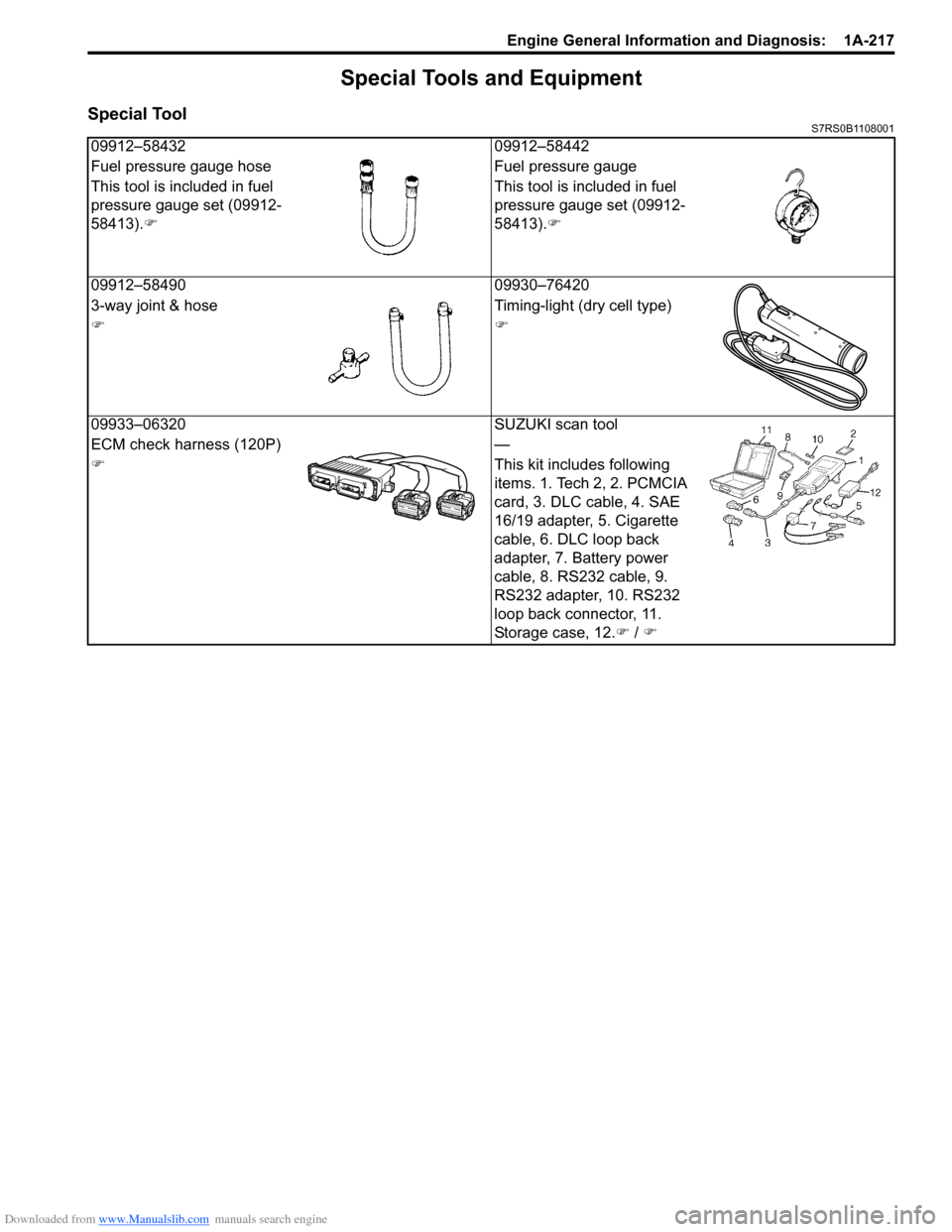

Special Tools and Equipment

Special ToolS7RS0B1108001

09912–5843209912–58442

Fuel pressure gauge hose Fuel pressure gauge

This tool is included in fuel

pressure gauge set (09912-

58413). �) This tool is included in fuel

pressure gauge set (09912-

58413).

