AIR CON SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 670 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-26 Automatic Transmission/Transaxle:

TRANSAXLE RANGE

Transaxle range detected by signal fed from

transmission range sensor.

D RANGE SIGNAL

ON: Signal which TCM require ECM to increase idle

speed

OFF: Signal which TCM does not require ECM to

increase idle speed

THROTTLE POSITION (%)

Throttle opening ratio computed by CAN signal from

ECM.

BRAKE SWITCH

Inputted signal from brake light switch on pedal bracket.

ON: Brake pedal depressed

OFF: Brake pedal released

TORQUE REDUCTION SIGNAL

ON: Signal which TCM require ECM to reduce output

torque at shifting gear

OFF: Signal which TCM does not require ECM to reduce

output torque

ENGINE COOLANT TEMPERATURE ( °C, °F)

Engine coolant temperature computed by CAN signal

from ECM. AIR CONDITIONER SIGNAL

ON: Signal which inform that air conditioner compressor

is turned ON.

OFF: Signal which inform that air conditioner

compressor is not turned ON.

ENGINE TORQUE SIGNAL (N

⋅m)

Engine torque computed by duty pulse signal outputted

from ECM.

SLIP RPM (RPM)

This parameter indicates slip ping rotation in the torque

converter (difference between input shaft rotation and

engine rotation)

MIL REQUEST

ON: Signal which TCM requires combination meter to

turn on malfunction indicator lamp.

OFF: Signal which TCM does not require combination

meter to turn on malf unction indicator lamp.

FUEL CUT FLAG

ON: Signal which inform that fuel cut is operating.

OFF: Signal which inform that fuel cut is not operating.

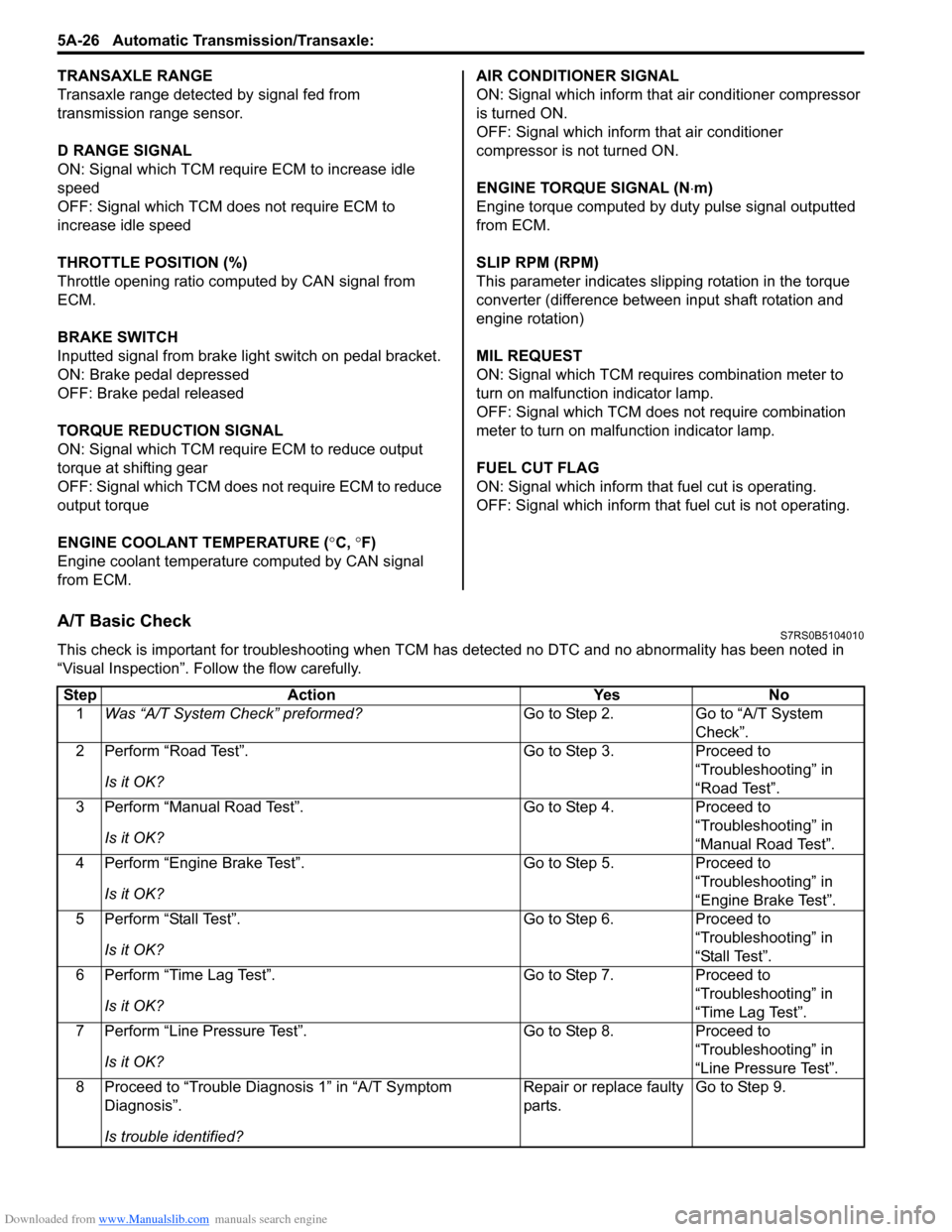

A/T Basic CheckS7RS0B5104010

This check is important for troubleshooting when TCM has detected no DTC and no abnormality has been noted in

“Visual Inspection”. Fo llow the flow carefully.

Step Action YesNo

1 Was “A/T System Check” preformed? Go to Step 2.Go to “A/T System

Check”.

2 Perform “Road Test”.

Is it OK? Go to Step 3.

Proceed to

“Troubleshooting” in

“Road Test”.

3 Perform “Manual Road Test”.

Is it OK? Go to Step 4.

Proceed to

“Troubleshooting” in

“Manual Road Test”.

4 Perform “Engine Brake Test”.

Is it OK? Go to Step 5.

Proceed to

“Troubleshooting” in

“Engine Brake Test”.

5 Perform “Stall Test”.

Is it OK? Go to Step 6.

Proceed to

“Troubleshooting” in

“Stall Test”.

6 Perform “Time Lag Test”.

Is it OK? Go to Step 7.

Proceed to

“Troubleshooting” in

“Time Lag Test”.

7 Perform “Line Pressure Test”.

Is it OK? Go to Step 8.

Proceed to

“Troubleshooting” in

“Line Pressure Test”.

