AIR CON SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 603 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-29

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC C1017 / C1023: Yaw Rate / G Sensor Assembly FailureS7RS0B4604025

DTC C1017: Lateral G Sensor Range / Performance

DTC C1023: Yaw Rate Sensor Failure

DTC Detecting Condition and Trouble AreaDTC Detecting Condition Trouble Area

Vehicle behavior and stop lamp switch signal is disagreed

for specified time. • Back up light switch circuit

• Back up light switch

•ECM

• ESP

® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch ON and check DTC for ESP ®.

Is DTC U1073 and/or U1100 detected? Go to applicable diag.

flow.

Go to Step 3.

3 Check stop lamp switch circuit

1) Check stop lamp, stop lamp (brake pedal) switch and

their circuit referring to “Brake Light Symptom Diagnosis

in Section 9B”.

Are they in good condition? Go to Step 4.

Repair or replace.

4 Check ECM circuit for stop lamp switch

1) Disconnect connectors from ECM.

2) Check for proper connection to “E23-20” wire of ECM

connector.

3) If connections are OK, check stop lamp switch circuit for

the following.

• Resistance of “GRN/WHT” wire terminal of stop lamp switch between stop lamp switch connector and ECM

connector is less than 1 Ω (continuity check)

• Resistance between “GRN/WHT” wire terminal of stop lamp switch connector and vehicle body ground is

infinity (ground short check)

• Voltage of between “GRN/WHT” wire terminal of stop switch connector and vehicle body ground is 0 V with

ignition switch tuned ON (power short check)

Are they in good condition? Substitute a known-

good ECM and recheck.

If DTC C1016 is still

detected, substitute a

known-good ESP

®

hydraulic unit / control

module assembly and

recheck. Repair or replace

defective wire.

DTC Detecting Condition

Trouble Area

C1017:

Lateral G sensor signal is out of specified range.

C1023:

• Yaw rate sensor signal is out of range.

• Vehicle behavior and yaw rate signal is disagreed. • Yaw rate / G sensor assembly

• ESP

® control module

Page 607 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-33

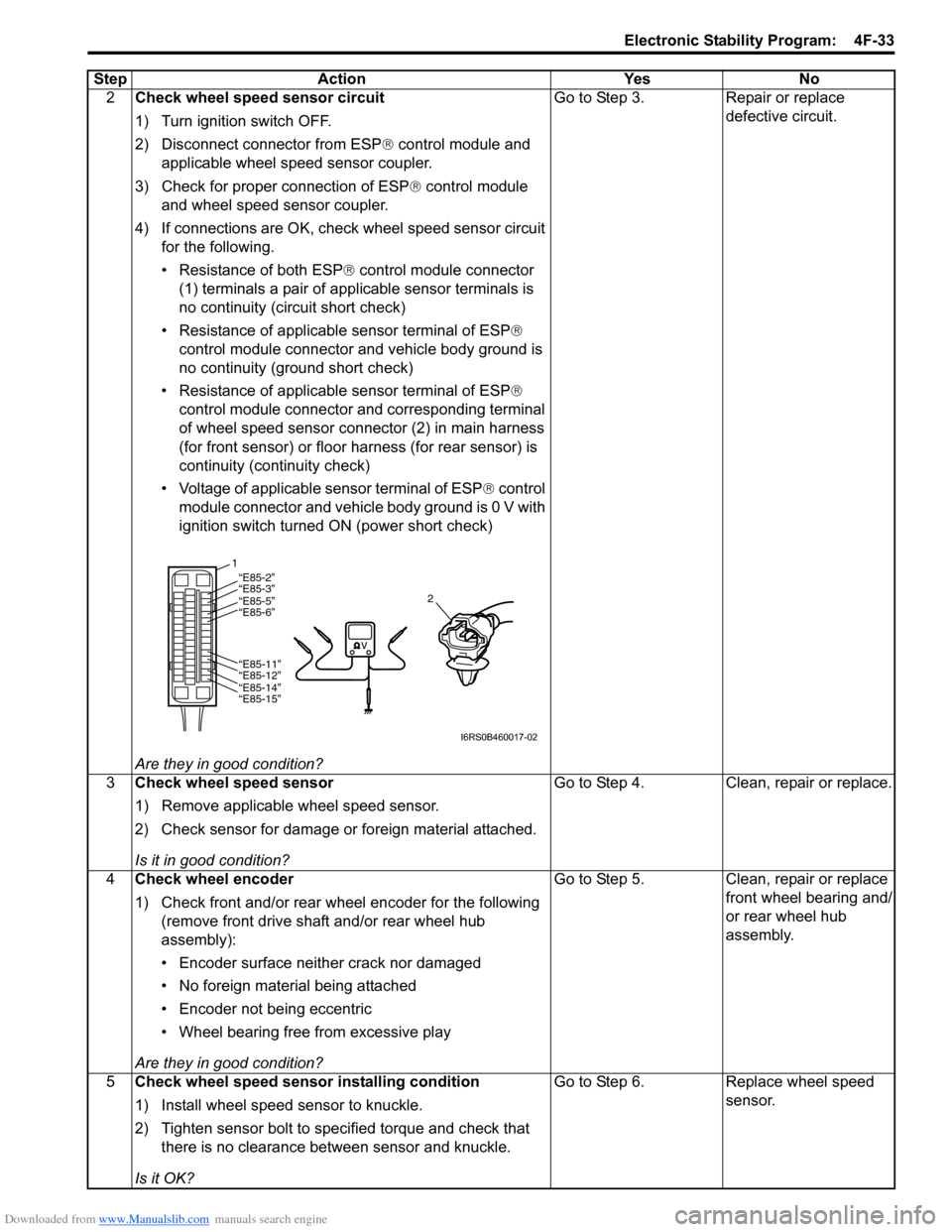

2Check wheel speed sensor circuit

1) Turn ignition switch OFF.