�)

09912–58490 09930–76420

3-way joint & hose Timing-light (dry cell type)

�)�)

09933–06320 SUZUKI scan tool

ECM check harness (120P) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12.�) / �)

Page 268 of 1496

Downloaded from www.Manualslib.com manuals search engine 1B-1 Aux. Emission Control Devices:

Engine

Aux. Emission Control Devices

Diagnostic Information and Procedures

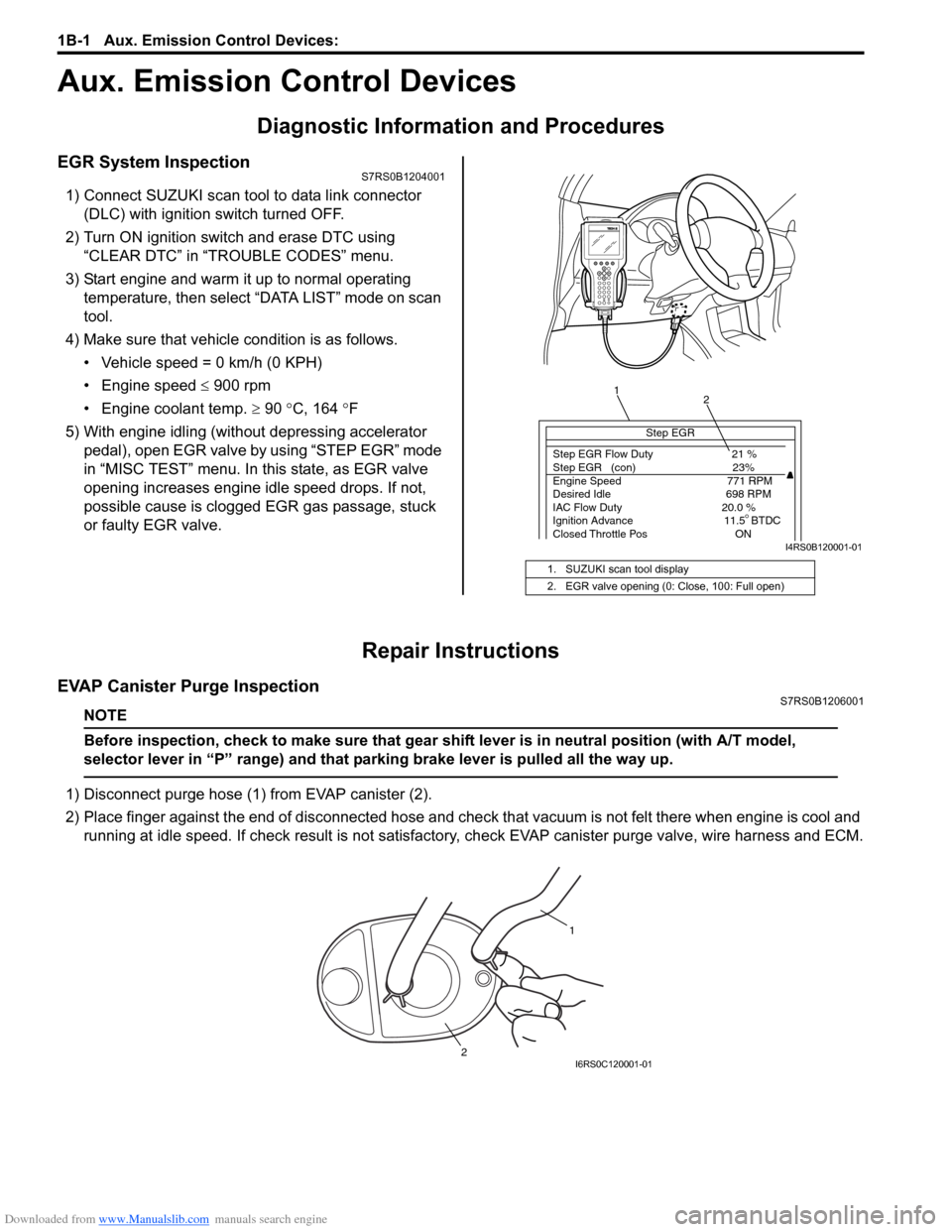

EGR System InspectionS7RS0B1204001

1) Connect SUZUKI scan tool to data link connector (DLC) with ignition switch turned OFF.

2) Turn ON ignition switch and erase DTC using “CLEAR DTC” in “TROUBLE CODES” menu.

3) Start engine and warm it up to normal operating temperature, then select “DATA LIST” mode on scan

tool.

4) Make sure that vehicle condition is as follows.