8 Proceed to “Trouble Diag nosis 1” in “A/T Symptom

Diagnosis”.

Is trouble identified? Repair or replace faulty

parts.

Go to Step 9.

Page 671 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-27

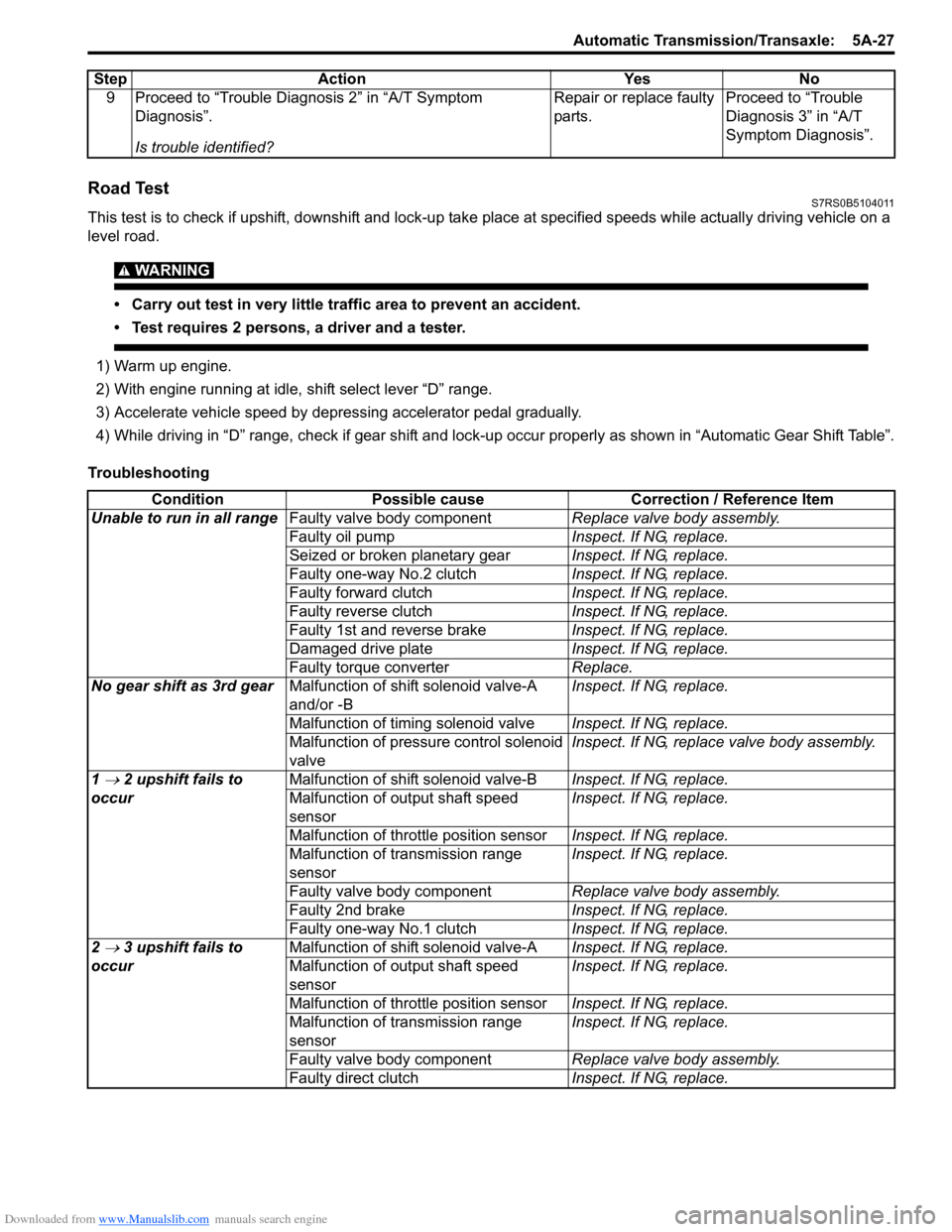

Road TestS7RS0B5104011

This test is to check if upshift, downshift and lock-up take place at specified speeds while actually driving vehicle on a

level road.

WARNING!

• Carry out test in very little traffic area to prevent an accident.

• Test requires 2 persons, a driver and a tester.

1) Warm up engine.

2) With engine running at idle, shift select lever “D” range.

3) Accelerate vehicle speed by depressing accelerator pedal gradually.

4) While driving in “D” range, check if gear shift and lock-up occur properly as shown in “Automatic Gear Shift Table”.

Troubleshooting 9 Proceed to “Trouble Diag

nosis 2” in “A/T Symptom

Diagnosis”.

Is trouble identified? Repair or replace faulty

parts.

Proceed to “Trouble

Diagnosis 3” in “A/T

Symptom Diagnosis”.

Step Action Yes No

Condition

Possible cause Correction / Reference Item

Unable to run in all range Faulty valve body component Replace valve body assembly.

Faulty oil pump Inspect. If NG, replace.

Seized or broken planetary gear Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Faulty forward clutch Inspect. If NG, replace.

Faulty reverse clutch Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Damaged drive plate Inspect. If NG, replace.

Faulty torque converter Replace.

No gear shift as 3rd gear Malfunction of shift solenoid valve-A

and/or -B Inspect. If NG, replace.

Malfunction of timing solenoid valve Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

1

→ 2 upshift fails to

occur Malfunction of shif

t solenoid valve-B Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Faulty valve body component Replace valve body assembly.

Faulty 2nd brake Inspect. If NG, replace.

Faulty one-way No.1 clutch Inspect. If NG, replace.

2

→ 3 upshift fails to

occur Malfunction of shif

t solenoid valve-A Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Faulty valve body component Replace valve body assembly.

Faulty direct clutch Inspect. If NG, replace.