2) Disconnect connector from ESP ® control module and

applicable wheel speed sensor coupler.

3) Check for proper connection of ESP ® control module

and wheel speed sensor coupler.

4) If connections are OK, che ck wheel speed sensor circuit

for the following.

• Resistance of both ESP ® control module connector

(1) terminals a pair of app licable sensor terminals is

no continuity (circuit short check)

• Resistance of applicable sensor terminal of ESP ®

control module connector and vehicle body ground is

no continuity (ground short check)

• Resistance of applicable sensor terminal of ESP ®

control module connector and corresponding terminal

of wheel speed sensor connector (2) in main harness

(for front sensor) or floor harness (for rear sensor) is

continuity (continuity check)

• Voltage of applicable sensor terminal of ESP ® control

module connector and vehicle body ground is 0 V with

ignition switch turned ON (power short check)

Are they in good condition? Go to Step 3. Repair or replace

defective circuit.

3 Check wheel speed sensor

1) Remove applicable wheel speed sensor.

2) Check sensor for damage or foreign material attached.

Is it in good condition? Go to Step 4. Clean, repair or replace.

4 Check wheel encoder

1) Check front and/or rear wheel encoder for the following

(remove front drive shaft and/or rear wheel hub

assembly):

• Encoder surface neither crack nor damaged

• No foreign material being attached

• Encoder not being eccentric

• Wheel bearing free from excessive play

Are they in good condition? Go to Step 5. Clean, repair or replace

front wheel bearing and/

or rear wheel hub

assembly.

5 Check wheel speed sensor installing condition

1) Install wheel speed sensor to knuckle.

2) Tighten sensor bolt to specified torque and check that

there is no clearance between sensor and knuckle.

Is it OK? Go to Step 6. Replace wheel speed

sensor.

Step Action Yes No

1

2“E85-2”“E85-3”“E85-5”

“E85-6”

“E85-11”

“E85-12”

“E85-14”

“E85-15”

I6RS0B460017-02

Page 609 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-35

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC C1028: Master Cylinder Pressure Sensor Circuit FailureS7RS0B4604031

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC Detecting Condition Trouble Area

Mechanical switch failure, fa ilure in switch wiring is

shorted to ground. • ESP

® OFF switch

• ESP ® OFF switch circuit

• ESP ® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 Check ESP ® OFF switch condition

Is ESP

® OFF switch is OFF condition? Go to Step 3. ESP

® OFF switch

turned OFF condition

and recheck.

3 Check ESP ® OFF switch

1) Turn ignition switch to OFF position.

2) Remove ESP® OFF switch referring to “ESP ® OFF

Switch Removal and Installation”.

3) Check for proper connection at each terminal of ESP ®

OFF switch.

4) If OK, then check ESP ® OFF switch referring to “ESP ®

OFF Switch Inspection”.

Is it good condition? Go to Step 4. Replace ESP

® OFF

switch.

4 Check ESP ® OFF switch circuit

1) Disconnect ESP ® control module connector.

2) Check for proper connection to ESP ® control module

connector at “E85-7” terminal.

3) If OK, then check resistance between “E85-7” terminal and vehicle body ground.

Is resistance infinity? Substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. “LT GRN/RED” wire

circuit is shorted to

ground.

DTC Detecting Condition

Trouble Area

Input signal voltage from master cylinder pressure sensor

in ESP ® control module is too high or low. • Leakage or air in the hydraulic brake system

• Clearance between brake pad and disc too high

Step

Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 Check brake system

1) Check brake system as follows.

• Leakage or air in the hydraulic brake system

• Clearance between brake pad and disc too high

Are they in good condition? Go to Step 3.

Repair, replace or

adjust.

3 Check sensor calibration

1) Calibrate master cylinder pressure sensor referring to

“Sensor Calibration”.

2) Clear all DTC(s) and recheck DTC.

Is DTC C1028 still detected? Substitute a known-

good ESP

® hydraulic

unit / control module

assembly recheck. Master cylinder

pressure sensor

calibration was

incompleted.