• Vehicle speed = 0 km/h (0 KPH)

• Engine speed ≤ 900 rpm

• Engine coolant temp. ≥ 90 °C, 164 °F

5) With engine idling (without depressing accelerator pedal), open EGR valve by using “STEP EGR” mode

in “MISC TEST” menu. In this state, as EGR valve

opening increases engine idle speed drops. If not,

possible cause is clogged EGR gas passage, stuck

or faulty EGR valve.

Repair Instructions

EVAP Canister Purge InspectionS7RS0B1206001

NOTE

Before inspection, check to make sure that gear shift lever is in neutral position (with A/T model,

selector lever in “P” range) and that parking brake lever is pulled all the way up.

1) Disconnect purge hose (1) from EVAP canister (2).

2) Place finger against the end of disconne cted hose and check that vacuum is not felt there when engine is cool and

running at idle speed. If check result is not satisfacto ry, check EVAP canister purge valve, wire harness and ECM.

1. SUZUKI scan tool display

2. EGR valve opening (0: Close, 100: Full open)

Step EGR

Step EGR Flow Duty 21 %

Step EGR (con) 23%

Engine Speed 771 RPM

Desired Idle 698 RPM

IAC Flow Duty 20.0 %

Ignition Advance 11.5 BTDC

Closed Throttle Pos ON

1 2

I4RS0B120001-01

1

2

I6RS0C120001-01

Page 269 of 1496

Downloaded from www.Manualslib.com manuals search engine Aux. Emission Control Devices: 1B-2

EVAP Canister Purge Valve and Its Circuit

Inspection

S7RS0B1206002

WARNING!

Do not apply vacuum by mouth; otherwise

harmful fuel vapor can be breathed in.

CAUTION!

Do not apply vacuum more than –86 kPa (–

12.47 psi); otherwise EVAP canister purge

valve could be damaged.

1) Prepare to operate EVAP canister purge valve as follows.