Page 672 of 1496

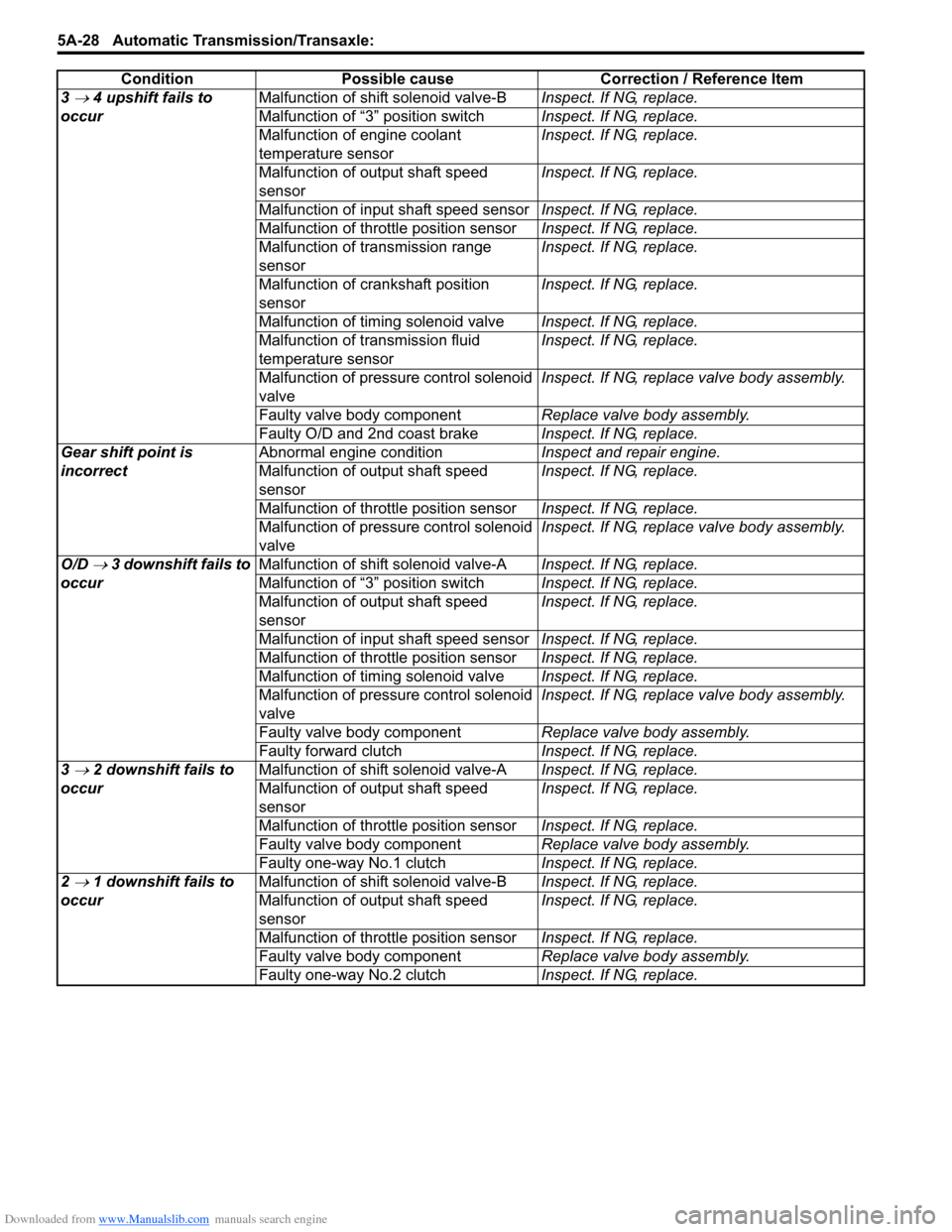

Downloaded from www.Manualslib.com manuals search engine 5A-28 Automatic Transmission/Transaxle:

3 → 4 upshift fails to

occur Malfunction of shift solenoid valve-B

Inspect. If NG, replace.

Malfunction of “3” position switch Inspect. If NG, replace.

Malfunction of engine coolant

temperature sensor Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of input shaft speed sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Malfunction of crankshaft position

sensor Inspect. If NG, replace.

Malfunction of timing solenoid valve Inspect. If NG, replace.

Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Faulty O/D and 2nd coast brake Inspect. If NG, replace.

Gear shift point is

incorrect Abnormal engine condition

Inspect and repair engine.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

O/D

→ 3 downshift fails to

occur Malfunction of shift solenoid valve-A

Inspect. If NG, replace.

Malfunction of “3” position switch Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of input shaft speed sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of timing solenoid valve Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Faulty forward clutch Inspect. If NG, replace.

3

→ 2 downshift fails to

occur Malfunction of shift solenoid valve-A

Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Faulty valve body component Replace valve body assembly.

Faulty one-way No.1 clutch Inspect. If NG, replace.

2

→ 1 downshift fails to

occur Malfunction of shift solenoid valve-B

Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Faulty valve body component Replace valve body assembly.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Condition Possible cause Correction / Reference Item