Page 619 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-45

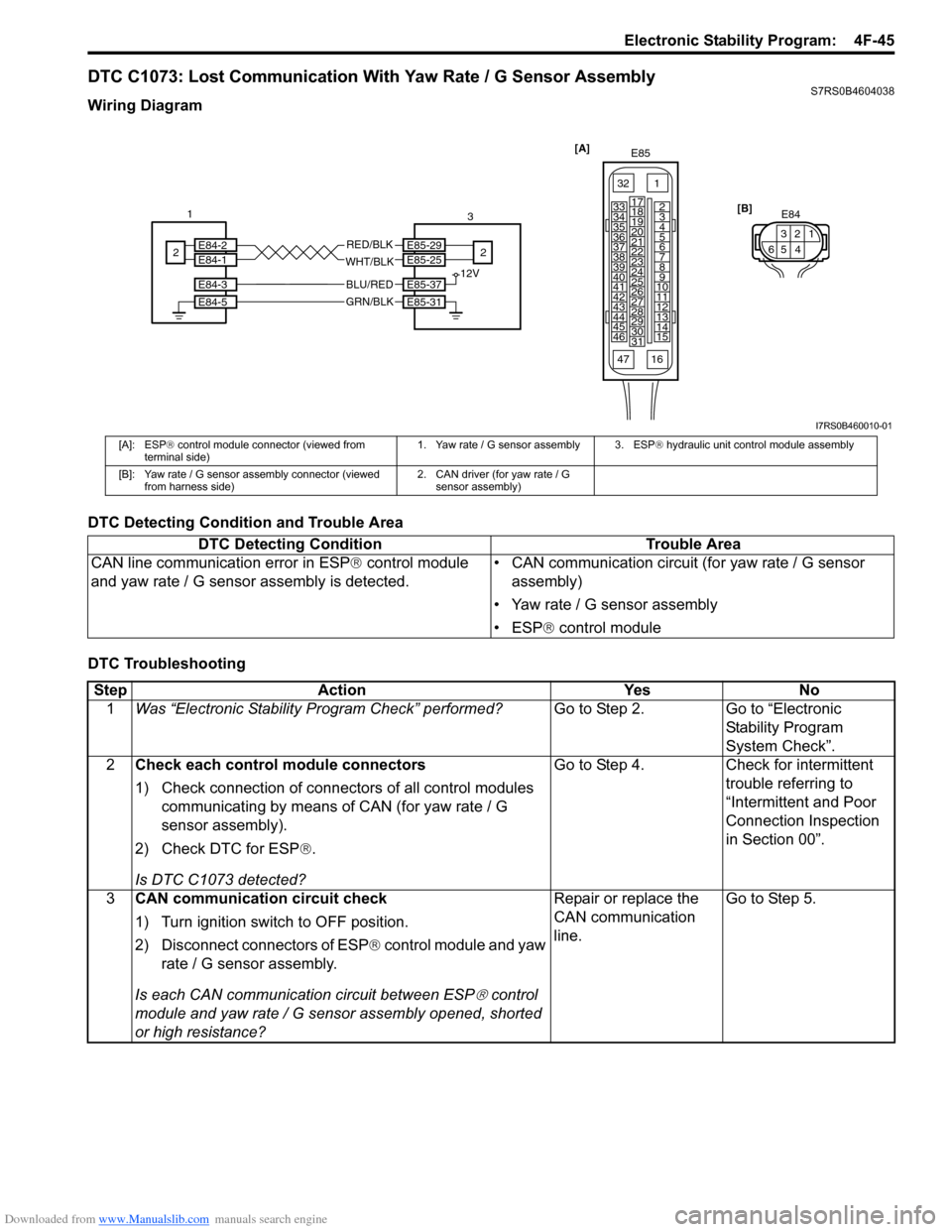

DTC C1073: Lost Communication With Yaw Rate / G Sensor AssemblyS7RS0B4604038

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

[A]E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

E85-29E85-25

E85-37

E85-31

E84-3

E84-5

E84-2E84-1 12V

GRN/BLK

BLU/RED

WHT/BLK

RED/BLK [B]

E843

521

46

1

2 3

2

I7RS0B460010-01

[A]: ESP ® control module connector (viewed from

terminal side) 1. Yaw rate / G sensor assembly 3. ESP

® hydraulic unit control module assembly

[B]: Yaw rate / G sensor assembly connector (viewed from harness side) 2. CAN driver (for yaw rate / G

sensor assembly)

DTC Detecting Condition Trouble Area

CAN line communication error in ESP ® control module

and yaw rate / G sensor assembly is detected. • CAN communication circuit (for yaw rate / G sensor

assembly)

• Yaw rate / G sensor assembly

• ESP ® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 Check each control module connectors

1) Check connection of connectors of all control modules

communicating by means of CAN (for yaw rate / G

sensor assembly).

2) Check DTC for ESP ®.

Is DTC C1073 detected? Go to Step 4.

Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

3 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of ESP ® control module and yaw

rate / G sensor assembly.

Is each CAN communicati on circuit between ESP

® control

module and yaw rate / G sensor assembly opened, shorted

or high resistance? Repair or replace the

CAN communication

line.

Go to Step 5.

Page 624 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-50 Electronic Stability Program:

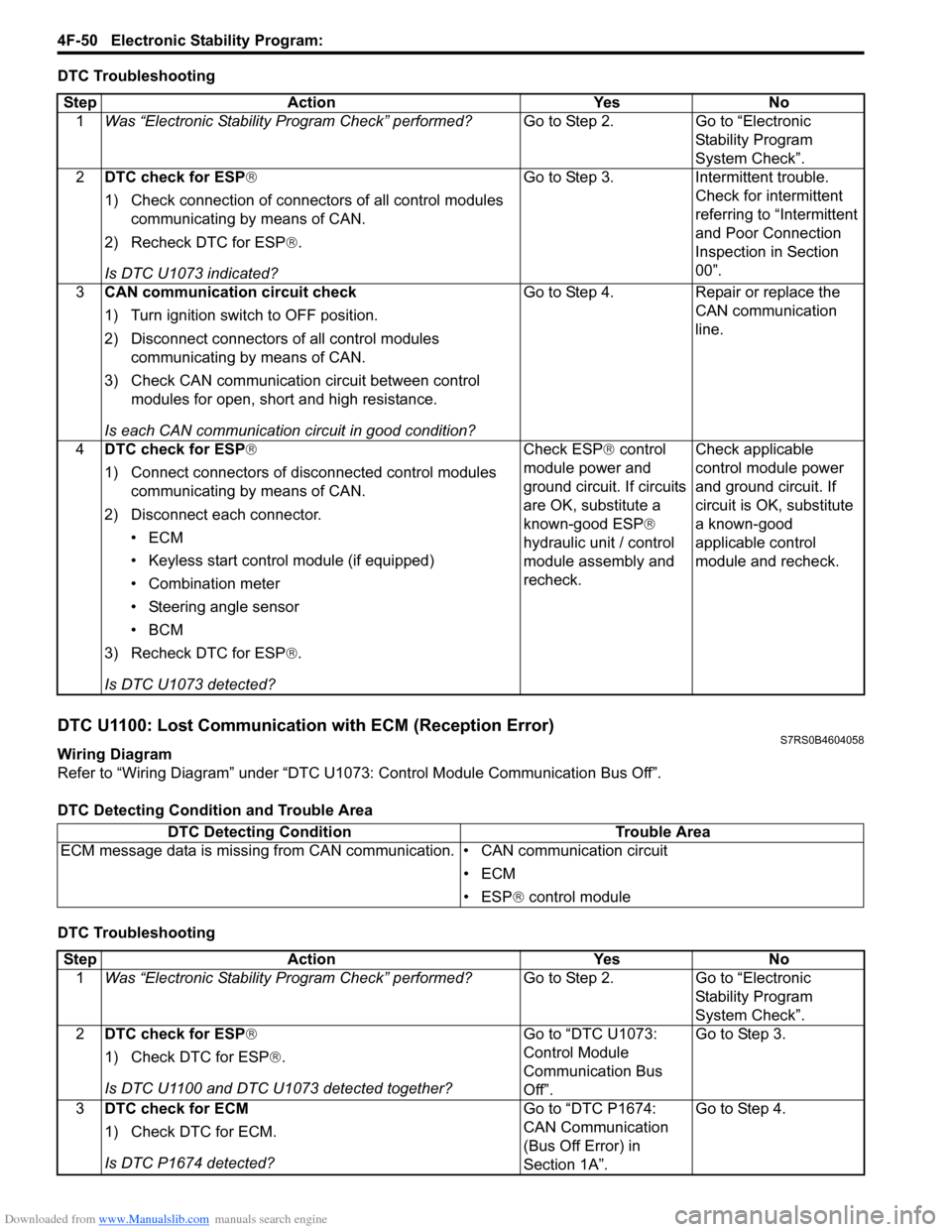

DTC Troubleshooting

DTC U1100: Lost Communication with ECM (Reception Error)S7RS0B4604058

Wiring Diagram

Refer to “Wiring Diagram” under “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC for ESP ®.

Is DTC U1073 indicated? Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 4. Repair or replace the

CAN communication

line.

4 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module (if equipped)

• Combination meter

• Steering angle sensor

•BCM

3) Recheck DTC for ESP ®.

Is DTC U1073 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

DTC Detecting Condition

Trouble Area

ECM message data is missing from CAN communication. • CAN communication circuit

•ECM

• ESP® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check DTC for ESP ®.

Is DTC U1100 and DTC U1073 detected together? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

3 DTC check for ECM

1) Check DTC for ECM.

Is DTC P1674 detected? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.Go to Step 4.