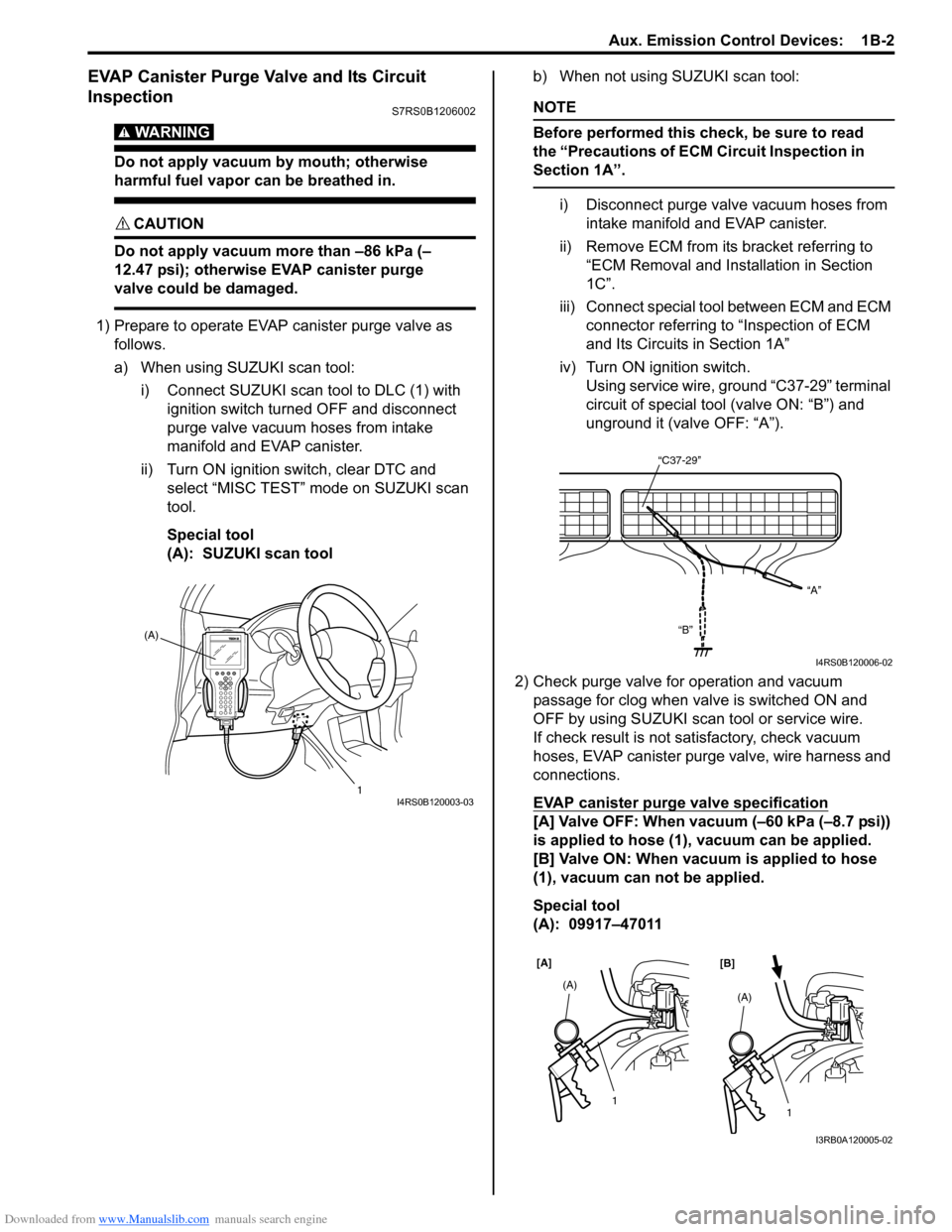

a) When using SUZUKI scan tool:

i) Connect SUZUKI scan tool to DLC (1) with ignition switch turned OFF and disconnect

purge valve vacuum hoses from intake

manifold and EVAP canister.

ii) Turn ON ignition switch, clear DTC and select “MISC TEST” mode on SUZUKI scan

tool.

Special tool

(A): SUZUKI scan tool b) When not using SUZUKI scan tool:

NOTE

Before performed this check, be sure to read

the “Precautions of ECM Circuit Inspection in

Section 1A”.

i) Disconnect purge valve vacuum hoses from

intake manifold and EVAP canister.

ii) Remove ECM from it s bracket referring to

“ECM Removal and Inst allation in Section

1C”.

iii) Connect special tool between ECM and ECM connector referring to “Inspection of ECM

and Its Circuits in Section 1A”