Page 675 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-31

Troubleshooting

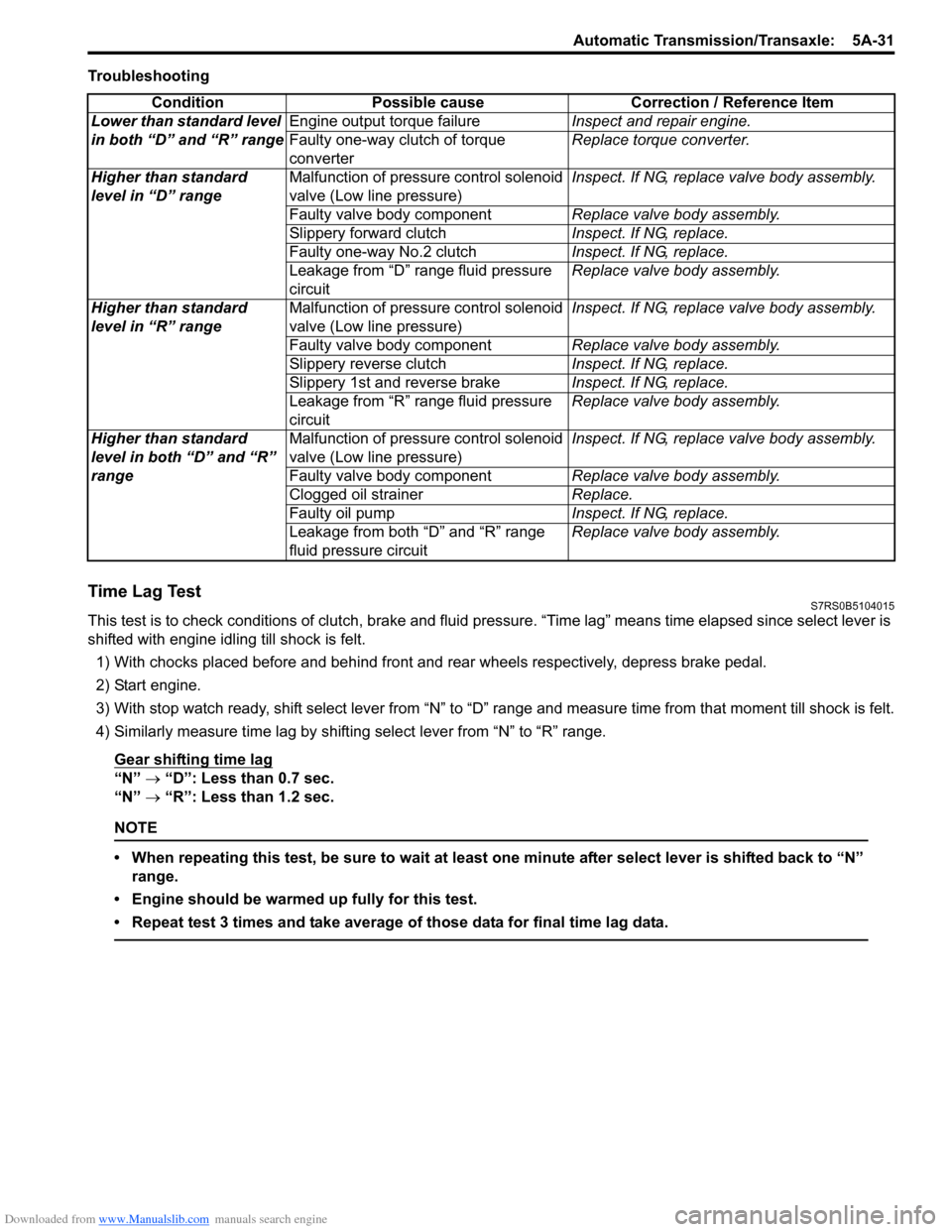

Time Lag TestS7RS0B5104015

This test is to check conditions of clutch, brake and fluid pressure. “Time lag” means time elapsed since select lever is

shifted with engine idling till shock is felt.

1) With chocks placed before and behind front and rear wheels respectively, depress brake pedal.

2) Start engine.

3) With stop watch ready, shift select lever from “N” to “D” range an d measure time from that moment till shock is felt.

4) Similarly measure time lag by shifting select lever from “N” to “R” range.

Gear shifting time lag

“N” → “D”: Less than 0.7 sec.

“N” → “R”: Less than 1.2 sec.

NOTE

• When repeating this test, be sure to wait at least one minute after select lever is shifted back to “N”

range.

• Engine should be warmed up fully for this test.

• Repeat test 3 times and take average of those data for final time lag data.

Condition Possible cause Correction / Reference Item

Lower than standard level

in both “D” and “R” range Engine output torque failure

Inspect and repair engine.

Faulty one-way clutch of torque

converter Replace torque converter.

Higher than standard

level in “D” range Malfunction of pressure control solenoid

valve (Low line pressure) Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Slippery forward clutch Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Leakage from “D” range fluid pressure

circuit Replace valve body assembly.

Higher than standard

level in “R” range Malfunction of pressure control solenoid

valve (Low line pressure) Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Slippery reverse clutch Inspect. If NG, replace.

Slippery 1st and reverse brake Inspect. If NG, replace.

Leakage from “R” range fluid pressure

circuit Replace valve body assembly.

Higher than standard

level in both “D” and “R”

range Malfunction of pressure control solenoid

valve (Low line pressure)

Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Clogged oil strainer Replace.

Faulty oil pump Inspect. If NG, replace.

Leakage from both “D” and “R” range

fluid pressure circuit Replace valve body assembly.

Page 676 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-32 Automatic Transmission/Transaxle:

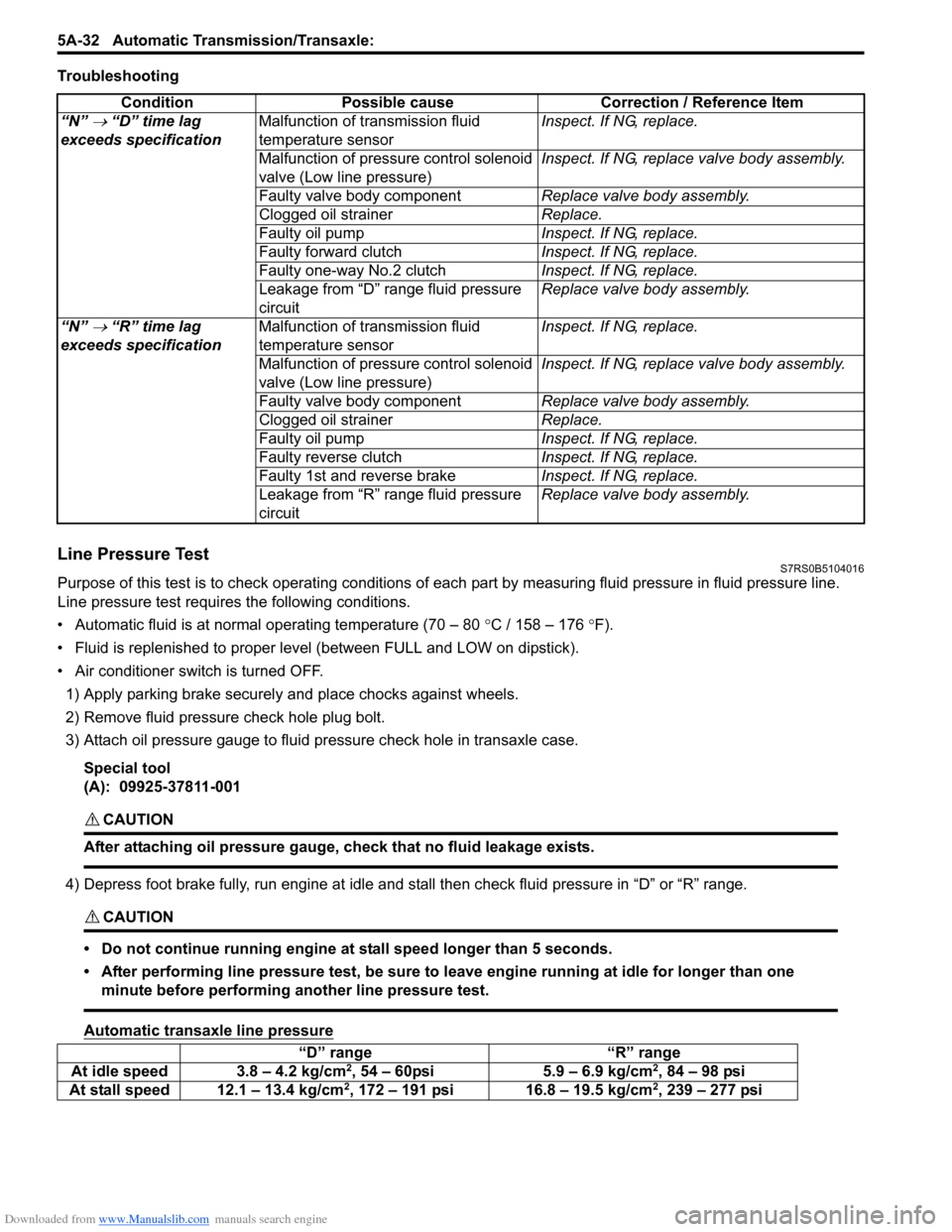

Troubleshooting

Line Pressure TestS7RS0B5104016

Purpose of this test is to check operat ing conditions of each part by measuring fluid pressure in fluid pressure line.