Page 625 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-51

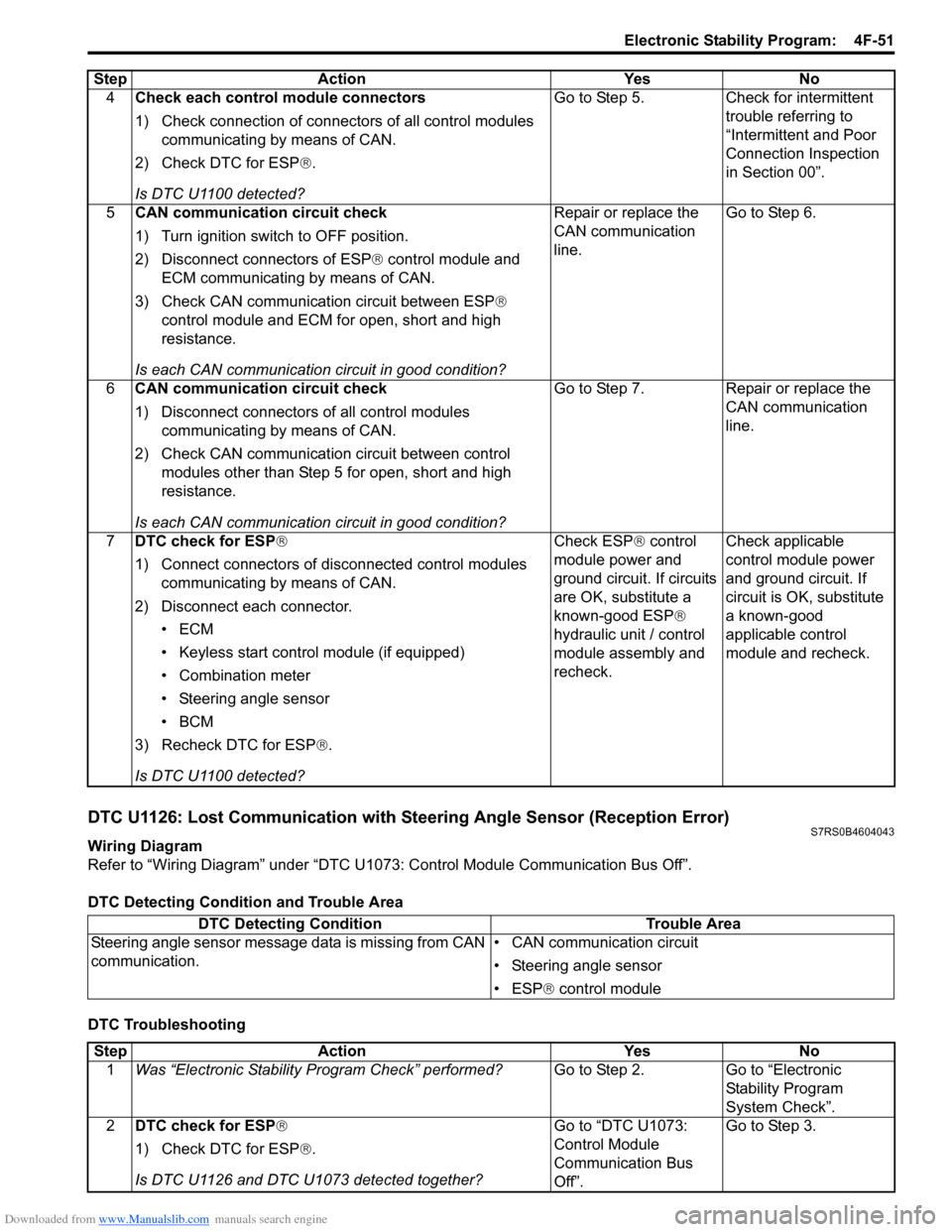

DTC U1126: Lost Communication with Steering Angle Sensor (Reception Error)S7RS0B4604043

Wiring Diagram

Refer to “Wiring Diagram” under “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition and Trouble Area

DTC Troubleshooting4

Check each control module connectors

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Check DTC for ESP ®.

Is DTC U1100 detected? Go to Step 5. Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

5 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of ESP ® control module and

ECM communicating by means of CAN.

3) Check CAN communication circuit between ESP®

control module and ECM for open, short and high

resistance.

Is each CAN communication circuit in good condition? Repair or replace the

CAN communication

line.

Go to Step 6.

6 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 5 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 7. Repair or replace the

CAN communication

line.

7 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module (if equipped)

• Combination meter

• Steering angle sensor

•BCM

3) Recheck DTC for ESP ®.

Is DTC U1100 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

Step Action Yes No

DTC Detecting Condition

Trouble Area

Steering angle sensor message data is missing from CAN

communication. • CAN communication circuit

• Steering angle sensor

• ESP

® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check DTC for ESP ®.

Is DTC U1126 and DTC U1073 detected together? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

Page 626 of 1496

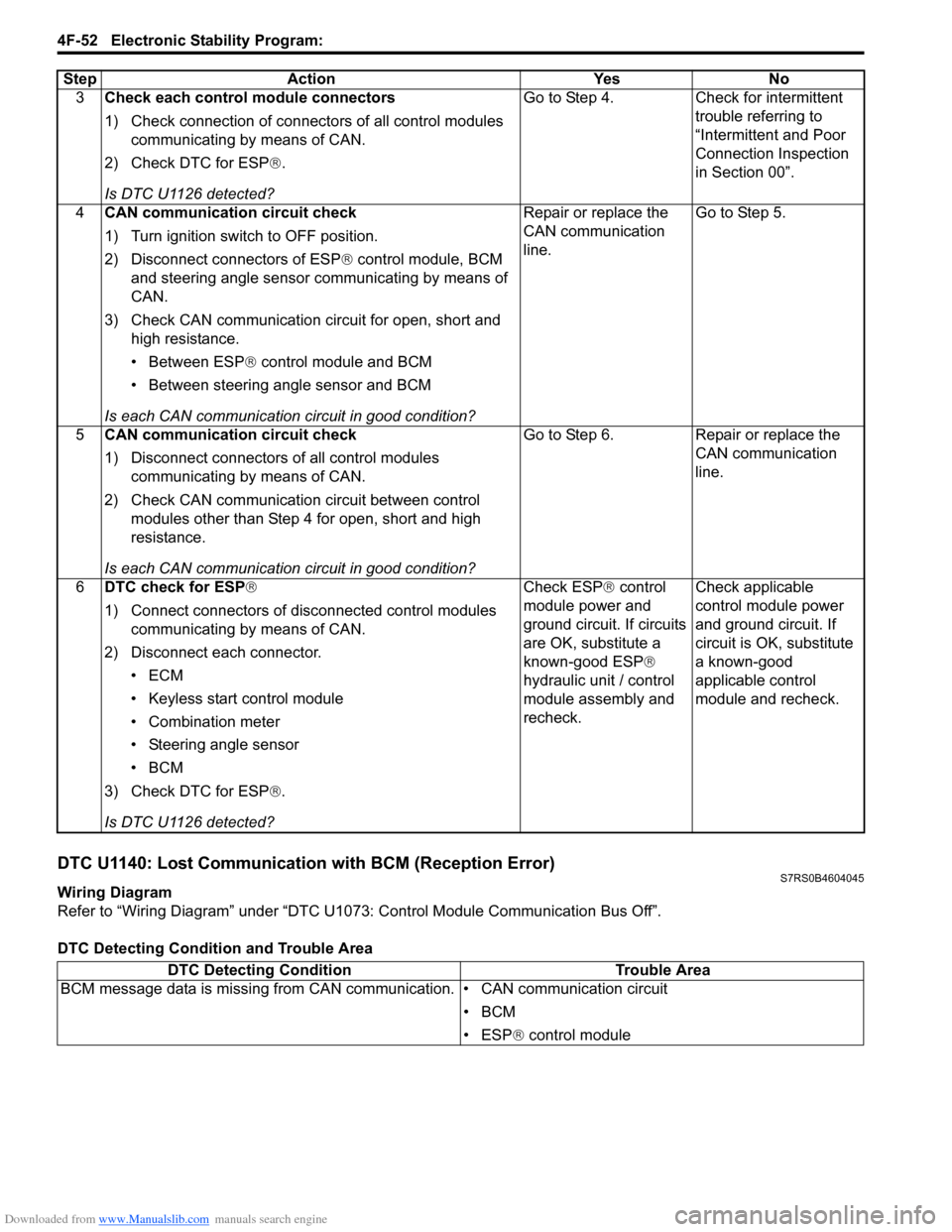

Downloaded from www.Manualslib.com manuals search engine 4F-52 Electronic Stability Program:

DTC U1140: Lost Communication with BCM (Reception Error)S7RS0B4604045

Wiring Diagram

Refer to “Wiring Diagram” under “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition and Trouble Area3

Check each control module connectors

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Check DTC for ESP ®.