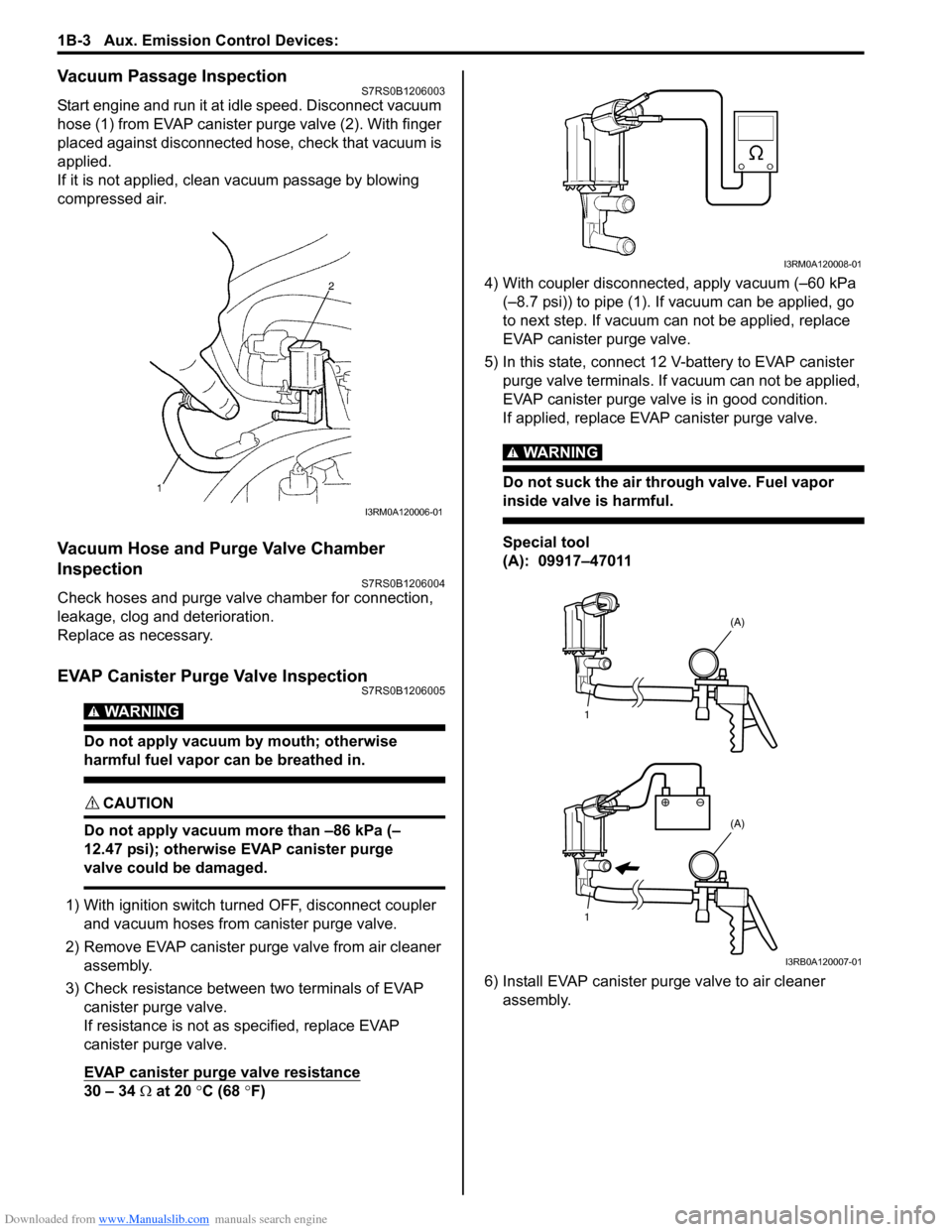

iv) Turn ON ignition switch. Using service wire, ground “C37-29” terminal

circuit of special tool (valve ON: “B”) and

unground it (valve OFF: “A”).

2) Check purge valve for operation and vacuum passage for clog when valve is switched ON and

OFF by using SUZUKI scan tool or service wire.

If check result is not satisfactory, check vacuum

hoses, EVAP canister purge valve, wire harness and

connections.

EVAP canister purge valve specification

[A] Valve OFF: When vacuum (–60 kPa (–8.7 psi))

is applied to hose (1), vacuum can be applied.

[B] Valve ON: When vacuum is applied to hose

(1), vacuum can not be applied.

Special tool

(A): 09917–47011

(A)

1

I4RS0B120003-03

“C37-29”“A”

“B”

I4RS0B120006-02

[A] [B]

1

(A)1

(A)

I3RB0A120005-02

Page 270 of 1496

Downloaded from www.Manualslib.com manuals search engine 1B-3 Aux. Emission Control Devices:

Vacuum Passage InspectionS7RS0B1206003

Start engine and run it at idle speed. Disconnect vacuum

hose (1) from EVAP canister purge valve (2). With finger

placed against disconnected hose, check that vacuum is

applied.

If it is not applied, clean vacuum passage by blowing

compressed air.

Vacuum Hose and Purge Valve Chamber

Inspection

S7RS0B1206004

Check hoses and purge valv e chamber for connection,

leakage, clog and deterioration.

Replace as necessary.

EVAP Canister Purge Valve InspectionS7RS0B1206005

WARNING!

Do not apply vacuum by mouth; otherwise

harmful fuel vapor can be breathed in.

CAUTION!

Do not apply vacuum more than –86 kPa (–

12.47 psi); otherwise EVAP canister purge

valve could be damaged.

1) With ignition switch turned OFF, disconnect coupler and vacuum hoses from canister purge valve.

2) Remove EVAP canister purge valve from air cleaner assembly.

3) Check resistance between two terminals of EVAP canister purge valve.

If resistance is not as specified, replace EVAP

canister purge valve.

EVAP canister purge valve resistance

30 – 34 Ω at 20 °C (68 °F) 4) With coupler disconnected, apply vacuum (–60 kPa

(–8.7 psi)) to pipe (1). If vacuum can be applied, go

to next step. If vacuum can not be applied, replace

EVAP canister purge valve.

5) In this state, connect 12 V-battery to EVAP canister purge valve terminals. If vacuum can not be applied,

EVAP canister purge valve is in good condition.

If applied, replace EVAP canister purge valve.

WARNING!

Do not suck the air through valve. Fuel vapor

inside valve is harmful.

Special tool

(A): 09917–47011

6) Install EVAP canister purge valve to air cleaner assembly.

I3RM0A120006-01

I3RM0A120008-01

1

1 (A)

(A)

I3RB0A120007-01