Line pressure test requires the following conditions.

• Automatic fluid is at normal operating temperature (70 – 80 °C / 158 – 176 °F).

• Fluid is replenished to proper level (between FULL and LOW on dipstick).

• Air conditioner switch is turned OFF.

1) Apply parking brake securely and place chocks against wheels.

2) Remove fluid pressure check hole plug bolt.

3) Attach oil pressure gauge to fluid pr essure check hole in transaxle case.

Special tool

(A): 09925-37811-001

CAUTION!

After attaching oil pressure gauge, check that no fluid leakage exists.

4) Depress foot brake fully, run engine at idle and stall then check fluid pressure in “D” or “R” range.

CAUTION!

• Do not continue running engine at stall speed longer than 5 seconds.

• After performing line pressure test, be sure to leave engine running at idle for longer than one minute before performing another line pressure test.

Automatic transaxle line pressure

Condition Possible cause Correction / Reference Item

“N”

→ “D” time lag

exceeds specification Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve (Low line pressure) Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Clogged oil strainer Replace.

Faulty oil pump Inspect. If NG, replace.

Faulty forward clutch Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Leakage from “D” range fluid pressure

circuit Replace valve body assembly.

“N”

→ “R” time lag

exceeds specification Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve (Low line pressure) Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Clogged oil strainer Replace.

Faulty oil pump Inspect. If NG, replace.

Faulty reverse clutch Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Leakage from “R” range fluid pressure

circuit Replace valve body assembly.

“D” range

“R” range

At idle speed 3.8 – 4.2 kg/cm2, 54 – 60psi 5.9 – 6.9 kg/cm2, 84 – 98 psi

At stall speed 12.1 – 13.4 kg/cm2, 172 – 191 psi 16.8 – 19.5 kg/cm2, 239 – 277 psi

Page 677 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-33

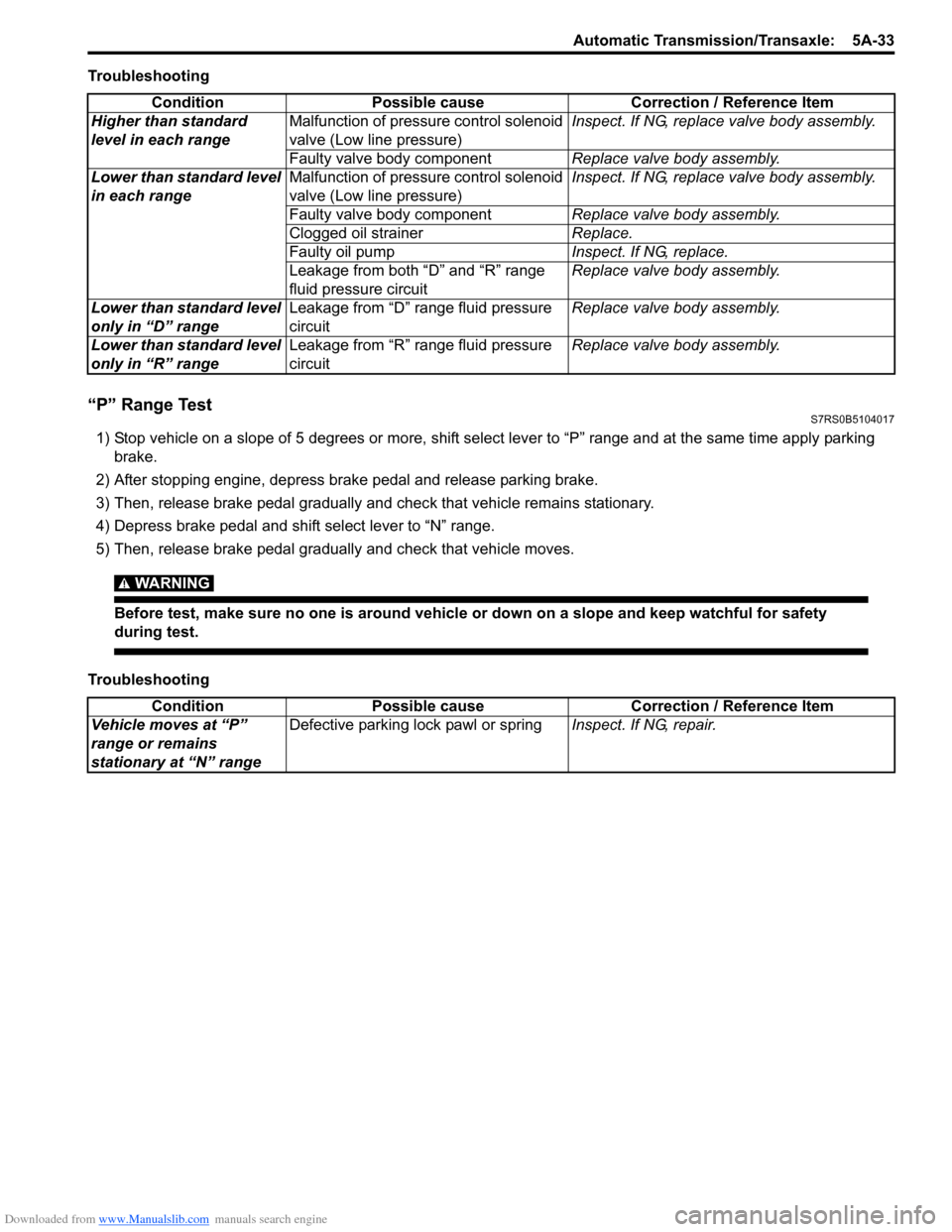

Troubleshooting

“P” Range TestS7RS0B5104017

1) Stop vehicle on a slope of 5 degrees or more, shift select lever to “P” range and at the same time apply parking brake.