Is DTC U1126 detected? Go to Step 4. Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

4 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of ESP ® control module, BCM

and steering angle sensor communicating by means of

CAN.

3) Check CAN communication circuit for open, short and high resistance.

• Between ESP ® control module and BCM

• Between steering angle sensor and BCM

Is each CAN communication circuit in good condition? Repair or replace the

CAN communication

line.

Go to Step 5.

5 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 4 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 6. Repair or replace the

CAN communication

line.

6 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module

• Combination meter

• Steering angle sensor

•BCM

3) Check DTC for ESP ®.

Is DTC U1126 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

Step Action Yes No

DTC Detecting Condition

Trouble Area

BCM message data is missing from CAN communication. • CAN communication circuit

•BCM

• ESP® control module

Page 627 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-53

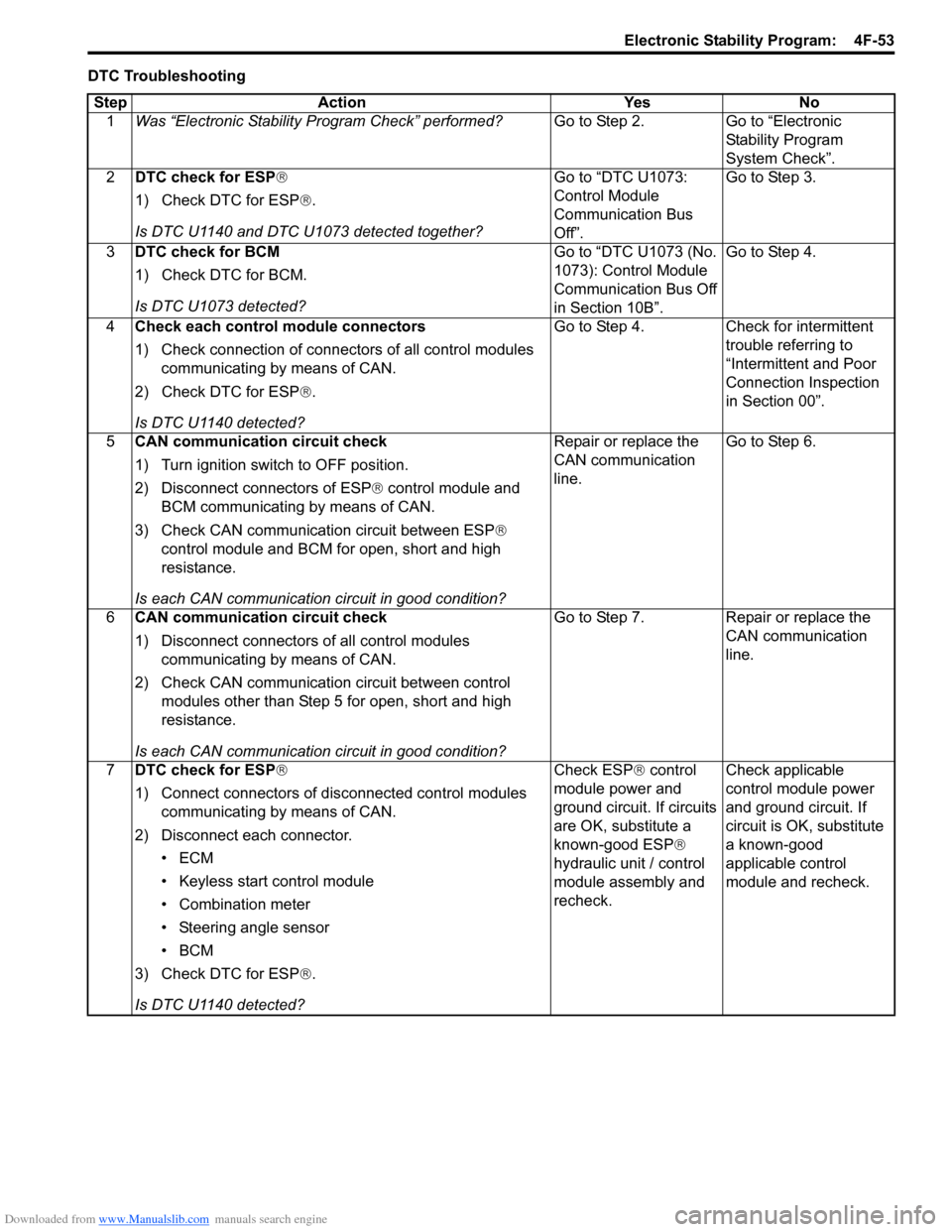

DTC TroubleshootingStep Action Yes No 1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check DTC for ESP ®.

Is DTC U1140 and DTC U1073 detected together? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

3 DTC check for BCM

1) Check DTC for BCM.

Is DTC U1073 detected? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus Off

in Section 10B”.Go to Step 4.

4 Check each control module connectors

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Check DTC for ESP ®.

Is DTC U1140 detected? Go to Step 4. Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

5 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of ESP ® control module and

BCM communicating by means of CAN.

3) Check CAN communication circuit between ESP®

control module and BCM for open, short and high

resistance.

Is each CAN communication circuit in good condition? Repair or replace the

CAN communication

line.

Go to Step 6.

6 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 5 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 7. Repair or replace the

CAN communication

line.