2) After stopping engine, depress brake pedal and release parking brake.

3) Then, release brake pedal gradually and check that vehicle remains stationary.

4) Depress brake pedal and shift select lever to “N” range.

5) Then, release brake pedal gradually and check that vehicle moves.

WARNING!

Before test, make sure no one is around vehicle or down on a slope and keep watchful for safety

during test.

Troubleshooting Condition Possible cause Correction / Reference Item

Higher than standard

level in each range Malfunction of pressure control solenoid

valve (Low line pressure) Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Lower than standard level

in each range Malfunction of pressure control solenoid

valve (Low line pressure) Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Clogged oil strainer Replace.

Faulty oil pump Inspect. If NG, replace.

Leakage from both “D” and “R” range

fluid pressure circuit Replace valve body assembly.

Lower than standard level

only in “D” range Leakage from “D” range fluid pressure

circuit Replace valve body assembly.

Lower than standard level

only in “R” range Leakage from “R” range fluid pressure

circuit Replace valve body assembly.

Condition

Possible cause Correction / Reference Item

Vehicle moves at “P”

range or remains

stationary at “N” range Defective parking lock pawl or spring

Inspect. If NG, repair.

Page 678 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-34 Automatic Transmission/Transaxle:

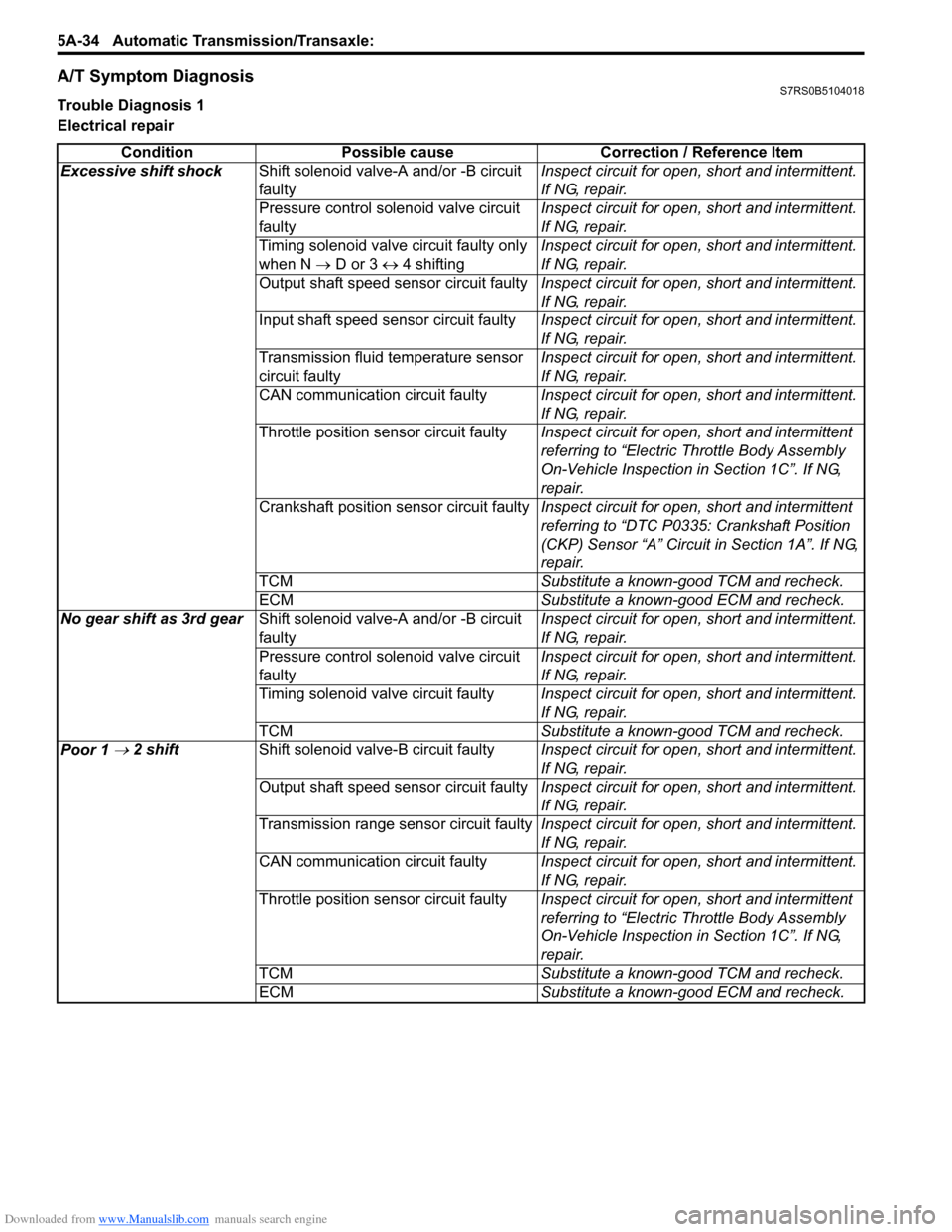

A/T Symptom DiagnosisS7RS0B5104018

Trouble Diagnosis 1

Electrical repair

Condition Possible cause Correction / Reference Item

Excessive shift shock Shift solenoid valve-A and/or -B circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Timing solenoid valve circuit faulty only

when N → D or 3 ↔ 4 shifting Inspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Input shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission fluid temperature sensor

circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

Crankshaft position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “DTC P0335: Crankshaft Position

(CKP) Sensor “A” Circuit in Section 1A”. If NG,

repair.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

No gear shift as 3rd gear Shift solenoid valve-A and/or -B circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Timing solenoid valve circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

TCM Substitute a known-good TCM and recheck.