7 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module

• Combination meter

• Steering angle sensor

•BCM

3) Check DTC for ESP ®.

Is DTC U1140 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

Page 628 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-54 Electronic Stability Program:

Repair Instructions

ESP® Hydraulic Unit Operation CheckS7RS0B4606025

1) Check that basic brake system other than ESP ® is

in good condition.

2) Check that battery voltage is 11 V or higher.

3) Lift up vehicle.

4) Set transmission to neutral and release parking brake.

5) Turn each wheel gradually by hand to check if braked ragging occurs. If it does, correct.

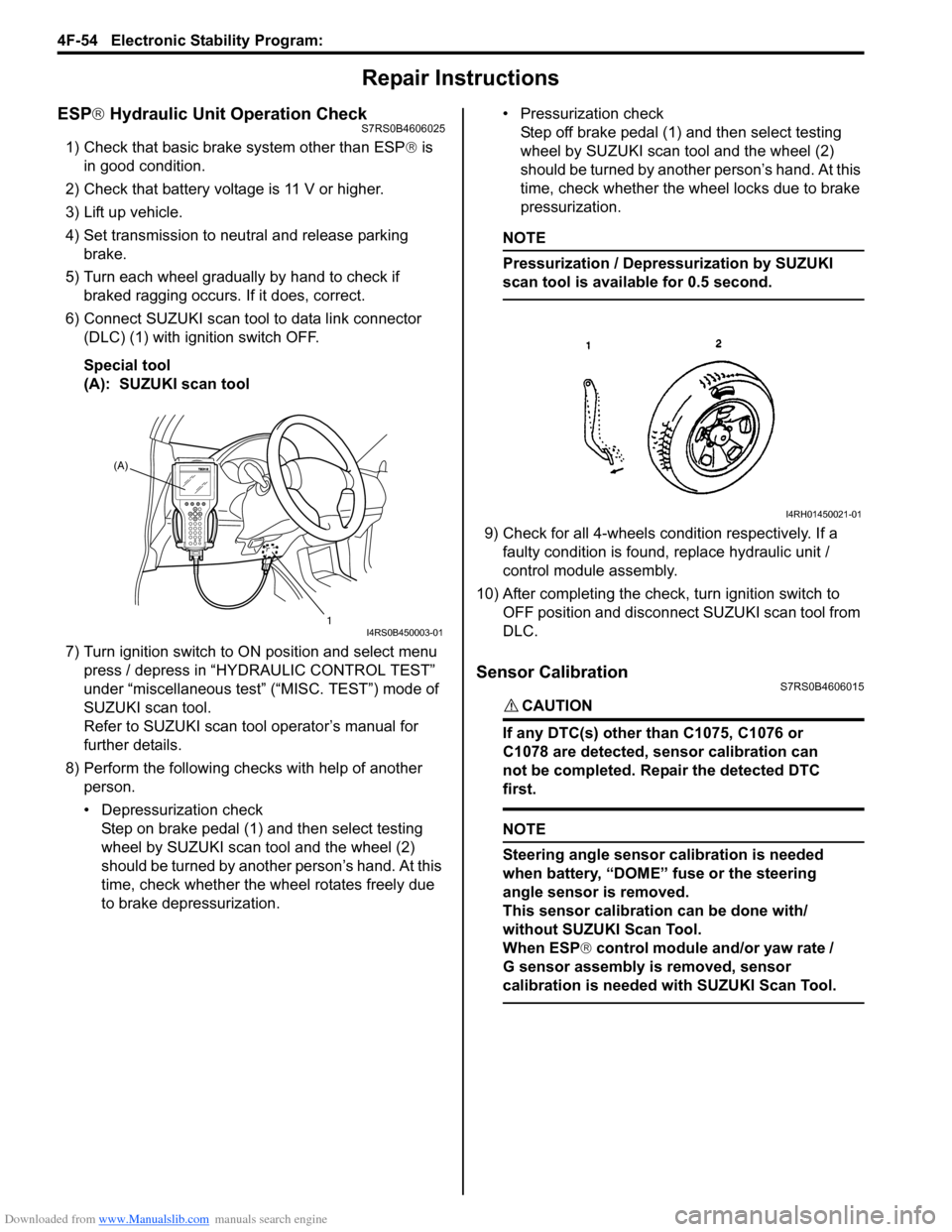

6) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

7) Turn ignition switch to ON position and select menu press / depress in “HYDRAULIC CONTROL TEST”

under “miscellaneous test” (“MISC. TEST”) mode of

SUZUKI scan tool.

Refer to SUZUKI scan tool operator’s manual for

further details.