Poor 1

→ 2 shift Shift solenoid valve-B circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission range sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

Page 679 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-35

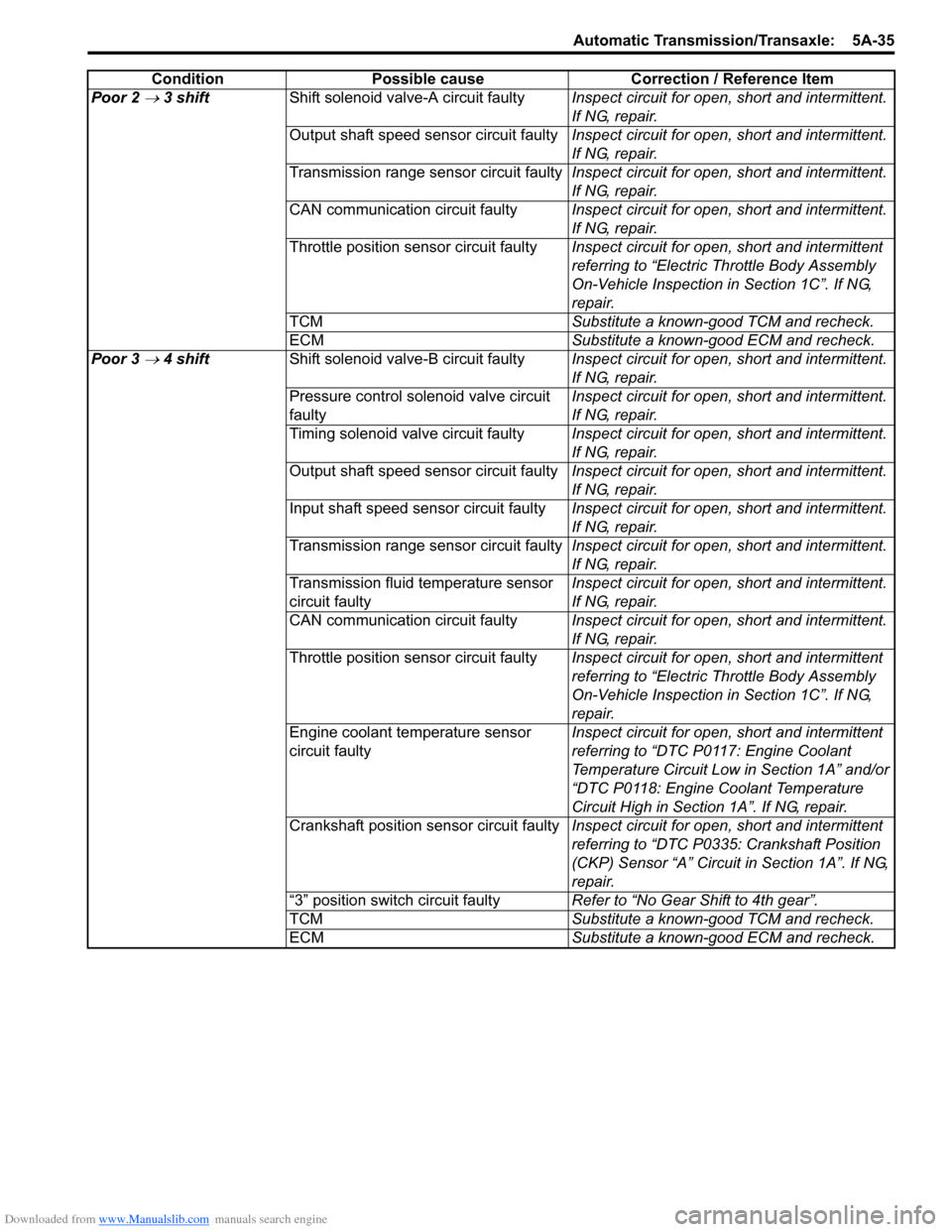

Poor 2 → 3 shiftShift solenoid valve-A circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission range sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

Poor 3

→ 4 shift Shift solenoid valve-B circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Timing solenoid valve circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Input shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission range sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission fluid temperature sensor

circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

Engine coolant temperature sensor

circuit faulty Inspect circuit for open, short and intermittent

referring to “DTC P0117: Engine Coolant

Temperature Circuit Low

in Section 1A” and/or

“DTC P0118: Engine Coolant Temperature

Circuit High in Section 1A”. If NG, repair.

Crankshaft position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “DTC P0335: Crankshaft Position

(CKP) Sensor “A” Circuit in Section 1A”. If NG,

repair.

“3” position switch circuit faulty Refer to “No Gear Shift to 4th gear”.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