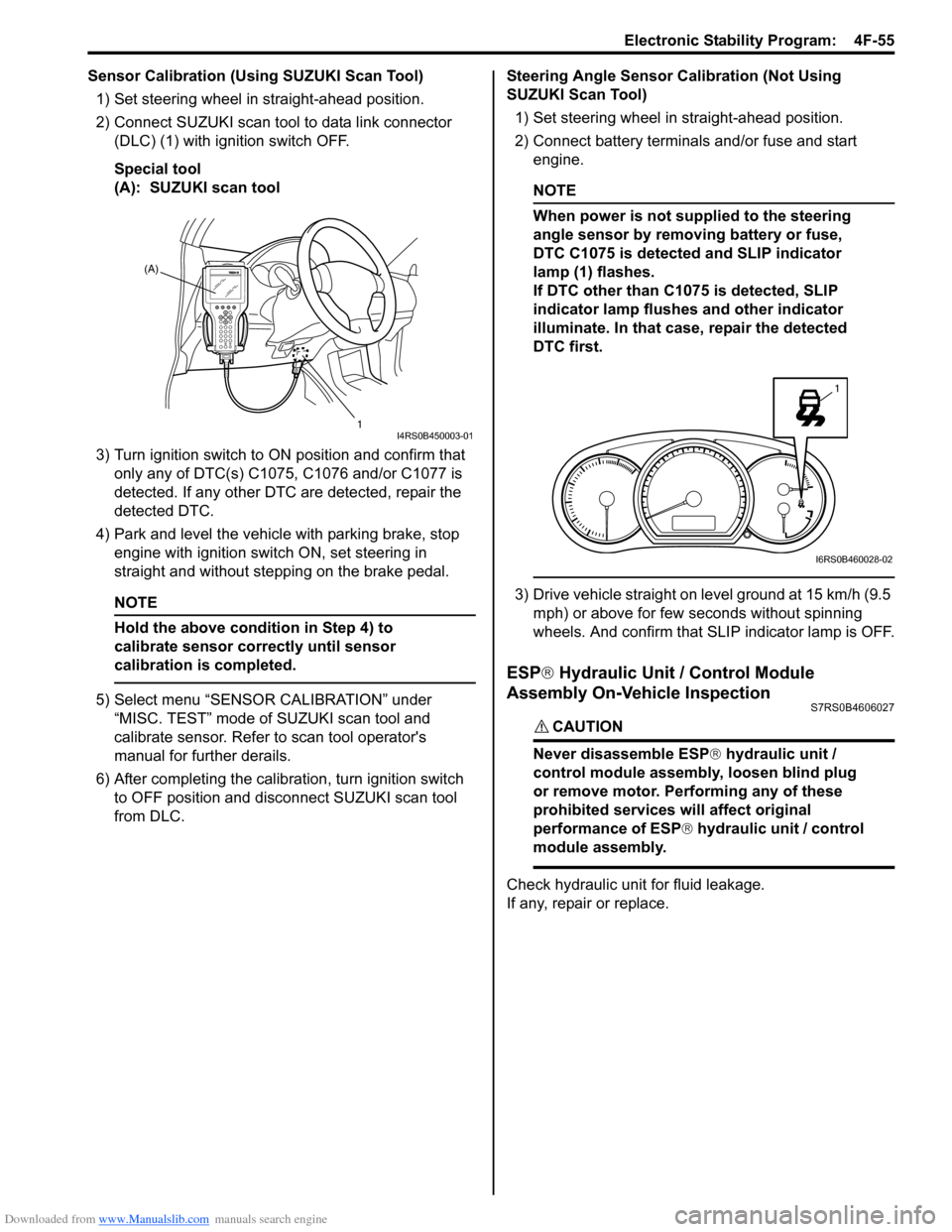

8) Perform the following checks with help of another person.

• Depressurization checkStep on brake pedal (1) and then select testing

wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check whether the wheel rotates freely due

to brake depressurization. • Pressurization check

Step off brake pedal (1) and then select testing

wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check whether the wheel locks due to brake

pressurization.

NOTE

Pressurization / Depressurization by SUZUKI

scan tool is available for 0.5 second.

9) Check for all 4-wheels condition respectively. If a faulty condition is found, replace hydraulic unit /

control module assembly.

10) After completing the check, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

Sensor CalibrationS7RS0B4606015

CAUTION!

If any DTC(s) other than C1075, C1076 or

C1078 are detected, sensor calibration can

not be completed. Repair the detected DTC

first.

NOTE

Steering angle sensor calibration is needed

when battery, “DOME” fuse or the steering

angle sensor is removed.

This sensor calibration can be done with/

without SUZUKI Scan Tool.

When ESP ® control module and/or yaw rate /

G sensor assembly is removed, sensor

calibration is needed with SUZUKI Scan Tool.

(A)

1

I4RS0B450003-01

I4RH01450021-01

Page 629 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-55

Sensor Calibration (Using SUZUKI Scan Tool)1) Set steering wheel in straight-ahead position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position and confirm that

only any of DTC(s) C1075, C1076 and/or C1077 is

detected. If any other DTC are detected, repair the

detected DTC.

4) Park and level the vehicle with parking brake, stop engine with ignition switch ON, set steering in

straight and without step ping on the brake pedal.

NOTE

Hold the above condition in Step 4) to

calibrate sensor correctly until sensor

calibration is completed.

5) Select menu “SENSOR CALIBRATION” under

“MISC. TEST” mode of SUZUKI scan tool and

calibrate sensor. Refer to scan tool operator's

manual for further derails.

6) After completing the calibra tion, turn ignition switch

to OFF position and disconnect SUZUKI scan tool

from DLC. Steering Angle Sensor Calibration (Not Using

SUZUKI Scan Tool)

1) Set steering wheel in straight-ahead position.

2) Connect battery terminals and/or fuse and start engine.

NOTE

When power is not supplied to the steering

angle sensor by removing battery or fuse,

DTC C1075 is detected and SLIP indicator

lamp (1) flashes.

If DTC other than C1075 is detected, SLIP

indicator lamp flushes and other indicator

illuminate. In that case, repair the detected

DTC first.

3) Drive vehicle straight on level ground at 15 km/h (9.5 mph) or above for few seconds without spinning

wheels. And confirm that SLIP indicator lamp is OFF.

ESP ® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection

S7RS0B4606027

CAUTION!

Never disassemble ESP ® hydraulic unit /

control module assembly, loosen blind plug

or remove motor. Pe rforming any of these

prohibited services will affect original

performance of ESP ® hydraulic unit / control

module assembly.

Check hydraulic unit for fluid leakage.

If any, repair or replace.

(A)

1

I4RS0B450003-01

1

I6RS0B460028-02