Condition Possible cause Correction / Reference Item

Page 680 of 1496

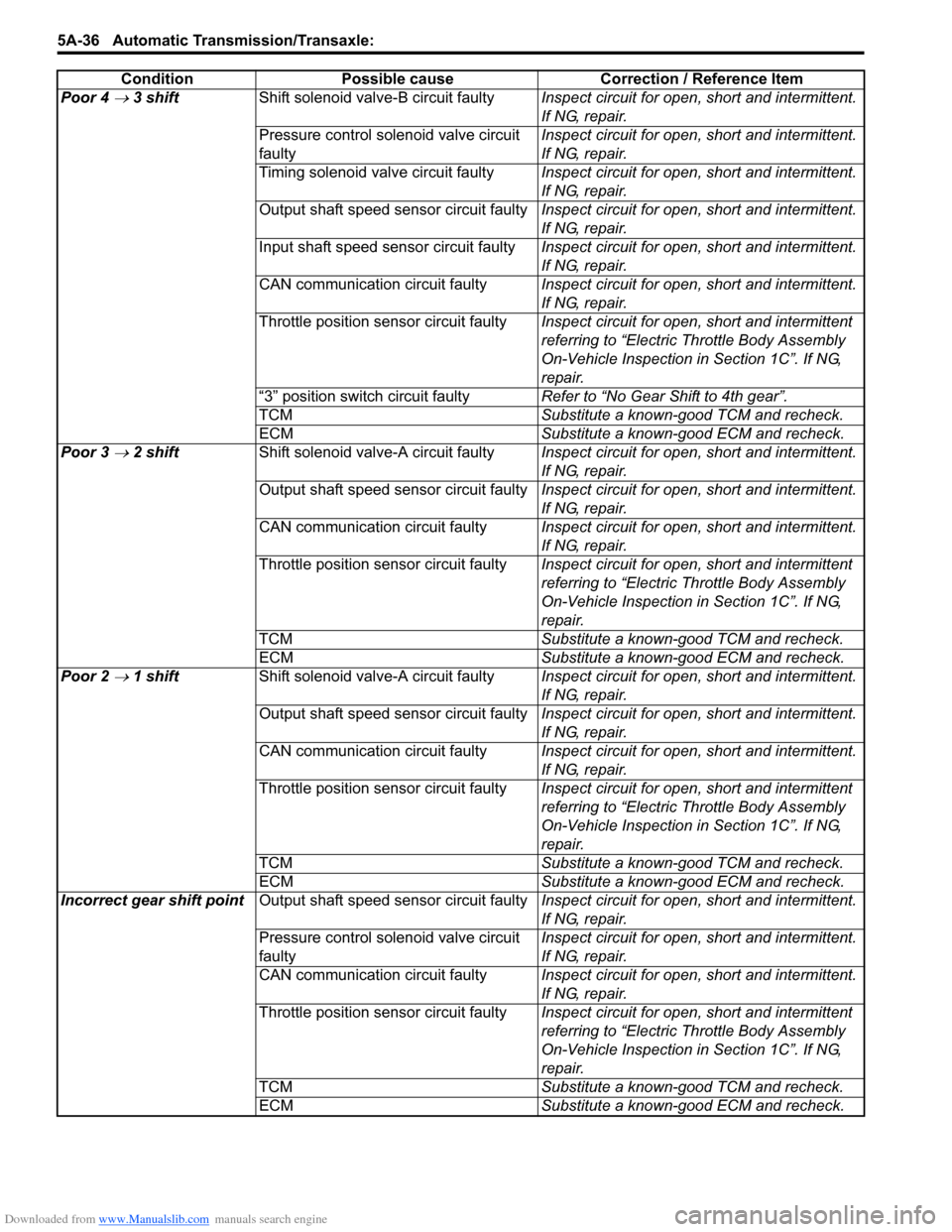

Downloaded from www.Manualslib.com manuals search engine 5A-36 Automatic Transmission/Transaxle:

Poor 4 → 3 shiftShift solenoid valve-B circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Timing solenoid valve circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Input shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

“3” position switch circuit faulty Refer to “No Gear Shift to 4th gear”.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

Poor 3

→ 2 shift Shift solenoid valve-A circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

Poor 2

→ 1 shift Shift solenoid valve-A circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

Incorrect gear shift point Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

Condition Possible cause Correction / Reference Item

Page 681 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-37

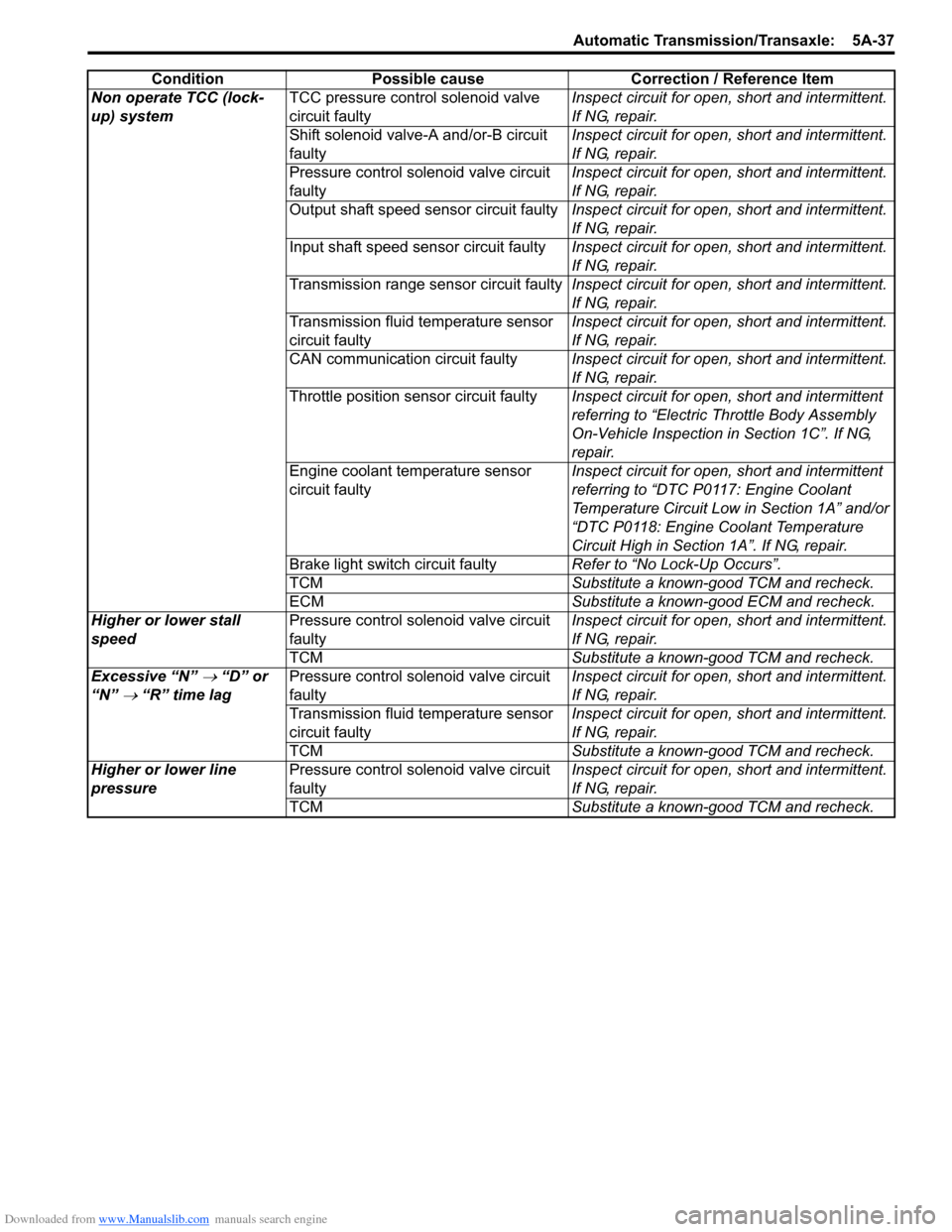

Non operate TCC (lock-

up) systemTCC pressure control solenoid valve

circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Shift solenoid valve-A and/or-B circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Input shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission range sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission fluid temperature sensor

circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faulty Inspect circuit for open, short and intermittent

referring to “Electric Throttle Body Assembly

On-Vehicle Inspection in Section 1C”. If NG,

repair.

Engine coolant temperature sensor

circuit faulty Inspect circuit for open, short and intermittent

referring to “DTC P0117: Engine Coolant

Temperature Circuit Low

in Section 1A” and/or

“DTC P0118: Engine Coolant Temperature

Circuit High in Section 1A”. If NG, repair.

Brake light switch circuit faulty Refer to “No Lock-Up Occurs”.

TCM Substitute a known-good TCM and recheck.

ECM Substitute a known-good ECM and recheck.

Higher or lower stall

speed Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

TCM Substitute a known-good TCM and recheck.

Excessive “N”

→ “D” or

“N”

→ “R” time lag Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission fluid temperature sensor

circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

TCM Substitute a known-good TCM and recheck.

Higher or lower line

pressure Pressure control solenoid valve circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

TCM Substitute a known-good TCM and recheck.

Condition Possible cause Correction / Reference Item